tow DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2617 of 2895

UPPER RADIATOR

CROSSMEMBER

REMOVAL

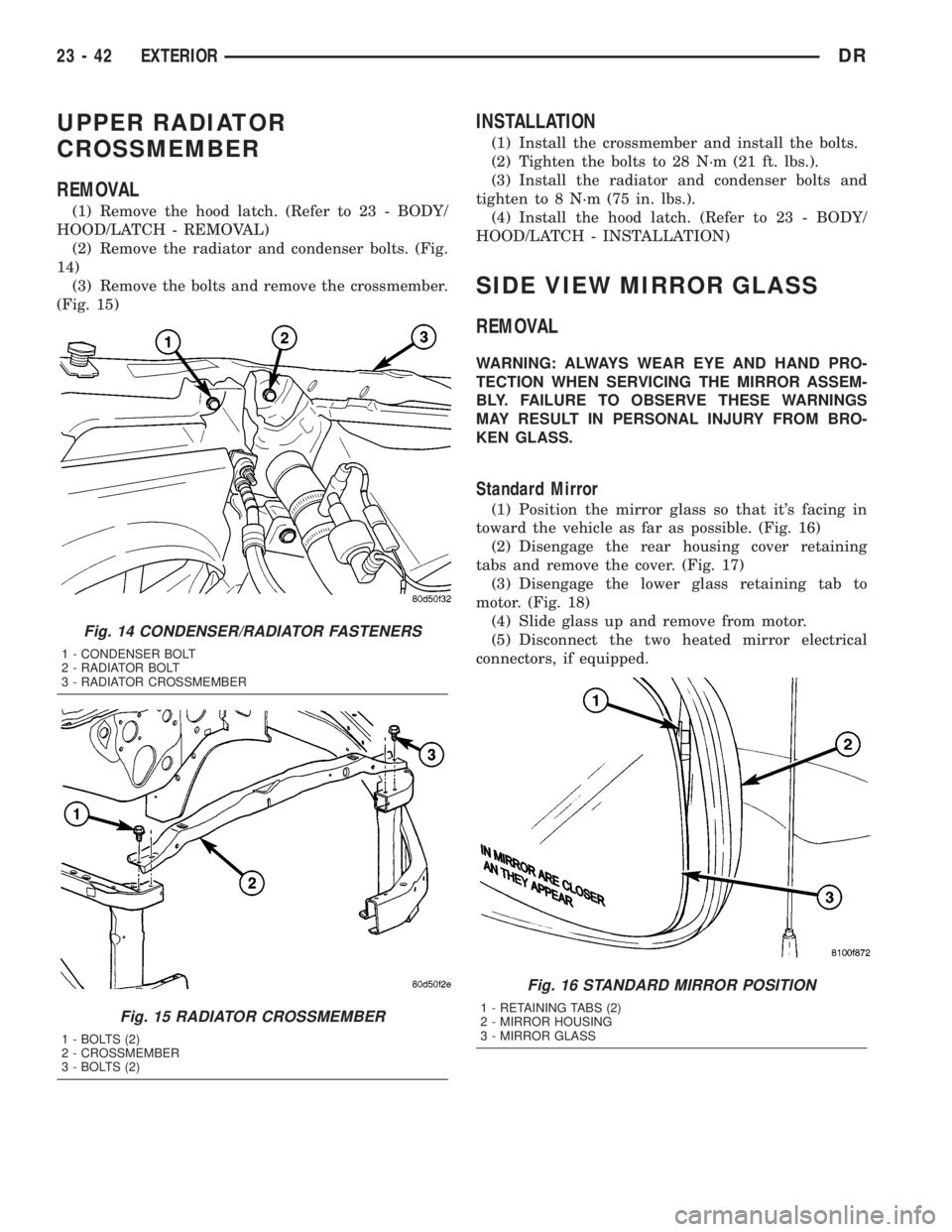

(1) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)

(2) Remove the radiator and condenser bolts. (Fig.

14)

(3) Remove the bolts and remove the crossmember.

(Fig. 15)

INSTALLATION

(1) Install the crossmember and install the bolts.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.).

(3) Install the radiator and condenser bolts and

tighten to 8 N´m (75 in. lbs.).

(4) Install the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - INSTALLATION)

SIDE VIEW MIRROR GLASS

REMOVAL

WARNING: ALWAYS WEAR EYE AND HAND PRO-

TECTION WHEN SERVICING THE MIRROR ASSEM-

BLY. FAILURE TO OBSERVE THESE WARNINGS

MAY RESULT IN PERSONAL INJURY FROM BRO-

KEN GLASS.

Standard Mirror

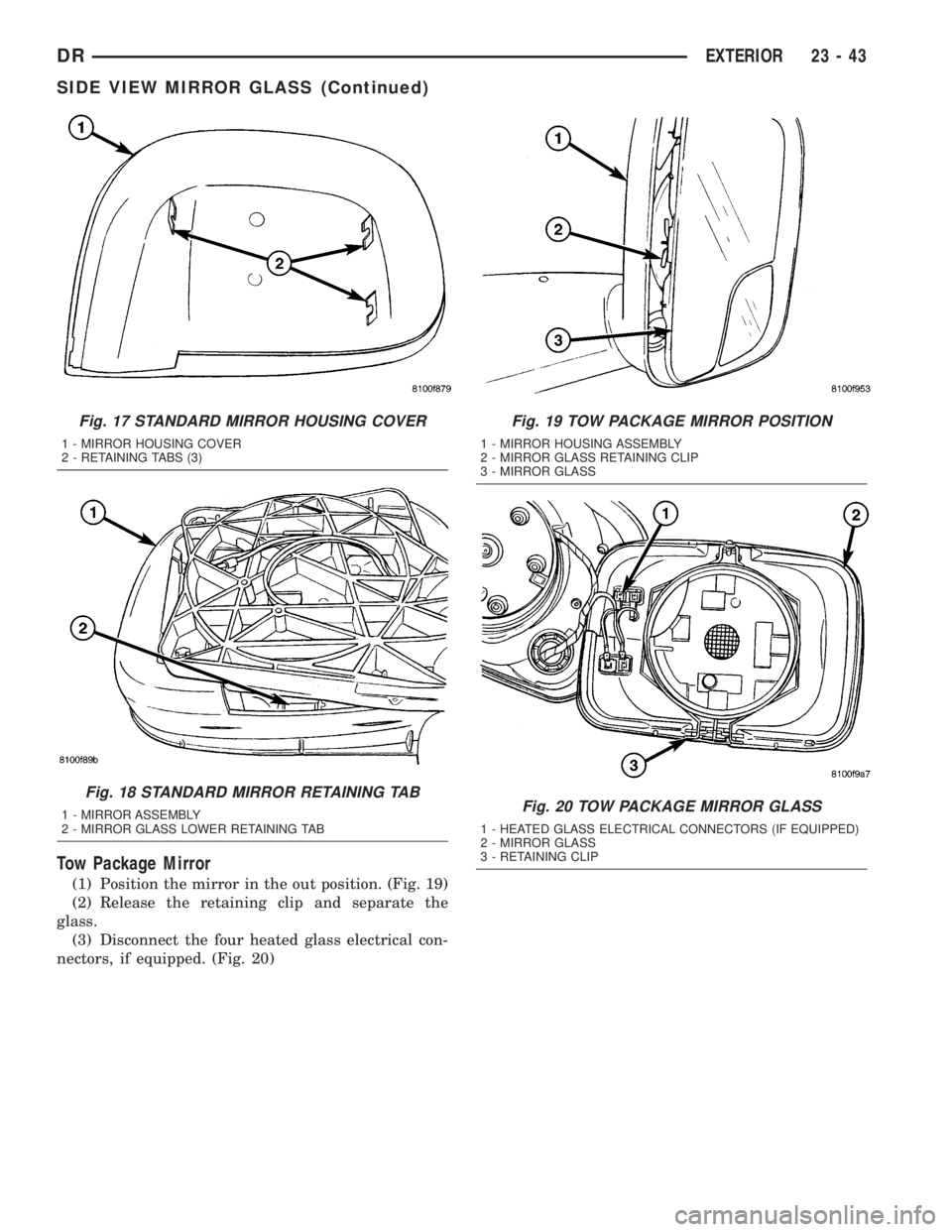

(1) Position the mirror glass so that it's facing in

toward the vehicle as far as possible. (Fig. 16)

