DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1571 of 2895

CRANKSHAFT AND GEAR

DESCRIPTION

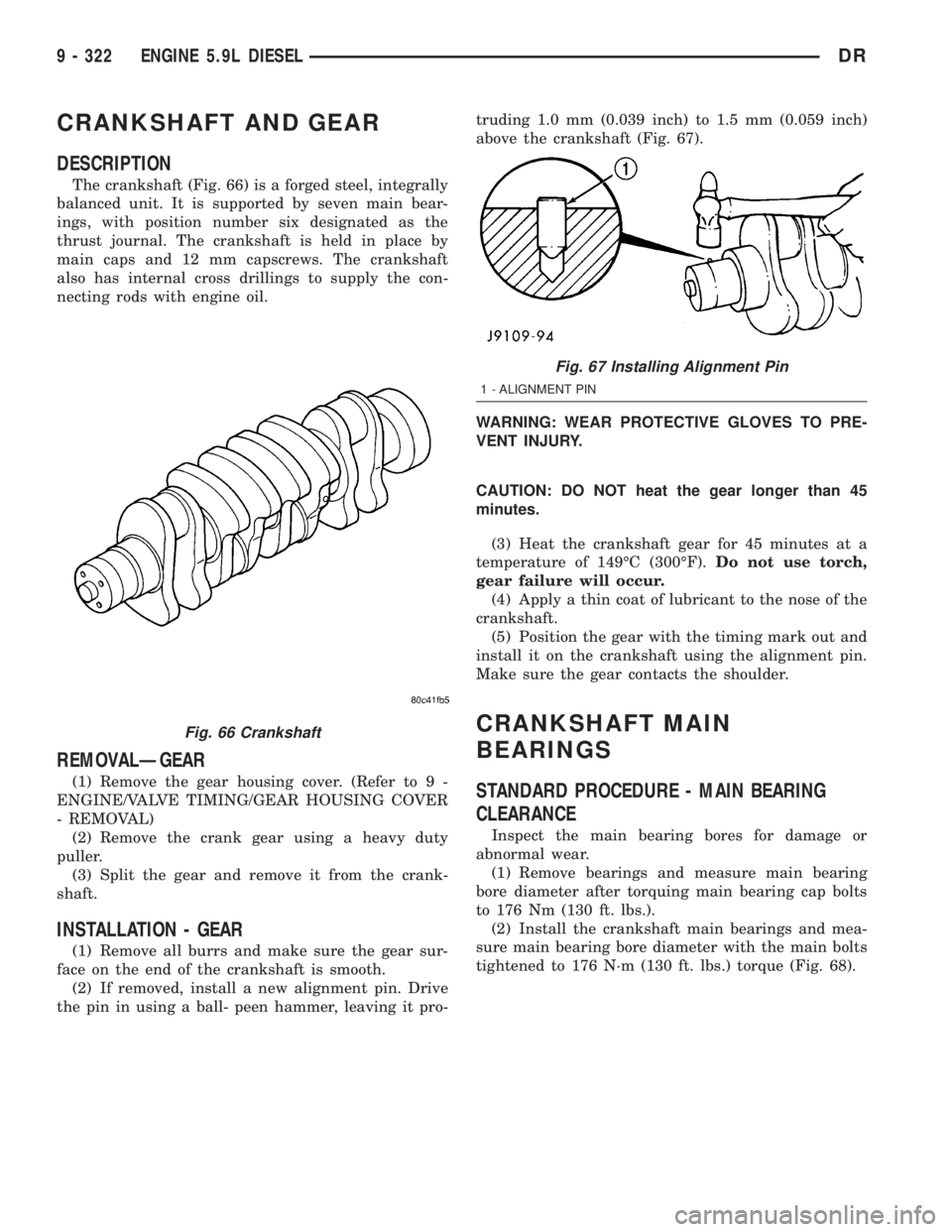

The crankshaft (Fig. 66) is a forged steel, integrally

balanced unit. It is supported by seven main bear-

ings, with position number six designated as the

thrust journal. The crankshaft is held in place by

main caps and 12 mm capscrews. The crankshaft

also has internal cross drillings to supply the con-

necting rods with engine oil.

REMOVALÐGEAR

(1) Remove the gear housing cover. (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL)

(2) Remove the crank gear using a heavy duty

puller.

(3) Split the gear and remove it from the crank-

shaft.

INSTALLATION - GEAR

(1) Remove all burrs and make sure the gear sur-

face on the end of the crankshaft is smooth.

