adding oil DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2381 of 2895

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should be replaced whenever

a failure generates sludge and debris. This is neces-

sary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicleon level ground.At normal operating temperature

(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5) Hook up DRBtscan tool and select transmis-

sion.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

chart. (Fig. 66)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4) Loosen bolts holding rear of pan to transmis-

sion.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

(9) Remove screw holding filter to valve body (Fig.

67).

21 - 542 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

FLUID AND FILTER (Continued)

Page 2579 of 2895

Adhesion Promoter/Surface Modifier:

Adhesion Promoters/Surface Modifiers are required

for certain plastics. All three categories may have

plastics that require the use of adhesion promoter/

surface modifiers. Always follow repair material man-

ufacturer's plastic identification and repair

procedures.

SAFETY PRECAUTION AND WARNINGS

WARNING:

²EYE PROTECTION SHOULD BE USED WHEN

SERVICING COMPONENTS. PERSONAL INJURY

CAN RESULT.

²USE AN OSHA APPROVED BREATHING MASK

WHEN MIXING EPOXY, GRINDING, AND SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT.²AVOID PROLONGED SKIN CONTACT WITH

RESIN, PETROLEUM, OR ALCOHOL BASED SOL-

VENTS. PERSONAL INJURY CAN RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT PROPERLY SUPPORTED ON

SAFETY STANDS. PERSONAL INJURY CAN

RESULT.

NOTE:

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components

and electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds

on undamaged painted surfaces around repair

areas. Damage to finish can result.

