ABS DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 268 of 2895

DESCRIPTION N´m Ft. Lbs. In. Lbs.

RWAL Valve

Brake Line Fittings19 Ð 170

Rear Wheel Speed Sensor

Mounting Bolt24 Ð 200

FRONT WHEEL SPEED

SENSOR

DESCRIPTION

The ABS brake system uses 3 wheel speed sensors.

A sensor is mounted to each front hub/bearings. The

third sensor is mounted on top of the rear axle dif-

ferential housing.

OPERATION

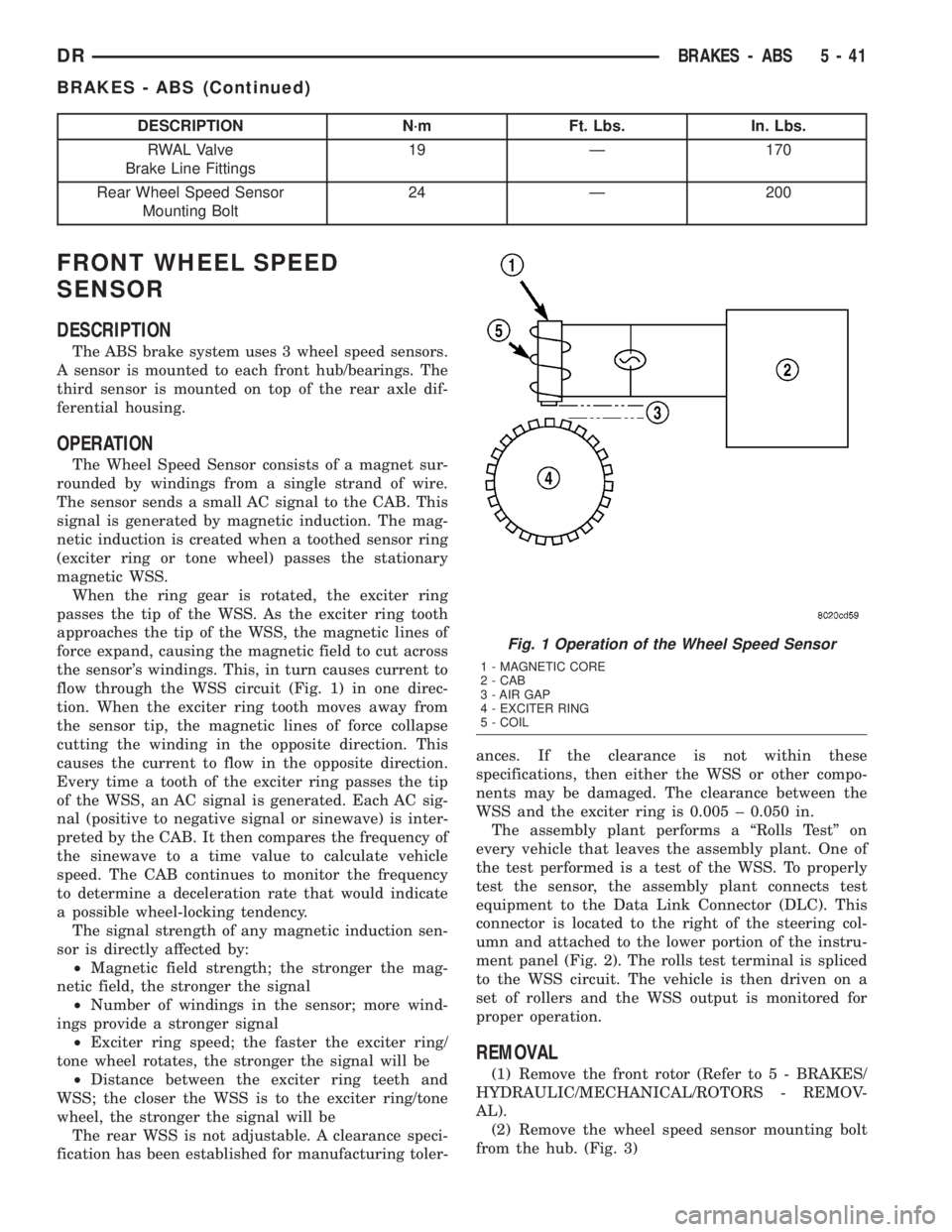

The Wheel Speed Sensor consists of a magnet sur-

rounded by windings from a single strand of wire.

The sensor sends a small AC signal to the CAB. This

signal is generated by magnetic induction. The mag-

netic induction is created when a toothed sensor ring

(exciter ring or tone wheel) passes the stationary

magnetic WSS.

When the ring gear is rotated, the exciter ring

passes the tip of the WSS. As the exciter ring tooth

approaches the tip of the WSS, the magnetic lines of

force expand, causing the magnetic field to cut across

the sensor's windings. This, in turn causes current to

flow through the WSS circuit (Fig. 1) in one direc-

tion. When the exciter ring tooth moves away from

the sensor tip, the magnetic lines of force collapse

cutting the winding in the opposite direction. This

causes the current to flow in the opposite direction.

Every time a tooth of the exciter ring passes the tip

of the WSS, an AC signal is generated. Each AC sig-

nal (positive to negative signal or sinewave) is inter-

preted by the CAB. It then compares the frequency of

the sinewave to a time value to calculate vehicle

speed. The CAB continues to monitor the frequency

to determine a deceleration rate that would indicate

a possible wheel-locking tendency.