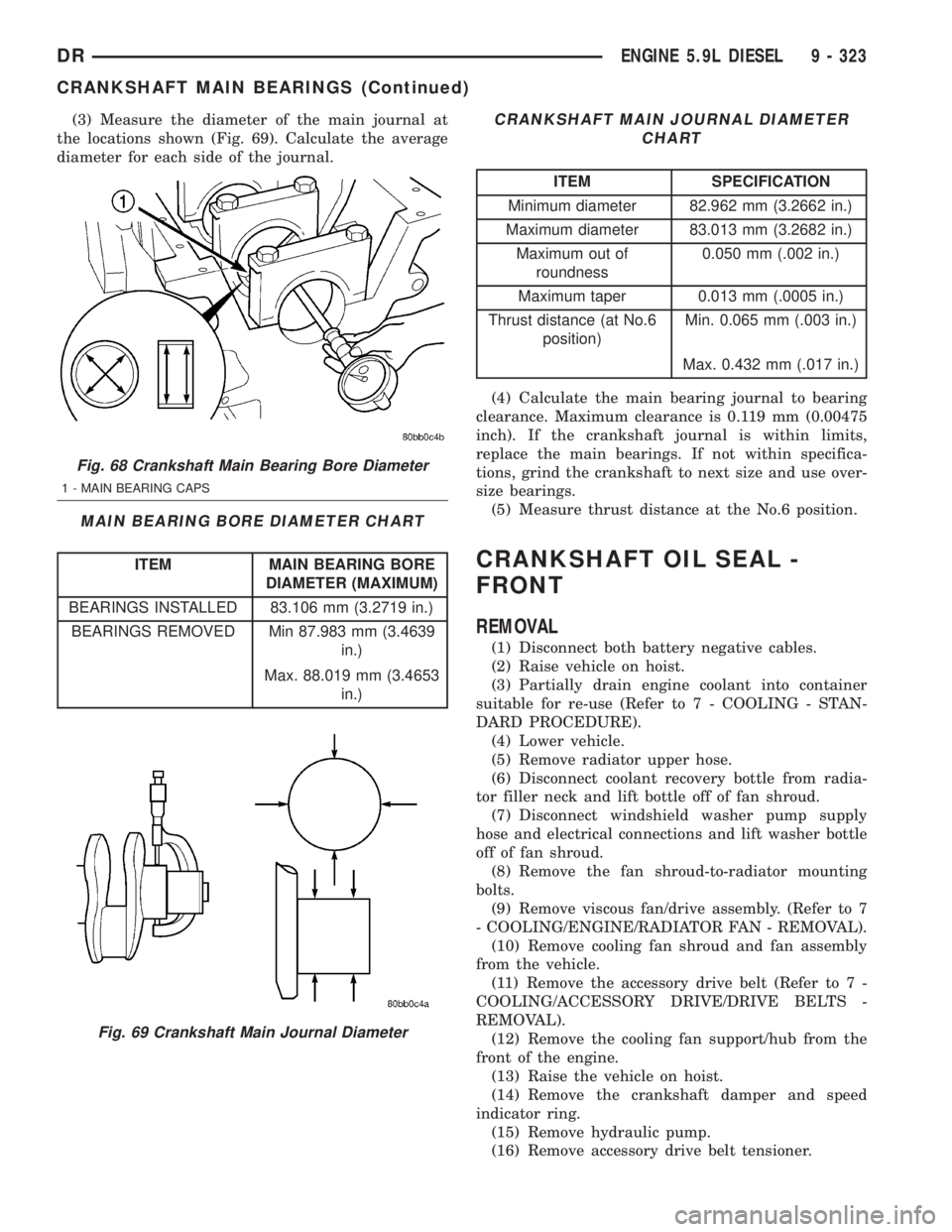

(2) If removed, install a new alignment pin. Drive

the pin in using a ball- peen hammer, leaving it pro-truding 1.0 mm (0.039 inch) to 1.5 mm (0.059 inch)

above the crankshaft (Fig. 67).

WARNING: WEAR PROTECTIVE GLOVES TO PRE-

VENT INJURY.

CAUTION: DO NOT heat the gear longer than 45

minutes.

(3) Heat the crankshaft gear for 45 minutes at a

temperature of 149ÉC (300ÉF).Do not use torch,

gear failure will occur.

(4) Apply a thin coat of lubricant to the nose of the

crankshaft.

(5) Position the gear with the timing mark out and

install it on the crankshaft using the alignment pin.

Make sure the gear contacts the shoulder.

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE

Inspect the main bearing bores for damage or

abnormal wear.

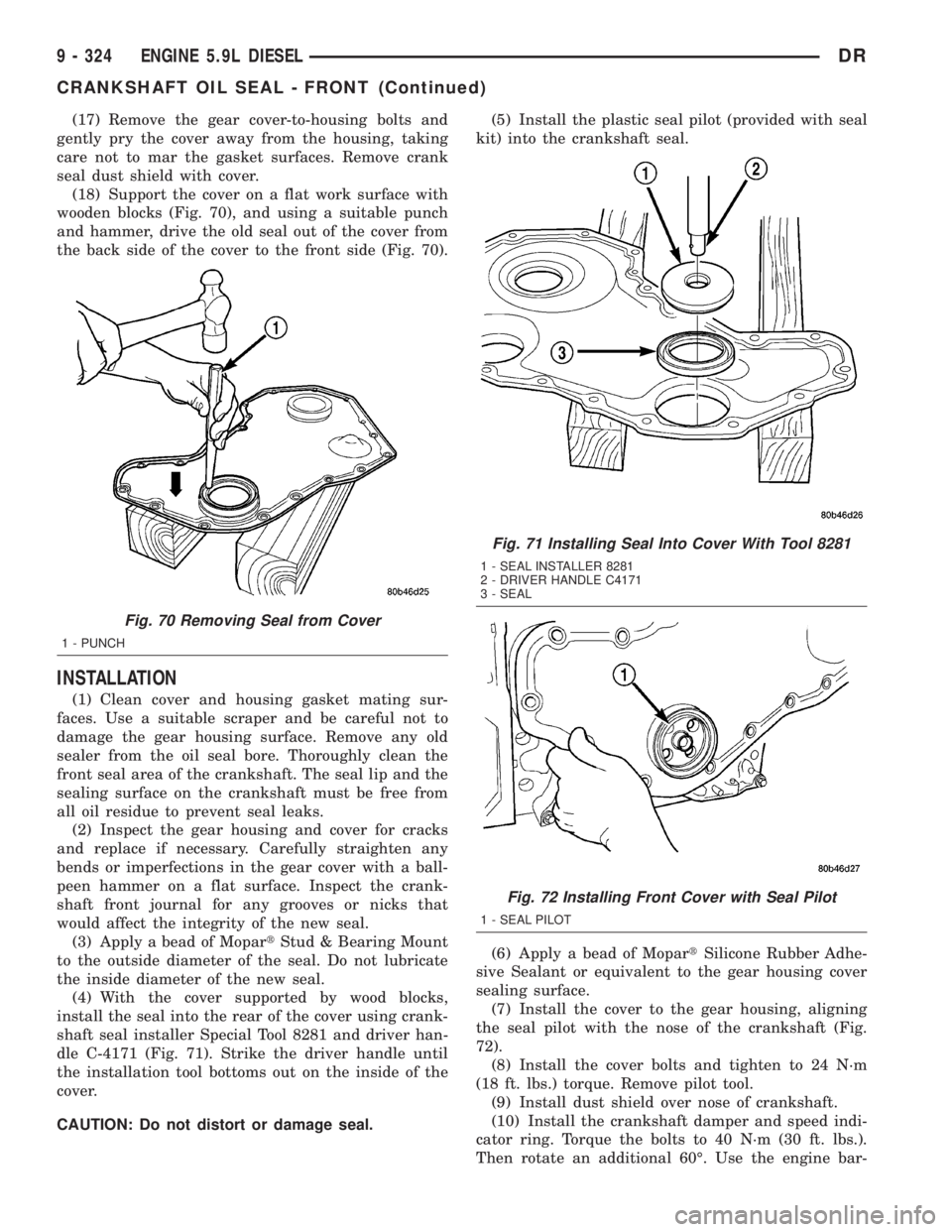

(1) Remove bearings and measure main bearing

bore diameter after torquing main bearing cap bolts

to 176 Nm (130 ft. lbs.).

(2) Install the crankshaft main bearings and mea-

sure main bearing bore diameter with the main bolts

tightened to 176 N´m (130 ft. lbs.) torque (Fig. 68).

Fig. 66 Crankshaft

Fig. 67 Installing Alignment Pin

1 - ALIGNMENT PIN

9 - 322 ENGINE 5.9L DIESELDR

Page 1572 of 2895

(3) Measure the diameter of the main journal at

the locations shown (Fig. 69). Calculate the average

diameter for each side of the journal.

MAIN BEARING BORE DIAMETER CHART

ITEM MAIN BEARING BORE

DIAMETER (MAXIMUM)

BEARINGS INSTALLED 83.106 mm (3.2719 in.)

BEARINGS REMOVED Min 87.983 mm (3.4639

in.)

Max. 88.019 mm (3.4653

in.)

CRANKSHAFT MAIN JOURNAL DIAMETER

CHART

ITEM SPECIFICATION

Minimum diameter 82.962 mm (3.2662 in.)

Maximum diameter 83.013 mm (3.2682 in.)

Maximum out of

roundness0.050 mm (.002 in.)

Maximum taper 0.013 mm (.0005 in.)

Thrust distance (at No.6

position)Min. 0.065 mm (.003 in.)

Max. 0.432 mm (.017 in.)

