wheel bolt torque DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 57 of 2255

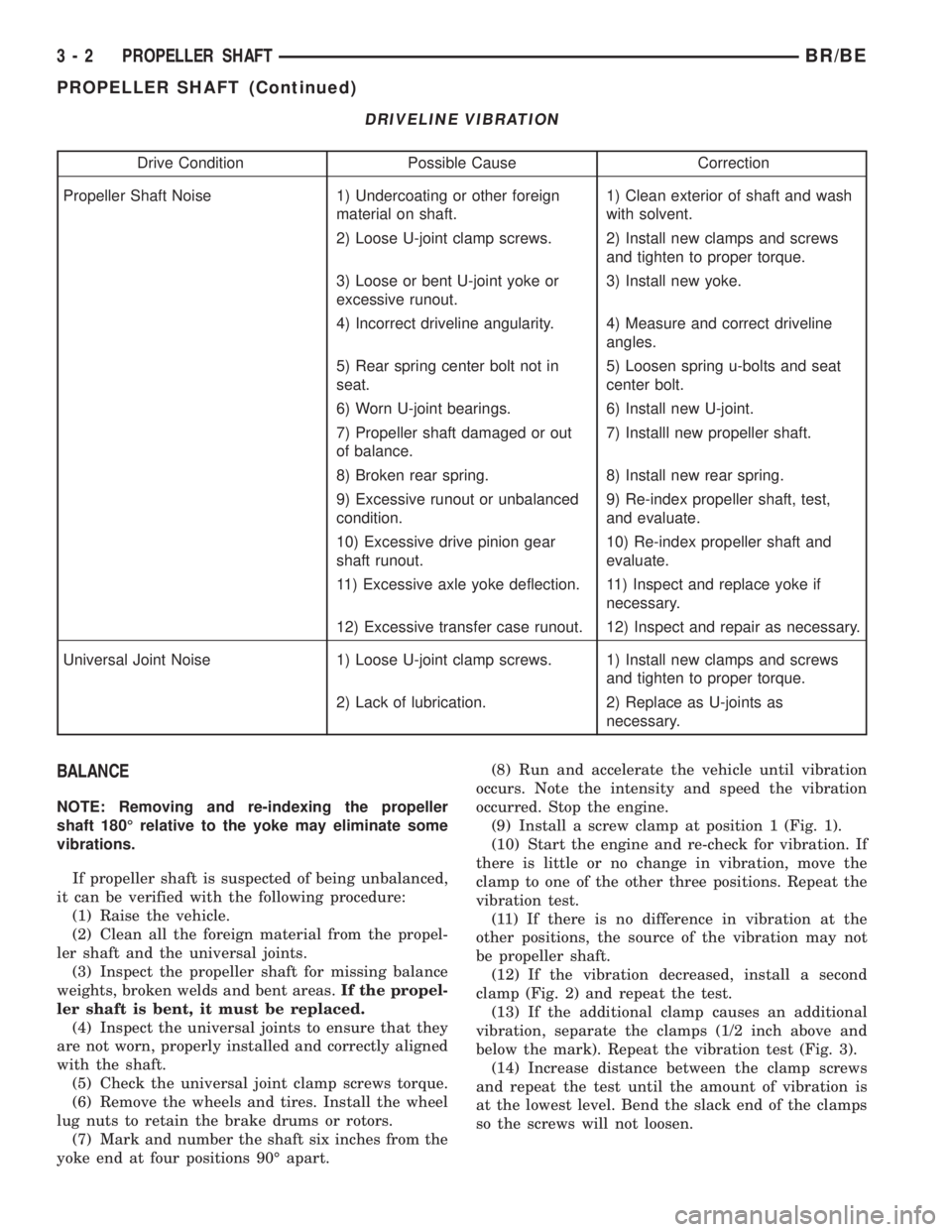

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

BALANCE

NOTE: Removing and re-indexing the propeller

shaft 180É relative to the yoke may eliminate some

vibrations.

If propeller shaft is suspected of being unbalanced,

it can be verified with the following procedure:

(1) Raise the vehicle.

(2) Clean all the foreign material from the propel-

ler shaft and the universal joints.

(3) Inspect the propeller shaft for missing balance

weights, broken welds and bent areas.If the propel-

ler shaft is bent, it must be replaced.

(4) Inspect the universal joints to ensure that they

are not worn, properly installed and correctly aligned

with the shaft.

(5) Check the universal joint clamp screws torque.

(6) Remove the wheels and tires. Install the wheel

lug nuts to retain the brake drums or rotors.

(7) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.(8) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration

occurred. Stop the engine.

(9) Install a screw clamp at position 1 (Fig. 1).

(10) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(11) If there is no difference in vibration at the

other positions, the source of the vibration may not

be propeller shaft.

(12) If the vibration decreased, install a second

clamp (Fig. 2) and repeat the test.

(13) If the additional clamp causes an additional

vibration, separate the clamps (1/2 inch above and

below the mark). Repeat the vibration test (Fig. 3).

(14) Increase distance between the clamp screws

and repeat the test until the amount of vibration is

at the lowest level. Bend the slack end of the clamps

so the screws will not loosen.

3 - 2 PROPELLER SHAFTBR/BE

PROPELLER SHAFT (Continued)

