air bleeding DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1364 of 2255

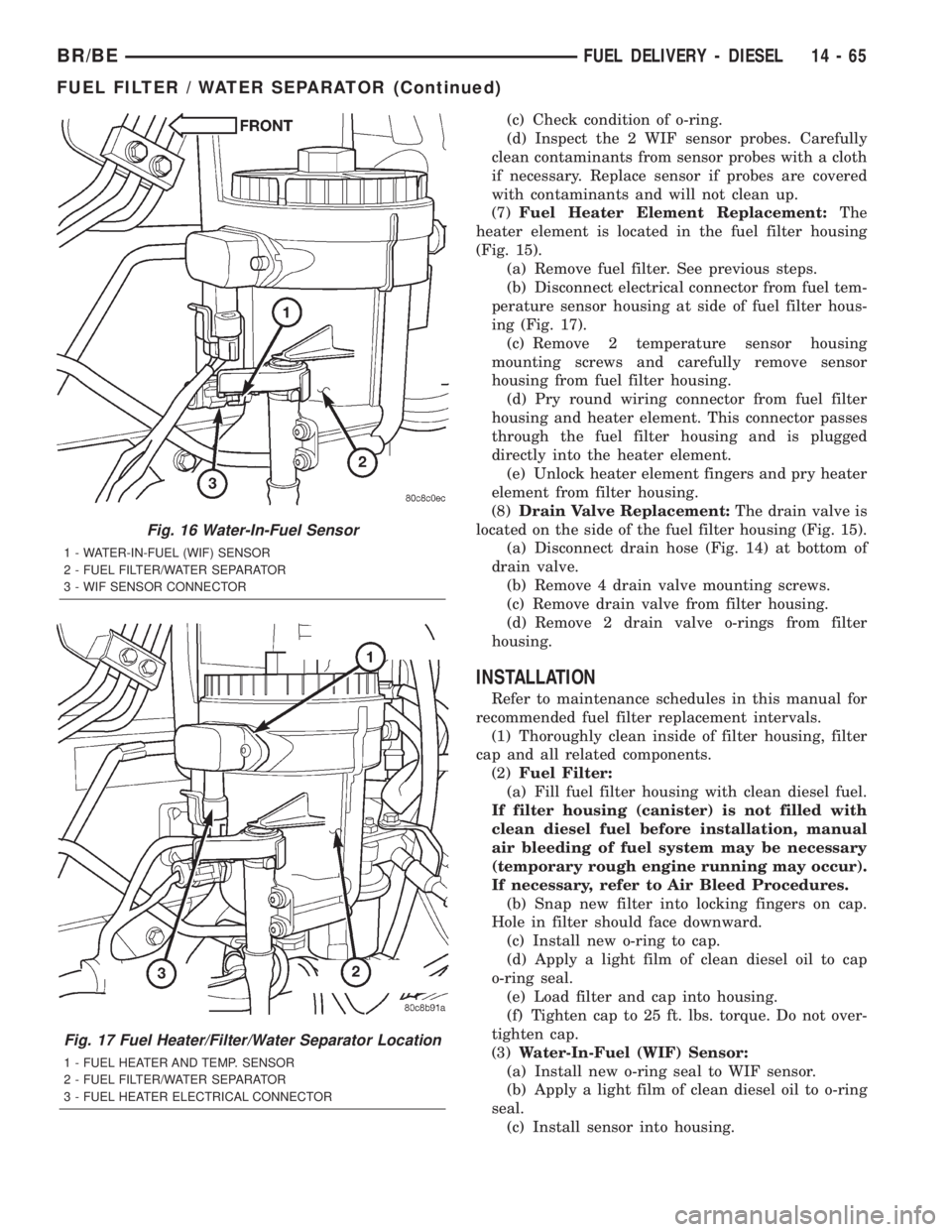

(c) Check condition of o-ring.

(d) Inspect the 2 WIF sensor probes. Carefully

clean contaminants from sensor probes with a cloth

if necessary. Replace sensor if probes are covered

with contaminants and will not clean up.

(7)Fuel Heater Element Replacement:The

heater element is located in the fuel filter housing

(Fig. 15).

(a) Remove fuel filter. See previous steps.

(b) Disconnect electrical connector from fuel tem-

perature sensor housing at side of fuel filter hous-

ing (Fig. 17).

(c) Remove 2 temperature sensor housing

mounting screws and carefully remove sensor

housing from fuel filter housing.

(d) Pry round wiring connector from fuel filter

housing and heater element. This connector passes

through the fuel filter housing and is plugged

directly into the heater element.

(e) Unlock heater element fingers and pry heater

element from filter housing.

(8)Drain Valve Replacement:The drain valve is

located on the side of the fuel filter housing (Fig. 15).

(a) Disconnect drain hose (Fig. 14) at bottom of

drain valve.

(b) Remove 4 drain valve mounting screws.

(c) Remove drain valve from filter housing.

(d) Remove 2 drain valve o-rings from filter

housing.

INSTALLATION

Refer to maintenance schedules in this manual for

recommended fuel filter replacement intervals.

(1) Thoroughly clean inside of filter housing, filter

cap and all related components.

(2)Fuel Filter:

(a) Fill fuel filter housing with clean diesel fuel.

If filter housing (canister) is not filled with

clean diesel fuel before installation, manual

air bleeding of fuel system may be necessary

(temporary rough engine running may occur).

If necessary, refer to Air Bleed Procedures.

(b) Snap new filter into locking fingers on cap.

Hole in filter should face downward.

(c) Install new o-ring to cap.

(d) Apply a light film of clean diesel oil to cap

o-ring seal.

(e) Load filter and cap into housing.

(f) Tighten cap to 25 ft. lbs. torque. Do not over-

tighten cap.

(3)Water-In-Fuel (WIF) Sensor:

(a) Install new o-ring seal to WIF sensor.

(b) Apply a light film of clean diesel oil to o-ring

seal.

(c) Install sensor into housing.

Fig. 16 Water-In-Fuel Sensor

1 - WATER-IN-FUEL (WIF) SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - WIF SENSOR CONNECTOR

Fig. 17 Fuel Heater/Filter/Water Separator Location

1 - FUEL HEATER AND TEMP. SENSOR

2 - FUEL FILTER/WATER SEPARATOR

3 - FUEL HEATER ELECTRICAL CONNECTOR

BR/BEFUEL DELIVERY - DIESEL 14 - 65

FUEL FILTER / WATER SEPARATOR (Continued)

