set clock DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1508 of 2895

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

LEAK-DOWN TEST

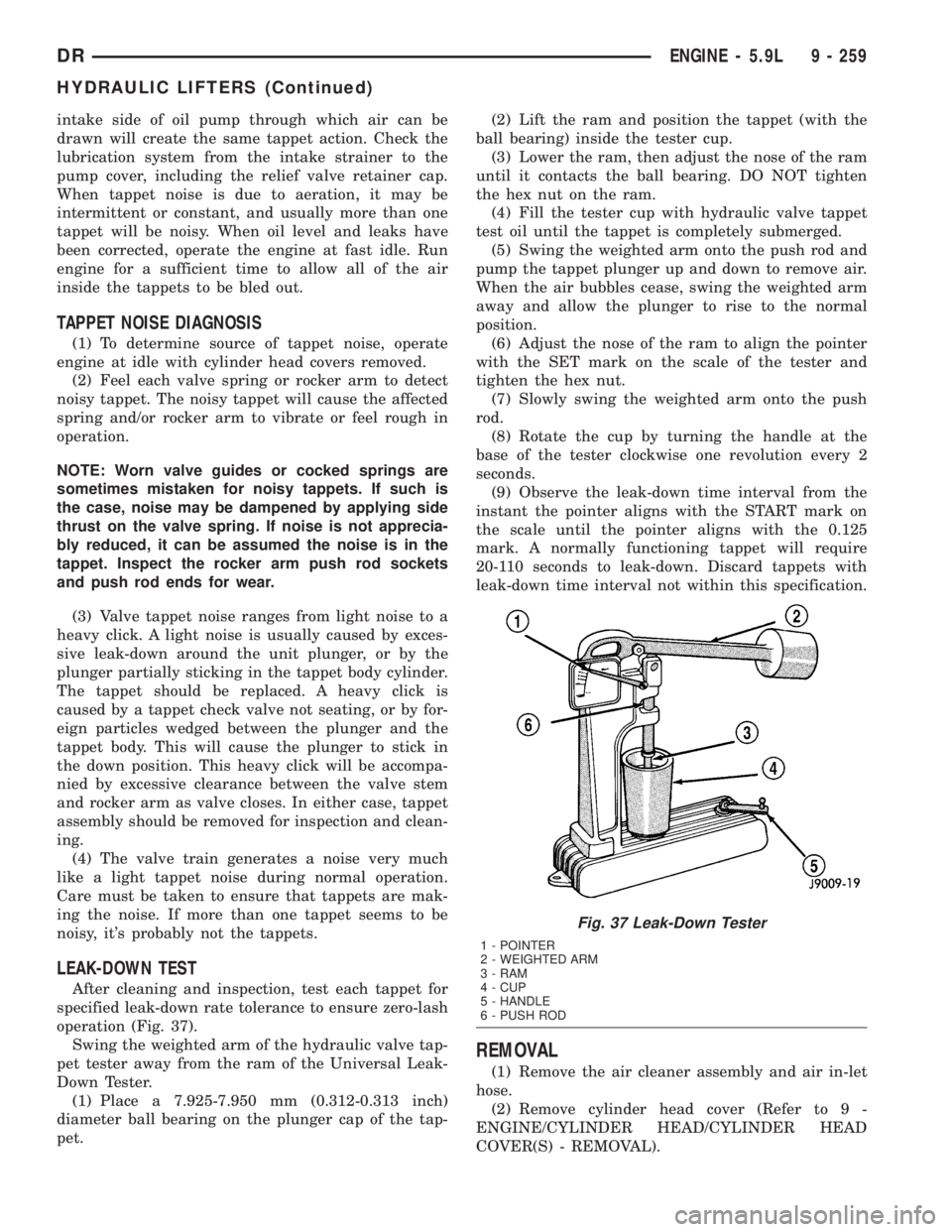

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 37).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Remove the air cleaner assembly and air in-let

hose.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

Fig. 37 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

DRENGINE - 5.9L 9 - 259

HYDRAULIC LIFTERS (Continued)

