ECU DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1991 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

NO 3-4 UPSHIFT 1. O/D Switch In OFF Position. 1. Turn control switch to ON position.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed

and repair as necessary (i.e., shorts or

grounds in circuit).

3. O/D Switch Wire Shorted/Open

Cut.3. Check wires/connections with 12V test

lamp and voltmeter. Repair damaged or

loose wire/connection as necessary.

4. Distance or Coolant Sensor

Malfunction.4. Check with DRBTscan tool and repair or

replace as necessary.

5. TPS Malfunction. 5. Check with DRBTscan tool and replace

if necessary.

6. Neutral Sense to PCM Wire

Shorted/Cut.6. Test switch/sensor as described in

service section and replace if necessary.

Engine no start.

7. PCM Malfunction. 7. Check with DRBTscan tool and replace

if necessary.

8. Overdrive Solenoid Shorted/Open. 8. Replace solenoid if shorted or open and

repair loose or damaged wires (DRBTscan

tool).

9. Solenoid Feed Orifice in Valve

Body Blocked.9. Remove, disassemble, and clean valve

body thoroughly. Check feed orifice.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as

needed.

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

cause.

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing

valve.

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

correct spacer.

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

assembly (in piston retainer). Check ball

bleed orifice.

21 - 152 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1992 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

SLIPS IN OVERDRIVE

FOURTH GEAR1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Overdrive Clutch Pack Worn. 2. Remove overdrive unit and rebuild clutch

pack.

3. Overdrive Piston Retainer Bleed

Orifice Blown Out.3. Disassemble transmission, remove

retainer and replace orifice.

4. Overdrive Piston or Seal

Malfunction.4. Remove overdrive unit. Replace seals if

worn. Replace piston if damaged. If piston

retainer is damaged, remove and

disassemble the transmission.

5. 3-4 Shift Valve, Timing Valve or

Accumulator Malfunction.5. Remove and overhaul valve body.

Replace accumulator seals. Make sure all

valves operate freely in bores and do not

bind or stick. Make sure valve body screws

are correctly tightened and separator plates

are properly positioned.

6. Overdrive Unit Thrust Bearing

Failure.6. Disassemble overdrive unit and replace

thrust bearing (NO. 1 thrust bearing is

between overdrive piston and clutch hub;

NO. 2 thrust bearing is between the

planetary gear and the direct clutch spring

plate; NO. 3 thrust bearing is between

overrunning clutch hub and output shaft).

7. O/D Check Valve/Bleed Orifice

Failure.7. Check for function/secure orifice insert in

O/D piston retainer.

DELAYED 3-4 UPSHIFT

(SLOW TO ENGAGE)1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Throttle Valve Cable Mis-adjusted. 2. Adjust throttle valve cable.

3. Overdrive Clutch Pack Worn/

Burnt.3. Remove unit and rebuild clutch pack.

4. TPS Faulty. 4. Test with DRBTscan tool and replace as

necessary

5. Overdrive Clutch Bleed Orifice

Plugged.5. Disassemble transmission and replace

orifice.

6. Overdrive Solenoid or Wiring

Shorted/Open.6. Test solenoid and check wiring for

loose/corroded connections or shorts/

grounds. Replace solenoid if faulty and

repair wiring if necessary.

7. Overdrive Excess Clearance. 7. Remove unit. Measure end play and

select proper spacer.

8. O/D Check Valve Missing or

Stuck.8. Check for presence of check valve.

Repair or replace as required.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2, 2-3, 3-4 OR

3-2 SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 153

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1996 of 2895

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(12) Disconnect wires from the transmission range

sensor and transmission solenoid connector.

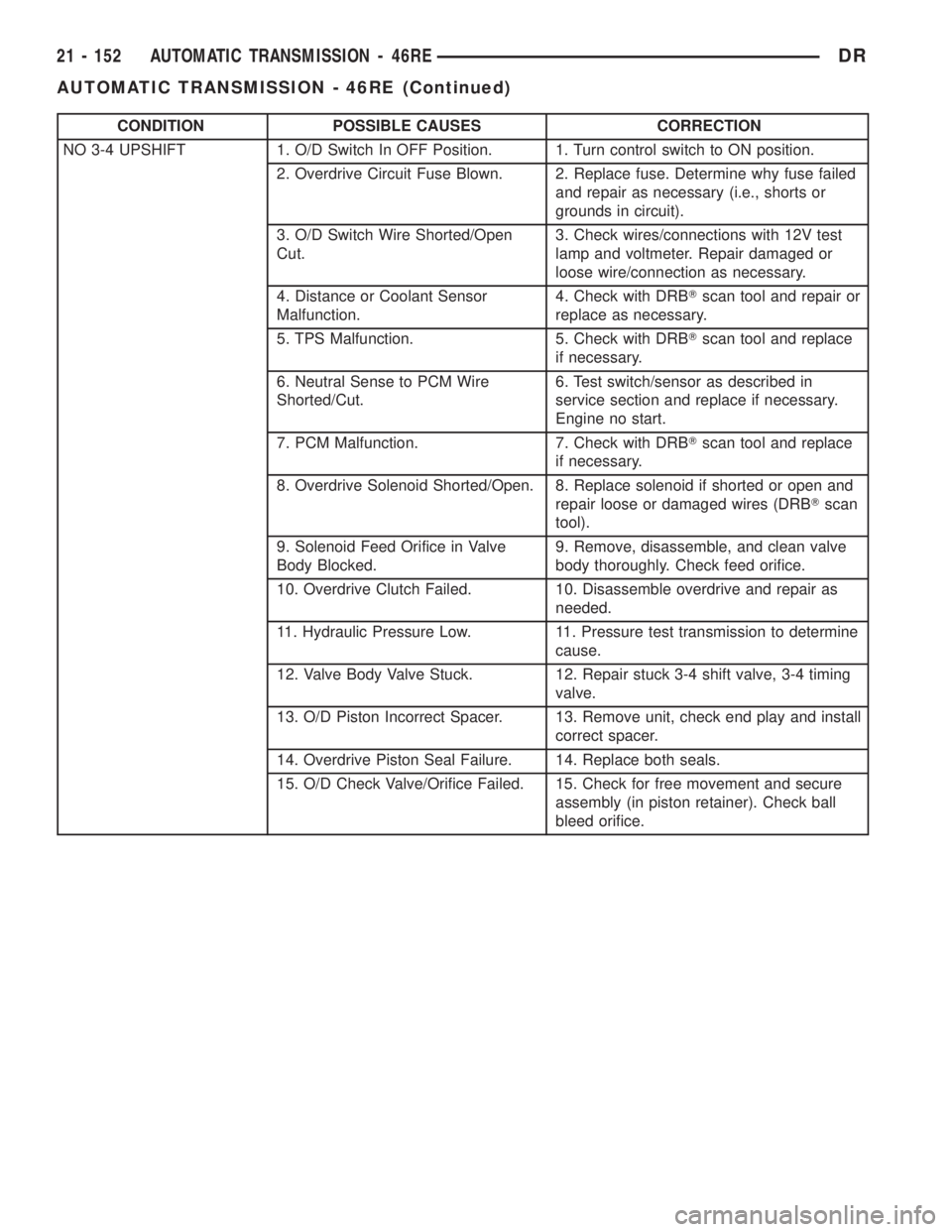

(13) Disconnect gearshift cable (Fig. 15) from the

transmission.