Page 1369 of 2255

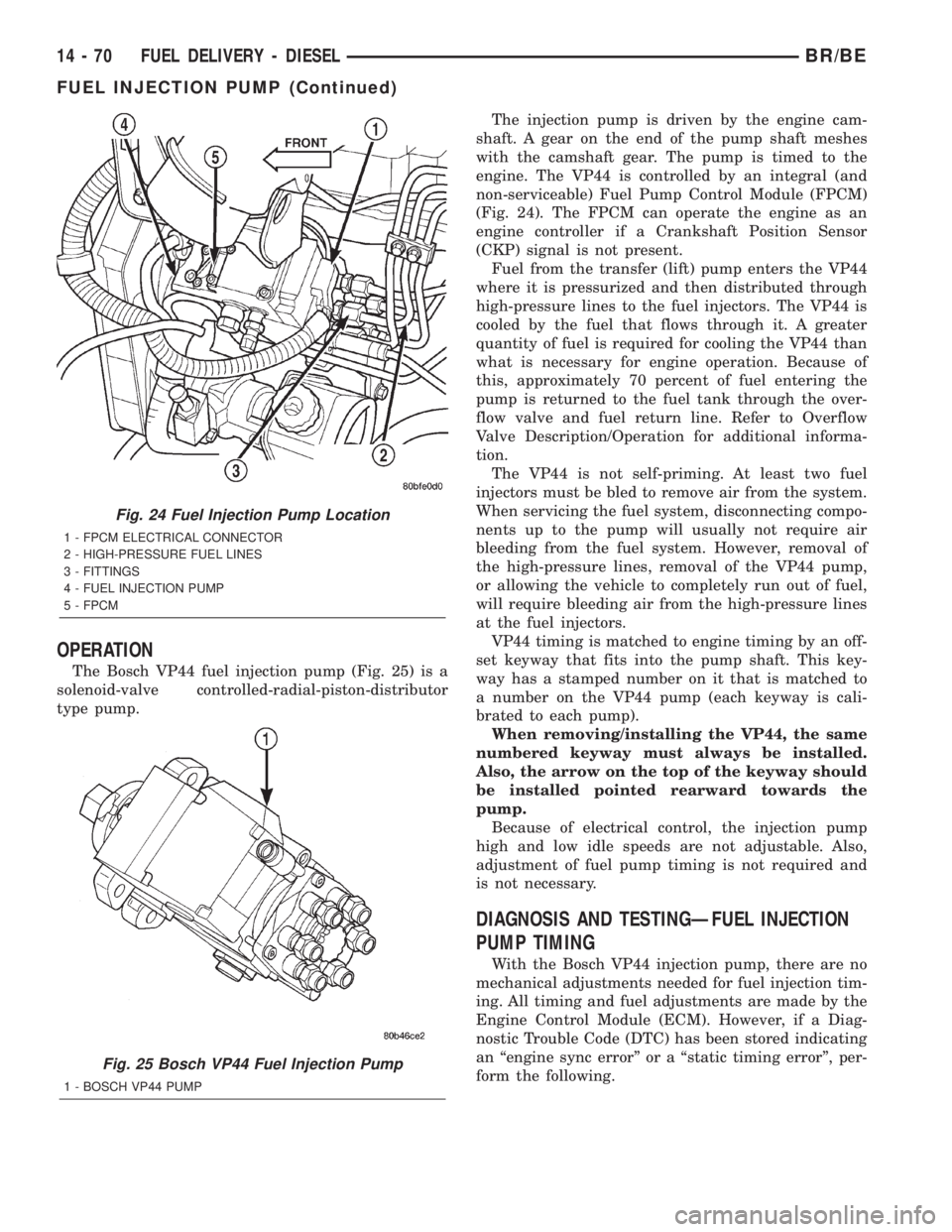

OPERATION

The Bosch VP44 fuel injection pump (Fig. 25) is a

solenoid-valve controlled-radial-piston-distributor

type pump.The injection pump is driven by the engine cam-

shaft. A gear on the end of the pump shaft meshes

with the camshaft gear. The pump is timed to the

engine. The VP44 is controlled by an integral (and

non-serviceable) Fuel Pump Control Module (FPCM)

(Fig. 24). The FPCM can operate the engine as an

engine controller if a Crankshaft Position Sensor

(CKP) signal is not present.

Fuel from the transfer (lift) pump enters the VP44

where it is pressurized and then distributed through

high-pressure lines to the fuel injectors. The VP44 is

cooled by the fuel that flows through it. A greater

quantity of fuel is required for cooling the VP44 than

what is necessary for engine operation. Because of

this, approximately 70 percent of fuel entering the

pump is returned to the fuel tank through the over-

flow valve and fuel return line. Refer to Overflow

Valve Description/Operation for additional informa-

tion.

The VP44 is not self-priming. At least two fuel

injectors must be bled to remove air from the system.

When servicing the fuel system, disconnecting compo-

nents up to the pump will usually not require air

bleeding from the fuel system. However, removal of

the high-pressure lines, removal of the VP44 pump,

or allowing the vehicle to completely run out of fuel,

will require bleeding air from the high-pressure lines

at the fuel injectors.

VP44 timing is matched to engine timing by an off-

set keyway that fits into the pump shaft. This key-

way has a stamped number on it that is matched to

a number on the VP44 pump (each keyway is cali-

brated to each pump).

When removing/installing the VP44, the same

numbered keyway must always be installed.

Also, the arrow on the top of the keyway should

be installed pointed rearward towards the

pump.

Because of electrical control, the injection pump

high and low idle speeds are not adjustable. Also,

adjustment of fuel pump timing is not required and

is not necessary.

DIAGNOSIS AND TESTINGÐFUEL INJECTION

PUMP TIMING

With the Bosch VP44 injection pump, there are no

mechanical adjustments needed for fuel injection tim-

ing. All timing and fuel adjustments are made by the

Engine Control Module (ECM). However, if a Diag-

nostic Trouble Code (DTC) has been stored indicating

an ªengine sync errorº or a ªstatic timing errorº, per-

form the following.

Fig. 24 Fuel Injection Pump Location

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

Fig. 25 Bosch VP44 Fuel Injection Pump

1 - BOSCH VP44 PUMP

14 - 70 FUEL DELIVERY - DIESELBR/BE

FUEL INJECTION PUMP (Continued)

Page 1381 of 2255

CAUTION: Be sure that the high-pressure fuel lines

are installed in the same order that they were

removed.

(1) Lubricate threads of injector line fittings with

clean engine oil.

(2) Loosen, but do not remove, all fuel line support

bracket bolts.

(3) Installrearinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(4) Tighten fittings at fuel injector ends for cylin-

ders number 6 and 5 to 38 N´m (28 ft. lbs.) torque.

Do not tighten number 3 line at this time. It

will be tightened during bleeding procedure.

(5) Tighten 3 fittings at fuel injection pump ends

to 24 N´m (18 ft. lbs.) torque.

(6) Installfrontinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(7) Tighten fitting at fuel injector end for cylinder

number 2 to 38 N´m (28 ft. lbs.) torque.Do not

tighten lines number 1 or 4 at this time. They

will be tightened during bleeding procedure.

(8) Tighten remaining 3 fittings at fuel injection

pump ends to 24 N´m (18 ft. lbs.) torque.

(9) Install fuel line support bracket bolts to intake

manifold and tighten to 24 N´m (18 ft. lbs.) torque.

CAUTION: Be sure fuel lines are not contacting

each other or any other component. Noise will

result.

(10) Install engine lifting bracket at rear of intake

manifold. Tighten 2 bolts to 77 N´m (57 ft. lbs.)

torque.

(11) Install cable bracket housing/cable assembly

and tighten 3 mounting bolts to 24 N´m (18 ft. lbs.)

torque.

(12) Clean any old gasket material below and

above intake manifold air heater element block. Also

clean mating areas at intake manifold and air intake

housing.

(13) Using new gaskets, position intake manifold

air heater element block to engine.

(14) Install air intake housing and position ground

cable. Install 4 mounting bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(15) Install air tube (intake manifold-to-charge air

cooler) (Fig. 49). Tighten clamps to 8 N´m (72 in. lbs.)

torque.

(16) Install engine oil dipstick tube support mount-

ing bolt and tighten to 24 N´m (18 ft. lbs.) torque.

(17) Install engine oil dipstick to engine.(18) Connect 2 electrical cables to cable mounting

studs.

(19) Connect electrical connector to bottom of

APPS by pushing connector upward until it snaps

into position.

(20) Connect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 48).

(21) Connect front wiring clip (Fig. 49) to cable

bracket housing.

(22) Install cable cover (Fig. 47).

(23) Connect both negative battery cables to both

batteries.

(24) Bleed air from fuel system. Do this at fuel

injector ends of lines. Use cylinders numbers 1, 3 and

4 for bleeding. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). After

bleeding, tighten fittings to 38 N´m (28 ft. lbs.)

torque.

(25) Check lines/fittings for leaks.

FUEL TANK

DESCRIPTION - DIESEL FUEL TANK

The fuel tank is similar to the tank used with gas-

oline powered models. The tank is equipped with a

separate fuel return line and a different fuel tank

module for diesel powered models. A fuel tank

mounted, electric fuel pump is not used with diesel

powered models. Refer to Fuel Tank Module for addi-

tional information.

For removal and installation procedures, refer to

Fuel Tank - Gasoline Engines.

FUEL TANK MODULE

DESCRIPTION

An electric fuel pump isnot usedin the fuel tank

module for diesel powered engines. Fuel is supplied

by the engine mounted fuel transfer pump and the

fuel injection pump.

The fuel tank module is installed in the top of the

fuel tank (Fig. 56). The fuel tank module (Fig. 56)

contains the following components:

²Fuel reservoir

²A separate in-tank fuel filter

²Rollover valve

²Fuel gauge sending unit (fuel level sensor)

²Fuel supply line connection

²Fuel return line connection

²Auxiliary non-pressurized fuel supply fitting

OPERATION

Refer to Fuel Gauge Sending Unit.