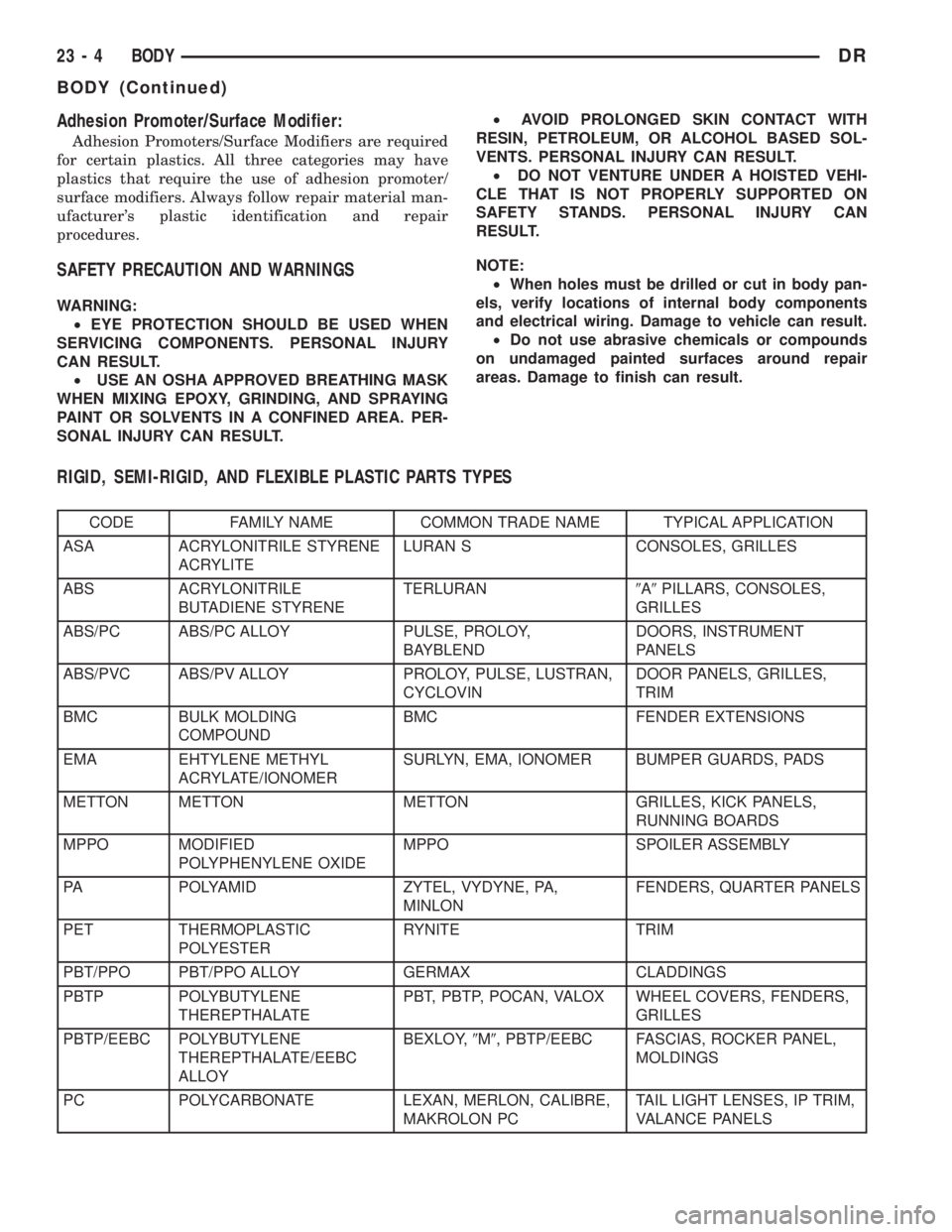

RIGID, SEMI-RIGID, AND FLEXIBLE PLASTIC PARTS TYPES

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

ASA ACRYLONITRILE STYRENE

ACRYLITELURAN S CONSOLES, GRILLES

ABS ACRYLONITRILE

BUTADIENE STYRENETERLURAN9A9PILLARS, CONSOLES,

GRILLES

ABS/PC ABS/PC ALLOY PULSE, PROLOY,

BAYBLENDDOORS, INSTRUMENT

PANELS

ABS/PVC ABS/PV ALLOY PROLOY, PULSE, LUSTRAN,

CYCLOVINDOOR PANELS, GRILLES,

TRIM

BMC BULK MOLDING

COMPOUNDBMC FENDER EXTENSIONS

EMA EHTYLENE METHYL

ACRYLATE/IONOMERSURLYN, EMA, IONOMER BUMPER GUARDS, PADS

METTON METTON METTON GRILLES, KICK PANELS,

RUNNING BOARDS

MPPO MODIFIED

POLYPHENYLENE OXIDEMPPO SPOILER ASSEMBLY

PA POLYAMID ZYTEL, VYDYNE, PA,

MINLONFENDERS, QUARTER PANELS

PET THERMOPLASTIC

POLYESTERRYNITE TRIM

PBT/PPO PBT/PPO ALLOY GERMAX CLADDINGS

PBTP POLYBUTYLENE

THEREPTHALATEPBT, PBTP, POCAN, VALOX WHEEL COVERS, FENDERS,

GRILLES

PBTP/EEBC POLYBUTYLENE

THEREPTHALATE/EEBC

ALLOYBEXLOY,9M9, PBTP/EEBC FASCIAS, ROCKER PANEL,

MOLDINGS

PC POLYCARBONATE LEXAN, MERLON, CALIBRE,

MAKROLON PCTAIL LIGHT LENSES, IP TRIM,

VALANCE PANELS

23 - 4 BODYDR

BODY (Continued)