(4) Calculate the main bearing journal to bearing

clearance. Maximum clearance is 0.119 mm (0.00475

inch). If the crankshaft journal is within limits,

replace the main bearings. If not within specifica-

tions, grind the crankshaft to next size and use over-

size bearings.

(5) Measure thrust distance at the No.6 position.

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle from radia-

tor filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove the fan shroud-to-radiator mounting

bolts.

(9) Remove viscous fan/drive assembly. (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove cooling fan shroud and fan assembly

from the vehicle.

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper and speed

indicator ring.

(15) Remove hydraulic pump.

(16) Remove accessory drive belt tensioner.

Fig. 68 Crankshaft Main Bearing Bore Diameter

1 - MAIN BEARING CAPS

Fig. 69 Crankshaft Main Journal Diameter

DRENGINE 5.9L DIESEL 9 - 323

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1573 of 2895

(17) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces. Remove crank

seal dust shield with cover.

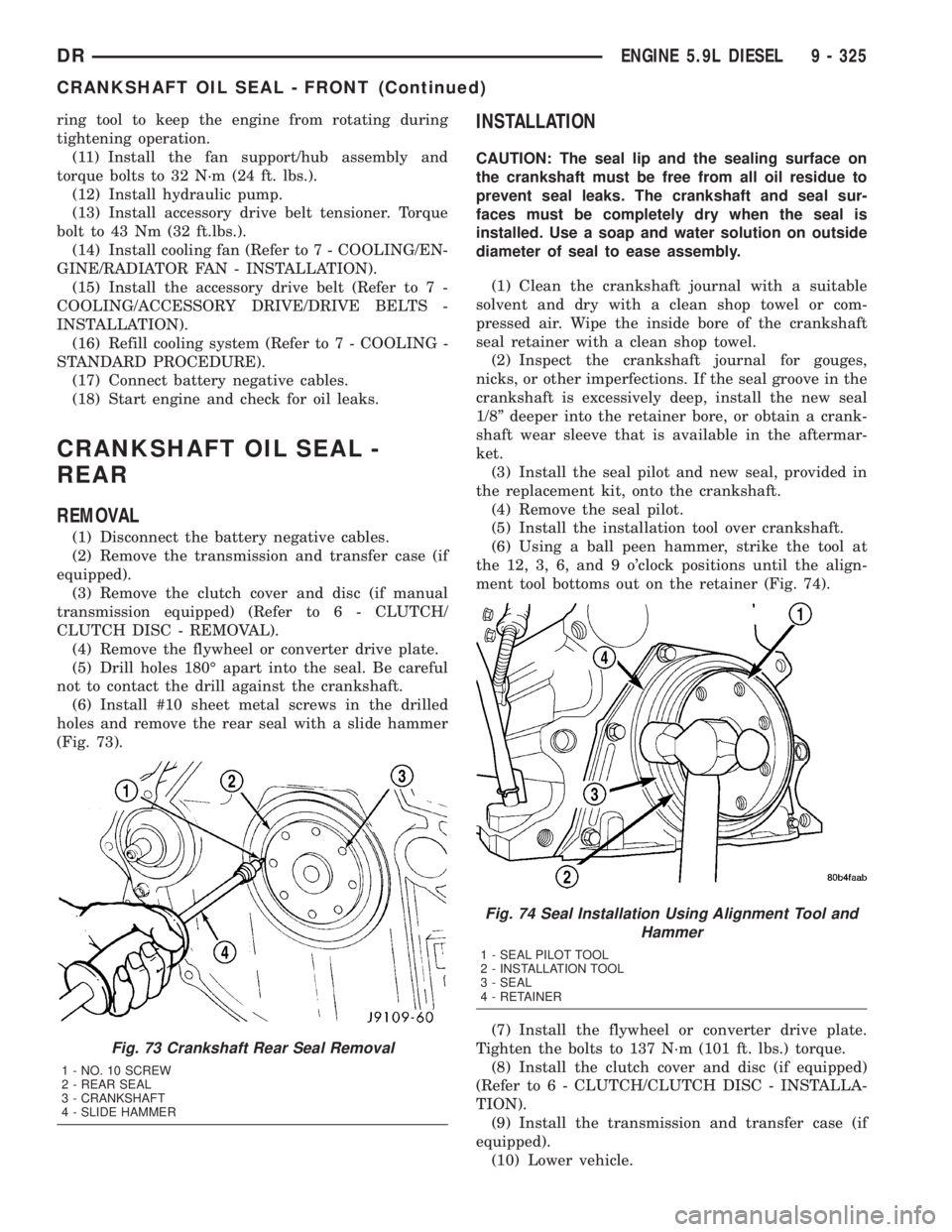

(18) Support the cover on a flat work surface with

wooden blocks (Fig. 70), and using a suitable punch

and hammer, drive the old seal out of the cover from

the back side of the cover to the front side (Fig. 70).

INSTALLATION

(1) Clean cover and housing gasket mating sur-

faces. Use a suitable scraper and be careful not to

damage the gear housing surface. Remove any old

sealer from the oil seal bore. Thoroughly clean the

front seal area of the crankshaft. The seal lip and the

sealing surface on the crankshaft must be free from

all oil residue to prevent seal leaks.

(2) Inspect the gear housing and cover for cracks

and replace if necessary. Carefully straighten any

bends or imperfections in the gear cover with a ball-

peen hammer on a flat surface. Inspect the crank-

shaft front journal for any grooves or nicks that

would affect the integrity of the new seal.

(3) Apply a bead of MopartStud & Bearing Mount

to the outside diameter of the seal. Do not lubricate

the inside diameter of the new seal.

(4) With the cover supported by wood blocks,

install the seal into the rear of the cover using crank-

shaft seal installer Special Tool 8281 and driver han-

dle C-4171 (Fig. 71). Strike the driver handle until

the installation tool bottoms out on the inside of the

cover.

CAUTION: Do not distort or damage seal.(5) Install the plastic seal pilot (provided with seal

kit) into the crankshaft seal.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the cover to the gear housing, aligning

the seal pilot with the nose of the crankshaft (Fig.

72).

(8) Install the cover bolts and tighten to 24 N´m

(18 ft. lbs.) torque. Remove pilot tool.

(9) Install dust shield over nose of crankshaft.

(10) Install the crankshaft damper and speed indi-

cator ring. Torque the bolts to 40 N´m (30 ft. lbs.).

Then rotate an additional 60É. Use the engine bar-

Fig. 70 Removing Seal from Cover

1 - PUNCH

Fig. 71 Installing Seal Into Cover With Tool 8281

1 - SEAL INSTALLER 8281

2 - DRIVER HANDLE C4171

3 - SEAL

Fig. 72 Installing Front Cover with Seal Pilot

1 - SEAL PILOT

9 - 324 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1574 of 2895

ring tool to keep the engine from rotating during

tightening operation.

(11) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(12) Install hydraulic pump.

(13) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft.lbs.).

(14) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(15) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(16) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Connect battery negative cables.

(18) Start engine and check for oil leaks.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).

(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 73).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-

shaft wear sleeve that is available in the aftermar-

ket.