14 - 82 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1389 of 2255

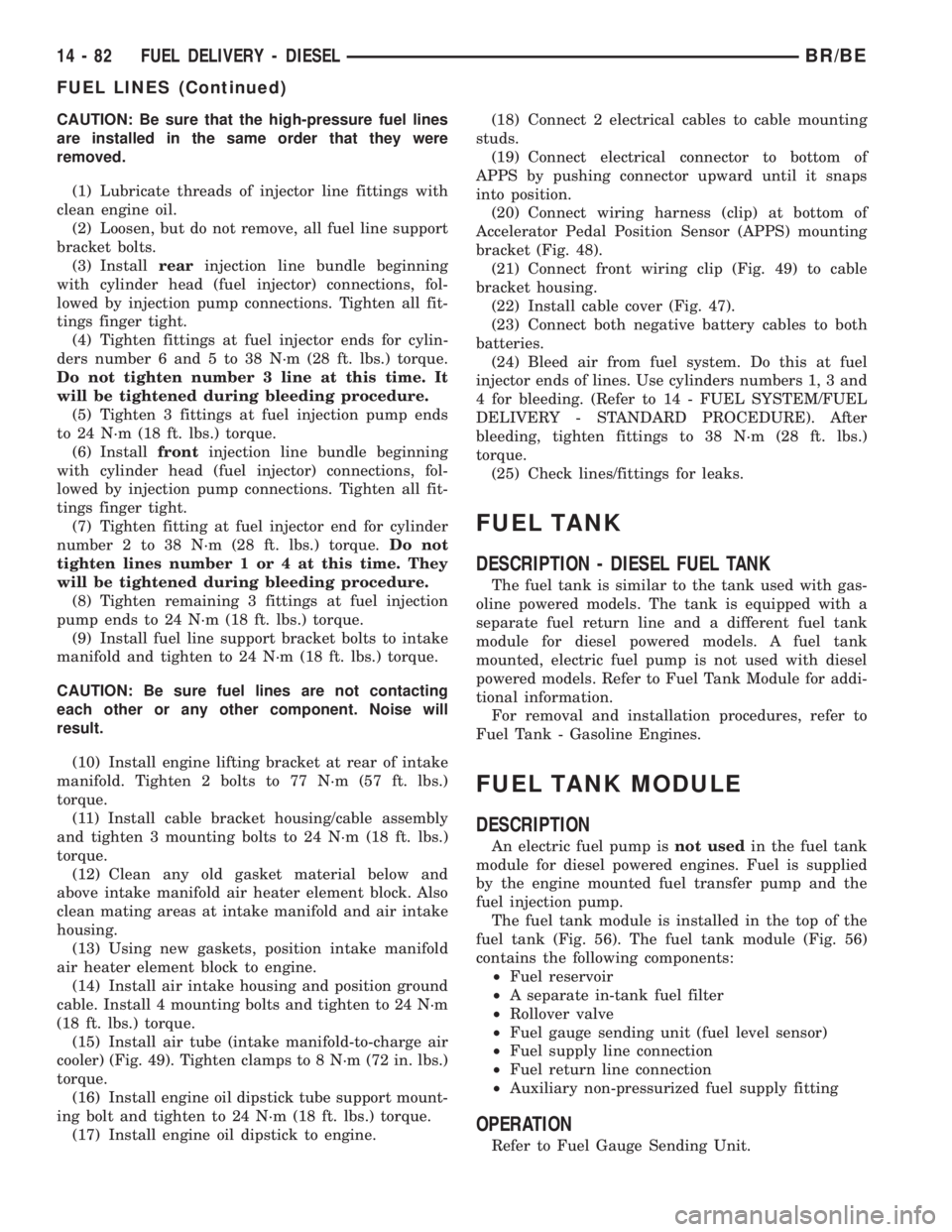

REMOVAL

The fuel drain manifold (line) connects a fuel

return passage within the cylinder head to a ªTº fit-

ting on the fuel return line. It is located at the rear

of the cylinder head.

(1) Disconnect both negative battery cables at both

batteries.

(2) Remove starter motor. Refer to Group 8B for

procedures.

(3) Disconnect fitting at ªTº (Fig. 70).(4) Remove banjo bolt at rear of cylinder head.

Discard old sealing washers.

(5) Remove fuel line from vehicle.

(6) Clean connection at rear of cylinder head

before line installation.

INSTALLATION

The fuel drain manifold (line) connects a fuel

return passage within the cylinder head to a ªTº fit-

ting on the fuel return line. It is located at the rear

of the cylinder head.

Servicing fuel return components will not require

air bleeding.

(1) Using new sealing washers, assemble banjo

bolt to fuel line.

(2) Position line to engine and loosely tighten fas-

teners.

(3) Tighten banjo bolt to 24 N´m (18 ft. lbs.)

torque.

(4) Tighten fitting at ªTº to 12 N´m (106 in. lbs.)

torque.

(5) Install starter motor. Refer to 8, Starter for

procedures.

(6) Connect both negative battery cables at both

batteries.

Fig. 70 Fuel Return Line at Rear of Cylinder Head

1 - REAR OF CYLINDER HEAD

2 - BANJO FITTING/BOLT

3 - FUEL RETURN TO TANK

4 - FUEL RETURN LINES

5 - FUEL RETURN LINE FROM PUMP OVERFLOW VALVE

6 - FUEL DRAIN MANIFOLD PASSAGE

7 - ªTº

14 - 90 FUEL DELIVERY - DIESELBR/BE

FUEL DRAIN MANIFOLD (Continued)

Page 1398 of 2255

lines before opening up any fuel system component.

Always cover or cap any open fuel connections before

a fuel system repair is performed.

Each fuel injector connector tube contains an edge

filter (Fig. 13) that breaks up small contaminants

that enter the injector. The edge filter uses the injec-

tors pulsating high-pressure to break up most parti-

cles so they are small enough to pass through the

injector.The edge filters are not a substitute for

proper cleaning and covering of all fuel system

components during repair.

The bottom of each fuel injector is sealed to the

cylinder head with a1.5mmthick copper shim (gas-

ket) (Fig. 12). The correct thickness shim must

always be re-installed after removing an injector.

Fuel pressure in the injector circuit decreases after

injection. The injector needle valve is immediately

closed by the needle valve spring and fuel flow into

the combustion chamber is stopped. Exhaust gases

are prevented from entering the injector nozzle by

the needle valve.

DIAGNOSIS AND TESTINGÐFUEL INJECTOR

TEST

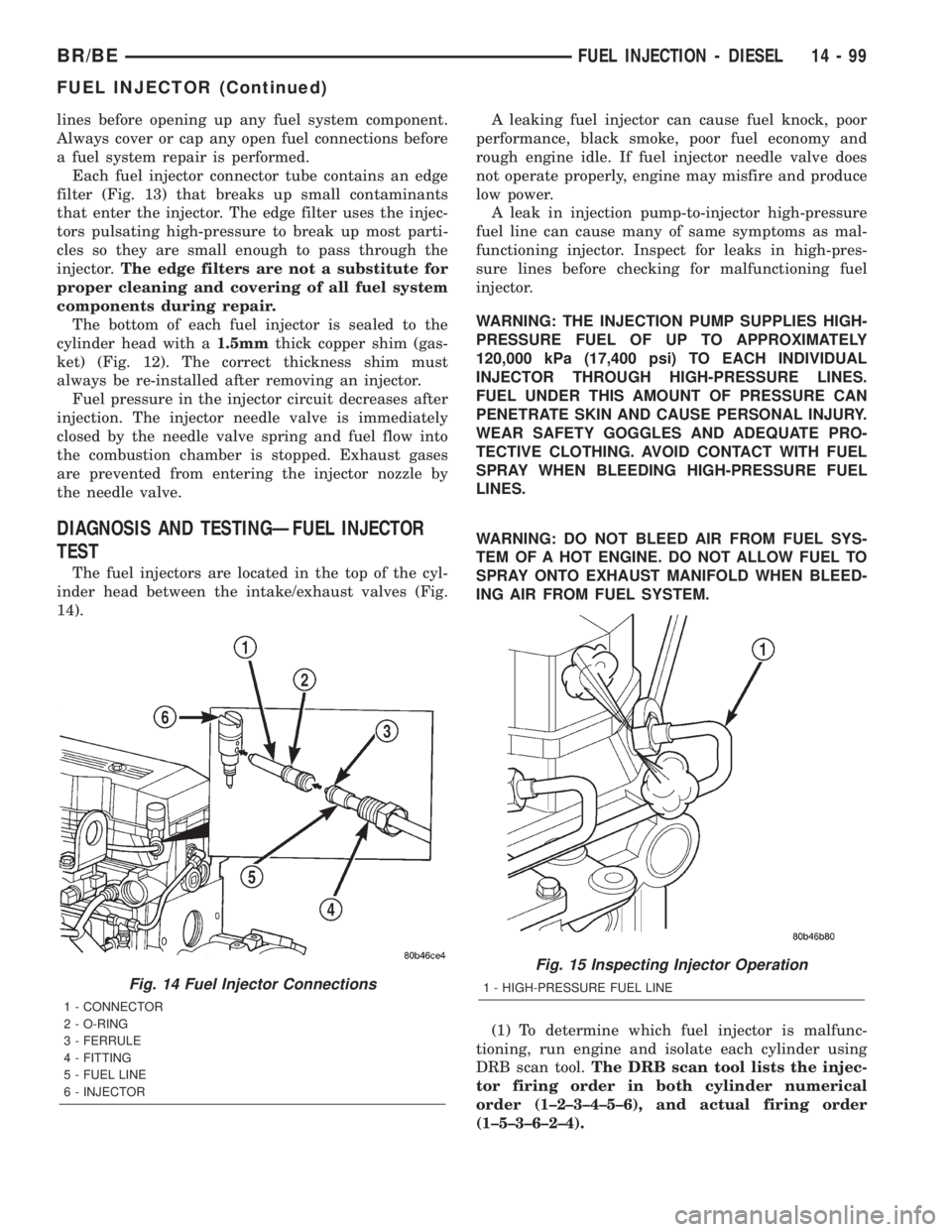

The fuel injectors are located in the top of the cyl-

inder head between the intake/exhaust valves (Fig.

14).A leaking fuel injector can cause fuel knock, poor

performance, black smoke, poor fuel economy and

rough engine idle. If fuel injector needle valve does

not operate properly, engine may misfire and produce

low power.

A leak in injection pump-to-injector high-pressure

fuel line can cause many of same symptoms as mal-

functioning injector. Inspect for leaks in high-pres-

sure lines before checking for malfunctioning fuel

injector.

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

PRESSURE FUEL OF UP TO APPROXIMATELY

120,000 kPa (17,400 psi) TO EACH INDIVIDUAL

INJECTOR THROUGH HIGH-PRESSURE LINES.