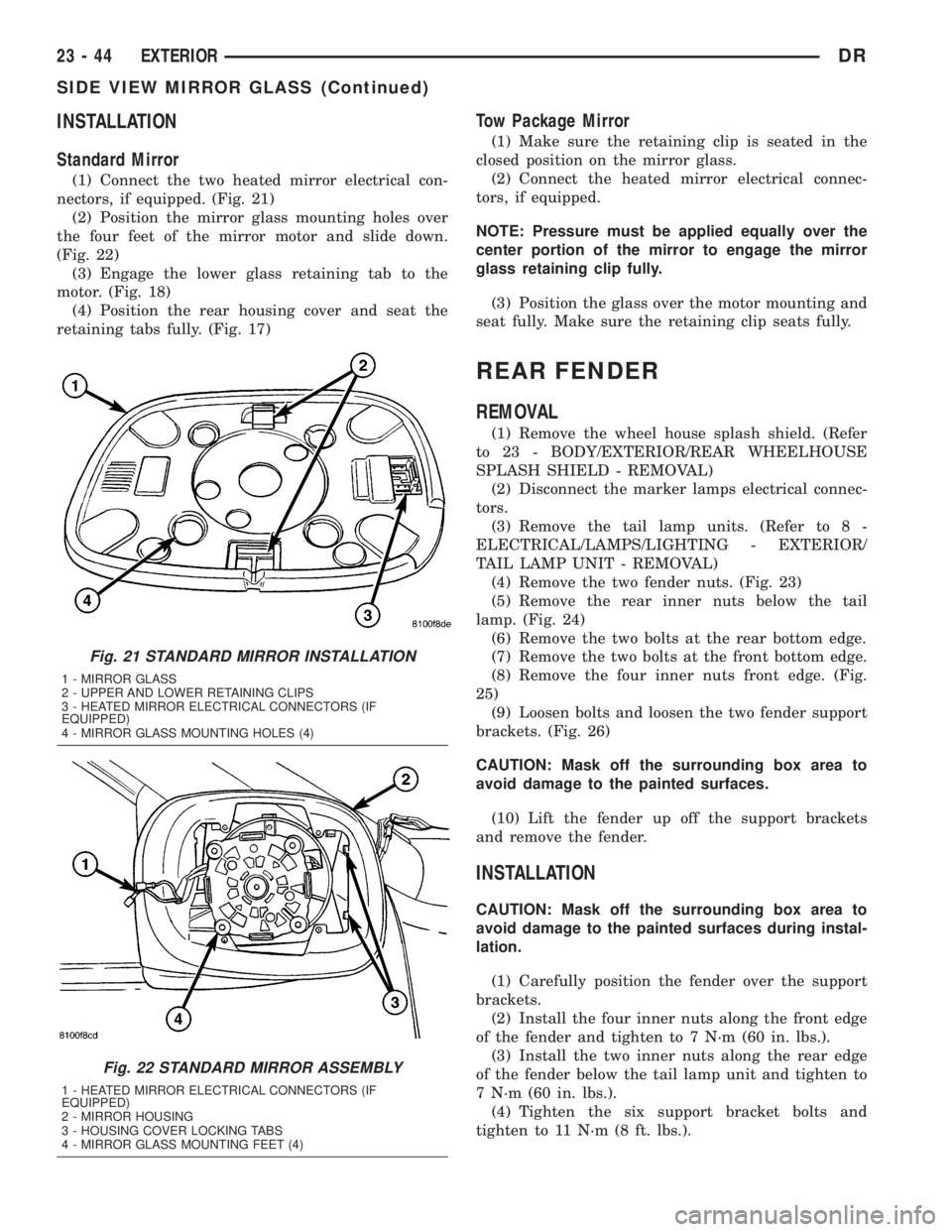

(2) Disengage the rear housing cover retaining

tabs and remove the cover. (Fig. 17)

(3) Disengage the lower glass retaining tab to

motor. (Fig. 18)

(4) Slide glass up and remove from motor.

(5) Disconnect the two heated mirror electrical

connectors, if equipped.

Fig. 14 CONDENSER/RADIATOR FASTENERS

1 - CONDENSER BOLT

2 - RADIATOR BOLT

3 - RADIATOR CROSSMEMBER

Fig. 15 RADIATOR CROSSMEMBER

1 - BOLTS (2)

2 - CROSSMEMBER

3 - BOLTS (2)

Fig. 16 STANDARD MIRROR POSITION

1 - RETAINING TABS (2)

2 - MIRROR HOUSING

3 - MIRROR GLASS

23 - 42 EXTERIORDR

Page 2618 of 2895

Tow Package Mirror

(1) Position the mirror in the out position. (Fig. 19)

(2) Release the retaining clip and separate the

glass.

(3) Disconnect the four heated glass electrical con-

nectors, if equipped. (Fig. 20)

Fig. 17 STANDARD MIRROR HOUSING COVER

1 - MIRROR HOUSING COVER

2 - RETAINING TABS (3)

Fig. 18 STANDARD MIRROR RETAINING TAB

1 - MIRROR ASSEMBLY

2 - MIRROR GLASS LOWER RETAINING TAB

Fig. 19 TOW PACKAGE MIRROR POSITION

1 - MIRROR HOUSING ASSEMBLY

2 - MIRROR GLASS RETAINING CLIP

3 - MIRROR GLASS

Fig. 20 TOW PACKAGE MIRROR GLASS

1 - HEATED GLASS ELECTRICAL CONNECTORS (IF EQUIPPED)

2 - MIRROR GLASS

3 - RETAINING CLIP

DREXTERIOR 23 - 43

SIDE VIEW MIRROR GLASS (Continued)

Page 2619 of 2895

INSTALLATION

Standard Mirror

(1) Connect the two heated mirror electrical con-

nectors, if equipped. (Fig. 21)

(2) Position the mirror glass mounting holes over

the four feet of the mirror motor and slide down.

(Fig. 22)

(3) Engage the lower glass retaining tab to the

motor. (Fig. 18)

(4) Position the rear housing cover and seat the

retaining tabs fully. (Fig. 17)

Tow Package Mirror

(1) Make sure the retaining clip is seated in the

closed position on the mirror glass.

(2) Connect the heated mirror electrical connec-

tors, if equipped.

NOTE: Pressure must be applied equally over the

center portion of the mirror to engage the mirror

glass retaining clip fully.

(3) Position the glass over the motor mounting and

seat fully. Make sure the retaining clip seats fully.

REAR FENDER

REMOVAL

(1) Remove the wheel house splash shield. (Refer

to 23 - BODY/EXTERIOR/REAR WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(2) Disconnect the marker lamps electrical connec-

tors.

(3) Remove the tail lamp units. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

TAIL LAMP UNIT - REMOVAL)

(4) Remove the two fender nuts. (Fig. 23)

(5) Remove the rear inner nuts below the tail

lamp. (Fig. 24)

(6) Remove the two bolts at the rear bottom edge.

(7) Remove the two bolts at the front bottom edge.

(8) Remove the four inner nuts front edge. (Fig.

25)

(9) Loosen bolts and loosen the two fender support

brackets. (Fig. 26)

CAUTION: Mask off the surrounding box area to

avoid damage to the painted surfaces.

(10) Lift the fender up off the support brackets

and remove the fender.

INSTALLATION

CAUTION: Mask off the surrounding box area to

avoid damage to the painted surfaces during instal-

lation.

(1) Carefully position the fender over the support

brackets.

(2) Install the four inner nuts along the front edge

of the fender and tighten to 7 N´m (60 in. lbs.).