(14) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever.

(15) On 4X4 models, disconnect shift rod from

transfer case shift lever.

(16) Support rear of engine with safety stand or

jack.

(17) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

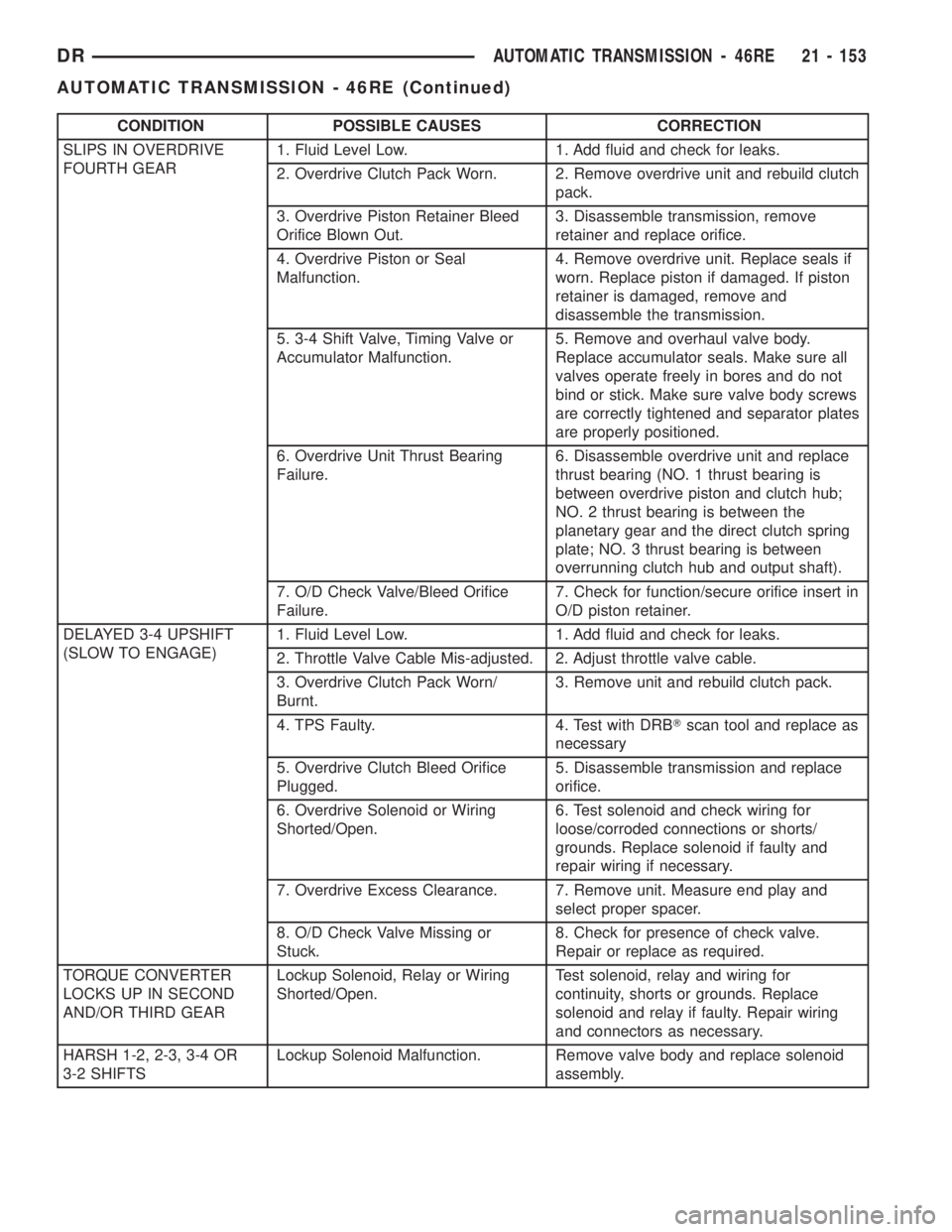

(18) Remove bolts securing rear support and cush-

ion (Fig. 16) and (Fig. 17) to transmission and cross-

member and remove rear support.

(19) Remove bolts attaching crossmember to frame

and remove crossmember.

(20) On 4X4 models, remove transfer case with

transmission jack or aid of helper.

Fig. 15 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 16 Engine Rear Mount - 4X2 Automatic