The signal strength of any magnetic induction sen-

sor is directly affected by:

²Magnetic field strength; the stronger the mag-

netic field, the stronger the signal

²Number of windings in the sensor; more wind-

ings provide a stronger signal

²Exciter ring speed; the faster the exciter ring/

tone wheel rotates, the stronger the signal will be

²Distance between the exciter ring teeth and

WSS; the closer the WSS is to the exciter ring/tone

wheel, the stronger the signal will be

The rear WSS is not adjustable. A clearance speci-

fication has been established for manufacturing toler-ances. If the clearance is not within these

specifications, then either the WSS or other compo-

nents may be damaged. The clearance between the

WSS and the exciter ring is 0.005 ± 0.050 in.

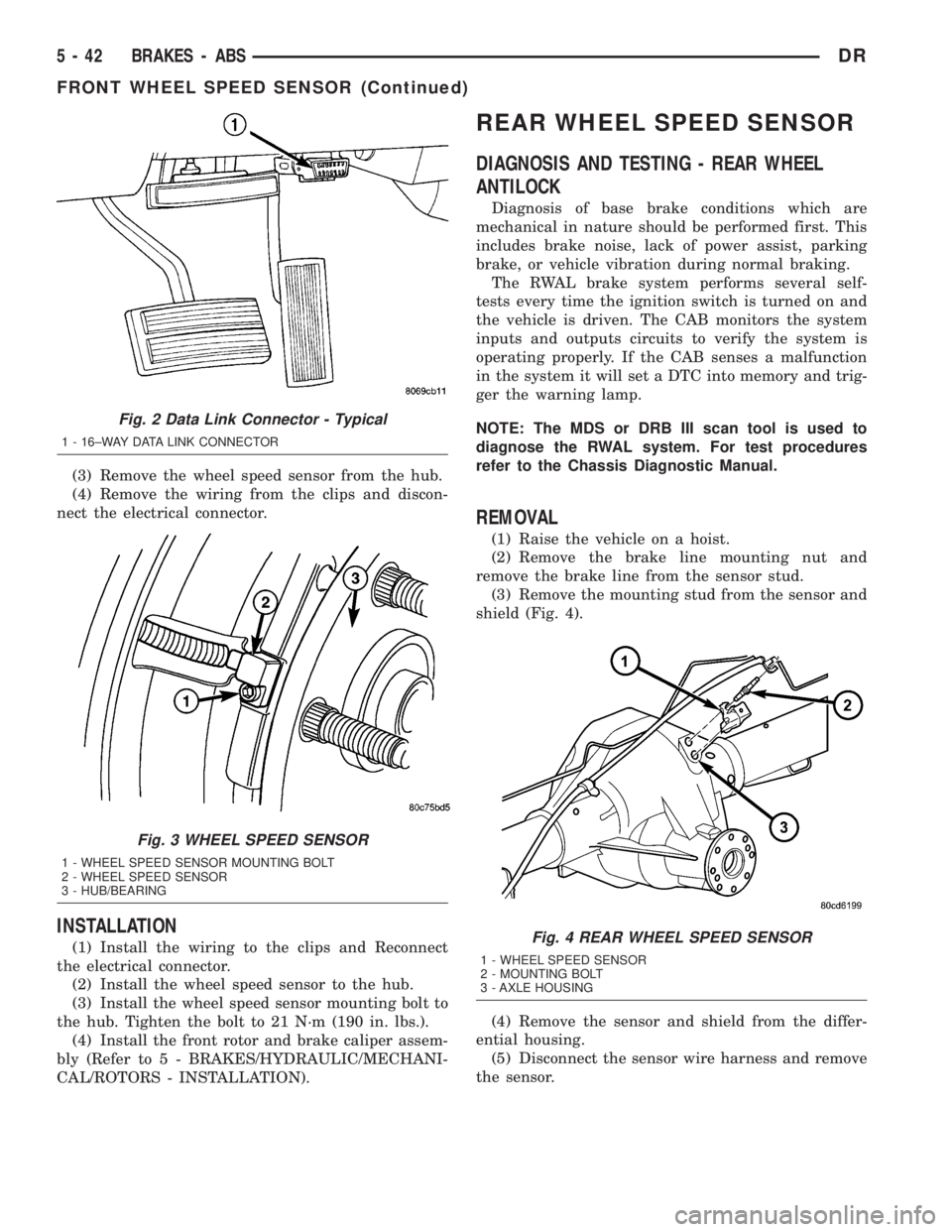

The assembly plant performs a ªRolls Testº on

every vehicle that leaves the assembly plant. One of

the test performed is a test of the WSS. To properly

test the sensor, the assembly plant connects test

equipment to the Data Link Connector (DLC). This

connector is located to the right of the steering col-

umn and attached to the lower portion of the instru-

ment panel (Fig. 2). The rolls test terminal is spliced

to the WSS circuit. The vehicle is then driven on a

set of rollers and the WSS output is monitored for

proper operation.

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - REMOV-

AL).