FUEL UNDER THIS AMOUNT OF PRESSURE CAN

PENETRATE SKIN AND CAUSE PERSONAL INJURY.

WEAR SAFETY GOGGLES AND ADEQUATE PRO-

TECTIVE CLOTHING. AVOID CONTACT WITH FUEL

SPRAY WHEN BLEEDING HIGH-PRESSURE FUEL

LINES.

WARNING: DO NOT BLEED AIR FROM FUEL SYS-

TEM OF A HOT ENGINE. DO NOT ALLOW FUEL TO

SPRAY ONTO EXHAUST MANIFOLD WHEN BLEED-

ING AIR FROM FUEL SYSTEM.

(1) To determine which fuel injector is malfunc-

tioning, run engine and isolate each cylinder using

DRB scan tool.The DRB scan tool lists the injec-

tor firing order in both cylinder numerical

order (1±2±3±4±5±6), and actual firing order

(1±5±3±6±2±4).

Fig. 14 Fuel Injector Connections

1 - CONNECTOR

2 - O-RING

3 - FERRULE

4 - FITTING

5 - FUEL LINE

6 - INJECTOR

Fig. 15 Inspecting Injector Operation

1 - HIGH-PRESSURE FUEL LINE

BR/BEFUEL INJECTION - DIESEL 14 - 99

FUEL INJECTOR (Continued)

Page 1617 of 2255

FRONT SERVO

DESCRIPTION

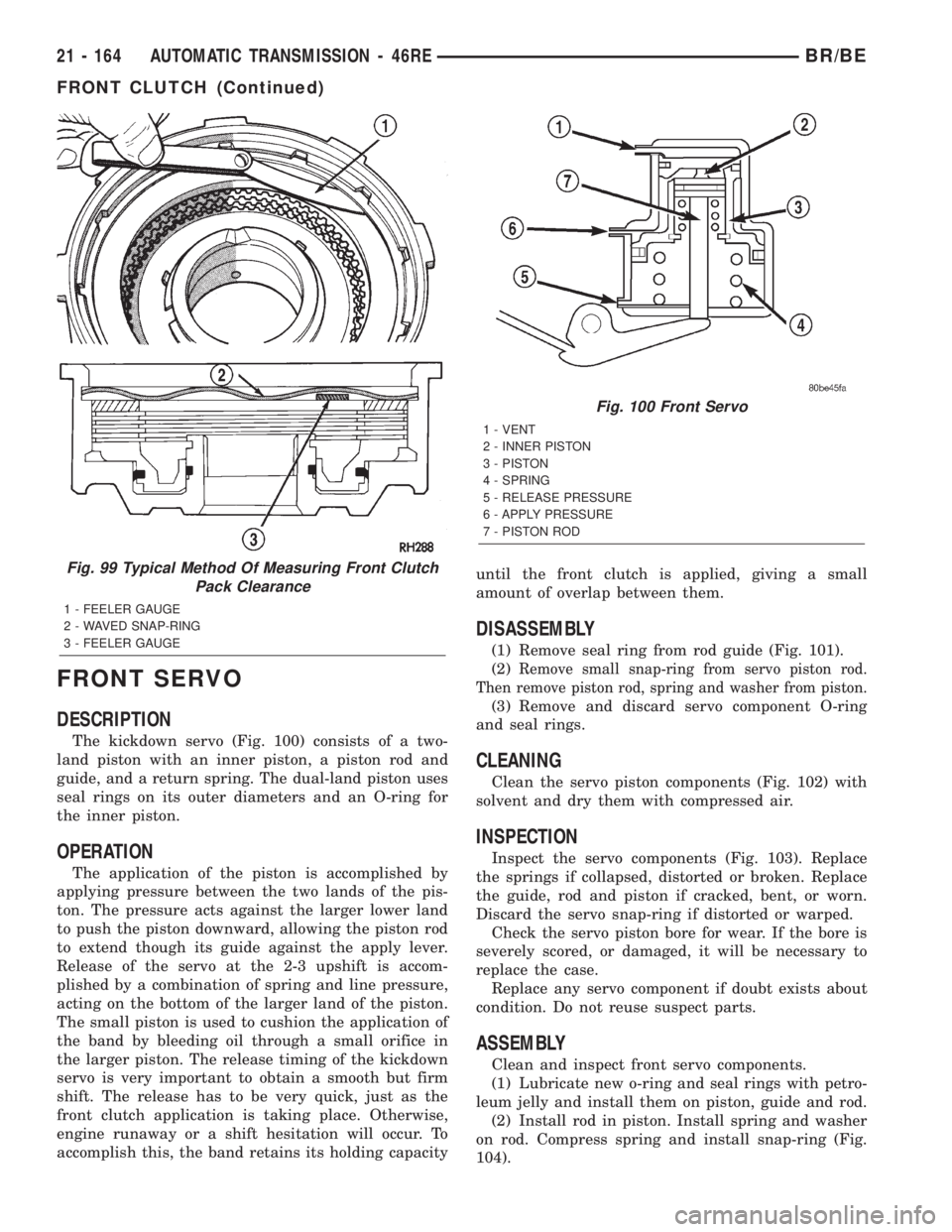

The kickdown servo (Fig. 100) consists of a two-

land piston with an inner piston, a piston rod and

guide, and a return spring. The dual-land piston uses

seal rings on its outer diameters and an O-ring for

the inner piston.

OPERATION

The application of the piston is accomplished by

applying pressure between the two lands of the pis-

ton. The pressure acts against the larger lower land

to push the piston downward, allowing the piston rod

to extend though its guide against the apply lever.

Release of the servo at the 2-3 upshift is accom-

plished by a combination of spring and line pressure,

acting on the bottom of the larger land of the piston.

The small piston is used to cushion the application of

the band by bleeding oil through a small orifice in

the larger piston. The release timing of the kickdown

servo is very important to obtain a smooth but firm

shift. The release has to be very quick, just as the

front clutch application is taking place. Otherwise,

engine runaway or a shift hesitation will occur. To

accomplish this, the band retains its holding capacityuntil the front clutch is applied, giving a small

amount of overlap between them.

DISASSEMBLY

(1) Remove seal ring from rod guide (Fig. 101).

(2)

Remove small snap-ring from servo piston rod.

Then remove piston rod, spring and washer from piston.

(3) Remove and discard servo component O-ring

and seal rings.

CLEANING

Clean the servo piston components (Fig. 102) with

solvent and dry them with compressed air.

INSPECTION

Inspect the servo components (Fig. 103). Replace

the springs if collapsed, distorted or broken. Replace

the guide, rod and piston if cracked, bent, or worn.

Discard the servo snap-ring if distorted or warped.

Check the servo piston bore for wear. If the bore is

severely scored, or damaged, it will be necessary to

replace the case.

Replace any servo component if doubt exists about

condition. Do not reuse suspect parts.

ASSEMBLY

Clean and inspect front servo components.

(1) Lubricate new o-ring and seal rings with petro-

leum jelly and install them on piston, guide and rod.

(2) Install rod in piston. Install spring and washer

on rod. Compress spring and install snap-ring (Fig.

104).

Fig. 99 Typical Method Of Measuring Front Clutch

Pack Clearance

1 - FEELER GAUGE

2 - WAVED SNAP-RING

3 - FEELER GAUGE

Fig. 100 Front Servo

1 - VENT

2 - INNER PISTON

3 - PISTON

4 - SPRING

5 - RELEASE PRESSURE

6 - APPLY PRESSURE

7 - PISTON ROD

21 - 164 AUTOMATIC TRANSMISSION - 46REBR/BE

FRONT CLUTCH (Continued)