Transmission

1 - ENGINE REAR MOUNT

2 - BOLT

3 - NUT

4 - THROUGH BOLT NUT

5 - TRANSMISSION

Fig. 17 Engine Rear Mount - 4X4 Automatic

Transmission

1 - TRANSMISSION

2 - ENGINE REAR MOUNT

3 - BOLT

DRAUTOMATIC TRANSMISSION - 46RE 21 - 157

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1997 of 2895

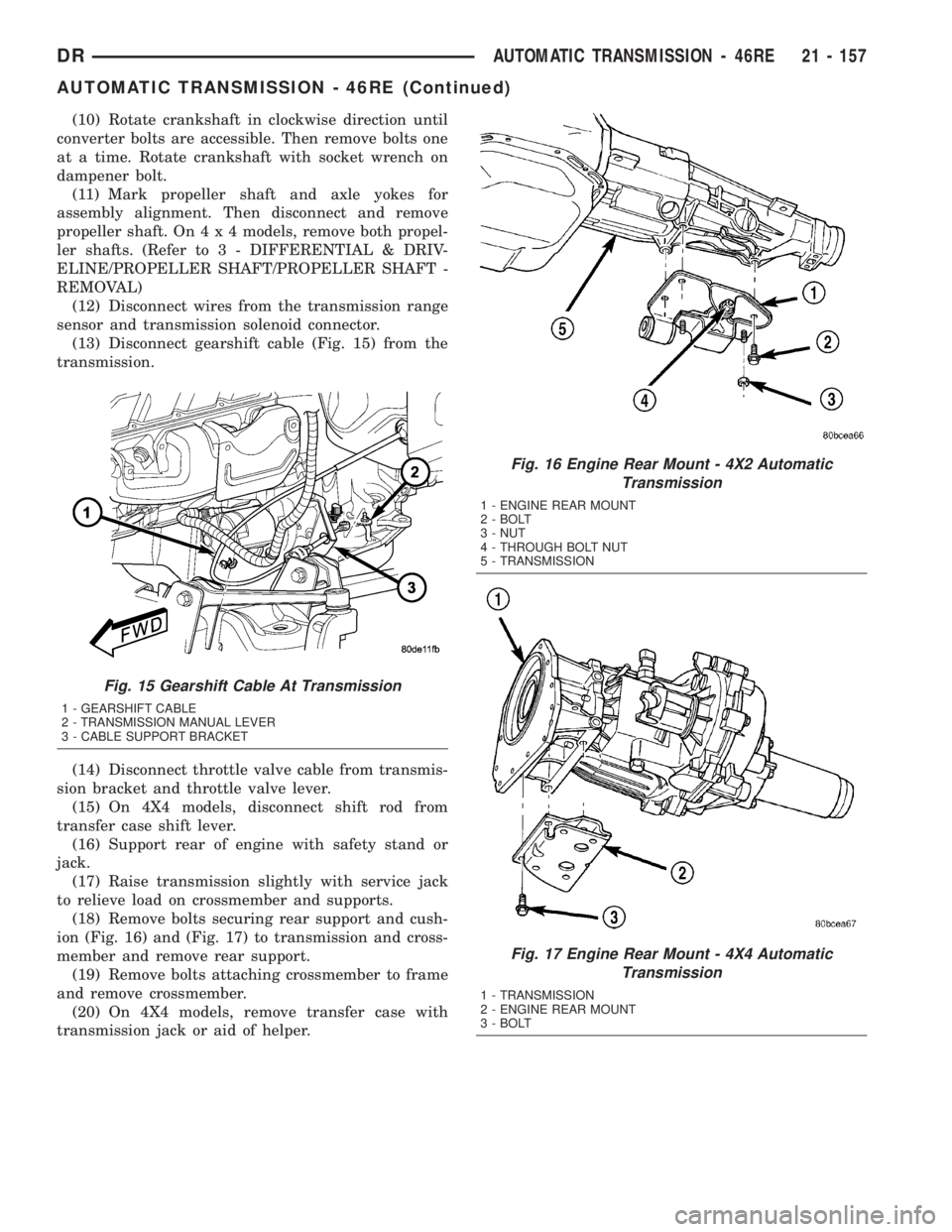

(21) Disconnect fluid cooler lines at transmission

(Fig. 18).

(22) Remove fill tube bracket bolts and pull tube

out of transmission. Retain fill tube seal. On 4X4

models, it will also be necessary to remove bolt

attaching transfer case vent tube to converter hous-

ing (Fig. 19).

(23) Remove all converter housing bolts.

(24) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(25) Lower transmission and remove assembly

from under the vehicle.(26) To remove torque converter, remove C-clamp

from edge of bell housing and carefully slide torque

converter out of the transmission.

DISASSEMBLY

(1) Clean exterior of transmission with suitable

solvent or pressure washer.

(2) Place transmission in vertical position.

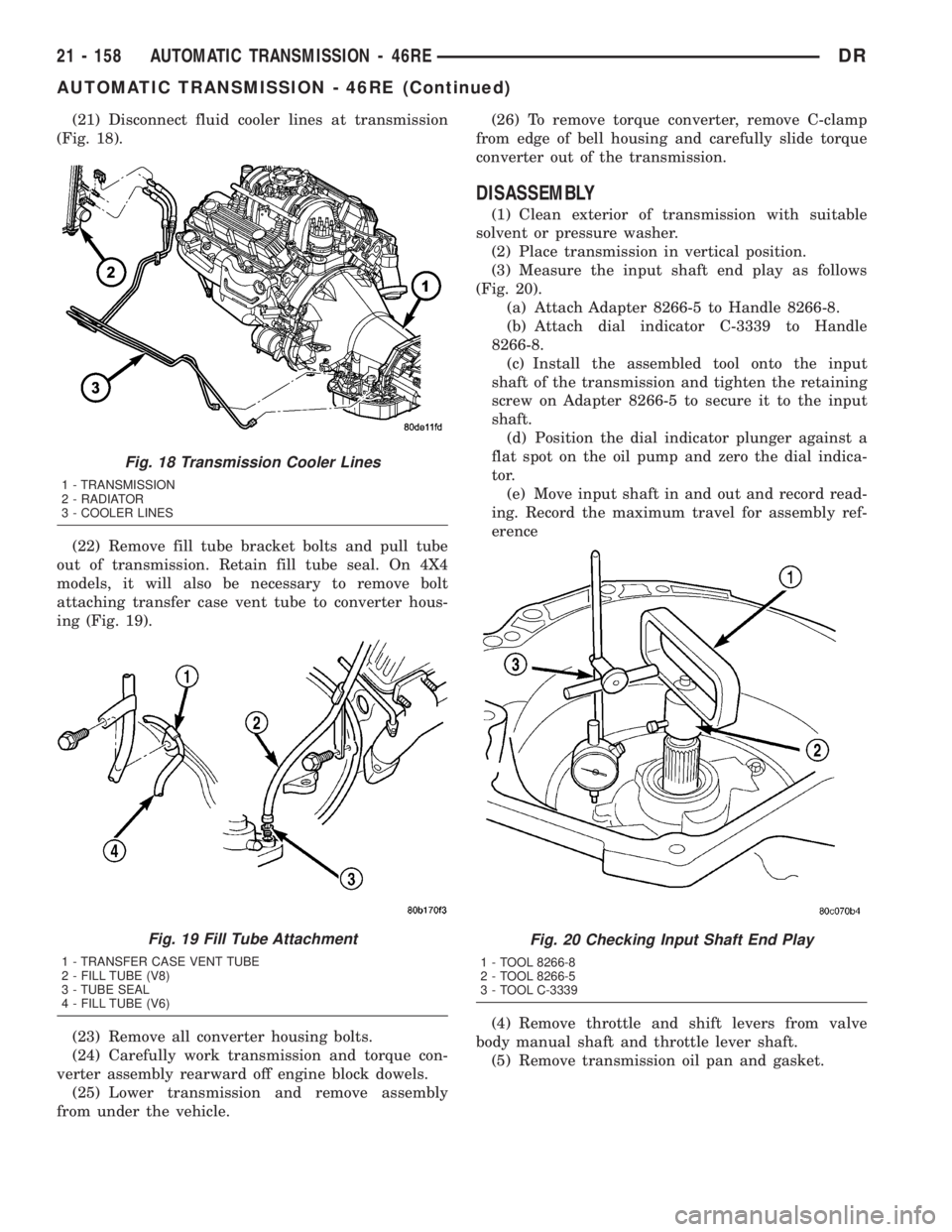

(3) Measure the input shaft end play as follows

(Fig. 20).

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. Record the maximum travel for assembly ref-

erence

(4) Remove throttle and shift levers from valve

body manual shaft and throttle lever shaft.

(5) Remove transmission oil pan and gasket.