(3) Install the seal pilot and new seal, provided in

the replacement kit, onto the crankshaft.

(4) Remove the seal pilot.

(5) Install the installation tool over crankshaft.

(6) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 74).

(7) Install the flywheel or converter drive plate.

Tighten the bolts to 137 N´m (101 ft. lbs.) torque.

(8) Install the clutch cover and disc (if equipped)

(Refer to 6 - CLUTCH/CLUTCH DISC - INSTALLA-

TION).

(9) Install the transmission and transfer case (if

equipped).

(10) Lower vehicle.

Fig. 73 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

Fig. 74 Seal Installation Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

DRENGINE 5.9L DIESEL 9 - 325

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1575 of 2895

(11) Connect battery negative cables.

(12) Check engine oil level and adjust, if necessary.

(13) Start engine and check for oil leaks.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove the oil pan drain plug and drain the

engine oil. Re-install plug and torque to 50 N´m (44

ft. lbs.) torque.

(4) Remove transmission and transfer case (if

equipped) from vehicle.

(5) Remove flywheel or torque converter drive

plate.

(6) Disconnect starter cables from starter motor.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(8) Remove four (4) oil pan rear bolts. Slide a

feeler guage between the seal retainer and oil pan

gasket to break the seal.

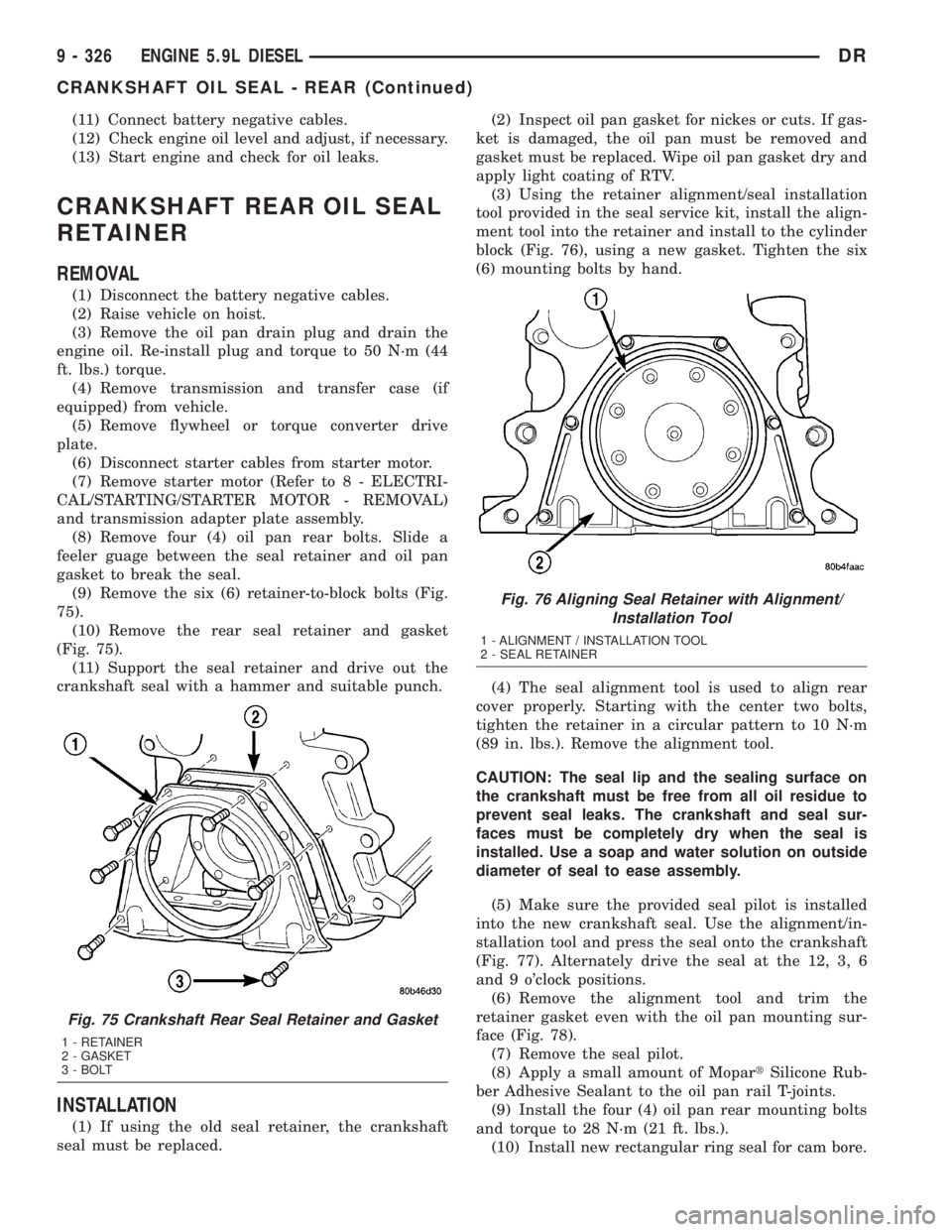

(9) Remove the six (6) retainer-to-block bolts (Fig.

75).

(10) Remove the rear seal retainer and gasket

(Fig. 75).

(11) Support the seal retainer and drive out the

crankshaft seal with a hammer and suitable punch.

INSTALLATION

(1) If using the old seal retainer, the crankshaft

seal must be replaced.(2) Inspect oil pan gasket for nickes or cuts. If gas-

ket is damaged, the oil pan must be removed and

gasket must be replaced. Wipe oil pan gasket dry and

apply light coating of RTV.