Page 73 of 2255

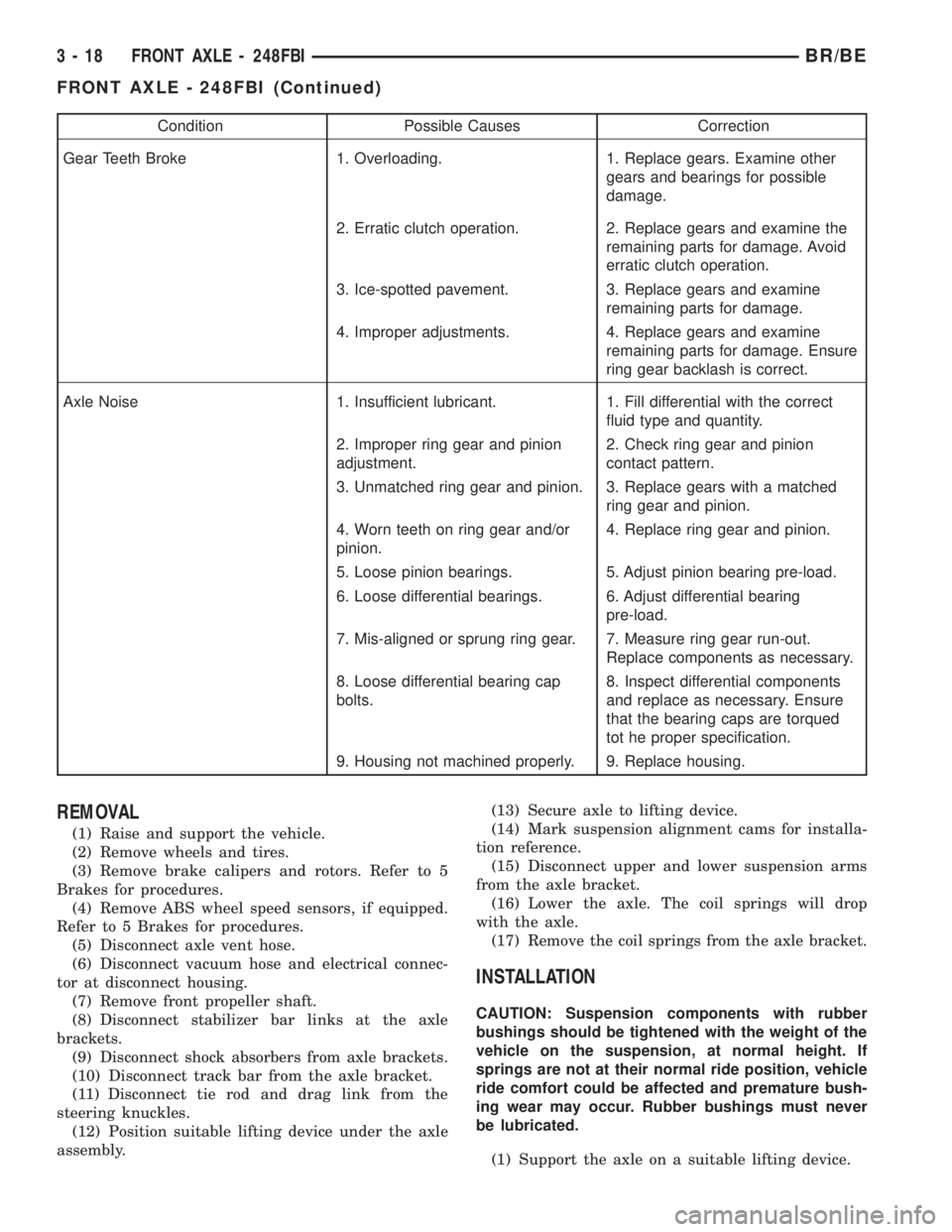

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheels and tires.

(3) Remove brake calipers and rotors. Refer to 5

Brakes for procedures.

(4) Remove ABS wheel speed sensors, if equipped.

Refer to 5 Brakes for procedures.

(5) Disconnect axle vent hose.

(6) Disconnect vacuum hose and electrical connec-

tor at disconnect housing.

(7) Remove front propeller shaft.

(8) Disconnect stabilizer bar links at the axle

brackets.

(9) Disconnect shock absorbers from axle brackets.

(10) Disconnect track bar from the axle bracket.

(11) Disconnect tie rod and drag link from the

steering knuckles.

(12) Position suitable lifting device under the axle

assembly.(13) Secure axle to lifting device.

(14) Mark suspension alignment cams for installa-

tion reference.

(15) Disconnect upper and lower suspension arms

from the axle bracket.

(16) Lower the axle. The coil springs will drop

with the axle.

(17) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the weight of the

vehicle on the suspension, at normal height. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur. Rubber bushings must never

be lubricated.

(1) Support the axle on a suitable lifting device.

3 - 18 FRONT AXLE - 248FBIBR/BE

FRONT AXLE - 248FBI (Continued)

Page 101 of 2255

REAR AXLE - 248RBI

TABLE OF CONTENTS

page page

REAR AXLE - 248RBI

DESCRIPTION.........................46

OPERATION...........................46

DIAGNOSIS AND TESTING - AXLE..........47

REMOVAL.............................51

INSTALLATION.........................51

ADJUSTMENTS........................51

SPECIFICATIONS

REAR AXLE - 248RBI..................59

SPECIAL TOOLS

REAR AXLE - 248RBI..................59

AXLE SHAFTS

REMOVAL.............................62

INSTALLATION.........................62

AXLE BEARINGS

REMOVAL.............................62

INSTALLATION.........................62

PINION SEAL

REMOVAL.............................63INSTALLATION.........................63

DIFFERENTIAL

REMOVAL.............................64

DISASSEMBLY.........................65

ASSEMBLY............................66

INSTALLATION.........................66

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT.....67

DISASSEMBLY.........................68

ASSEMBLY............................70

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................72

INSTALLATION.........................72

PINION GEAR/RING GEAR/TONE RING

REMOVAL.............................73

INSTALLATION.........................75

REAR AXLE - 248RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housings consist

of an iron center casting (differential housing) with axle

shaft tubes extending from either side. The tubes are

pressed into the differential housing and welded. The

axles are equipped with full-floating axle shafts, meaning

that loads are supported by the axle housing tubes.

The differential case for the standard differentials

and the Trac-loktdifferential are a one-piece design.

Differential bearing preload and ring gear backlash

are adjusted by the use of shims located between the

differential bearing cones and case. Pinion bearing

preload is set and maintained by the use of a collaps-

ible spacer. The removable, stamped steel cover pro-

vides a means for inspection and service.