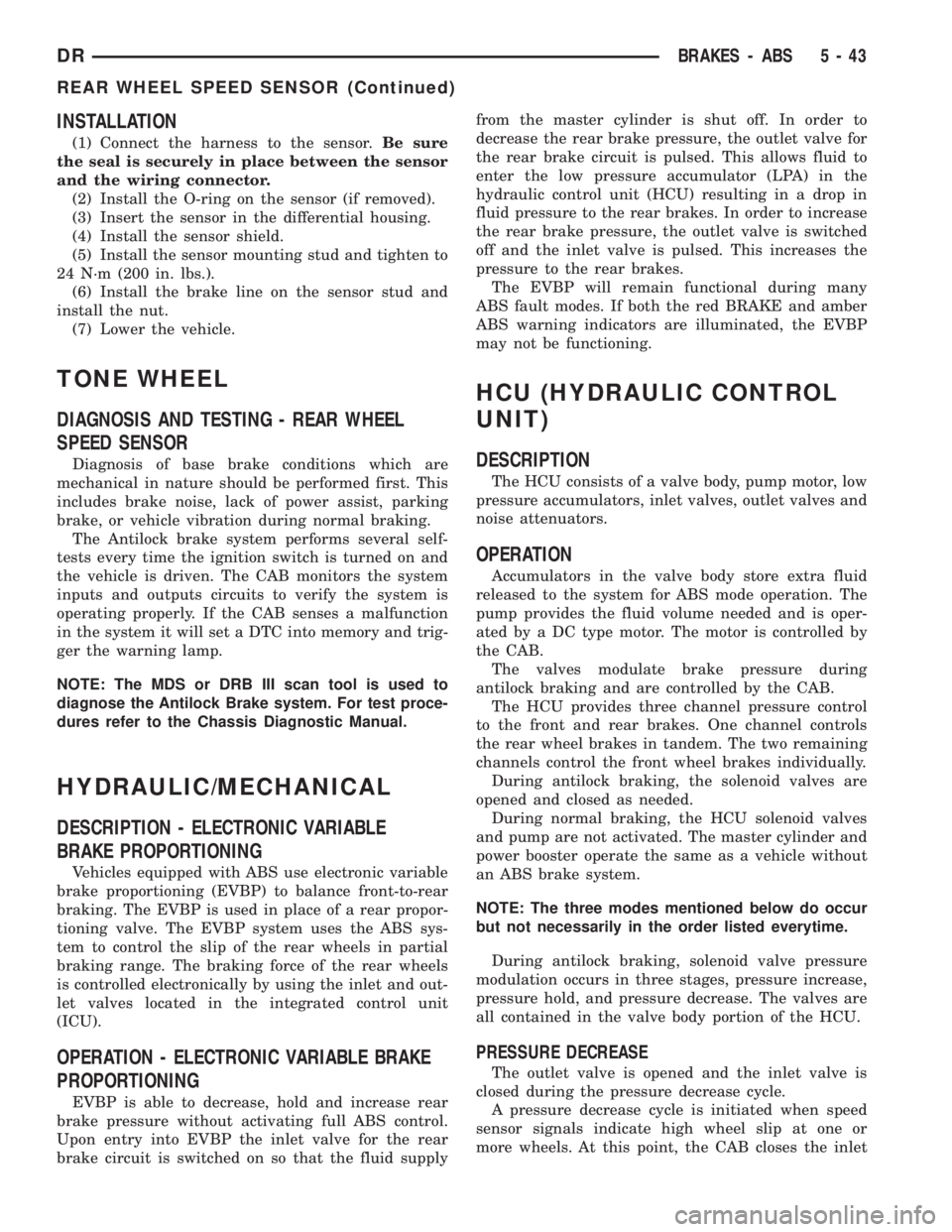

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

Fig. 1 Operation of the Wheel Speed Sensor

1 - MAGNETIC CORE

2 - CAB

3 - AIR GAP

4 - EXCITER RING

5 - COIL

DRBRAKES - ABS 5 - 41

BRAKES - ABS (Continued)

Page 269 of 2895

(3) Remove the wheel speed sensor from the hub.

(4) Remove the wiring from the clips and discon-

nect the electrical connector.

INSTALLATION

(1) Install the wiring to the clips and Reconnect

the electrical connector.

(2) Install the wheel speed sensor to the hub.

(3) Install the wheel speed sensor mounting bolt to

the hub. Tighten the bolt to 21 N´m (190 in. lbs.).

(4) Install the front rotor and brake caliper assem-

bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/ROTORS - INSTALLATION).

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The RWAL brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the RWAL system. For test procedures

refer to the Chassis Diagnostic Manual.