Page 1512 of 2895

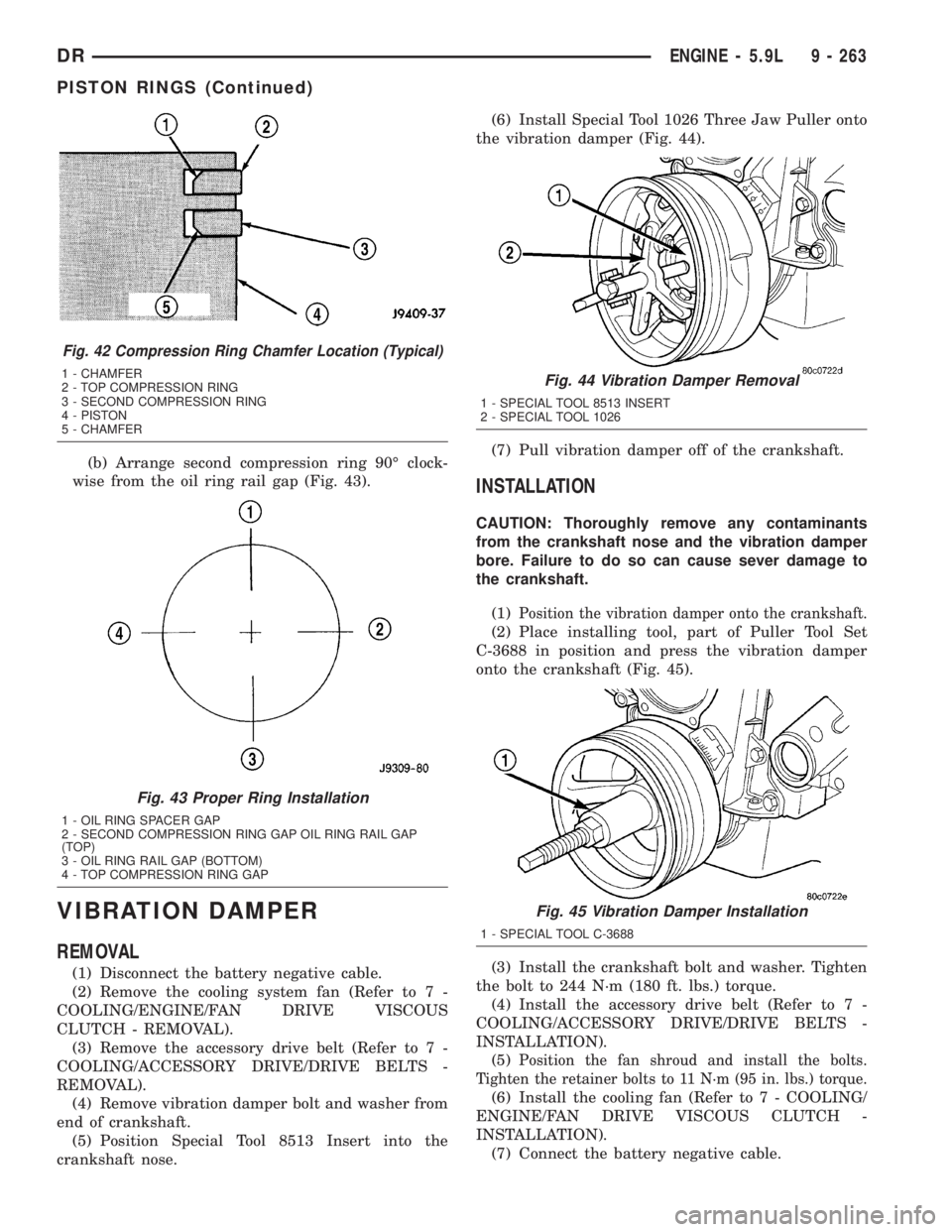

(b) Arrange second compression ring 90É clock-

wise from the oil ring rail gap (Fig. 43).

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove vibration damper bolt and washer from

end of crankshaft.

(5) Position Special Tool 8513 Insert into the

crankshaft nose.(6) Install Special Tool 1026 Three Jaw Puller onto

the vibration damper (Fig. 44).

(7) Pull vibration damper off of the crankshaft.

INSTALLATION

CAUTION: Thoroughly remove any contaminants

from the crankshaft nose and the vibration damper

bore. Failure to do so can cause sever damage to

the crankshaft.

(1)

Position the vibration damper onto the crankshaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 45).

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 244 N´m (180 ft. lbs.) torque.

(4) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(5)

Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N´m (95 in. lbs.) torque.

(6) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

(7) Connect the battery negative cable.

Fig. 42 Compression Ring Chamfer Location (Typical)

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

Fig. 43 Proper Ring Installation

1 - OIL RING SPACER GAP

2 - SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 - OIL RING RAIL GAP (BOTTOM)

4 - TOP COMPRESSION RING GAP

Fig. 44 Vibration Damper Removal

1 - SPECIAL TOOL 8513 INSERT

2 - SPECIAL TOOL 1026

Fig. 45 Vibration Damper Installation

1 - SPECIAL TOOL C-3688

DRENGINE - 5.9L 9 - 263

PISTON RINGS (Continued)

Page 1557 of 2895

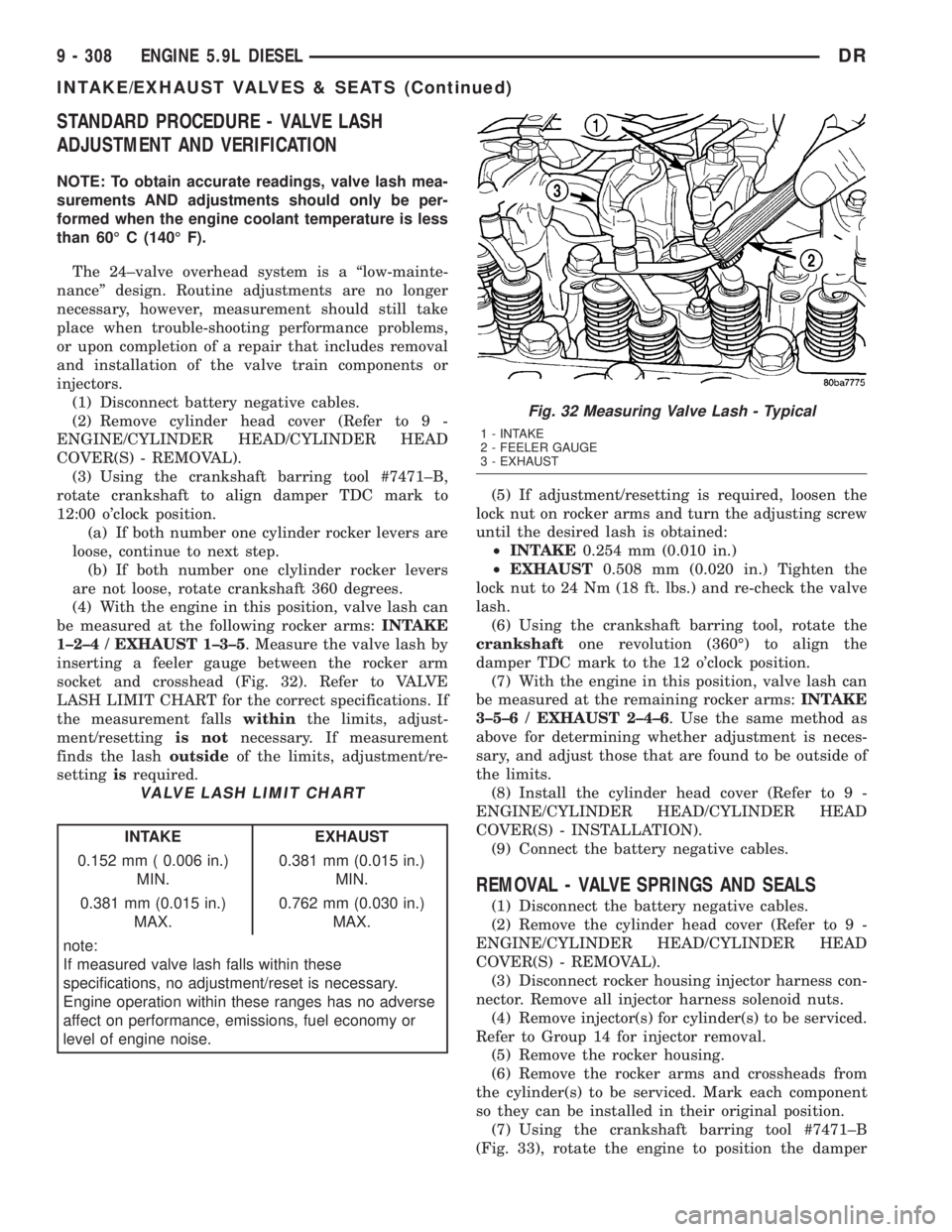

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION

NOTE: To obtain accurate readings, valve lash mea-

surements AND adjustments should only be per-

formed when the engine coolant temperature is less

than 60É C (140É F).

