boot DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1528 of 2255

(7) Install input shaft oil guide with C-3972-A and

Handle C-4171.

(8) Apply sealer to the input shaft retainer and

install retainer onto the clutch housing. Install bolts

and tighten to 28 N´m (20 ft.lbs.).

REVERSE GEAR

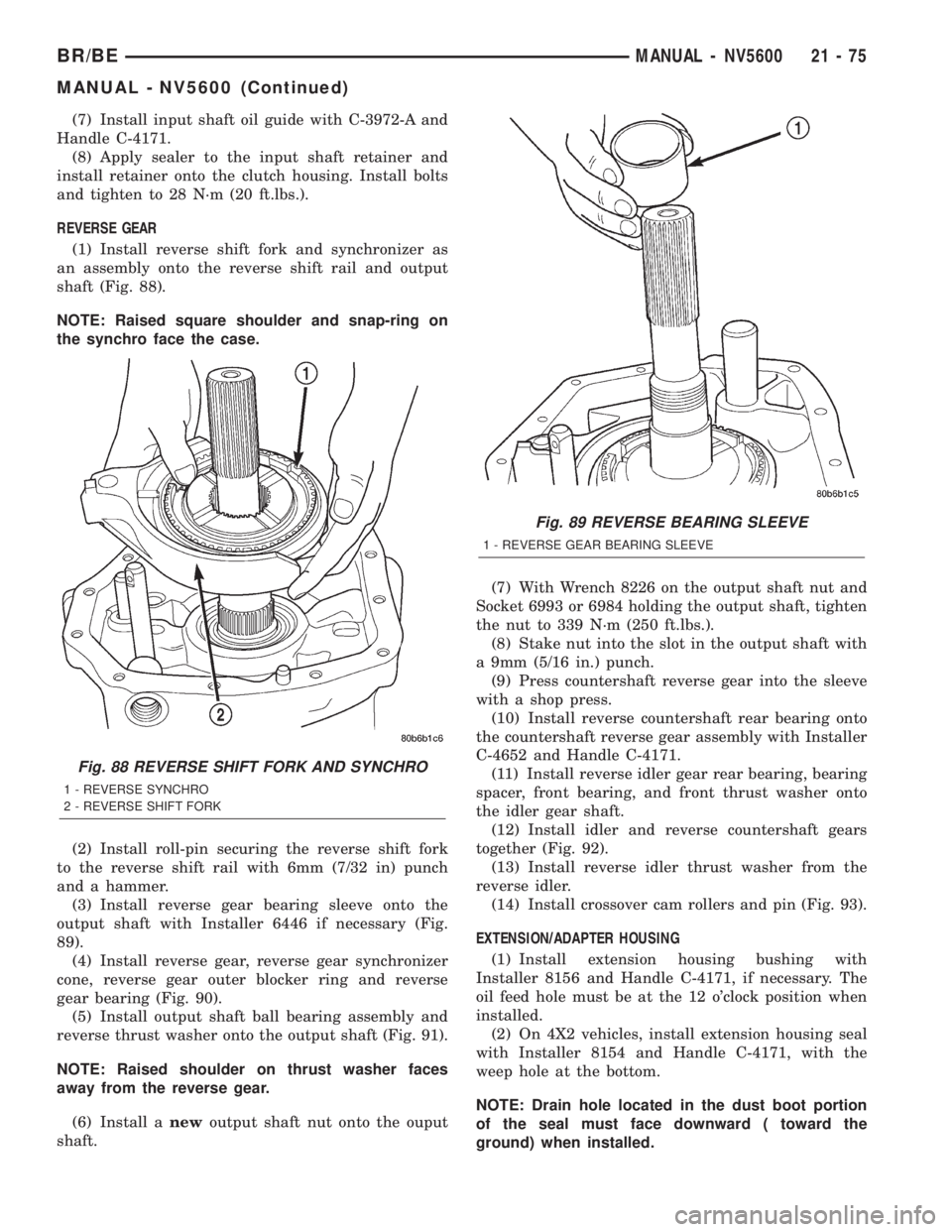

(1) Install reverse shift fork and synchronizer as

an assembly onto the reverse shift rail and output

shaft (Fig. 88).

NOTE: Raised square shoulder and snap-ring on

the synchro face the case.

(2) Install roll-pin securing the reverse shift fork

to the reverse shift rail with 6mm (7/32 in) punch

and a hammer.

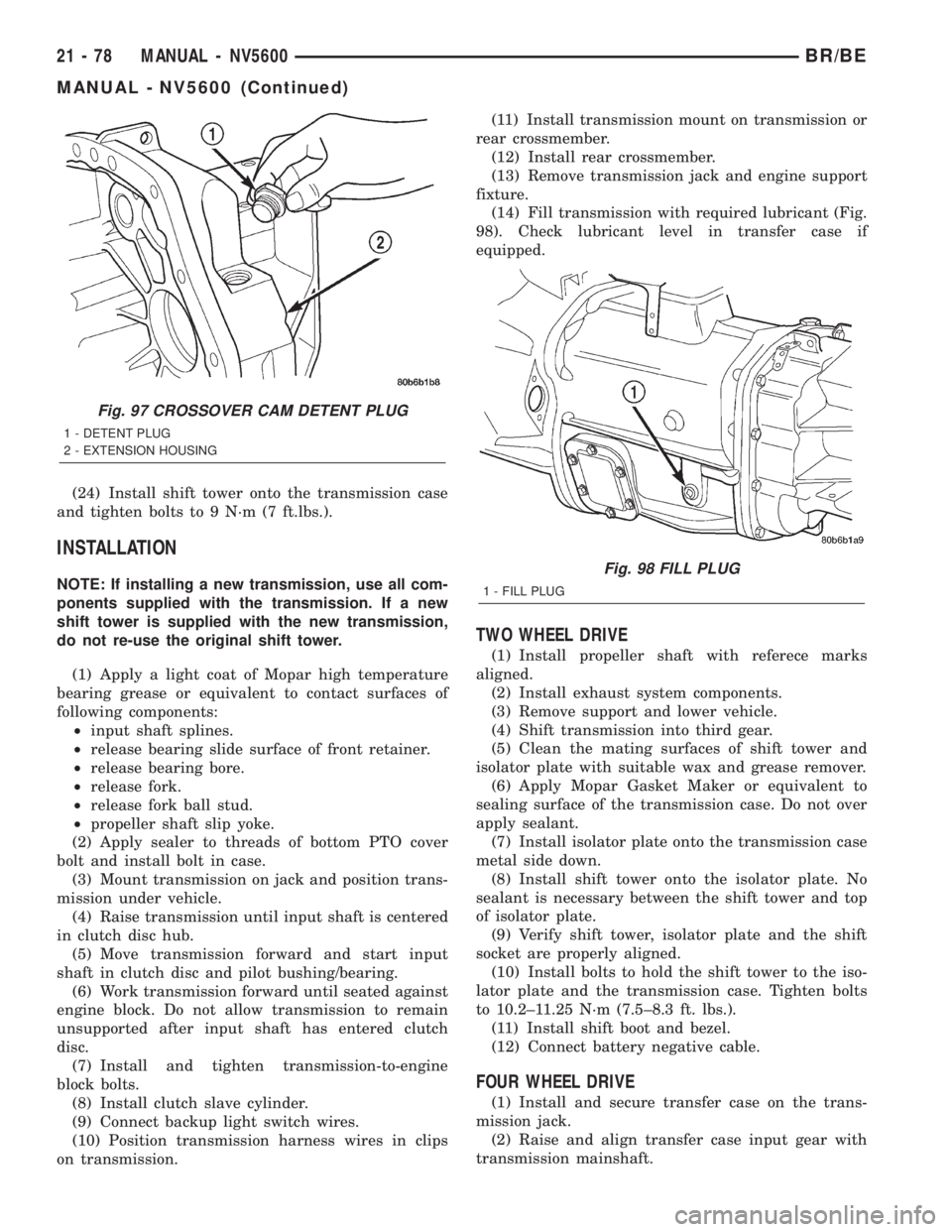

(3) Install reverse gear bearing sleeve onto the

output shaft with Installer 6446 if necessary (Fig.