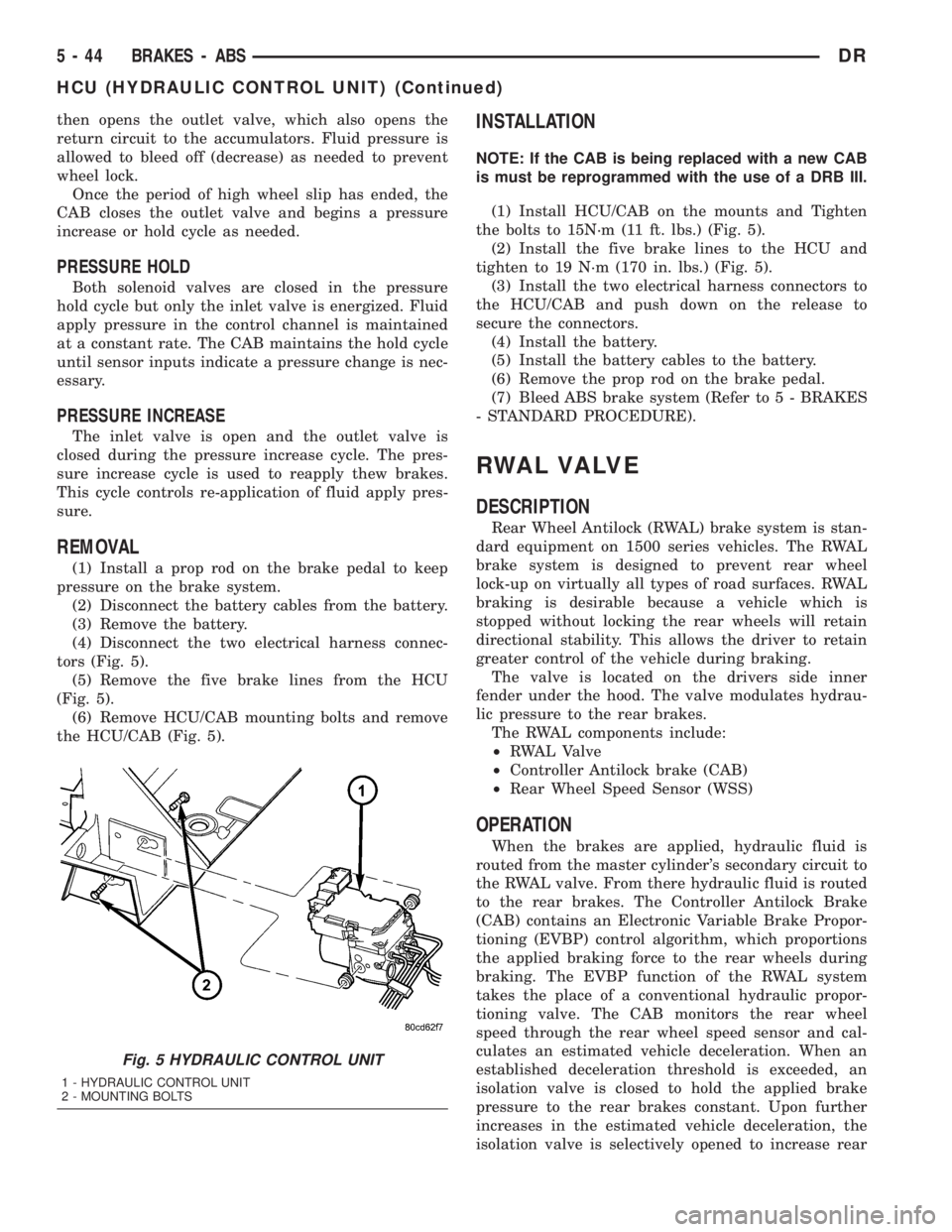

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Remove the brake line mounting nut and

remove the brake line from the sensor stud.

(3) Remove the mounting stud from the sensor and

shield (Fig. 4).

(4) Remove the sensor and shield from the differ-

ential housing.

(5) Disconnect the sensor wire harness and remove

the sensor.

Fig. 2 Data Link Connector - Typical

1 - 16±WAY DATA LINK CONNECTOR

Fig. 3 WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - HUB/BEARING

Fig. 4 REAR WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

3 - AXLE HOUSING

5 - 42 BRAKES - ABSDR

FRONT WHEEL SPEED SENSOR (Continued)

Page 270 of 2895

INSTALLATION

(1) Connect the harness to the sensor.Be sure

the seal is securely in place between the sensor

and the wiring connector.

(2) Install the O-ring on the sensor (if removed).

(3) Insert the sensor in the differential housing.

(4) Install the sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (200 in. lbs.).

(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower the vehicle.

TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the Antilock Brake system. For test proce-

dures refer to the Chassis Diagnostic Manual.

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING

Vehicles equipped with ABS use electronic variable

brake proportioning (EVBP) to balance front-to-rear

braking. The EVBP is used in place of a rear propor-

tioning valve. The EVBP system uses the ABS sys-

tem to control the slip of the rear wheels in partial

braking range. The braking force of the rear wheels

is controlled electronically by using the inlet and out-

let valves located in the integrated control unit

(ICU).

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

EVBP is able to decrease, hold and increase rear

brake pressure without activating full ABS control.

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supplyfrom the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump provides the fluid volume needed and is oper-

ated by a DC type motor. The motor is controlled by

the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

NOTE: The three modes mentioned below do occur

but not necessarily in the order listed everytime.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

DRBRAKES - ABS 5 - 43

REAR WHEEL SPEED SENSOR (Continued)

Page 271 of 2895

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

PRESSURE HOLD

Both solenoid valves are closed in the pressure

hold cycle but only the inlet valve is energized. Fluid

apply pressure in the control channel is maintained

at a constant rate. The CAB maintains the hold cycle

until sensor inputs indicate a pressure change is nec-

essary.

PRESSURE INCREASE

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle. The pres-

sure increase cycle is used to reapply thew brakes.

This cycle controls re-application of fluid apply pres-

sure.

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery.

(3) Remove the battery.

(4) Disconnect the two electrical harness connec-

tors (Fig. 5).

(5) Remove the five brake lines from the HCU

(Fig. 5).

(6) Remove HCU/CAB mounting bolts and remove

the HCU/CAB (Fig. 5).

INSTALLATION

NOTE: If the CAB is being replaced with a new CAB

is must be reprogrammed with the use of a DRB III.