(3) Install the two inner nuts along the rear edge

of the fender below the tail lamp unit and tighten to

7 N´m (60 in. lbs.).

(4) Tighten the six support bracket bolts and

tighten to 11 N´m (8 ft. lbs.).

Fig. 21 STANDARD MIRROR INSTALLATION

1 - MIRROR GLASS

2 - UPPER AND LOWER RETAINING CLIPS

3 - HEATED MIRROR ELECTRICAL CONNECTORS (IF

EQUIPPED)

4 - MIRROR GLASS MOUNTING HOLES (4)

Fig. 22 STANDARD MIRROR ASSEMBLY

1 - HEATED MIRROR ELECTRICAL CONNECTORS (IF

EQUIPPED)

2 - MIRROR HOUSING

3 - HOUSING COVER LOCKING TABS

4 - MIRROR GLASS MOUNTING FEET (4)

23 - 44 EXTERIORDR

SIDE VIEW MIRROR GLASS (Continued)

Page 2646 of 2895

REAR VIEW MIRROR

REMOVAL

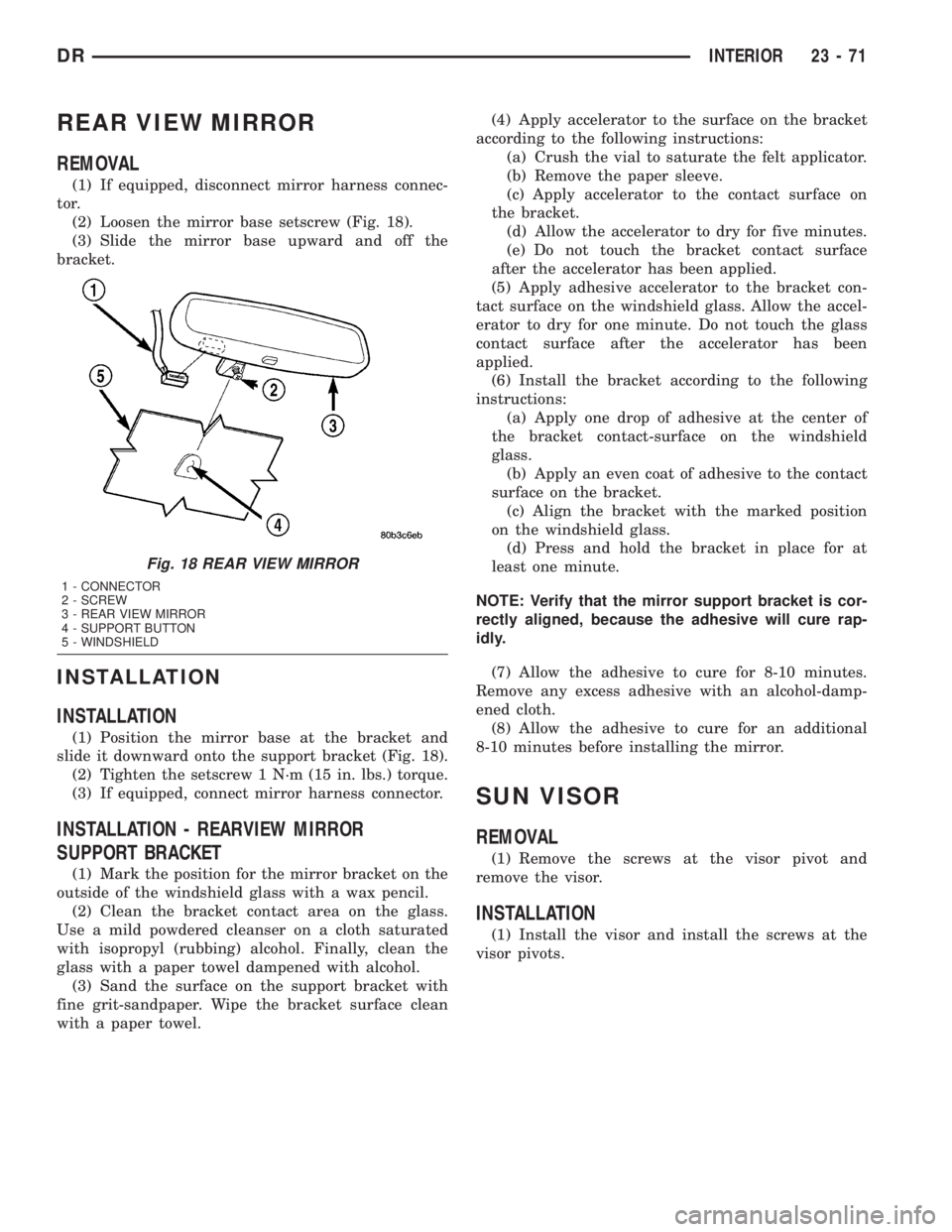

(1) If equipped, disconnect mirror harness connec-

tor.

(2) Loosen the mirror base setscrew (Fig. 18).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket (Fig. 18).

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness connector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.(4) Apply accelerator to the surface on the bracket

according to the following instructions:

(a) Crush the vial to saturate the felt applicator.

(b) Remove the paper sleeve.

(c) Apply accelerator to the contact surface on

the bracket.

(d) Allow the accelerator to dry for five minutes.

(e) Do not touch the bracket contact surface

after the accelerator has been applied.

(5) Apply adhesive accelerator to the bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute. Do not touch the glass

contact surface after the accelerator has been

applied.

(6) Install the bracket according to the following

instructions:

(a) Apply one drop of adhesive at the center of

the bracket contact-surface on the windshield

glass.

(b) Apply an even coat of adhesive to the contact

surface on the bracket.

(c) Align the bracket with the marked position

on the windshield glass.

(d) Press and hold the bracket in place for at

least one minute.

NOTE: Verify that the mirror support bracket is cor-

rectly aligned, because the adhesive will cure rap-

idly.

(7) Allow the adhesive to cure for 8-10 minutes.

Remove any excess adhesive with an alcohol-damp-

ened cloth.

(8) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror.

SUN VISOR

REMOVAL

(1) Remove the screws at the visor pivot and

remove the visor.

INSTALLATION

(1) Install the visor and install the screws at the

visor pivots.