Page 1787 of 2255

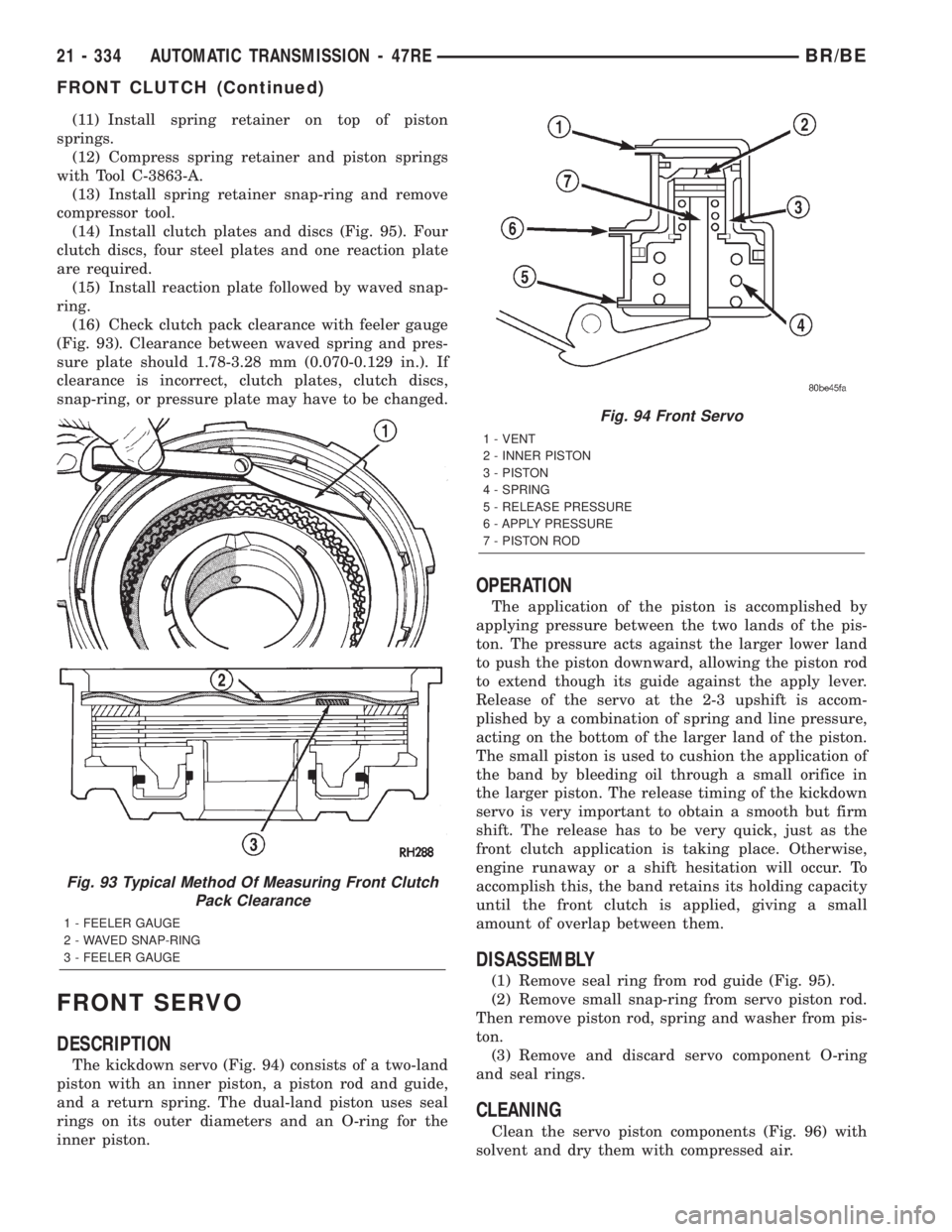

(11) Install spring retainer on top of piston

springs.

(12) Compress spring retainer and piston springs

with Tool C-3863-A.

(13) Install spring retainer snap-ring and remove

compressor tool.

(14) Install clutch plates and discs (Fig. 95). Four

clutch discs, four steel plates and one reaction plate

are required.

(15) Install reaction plate followed by waved snap-

ring.

(16) Check clutch pack clearance with feeler gauge

(Fig. 93). Clearance between waved spring and pres-

sure plate should 1.78-3.28 mm (0.070-0.129 in.). If

clearance is incorrect, clutch plates, clutch discs,

snap-ring, or pressure plate may have to be changed.

FRONT SERVO

DESCRIPTION

The kickdown servo (Fig. 94) consists of a two-land

piston with an inner piston, a piston rod and guide,

and a return spring. The dual-land piston uses seal

rings on its outer diameters and an O-ring for the

inner piston.

OPERATION

The application of the piston is accomplished by

applying pressure between the two lands of the pis-

ton. The pressure acts against the larger lower land

to push the piston downward, allowing the piston rod

to extend though its guide against the apply lever.

Release of the servo at the 2-3 upshift is accom-

plished by a combination of spring and line pressure,

acting on the bottom of the larger land of the piston.

The small piston is used to cushion the application of

the band by bleeding oil through a small orifice in

the larger piston. The release timing of the kickdown

servo is very important to obtain a smooth but firm

shift. The release has to be very quick, just as the

front clutch application is taking place. Otherwise,

engine runaway or a shift hesitation will occur. To

accomplish this, the band retains its holding capacity

until the front clutch is applied, giving a small

amount of overlap between them.

DISASSEMBLY

(1) Remove seal ring from rod guide (Fig. 95).

(2) Remove small snap-ring from servo piston rod.

Then remove piston rod, spring and washer from pis-

ton.

(3) Remove and discard servo component O-ring

and seal rings.

CLEANING

Clean the servo piston components (Fig. 96) with

solvent and dry them with compressed air.

Fig. 93 Typical Method Of Measuring Front Clutch

Pack Clearance

1 - FEELER GAUGE

2 - WAVED SNAP-RING

3 - FEELER GAUGE

Fig. 94 Front Servo

1 - VENT

2 - INNER PISTON

3 - PISTON

4 - SPRING

5 - RELEASE PRESSURE

6 - APPLY PRESSURE

7 - PISTON ROD

21 - 334 AUTOMATIC TRANSMISSION - 47REBR/BE

FRONT CLUTCH (Continued)

Page 2149 of 2255

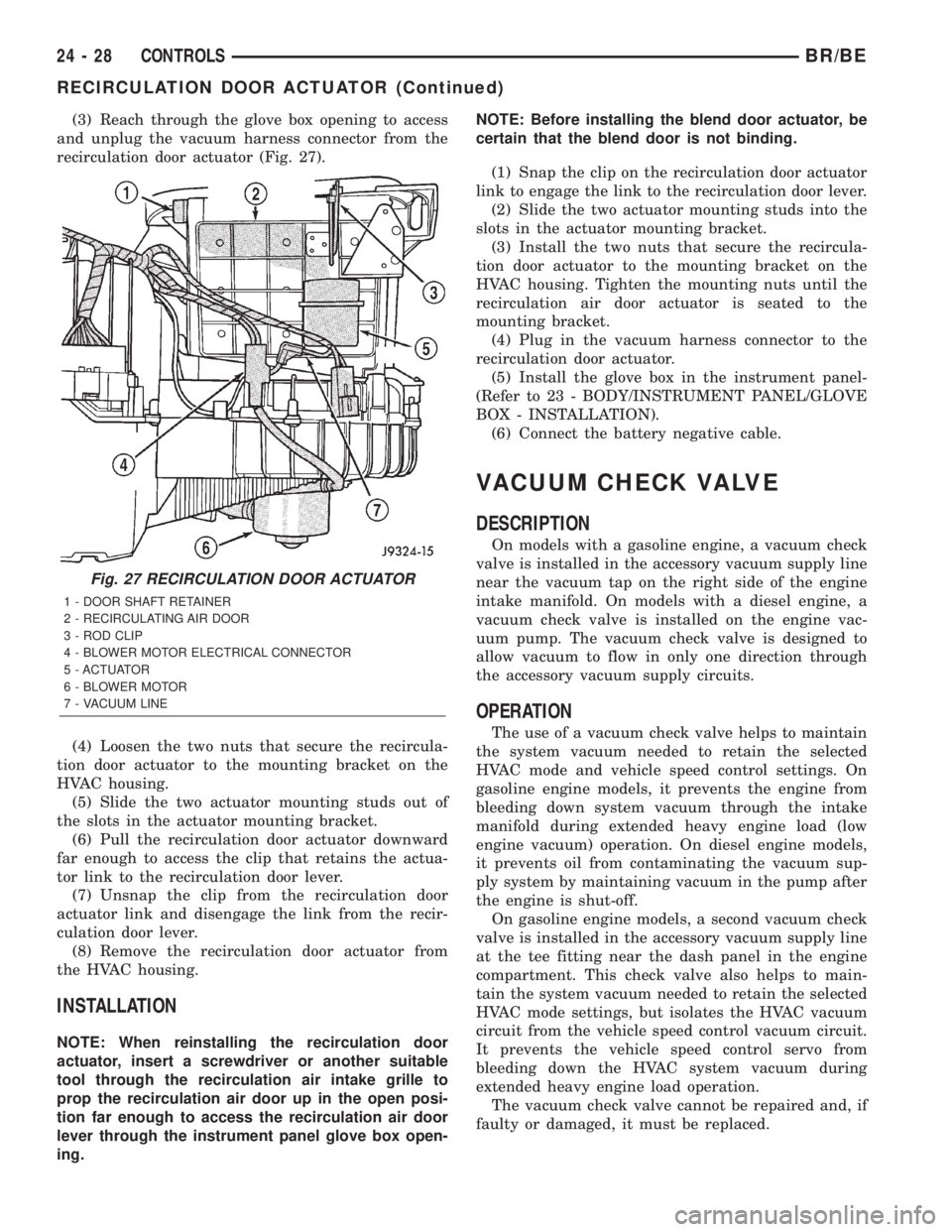

(3) Reach through the glove box opening to access

and unplug the vacuum harness connector from the

recirculation door actuator (Fig. 27).

(4) Loosen the two nuts that secure the recircula-

tion door actuator to the mounting bracket on the

HVAC housing.

(5) Slide the two actuator mounting studs out of

the slots in the actuator mounting bracket.

(6) Pull the recirculation door actuator downward

far enough to access the clip that retains the actua-

tor link to the recirculation door lever.

(7) Unsnap the clip from the recirculation door

actuator link and disengage the link from the recir-

culation door lever.

(8) Remove the recirculation door actuator from

the HVAC housing.