(1) Install HCU/CAB on the mounts and Tighten

the bolts to 15N´m (11 ft. lbs.) (Fig. 5).

(2) Install the five brake lines to the HCU and

tighten to 19 N´m (170 in. lbs.) (Fig. 5).

(3) Install the two electrical harness connectors to

the HCU/CAB and push down on the release to

secure the connectors.

(4) Install the battery.

(5) Install the battery cables to the battery.

(6) Remove the prop rod on the brake pedal.

(7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

RWAL VALVE

DESCRIPTION

Rear Wheel Antilock (RWAL) brake system is stan-

dard equipment on 1500 series vehicles. The RWAL

brake system is designed to prevent rear wheel

lock-up on virtually all types of road surfaces. RWAL

braking is desirable because a vehicle which is

stopped without locking the rear wheels will retain

directional stability. This allows the driver to retain

greater control of the vehicle during braking.

The valve is located on the drivers side inner

fender under the hood. The valve modulates hydrau-

lic pressure to the rear brakes.

The RWAL components include:

²RWAL Valve

²Controller Antilock brake (CAB)

²Rear Wheel Speed Sensor (WSS)

OPERATION

When the brakes are applied, hydraulic fluid is

routed from the master cylinder's secondary circuit to

the RWAL valve. From there hydraulic fluid is routed

to the rear brakes. The Controller Antilock Brake

(CAB) contains an Electronic Variable Brake Propor-

tioning (EVBP) control algorithm, which proportions

the applied braking force to the rear wheels during

braking. The EVBP function of the RWAL system

takes the place of a conventional hydraulic propor-

tioning valve. The CAB monitors the rear wheel

speed through the rear wheel speed sensor and cal-

culates an estimated vehicle deceleration. When an

established deceleration threshold is exceeded, an

isolation valve is closed to hold the applied brake

pressure to the rear brakes constant. Upon further

increases in the estimated vehicle deceleration, the

isolation valve is selectively opened to increase rear

Fig. 5 HYDRAULIC CONTROL UNIT

1 - HYDRAULIC CONTROL UNIT

2 - MOUNTING BOLTS

5 - 44 BRAKES - ABSDR

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 272 of 2895

brake pressure in proportion to the front brake pres-

sure. If impending rear wheel lock-up is sensed, the

CAB signals the RWAL valve to modulate hydraulic

brake pressure to the rear wheels to prevent lock-up.

NORMAL BRAKING Since the RWAL valve also

performs the EVBP or proportioning function, vehicle

deceleration under normal braking may be sufficient

to trigger the EVBP function of the RWAL system

without full RWAL activity as would normally occur

during an impending rear wheel lock-up. As previ-

ously mentioned, the isolation valve is selectively

closed and opened to increase rear brake pressure in

proportion to the front brake pressure under EVBP

control. Slight brake pedal pulsations may be noticed

as the isolation valve is opened.

