warning DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 190 of 2255

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 35

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

SPECIFICATIONS

BASE BRAKE.........................2

TORQUE CHART......................3

SPECIAL TOOLS

BASE BRAKES........................4

HYDRAULIC/MECHANICAL

DESCRIPTION..........................4

WARNING.............................4

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM.............................5

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................7

STANDARD PROCEDURE - PRESSURE

BLEEDING............................8

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING....................8

STANDARD PROCEDURE - ISO FLARING . . . 8

COMBINATION VALVE

DESCRIPTION..........................8

OPERATION............................9

DIAGNOSIS AND TESTING - COMBINATION

VALVE ...............................9

REMOVAL.............................9

INSTALLATION..........................9

DISC BRAKE CALIPERS

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL

REMOVAL - REAR.....................10

REMOVAL - FRONT....................11

DISASSEMBLY.........................11

CLEANING............................12

INSPECTION..........................12ASSEMBLY............................13

INSTALLATION

INSTALLATION - REAR.................14

INSTALLATION - FRONT................14

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................15

STANDARD PROCEDURE - BRAKE FLUID

LEVEL..............................15

SPECIFICATIONS

BRAKE FLUID........................15

FLUID RESERVOIR

REMOVAL.............................15

INSTALLATION.........................15

PEDAL

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................17

POWER BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER...........................18

STANDARD PROCEDURE - BLEEDING......19

REMOVAL.............................19

INSTALLATION.........................19

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR..................20

REMOVAL

REMOVAL - REAR.....................21

REMOVAL - FRONT ± 2500..............22

REMOVAL - FRONT - 3500..............22

INSTALLATION

INSTALLATION - REAR.................22

INSTALLATION - FRONT ± 2500..........23

INSTALLATION - FRONT - 3500...........23

BR/BEBRAKES 5 - 1

Page 193 of 2255

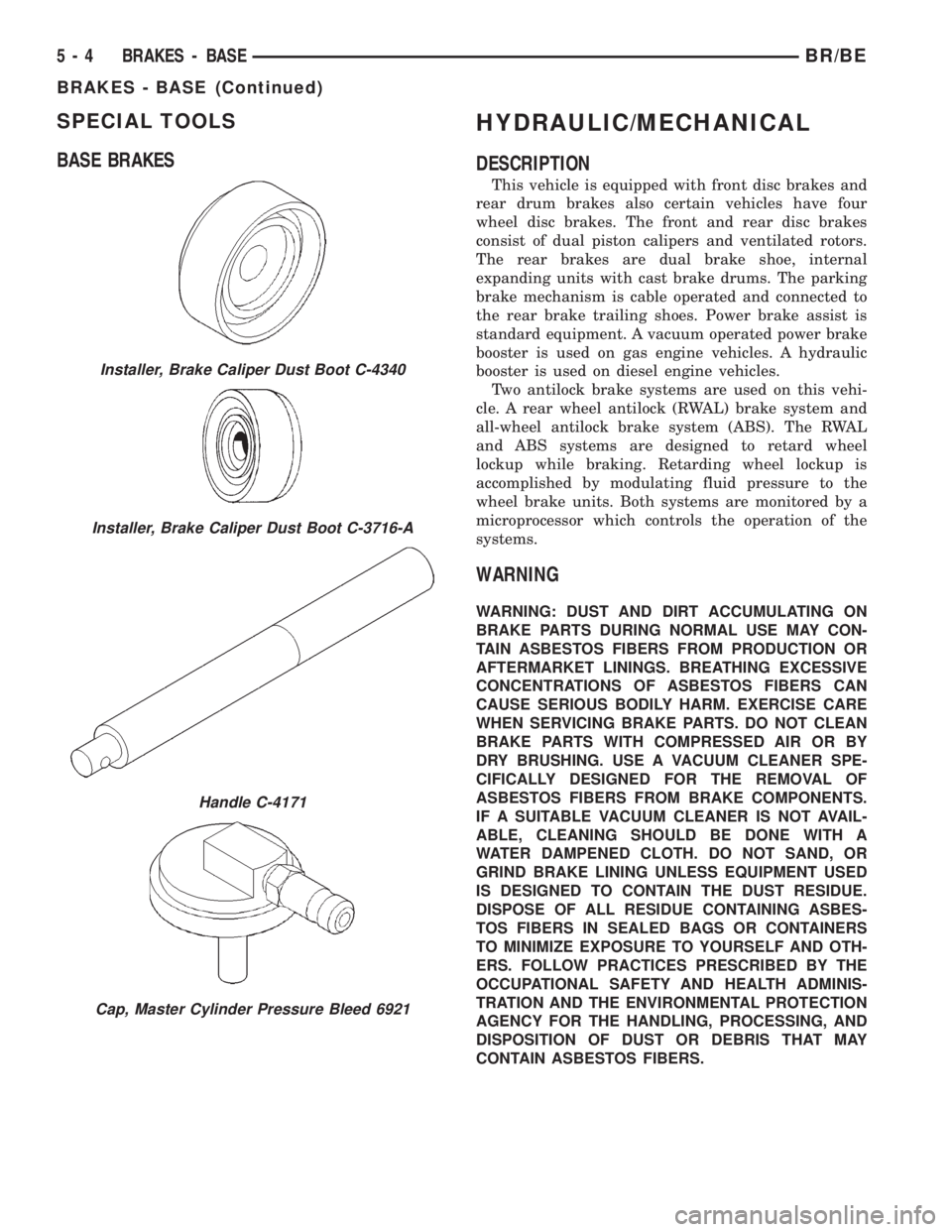

SPECIAL TOOLS

BASE BRAKESHYDRAULIC/MECHANICAL

DESCRIPTION

This vehicle is equipped with front disc brakes and

rear drum brakes also certain vehicles have four

wheel disc brakes. The front and rear disc brakes

consist of dual piston calipers and ventilated rotors.