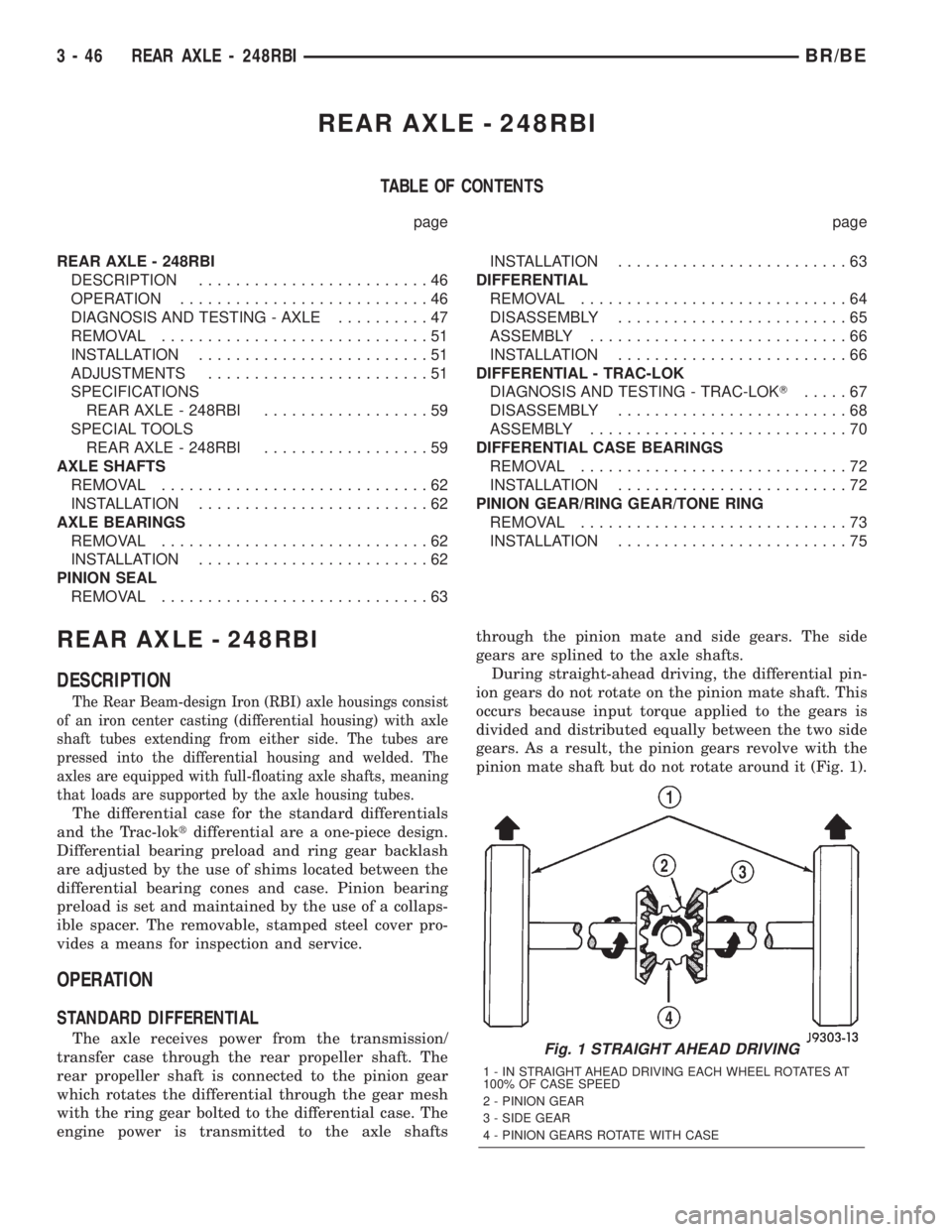

OPERATION

STANDARD DIFFERENTIAL

The axle receives power from the transmission/

transfer case through the rear propeller shaft. The

rear propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shaftsthrough the pinion mate and side gears. The side

gears are splined to the axle shafts.

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).Fig. 1 STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

3 - 46 REAR AXLE - 248RBIBR/BE

Page 122 of 2255

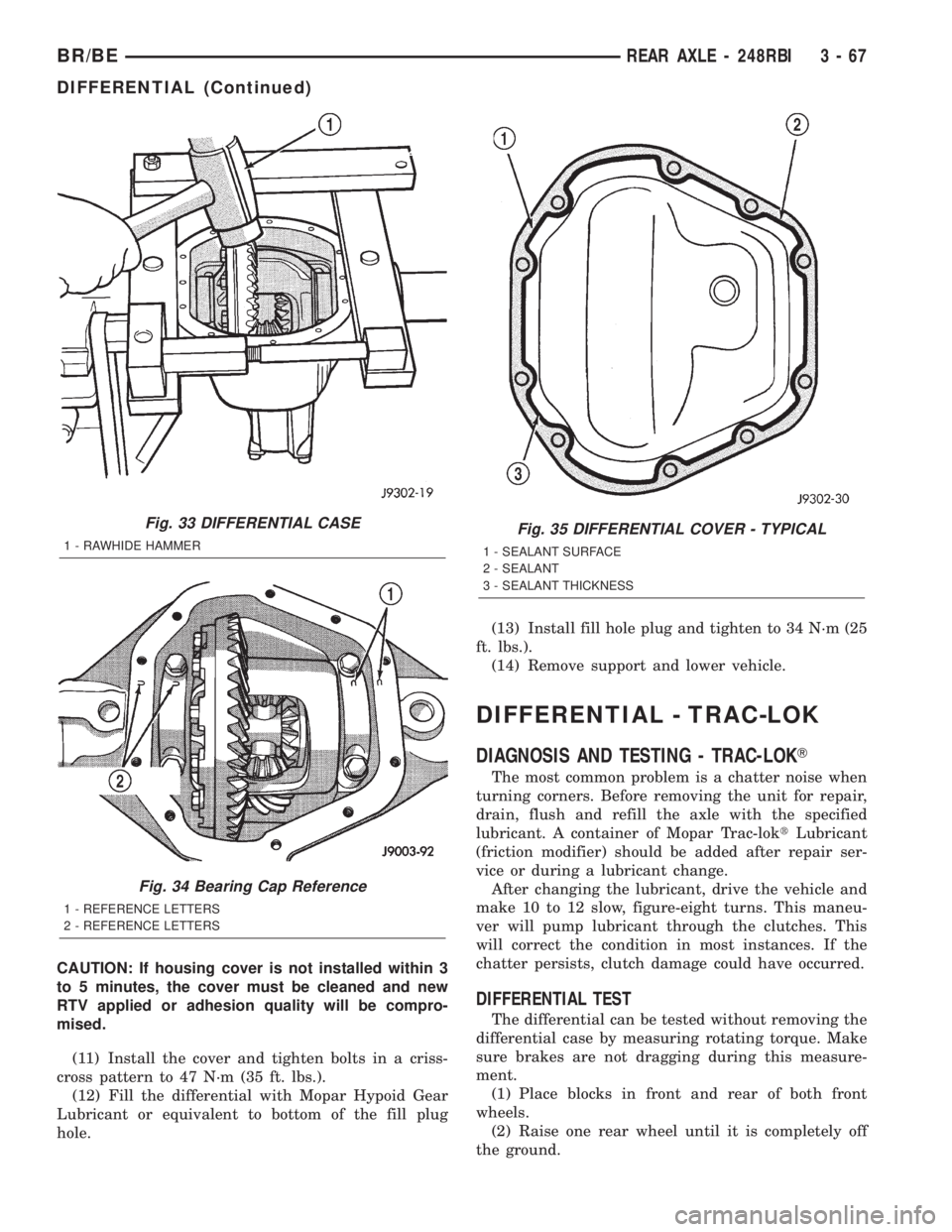

CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied or adhesion quality will be compro-

mised.