89).

(4) Install reverse gear, reverse gear synchronizer

cone, reverse gear outer blocker ring and reverse

gear bearing (Fig. 90).

(5) Install output shaft ball bearing assembly and

reverse thrust washer onto the output shaft (Fig. 91).

NOTE: Raised shoulder on thrust washer faces

away from the reverse gear.

(6) Install anewoutput shaft nut onto the ouput

shaft.(7) With Wrench 8226 on the output shaft nut and

Socket 6993 or 6984 holding the output shaft, tighten

the nut to 339 N´m (250 ft.lbs.).

(8) Stake nut into the slot in the output shaft with

a 9mm (5/16 in.) punch.

(9) Press countershaft reverse gear into the sleeve

with a shop press.

(10) Install reverse countershaft rear bearing onto

the countershaft reverse gear assembly with Installer

C-4652 and Handle C-4171.

(11) Install reverse idler gear rear bearing, bearing

spacer, front bearing, and front thrust washer onto

the idler gear shaft.

(12) Install idler and reverse countershaft gears

together (Fig. 92).

(13) Install reverse idler thrust washer from the

reverse idler.

(14) Install crossover cam rollers and pin (Fig. 93).

EXTENSION/ADAPTER HOUSING

(1) Install extension housing bushing with

Installer 8156 and Handle C-4171, if necessary. The

oil feed hole must be at the 12 o'clock position when

installed.

(2) On 4X2 vehicles, install extension housing seal

with Installer 8154 and Handle C-4171, with the

weep hole at the bottom.

NOTE: Drain hole located in the dust boot portion

of the seal must face downward ( toward the

ground) when installed.

Fig. 88 REVERSE SHIFT FORK AND SYNCHRO

1 - REVERSE SYNCHRO

2 - REVERSE SHIFT FORK

Fig. 89 REVERSE BEARING SLEEVE

1 - REVERSE GEAR BEARING SLEEVE

BR/BEMANUAL - NV5600 21 - 75

MANUAL - NV5600 (Continued)

Page 1531 of 2255

(24) Install shift tower onto the transmission case

and tighten bolts to 9 N´m (7 ft.lbs.).

INSTALLATION

NOTE: If installing a new transmission, use all com-

ponents supplied with the transmission. If a new

shift tower is supplied with the new transmission,

do not re-use the original shift tower.

(1) Apply a light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces of

following components:

²input shaft splines.

²release bearing slide surface of front retainer.

²release bearing bore.

²release fork.

²release fork ball stud.

²propeller shaft slip yoke.

(2) Apply sealer to threads of bottom PTO cover

bolt and install bolt in case.

(3) Mount transmission on jack and position trans-

mission under vehicle.

(4) Raise transmission until input shaft is centered

in clutch disc hub.

(5) Move transmission forward and start input

shaft in clutch disc and pilot bushing/bearing.

(6) Work transmission forward until seated against

engine block. Do not allow transmission to remain

unsupported after input shaft has entered clutch

disc.

(7) Install and tighten transmission-to-engine

block bolts.

(8) Install clutch slave cylinder.

(9) Connect backup light switch wires.

(10) Position transmission harness wires in clips

on transmission.(11) Install transmission mount on transmission or

rear crossmember.

(12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture.

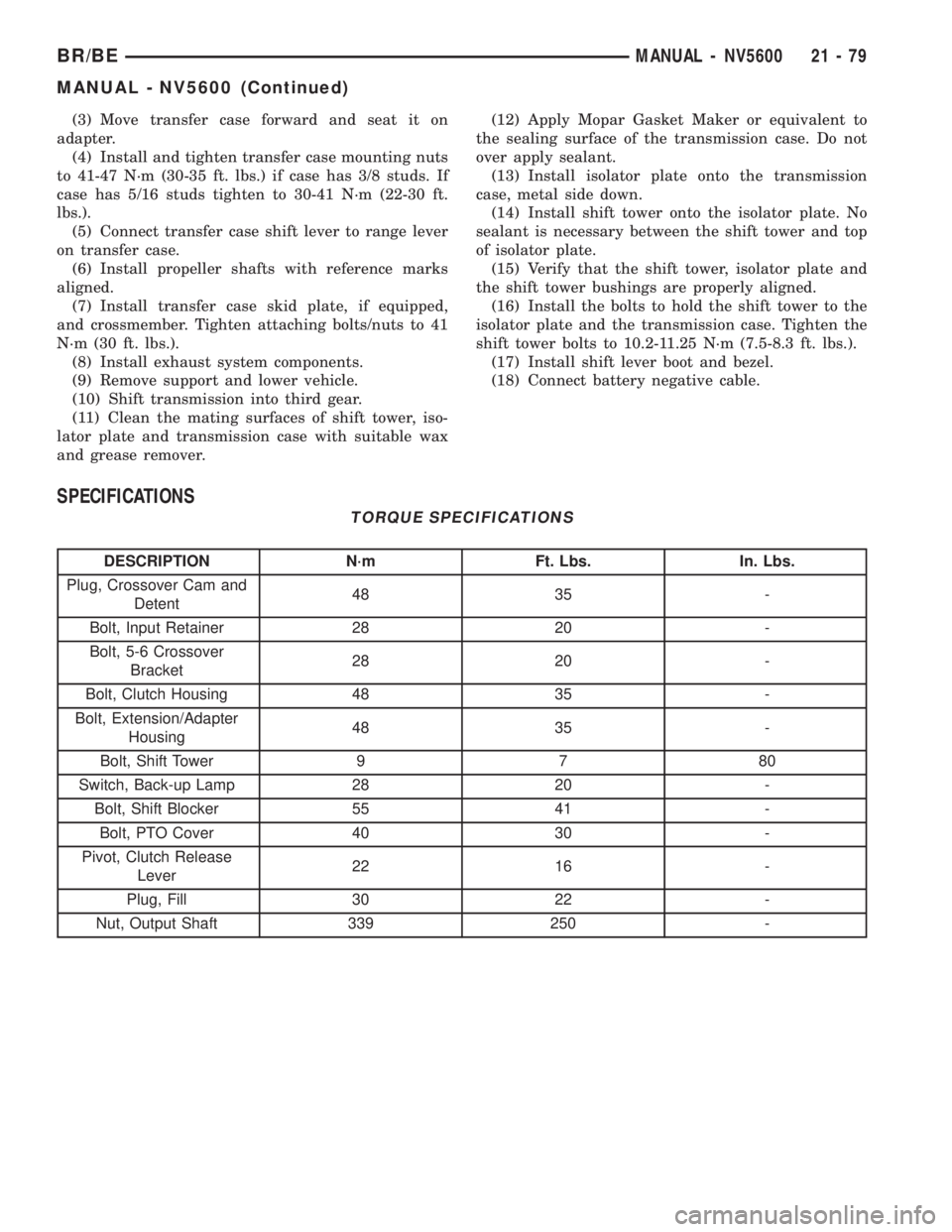

(14) Fill transmission with required lubricant (Fig.