Fig. 18 REAR VIEW MIRROR

1 - CONNECTOR

2 - SCREW

3 - REAR VIEW MIRROR

4 - SUPPORT BUTTON

5 - WINDSHIELD

DRINTERIOR 23 - 71

Page 2648 of 2895

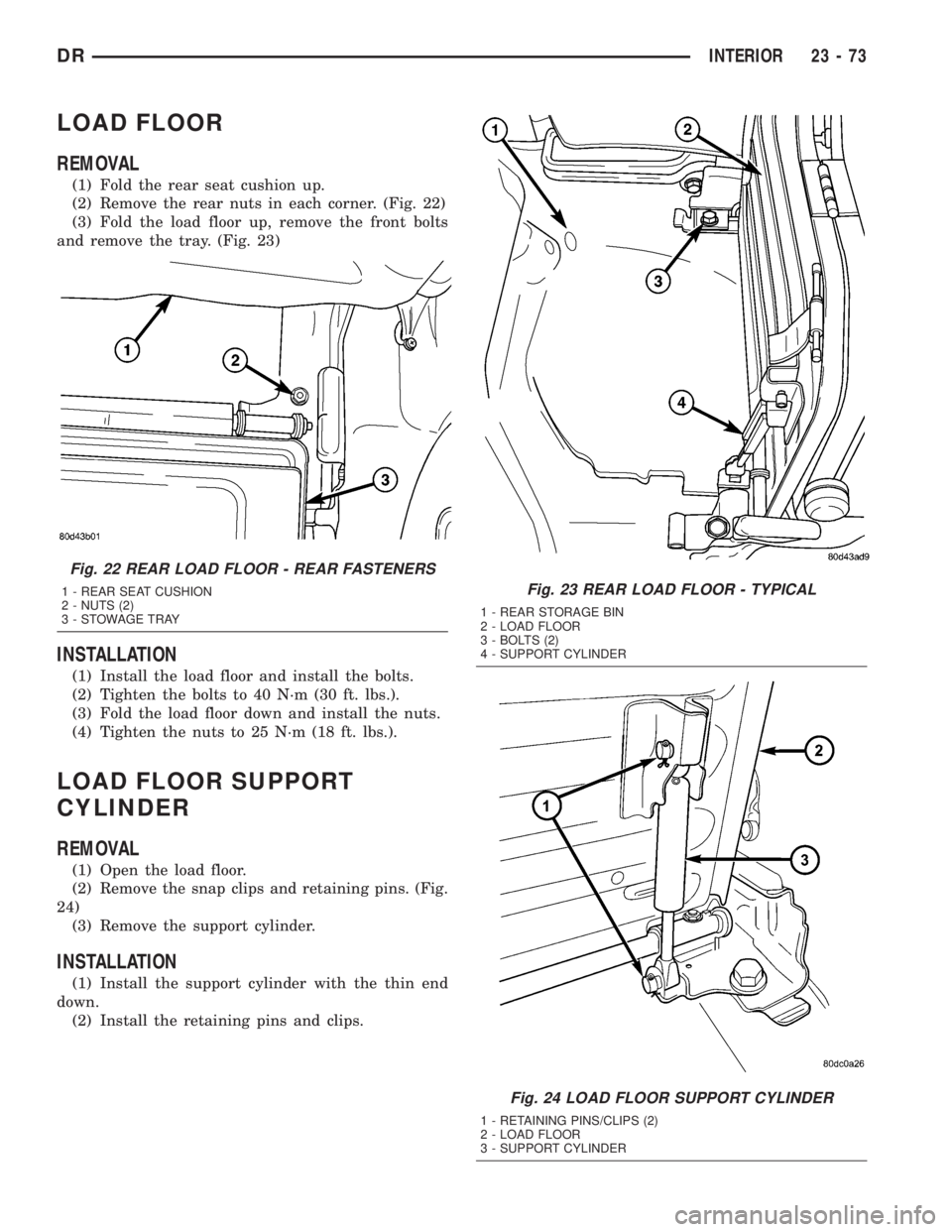

LOAD FLOOR

REMOVAL

(1) Fold the rear seat cushion up.

(2) Remove the rear nuts in each corner. (Fig. 22)

(3) Fold the load floor up, remove the front bolts

and remove the tray. (Fig. 23)

INSTALLATION

(1) Install the load floor and install the bolts.

(2) Tighten the bolts to 40 N´m (30 ft. lbs.).

(3) Fold the load floor down and install the nuts.

(4) Tighten the nuts to 25 N´m (18 ft. lbs.).

LOAD FLOOR SUPPORT

CYLINDER

REMOVAL

(1) Open the load floor.

(2) Remove the snap clips and retaining pins. (Fig.

24)

(3) Remove the support cylinder.

INSTALLATION

(1) Install the support cylinder with the thin end

down.

(2) Install the retaining pins and clips.

Fig. 22 REAR LOAD FLOOR - REAR FASTENERS

1 - REAR SEAT CUSHION

2 - NUTS (2)

3 - STOWAGE TRAYFig. 23 REAR LOAD FLOOR - TYPICAL

1 - REAR STORAGE BIN

2 - LOAD FLOOR

3 - BOLTS (2)

4 - SUPPORT CYLINDER

Fig. 24 LOAD FLOOR SUPPORT CYLINDER

1 - RETAINING PINS/CLIPS (2)

2 - LOAD FLOOR

3 - SUPPORT CYLINDER

DRINTERIOR 23 - 73

Page 2800 of 2895

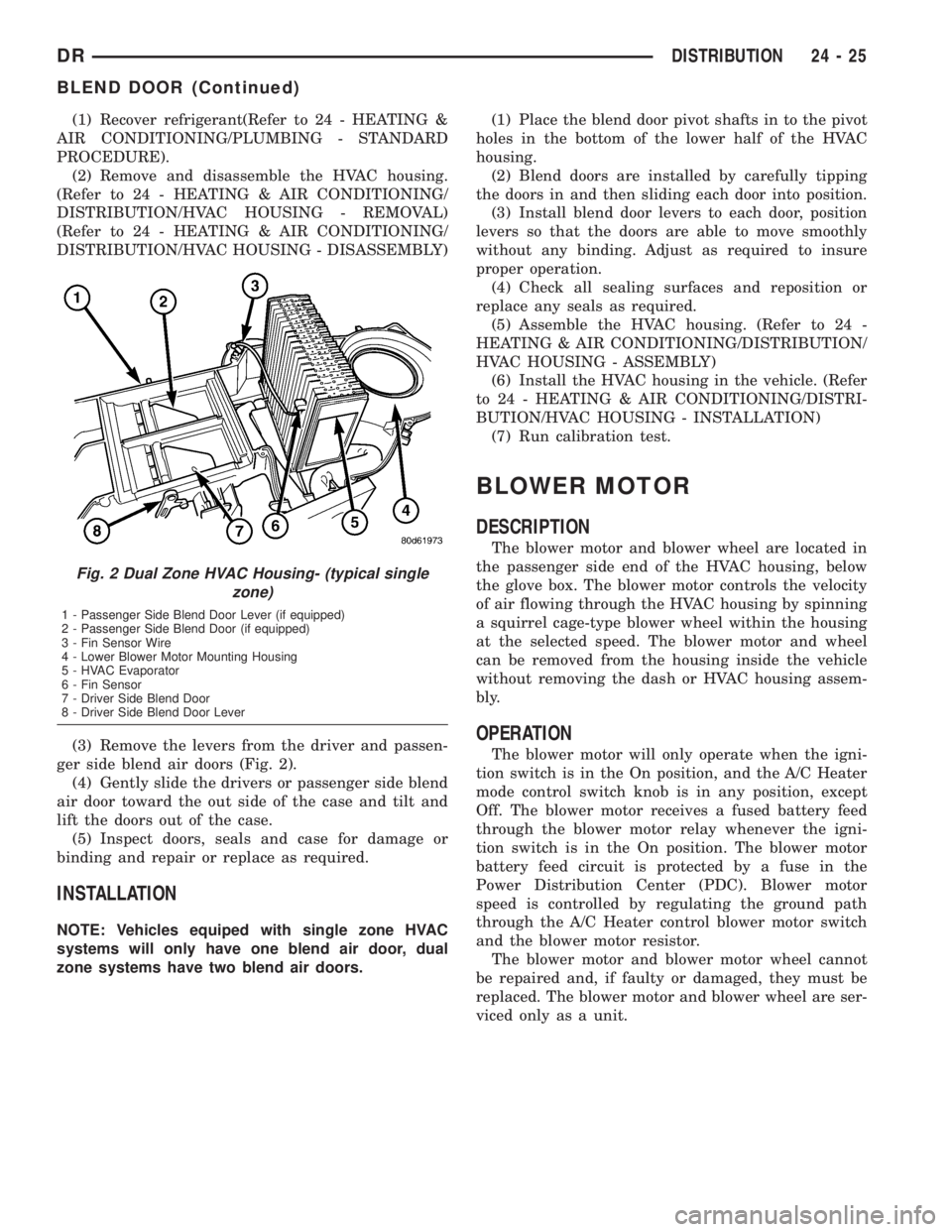

(1) Recover refrigerant(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

(2) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

(3) Remove the levers from the driver and passen-

ger side blend air doors (Fig. 2).

(4) Gently slide the drivers or passenger side blend

air door toward the out side of the case and tilt and

lift the doors out of the case.

(5) Inspect doors, seals and case for damage or

binding and repair or replace as required.

INSTALLATION

NOTE: Vehicles equiped with single zone HVAC

systems will only have one blend air door, dual

zone systems have two blend air doors.(1) Place the blend door pivot shafts in to the pivot

holes in the bottom of the lower half of the HVAC

housing.

(2) Blend doors are installed by carefully tipping

the doors in and then sliding each door into position.