The rear brakes are dual brake shoe, internal

expanding units with cast brake drums. The parking

brake mechanism is cable operated and connected to

the rear brake trailing shoes. Power brake assist is

standard equipment. A vacuum operated power brake

booster is used on gas engine vehicles. A hydraulic

booster is used on diesel engine vehicles.

Two antilock brake systems are used on this vehi-

cle. A rear wheel antilock (RWAL) brake system and

all-wheel antilock brake system (ABS). The RWAL

and ABS systems are designed to retard wheel

lockup while braking. Retarding wheel lockup is

accomplished by modulating fluid pressure to the

wheel brake units. Both systems are monitored by a

microprocessor which controls the operation of the

systems.

WARNING

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET LININGS. BREATHING EXCESSIVE

CONCENTRATIONS OF ASBESTOS FIBERS CAN

CAUSE SERIOUS BODILY HARM. EXERCISE CARE

WHEN SERVICING BRAKE PARTS. DO NOT CLEAN

BRAKE PARTS WITH COMPRESSED AIR OR BY

DRY BRUSHING. USE A VACUUM CLEANER SPE-

CIFICALLY DESIGNED FOR THE REMOVAL OF

ASBESTOS FIBERS FROM BRAKE COMPONENTS.

IF A SUITABLE VACUUM CLEANER IS NOT AVAIL-

ABLE, CLEANING SHOULD BE DONE WITH A

WATER DAMPENED CLOTH. DO NOT SAND, OR

GRIND BRAKE LINING UNLESS EQUIPMENT USED

IS DESIGNED TO CONTAIN THE DUST RESIDUE.

DISPOSE OF ALL RESIDUE CONTAINING ASBES-

TOS FIBERS IN SEALED BAGS OR CONTAINERS

TO MINIMIZE EXPOSURE TO YOURSELF AND OTH-

ERS. FOLLOW PRACTICES PRESCRIBED BY THE

OCCUPATIONAL SAFETY AND HEALTH ADMINIS-

TRATION AND THE ENVIRONMENTAL PROTECTION

AGENCY FOR THE HANDLING, PROCESSING, AND

DISPOSITION OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

Installer, Brake Caliper Dust Boot C-4340

Installer, Brake Caliper Dust Boot C-3716-A

Handle C-4171

Cap, Master Cylinder Pressure Bleed 6921

5 - 4 BRAKES - BASEBR/BE

BRAKES - BASE (Continued)

Page 197 of 2255

STANDARD PROCEDURE - PRESSURE

BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

If pressure bleeding equipment will be used, the

front brake metering valve will have to be held open

to bleed the front brakes. The valve stem is located

in the forward end or top of the combination valve.

The stem must either be pressed inward, or held out-

ward slightly. A spring clip tool or helper is needed to

hold the valve stem in position.

Follow the manufacturers instructions carefully

when using pressure equipment. Do not exceed the

tank manufacturers pressure recommendations. Gen-

erally, a tank pressure of 15-20 psi is sufficient for

bleeding.

Fill the bleeder tank with recommended fluid and

purge air from the tank lines before bleeding.

Do not pressure bleed without a proper master cyl-

inder adapter. The wrong adapter can lead to leak-

age, or drawing air back into the system. Use

adapter provided with the equipment or Adapter

6921.

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE INVERTED

FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

(1) Cut off damaged tube with Tubing Cutter.

(2) Ream cut edges of tubing to ensure proper

flare.

(3) Install replacement tube nut on the tube.

(4) Insert tube in flaring tool.

(5) Place gauge form over the end of the tube.

(6) Push tubing through flaring tool jaws until

tube contacts recessed notch in gauge that matches

tube diameter.

(7) Tighten the tool bar on the tube

(8) Insert plug on gauge in the tube. Then swing

compression disc over gauge and center tapered flar-

ing screw in recess of compression disc (Fig. 2).

(9) Tighten tool handle until plug gauge is

squarely seated on jaws of flaring tool. This will start

the inverted flare.

(10) Remove the plug gauge and complete the

inverted flare.

STANDARD PROCEDURE - ISO FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

To make a ISO flare use an ISO flaring tool kit.

(1) Cut off damaged tube with Tubing Cutter.

(2) Remove any burrs from the inside of the tube.

(3) Install tube nut on the tube.

(4) Position the tube in the flaring tool flush with

the top of the tool bar (Fig. 3). Then tighten the tool

bar on the tube.

(5) Install the correct size adaptor on the flaring

tool yoke screw.

(6) Lubricate the adaptor.

(7) Align the adaptor and yoke screw over the tube

(Fig. 3).

(8) Turn the yoke screw in until the adaptor is

squarely seated on the tool bar.