98). Check lubricant level in transfer case if

equipped.

TWO WHEEL DRIVE

(1) Install propeller shaft with referece marks

aligned.

(2) Install exhaust system components.

(3) Remove support and lower vehicle.

(4) Shift transmission into third gear.

(5) Clean the mating surfaces of shift tower and

isolator plate with suitable wax and grease remover.

(6) Apply Mopar Gasket Maker or equivalent to

sealing surface of the transmission case. Do not over

apply sealant.

(7) Install isolator plate onto the transmission case

metal side down.

(8) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and top

of isolator plate.

(9) Verify shift tower, isolator plate and the shift

socket are properly aligned.

(10) Install bolts to hold the shift tower to the iso-

lator plate and the transmission case. Tighten bolts

to 10.2±11.25 N´m (7.5±8.3 ft. lbs.).

(11) Install shift boot and bezel.

(12) Connect battery negative cable.

FOUR WHEEL DRIVE

(1) Install and secure transfer case on the trans-

mission jack.

(2) Raise and align transfer case input gear with

transmission mainshaft.

Fig. 97 CROSSOVER CAM DETENT PLUG

1 - DETENT PLUG

2 - EXTENSION HOUSING

Fig. 98 FILL PLUG

1 - FILL PLUG

21 - 78 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1532 of 2255

(3) Move transfer case forward and seat it on

adapter.

(4) Install and tighten transfer case mounting nuts

to 41-47 N´m (30-35 ft. lbs.) if case has 3/8 studs. If

case has 5/16 studs tighten to 30-41 N´m (22-30 ft.

lbs.).

(5) Connect transfer case shift lever to range lever

on transfer case.

(6) Install propeller shafts with reference marks

aligned.

(7) Install transfer case skid plate, if equipped,

and crossmember. Tighten attaching bolts/nuts to 41

N´m (30 ft. lbs.).

(8) Install exhaust system components.

(9) Remove support and lower vehicle.

(10) Shift transmission into third gear.

(11) Clean the mating surfaces of shift tower, iso-

lator plate and transmission case with suitable wax

and grease remover.(12) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the transmission case. Do not

over apply sealant.

(13) Install isolator plate onto the transmission

case, metal side down.

(14) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and top

of isolator plate.

(15) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(16) Install the bolts to hold the shift tower to the

isolator plate and the transmission case. Tighten the

shift tower bolts to 10.2-11.25 N´m (7.5-8.3 ft. lbs.).

(17) Install shift lever boot and bezel.

(18) Connect battery negative cable.

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Plug, Crossover Cam and

Detent48 35 -

Bolt, Input Retainer 28 20 -

Bolt, 5-6 Crossover

Bracket28 20 -

Bolt, Clutch Housing 48 35 -

Bolt, Extension/Adapter

Housing48 35 -

Bolt, Shift Tower 9 7 80

Switch, Back-up Lamp 28 20 -

Bolt, Shift Blocker 55 41 -

Bolt, PTO Cover 40 30 -

Pivot, Clutch Release

Lever22 16 -

Plug, Fill 30 22 -

Nut, Output Shaft 339 250 -

BR/BEMANUAL - NV5600 21 - 79

MANUAL - NV5600 (Continued)

Page 1539 of 2255

SHIFT COVER - NV5600

REMOVAL

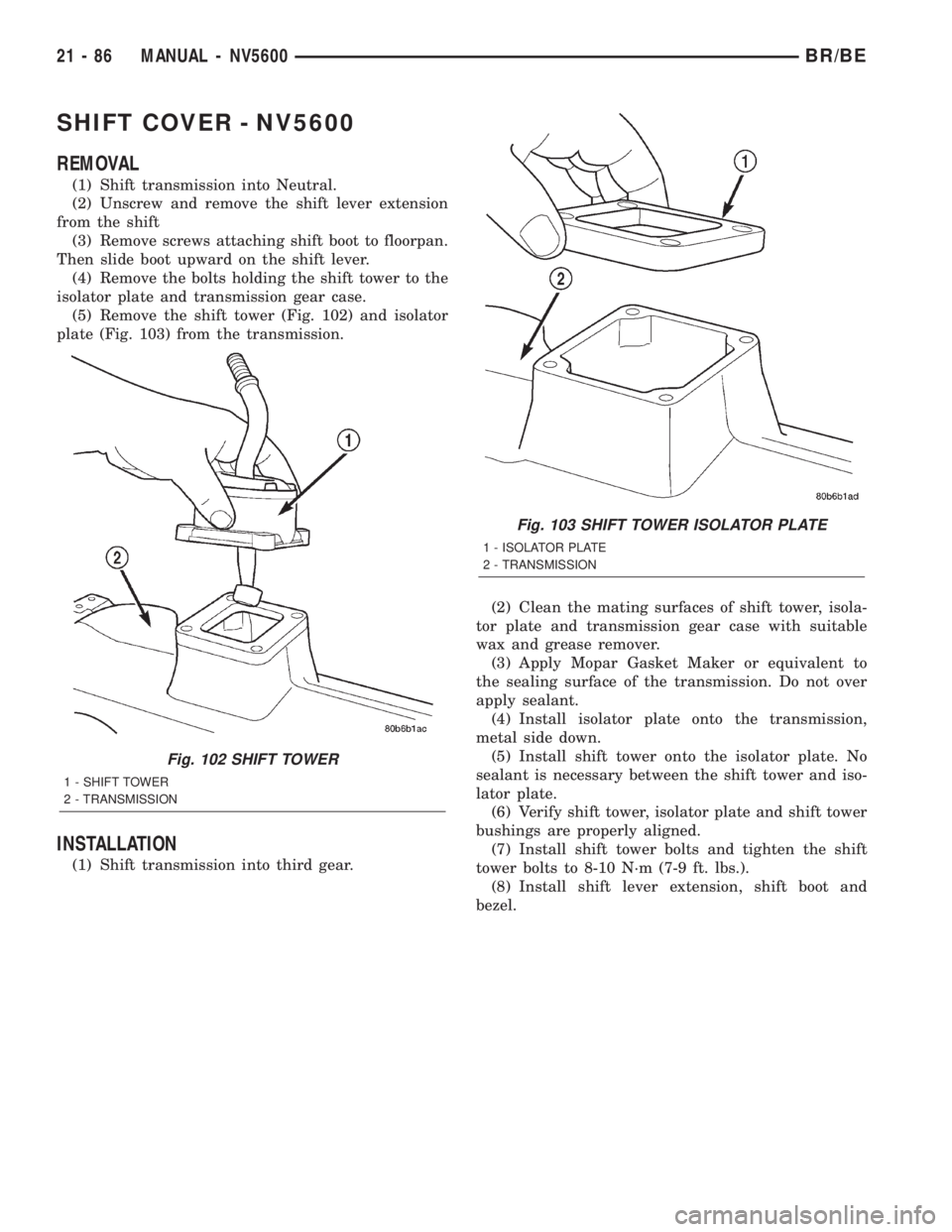

(1) Shift transmission into Neutral.