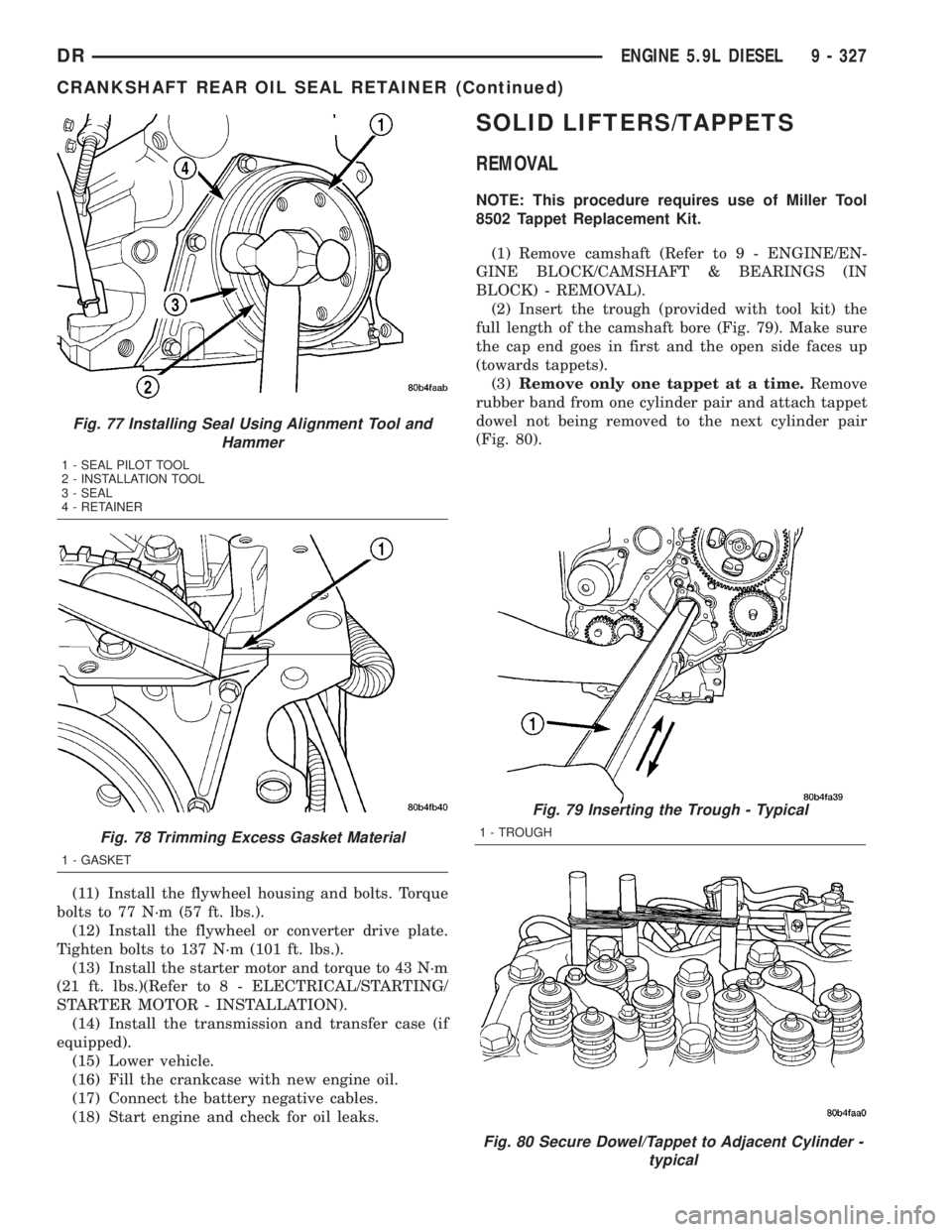

(3) Using the retainer alignment/seal installation

tool provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block (Fig. 76), using a new gasket. Tighten the six

(6) mounting bolts by hand.

(4) The seal alignment tool is used to align rear

cover properly. Starting with the center two bolts,

tighten the retainer in a circular pattern to 10 N´m

(89 in. lbs.). Remove the alignment tool.

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

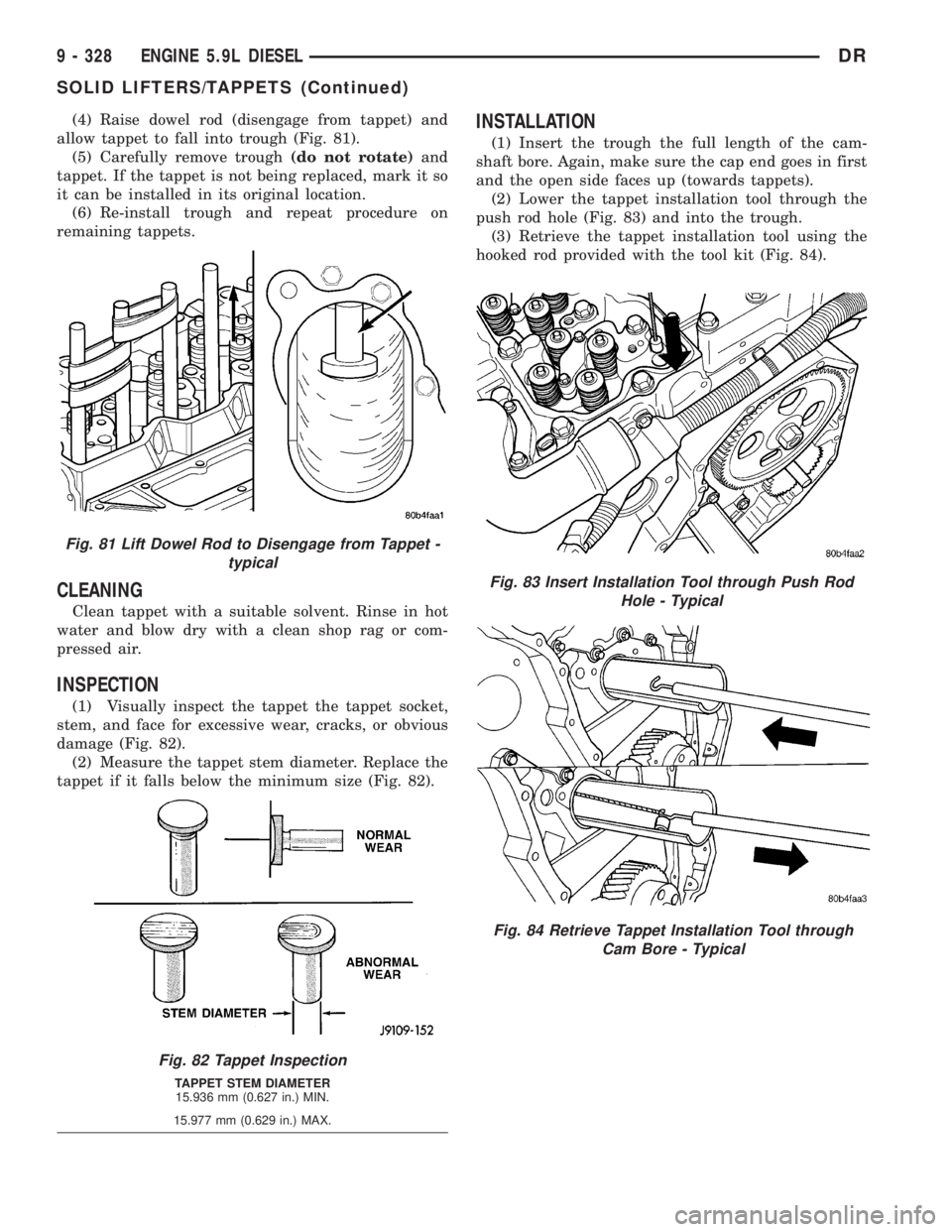

(5) Make sure the provided seal pilot is installed

into the new crankshaft seal. Use the alignment/in-

stallation tool and press the seal onto the crankshaft

(Fig. 77). Alternately drive the seal at the 12, 3, 6

and 9 o'clock positions.

(6) Remove the alignment tool and trim the

retainer gasket even with the oil pan mounting sur-

face (Fig. 78).

(7) Remove the seal pilot.

(8) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the oil pan rail T-joints.

(9) Install the four (4) oil pan rear mounting bolts

and torque to 28 N´m (21 ft. lbs.).

(10) Install new rectangular ring seal for cam bore.

Fig. 75 Crankshaft Rear Seal Retainer and Gasket

1 - RETAINER

2 - GASKET

3 - BOLT

Fig. 76 Aligning Seal Retainer with Alignment/

Installation Tool

1 - ALIGNMENT / INSTALLATION TOOL

2 - SEAL RETAINER

9 - 326 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1576 of 2895

(11) Install the flywheel housing and bolts. Torque

bolts to 77 N´m (57 ft. lbs.).