The 24±valve overhead system is a ªlow-mainte-

nanceº design. Routine adjustments are no longer

necessary, however, measurement should still take

place when trouble-shooting performance problems,

or upon completion of a repair that includes removal

and installation of the valve train components or

injectors.

(1) Disconnect battery negative cables.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Using the crankshaft barring tool #7471±B,

rotate crankshaft to align damper TDC mark to

12:00 o'clock position.

(a) If both number one cylinder rocker levers are

loose, continue to next step.

(b) If both number one clylinder rocker levers

are not loose, rotate crankshaft 360 degrees.

(4) With the engine in this position, valve lash can

be measured at the following rocker arms:INTAKE

1±2±4 / EXHAUST 1±3±5. Measure the valve lash by

inserting a feeler gauge between the rocker arm

socket and crosshead (Fig. 32). Refer to VALVE

LASH LIMIT CHART for the correct specifications. If

the measurement fallswithinthe limits, adjust-

ment/resettingis notnecessary. If measurement

finds the lashoutsideof the limits, adjustment/re-

settingisrequired.

VALVE LASH LIMIT CHART

INTAKE EXHAUST

0.152 mm ( 0.006 in.)

MIN.0.381 mm (0.015 in.)

MIN.

0.381 mm (0.015 in.)

MAX.0.762 mm (0.030 in.)

MAX.

note:

If measured valve lash falls within these

specifications, no adjustment/reset is necessary.

Engine operation within these ranges has no adverse

affect on performance, emissions, fuel economy or

level of engine noise.(5) If adjustment/resetting is required, loosen the

lock nut on rocker arms and turn the adjusting screw

until the desired lash is obtained:

²INTAKE0.254 mm (0.010 in.)

²EXHAUST0.508 mm (0.020 in.) Tighten the

lock nut to 24 Nm (18 ft. lbs.) and re-check the valve

lash.

(6) Using the crankshaft barring tool, rotate the

crankshaftone revolution (360É) to align the

damper TDC mark to the 12 o'clock position.

(7) With the engine in this position, valve lash can

be measured at the remaining rocker arms:INTAKE

3±5±6 / EXHAUST 2±4±6. Use the same method as

above for determining whether adjustment is neces-

sary, and adjust those that are found to be outside of

the limits.

(8) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(9) Connect the battery negative cables.

REMOVAL - VALVE SPRINGS AND SEALS

(1) Disconnect the battery negative cables.

(2) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Disconnect rocker housing injector harness con-

nector. Remove all injector harness solenoid nuts.

(4) Remove injector(s) for cylinder(s) to be serviced.

Refer to Group 14 for injector removal.

(5) Remove the rocker housing.

(6) Remove the rocker arms and crossheads from

the cylinder(s) to be serviced. Mark each component

so they can be installed in their original position.

(7) Using the crankshaft barring tool #7471±B

(Fig. 33), rotate the engine to position the damper

Fig. 32 Measuring Valve Lash - Typical

1 - INTAKE

2 - FEELER GAUGE

3 - EXHAUST

9 - 308 ENGINE 5.9L DIESELDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1582 of 2895