(2) Unscrew and remove the shift lever extension

from the shift

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(4) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(5) Remove the shift tower (Fig. 102) and isolator

plate (Fig. 103) from the transmission.

INSTALLATION

(1) Shift transmission into third gear.(2) Clean the mating surfaces of shift tower, isola-

tor plate and transmission gear case with suitable

wax and grease remover.

(3) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the transmission. Do not over

apply sealant.

(4) Install isolator plate onto the transmission,

metal side down.

(5) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and iso-

lator plate.

(6) Verify shift tower, isolator plate and shift tower

bushings are properly aligned.

(7) Install shift tower bolts and tighten the shift

tower bolts to 8-10 N´m (7-9 ft. lbs.).

(8) Install shift lever extension, shift boot and

bezel.

Fig. 102 SHIFT TOWER

1 - SHIFT TOWER

2 - TRANSMISSION

Fig. 103 SHIFT TOWER ISOLATOR PLATE

1 - ISOLATOR PLATE

2 - TRANSMISSION

21 - 86 MANUAL - NV5600BR/BE

Page 1915 of 2255

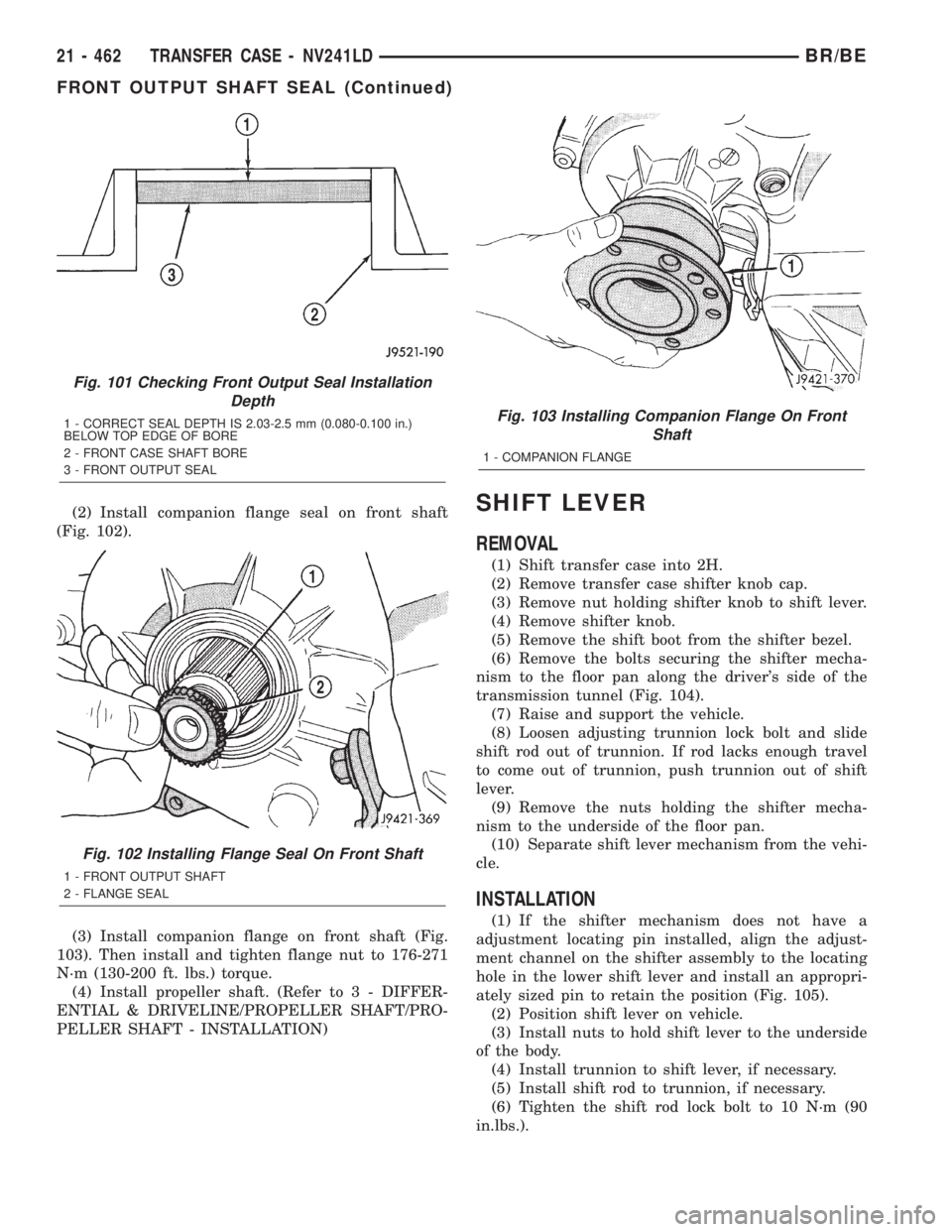

(2) Install companion flange seal on front shaft

(Fig. 102).