Fig. 18 Transmission Cooler Lines

1 - TRANSMISSION

2 - RADIATOR

3 - COOLER LINES

Fig. 19 Fill Tube Attachment

1 - TRANSFER CASE VENT TUBE

2 - FILL TUBE (V8)

3 - TUBE SEAL

4 - FILL TUBE (V6)

Fig. 20 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

21 - 158 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2007 of 2895

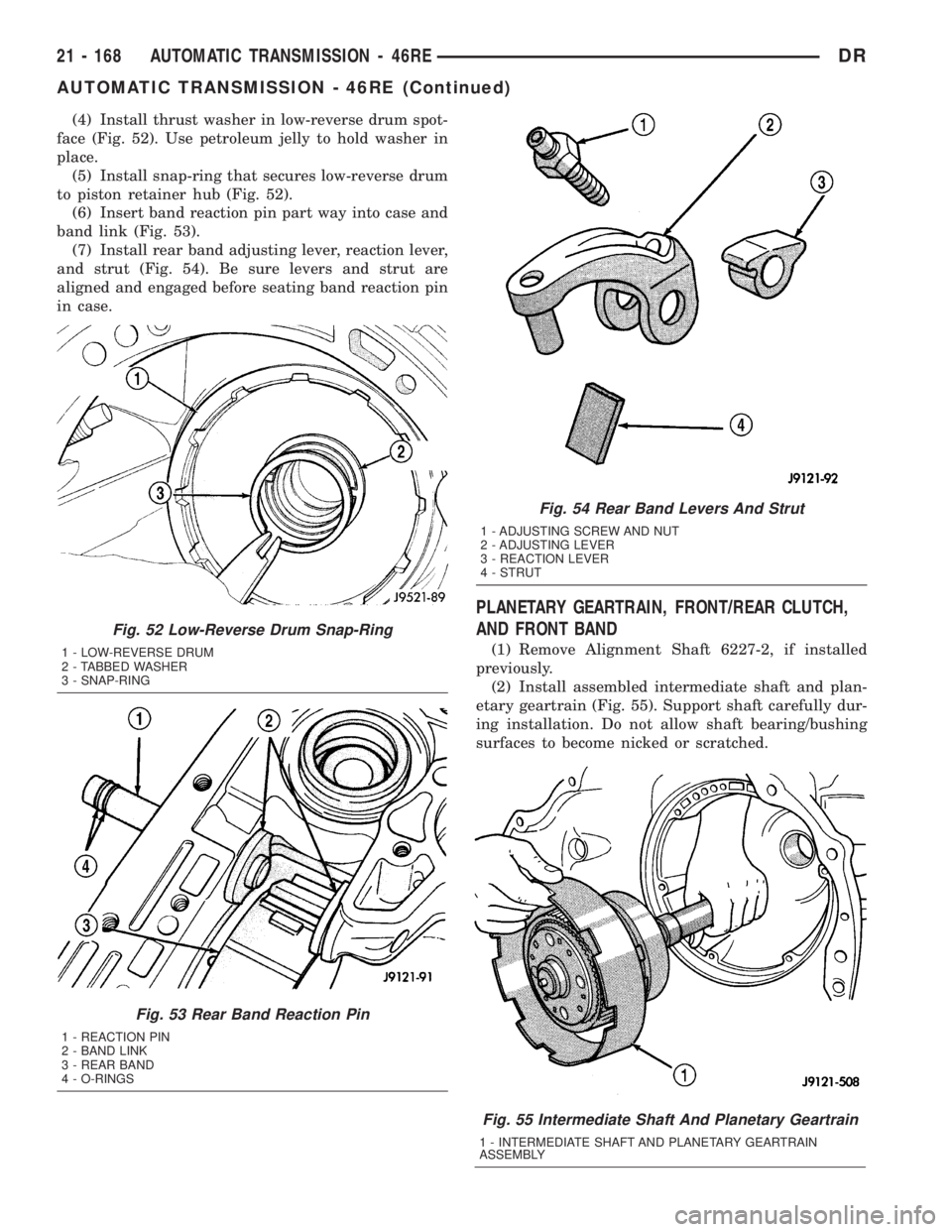

(4) Install thrust washer in low-reverse drum spot-

face (Fig. 52). Use petroleum jelly to hold washer in

place.

(5) Install snap-ring that secures low-reverse drum

to piston retainer hub (Fig. 52).

(6) Insert band reaction pin part way into case and

band link (Fig. 53).

(7) Install rear band adjusting lever, reaction lever,

and strut (Fig. 54). Be sure levers and strut are

aligned and engaged before seating band reaction pin

in case.

PLANETARY GEARTRAIN, FRONT/REAR CLUTCH,

AND FRONT BAND

(1) Remove Alignment Shaft 6227-2, if installed

previously.

(2) Install assembled intermediate shaft and plan-

etary geartrain (Fig. 55). Support shaft carefully dur-

ing installation. Do not allow shaft bearing/bushing

surfaces to become nicked or scratched.