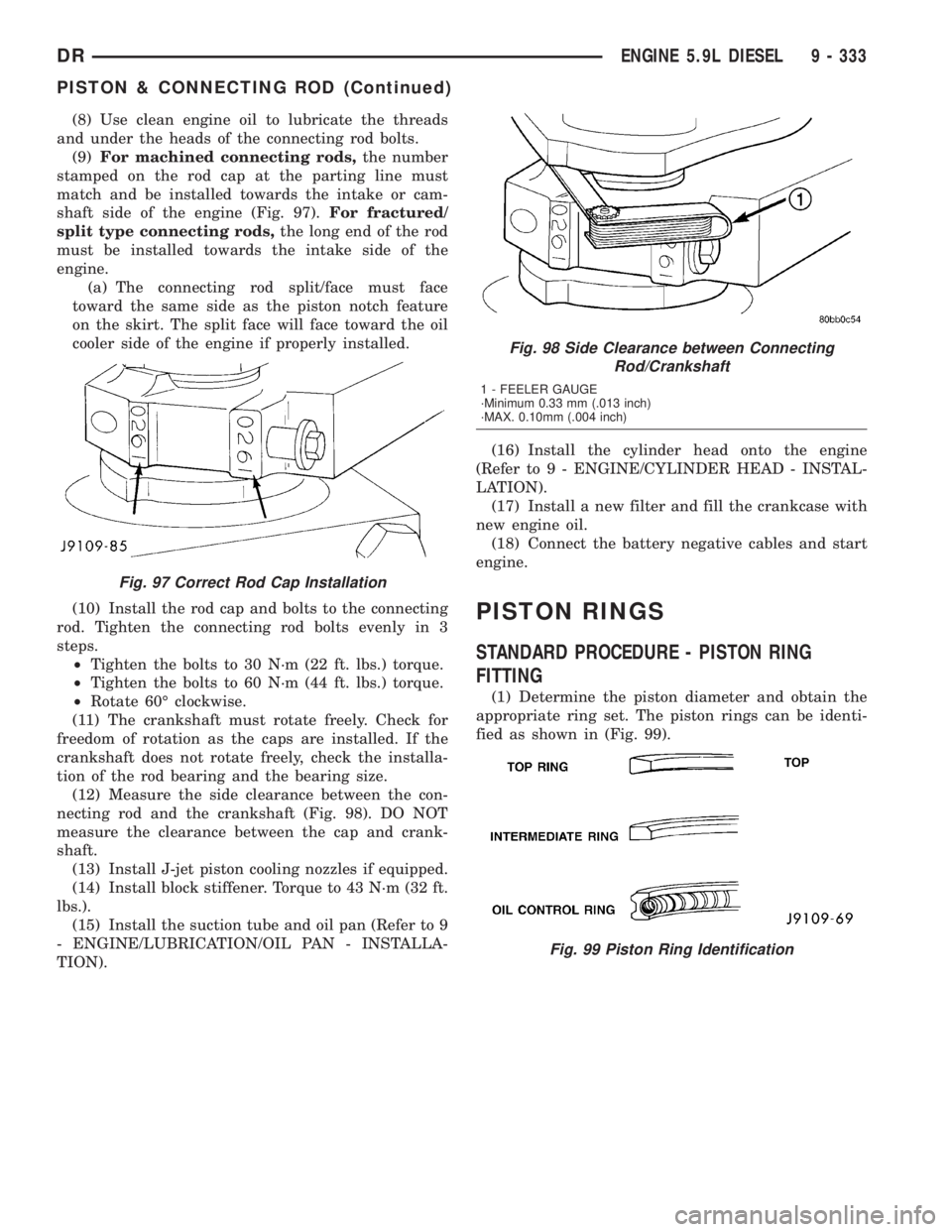

(8) Use clean engine oil to lubricate the threads

and under the heads of the connecting rod bolts.

(9)For machined connecting rods,the number

stamped on the rod cap at the parting line must

match and be installed towards the intake or cam-

shaft side of the engine (Fig. 97).For fractured/

split type connecting rods,the long end of the rod

must be installed towards the intake side of the

engine.

(a) The connecting rod split/face must face

toward the same side as the piston notch feature

on the skirt. The split face will face toward the oil

cooler side of the engine if properly installed.

(10) Install the rod cap and bolts to the connecting

rod. Tighten the connecting rod bolts evenly in 3

steps.

²Tighten the bolts to 30 N´m (22 ft. lbs.) torque.

²Tighten the bolts to 60 N´m (44 ft. lbs.) torque.

²Rotate 60É clockwise.

(11) The crankshaft must rotate freely. Check for

freedom of rotation as the caps are installed. If the

crankshaft does not rotate freely, check the installa-

tion of the rod bearing and the bearing size.

(12) Measure the side clearance between the con-

necting rod and the crankshaft (Fig. 98). DO NOT

measure the clearance between the cap and crank-

shaft.

(13) Install J-jet piston cooling nozzles if equipped.

(14) Install block stiffener. Torque to 43 N´m (32 ft.

lbs.).

(15) Install the suction tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).(16) Install the cylinder head onto the engine

(Refer to 9 - ENGINE/CYLINDER HEAD - INSTAL-

LATION).

(17) Install a new filter and fill the crankcase with

new engine oil.

(18) Connect the battery negative cables and start

engine.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

(1) Determine the piston diameter and obtain the

appropriate ring set. The piston rings can be identi-

fied as shown in (Fig. 99).

Fig. 97 Correct Rod Cap Installation

Fig. 98 Side Clearance between Connecting

Rod/Crankshaft

1 - FEELER GAUGE

´Minimum 0.33 mm (.013 inch)

´MAX. 0.10mm (.004 inch)

Fig. 99 Piston Ring Identification

DRENGINE 5.9L DIESEL 9 - 333

PISTON & CONNECTING ROD (Continued)