(3) Install blend door levers to each door, position

levers so that the doors are able to move smoothly

without any binding. Adjust as required to insure

proper operation.

(4) Check all sealing surfaces and reposition or

replace any seals as required.

(5) Assemble the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY)

(6) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

(7) Run calibration test.

BLOWER MOTOR

DESCRIPTION

The blower motor and blower wheel are located in

the passenger side end of the HVAC housing, below

the glove box. The blower motor controls the velocity

of air flowing through the HVAC housing by spinning

a squirrel cage-type blower wheel within the housing

at the selected speed. The blower motor and wheel

can be removed from the housing inside the vehicle

without removing the dash or HVAC housing assem-

bly.

OPERATION

The blower motor will only operate when the igni-

tion switch is in the On position, and the A/C Heater

mode control switch knob is in any position, except

Off. The blower motor receives a fused battery feed

through the blower motor relay whenever the igni-

tion switch is in the On position. The blower motor

battery feed circuit is protected by a fuse in the

Power Distribution Center (PDC). Blower motor

speed is controlled by regulating the ground path

through the A/C Heater control blower motor switch

and the blower motor resistor.

The blower motor and blower motor wheel cannot

be repaired and, if faulty or damaged, they must be

replaced. The blower motor and blower wheel are ser-

viced only as a unit.

Fig. 2 Dual Zone HVAC Housing- (typical single

zone)

1 - Passenger Side Blend Door Lever (if equipped)

2 - Passenger Side Blend Door (if equipped)

3 - Fin Sensor Wire

4 - Lower Blower Motor Mounting Housing

5 - HVAC Evaporator

6 - Fin Sensor

7 - Driver Side Blend Door

8 - Driver Side Blend Door Lever

DRDISTRIBUTION 24 - 25

BLEND DOOR (Continued)

Page 2848 of 2895

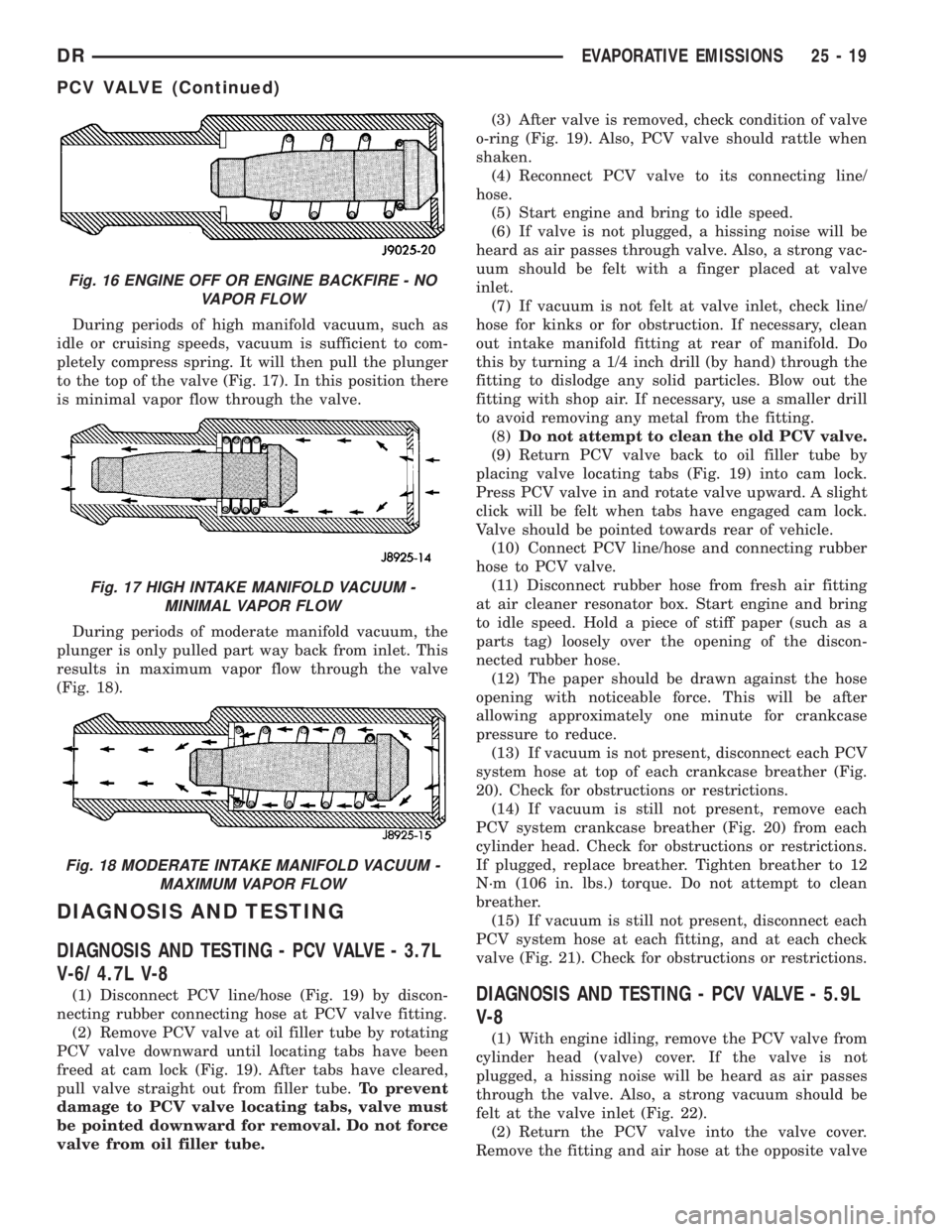

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 17). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 18).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PCV VALVE - 3.7L

V-6/ 4.7L V-8

(1) Disconnect PCV line/hose (Fig. 19) by discon-

necting rubber connecting hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward until locating tabs have been

freed at cam lock (Fig. 19). After tabs have cleared,

pull valve straight out from filler tube.To prevent

damage to PCV valve locating tabs, valve must

be pointed downward for removal. Do not force

valve from oil filler tube.(3) After valve is removed, check condition of valve

o-ring (Fig. 19). Also, PCV valve should rattle when

shaken.

(4) Reconnect PCV valve to its connecting line/

hose.

(5) Start engine and bring to idle speed.

(6) If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong vac-

uum should be felt with a finger placed at valve

inlet.

(7) If vacuum is not felt at valve inlet, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at rear of manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out the

fitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(8)Do not attempt to clean the old PCV valve.

(9) Return PCV valve back to oil filler tube by

placing valve locating tabs (Fig. 19) into cam lock.

Press PCV valve in and rotate valve upward. A slight

click will be felt when tabs have engaged cam lock.

Valve should be pointed towards rear of vehicle.

(10) Connect PCV line/hose and connecting rubber

hose to PCV valve.

(11) Disconnect rubber hose from fresh air fitting

at air cleaner resonator box. Start engine and bring

to idle speed. Hold a piece of stiff paper (such as a

parts tag) loosely over the opening of the discon-

nected rubber hose.

(12) The paper should be drawn against the hose

opening with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

(13) If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather (Fig.

20). Check for obstructions or restrictions.

(14) If vacuum is still not present, remove each

PCV system crankcase breather (Fig. 20) from each

cylinder head. Check for obstructions or restrictions.

If plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather.

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting, and at each check

valve (Fig. 21). Check for obstructions or restrictions.DIAGNOSIS AND TESTING - PCV VALVE - 5.9L

V-8

(1) With engine idling, remove the PCV valve from

cylinder head (valve) cover. If the valve is not

plugged, a hissing noise will be heard as air passes

through the valve. Also, a strong vacuum should be

felt at the valve inlet (Fig. 22).

(2) Return the PCV valve into the valve cover.

Remove the fitting and air hose at the opposite valve

Fig. 16 ENGINE OFF OR ENGINE BACKFIRE - NO

VAPOR FLOW

Fig. 17 HIGH INTAKE MANIFOLD VACUUM -

MINIMAL VAPOR FLOW

Fig. 18 MODERATE INTAKE MANIFOLD VACUUM -

MAXIMUM VAPOR FLOW

DREVAPORATIVE EMISSIONS 25 - 19

PCV VALVE (Continued)

Page 2851 of 2895

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 25).