Fig. 55 Intermediate Shaft And Planetary Geartrain

1 - INTERMEDIATE SHAFT AND PLANETARY GEARTRAIN

ASSEMBLY

Fig. 52 Low-Reverse Drum Snap-Ring

1 - LOW-REVERSE DRUM

2 - TABBED WASHER

3 - SNAP-RING

Fig. 53 Rear Band Reaction Pin

1 - REACTION PIN

2 - BAND LINK

3 - REAR BAND

4 - O-RINGS

Fig. 54 Rear Band Levers And Strut

1 - ADJUSTING SCREW AND NUT

2 - ADJUSTING LEVER

3 - REACTION LEVER

4 - STRUT

21 - 168 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2011 of 2895

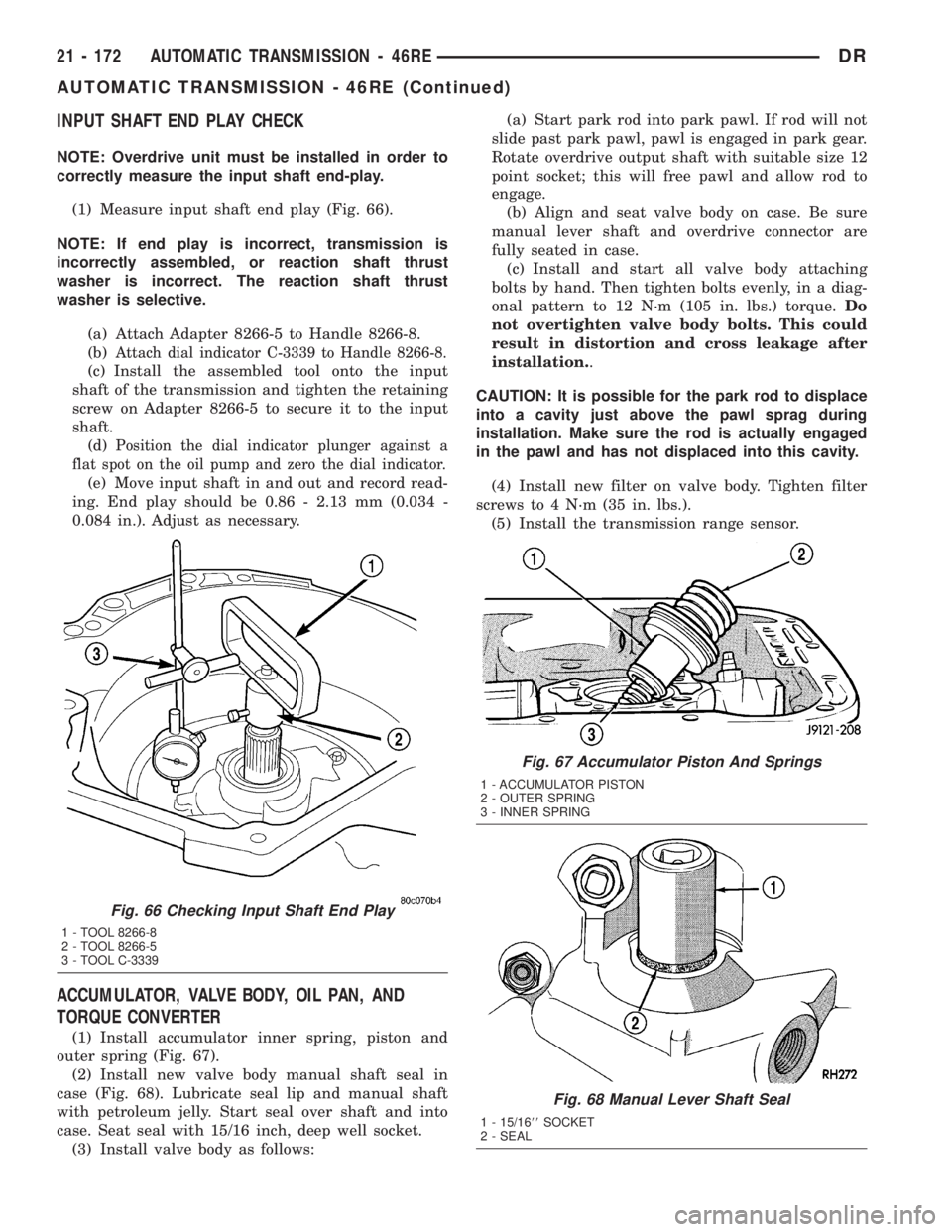

INPUT SHAFT END PLAY CHECK

NOTE: Overdrive unit must be installed in order to

correctly measure the input shaft end-play.

(1) Measure input shaft end play (Fig. 66).

NOTE: If end play is incorrect, transmission is

incorrectly assembled, or reaction shaft thrust

washer is incorrect. The reaction shaft thrust

washer is selective.

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b)

Attach dial indicator C-3339 to Handle 8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d)

Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indicator.

(e) Move input shaft in and out and record read-

ing. End play should be 0.86 - 2.13 mm (0.034 -

0.084 in.). Adjust as necessary.

ACCUMULATOR, VALVE BODY, OIL PAN, AND

TORQUE CONVERTER

(1) Install accumulator inner spring, piston and

outer spring (Fig. 67).

(2) Install new valve body manual shaft seal in

case (Fig. 68). Lubricate seal lip and manual shaft

with petroleum jelly. Start seal over shaft and into

case. Seat seal with 15/16 inch, deep well socket.

(3) Install valve body as follows:(a) Start park rod into park pawl. If rod will not

slide past park pawl, pawl is engaged in park gear.

Rotate overdrive output shaft with suitable size 12

point socket; this will free pawl and allow rod to

engage.

(b) Align and seat valve body on case. Be sure

manual lever shaft and overdrive connector are

fully seated in case.

(c) Install and start all valve body attaching

bolts by hand. Then tighten bolts evenly, in a diag-

onal pattern to 12 N´m (105 in. lbs.) torque.Do

not overtighten valve body bolts. This could

result in distortion and cross leakage after

installation..

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(4) Install new filter on valve body. Tighten filter

screws to 4 N´m (35 in. lbs.).

(5) Install the transmission range sensor.

Fig. 66 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

Fig. 67 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

Fig. 68 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

21 - 172 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2012 of 2895

CAUTION: If the condition of the transmission

before the overhaul procedure caused excessive

metallic or fiber contamination in the fluid, replace

the torque converter. Fluid contamination and trans-

mission failure can result if not done.

(6) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 2-7/8

turns.

(d) Back off rear band adjusting screw 2 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 17 N´m (13 ft. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and transmis-

sion range sensor.

(6) Fill transmission with recommended fluid.

Refer to Service Procedures section of this group.

INSTALLATION

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish the hub and notches with 320/400 grit paper

and crocus cloth if necessary. The hub must be

smooth to avoid damaging pump seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