INSTALLATION

NOTE: When reinstalling the recirculation door

actuator, insert a screwdriver or another suitable

tool through the recirculation air intake grille to

prop the recirculation air door up in the open posi-

tion far enough to access the recirculation air door

lever through the instrument panel glove box open-

ing.NOTE: Before installing the blend door actuator, be

certain that the blend door is not binding.

(1) Snap the clip on the recirculation door actuator

link to engage the link to the recirculation door lever.

(2) Slide the two actuator mounting studs into the

slots in the actuator mounting bracket.

(3) Install the two nuts that secure the recircula-

tion door actuator to the mounting bracket on the

HVAC housing. Tighten the mounting nuts until the

recirculation air door actuator is seated to the

mounting bracket.

(4) Plug in the vacuum harness connector to the

recirculation door actuator.

(5) Install the glove box in the instrument panel-

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - INSTALLATION).

(6) Connect the battery negative cable.

VACUUM CHECK VALVE

DESCRIPTION

On models with a gasoline engine, a vacuum check

valve is installed in the accessory vacuum supply line

near the vacuum tap on the right side of the engine

intake manifold. On models with a diesel engine, a

vacuum check valve is installed on the engine vac-

uum pump. The vacuum check valve is designed to

allow vacuum to flow in only one direction through

the accessory vacuum supply circuits.

OPERATION

The use of a vacuum check valve helps to maintain

the system vacuum needed to retain the selected

HVAC mode and vehicle speed control settings. On

gasoline engine models, it prevents the engine from

bleeding down system vacuum through the intake

manifold during extended heavy engine load (low

engine vacuum) operation. On diesel engine models,

it prevents oil from contaminating the vacuum sup-

ply system by maintaining vacuum in the pump after

the engine is shut-off.

On gasoline engine models, a second vacuum check

valve is installed in the accessory vacuum supply line

at the tee fitting near the dash panel in the engine

compartment. This check valve also helps to main-

tain the system vacuum needed to retain the selected

HVAC mode settings, but isolates the HVAC vacuum

circuit from the vehicle speed control vacuum circuit.

It prevents the vehicle speed control servo from

bleeding down the HVAC system vacuum during

extended heavy engine load operation.

The vacuum check valve cannot be repaired and, if

faulty or damaged, it must be replaced.

Fig. 27 RECIRCULATION DOOR ACTUATOR

1 - DOOR SHAFT RETAINER

2 - RECIRCULATING AIR DOOR

3 - ROD CLIP

4 - BLOWER MOTOR ELECTRICAL CONNECTOR

5 - ACTUATOR

6 - BLOWER MOTOR

7 - VACUUM LINE

24 - 28 CONTROLSBR/BE

RECIRCULATION DOOR ACTUATOR (Continued)

Page 2218 of 2255

ABS - DESCRIPTION, BRAKES...........5-35

ABS - OPERATION, BRAKES.............5-36

ABS BRAKE SYSTEM - STANDARD

PROCEDURE, BLEEDING................5-36

ABS INDICATOR - DESCRIPTION.........8J-14

ABS INDICATOR - OPERATION..........8J-14

A/C APPLICATION TABLE,

SPECIFICATIONS......................24-7

A/C COMPRESSOR - DESCRIPTION......24-46

A/C COMPRESSOR - DIAGNOSIS AND

TESTING...........................24-47

A/C COMPRESSOR - INSTALLATION......24-48

A/C COMPRESSOR - OPERATION........24-46

A/C COMPRESSOR - REMOVAL.........24-47

A/C COMPRESSOR CLUTCH -

DESCRIPTION.......................24-11

A/C COMPRESSOR CLUTCH -

INSPECTION........................24-15

A/C COMPRESSOR CLUTCH -

INSTALLATION.......................24-15

A/C COMPRESSOR CLUTCH -

OPERATION.........................24-13

A/C COMPRESSOR CLUTCH - REMOVAL . . 24-13

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-13

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-13

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-17

A/C COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING...............24-17

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-18

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-17

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-18

A/C CONDENSER - DESCRIPTION........24-49

A/C CONDENSER - INSTALLATION.......24-50

A/C CONDENSER - OPERATION..........24-49

A/C CONDENSER - REMOVAL...........24-49

A/C EVAPORATOR - DESCRIPTION.......24-53

A/C EVAPORATOR - INSTALLATION......24-53

A/C EVAPORATOR - OPERATION.........24-53

A/C EVAPORATOR - REMOVAL..........24-53

A/C HEATER CONTROL - DIAGNOSIS

AND TESTING.......................24-18

A/C HIGH PRESSURE SWITCH -

DESCRIPTION.......................24-20

A/C HIGH PRESSURE SWITCH -

DIAGNOSIS AND TESTING.............24-20

A/C HIGH PRESSURE SWITCH -

INSTALLATION.......................24-20

A/C HIGH PRESSURE SWITCH -

OPERATION.........................24-20

A/C HIGH PRESSURE SWITCH -

REMOVAL..........................24-20

A/C LINE COUPLERS - DESCRIPTION.....24-40

A/C LINE COUPLERS - OPERATION......24-41

A/C LINE COUPLERS - STANDARD

PROCEDURE........................24-44

A/C LOW PRESSURE SWITCH -

DESCRIPTION.......................24-21

A/C LOW PRESSURE SWITCH -

DIAGNOSIS AND TESTING.............24-21

A/C LOW PRESSURE SWITCH -

INSTALLATION.......................24-21

A/C LOW PRESSURE SWITCH -

OPERATION

.........................24-21

A/C LOW PRESSURE SWITCH -

REMOVAL

..........................24-21

A/C ORIFICE TUBE - DESCRIPTION

.......24-54

A/C ORIFICE TUBE - INSTALLATION

......24-54

A/C ORIFICE TUBE - OPERATION

........24-54

A/C ORIFICE TUBE - REMOVAL

..........24-54

A/C PERFORMANCE - DIAGNOSIS AND

TESTING

............................24-2

ACCELERATOR PEDAL - INSTALLATION

. . . 14-37

ACCELERATOR PEDAL - REMOVAL

.......14-36

ACCELERATOR PEDAL POSITION

SENSOR - DESCRIPTION

...............14-95

ACCELERATOR PEDAL POSITION

SENSOR - INSTALLATION

..............14-97

ACCELERATOR PEDAL POSITION

SENSOR - OPERATION

................14-95

ACCELERATOR PEDAL POSITION

SENSOR - REMOVAL

..................14-95ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING................7-24,7-27,7-30

ACCUMULATOR - DESCRIPTION.........24-55

ACCUMULATOR - DESCRIPTION . . 21-149,21-319

ACCUMULATOR - INSPECTION . . . 21-150,21-320

ACCUMULATOR - INSTALLATION........24-55

ACCUMULATOR - OPERATION..........24-55

ACCUMULATOR - OPERATION....21-150,21-320

ACCUMULATOR - REMOVAL............24-55

A/C-HEATER CONTROL - DESCRIPTION . . . 24-18

A/C-HEATER CONTROL - INSTALLATION . . . 24-19

A/C-HEATER CONTROL - OPERATION.....24-18

A/C-HEATER CONTROL - REMOVAL......24-19

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT.............................25-2