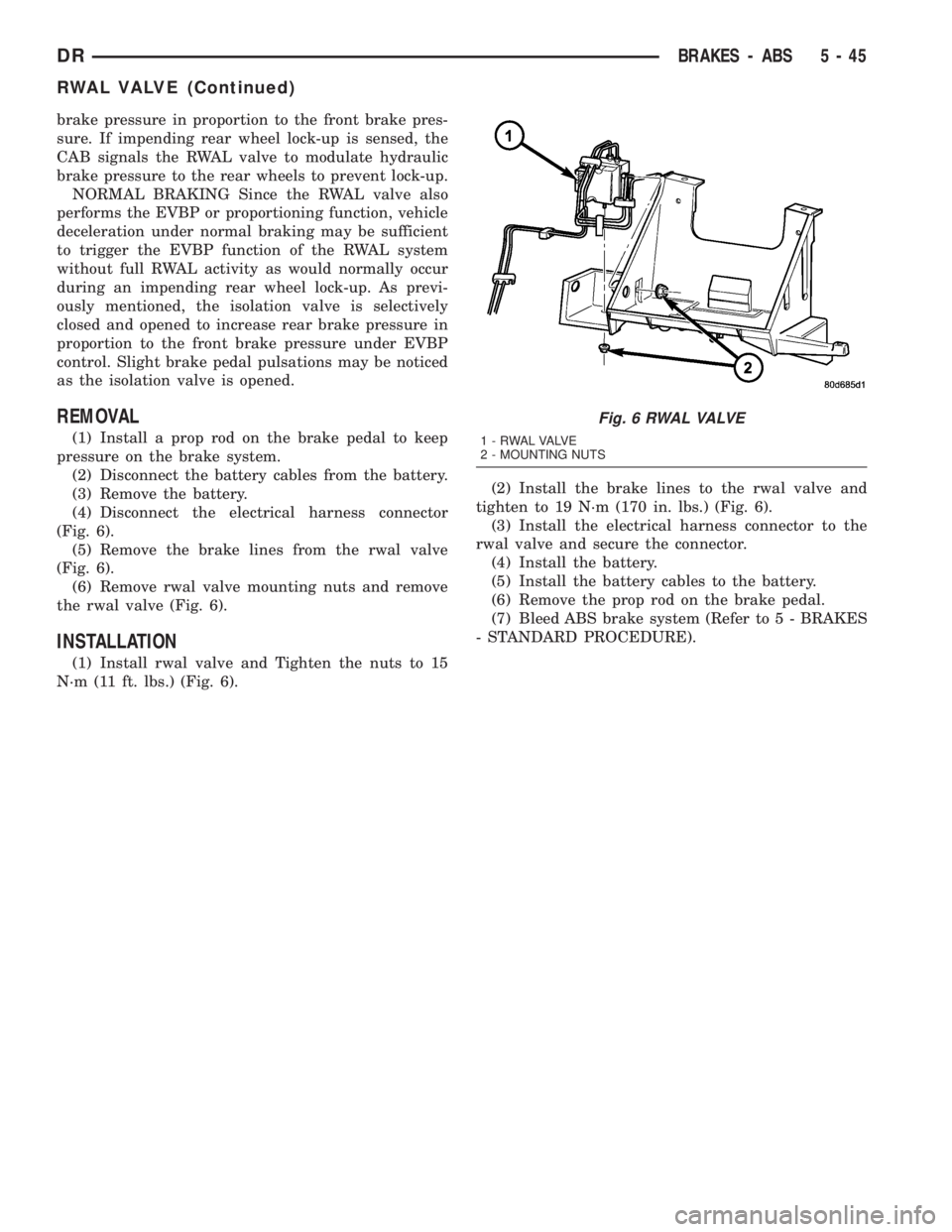

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery.

(3) Remove the battery.

(4) Disconnect the electrical harness connector

(Fig. 6).

(5) Remove the brake lines from the rwal valve

(Fig. 6).

(6) Remove rwal valve mounting nuts and remove

the rwal valve (Fig. 6).

INSTALLATION

(1) Install rwal valve and Tighten the nuts to 15

N´m (11 ft. lbs.) (Fig. 6).(2) Install the brake lines to the rwal valve and

tighten to 19 N´m (170 in. lbs.) (Fig. 6).

(3) Install the electrical harness connector to the

rwal valve and secure the connector.

(4) Install the battery.

(5) Install the battery cables to the battery.

(6) Remove the prop rod on the brake pedal.

(7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

Fig. 6 RWAL VALVE

1 - RWAL VALVE

2 - MOUNTING NUTS

DRBRAKES - ABS 5 - 45

RWAL VALVE (Continued)

Page 275 of 2895

WARNING

WARNING:: EXERCISE CARE WHEN SERVICING

CLUTCH COMPONENTS. FACTORY INSTALLED

CLUTCH DISCS DO NOT CONTAIN ASBESTOS

FIBERS. DUST AND DIRT ON CLUTCH PARTS MAY

CONTAIN ASBESTOS FIBERS FROM AFTERMAR-

KET COMPONENTS. BREATHING EXCESSIVE CON-

CENTRATIONS OF THESE FIBERS CAN CAUSE

SERIOUS BODILY HARM. WEAR A RESPIRATOR

DURING SERVICE AND NEVER CLEAN CLUTCH

COMPONENTS WITH COMPRESSED AIR OR WITH

A DRY BRUSH. EITHER CLEAN THE COMPONENTS

WITH A WATER DAMPENED RAGS OR USE A VAC-

UUM CLEANER SPECIFICALLY DESIGNED FOR

REMOVING ASBESTOS FIBERS AND DUST. DO NOT

CREATE DUST BY SANDING A CLUTCH DISC.

REPLACE THE DISC IF THE FRICTION MATERIAL IS

DAMAGED OR CONTAMINATED. DISPOSE OF ALL

DUST AND DIRT CONTAINING ASBESTOS FIBERS

IN SEALED BAGS OR CONTAINERS. THIS WILL

HELP MINIMIZE EXPOSURE TO YOURSELF AND TO

OTHERS. FOLLOW ALL RECOMMENDED SAFETY

PRACTICES PRESCRIBED BY THE OCCUPATIONAL

SAFETY AND HEALTH ADMINISTRATION (OSHA)

AND THE ENVIRONMENTAL SAFETY AGENCY(EPA), FOR THE HANDLING AND DISPOSAL OF

PRODUCTS CONTAINING ASBESTOS.

DIAGNOSIS AND TESTING

A road test and component inspection is recom-

mended to determine a clutch problem. During a

road test, drive the vehicle at normal speeds. Shift

the transmission through all gear ranges and observe

clutch action. If the clutch chatters, grabs, slips or

does not release properly, remove and inspect the

clutch components. If the problem is noise or hard

shifting, further diagnosis may be needed as the

transmission or another driveline component may be

at fault.

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, water or clutch fluid on the clutch

disc and pressure plate surfaces will cause chatter,

slip and grab. Inspect components for oil, hydraulic

fluid or water/road splash contamination.

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft. Clutch

fluid leaks are usually from damaged slave cylinder

push rod seals. Heat buildup caused by slippage

between the pressure plate, disc and flywheel can

bake the oil residue onto the components. The glaze-

like residue ranges in color from amber to black.

Road splash contamination is dirt/water entering

the clutch housing due to loose bolts, housing cracks.

Driving through deep water puddles can force water/

road splash into the housing through such openings.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems can be

caused by worn or damage clutch components. A

visual inspection of the release components will usu-

ally reveal the problem part.

Release problems can result in hard shifting and

noise. Look for leaks at the clutch cylinders and

interconnecting line and loose slave cylinder bolts.

Also worn/loose release fork, pivot stud, clutch disc,

pressure plate or release bearing.