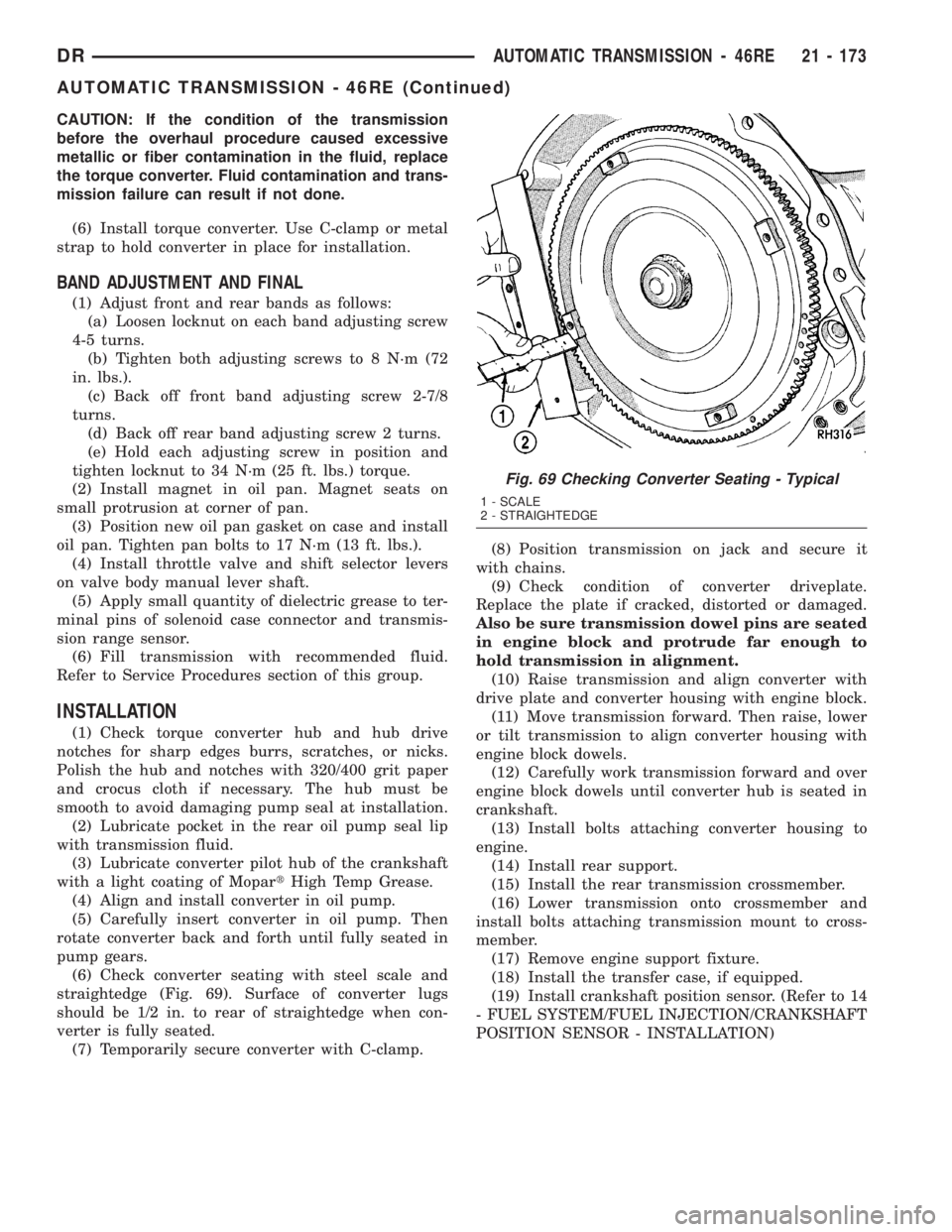

(6) Check converter seating with steel scale and

straightedge (Fig. 69). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) Temporarily secure converter with C-clamp.(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support.

(15) Install the rear transmission crossmember.

(16) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member.

(17) Remove engine support fixture.

(18) Install the transfer case, if equipped.

(19) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

Fig. 69 Checking Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

DRAUTOMATIC TRANSMISSION - 46RE 21 - 173

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2045 of 2895

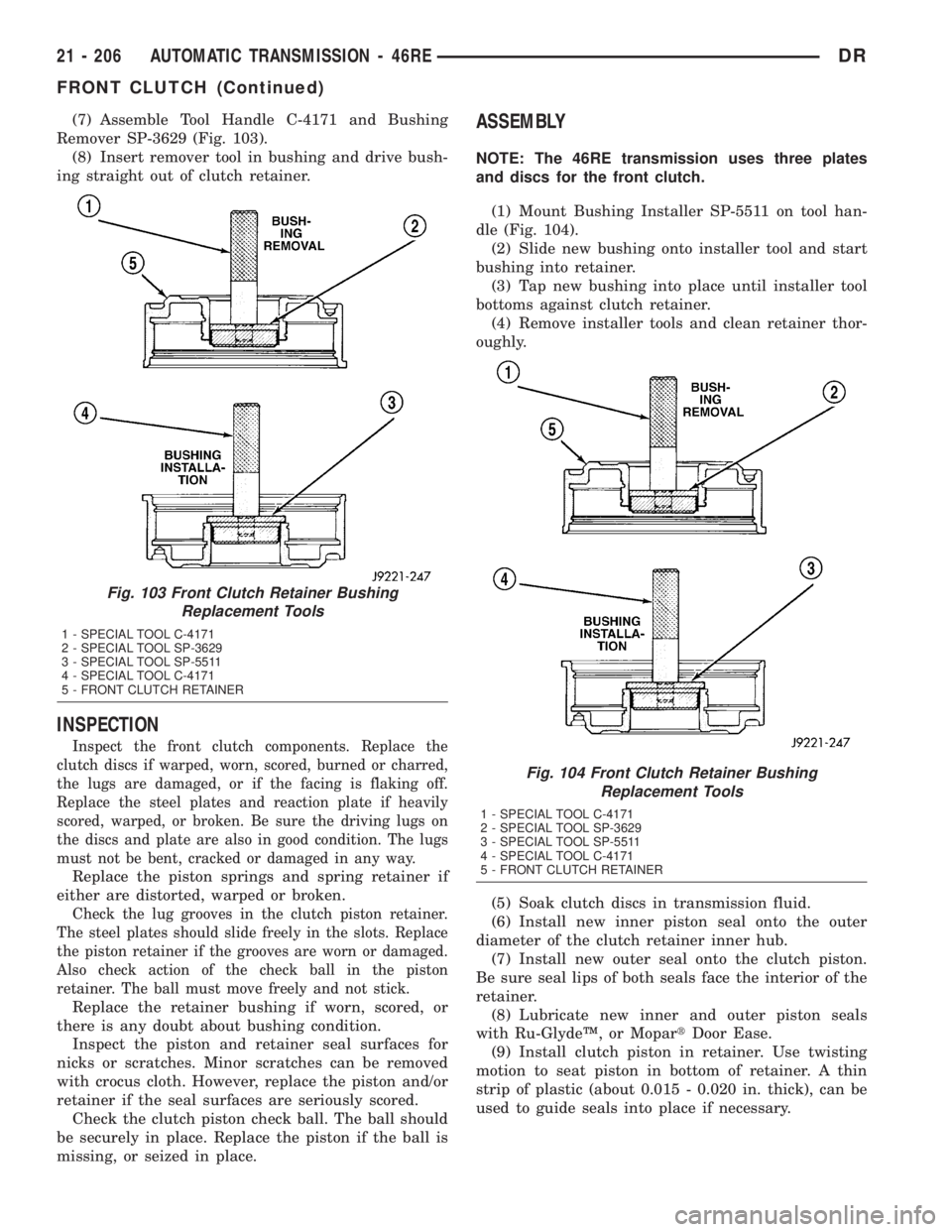

(7) Assemble Tool Handle C-4171 and Bushing

Remover SP-3629 (Fig. 103).

(8) Insert remover tool in bushing and drive bush-

ing straight out of clutch retainer.

INSPECTION

Inspect the front clutch components. Replace the

clutch discs if warped, worn, scored, burned or charred,

the lugs are damaged, or if the facing is flaking off.

Replace the steel plates and reaction plate if heavily

scored, warped, or broken. Be sure the driving lugs on

the discs and plate are also in good condition. The lugs

must not be bent, cracked or damaged in any way.

Replace the piston springs and spring retainer if

either are distorted, warped or broken.

Check the lug grooves in the clutch piston retainer.

The steel plates should slide freely in the slots. Replace

the piston retainer if the grooves are worn or damaged.