(11) Install the cover and tighten bolts in a criss-

cross pattern to 47 N´m (35 ft. lbs.).

(12) Fill the differential with Mopar Hypoid Gear

Lubricant or equivalent to bottom of the fill plug

hole.(13) Install fill hole plug and tighten to 34 N´m (25

ft. lbs.).

(14) Remove support and lower vehicle.

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

Fig. 33 DIFFERENTIAL CASE

1 - RAWHIDE HAMMER

Fig. 34 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

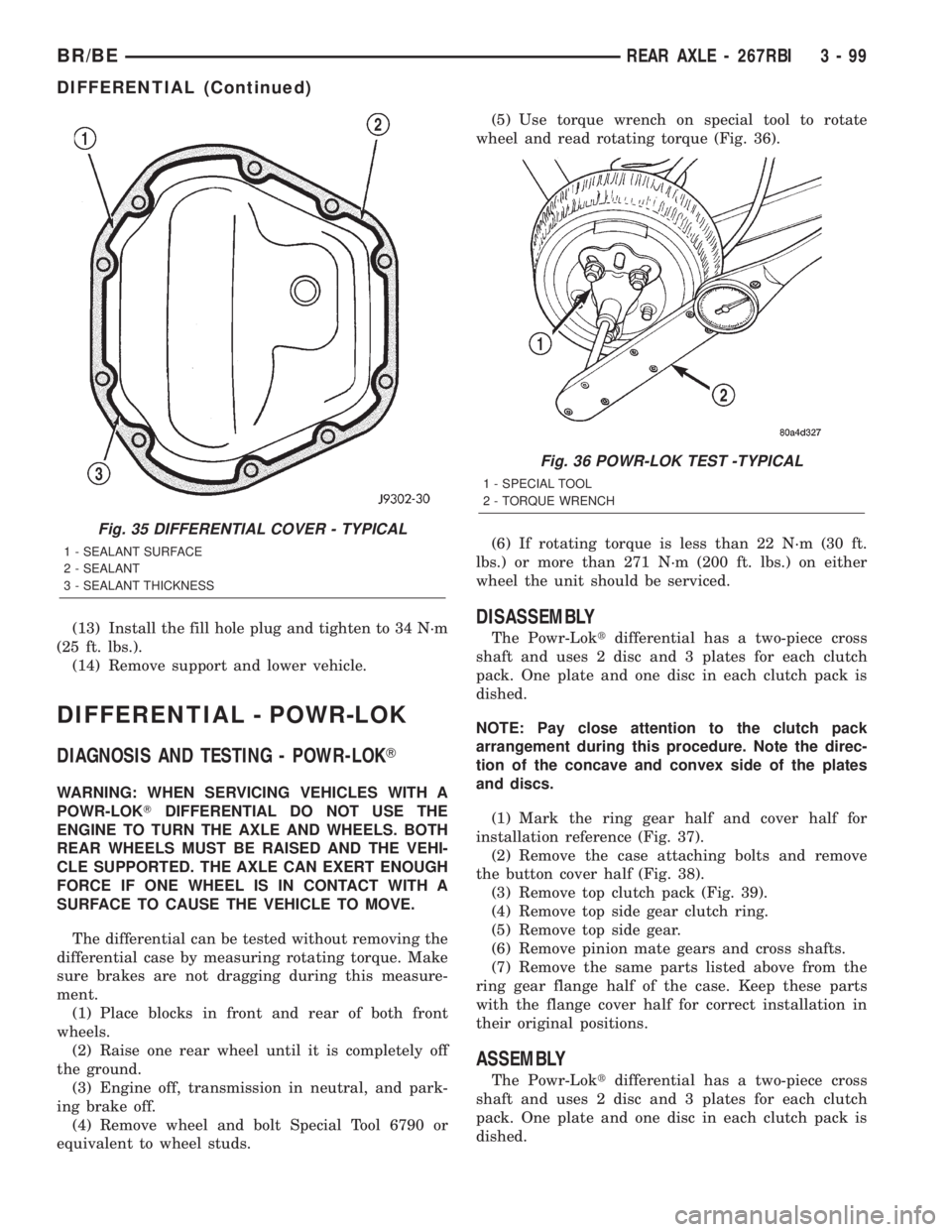

Fig. 35 DIFFERENTIAL COVER - TYPICAL

1 - SEALANT SURFACE

2 - SEALANT

3 - SEALANT THICKNESS

BR/BEREAR AXLE - 248RBI 3 - 67

DIFFERENTIAL (Continued)