Page 1636 of 2895

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

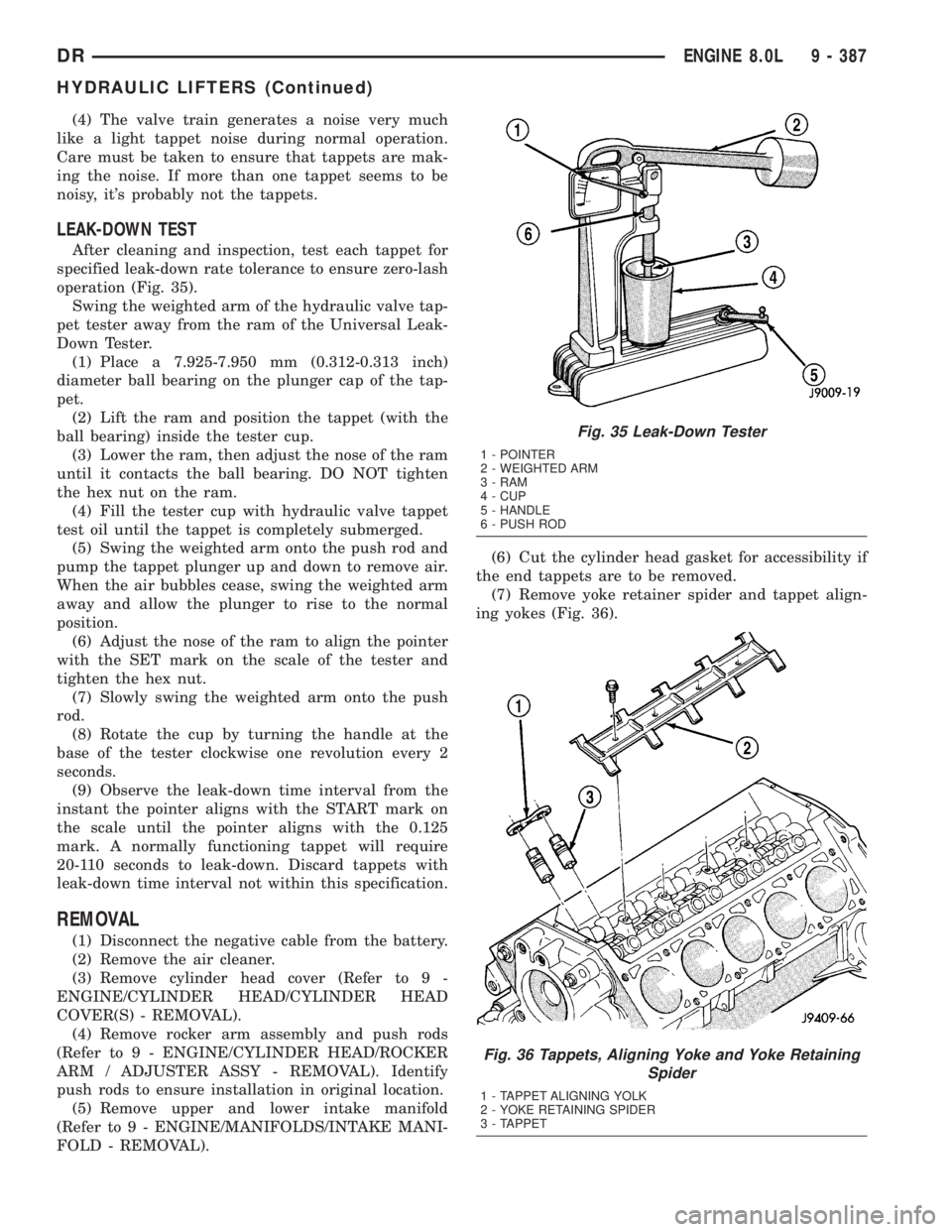

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 35).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner.

(3) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(4) Remove rocker arm assembly and push rods

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(5) Remove upper and lower intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL).(6) Cut the cylinder head gasket for accessibility if

the end tappets are to be removed.

(7) Remove yoke retainer spider and tappet align-

ing yokes (Fig. 36).

Fig. 35 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

Fig. 36 Tappets, Aligning Yoke and Yoke Retaining

Spider

1 - TAPPET ALIGNING YOLK

2 - YOKE RETAINING SPIDER

3 - TAPPET

DRENGINE 8.0L 9 - 387

HYDRAULIC LIFTERS (Continued)

Page 1974 of 2895

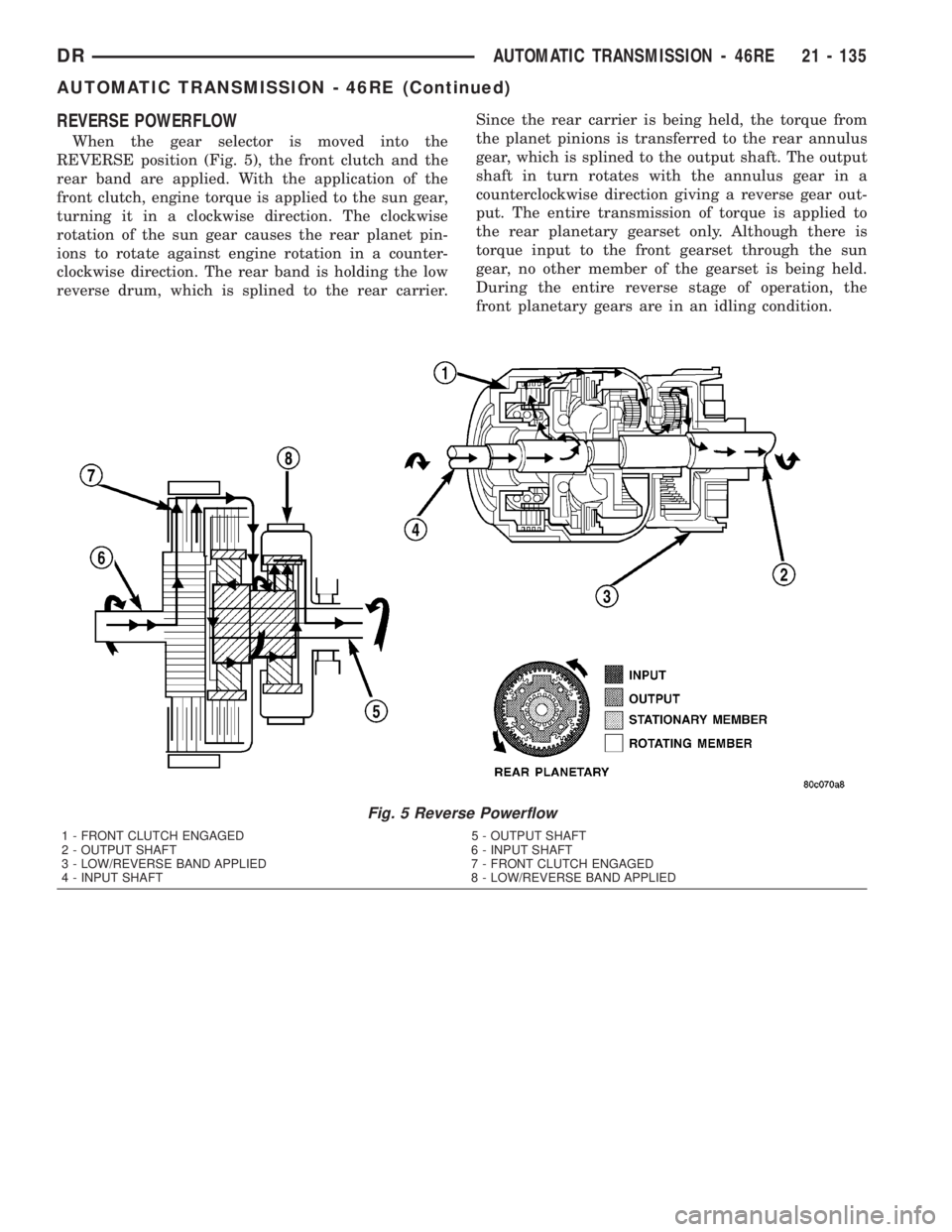

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.Since the rear carrier is being held, the torque from

the planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 5 Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