(12) Install the flywheel or converter drive plate.

Tighten bolts to 137 N´m (101 ft. lbs.).

(13) Install the starter motor and torque to 43 N´m

(21 ft. lbs.)(Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(14) Install the transmission and transfer case (if

equipped).

(15) Lower vehicle.

(16) Fill the crankcase with new engine oil.

(17) Connect the battery negative cables.

(18) Start engine and check for oil leaks.

SOLID LIFTERS/TAPPETS

REMOVAL

NOTE: This procedure requires use of Miller Tool

8502 Tappet Replacement Kit.

(1) Remove camshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Insert the trough (provided with tool kit) the

full length of the camshaft bore (Fig. 79). Make sure

the cap end goes in first and the open side faces up

(towards tappets).

(3)Remove only one tappet at a time.Remove

rubber band from one cylinder pair and attach tappet

dowel not being removed to the next cylinder pair

(Fig. 80).

Fig. 79 Inserting the Trough - Typical

1 - TROUGH

Fig. 80 Secure Dowel/Tappet to Adjacent Cylinder -

typical

Fig. 77 Installing Seal Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

Fig. 78 Trimming Excess Gasket Material

1 - GASKET

DRENGINE 5.9L DIESEL 9 - 327

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1577 of 2895

(4) Raise dowel rod (disengage from tappet) and

allow tappet to fall into trough (Fig. 81).

(5) Carefully remove trough(do not rotate)and

tappet. If the tappet is not being replaced, mark it so

it can be installed in its original location.

(6) Re-install trough and repeat procedure on

remaining tappets.

CLEANING

Clean tappet with a suitable solvent. Rinse in hot

water and blow dry with a clean shop rag or com-

pressed air.

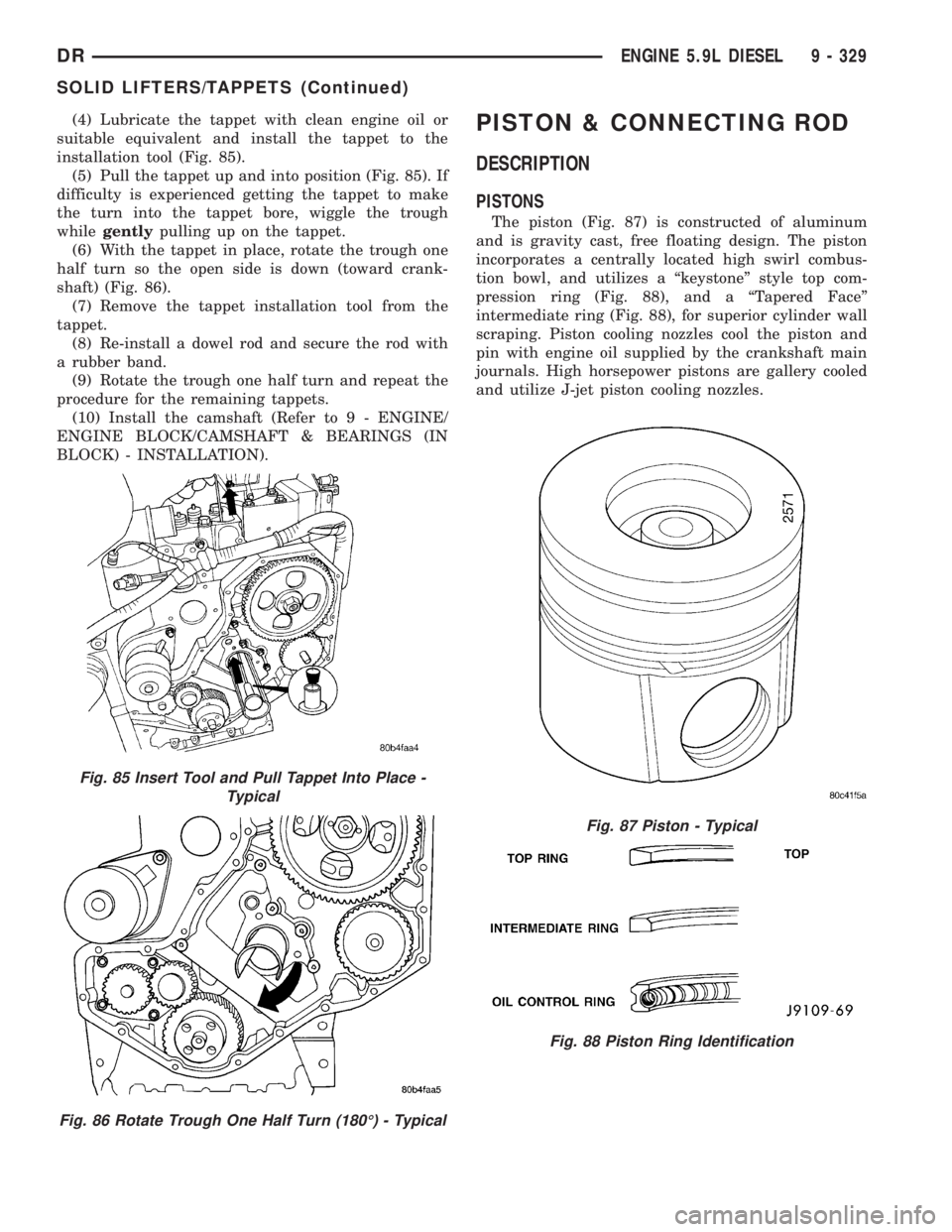

INSPECTION

(1) Visually inspect the tappet the tappet socket,

stem, and face for excessive wear, cracks, or obvious

damage (Fig. 82).

(2) Measure the tappet stem diameter. Replace the

tappet if it falls below the minimum size (Fig. 82).

INSTALLATION

(1) Insert the trough the full length of the cam-

shaft bore. Again, make sure the cap end goes in first

and the open side faces up (towards tappets).

(2) Lower the tappet installation tool through the

push rod hole (Fig. 83) and into the trough.

(3) Retrieve the tappet installation tool using the

hooked rod provided with the tool kit (Fig. 84).

Fig. 83 Insert Installation Tool through Push Rod

Hole - Typical

Fig. 84 Retrieve Tappet Installation Tool through

Cam Bore - Typical

Fig. 81 Lift Dowel Rod to Disengage from Tappet -

typical

Fig. 82 Tappet Inspection

TAPPET STEM DIAMETER

15.936 mm (0.627 in.) MIN.

15.977 mm (0.629 in.) MAX.

9 - 328 ENGINE 5.9L DIESELDR

SOLID LIFTERS/TAPPETS (Continued)

Page 1578 of 2895

(4) Lubricate the tappet with clean engine oil or

suitable equivalent and install the tappet to the

installation tool (Fig. 85).

(5) Pull the tappet up and into position (Fig. 85). If

difficulty is experienced getting the tappet to make

the turn into the tappet bore, wiggle the trough

whilegentlypulling up on the tappet.