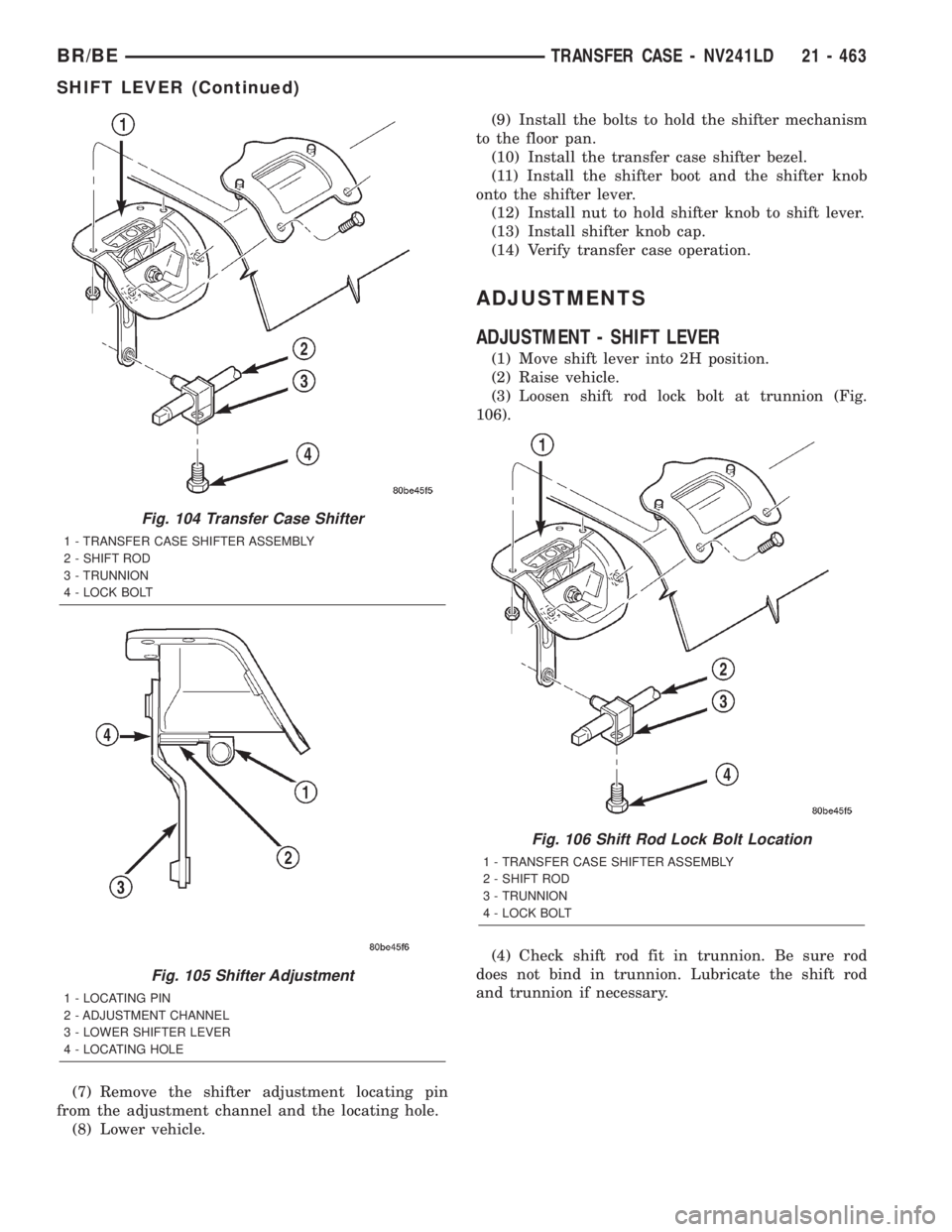

(3) Install companion flange on front shaft (Fig.

103). Then install and tighten flange nut to 176-271

N´m (130-200 ft. lbs.) torque.

(4) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)SHIFT LEVER

REMOVAL

(1) Shift transfer case into 2H.

(2) Remove transfer case shifter knob cap.

(3) Remove nut holding shifter knob to shift lever.

(4) Remove shifter knob.

(5) Remove the shift boot from the shifter bezel.

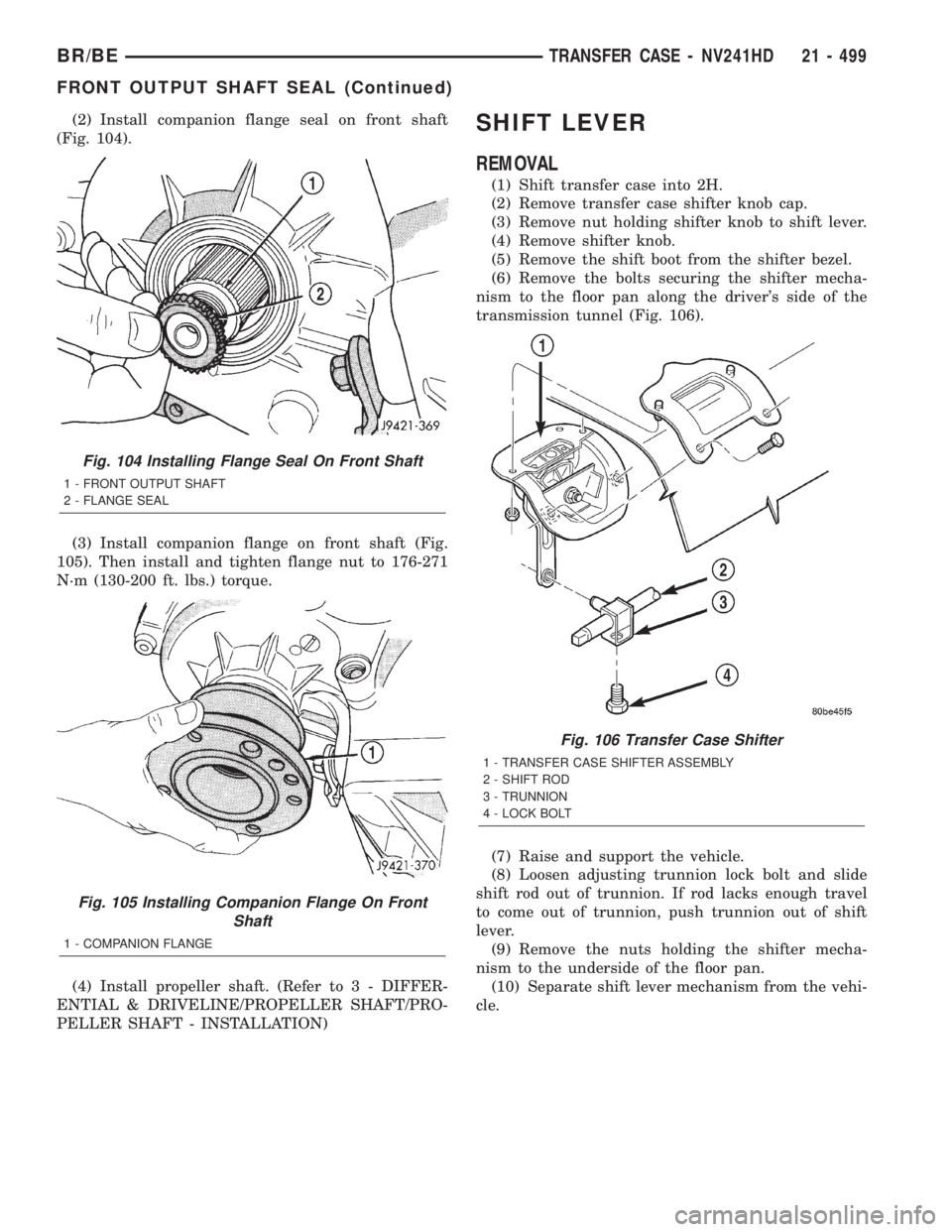

(6) Remove the bolts securing the shifter mecha-

nism to the floor pan along the driver's side of the

transmission tunnel (Fig. 104).

(7) Raise and support the vehicle.

(8) Loosen adjusting trunnion lock bolt and slide

shift rod out of trunnion. If rod lacks enough travel

to come out of trunnion, push trunnion out of shift

lever.

(9) Remove the nuts holding the shifter mecha-

nism to the underside of the floor pan.

(10) Separate shift lever mechanism from the vehi-

cle.