DRAUTOMATIC TRANSMISSION - 46RE 21 - 135

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1976 of 2895

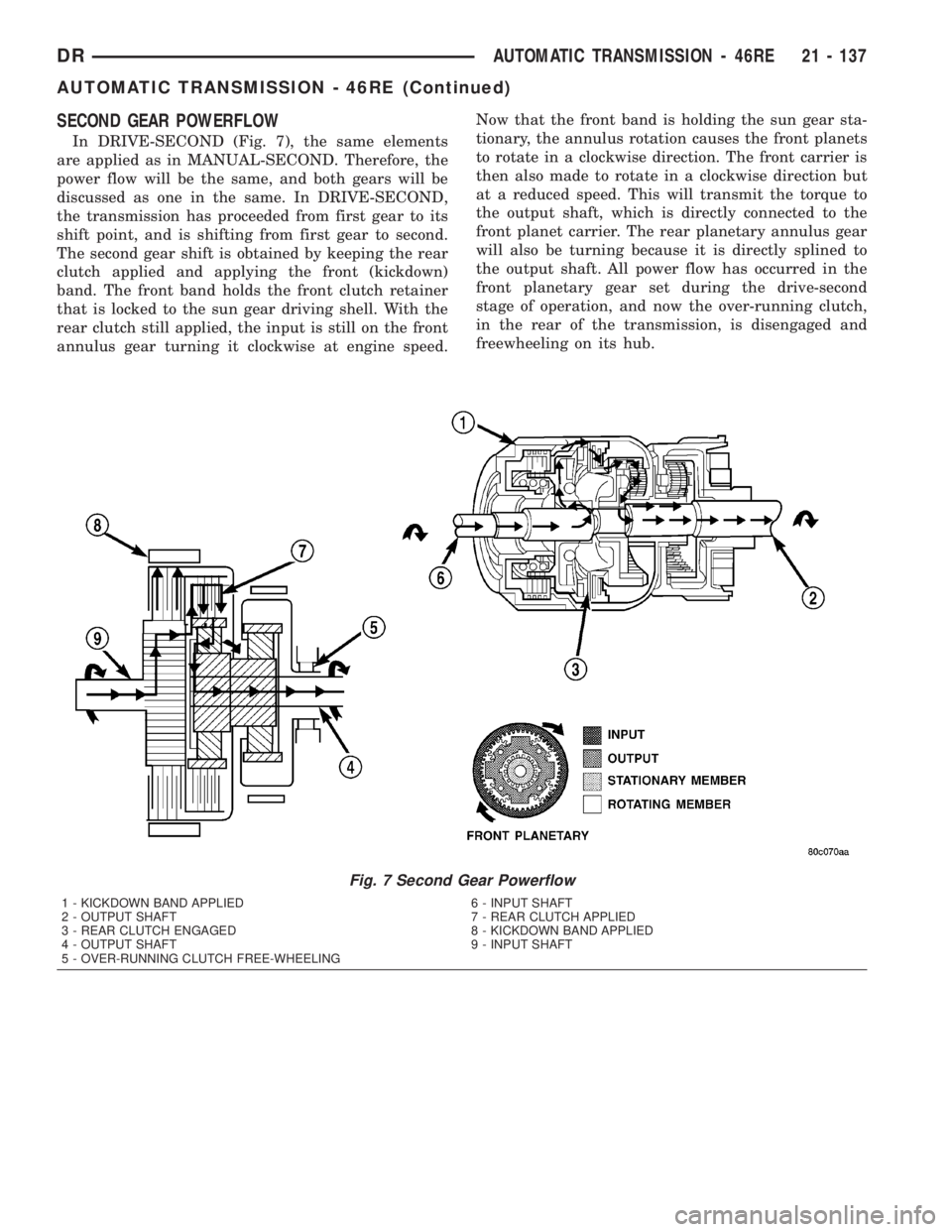

SECOND GEAR POWERFLOW

In DRIVE-SECOND (Fig. 7), the same elements

are applied as in MANUAL-SECOND. Therefore, the

power flow will be the same, and both gears will be

discussed as one in the same. In DRIVE-SECOND,

the transmission has proceeded from first gear to its

shift point, and is shifting from first gear to second.

The second gear shift is obtained by keeping the rear

clutch applied and applying the front (kickdown)

band. The front band holds the front clutch retainer

that is locked to the sun gear driving shell. With the

rear clutch still applied, the input is still on the front

annulus gear turning it clockwise at engine speed.Now that the front band is holding the sun gear sta-

tionary, the annulus rotation causes the front planets

to rotate in a clockwise direction. The front carrier is

then also made to rotate in a clockwise direction but

at a reduced speed. This will transmit the torque to

the output shaft, which is directly connected to the

front planet carrier. The rear planetary annulus gear

will also be turning because it is directly splined to

the output shaft. All power flow has occurred in the

front planetary gear set during the drive-second

stage of operation, and now the over-running clutch,

in the rear of the transmission, is disengaged and

freewheeling on its hub.