5.7L V-8

The PCV valve is mounted into the top of the

intake manifold, located to the right / rear of the

throttle body (Fig. 12). The PCV valve is sealed to

the intake manifold with 2 o-rings (Fig. 13).

(1) Remove PCV valve by rotating counter-clock-

wise 90 degrees until locating tabs have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

(2) After valve is removed, check condition of 2

valve o-rings.

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

5.7L V-8

(1) Clean out intake manifold opening.

(2) Check condition of 2 o-rings on PCV valve.

(3) Apply engine oil to 2 o-rings.

(4) Place PCV valve into intake manifold and

rotate 90 degrees clockwise for installation.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the vehicles VECI label. Refer to Vehicle

Emission Control Information (VECI) Label for label

location.

VAPOR CANISTER

DESCRIPTION

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

OPERATION

Two, maintenance free, EVAP canisters are

used.The EVAP canisters are filled with granules of

an activated carbon mixture. Fuel vapors entering

the EVAP canisters are absorbed by the charcoal

granules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

REMOVAL

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

(1) Raise and support vehicle.

(2) Remove fuel tubes/lines at each EVAP canister.

Note location of tubes/lines before removal for easier

installation.

(3) Remove lower support bracket (Fig. 27).

(4) Remove mounting nuts at top of each canister

(Fig. 27).

Fig. 26 LOCATION, EVAP CANISTERS

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 22 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)

Page 2869 of 2895

FLUID RESERVOIR - REMOVAL..........5-19

FLUID, SPECIFICATIONS - BRAKE.........5-18

FLUSH - SPECIFICATIONS, GAP.........23-95

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-39

FLYWHEEL - ASSEMBLY................6-12

FLYWHEEL - DIAGNOSIS AND TESTING....6-11

FLYWHEEL - DISASSEMBLY.............6-12

FLYWHEEL - INSTALLATION.............6-12

FLYWHEEL - REMOVAL.................6-12

FOG LAMP - INSTALLATION............8L-11

FOG LAMP - REMOVAL................8L-11

FOG LAMP RELAY - DESCRIPTION.......8L-11

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT.....................8L-12

FOG LAMP RELAY - INSTALLATION......8L-13

FOG LAMP RELAY - OPERATION.........8L-12

FOG LAMP RELAY - REMOVAL..........8L-13

FOOTMANS LOOP BRACKETS -

INSTALLATION, SEAT BACK REAR.......23-85

FOOTMANS LOOP BRACKETS -

REMOVAL, SEAT BACK REAR...........23-85

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE.....9-232,

9-289,9-360,9-9,9-93

FRAME - INSTALLATION, GRILLE........23-40

FRAME - REAR - INSTALLATION, SEAT

CUSHION...........................23-85

FRAME - REAR - REMOVAL, SEAT

CUSHION...........................23-85

FRAME - REMOVAL, GRILLE............23-40

FRAME DIMENSIONS - SPECIFICATIONS . . 13-17

FRAME H-SECTION REPLACEMENT -

STANDARD PROCEDURE, REAR.........13-15

FRAME RAIL TIP REPLACEMENT -

STANDARD PROCEDURE, LIGHT DUTY

FRONT..............................13-4

FRONT - DESCRIPTION, CRANKSHAFT

OIL SEAL...........................9-254

FRONT - INSTALLATION........5-16,5-17,5-29

FRONT - INSTALLATION...............22-15

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL........9-134,9-203,9-255,9-324,9-45

FRONT - INSTALLATION, SEAT..........23-82

FRONT - INSTALLATION, SEAT BACK

CUSHION / COVER...................23-83

FRONT - INSTALLATION, SEAT CUSHION

/ COVER............................23-83

FRONT - OPERATION, CRANKSHAFT OIL

SEAL..............................9-254

FRONT - REMOVAL............5-12,5-16,5-28

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL...........9-134,9-203,9-254,9-323,9-44

FRONT - REMOVAL, SEAT..............23-82

FRONT - REMOVAL, SEAT BACK

CUSHION / COVER...................23-83

FRONT - REMOVAL, SEAT CUSHION /

COVER.............................23-83

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-2

FRONT AXLE - 9 1/4 AA -

ADJUSTMENTS.......................3-49

FRONT AXLE - 9 1/4 AA - DESCRIPTION . . . 3-45

FRONT AXLE - 9 1/4 AA - DIAGNOSIS

AND TESTING........................3-45

FRONT AXLE - 9 1/4 AA - INSTALLATION . . . 3-48

FRONT AXLE - 9 1/4 AA - OPERATION.....3-45

FRONT AXLE - 9 1/4 AA - REMOVAL......3-48

FRONT AXLE - 9 1/4 AA - SPECIAL

TOOLS..............................3-53

FRONT AXLE - 9 1/4 AA -

SPECIFICATIONS......................3-53

FRONT AXLE - C205F - ADJUSTMENTS....3-21

FRONT AXLE - C205F - DESCRIPTION.....3-18

FRONT AXLE - C205F - DIAGNOSIS AND

TESTING............................3-18

FRONT AXLE - C205F - INSTALLATION.....3-21

FRONT AXLE - C205F - OPERATION.......3-18

FRONT AXLE - C205F - REMOVAL

........3-21

FRONT AXLE - C205F - SPECIAL TOOLS

. . . 3-30

FRONT AXLE - C205F - SPECIFICATIONS

. . . 3-29

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT

...............21-217,21-395

FRONT BEARING - REMOVAL, OUTPUT

SHAFT

......................21-217,21-395FRONT BRAKE HOSE - INSTALLATION......5-9

FRONT BUMPER - INSTALLATION.........13-2

FRONT BUMPER - REMOVAL............13-2

FRONT CENTER SEAT BELT -

INSTALLATION......................8O-27

FRONT CENTER SEAT BELT - REMOVAL . . 8O-26

FRONT CENTER SEAT BELT &

RETRACTOR - INSTALLATION...........8O-26

FRONT CENTER SEAT BELT &

RETRACTOR - REMOVAL..............8O-25

FRONT CLUTCH - ASSEMBLY....21-206,21-386

FRONT CLUTCH - DESCRIPTION . . 21-204,21-384

FRONT CLUTCH - DISASSEMBLY . 21-205,21-384

FRONT CLUTCH - INSPECTION . . . 21-206,21-385

FRONT CLUTCH - OPERATION . . . 21-204,21-384

FRONT CONTROL MODULE -

DESCRIPTION.....................8W-97-4

FRONT CONTROL MODULE -

DESCRIPTION........................8E-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING.....................8W-97-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING........................8E-6

FRONT CONTROL MODULE -

INSTALLATION....................8W-97-5

FRONT CONTROL MODULE -

INSTALLATION........................8E-6

FRONT CONTROL MODULE - OPERATION . 8W-97-5

FRONT CONTROL MODULE - OPERATION . . 8E-5

FRONT CONTROL MODULE - REMOVAL . . 8W-97-5

FRONT CONTROL MODULE - REMOVAL....8E-6

FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL SEAL........9-384

FRONT COVER INSTALLED - REMOVAL,

FRONT OIL SEAL.....................9-384

FRONT COVER REMOVED -

INSTALLATION, FRONT OIL SEAL........9-384

FRONT COVER REMOVED - REMOVAL,

FRONT OIL SEAL.....................9-384

FRONT CROSSMEMBER - INSTALLATION . . 13-23

FRONT CROSSMEMBER - REMOVAL.....13-23

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-92

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-92

FRONT DOOR INNER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR INNER BELT MOLDING -