INSTALLATION

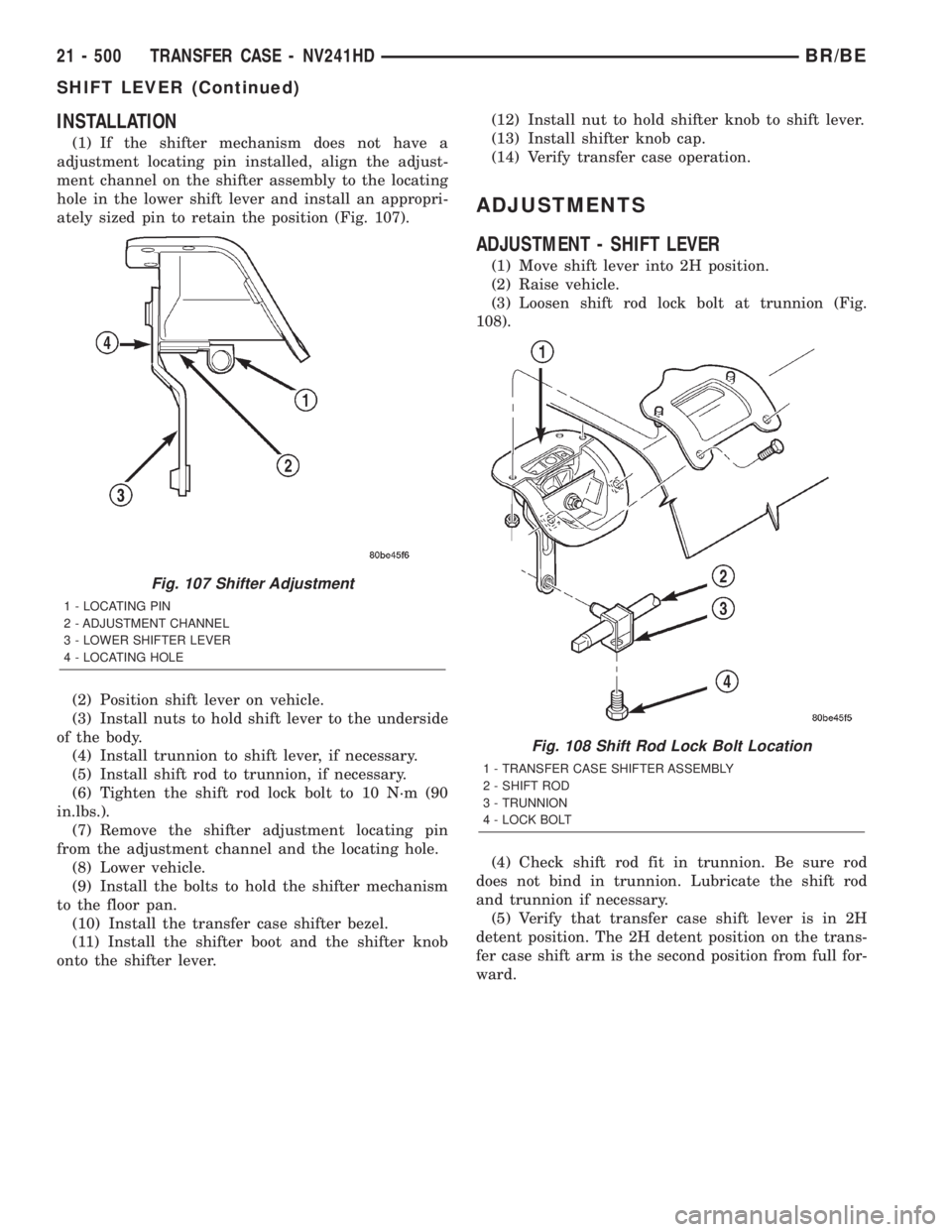

(1) If the shifter mechanism does not have a

adjustment locating pin installed, align the adjust-

ment channel on the shifter assembly to the locating

hole in the lower shift lever and install an appropri-

ately sized pin to retain the position (Fig. 105).

(2) Position shift lever on vehicle.

(3) Install nuts to hold shift lever to the underside

of the body.

(4) Install trunnion to shift lever, if necessary.

(5) Install shift rod to trunnion, if necessary.

(6) Tighten the shift rod lock bolt to 10 N´m (90

in.lbs.).

Fig. 101 Checking Front Output Seal Installation

Depth

1 - CORRECT SEAL DEPTH IS 2.03-2.5 mm (0.080-0.100 in.)

BELOW TOP EDGE OF BORE

2 - FRONT CASE SHAFT BORE

3 - FRONT OUTPUT SEAL

Fig. 102 Installing Flange Seal On Front Shaft

1 - FRONT OUTPUT SHAFT

2 - FLANGE SEAL

Fig. 103 Installing Companion Flange On Front

Shaft

1 - COMPANION FLANGE

21 - 462 TRANSFER CASE - NV241LDBR/BE

FRONT OUTPUT SHAFT SEAL (Continued)

Page 1916 of 2255

(7) Remove the shifter adjustment locating pin

from the adjustment channel and the locating hole.

(8) Lower vehicle.(9) Install the bolts to hold the shifter mechanism

to the floor pan.

(10) Install the transfer case shifter bezel.

(11) Install the shifter boot and the shifter knob

onto the shifter lever.

(12) Install nut to hold shifter knob to shift lever.

(13) Install shifter knob cap.

(14) Verify transfer case operation.

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER

(1) Move shift lever into 2H position.

(2) Raise vehicle.

(3) Loosen shift rod lock bolt at trunnion (Fig.

106).

(4) Check shift rod fit in trunnion. Be sure rod

does not bind in trunnion. Lubricate the shift rod

and trunnion if necessary.

Fig. 104 Transfer Case Shifter

1 - TRANSFER CASE SHIFTER ASSEMBLY

2 - SHIFT ROD

3 - TRUNNION

4 - LOCK BOLT

Fig. 105 Shifter Adjustment

1 - LOCATING PIN

2 - ADJUSTMENT CHANNEL

3 - LOWER SHIFTER LEVER

4 - LOCATING HOLE

Fig. 106 Shift Rod Lock Bolt Location

1 - TRANSFER CASE SHIFTER ASSEMBLY

2 - SHIFT ROD

3 - TRUNNION

4 - LOCK BOLT

BR/BETRANSFER CASE - NV241LD 21 - 463

SHIFT LEVER (Continued)

Page 1952 of 2255

(2) Install companion flange seal on front shaft

(Fig. 104).

(3) Install companion flange on front shaft (Fig.

105). Then install and tighten flange nut to 176-271

N´m (130-200 ft. lbs.) torque.

(4) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)SHIFT LEVER

REMOVAL

(1) Shift transfer case into 2H.

(2) Remove transfer case shifter knob cap.

(3) Remove nut holding shifter knob to shift lever.

(4) Remove shifter knob.

(5) Remove the shift boot from the shifter bezel.

(6) Remove the bolts securing the shifter mecha-

nism to the floor pan along the driver's side of the

transmission tunnel (Fig. 106).

(7) Raise and support the vehicle.

(8) Loosen adjusting trunnion lock bolt and slide

shift rod out of trunnion. If rod lacks enough travel

to come out of trunnion, push trunnion out of shift

lever.

(9) Remove the nuts holding the shifter mecha-

nism to the underside of the floor pan.

(10) Separate shift lever mechanism from the vehi-

cle.