Fig. 7 Second Gear Powerflow

1 - KICKDOWN BAND APPLIED 6 - INPUT SHAFT

2 - OUTPUT SHAFT 7 - REAR CLUTCH APPLIED

3 - REAR CLUTCH ENGAGED 8 - KICKDOWN BAND APPLIED

4 - OUTPUT SHAFT 9 - INPUT SHAFT

5 - OVER-RUNNING CLUTCH FREE-WHEELING

DRAUTOMATIC TRANSMISSION - 46RE 21 - 137

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1977 of 2895

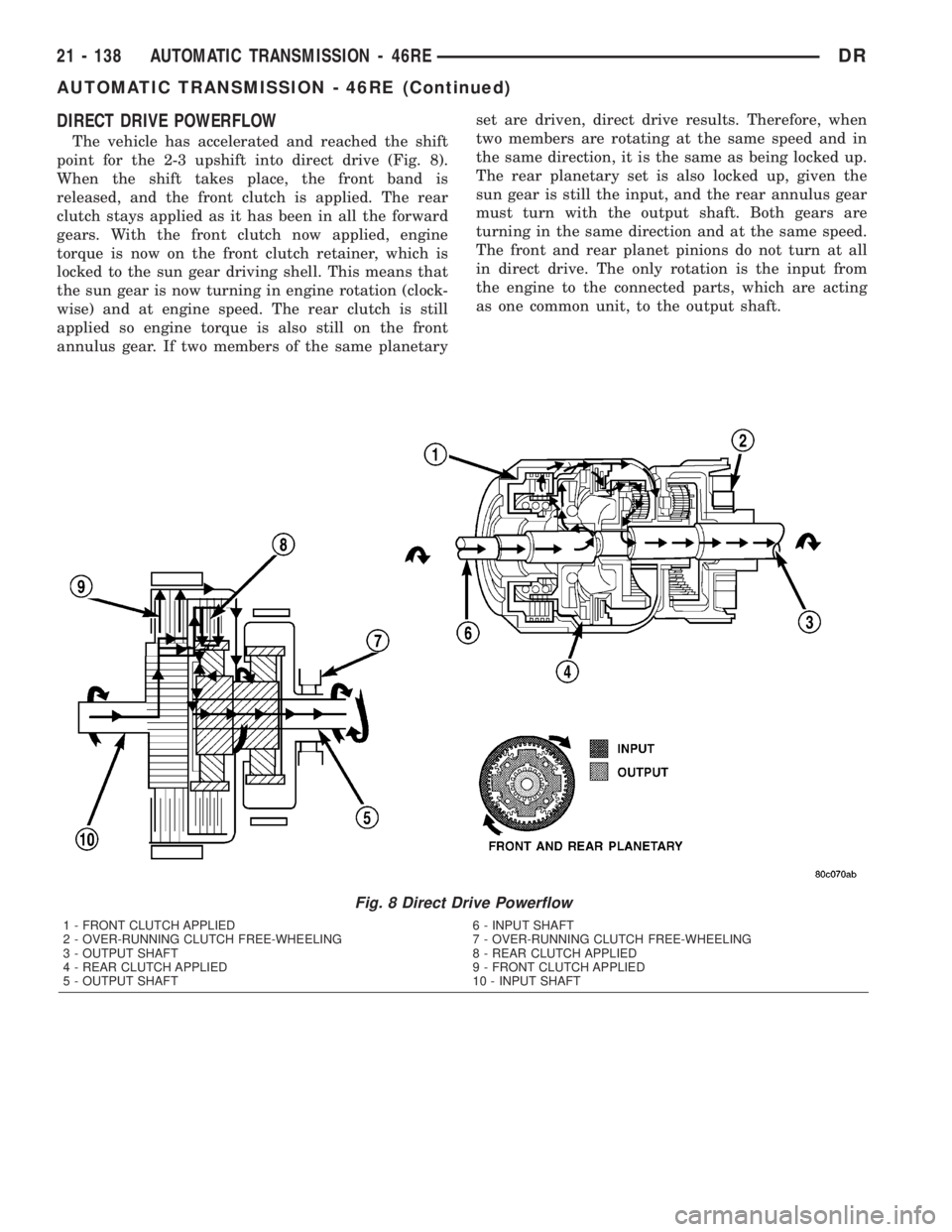

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift

point for the 2-3 upshift into direct drive (Fig. 8).

When the shift takes place, the front band is

released, and the front clutch is applied. The rear

clutch stays applied as it has been in all the forward

gears. With the front clutch now applied, engine

torque is now on the front clutch retainer, which is

locked to the sun gear driving shell. This means that

the sun gear is now turning in engine rotation (clock-

wise) and at engine speed. The rear clutch is still

applied so engine torque is also still on the front

annulus gear. If two members of the same planetaryset are driven, direct drive results. Therefore, when

two members are rotating at the same speed and in

the same direction, it is the same as being locked up.

The rear planetary set is also locked up, given the

sun gear is still the input, and the rear annulus gear

must turn with the output shaft. Both gears are

turning in the same direction and at the same speed.

The front and rear planet pinions do not turn at all

in direct drive. The only rotation is the input from

the engine to the connected parts, which are acting

as one common unit, to the output shaft.

Fig. 8 Direct Drive Powerflow

1 - FRONT CLUTCH APPLIED 6 - INPUT SHAFT

2 - OVER-RUNNING CLUTCH FREE-WHEELING 7 - OVER-RUNNING CLUTCH FREE-WHEELING

3 - OUTPUT SHAFT 8 - REAR CLUTCH APPLIED

4 - REAR CLUTCH APPLIED 9 - FRONT CLUTCH APPLIED

5 - OUTPUT SHAFT 10 - INPUT SHAFT

21 - 138 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2147 of 2895

(15) Check and adjust front and rear bands if nec-

essary.

(16) Connect solenoid case connector wires.

(17) Install the transmission range sensor.

(18) Install oil pan and new gasket. Tighten pan

bolts to 17 N´m (13 ft. lbs.) torque.

(19) Lower vehicle and fill transmission with

MopartATF +4, Automatic Transmission fluid.