Page 123 of 2255

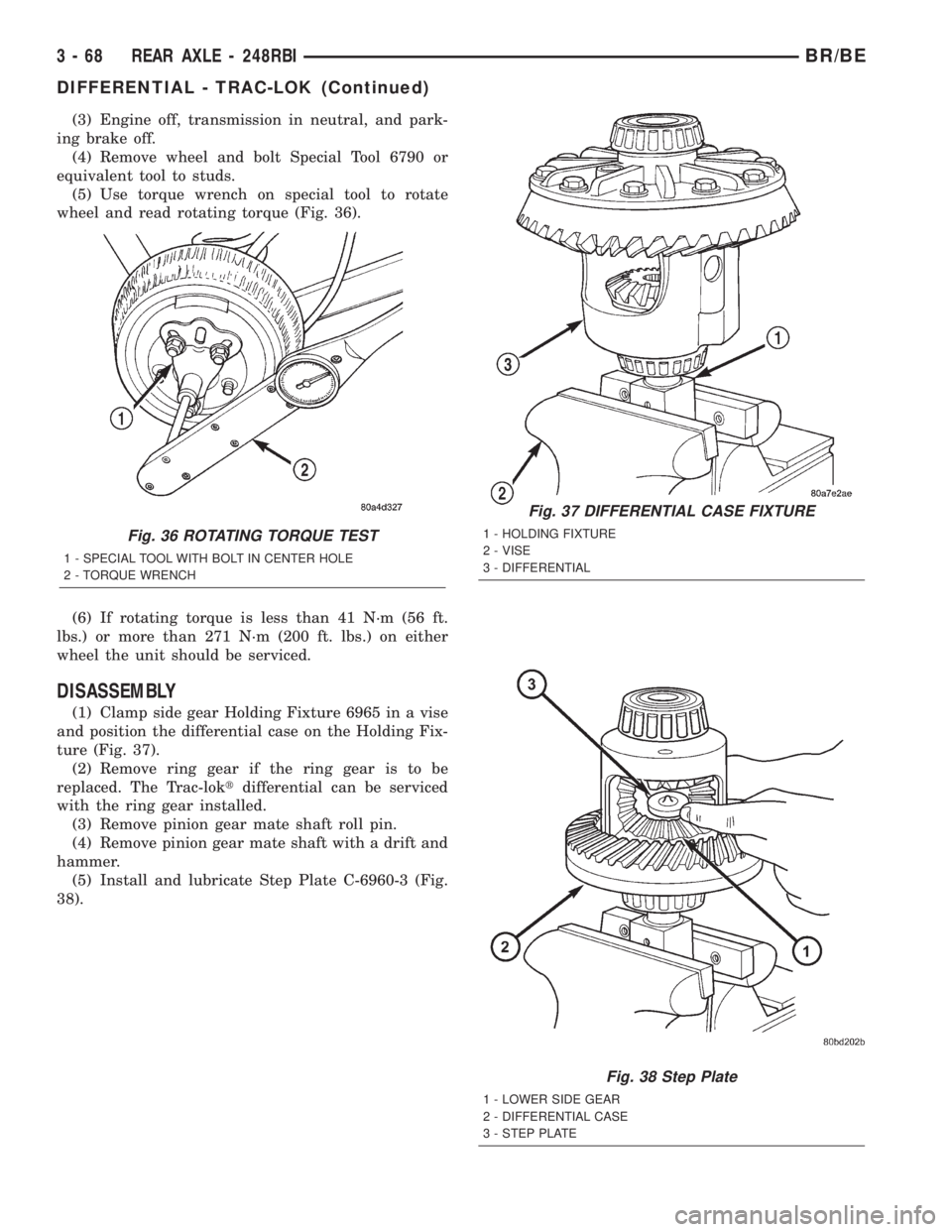

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 36).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

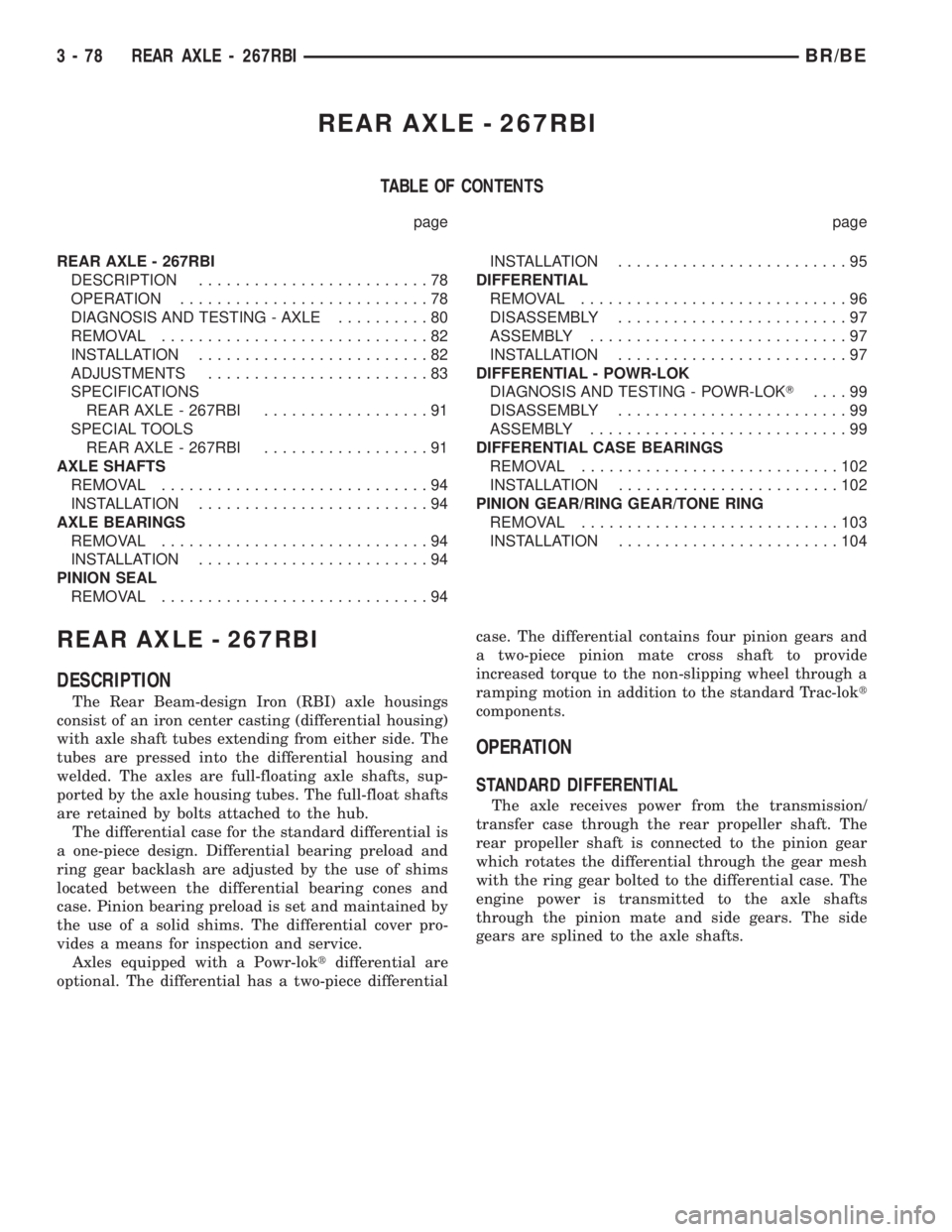

DISASSEMBLY

(1) Clamp side gear Holding Fixture 6965 in a vise

and position the differential case on the Holding Fix-

ture (Fig. 37).