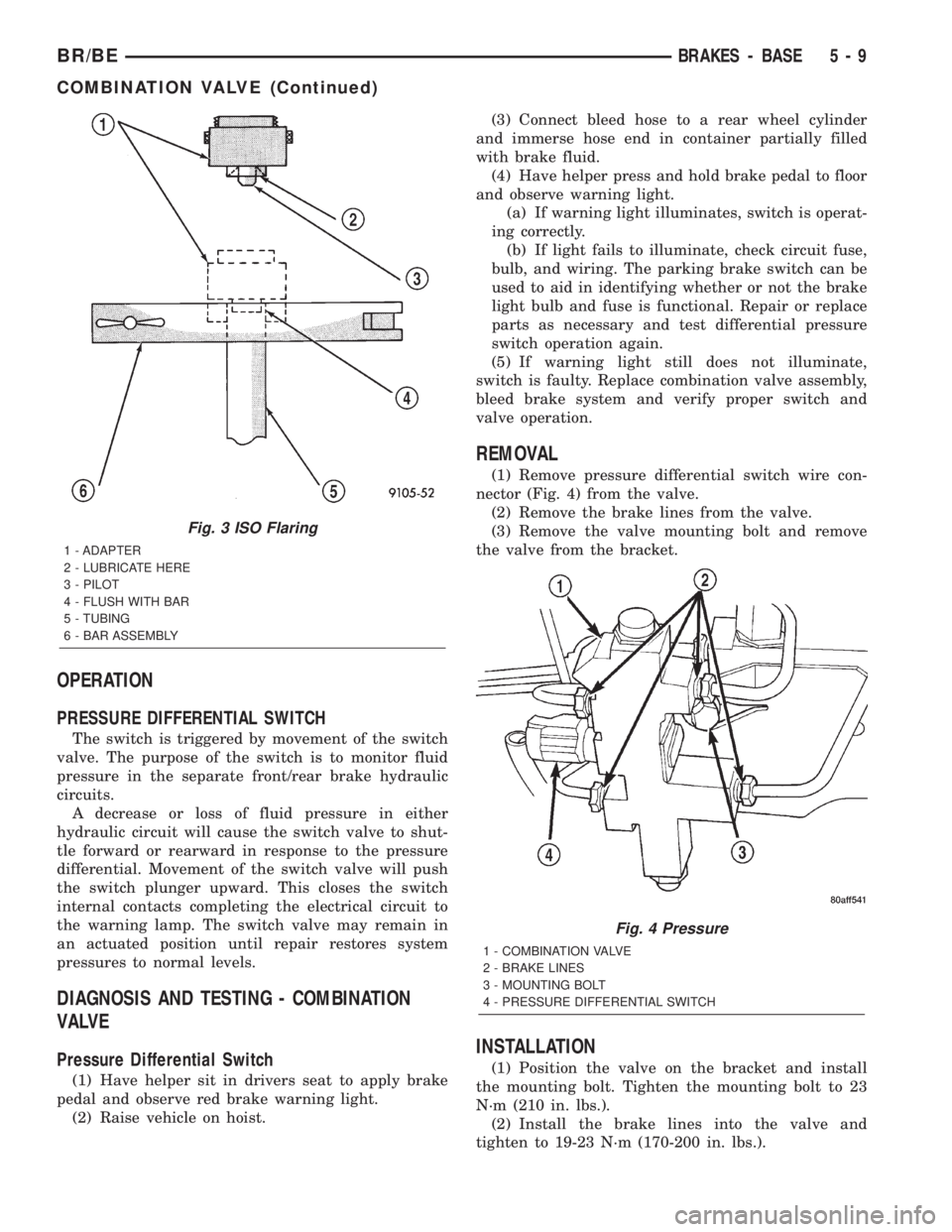

COMBINATION VALVE

DESCRIPTION

The combination valve/rear brake proportioning

valve are not repairable and must be replaced as an

assembly.

The pressure differential switch is connected to the

brake warning lamp.

Fig. 2 Inverted Flare Tools

5 - 8 BRAKES - BASEBR/BE

HYDRAULIC/MECHANICAL (Continued)

Page 198 of 2255

OPERATION

PRESSURE DIFFERENTIAL SWITCH

The switch is triggered by movement of the switch

valve. The purpose of the switch is to monitor fluid

pressure in the separate front/rear brake hydraulic

circuits.

A decrease or loss of fluid pressure in either

hydraulic circuit will cause the switch valve to shut-

tle forward or rearward in response to the pressure

differential. Movement of the switch valve will push

the switch plunger upward. This closes the switch

internal contacts completing the electrical circuit to

the warning lamp. The switch valve may remain in

an actuated position until repair restores system

pressures to normal levels.

DIAGNOSIS AND TESTING - COMBINATION

VALVE

Pressure Differential Switch

(1) Have helper sit in drivers seat to apply brake

pedal and observe red brake warning light.

(2) Raise vehicle on hoist.(3) Connect bleed hose to a rear wheel cylinder

and immerse hose end in container partially filled

with brake fluid.

(4) Have helper press and hold brake pedal to floor

and observe warning light.

(a) If warning light illuminates, switch is operat-

ing correctly.

(b) If light fails to illuminate, check circuit fuse,

bulb, and wiring. The parking brake switch can be

used to aid in identifying whether or not the brake

light bulb and fuse is functional. Repair or replace

parts as necessary and test differential pressure

switch operation again.

(5) If warning light still does not illuminate,

switch is faulty. Replace combination valve assembly,

bleed brake system and verify proper switch and

valve operation.

REMOVAL

(1) Remove pressure differential switch wire con-

nector (Fig. 4) from the valve.

(2) Remove the brake lines from the valve.

(3) Remove the valve mounting bolt and remove

the valve from the bracket.

INSTALLATION

(1) Position the valve on the bracket and install

the mounting bolt. Tighten the mounting bolt to 23

N´m (210 in. lbs.).

(2) Install the brake lines into the valve and

tighten to 19-23 N´m (170-200 in. lbs.).