ACTUATOR - INSTALLATION, BLEND

DOOR.............................24-25

ACTUATOR - INSTALLATION, HEAT/

DEFROST DOOR.....................24-27

ACTUATOR - INSTALLATION, INSIDE

HANDLE.......................23-72,23-80

ACTUATOR - INSTALLATION, PANEL/

DEFROST DOOR.....................24-27

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-28

ACTUATOR - REMOVAL, BLEND DOOR....24-25

ACTUATOR - REMOVAL, HEAT/DEFROST

DOOR.............................24-26

ACTUATOR - REMOVAL, INSIDE HANDLE . 23-72,

23-80

ACTUATOR - REMOVAL, PANEL/DEFROST

DOOR.............................24-26

ACTUATOR - REMOVAL, RECIRCULATION

DOOR.............................24-27

ADAPTER - INSTALLATION, DEFROSTER

AND DEMISTER DUCT.................24-33

ADAPTER - REMOVAL, DEFROSTER AND

DEMISTER DUCT.....................24-33

ADAPTER BRACKET - INSTALLATION,

CAB CHASSIS.......................13-10

ADAPTER BRACKET - REMOVAL, CAB

CHASSIS...........................13-10

ADAPTER HOUSING SEAL - NV4500 -

INSTALLATION.......................21-42

ADAPTER HOUSING SEAL - NV4500 -

REMOVAL..........................21-42

ADAPTER HOUSING SEAL - NV5600 -

INSTALLATION.......................21-85

ADAPTER HOUSING SEAL - NV5600 -

REMOVAL..........................21-85

ADDING ADDITIONAL COOLANT -

STANDARD PROCEDURE................7-16

ADDITIONAL COOLANT - STANDARD

PROCEDURE, ADDING..................7-16

ADDITIVES - STANDARD PROCEDURE,

COOLANT SELECTION..................7-17

ADHESIVE LOCATIONS, SPECIFICATIONS

- STRUCTURAL......................23-44

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-29

ADJUSTER - INSTALLATION, SEAT

TRACK............................23-143

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-29

ADJUSTER - REMOVAL, SEAT TRACK....23-143

ADJUSTER ASSEMBLY - INSTALLATION,

ROCKER ARM........................9-26

ADJUSTER ASSEMBLY - REMOVAL,

ROCKER ARM........................9-26

ADJUSTER ASSY - CLEANING, ROCKER

ARM ..............................9-146

ADJUSTER ASSY - DESCRIPTION,

ROCKER ARM.......................9-145

ADJUSTER ASSY - INSPECTION,

ROCKER ARM.......................9-146

ADJUSTER ASSY - INSTALLATION,

ROCKER ARM...................9-148,9-84

ADJUSTER ASSY - REMOVAL, ROCKER

ARM ..........................9-145,9-84

ADJUSTER KNOB - INSTALLATION,

TURNING LOOP HGT

.................8O-30

ADJUSTER KNOB - REMOVAL, TURNING

LOOP HGT

..........................8O-30

ADJUSTMENT - STANDARD

PROCEDURE, COMPASS VARIATION

......8M-4

ADJUSTMENT, ADJUSTMENTS

. . . 23-101,23-102,

23-103

ADJUSTMENT, ADJUSTMENTS

...........5-30ADJUSTMENT, ADJUSTMENTS...........13-2

ADJUSTMENT, ADJUSTMENTS . . . 21-208,21-380

ADJUSTMENT AND VERIFICATION -

STANDARD PROCEDURE, VALVE LASH....9-141

ADJUSTMENT, BANDS..........21-151,21-321

ADJUSTMENT, CARGO DOOR...........23-78

ADJUSTMENT, CENTER BEARING..........3-8

ADJUSTMENT, FRONT DOOR FORE/AFT . . . 23-69

ADJUSTMENT, FRONT DOOR IN/OUT.....23-70

ADJUSTMENT, FRONT DOOR LATCH......23-73

ADJUSTMENT, FRONT DOOR UP/DOWN . . . 23-70

ADJUSTMENT, PARKING BRAKE SHOES....5-33

ADJUSTMENT, SHIFT LEVER.....21-463,21-500

ADJUSTMENTS - ADJUSTMENT . . 23-101,23-102,

23-103

ADJUSTMENTS - ADJUSTMENT..........5-30

ADJUSTMENTS - ADJUSTMENT..........13-2

ADJUSTMENTS - ADJUSTMENT . . 21-208,21-380

ADJUSTMENTS, FOG LAMP UNIT........8L-13

ADJUSTMENTS, FRONT AXLE - 248FBI....3-19

ADJUSTMENTS, GEAR.................19-18

ADJUSTMENTS, HEADLAMP UNIT.......8L-21

ADJUSTMENTS, REAR AXLE - 248RBI.....3-51

ADJUSTMENTS, REAR AXLE - 267RBI.....3-83

ADJUSTMENTS, REAR AXLE - 286RBI....3-112

ADJUSTMENTS, TRANSMISSION

THROTTLE VALVE CABLE.........21-210,21-382

ADJUSTMENTS, VALVE BODY....21-257,21-428

AIR BLEED - STANDARD PROCEDURE....14-61

AIR CLEANER ELEMENT - INSTALLATION . . 9-130

AIR CLEANER ELEMENT - REMOVAL.....9-129

AIR CONDITIONER - DESCRIPTION,

HEATER .............................24-1

AIR CONDITIONER - OPERATION,

HEATER .............................24-1

AIR CONDITIONING - INSTALLATION,

WATER PUMP BYPASS HOSE WITH.......7-76

AIR CONDITIONING - INSTALLATION,

WATER PUMP BYPASS HOSE

WITHOUT............................7-77

AIR CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH.............7-73

AIR CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT..........7-76

AIR CONTROL MOTOR - DESCRIPTION,

IDLE...............................14-40

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-40

AIR COOLER AND PLUMBING -

CLEANING, CHARGE..................11-19

AIR COOLER AND PLUMBING -

DESCRIPTION, CHARGE...............11-18

AIR COOLER AND PLUMBING -

INSPECTION, CHARGE.................11-19

AIR COOLER AND PLUMBING -

INSTALLATION, CHARGE...............11-20

AIR COOLER AND PLUMBING -

OPERATION, CHARGE.................11-18

AIR COOLER AND PLUMBING -

REMOVAL, CHARGE..................11-18

AIR COOLER SYSTEM - LEAKS -

DIAGNOSIS AND TESTING, CHARGE......11-18

AIR DAM - INSTALLATION, FRONT........13-2

AIR DAM - REMOVAL, FRONT...........13-2

AIR EXHAUSTER - INSTALLATION.......23-77

AIR EXHAUSTER - REMOVAL...........23-77

AIR HEATER - DESCRIPTION, INTAKE....14-104

AIR HEATER - INSTALLATION, INTAKE . . . 14-105

AIR HEATER - OPERATION, INTAKE.....14-104

AIR HEATER - REMOVAL, INTAKE.......14-104

AIR HEATER RELAY - DESCRIPTION,

INTAKE............................14-105

AIR HEATER RELAY - INSTALLATION,

INTAKE............................14-106

AIR HEATER RELAY - OPERATION,

INTAKE............................14-105

AIR HEATER RELAY - REMOVAL, INTAKE . 14-106

AIR IN FUEL SYSTEM - DIAGNOSIS AND

TESTING...........................14-60

AIR INJECTION PUMP - DESCRIPTION....25-29

AIR INJECTION PUMP - DIAGNOSIS AND

TESTING...........................25-29

AIR INJECTION PUMP - INSTALLATION . . . 25-30

AIR INJECTION PUMP - OPERATION

.....25-29

AIR INJECTION PUMP - REMOVAL

.......25-30

AIR INJECTION SYSTEM - DESCRIPTION

. . 25-26

AIR INJECTION SYSTEM - OPERATION

....25-28

AIR INJECTION SYSTEM - TORQUE

......25-29

BR/BEINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 2220 of 2255

AXLE BEARINGS - INSTALLATION . . . 3-123,3-62,

3-94

AXLE BEARINGS - REMOVAL . . . 3-123,3-62,3-94

AXLE LUBRICATION - DESCRIPTION.......0-5

AXLE SHAFT SEALS - INSTALLATION......3-31

AXLE SHAFT SEALS - REMOVAL.........3-31

AXLE SHAFTS - INSTALLATION . 3-123,3-29,3-62,

3-94

AXLE SHAFTS - INTERMEDIATE -

REMOVAL...........................3-30

AXLE SHAFTS - REMOVAL . 3-123,3-29,3-62,3-94

AXLE, SPECIAL TOOLS - FRONT..........3-27

AXLE VACUUM MOTOR - ASSEMBLY......3-34

AXLE VACUUM MOTOR - DESCRIPTION....3-31

AXLE VACUUM MOTOR - DISASSEMBLY . . . 3-34

AXLE VACUUM MOTOR - INSTALLATION . . . 3-34

AXLE VACUUM MOTOR - OPERATION.....3-31

AXLE VACUUM MOTOR - REMOVAL.......3-34

BACKLITE - INSTALLATION............23-145

BACKLITE - REMOVAL................23-145

BACKLITE LATCH AND KEEPER -

INSTALLATION......................23-146

BACKLITE LATCH AND KEEPER -

REMOVAL.........................23-146

BACKLITE VENT GLASS - INSTALLATION . 23-146

BACKLITE VENT GLASS - REMOVAL.....23-146

BAFFLE - INSTALLATION, HVAC

HOUSING INLET.....................24-36

BAFFLE - REMOVAL, HVAC HOUSING

INLET..............................24-35

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL.....................22-4

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.............................2-10

BALL JOINT - DIAGNOSIS AND TESTING,

UPPER..............................2-12

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING

TRANSMISSION CLUTCH.......21-100,21-272

BANDS - ADJUSTMENT.........21-151,21-321

BANDS - DESCRIPTION.........21-150,21-320

BANDS - OPERATION..........21-151,21-321

BAR - DIAGNOSIS AND TESTING, TRACK . . . 2-24

BAR - INSTALLATION, STABILIZER . . . 2-12,2-23,

2-29

BAR - INSTALLATION, TRACK............2-24

BAR - REMOVAL, STABILIZER . . . 2-12,2-23,2-29

BAR - REMOVAL, TRACK...............2-24

BARRELS - INSTALLATION, PANEL

OUTLET............................24-31

BARRELS - REMOVAL, PANEL OUTLET . . . 24-31

BASE BRAKE, SPECIFICATIONS............5-2

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-5

BASE BRAKES, SPECIAL TOOLS...........5-4

BASE COAT/CLEAR COAT FINISH -

DESCRIPTION......................23-129

BASE COAT/CLEAR COAT FINISH -

OPERATION........................23-129

BATTERIES - STANDARD PROCEDURE,

REMOTE KEYLESS ENTRY

TRANSMITTER.......................8N-8

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY CABLE - DESCRIPTION........8F-18