(2) Remove ring gear if the ring gear is to be

replaced. The Trac-loktdifferential can be serviced

with the ring gear installed.

(3) Remove pinion gear mate shaft roll pin.

(4) Remove pinion gear mate shaft with a drift and

hammer.

(5) Install and lubricate Step Plate C-6960-3 (Fig.

38).

Fig. 36 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 37 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 38 Step Plate

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - STEP PLATE

3 - 68 REAR AXLE - 248RBIBR/BE

DIFFERENTIAL - TRAC-LOK (Continued)

Page 133 of 2255

REAR AXLE - 267RBI

TABLE OF CONTENTS

page page

REAR AXLE - 267RBI

DESCRIPTION.........................78

OPERATION...........................78

DIAGNOSIS AND TESTING - AXLE..........80

REMOVAL.............................82

INSTALLATION.........................82

ADJUSTMENTS........................83

SPECIFICATIONS

REAR AXLE - 267RBI..................91

SPECIAL TOOLS

REAR AXLE - 267RBI..................91

AXLE SHAFTS

REMOVAL.............................94

INSTALLATION.........................94

AXLE BEARINGS

REMOVAL.............................94

INSTALLATION.........................94

PINION SEAL

REMOVAL.............................94INSTALLATION.........................95

DIFFERENTIAL

REMOVAL.............................96

DISASSEMBLY.........................97

ASSEMBLY............................97

INSTALLATION.........................97

DIFFERENTIAL - POWR-LOK

DIAGNOSIS AND TESTING - POWR-LOKT....99

DISASSEMBLY.........................99

ASSEMBLY............................99

DIFFERENTIAL CASE BEARINGS

REMOVAL............................102

INSTALLATION........................102

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................103

INSTALLATION........................104

REAR AXLE - 267RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housings

consist of an iron center casting (differential housing)

with axle shaft tubes extending from either side. The

tubes are pressed into the differential housing and

welded. The axles are full-floating axle shafts, sup-

ported by the axle housing tubes. The full-float shafts

are retained by bolts attached to the hub.

The differential case for the standard differential is

a one-piece design. Differential bearing preload and

ring gear backlash are adjusted by the use of shims

located between the differential bearing cones and

case. Pinion bearing preload is set and maintained by

the use of a solid shims. The differential cover pro-

vides a means for inspection and service.

Axles equipped with a Powr-loktdifferential are

optional. The differential has a two-piece differentialcase. The differential contains four pinion gears and

a two-piece pinion mate cross shaft to provide

increased torque to the non-slipping wheel through a

ramping motion in addition to the standard Trac-lokt

components.

OPERATION

STANDARD DIFFERENTIAL

The axle receives power from the transmission/

transfer case through the rear propeller shaft. The

rear propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

3 - 78 REAR AXLE - 267RBIBR/BE

Page 137 of 2255

Condition Possible Causes Correction

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct fluid

type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct fluid

type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion contact

pattern. Adjust backlash or pinion

depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched ring

gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued tot

he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position an axle lift under the axle and secure

it to the axle.

(3) Remove the wheels and tires.

(4) Remove RWAL sensor from the differential

housing, if necessary.

(5) Remove brake hose from the axle junction

block.

(6) Disconnect parking brake cables and cable

brackets.

(7) Remove vent hose from the axle shaft tube.(8) Mark propeller shaft and yoke for installation

alignment reference.

(9) Remove propeller shaft.

(10) Remove shock absorbers from the axle brack-

ets.

(11) Remove spring clamps and spring brackets.

(12) Remove axle from the vehicle.

INSTALLATION

(1) Raise axle with lift and align to the leaf spring

centering bolts.

(2) Install spring clamps and spring brackets.

3 - 82 REAR AXLE - 267RBIBR/BE

REAR AXLE - 267RBI (Continued)

Page 149 of 2255

AXLE SHAFTS

REMOVAL

(1) Remove the axle shaft flange bolts.

(2) Slide the axle shaft out from the axle tube.

INSTALLATION

(1) Clean the gasket contact surface area on the

flange with an appropriate solvent. Install a new

flange gasket and slide the axle shaft into the tube.

(2) Install the bolts and tighten to 129 N´m (95 ft.

lbs.).

AXLE BEARINGS

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove brake drum.

(3) Remove the axle shaft.

(4) Remove the lock wedge and adjustment nut.

Use Socket DD-1241±JD to remove the adjustment

nut.

(5) Remove the hub assembly. The outer axle bear-

ing will slide out as the hub is being removed.

(6) Remove inner grease seal and discard. Use

Installer 5064 and Handle C-4171 to drive grease

seal and inner axle bearing from the hub.

(7) Remove the bearing cups from the hub bore.

Use a brass drift, or an appropriate removal tool, to

tap out the cups.

INSTALLATION

(1) Thoroughly clean both axle bearings and inte-

rior of the hub with an appropriate cleaning solvent.

(2) Install bearing cups with Installer 8151 and

Handle C-4171.

(3)Pack inner and outer bearings with

Mopar wheel bearing grease or equivalent.

(4) Apply grease to inner and outer bearing cup

surfaces.

(5) Install inner axle bearing in the hub.

(6) Installnewgrease seal in hub with Installer

8149 and Handle C-4171.

(7) Inspect bearing and seal contact surfaces on

the axle tube for burrs/roughness. Remove all the

rough contact surfaces from the axle tube.

(8) Carefully slide the hub onto the axle.

CAUTION: Do not let grease seal contact axle tube

threads during installtion.

(9) Install outer axle bearing.

(10) Install hub bearing adjustment nut with

Socket DD-1241±JD.(11) Tighten adjustment nut to 163-190 N´m (120-

140 ft. lbs.) while rotating the wheel. Then loosen

adjustment nut 1/8 to 1/3 of-a-turn to provide 0.025-

0.250mm (0.001-0.009 in.) wheel bearing end play.