Page 2856 of 2895

ABS - DESCRIPTION, BRAKES...........5-39

ABS - OPERATION, BRAKES.............5-39

ABS BRAKE BLEEDING - STANDARD

PROCEDURE.........................5-40

ABS INDICATOR - DESCRIPTION.........8J-17

ABS INDICATOR - OPERATION..........8J-17

A/C APPLICATION TABLE,

SPECIFICATIONS......................24-7

A/C COMPRESSOR CLUTCH -

DESCRIPTION........................24-9

A/C COMPRESSOR CLUTCH -

INSPECTION........................24-12

A/C COMPRESSOR CLUTCH -

INSTALLATION.......................24-12

A/C COMPRESSOR CLUTCH -

OPERATION..........................24-9

A/C COMPRESSOR CLUTCH - REMOVAL . . 24-10

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-10

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-10

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-13

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-14

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-13

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-14

A/C COMPRESSOR NOISE - DIAGNOSIS

AND TESTING.......................24-36

A/C CONDENSER - DESCRIPTION.........24-39

A/C CONDENSER - OPERATION..........24-39

A/C EVAPORATOR - DESCRIPTION.......24-47

A/C EVAPORATOR - INSTALLATION......24-47

A/C EVAPORATOR - OPERATION.........24-47

A/C EVAPORATOR - REMOVAL..........24-47

A/C HEATER CONTROL - DESCRIPTION . . . 24-14

A/C HEATER CONTROL - INSTALLATION . . . 24-15

A/C HEATER CONTROL - REMOVAL......24-14

A/C ORIFICE TUBE - DESCRIPTION.......24-48

A/C ORIFICE TUBE - INSTALLATION......24-49

A/C ORIFICE TUBE - OPERATION........24-48

A/C ORIFICE TUBE - REMOVAL..........24-49

A/C PERFORMANCE - DIAGNOSIS AND

TESTING............................24-2

A/C PRESSURE TRANSDUCER -

DESCRIPTION.......................24-15

A/C PRESSURE TRANSDUCER -

DIAGNOSIS AND TESTING.............24-15

A/C PRESSURE TRANSDUCER -

INSTALLATION.......................24-16

A/C PRESSURE TRANSDUCER -

OPERATION.........................24-15

A/C PRESSURE TRANSDUCER -

REMOVAL..........................24-16

ACCELERATOR PEDAL - INSTALLATION . . . 14-24

ACCELERATOR PEDAL - REMOVAL.......14-24

ACCELERATOR PEDAL POSITION

SENSOR - DESCRIPTION...............14-25

ACCELERATOR PEDAL POSITION

SENSOR - INSTALLATION..............14-25

ACCELERATOR PEDAL POSITION

SENSOR - OPERATION................14-25

ACCELERATOR PEDAL POSITION

SENSOR - REMOVAL..................14-25

ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING................7-25,7-28,7-31