Fig. 3 ISO Flaring

1 - ADAPTER

2 - LUBRICATE HERE

3 - PILOT

4 - FLUSH WITH BAR

5 - TUBING

6 - BAR ASSEMBLY

Fig. 4 Pressure

1 - COMBINATION VALVE

2 - BRAKE LINES

3 - MOUNTING BOLT

4 - PRESSURE DIFFERENTIAL SWITCH

BR/BEBRAKES - BASE 5 - 9

COMBINATION VALVE (Continued)

Page 201 of 2255

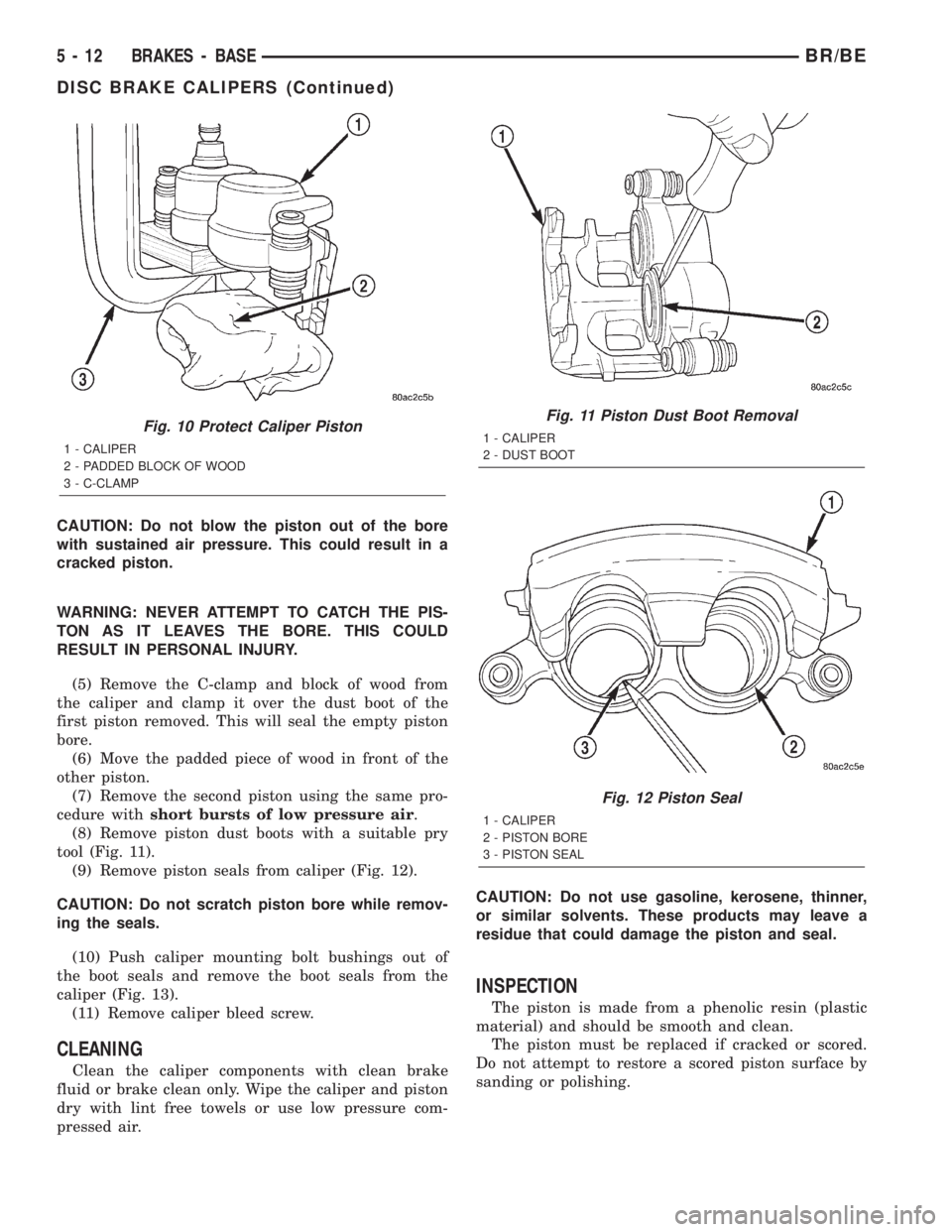

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston.

WARNING: NEVER ATTEMPT TO CATCH THE PIS-

TON AS IT LEAVES THE BORE. THIS COULD

RESULT IN PERSONAL INJURY.

(5) Remove the C-clamp and block of wood from

the caliper and clamp it over the dust boot of the

first piston removed. This will seal the empty piston

bore.

(6) Move the padded piece of wood in front of the

other piston.

(7) Remove the second piston using the same pro-

cedure withshort bursts of low pressure air.

(8) Remove piston dust boots with a suitable pry

tool (Fig. 11).

(9) Remove piston seals from caliper (Fig. 12).

CAUTION: Do not scratch piston bore while remov-

ing the seals.

(10) Push caliper mounting bolt bushings out of

the boot seals and remove the boot seals from the

caliper (Fig. 13).

(11) Remove caliper bleed screw.

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure com-

pressed air.CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

Fig. 10 Protect Caliper Piston

1 - CALIPER

2 - PADDED BLOCK OF WOOD

3 - C-CLAMP

Fig. 11 Piston Dust Boot Removal

1 - CALIPER

2 - DUST BOOT

Fig. 12 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

5 - 12 BRAKES - BASEBR/BE

DISC BRAKE CALIPERS (Continued)