(12) Tap locking wedge into the spindle keyway

and adjustment nut.

NOTE: Located locking wedge in a new position in

the adjustment nut.

(13) Install axle shaft and brake drum.

(14) Install the wheel and tire assembly.

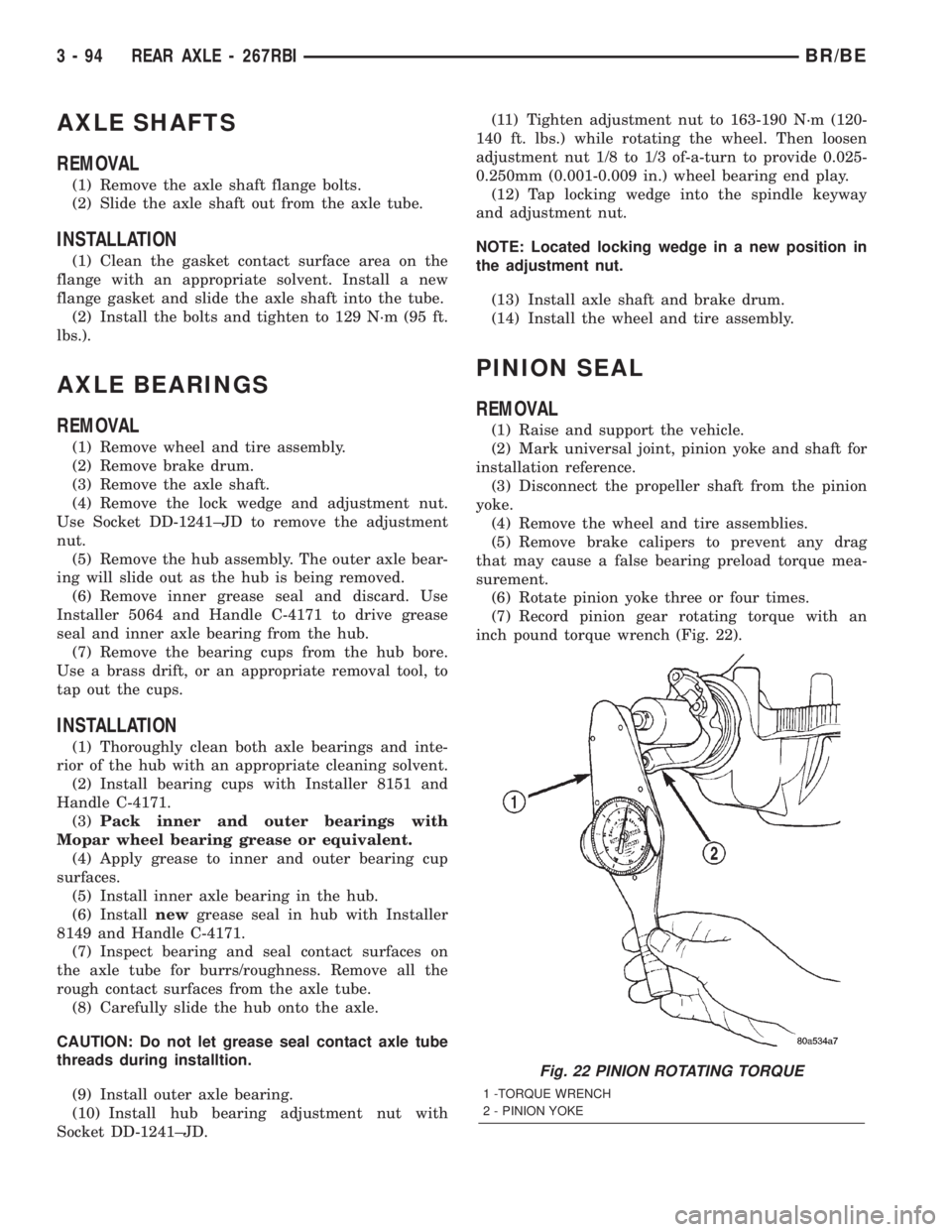

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark universal joint, pinion yoke and shaft for

installation reference.

(3) Disconnect the propeller shaft from the pinion

yoke.

(4) Remove the wheel and tire assemblies.

(5) Remove brake calipers to prevent any drag

that may cause a false bearing preload torque mea-

surement.

(6) Rotate pinion yoke three or four times.

(7) Record pinion gear rotating torque with an

inch pound torque wrench (Fig. 22).

Fig. 22 PINION ROTATING TORQUE

1 -TORQUE WRENCH

2 - PINION YOKE

3 - 94 REAR AXLE - 267RBIBR/BE

Page 154 of 2255

(13) Install the fill hole plug and tighten to 34 N´m

(25 ft. lbs.).

(14) Remove support and lower vehicle.