Also check action of the check ball in the piston

retainer. The ball must move freely and not stick.

Replace the retainer bushing if worn, scored, or

there is any doubt about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check the clutch piston check ball. The ball should

be securely in place. Replace the piston if the ball is

missing, or seized in place.

ASSEMBLY

NOTE: The 46RE transmission uses three plates

and discs for the front clutch.

(1) Mount Bushing Installer SP-5511 on tool han-

dle (Fig. 104).

(2) Slide new bushing onto installer tool and start

bushing into retainer.

(3) Tap new bushing into place until installer tool

bottoms against clutch retainer.

(4) Remove installer tools and clean retainer thor-

oughly.

(5) Soak clutch discs in transmission fluid.

(6) Install new inner piston seal onto the outer

diameter of the clutch retainer inner hub.

(7) Install new outer seal onto the clutch piston.

Be sure seal lips of both seals face the interior of the

retainer.

(8) Lubricate new inner and outer piston seals

with Ru-GlydeŸ, or MopartDoor Ease.

(9) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.015 - 0.020 in. thick), can be

used to guide seals into place if necessary.

Fig. 103 Front Clutch Retainer Bushing

Replacement Tools

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL SP-3629

3 - SPECIAL TOOL SP-5511

4 - SPECIAL TOOL C-4171

5 - FRONT CLUTCH RETAINER

Fig. 104 Front Clutch Retainer Bushing

Replacement Tools

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL SP-3629

3 - SPECIAL TOOL SP-5511

4 - SPECIAL TOOL C-4171

5 - FRONT CLUTCH RETAINER

21 - 206 AUTOMATIC TRANSMISSION - 46REDR

FRONT CLUTCH (Continued)

Page 2050 of 2895

(4) Raise the vehicle.

(5) Place the transmission manual shift lever in

the ªPARKº detent (rearmost) position and rotate

prop shaft to ensure transmission is in PARK.

(6) Route the gearshift cable through the transmis-

sion mounting bracket and secure the cable by snap-

ping the cable retaining ears into the transmission

bracket and snapping the cable eyelet on the manual

shift lever ball stud.

(7) Lower vehicle.

(8) Lock the shift cable adjustment by pressing the

cable adjuster lock tab downward until it snaps into

place.

(9) Check for proper operation of the transmission

range sensor.

(10) Adjust the gearshift cable and BTSI mecha-

nism as necessary.

ADJUSTMENTS

GEARSHIFT CABLE

Check adjustment by starting the engine in PARK

and NEUTRAL. Adjustment is CORRECT if the

engine starts only in these positions. Adjustment is

INCORRECT if the engine starts in one but not both

positions. If the engine starts in any position other

than PARK or NEUTRAL, or if the engine will not

start at all, the transmission range sensor may be

faulty.

Gearshift Adjustment Procedure

(1) Shift transmission into PARK.

(2) Release cable adjuster lock tab (underneath the

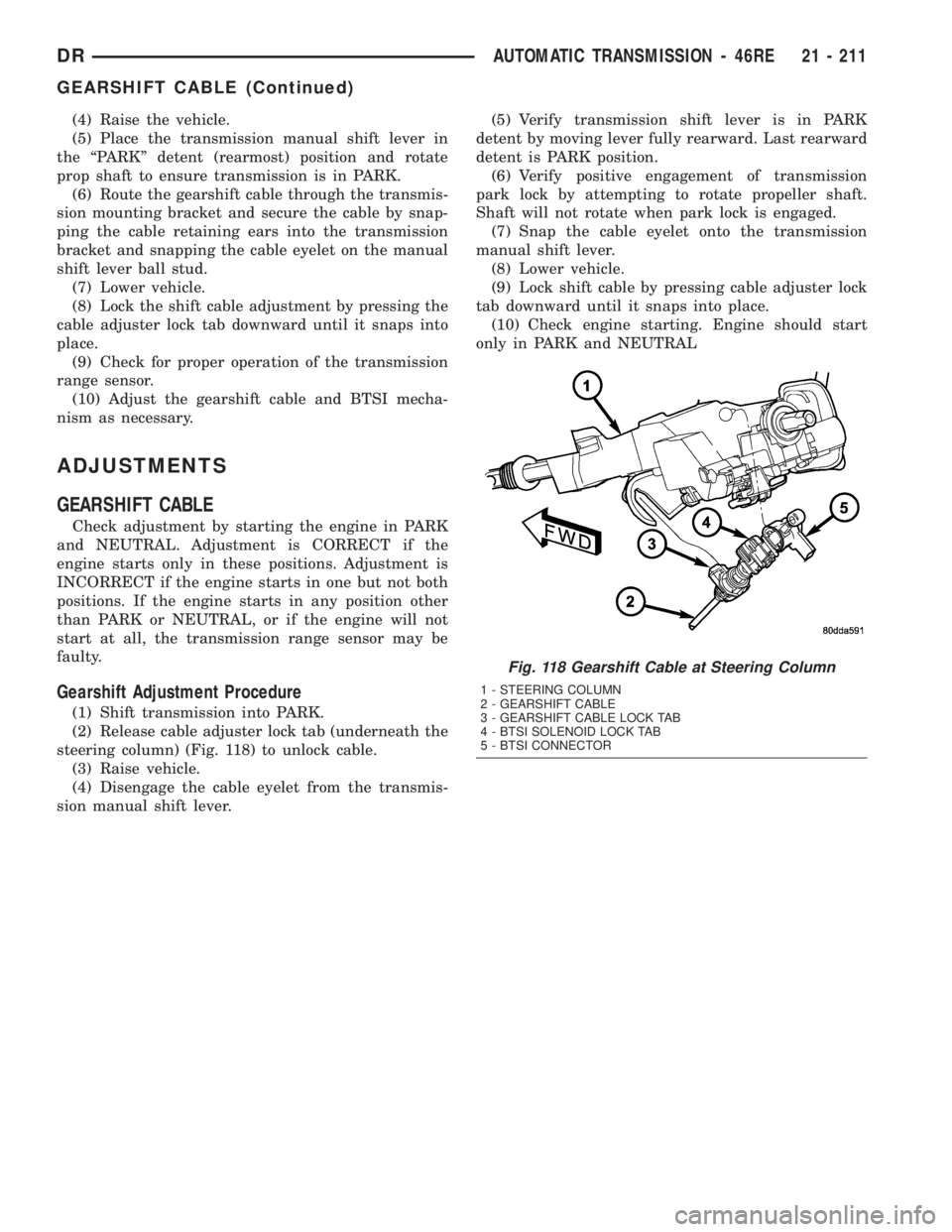

steering column) (Fig. 118) to unlock cable.

(3) Raise vehicle.

(4) Disengage the cable eyelet from the transmis-

sion manual shift lever.(5) Verify transmission shift lever is in PARK

detent by moving lever fully rearward. Last rearward

detent is PARK position.