Page 208 of 2255

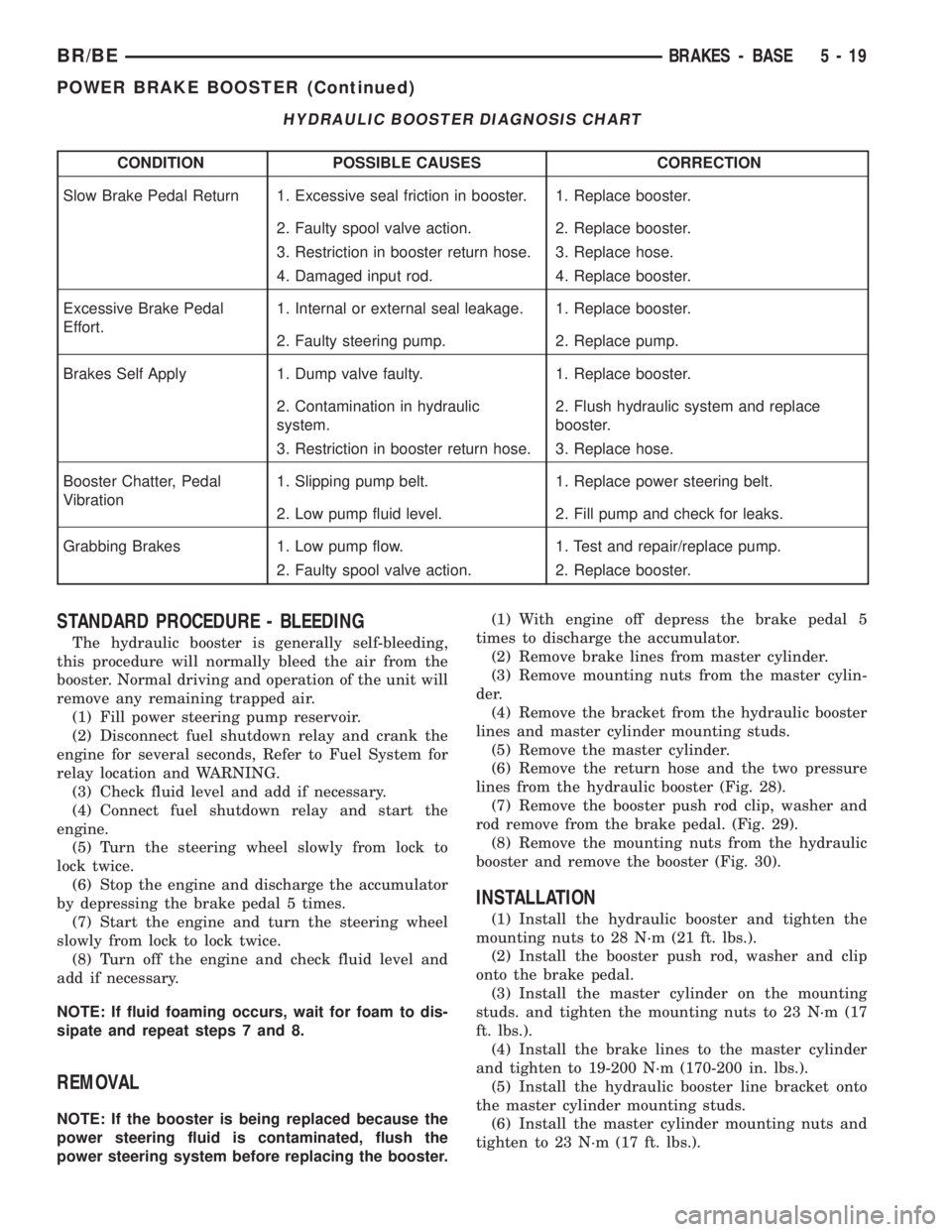

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 28).

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal. (Fig. 29).

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster (Fig. 30).

INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N´m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

onto the brake pedal.

(3) Install the master cylinder on the mounting

studs. and tighten the mounting nuts to 23 N´m (17

ft. lbs.).

(4) Install the brake lines to the master cylinder

and tighten to 19-200 N´m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N´m (17 ft. lbs.).

BR/BEBRAKES - BASE 5 - 19

POWER BRAKE BOOSTER (Continued)