Fig. 104 Installing Flange Seal On Front Shaft

1 - FRONT OUTPUT SHAFT

2 - FLANGE SEAL

Fig. 105 Installing Companion Flange On Front

Shaft

1 - COMPANION FLANGE

Fig. 106 Transfer Case Shifter

1 - TRANSFER CASE SHIFTER ASSEMBLY

2 - SHIFT ROD

3 - TRUNNION

4 - LOCK BOLT

BR/BETRANSFER CASE - NV241HD 21 - 499

FRONT OUTPUT SHAFT SEAL (Continued)

Page 1953 of 2255

INSTALLATION

(1) If the shifter mechanism does not have a

adjustment locating pin installed, align the adjust-

ment channel on the shifter assembly to the locating

hole in the lower shift lever and install an appropri-

ately sized pin to retain the position (Fig. 107).

(2) Position shift lever on vehicle.

(3) Install nuts to hold shift lever to the underside

of the body.

(4) Install trunnion to shift lever, if necessary.

(5) Install shift rod to trunnion, if necessary.

(6) Tighten the shift rod lock bolt to 10 N´m (90

in.lbs.).

(7) Remove the shifter adjustment locating pin

from the adjustment channel and the locating hole.

(8) Lower vehicle.

(9) Install the bolts to hold the shifter mechanism

to the floor pan.

(10) Install the transfer case shifter bezel.

(11) Install the shifter boot and the shifter knob

onto the shifter lever.(12) Install nut to hold shifter knob to shift lever.

(13) Install shifter knob cap.

(14) Verify transfer case operation.

ADJUSTMENTS

ADJUSTMENT - SHIFT LEVER

(1) Move shift lever into 2H position.

(2) Raise vehicle.

(3) Loosen shift rod lock bolt at trunnion (Fig.

108).

(4) Check shift rod fit in trunnion. Be sure rod

does not bind in trunnion. Lubricate the shift rod

and trunnion if necessary.

(5) Verify that transfer case shift lever is in 2H

detent position. The 2H detent position on the trans-

fer case shift arm is the second position from full for-

ward.

Fig. 107 Shifter Adjustment

1 - LOCATING PIN

2 - ADJUSTMENT CHANNEL

3 - LOWER SHIFTER LEVER

4 - LOCATING HOLE

Fig. 108 Shift Rod Lock Bolt Location

1 - TRANSFER CASE SHIFTER ASSEMBLY

2 - SHIFT ROD

3 - TRUNNION

4 - LOCK BOLT

21 - 500 TRANSFER CASE - NV241HDBR/BE

SHIFT LEVER (Continued)

Page 2085 of 2255

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION............................118

A-PILLAR GRAB HANDLE

REMOVAL............................119

INSTALLATION........................119

A-PILLAR TRIM

REMOVAL............................119

INSTALLATION........................119

COWL TRIM COVER

REMOVAL............................119

INSTALLATION........................120

B-PILLAR TRIM

REMOVAL............................120

INSTALLATION........................120

REAR CLOSURE PANEL TRIM

REMOVAL............................120

INSTALLATION........................121

REAR FLOOR STOWAGE TRAY

REMOVAL............................121

INSTALLATION........................121

DOOR SILL TRIM

REMOVAL............................121

INSTALLATION........................121

SHIFT BOOT - MANUAL TRANSMISSION

REMOVAL............................122

INSTALLATION........................122

4WD FLOOR SHIFT BOOT

REMOVAL............................122

INSTALLATION........................122

CENTER CONSOLE

REMOVAL............................122INSTALLATION........................122

CARPETS AND FLOOR MATS

REMOVAL............................123

INSTALLATION........................123

ASSIST HANDLE

REMOVAL............................124

INSTALLATION........................124

COAT HOOK

REMOVAL............................124

INSTALLATION........................125

HEADLINER

REMOVAL............................125

INSTALLATION........................125

BODY VENT

REMOVAL............................126

INSTALLATION........................126

REAR VIEW MIRROR

REMOVAL............................126

INSTALLATION

INSTALLATION......................126

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET..................126

SUN VISOR

REMOVAL............................127

INSTALLATION........................127

QUARTER TRIM PANEL

REMOVAL............................128

INSTALLATION........................128

C-PILLAR TRIM

REMOVAL............................128

INSTALLATION........................128

INTERIOR

CAUTION

CAUTION: Do not attempt to remove interior trim

panels/moldings without first removing the neces-sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

23 - 118 INTERIORBR/BE

Page 2089 of 2255

SHIFT BOOT - MANUAL

TRANSMISSION

REMOVAL

(1) Using a trim stick C-4755 or equivalent, pry

the corner of the shift boot up expose the fasteners.

(2) Remove the screws attaching the shift boot to

the console.

(3) Remove the insert from the shift knob, remove

nut attaching knob to the lever, and remove the shift

knob.

(4) Lift floor shift boot off shifter.

INSTALLATION

(1) Install shift boot over the shift lever, position

boot on console and install the fasteners attaching

boot to concole.

(2) Install the shift knob, shift knob nut, and

tighten to 27 N´m (20 ft.lbs) torque.

(3) Install the shift knob insert.