Engagement problems can result in slip, chatter/

shudder and noisy operation. The causes may be

clutch disc contamination, wear, distortion or fly-

wheel damage. Visually inspect to determine the

actual cause of the problem.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

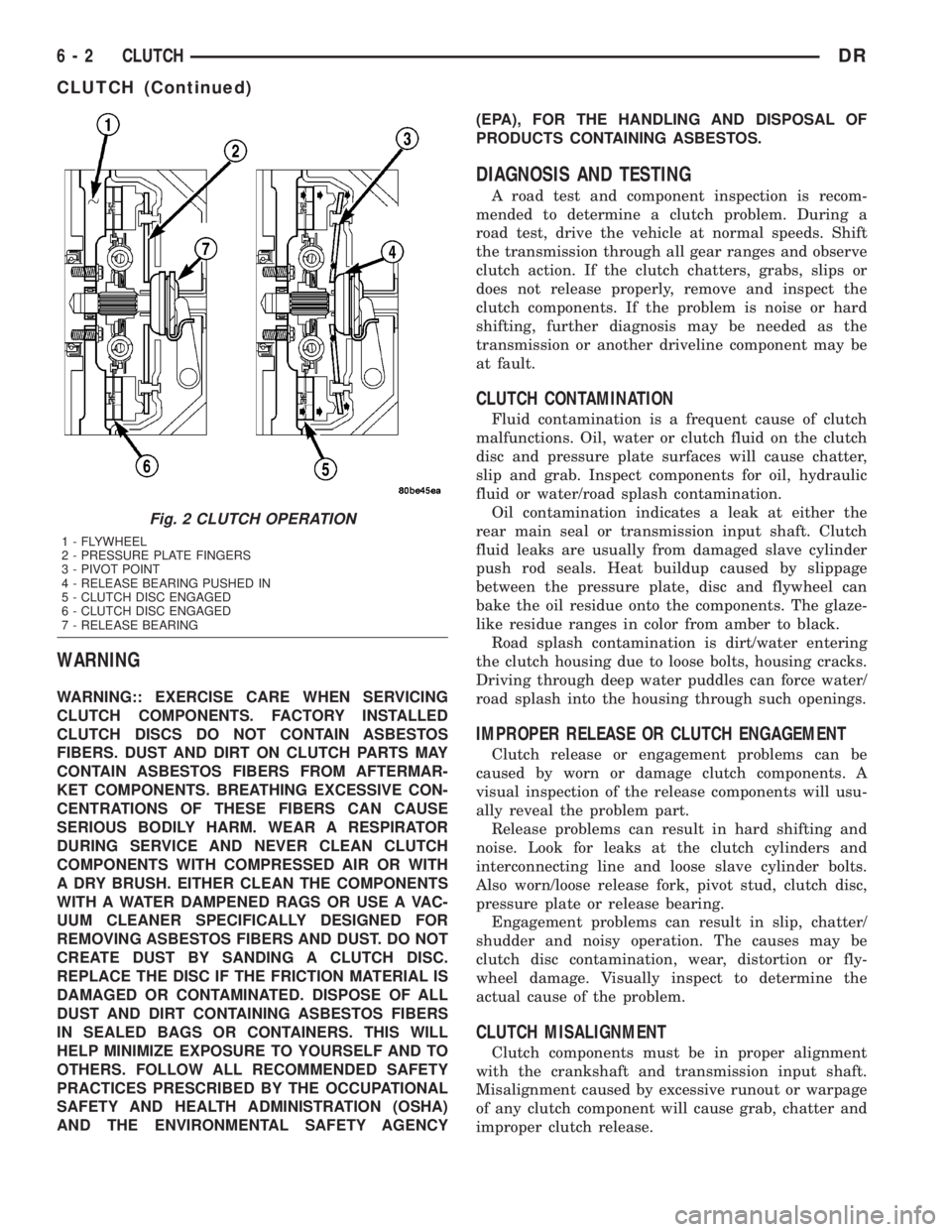

Fig. 2 CLUTCH OPERATION

1 - FLYWHEEL

2 - PRESSURE PLATE FINGERS

3 - PIVOT POINT

4 - RELEASE BEARING PUSHED IN

5 - CLUTCH DISC ENGAGED

6 - CLUTCH DISC ENGAGED

7 - RELEASE BEARING

6 - 2 CLUTCHDR

CLUTCH (Continued)

Page 292 of 2895

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

5.9L, 5.9L Diesel, and 8.0L engines utilize an

ambient overflow bottle for coolant recovery/reserve.

The 3.7L and 4.7L engines utilize a pressurized

degas bottle for coolant deaeration and reserve. This

degas bottle has coolant flowing through it continu-

ously, supplied by a vent in the hot side radiator

tank and returning to the heater return hose.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

OPERATIONÐHOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The Engine Control Module (ECM) has been pro-

grammed to monitor certain cooling system compo-

nents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.²If an open or shorted condition has developed in

the electronically controlled viscous fan clutch circuit,

a Diagnostic Trouble Code (DTC) can be set.

²If fan speed is not detected a DTC will be set.

²Coolant temperature sensor circuit problems can

set a DTC.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the ECM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the

DRBIIItscan tool to erase a DTC. Refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice information for operation of the DRBIIItscan

tool.