Page 217 of 2255

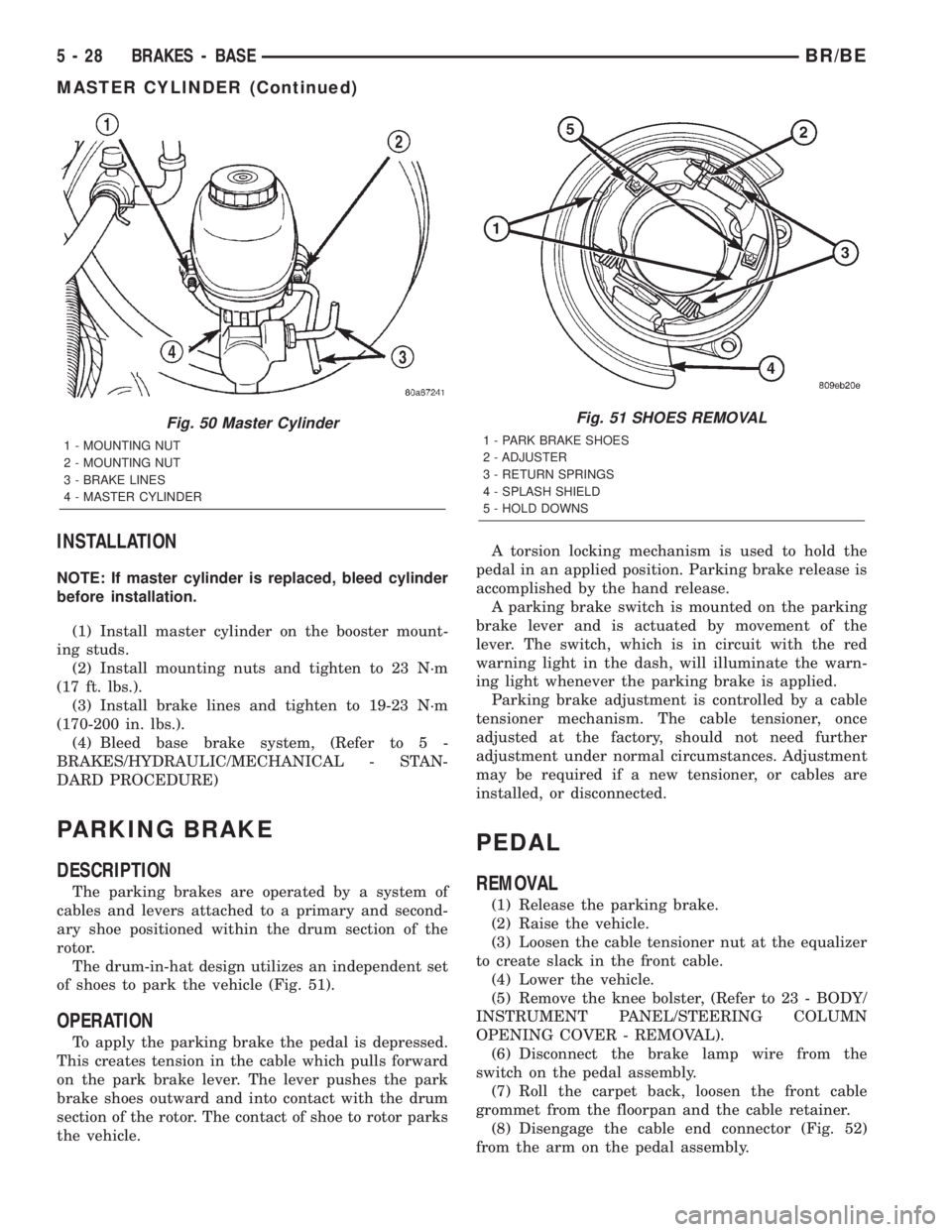

INSTALLATION

NOTE: If master cylinder is replaced, bleed cylinder

before installation.

(1) Install master cylinder on the booster mount-

ing studs.

(2) Install mounting nuts and tighten to 23 N´m

(17 ft. lbs.).

(3) Install brake lines and tighten to 19-23 N´m

(170-200 in. lbs.).

(4) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE)

PARKING BRAKE

DESCRIPTION

The parking brakes are operated by a system of

cables and levers attached to a primary and second-

ary shoe positioned within the drum section of the

rotor.

The drum-in-hat design utilizes an independent set

of shoes to park the vehicle (Fig. 51).

OPERATION

To apply the parking brake the pedal is depressed.

This creates tension in the cable which pulls forward

on the park brake lever. The lever pushes the park

brake shoes outward and into contact with the drum

section of the rotor. The contact of shoe to rotor parks

the vehicle.A torsion locking mechanism is used to hold the

pedal in an applied position. Parking brake release is

accomplished by the hand release.

A parking brake switch is mounted on the parking

brake lever and is actuated by movement of the

lever. The switch, which is in circuit with the red

warning light in the dash, will illuminate the warn-

ing light whenever the parking brake is applied.

Parking brake adjustment is controlled by a cable

tensioner mechanism. The cable tensioner, once

adjusted at the factory, should not need further

adjustment under normal circumstances. Adjustment

may be required if a new tensioner, or cables are

installed, or disconnected.

PEDAL

REMOVAL

(1) Release the parking brake.

(2) Raise the vehicle.

(3) Loosen the cable tensioner nut at the equalizer

to create slack in the front cable.

(4) Lower the vehicle.

(5) Remove the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(6) Disconnect the brake lamp wire from the

switch on the pedal assembly.

(7) Roll the carpet back, loosen the front cable

grommet from the floorpan and the cable retainer.

(8) Disengage the cable end connector (Fig. 52)

from the arm on the pedal assembly.

Fig. 50 Master Cylinder

1 - MOUNTING NUT

2 - MOUNTING NUT

3 - BRAKE LINES

4 - MASTER CYLINDER

Fig. 51 SHOES REMOVAL

1 - PARK BRAKE SHOES

2 - ADJUSTER

3 - RETURN SPRINGS

4 - SPLASH SHIELD

5 - HOLD DOWNS

5 - 28 BRAKES - BASEBR/BE

MASTER CYLINDER (Continued)

Page 224 of 2255

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................35

OPERATION...........................36

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES............................36