(6) Verify positive engagement of transmission

park lock by attempting to rotate propeller shaft.

Shaft will not rotate when park lock is engaged.

(7) Snap the cable eyelet onto the transmission

manual shift lever.

(8) Lower vehicle.

(9) Lock shift cable by pressing cable adjuster lock

tab downward until it snaps into place.

(10) Check engine starting. Engine should start

only in PARK and NEUTRAL

Fig. 118 Gearshift Cable at Steering Column

1 - STEERING COLUMN

2 - GEARSHIFT CABLE

3 - GEARSHIFT CABLE LOCK TAB

4 - BTSI SOLENOID LOCK TAB

5 - BTSI CONNECTOR

DRAUTOMATIC TRANSMISSION - 46RE 21 - 211

GEARSHIFT CABLE (Continued)

Page 2055 of 2895

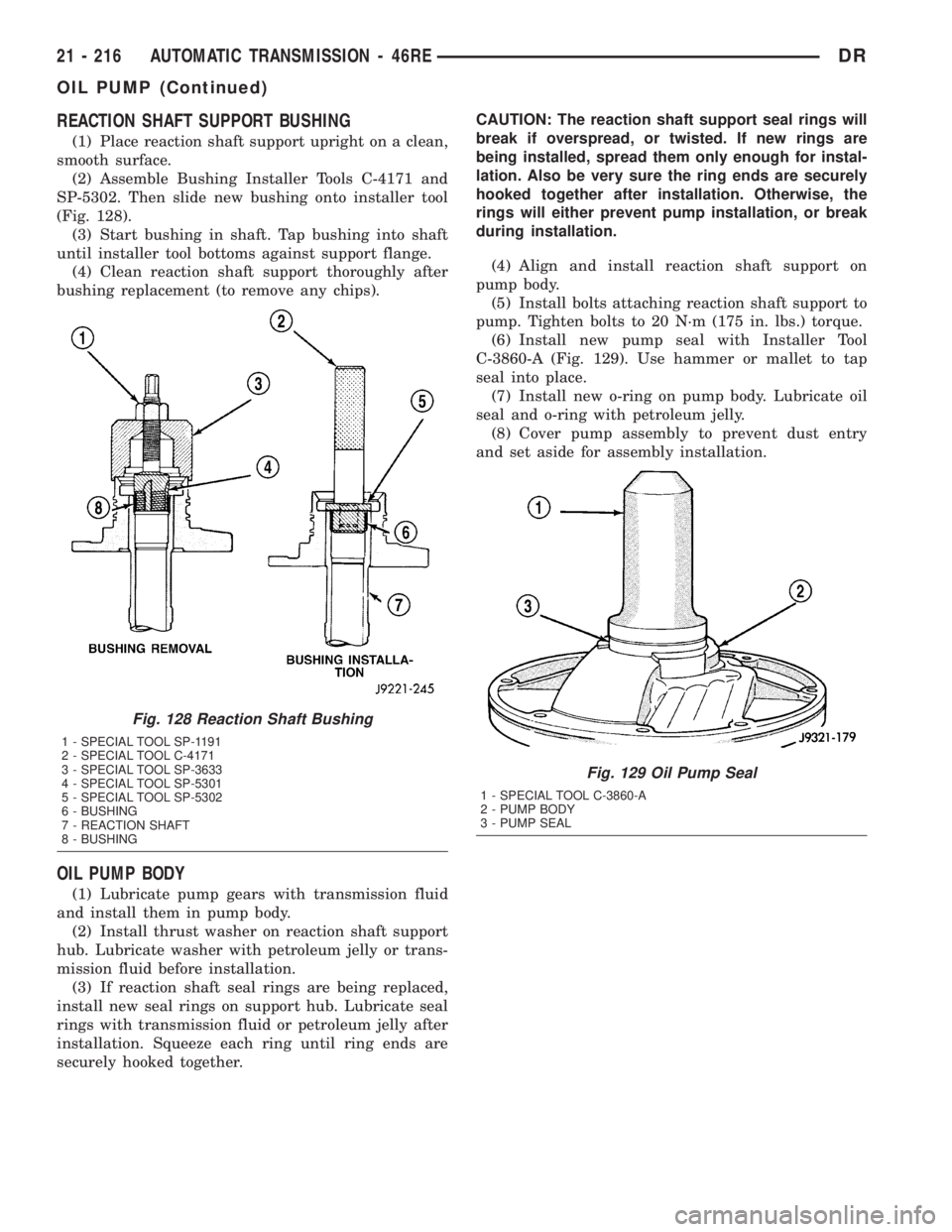

REACTION SHAFT SUPPORT BUSHING

(1) Place reaction shaft support upright on a clean,

smooth surface.

(2) Assemble Bushing Installer Tools C-4171 and

SP-5302. Then slide new bushing onto installer tool

(Fig. 128).

(3) Start bushing in shaft. Tap bushing into shaft

until installer tool bottoms against support flange.

(4) Clean reaction shaft support thoroughly after

bushing replacement (to remove any chips).

OIL PUMP BODY

(1) Lubricate pump gears with transmission fluid

and install them in pump body.

(2) Install thrust washer on reaction shaft support

hub. Lubricate washer with petroleum jelly or trans-

mission fluid before installation.

(3) If reaction shaft seal rings are being replaced,

install new seal rings on support hub. Lubricate seal

rings with transmission fluid or petroleum jelly after

installation. Squeeze each ring until ring ends are

securely hooked together.CAUTION: The reaction shaft support seal rings will

break if overspread, or twisted. If new rings are

being installed, spread them only enough for instal-

lation. Also be very sure the ring ends are securely

hooked together after installation. Otherwise, the

rings will either prevent pump installation, or break

during installation.

(4) Align and install reaction shaft support on

pump body.

(5) Install bolts attaching reaction shaft support to

pump. Tighten bolts to 20 N´m (175 in. lbs.) torque.

(6) Install new pump seal with Installer Tool

C-3860-A (Fig. 129). Use hammer or mallet to tap

seal into place.

(7) Install new o-ring on pump body. Lubricate oil

seal and o-ring with petroleum jelly.

(8) Cover pump assembly to prevent dust entry

and set aside for assembly installation.

Fig. 128 Reaction Shaft Bushing

1 - SPECIAL TOOL SP-1191

2 - SPECIAL TOOL C-4171

3 - SPECIAL TOOL SP-3633

4 - SPECIAL TOOL SP-5301

5 - SPECIAL TOOL SP-5302

6 - BUSHING

7 - REACTION SHAFT

8 - BUSHING

Fig. 129 Oil Pump Seal

1 - SPECIAL TOOL C-3860-A

2 - PUMP BODY

3 - PUMP SEAL

21 - 216 AUTOMATIC TRANSMISSION - 46REDR

OIL PUMP (Continued)