(6) With the tappet in place, rotate the trough one

half turn so the open side is down (toward crank-

shaft) (Fig. 86).

(7) Remove the tappet installation tool from the

tappet.

(8) Re-install a dowel rod and secure the rod with

a rubber band.

(9) Rotate the trough one half turn and repeat the

procedure for the remaining tappets.

(10) Install the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - INSTALLATION).PISTON & CONNECTING ROD

DESCRIPTION

PISTONS

The piston (Fig. 87) is constructed of aluminum

and is gravity cast, free floating design. The piston

incorporates a centrally located high swirl combus-

tion bowl, and utilizes a ªkeystoneº style top com-

pression ring (Fig. 88), and a ªTapered Faceº

intermediate ring (Fig. 88), for superior cylinder wall

scraping. Piston cooling nozzles cool the piston and

pin with engine oil supplied by the crankshaft main

journals. High horsepower pistons are gallery cooled

and utilize J-jet piston cooling nozzles.

Fig. 85 Insert Tool and Pull Tappet Into Place -

Typical

Fig. 86 Rotate Trough One Half Turn (180É) - Typical

Fig. 87 Piston - Typical

Fig. 88 Piston Ring Identification

DRENGINE 5.9L DIESEL 9 - 329

SOLID LIFTERS/TAPPETS (Continued)

Page 1579 of 2895

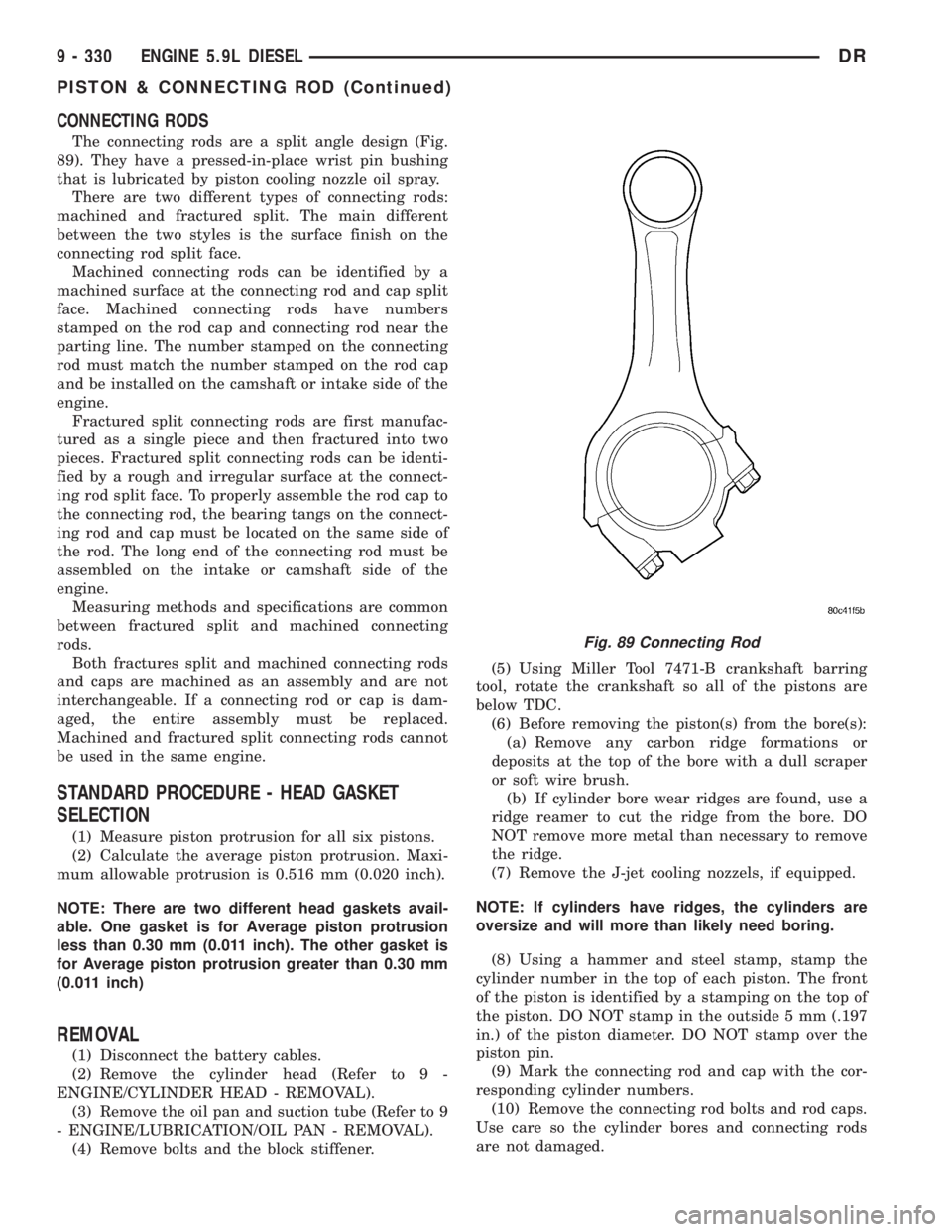

CONNECTING RODS

The connecting rods are a split angle design (Fig.

89). They have a pressed-in-place wrist pin bushing

that is lubricated by piston cooling nozzle oil spray.

There are two different types of connecting rods:

machined and fractured split. The main different

between the two styles is the surface finish on the

connecting rod split face.

Machined connecting rods can be identified by a

machined surface at the connecting rod and cap split

face. Machined connecting rods have numbers

stamped on the rod cap and connecting rod near the

parting line. The number stamped on the connecting

rod must match the number stamped on the rod cap

and be installed on the camshaft or intake side of the

engine.

Fractured split connecting rods are first manufac-

tured as a single piece and then fractured into two

pieces. Fractured split connecting rods can be identi-

fied by a rough and irregular surface at the connect-

ing rod split face. To properly assemble the rod cap to

the connecting rod, the bearing tangs on the connect-

ing rod and cap must be located on the same side of

the rod. The long end of the connecting rod must be

assembled on the intake or camshaft side of the

engine.

Measuring methods and specifications are common

between fractured split and machined connecting

rods.

Both fractures split and machined connecting rods

and caps are machined as an assembly and are not

interchangeable. If a connecting rod or cap is dam-

aged, the entire assembly must be replaced.

Machined and fractured split connecting rods cannot

be used in the same engine.

STANDARD PROCEDURE - HEAD GASKET

SELECTION

(1) Measure piston protrusion for all six pistons.

(2) Calculate the average piston protrusion. Maxi-

mum allowable protrusion is 0.516 mm (0.020 inch).

NOTE: There are two different head gaskets avail-

able. One gasket is for Average piston protrusion

less than 0.30 mm (0.011 inch). The other gasket is

for Average piston protrusion greater than 0.30 mm

(0.011 inch)

REMOVAL

(1) Disconnect the battery cables.

(2) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan and suction tube (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(4) Remove bolts and the block stiffener.(5) Using Miller Tool 7471-B crankshaft barring

tool, rotate the crankshaft so all of the pistons are

below TDC.