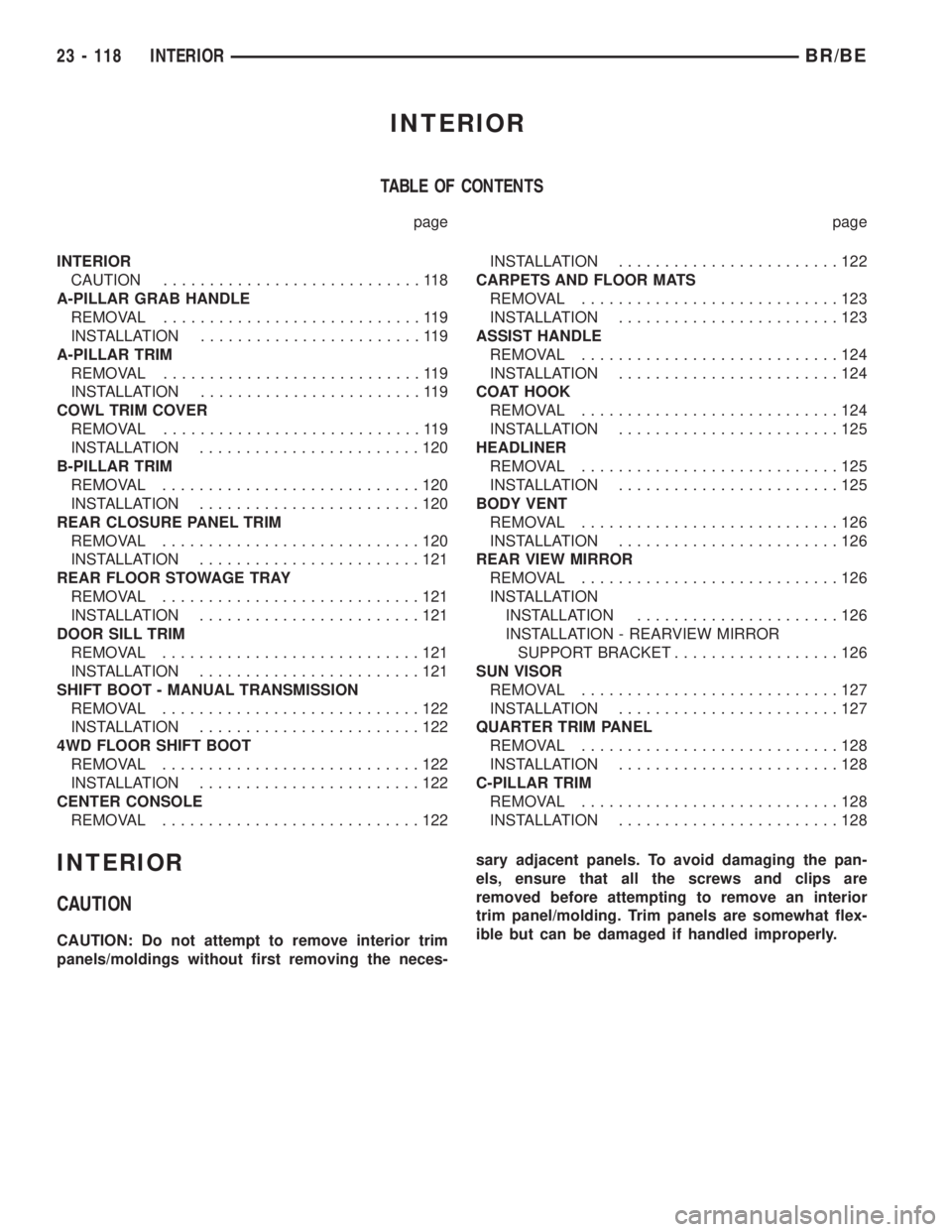

4WD FLOOR SHIFT BOOT

REMOVAL

(1) Remove insert from shift knob.

(2) Remove nut attaching shift knob to shift lever.

(3) Remove shift knob.

(4) Using a trim stick C-4755 or equivalent, disen-

gage retainers attaching boot to shifter base (Fig. 9).

Automatic transmission vehicle shown, manual

transmission similar.

(5) Lift floor shift boot off shift lever.

INSTALLATION

(1) Place shift boot over shifter.

(2) Engage retainers attaching boot to shifter base.

(3) Position shift knob on shift lever.

(4) Install nut attaching shift knob to shift lever.

(5) Install insert on shift knob.

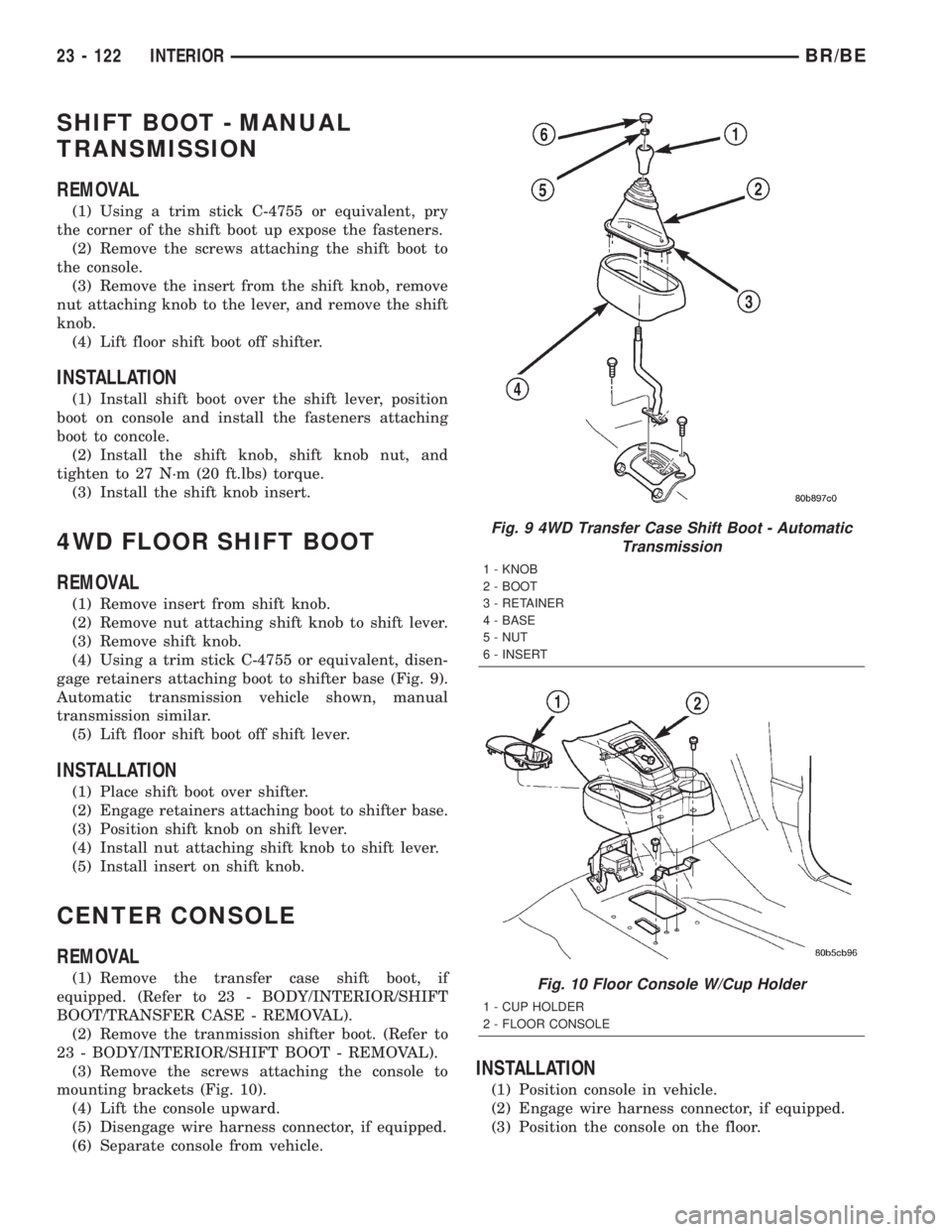

CENTER CONSOLE

REMOVAL

(1) Remove the transfer case shift boot, if

equipped. (Refer to 23 - BODY/INTERIOR/SHIFT

BOOT/TRANSFER CASE - REMOVAL).

(2) Remove the tranmission shifter boot. (Refer to

23 - BODY/INTERIOR/SHIFT BOOT - REMOVAL).

(3) Remove the screws attaching the console to

mounting brackets (Fig. 10).

(4) Lift the console upward.

(5) Disengage wire harness connector, if equipped.

(6) Separate console from vehicle.

INSTALLATION

(1) Position console in vehicle.

(2) Engage wire harness connector, if equipped.

(3) Position the console on the floor.

Fig. 9 4WD Transfer Case Shift Boot - Automatic

Transmission

1 - KNOB

2 - BOOT

3 - RETAINER

4 - BASE

5 - NUT

6 - INSERT

Fig. 10 Floor Console W/Cup Holder

1 - CUP HOLDER

2 - FLOOR CONSOLE

23 - 122 INTERIORBR/BE