REMOVAL..........................23-93

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR OUTER BELT MOLDING -

REMOVAL..........................23-93

FRONT FASCIA - INSTALLATION..........13-3

FRONT FASCIA - REMOVAL..............13-3

FRONT FENDER - INSTALLATION........23-39

FRONT FENDER - REMOVAL............23-39

FRONT FOG LAMP RELAY - DIAGNOSIS

AND TESTING.......................8L-12

FRONT FRAME RAIL TIP REPLACEMENT

- STANDARD PROCEDURE, LIGHT

DUTY...............................13-4

FRONT HOSE - REMOVAL

................5-9

FRONT MOUNT - INSTALLATION

. . . 9-144,9-211,

9-265,9-335,9-392,9-58

FRONT MOUNT - REMOVAL

. . 9-144,9-211,9-264,

9-335,9-392,9-57

FRONT OIL SEAL - FRONT COVER

INSTALLED - INSTALLATION

............9-384

FRONT OIL SEAL - FRONT COVER

INSTALLED - REMOVAL

...............9-384

FRONT OIL SEAL - FRONT COVER

REMOVED - INSTALLATION

.............9-384

FRONT OIL SEAL - FRONT COVER

REMOVED - REMOVAL

................9-384

FRONT OUTBOARD SEAT BELT BUCKLE -

INSTALLATION

......................8O-34

FRONT OUTBOARD SEAT BELT BUCKLE -

REMOVAL

..........................8O-33

FRONT OUTPUT SHAFT SEAL -

INSTALLATION

....21-618,21-653,21-683,21-717

FRONT OUTPUT SHAFT SEAL -

REMOVAL

.......21-617,21-653,21-683,21-717

FRONT PARKING BRAKE CABLE -

INSTALLATION

........................5-32

FRONT PARKING BRAKE CABLE -

REMOVAL

...........................5-31FRONT PROPELLER SHAFT -

INSTALLATION.........................3-7

FRONT PROPELLER SHAFT - REMOVAL.....3-6

FRONT SEAL - INSTALLATION, OIL

PUMP............................21-567

FRONT SEAL - REMOVAL, OIL PUMP....21-567

FRONT SERVO - ASSEMBLY.....21-209,21-388

FRONT SERVO - CLEANING.....21-208,21-388

FRONT SERVO - DESCRIPTION . . . 21-207,21-387

FRONT SERVO - DISASSEMBLY . . 21-208,21-388

FRONT SERVO - INSPECTION....21-208,21-388

FRONT SERVO - OPERATION....21-208,21-387

FRONT SKID PLATE - INSTALLATION.....13-24

FRONT SKID PLATE - REMOVAL.........13-24

FRONT SUSPENSION - DESCRIPTION,

GEAR - INDEPENDENT................19-16

FRONT SUSPENSION - INSTALLATION,

GEAR - INDEPENDENT................19-17

FRONT SUSPENSION - REMOVAL, GEAR

- INDEPENDENT.....................19-16

FRONT SUSPENSION, SPECIAL TOOLS....2-11

FRONT TOW HOOK ASSEMBLY -

INSTALLATION.......................13-26

FRONT TOW HOOK ASSEMBLY -

REMOVAL..........................13-26

FRONT WHEEL SPEED SENSOR -

DESCRIPTION........................5-41

FRONT WHEEL SPEED SENSOR -

INSTALLATION........................5-42

FRONT WHEEL SPEED SENSOR -

OPERATION..........................5-41

FRONT WHEEL SPEED SENSOR -

REMOVAL...........................5-41

FRONT WHEELHOUSE SPLASH SHIELD -

INSTALLATION.......................23-41

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL..........................23-40