(6) Before removing the piston(s) from the bore(s):

(a) Remove any carbon ridge formations or

deposits at the top of the bore with a dull scraper

or soft wire brush.

(b) If cylinder bore wear ridges are found, use a

ridge reamer to cut the ridge from the bore. DO

NOT remove more metal than necessary to remove

the ridge.

(7) Remove the J-jet cooling nozzels, if equipped.

NOTE: If cylinders have ridges, the cylinders are

oversize and will more than likely need boring.

(8) Using a hammer and steel stamp, stamp the

cylinder number in the top of each piston. The front

of the piston is identified by a stamping on the top of

the piston. DO NOT stamp in the outside 5 mm (.197

in.) of the piston diameter. DO NOT stamp over the

piston pin.

(9) Mark the connecting rod and cap with the cor-

responding cylinder numbers.

(10) Remove the connecting rod bolts and rod caps.

Use care so the cylinder bores and connecting rods

are not damaged.

Fig. 89 Connecting Rod

9 - 330 ENGINE 5.9L DIESELDR

PISTON & CONNECTING ROD (Continued)

Page 1580 of 2895

(11) Use a hammer handle or similar object to

push the piston and connecting rod through the cyl-

inder bore.

(12) Store the piston/rod assemblies in a rack.

CLEANINGÐPISTON AND CONNECTING ROD

CAUTION: DO NOT use bead blast to clean the pis-

tons. DO NOT clean the pistons and rods in an acid

tank.

PISTON

Clean the pistons and pins in a suitable solvent,

rinse in hot water and blow dry with compressed air.

Soaking the pistons over night will loosen most of the

carbon build up. De-carbon the ring grooves with a

broken piston ring and again clean the pistons in sol-

vent. Rinse in hot water and blow dry with com-

pressed air.

CONNECTING ROD

Clean the connecting rods in a suitable solvent,

rinse in hot water and blow dry with compressed air.

INSPECTION

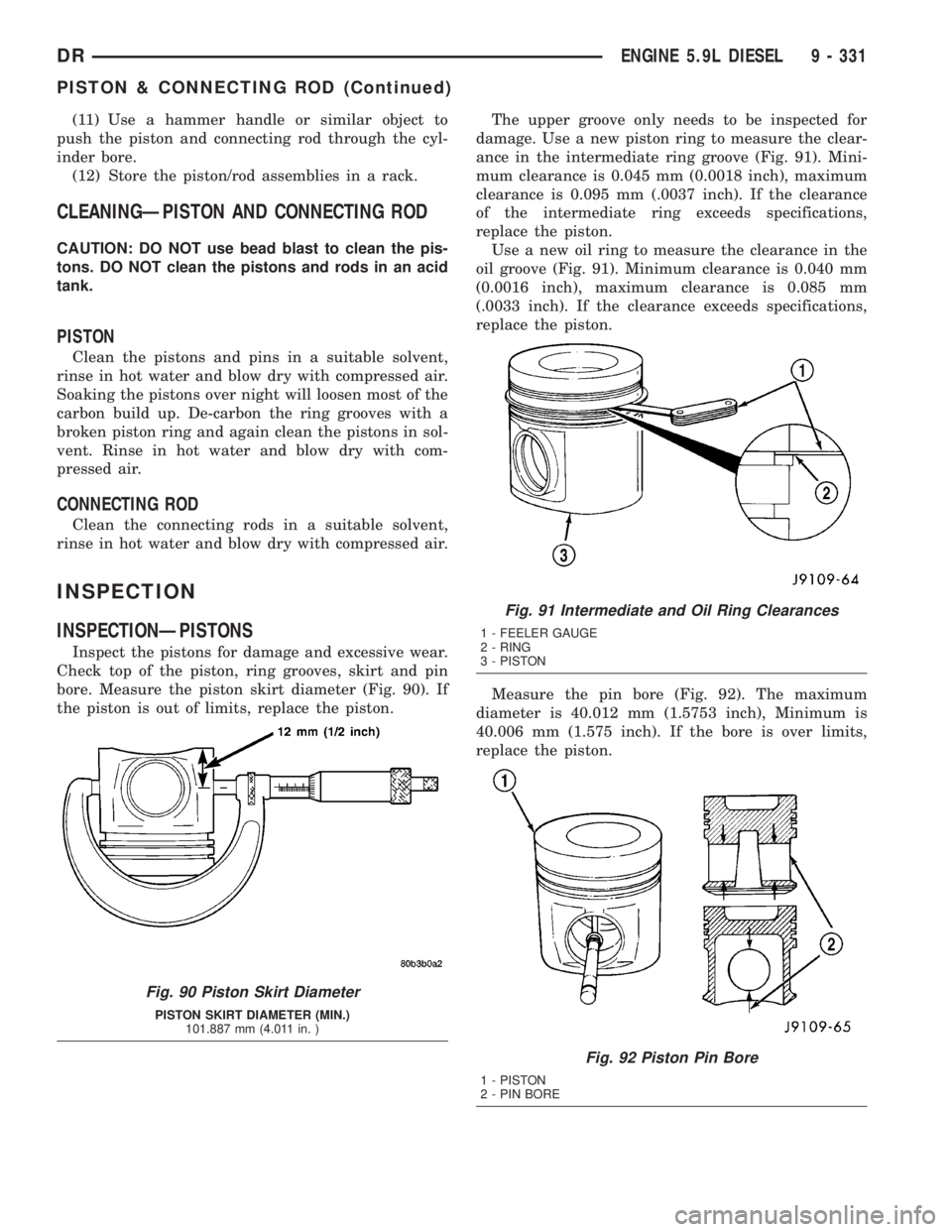

INSPECTIONÐPISTONS

Inspect the pistons for damage and excessive wear.

Check top of the piston, ring grooves, skirt and pin

bore. Measure the piston skirt diameter (Fig. 90). If

the piston is out of limits, replace the piston.The upper groove only needs to be inspected for

damage. Use a new piston ring to measure the clear-

ance in the intermediate ring groove (Fig. 91). Mini-

mum clearance is 0.045 mm (0.0018 inch), maximum

clearance is 0.095 mm (.0037 inch). If the clearance

of the intermediate ring exceeds specifications,

replace the piston.

Use a new oil ring to measure the clearance in the

oil groove (Fig. 91). Minimum clearance is 0.040 mm

(0.0016 inch), maximum clearance is 0.085 mm

(.0033 inch). If the clearance exceeds specifications,

replace the piston.

Measure the pin bore (Fig. 92). The maximum

diameter is 40.012 mm (1.5753 inch), Minimum is

40.006 mm (1.575 inch). If the bore is over limits,

replace the piston.

Fig. 90 Piston Skirt Diameter

PISTON SKIRT DIAMETER (MIN.)

101.887 mm (4.011 in. )

Fig. 91 Intermediate and Oil Ring Clearances

1 - FEELER GAUGE

2 - RING

3 - PISTON

Fig. 92 Piston Pin Bore

1 - PISTON

2 - PIN BORE

DRENGINE 5.9L DIESEL 9 - 331

PISTON & CONNECTING ROD (Continued)