(20) Check and adjust gearshift and throttle valve

cables, if necessary.ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

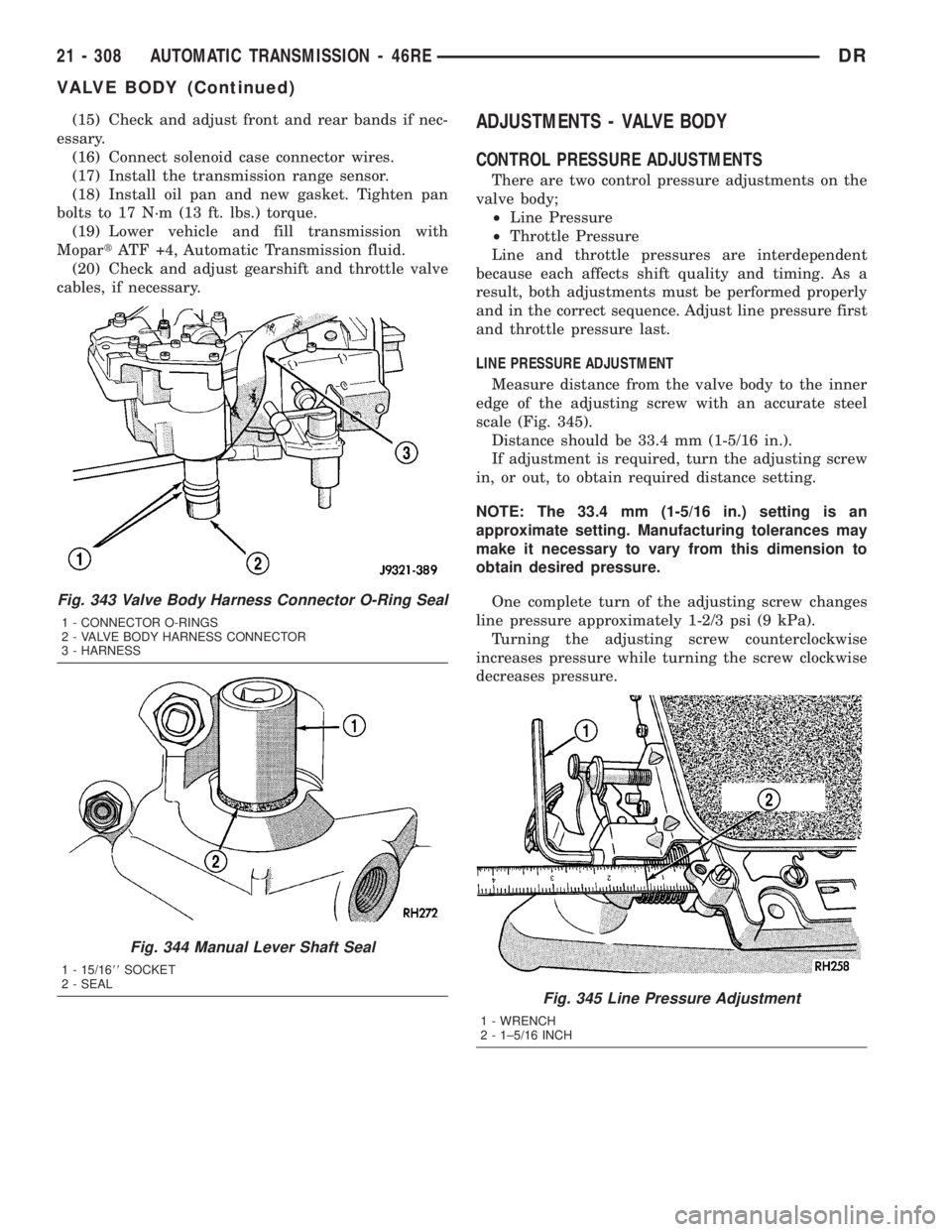

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 345).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

Fig. 343 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

Fig. 344 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 345 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

21 - 308 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2155 of 2895

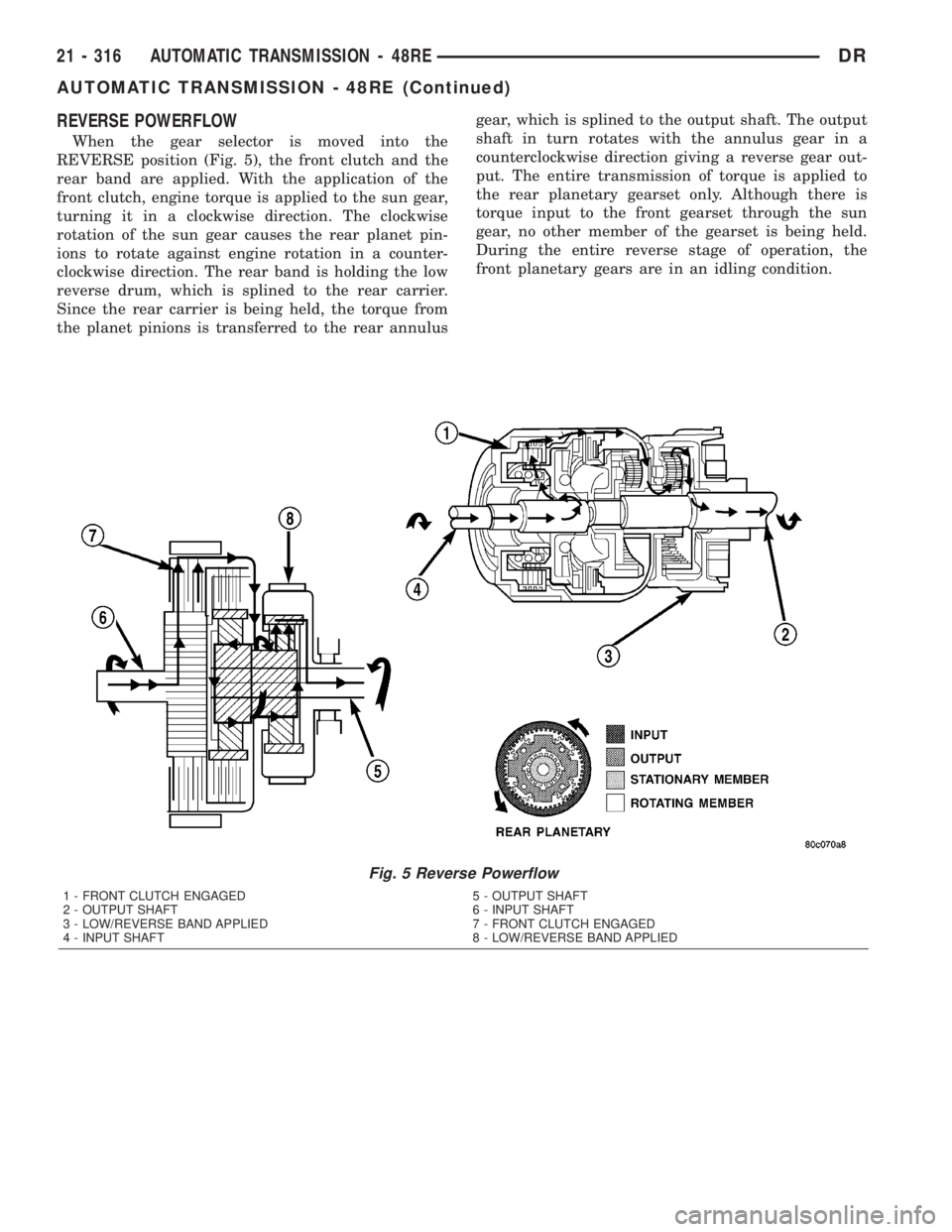

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque from

the planet pinions is transferred to the rear annulusgear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 5 Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

21 - 316 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)