STANDARD PROCEDURE

STANDARD PROCEDURE - RWAL SERVICE

PRECAUTIONS.......................36

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM......................36

SPECIFICATIONS

TORQUE CHART......................37

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................38

OPERATION...........................38

REMOVAL

REMOVAL - 4X2......................39REMOVAL - 4X4......................39

INSTALLATION

INSTALLATION - 4X2...................39

INSTALLATION - 4X4...................39

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR......................40

REMOVAL.............................40

INSTALLATION.........................40

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................40

OPERATION...........................40

REMOVAL.............................41

INSTALLATION.........................41

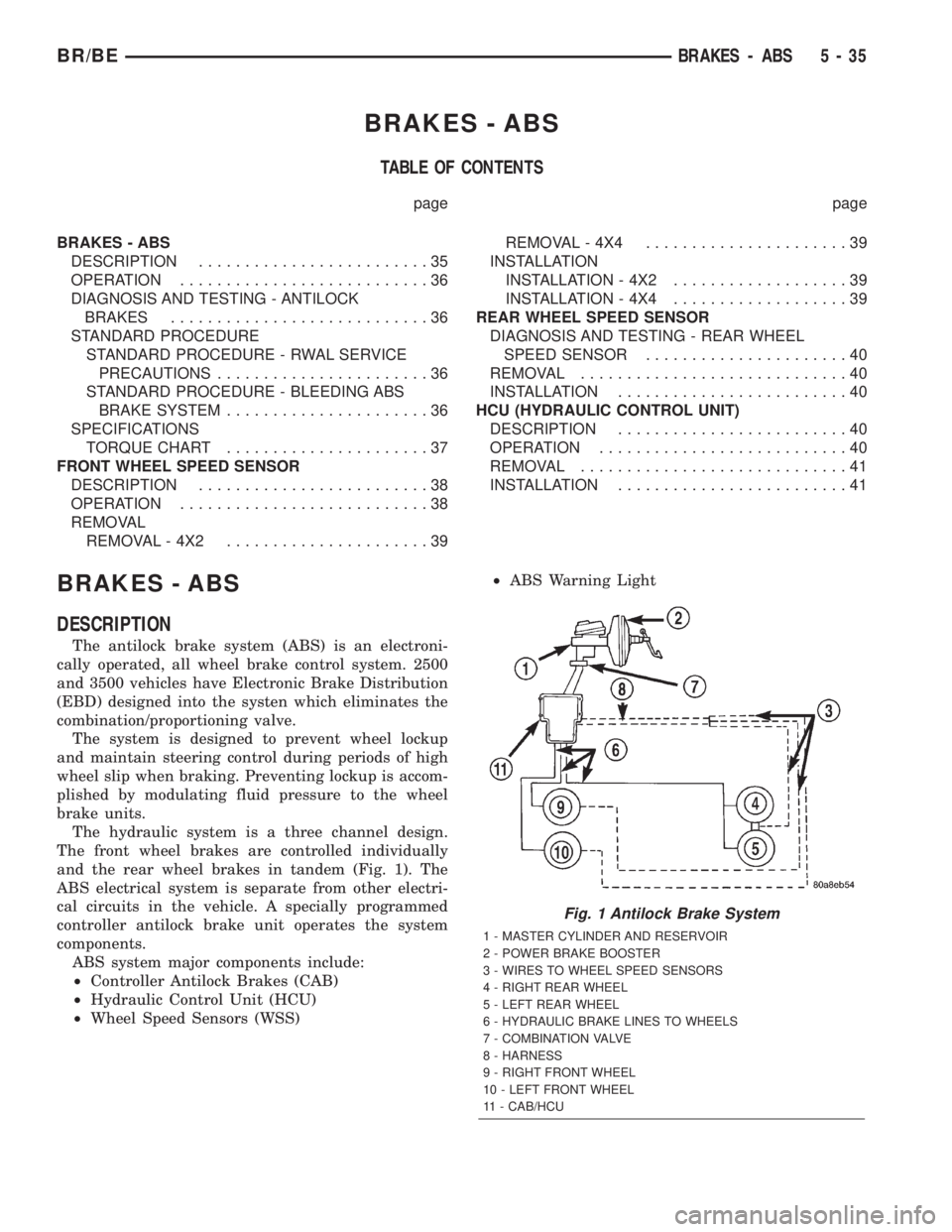

BRAKES - ABS

DESCRIPTION

The antilock brake system (ABS) is an electroni-

cally operated, all wheel brake control system. 2500

and 3500 vehicles have Electronic Brake Distribution

(EBD) designed into the systen which eliminates the

combination/proportioning valve.

The system is designed to prevent wheel lockup

and maintain steering control during periods of high

wheel slip when braking. Preventing lockup is accom-

plished by modulating fluid pressure to the wheel

brake units.

The hydraulic system is a three channel design.

The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 1). The

ABS electrical system is separate from other electri-

cal circuits in the vehicle. A specially programmed

controller antilock brake unit operates the system

components.

ABS system major components include:

²Controller Antilock Brakes (CAB)

²Hydraulic Control Unit (HCU)

²Wheel Speed Sensors (WSS)²ABS Warning Light

Fig. 1 Antilock Brake System

1 - MASTER CYLINDER AND RESERVOIR

2 - POWER BRAKE BOOSTER

3 - WIRES TO WHEEL SPEED SENSORS

4 - RIGHT REAR WHEEL

5 - LEFT REAR WHEEL

6 - HYDRAULIC BRAKE LINES TO WHEELS

7 - COMBINATION VALVE

8 - HARNESS

9 - RIGHT FRONT WHEEL

10 - LEFT FRONT WHEEL

11 - CAB/HCU

BR/BEBRAKES - ABS 5 - 35

Page 225 of 2255

OPERATION

Battery voltage is supplied to the CAB when a

speed of 15 miles per hour is reached. The CAB per-

forms a system initialization procedure at this point.

Initialization consists of a static and dynamic self

check of system electrical components.

The static and dynamic checks occurs at ignition

start up. During the dynamic check, the CAB briefly

cycles the pump and solenoids to verify operation. An

audible noise may be heard during this self check.

This noise should be considered normal.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

The CAB monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the CAB will not activate any ABS components as

long as sensor inputs indicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip. Periods

of wheel slip occur when brake stops involve high

pedal pressure and rate of vehicle deceleration.

The antilock system prevents lockup during a

wheel slip condition by modulating fluid apply pres-

sure to the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve actuates, Stop-

ping anymore pressure build Ðup to the calipers.

Then the Dump valve dumps off pressure until the

wheel unlocks. This will continue until the wheels

quit slipping altogether.

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES

The ABS brake system performs several self-tests

every time the ignition switch is turned on and the

vehicle is driven. The CAB monitors the systems

input and output circuits to verify the system is oper-

ating correctly. If the on board diagnostic system

senses that a circuit is malfunctioning the system

will set a trouble code in its memory.

NOTE: An audible noise may be heard during the

self-test. This noise should be considered normal.

NOTE: The MDS or DRB III scan tool is used to

diagnose the ABS system. For additional informa-

tion refer to the Antilock Brake section in Group

8W. For test procedures refer to the Chassis Diag-

nostic Manual.

STANDARD PROCEDURE

STANDARD PROCEDURE - RWAL SERVICE

PRECAUTIONS

The RWAL uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.In testing for open or short circuits, do

not ground or apply voltage to any of the cir-

cuits unless instructed to do so for a diagnostic

procedure.These circuits should only be tested

using a high impedance multi-meter or the DRB

tester as described in this section. Power should

never be removed or applied to any control module

with the ignition in the ON position. Before removing

or connecting battery cables, fuses, or connectors,

always turn the ignition to the OFF position.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of after-market electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, ect.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

5 - 36 BRAKES - ABSBR/BE

BRAKES - ABS (Continued)

Page 229 of 2255

NOTE: Check the sensor wire routing. Be sure the

wire is clear of all chassis components and is not

twisted or kinked at any spot.