FUEL CONTROL ACTUATOR -

DESCRIPTION.......................14-85

FUEL CONTROL ACTUATOR -

INSTALLATION.......................14-85

FUEL CONTROL ACTUATOR -

OPERATION.........................14-85

FUEL CONTROL ACTUATOR - REMOVAL . . . 14-85

FUEL DELIVERY - GAS - DESCRIPTION....14-1

FUEL DELIVERY - GAS - OPERATION......14-2

FUEL DRAIN CIRCUIT - OPERATION......14-78

FUEL FILL DOOR - INSTALLATION.......23-39

FUEL FILL DOOR - REMOVAL...........23-39

FUEL FILLER CAP - DESCRIPTION.......25-13

FUEL FILLER CAP - OPERATION.........25-13

FUEL FILTER - STANDARD

PROCEDURES, WATER DRAINING AT.....14-57

FUEL FILTER / WATER SEPARATOR -

DESCRIPTION.......................14-61

FUEL FILTER / WATER SEPARATOR -

INSTALLATION.......................14-62

FUEL FILTER / WATER SEPARATOR -

OPERATION.........................14-61

FUEL FILTER / WATER SEPARATOR -

REMOVAL..........................14-61

FUEL FILTER/PRESSURE REGULATOR -

DESCRIPTION........................14-6

FUEL FILTER/PRESSURE REGULATOR -

OPERATION..........................14-6

FUEL GAUGE - DESCRIPTION...........8J-25

FUEL GAUGE - OPERATION.............8J-26

FUEL HEATER - DESCRIPTION..........14-63

FUEL HEATER - DIAGNOSIS AND

TESTING...........................14-63

FUEL HEATER - OPERATION............14-63

FUEL HEATER RELAY - DESCRIPTION....14-64

FUEL HEATER RELAY - INSTALLATION....14-64

FUEL HEATER RELAY - OPERATION......14-64

FUEL HEATER RELAY - REMOVAL........14-64

FUEL INDICATOR - DESCRIPTION, LOW . . . 8J-29

FUEL INDICATOR - OPERATION, LOW.....8J-29

FUEL INJECTION PUMP - DESCRIPTION . . 14-64

FUEL INJECTION PUMP - INSTALLATION . . 14-67

FUEL INJECTION PUMP - OPERATION....14-64

FUEL INJECTION PUMP - REMOVAL......14-65

FUEL INJECTION PUMP TIMING -

DIAGNOSIS AND TESTING.............14-65

FUEL INJECTOR - DESCRIPTION

....14-32,14-85

FUEL INJECTOR - INSTALLATION

........14-87

FUEL INJECTOR - OPERATION

.....14-32,14-86

FUEL INJECTOR - REMOVAL

............14-87

FUEL INJECTOR FIRING ORDER, DIESEL

. . 14-60

14 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2872 of 2895

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-69

HINGE - INSTALLATION.....23-16,23-22,23-31,

23-46

HINGE - INSTALLATION, CENTER SEAT

BACK..............................23-80

HINGE - REMOVAL....23-16,23-22,23-31,23-46

HINGE - REMOVAL, CENTER SEAT BACK . . 23-79

HINGE COVER - INSTALLATION, CENTER

SEAT BACK INERTIA..................23-78

HINGE COVER - REMOVAL, CENTER

SEAT BACK INERTIA..................23-78

HITCH - INSTALLATION, TRAILER........13-25

HITCH - REMOVAL, TRAILER...........13-25

HOAT COOLANT - DESCRIPTION..........7-37

HOISTING - STANDARD PROCEDURE......0-14

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-14

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-14

HOLDDOWN - OPERATION, BATTERY.....8F-14

HOLDDOWN - REMOVAL, BATTERY......8F-14

HOLDER - INSTALLATION, CUP.........23-52

HOLDER - REMOVAL, CUP.............23-52

HOLDING CLUTCHES - DESCRIPTION....21-546

HOLDING CLUTCHES - OPERATION.....21-546

HOLE PLUG - INSTALLATION, CAMSHAFT

CORE..............................9-201

HOLE PLUG - REMOVAL, CAMSHAFT

CORE..............................9-200

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-9

HONING - STANDARD PROCEDURE,

CYLINDER BORE.......9-126,9-233,9-360,9-37

HOOD - INSTALLATION................23-47

HOOD - REMOVAL....................23-47

HOOK - INSTALLATION, COAT...........23-67

HOOK - REMOVAL, COAT..............23-67

HOOK ASSEMBLY - INSTALLATION,

FRONT TOW........................13-26

HOOK ASSEMBLY - REMOVAL, FRONT

TOW ..............................13-26

HORN - DIAGNOSIS AND TESTING.......8H-1

HORN - INSTALLATION.................8H-2

HORN - REMOVAL....................8H-2

HORN SWITCH - DESCRIPTION..........8H-2

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-2

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - GEAR TO COOLER -

INSTALLATION, RETURN..........19-43,19-44

HOSE - GEAR TO COOLER - REMOVAL,

RETURN............................19-43

HOSE - INSTALLATION, FRONT BRAKE......5-9

HOSE - INSTALLATION, PRESSURE . 19-43,19-44

HOSE - INSTALLATION, REAR BRAKE.......5-9

HOSE - REMOVAL, FRONT...............5-9

HOSE - REMOVAL, PRESSURE.....19-43,19-44

HOSE - REMOVAL, REAR BRAKE..........5-8

HOSE - RESERVOIR TO COOLER -

INSTALLATION, RETURN..........19-43,19-44

HOSE - RESERVOIR TO COOLER -

REMOVAL, RETURN.............19-43,19-44

HOSE ASSEMBLY - INSTALLATION, REAR

TUBE................................5-9

HOSE ASSEMBLY - REMOVAL, REAR

TUBE................................5-8

HOSE CLAMPS - DESCRIPTION...........7-3

HOSE CLAMPS - OPERATION.............7-5

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-70

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-68

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-70

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-69

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT..............24-33

HOSES/TUBES - DESCRIPTION, WASHER . 8R-11

HOSES/TUBES - OPERATION, WASHER . . . 8R-11

HOUSING - ASSEMBLY, HVAC

...........24-28

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH

..............................6-8

HOUSING - DISASSEMBLY, HVAC

........24-28

HOUSING - INSTALLATION, CLUTCH

......6-10

HOUSING - INSTALLATION, GEAR

........9-349HOUSING - INSTALLATION, HVAC........24-29

HOUSING - INSTALLATION, ROCKER.....9-304

HOUSING - REMOVAL, CLUTCH..........6-10

HOUSING - REMOVAL, GEAR...........9-348

HOUSING - REMOVAL, HVAC...........24-27

HOUSING - REMOVAL, ROCKER.........9-304

HOUSING BUSHING - INSTALLATION,

EXTENSION........................21-200

HOUSING BUSHING - REMOVAL,

EXTENSION........................21-200

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-616,21-682

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION.........21-616,21-682

HOUSING COVER - INSTALLATION, GEAR . 9-350

HOUSING COVER - REMOVAL, GEAR.....9-349

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER . . . 21-143,21-324,21-495

HOUSING SEAL - INSTALLATION,

ADAPTER...............21-127,21-539,21-83

HOUSING SEAL - INSTALLATION,

EXTENSION.......21-127,21-200,21-380,21-83

HOUSING SEAL - REMOVAL, ADAPTER . . 21-127,

21-539,21-83

HOUSING SEAL - REMOVAL,

EXTENSION.......21-127,21-200,21-380,21-83

HOUSING SEAL AND DUST BOOT -

INSTALLATION, EXTENSION.....21-652,21-716

HOUSING SEAL AND DUST BOOT -

REMOVAL, EXTENSION.........21-652,21-716

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

H-SECTION REPLACEMENT - STANDARD

PROCEDURE, REAR FRAME............13-15

HUB / BEARING - INSTALLATION.........2-31

HUB / BEARING - REMOVAL.............2-30

HVAC HOUSING - ASSEMBLY...........24-28

HVAC HOUSING - DISASSEMBLY........24-28

HVAC HOUSING - INSTALLATION........24-29

HVAC HOUSING - REMOVAL............24-27

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-25

HYDRAULIC LASH ADJUSTER -

DIAGNOSIS AND TESTING.........9-124,9-31

HYDRAULIC LIFTERS - CLEANING . . 9-260,9-388

HYDRAULIC LIFTERS - INSTALLATION . . . 9-260,

9-388

HYDRAULIC LIFTERS - REMOVAL . . . 9-259,9-387

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING......21-140,21-321,

21-493

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS........21-175,21-355,21-513

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING......................9-258,9-386

HYDROBOOST - INSTALLATION..........5-22

HYDROBOOST - INSTALLATION, ALL

EXCEPT.............................5-22

HYDROBOOST - REMOVAL..............5-21

HYDROBOOST - REMOVAL, ALL EXCEPT . . . 5-21

HYDRO-BOOST BRAKE BOOSTER -

INSTALLATION........................5-27

HYDRO-BOOST BRAKE BOOSTER -

REMOVAL...........................5-27

HYDROFORM FENDER RAIL REPAIR -

STANDARD PROCEDURE...............13-12

HYDROSTATIC LOCK - STANDARD

PROCEDURE.........9-186,9-232,9-290,9-361

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-6

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-2

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-33

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-35

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-33

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-34

IDLER SHAFT - INSTALLATION......9-175,9-80

IDLER SHAFT - REMOVAL

..........9-175,9-79

IGNITION - SPECIFICATIONS, TORQUE

.....8I-3

IGNITION CIRCUIT SENSE -

DESCRIPTION

.......................8E-10

IGNITION CIRCUIT SENSE - OPERATION

. . 8E-12

IGNITION COIL - DESCRIPTION

..........8I-19IGNITION COIL - INSTALLATION.........8I-24

IGNITION COIL - OPERATION............8I-20

IGNITION COIL - REMOVAL.............8I-23

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-33

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-33

IGNITION COIL CAPACITOR - OPERATION . . 8I-33

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-33

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-6

IGNITION COIL RESISTANCE, 4.7L V-8.....8I-6

IGNITION COIL RESISTANCE, 5.7L V-8.....8I-6

IGNITION COIL RESISTANCE, 5.9L.........8I-6

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-6

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION SWITCH - DESCRIPTION........19-9

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-11

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-9

IGNITION SWITCH - INSTALLATION......19-11

IGNITION SWITCH - OPERATION.........19-9

IGNITION SWITCH - REMOVAL..........19-10

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-11

IGNITION TIMING, SPECIFICATIONS.......8I-6

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE..........................8F-11

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY........................8E-15

IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY KEY......8Q-5

IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY KEY........8Q-5

IMMOBILIZER SYSTEM INITIALIZATION,

STANDARD PROCEDURE - SENTRY

KEY................................8Q-3

IMMOBILIZER SYSTEM (SKIS),

DESCRIPTION - SENTRY KEY............8Q-1

IMMOBILIZER SYSTEM TRANSPONDER

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY.............8Q-4

IMPACT AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE..................8O-53

IMPACT AIRBAG CONTROL MODULE -

OPERATION, SIDE....................8O-54

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF.....21-201,21-381,

21-541

INDEPENDENT FRONT SUSPENSION -

DESCRIPTION, GEAR..................19-16

INDEPENDENT FRONT SUSPENSION -

INSTALLATION, GEAR.................19-17

INDEPENDENT FRONT SUSPENSION -

REMOVAL, GEAR.....................19-16

INDICATOR - DESCRIPTION, ABS........8J-17

INDICATOR - DESCRIPTION, AIRBAG.....8J-18

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-18

INDICATOR - DESCRIPTION, CARGO

LAMP..............................8J-20

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-21

INDICATOR - DESCRIPTION, CRUISE.....8J-22

INDICATOR - DESCRIPTION, DOOR AJAR . . 8J-23

INDICATOR - DESCRIPTION, ETC........8J-24

INDICATOR - DESCRIPTION, GEAR

SELECTOR..........................8J-26

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-27

INDICATOR - DESCRIPTION, LAMP OUT . . . 8J-28

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-29

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-33

INDICATOR - DESCRIPTION, SEATBELT

. . . 8J-34

INDICATOR - DESCRIPTION, SECURITY

. . . 8J-34

INDICATOR - DESCRIPTION, SERVICE

4WD

...............................8J-35

INDICATOR - DESCRIPTION, TRANS

TEMP

..............................8J-38

INDICATOR - DESCRIPTION, TURN

SIGNAL

............................8J-39

DRINDEX 17

Description Group-Page Description Group-Page Description Group-Page