ACCUMULATOR - DESCRIPTION.........24-49

ACCUMULATOR - DESCRIPTION

. . 21-191,21-372

ACCUMULATOR - INSPECTION

. . . 21-192,21-373

ACCUMULATOR - INSTALLATION

........24-50

ACCUMULATOR - OPERATION

..........24-49

ACCUMULATOR - OPERATION

....21-192,21-373

ACCUMULATOR - REMOVAL

............24-49

ACM COVER - INSTALLATION

............8O-9

ACM COVER - REMOVAL

...............8O-9

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT

.............................25-1

ACTUATOR - DESCRIPTION, BLEND

DOOR

.............................24-16

ACTUATOR - DESCRIPTION, FUEL

CONTROL

..........................14-85

ACTUATOR - DESCRIPTION, MODE

DOOR

.............................24-20

ACTUATOR - DESCRIPTION,

RECIRCULATION DOOR

................24-22ACTUATOR - INSTALLATION, BLEND

DOOR.............................24-17

ACTUATOR - INSTALLATION, FLOOR -

DEFROST DOOR.....................24-20

ACTUATOR - INSTALLATION, FUEL

CONTROL..........................14-85

ACTUATOR - INSTALLATION, INSIDE

HANDLE.......................23-22,23-32

ACTUATOR - INSTALLATION, MODE

DOOR.............................24-22

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-23

ACTUATOR - OPERATION, BLEND DOOR . . 24-16

ACTUATOR - OPERATION, FUEL

CONTROL..........................14-85

ACTUATOR - OPERATION, MODE DOOR . . . 24-21

ACTUATOR - OPERATION,

RECIRCULATION DOOR................24-22

ACTUATOR - REMOVAL, BLEND DOOR....24-17

ACTUATOR - REMOVAL, FLOOR -

DEFROST DOOR.....................24-19

ACTUATOR - REMOVAL, FUEL CONTROL . . 14-85

ACTUATOR - REMOVAL, INSIDE HANDLE . 23-22,

23-31

ACTUATOR - REMOVAL, MODE DOOR....24-21

ACTUATOR - REMOVAL, RECIRCULATION

DOOR.............................24-22

ADAPTER HOUSING SEAL -

INSTALLATION...........21-127,21-539,21-83

ADAPTER HOUSING SEAL - REMOVAL . . 21-127,

21-539,21-83

ADAPTER MOUNT - INSTALLATION, DISC

BRAKE CALIPER......................5-17

ADDING ADDITIONAL COOLANT -

STANDARD PROCEDURE................7-19

ADDITIONAL COOLANT - STANDARD

PROCEDURE, ADDING..................7-19

ADHESIVE LOCATIONS -

SPECIFICATIONS, STRUCTURAL........23-113

ADJUSTABLE PEDAL MOTOR -

DESCRIPTION........................5-24

ADJUSTABLE PEDAL MOTOR -

INSTALLATION........................5-24

ADJUSTABLE PEDAL MOTOR - REMOVAL . . 5-24

ADJUSTABLE PEDAL SWITCH -

INSTALLATION.........................5-6

ADJUSTABLE PEDAL SWITCH -

REMOVAL............................5-6

ADJUSTER - DIAGNOSIS AND TESTING,

HYDRAULIC LASH................9-124,9-31

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-50

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-50

ADJUSTER ASSEMBLY - DESCRIPTION,

ROCKER ARM.......................9-124

ADJUSTER ASSEMBLY - INSTALLATION,

ROCKER ARM..................9-124,9-249

ADJUSTER ASSEMBLY - REMOVAL,

ROCKER ARM..................9-124,9-249

ADJUSTER ASSY - CLEANING, ROCKER

ARM

..............................9-310

ADJUSTER ASSY - DESCRIPTION,

ROCKER ARM

.......................9-310

ADJUSTER ASSY - INSPECTION,

ROCKER ARM

.......................9-311

ADJUSTER ASSY - INSTALLATION,

ROCKER ARM

.............9-198,9-312,9-379

ADJUSTER ASSY - REMOVAL, ROCKER

ARM

....................9-198,9-310,9-379

ADJUSTING TOOL - ADJUSTMENT, WITH

. . . 5-36

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE

.................8O-7

AIR CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING

..........................21-494

AIR CLEANER ELEMENT - INSTALLATION

. 9-105,

9-20,9-242,9-298,9-370

AIR CLEANER ELEMENT - REMOVAL

. 9-105,9-20,

9-242,9-297,9-370

AIR CONDITIONER - DESCRIPTION,

HEATER

.............................24-1

AIR CONDITIONER - OPERATION,

HEATER

.............................24-1

AIR CONDITIONING - INSTALLATION,

WATER PUMP BYPASS HOSE WITH

.......7-70AIR CONDITIONING - INSTALLATION,

WATER PUMP BYPASS HOSE

WITHOUT............................7-70

AIR CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH.............7-68

AIR CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT..........7-69

AIR CONTROL MOTOR - DESCRIPTION,

IDLE...............................14-33

AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-35

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-33

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-34

AIR COOLER AND PLUMBING -

CLEANING, CHARGE..................11-16

AIR COOLER AND PLUMBING -

DESCRIPTION, CHARGE...............11-15

AIR COOLER AND PLUMBING -

INSPECTION, CHARGE.................11-16

AIR COOLER AND PLUMBING -

INSTALLATION, CHARGE...............11-16

AIR COOLER AND PLUMBING -

OPERATION, CHARGE.................11-15

AIR COOLER AND PLUMBING -

REMOVAL, CHARGE..................11-15

AIR COOLER SYSTEM - LEAKS -

DIAGNOSIS AND TESTING, CHARGE......11-15

AIR DAM - INSTALLATION, FRONT........13-2

AIR DAM - REMOVAL, FRONT...........13-2

AIR HEATER - DESCRIPTION, INTAKE.....14-91

AIR HEATER - INSTALLATION, INTAKE....14-91

AIR HEATER - OPERATION, INTAKE......14-91

AIR HEATER - REMOVAL, INTAKE........14-91

AIR HEATER RELAY - DESCRIPTION,

INTAKE ............................14-92

AIR HEATER RELAY - INSTALLATION,

INTAKE ............................14-93

AIR HEATER RELAY - OPERATION,

INTAKE ............................14-92

AIR HEATER RELAY - REMOVAL, INTAKE . . 14-93

AIR INTAKE SYSTEM - INSTALLATION....9-194

AIR INTAKE SYSTEM - REMOVAL........9-194

AIR TEMPERATURE SENSOR -

DESCRIPTION, INTAKE................14-36

AIR TEMPERATURE SENSOR -

INSTALLATION, INTAKE................14-38

AIR TEMPERATURE SENSOR -

OPERATION, INTAKE..................14-36

AIR TEMPERATURE SENSOR -

REMOVAL, INTAKE...................14-36

AIR TEMPERATURE SENSOR/MAP

SENSOR - DESCRIPTION, INTAKE........14-93

AIR TEMPERATURE SENSOR/MAP

SENSOR - INSTALLATION, INTAKE.......14-94

AIR TEMPERATURE SENSOR/MAP

SENSOR - OPERATION, INTAKE.........14-93

AIR TEMPERATURE SENSOR/MAP

SENSOR - REMOVAL, INTAKE...........14-93

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET.........14-90

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET........14-90

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET..........14-90

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET............14-90

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING................21-143,21-324

AIR TO OIL COOLER - INSTALLATION.....7-75

AIR TO OIL COOLER - REMOVAL.........7-74

AIRBAG - DESCRIPTION, DRIVER........8O-22

AIRBAG - DESCRIPTION, PASSENGER....8O-34

AIRBAG - DESCRIPTION, SIDE CURTAIN . . 8O-51

AIRBAG - INSTALLATION, DRIVER.......8O-24

AIRBAG - INSTALLATION, PASSENGER . . . 8O-37

AIRBAG - INSTALLATION, SIDE CURTAIN . . 8O-53

AIRBAG - OPERATION, DRIVER.........8O-23

AIRBAG - OPERATION, PASSENGER......8O-35

AIRBAG - OPERATION, SIDE CURTAIN....8O-51

AIRBAG - REMOVAL, DRIVER

...........8O-23

AIRBAG - REMOVAL, PASSENGER

.......8O-35

AIRBAG - REMOVAL, SIDE CURTAIN

.....8O-52

AIRBAG CONTROL MODULE -

DESCRIPTION

.......................8O-10

AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE IMPACT

...........8O-53

DRINDEX 1

Description Group-Page Description Group-Page Description Group-Page