BATTERY CABLE - OPERATION..........8F-18

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-19

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION

....8F-17

BATTERY HOLDDOWN - INSTALLATION

. . . 8F-18

BATTERY HOLDDOWN - OPERATION

.....8F-17

BATTERY HOLDDOWN - REMOVAL

.......8F-17

BATTERY, SPECIFICATIONS

..............8F-6

BATTERY SYSTEM - CLEANING

...........8F-5

BATTERY SYSTEM - DESCRIPTION

........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING

............................8F-2

BATTERY SYSTEM - INSPECTION

.........8F-6

BATTERY SYSTEM - OPERATION

.........8F-2

BATTERY TEMPERATURE SENSOR -

DESCRIPTION

.......................8F-27

BATTERY TEMPERATURE SENSOR -

INSTALLATION

.......................8F-28

BATTERY TEMPERATURE SENSOR -

OPERATION

.........................8F-27BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-27

BATTERY TRAY - DESCRIPTION.........8F-23

BATTERY TRAY - INSTALLATION.........8F-24

BATTERY TRAY - OPERATION...........8F-23

BATTERY TRAY - REMOVAL............8F-23

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-21

BEAM INDICATOR - DIAGNOSIS AND

TESTING, HIGH......................8J-21

BEAM INDICATOR - OPERATION, HIGH....8J-21

BEARING - ADJUSTMENT, CENTER.........3-8

BEARING - INSTALLATION, CENTER........3-8

BEARING - INSTALLATION, CLUTCH

RELEASE............................6-12

BEARING - INSTALLATION, HUB.......2-17,2-9

BEARING - INSTALLATION, OUTPUT

SHAFT FRONT................21-171,21-342

BEARING - INSTALLATION, OUTPUT

SHAFT REAR.................21-172,21-343

BEARING - INSTALLATION, PILOT........6-14

BEARING - INSTALLATION, PITMAN......19-23

BEARING - REMOVAL, CENTER...........3-8

BEARING - REMOVAL, CLUTCH RELEASE . . . 6-12

BEARING - REMOVAL, HUB..........2-16,2-9

BEARING - REMOVAL, OUTPUT SHAFT

FRONT......................21-171,21-342

BEARING - REMOVAL, OUTPUT SHAFT

REAR.......................21-171,21-343

BEARING - REMOVAL, PILOT..............6-14

BEARING - REMOVAL, PITMAN..........19-22

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD........9-158

BEARING CLEARANCE - STANDARD

PROCEDURE, MAIN...................9-159

BEARING FITTING - STANDARD

PROCEDURE, CONNECTING ROD.....9-29,9-87

BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN........9-31

BEARINGS - DESCRIPTION,

CRANKSHAFT MAIN...................9-31

BEARINGS - INSTALLATION, AXLE . . . 3-123,3-62,

3-94

BEARINGS - INSTALLATION, CAMSHAFT . . 9-157,

9-28,9-86

BEARINGS - INSTALLATION,

CRANKSHAFT MAIN...............9-32,9-88

BEARINGS - INSTALLATION,

DIFFERENTIAL CASE.....3-102,3-129,3-41,3-72

BEARINGS - OPERATION, CRANKSHAFT

MAIN...............................9-31

BEARINGS - REMOVAL, AXLE . . . 3-123,3-62,3-94

BEARINGS - REMOVAL, CAMSHAFT . 9-152,9-27,

9-85

BEARINGS - REMOVAL, CRANKSHAFT

MAIN...........................9-31,9-88

BEARINGS - REMOVAL, DIFFERENTIAL

CASE.................3-102,3-129,3-40,3-72

BEARINGS - STANDARD PROCEDURE,

FITTING CRANKSHAFT MAIN............9-88

BELT / CHAIN COVER(S) -

INSTALLATION, TIMING...........9-110,9-54

BELT / CHAIN COVER(S) - REMOVAL,

TIMING........................9-110,9-53

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE............7-24,7-27,7-30

BELT & RETRACTOR - INSTALLATION,

REAR SEAT.........................8O-26

BELT & RETRACTOR - REMOVAL, REAR

SEAT ..............................8O-26

BELT BUCKLE - INSTALLATION, FRONT

SEAT ..............................8O-20

BELT BUCKLE - INSTALLATION, REAR

SEAT ..............................8O-27

BELT BUCKLE - REMOVAL, FRONT SEAT . . 8O-20

BELT BUCKLE - REMOVAL, REAR SEAT . . . 8O-27

BELT SWITCH - DESCRIPTION, SEAT.....8O-28

BELT SWITCH - DIAGNOSIS AND

TESTING, SEAT......................8O-28

BELT SWITCH - OPERATION, SEAT.......8O-28

BELT TENSIONERS - 5.9L -

DESCRIPTION

........................7-19

BELT TENSIONERS - 5.9L -

INSTALLATION

........................7-20

BELT TENSIONERS - 5.9L - OPERATION

....7-19

BELT TENSIONERS - 5.9L - REMOVAL

.....7-19

BELT TENSIONERS - 5.9L DIESEL -

DESCRIPTION

........................7-23BELT TENSIONERS - 5.9L DIESEL -

INSTALLATION........................7-23

BELT TENSIONERS - 5.9L DIESEL -

OPERATION..........................7-23

BELT TENSIONERS - 5.9L DIESEL -

REMOVAL...........................7-23

BELT TENSIONERS - 8.0L -

DESCRIPTION........................7-20

BELT TENSIONERS - 8.0L -

INSTALLATION........................7-22

BELT TENSIONERS - 8.0L - OPERATION....7-21

BELT TENSIONERS - 8.0L - REMOVAL.....7-21

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT.................8O-29

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT.....................8O-29

BELT WEATHERSTRIP - INSTALLATION,

FRONT DOOR INNER.................23-153

BELT WEATHERSTRIP - INSTALLATION,

FRONT DOOR OUTER................23-153

BELT WEATHERSTRIP - REMOVAL,

FRONT DOOR INNER.................23-153

BELT WEATHERSTRIP - REMOVAL,

FRONT DOOR OUTER................23-153

BELT/CHAIN AND SPROCKETS -

INSTALLATION, TIMING...........9-111,9-55

BELT/CHAIN AND SPROCKETS -

REMOVAL, TIMING...............9-111,9-54

BELTS - 5.9L - INSTALLATION, DRIVE.....7-26

BELTS - 5.9L - REMOVAL, DRIVE.........7-26

BELTS - 5.9L DIESEL - INSTALLATION,

DRIVE..............................7-32

BELTS - 5.9L DIESEL - REMOVAL, DRIVE . . 7-32

BELTS - 8.0L - INSTALLATION, DRIVE.....7-29

BELTS - 8.0L - REMOVAL, DRIVE.........7-29

BENCH - INSTALLATION, SEAT - SPLIT . . 23-134

BENCH - INSTALLATION, SEAT BACK -

SPLIT.............................23-136

BENCH - INSTALLATION, SEAT BACK

COVER - SPLIT.....................23-137

BENCH - INSTALLATION, SEAT CUSHION

COVER - SPLIT.....................23-140

BENCH - INSTALLATION, SEAT TRACK -

SPLIT.............................23-142

BENCH - REMOVAL, SEAT - SPLIT......23-133

BENCH - REMOVAL, SEAT BACK - SPLIT . 23-135

BENCH - REMOVAL, SEAT BACK COVER

- SPLIT...........................23-137

BENCH - REMOVAL, SEAT CUSHION

COVER - SPLIT.....................23-139

BENCH - REMOVAL, SEAT TRACK -

SPLIT.............................23-142

BENCH SEAT - INSTALLATION, SEAT....23-133

BENCH SEAT - INSTALLATION, SEAT

BACK.............................23-135

BENCH SEAT - REMOVAL, SEAT........23-133

BENCH SEAT - REMOVAL, SEAT BACK . . . 23-135

BEZEL - INSTALLATION, CLUSTER......23-108

BEZEL - REMOVAL, CLUSTER..........23-108

BIN - INSTALLATION, CUBBY..........23-109

BIN - INSTALLATION, STORAGE........23-114

BIN - REMOVAL, CUBBY..............23-108

BIN - REMOVAL, STORAGE............23-114

BLADE - DESCRIPTION, WIPER.........8R-12

BLADE - INSTALLATION, WIPER.........8R-13

BLADE - OPERATION, WIPER...........8R-13

BLADE - REMOVAL, WIPER............8R-13

BLEED - STANDARD PROCEDURE, AIR....14-61

BLEEDING - STANDARD PROCEDURE......5-19

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-7

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-27

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-8

BLEEDING ABS BRAKE SYSTEM -

STANDARD PROCEDURE................5-36

BLEND DOOR - INSTALLATION..........24-37

BLEND DOOR - REMOVAL.............24-37

BLEND DOOR ACTUATOR -

INSTALLATION.......................24-25

BLEND DOOR ACTUATOR - REMOVAL

....24-25

BLOCK - CLEANING, ENGINE

........9-27,9-85

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR

...................24-23

BLOCK - DESCRIPTION, JUNCTION

....8W-97-6

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR

............24-23

BR/BEINDEX 3

Description Group-Page Description Group-Page Description Group-Page