DIFFERENTIAL - POWR-LOK

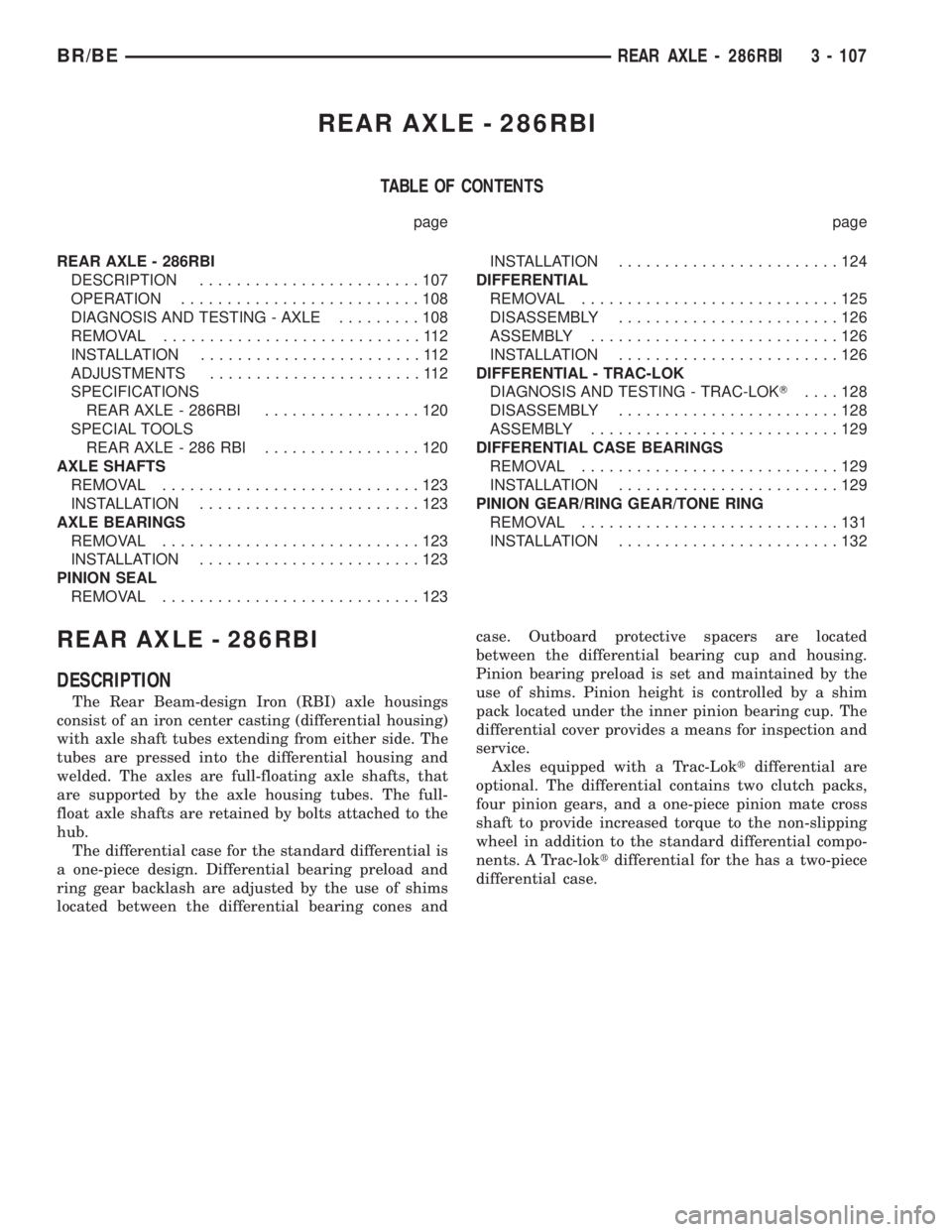

DIAGNOSIS AND TESTING - POWR-LOKT

WARNING: WHEN SERVICING VEHICLES WITH A

POWR-LOKTDIFFERENTIAL DO NOT USE THE

ENGINE TO TURN THE AXLE AND WHEELS. BOTH

REAR WHEELS MUST BE RAISED AND THE VEHI-

CLE SUPPORTED. THE AXLE CAN EXERT ENOUGH

FORCE IF ONE WHEEL IS IN CONTACT WITH A

SURFACE TO CAUSE THE VEHICLE TO MOVE.

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent to wheel studs.(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 36).

(6) If rotating torque is less than 22 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

The Powr-Loktdifferential has a two-piece cross

shaft and uses 2 disc and 3 plates for each clutch

pack. One plate and one disc in each clutch pack is

dished.

NOTE: Pay close attention to the clutch pack

arrangement during this procedure. Note the direc-

tion of the concave and convex side of the plates

and discs.

(1) Mark the ring gear half and cover half for

installation reference (Fig. 37).

(2) Remove the case attaching bolts and remove

the button cover half (Fig. 38).

(3) Remove top clutch pack (Fig. 39).

(4) Remove top side gear clutch ring.

(5) Remove top side gear.

(6) Remove pinion mate gears and cross shafts.

(7) Remove the same parts listed above from the

ring gear flange half of the case. Keep these parts

with the flange cover half for correct installation in

their original positions.

ASSEMBLY

The Powr-Loktdifferential has a two-piece cross

shaft and uses 2 disc and 3 plates for each clutch

pack. One plate and one disc in each clutch pack is

dished.

Fig. 35 DIFFERENTIAL COVER - TYPICAL

1 - SEALANT SURFACE

2 - SEALANT

3 - SEALANT THICKNESS

Fig. 36 POWR-LOK TEST -TYPICAL

1 - SPECIAL TOOL

2 - TORQUE WRENCH

BR/BEREAR AXLE - 267RBI 3 - 99

DIFFERENTIAL (Continued)

Page 162 of 2255

REAR AXLE - 286RBI

TABLE OF CONTENTS

page page

REAR AXLE - 286RBI

DESCRIPTION........................107

OPERATION..........................108

DIAGNOSIS AND TESTING - AXLE.........108

REMOVAL............................112

INSTALLATION........................112

ADJUSTMENTS.......................112

SPECIFICATIONS

REAR AXLE - 286RBI.................120

SPECIAL TOOLS

REAR AXLE - 286 RBI.................120

AXLE SHAFTS

REMOVAL............................123

INSTALLATION........................123

AXLE BEARINGS

REMOVAL............................123

INSTALLATION........................123

PINION SEAL

REMOVAL............................123INSTALLATION........................124

DIFFERENTIAL

REMOVAL............................125

DISASSEMBLY........................126

ASSEMBLY...........................126

INSTALLATION........................126

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT....128

DISASSEMBLY........................128

ASSEMBLY...........................129

DIFFERENTIAL CASE BEARINGS

REMOVAL............................129

INSTALLATION........................129

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................131

INSTALLATION........................132

REAR AXLE - 286RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housings

consist of an iron center casting (differential housing)

with axle shaft tubes extending from either side. The

tubes are pressed into the differential housing and

welded. The axles are full-floating axle shafts, that

are supported by the axle housing tubes. The full-

float axle shafts are retained by bolts attached to the

hub.

The differential case for the standard differential is

a one-piece design. Differential bearing preload and

ring gear backlash are adjusted by the use of shims

located between the differential bearing cones andcase. Outboard protective spacers are located

between the differential bearing cup and housing.

Pinion bearing preload is set and maintained by the

use of shims. Pinion height is controlled by a shim

pack located under the inner pinion bearing cup. The

differential cover provides a means for inspection and

service.

Axles equipped with a Trac-Loktdifferential are

optional. The differential contains two clutch packs,

four pinion gears, and a one-piece pinion mate cross

shaft to provide increased torque to the non-slipping

wheel in addition to the standard differential compo-

nents. A Trac-loktdifferential for the has a two-piece

differential case.

BR/BEREAR AXLE - 286RBI 3 - 107