(6) Install the tire and wheel assembly.

(7) Remove the support and lower the vehicle.

(8) Reconnect the ABS wheel speed sensor wire

electrical connector inside the engine compartment.

(9) Apply the brakes several times to seat the

brake shoes and caliper piston. Do not move the vehi-

cle until a firm brake pedal is obtained.

(10) Verify the wheel speed sensor operation with

a scan tool.

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the Antilock Brake system. For test proce-

dures refer to the Chassis Diagnostic Manual.

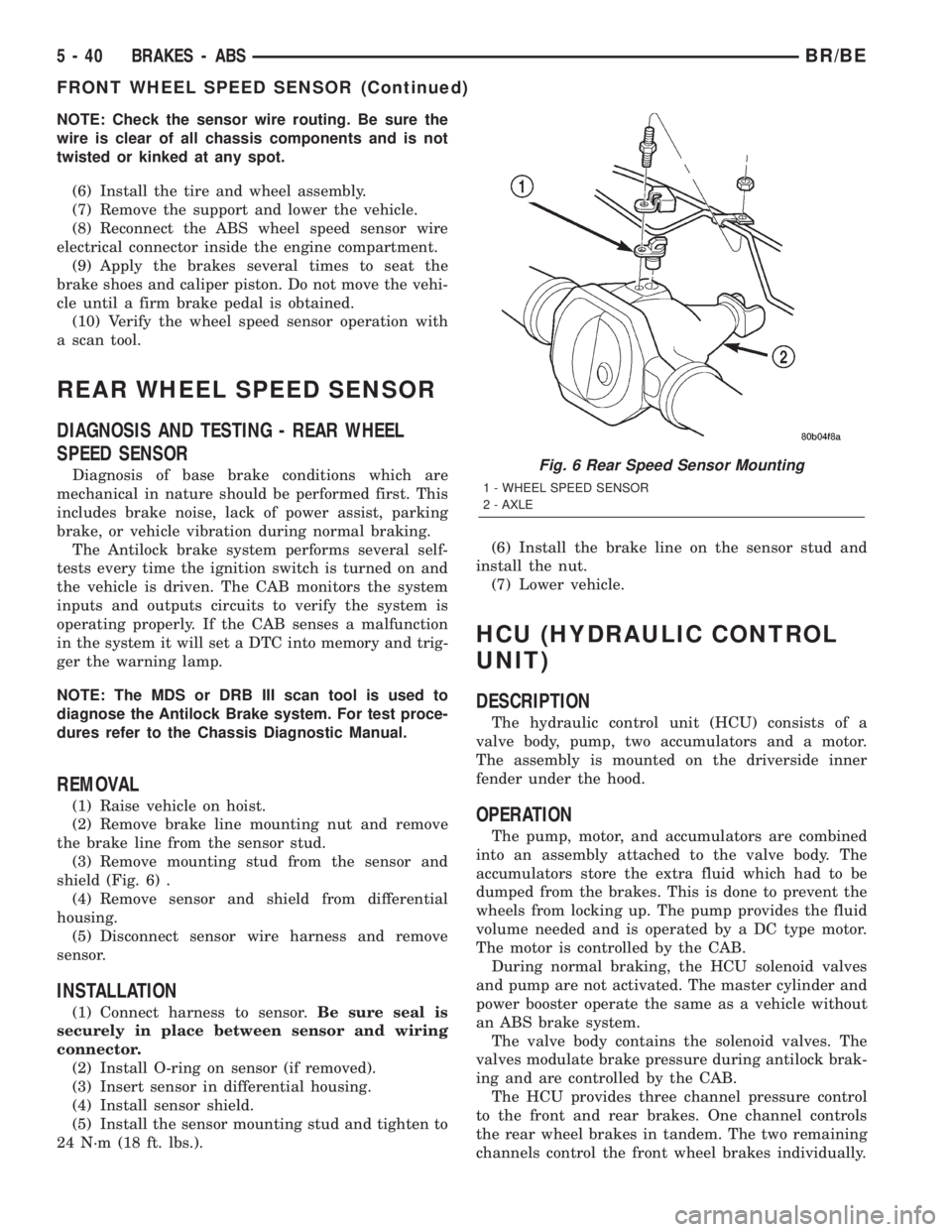

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove brake line mounting nut and remove

the brake line from the sensor stud.

(3) Remove mounting stud from the sensor and

shield (Fig. 6) .

(4) Remove sensor and shield from differential

housing.

(5) Disconnect sensor wire harness and remove

sensor.

INSTALLATION

(1) Connect harness to sensor.Be sure seal is

securely in place between sensor and wiring

connector.

(2) Install O-ring on sensor (if removed).

(3) Insert sensor in differential housing.

(4) Install sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (18 ft. lbs.).(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower vehicle.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) consists of a

valve body, pump, two accumulators and a motor.

The assembly is mounted on the driverside inner

fender under the hood.

OPERATION

The pump, motor, and accumulators are combined

into an assembly attached to the valve body. The

accumulators store the extra fluid which had to be

dumped from the brakes. This is done to prevent the

wheels from locking up. The pump provides the fluid

volume needed and is operated by a DC type motor.

The motor is controlled by the CAB.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

The valve body contains the solenoid valves. The

valves modulate brake pressure during antilock brak-

ing and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

Fig. 6 Rear Speed Sensor Mounting

1 - WHEEL SPEED SENSOR

2 - AXLE

5 - 40 BRAKES - ABSBR/BE

FRONT WHEEL SPEED SENSOR (Continued)