DIAGNOSIS AND TESTINGÐCOOLING SYSTEM

- TESTING FOR LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate the engine until the radi-

ator upper hose is warm to the touch. Aim the com-

mercially available black light tool at the components

to be checked. If leaks are present, the black light

will cause the additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if the cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inside of the filler neck and examine the

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

DRCOOLING 7 - 5

COOLING (Continued)

Page 324 of 2895

components. Also, once ethylene-glycol and propy-

lene-glycol based coolants are mixed in the vehicle,

conventional methods of determining freeze point will

not be accurate. Both the refractive index and spe-

cific gravity differ between ethylene glycol and propy-

lene glycol.

DESCRIPTION - HOAT COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE-GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE-GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene-Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene-glycol base coolant with organic corro-

sion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% ethylene-glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing ofcoolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise to as high as 149ÉC

(300ÉF). This temperature is hot enough to melt plas-

tic and soften solder. The increased temperature can

result in engine detonation. In addition, 100 percent

ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-34ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION AND ADDITIVES

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

DRENGINE 7 - 37

COOLANT (Continued)

Page 325 of 2895

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

OPERATION

Coolant flows through the engine block absorbing

the heat from the engine, then flows to the radiator

where the cooling fins in the radiator transfers the

heat from the coolant to the atmosphere. During cold

weather the ethylene-glycol or propylene-glycol cool-

ant prevents water present in the cooling system

from freezing within temperatures indicated by mix-

ture ratio of coolant to water.

COOLANT RECOVERY

CONTAINER-5.9L

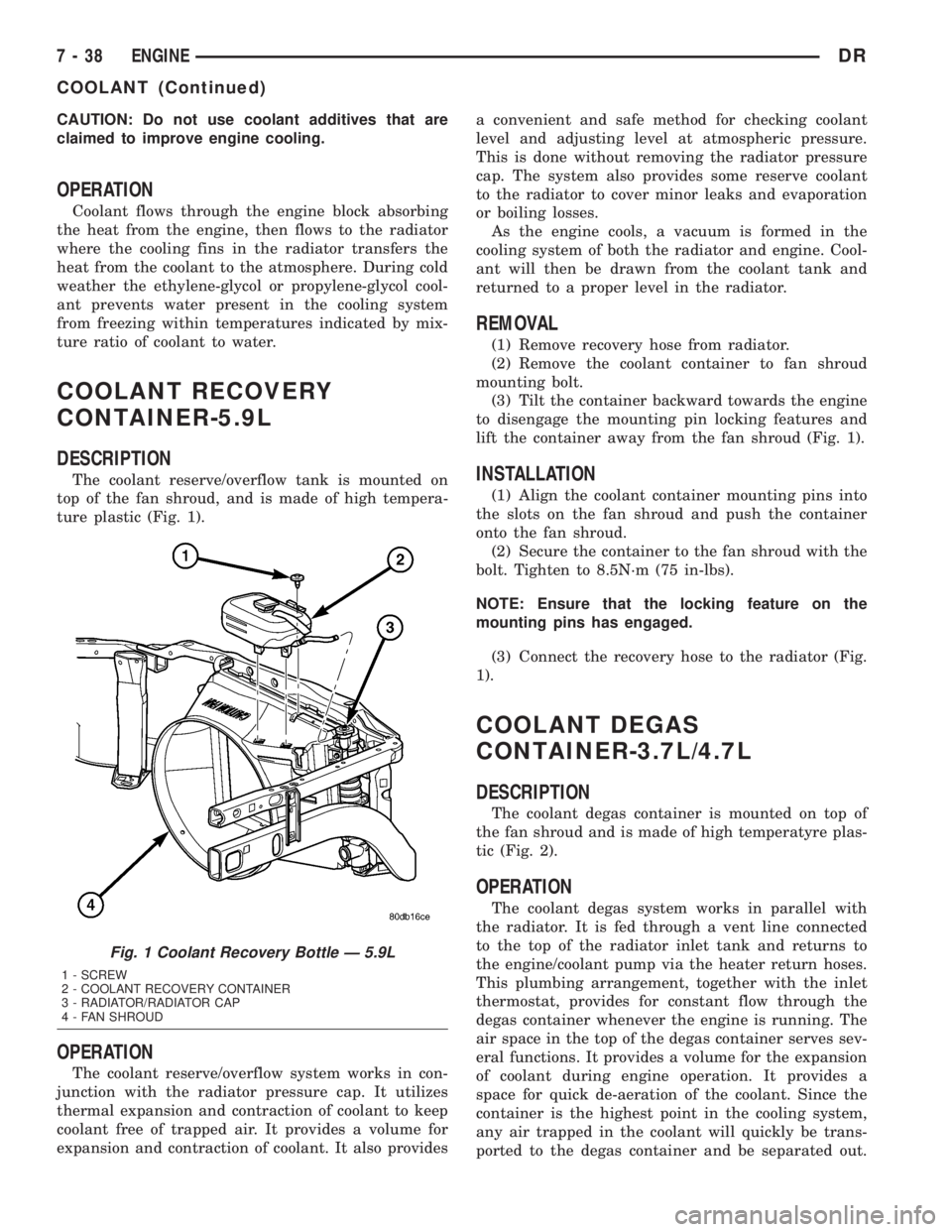

DESCRIPTION

The coolant reserve/overflow tank is mounted on

top of the fan shroud, and is made of high tempera-

ture plastic (Fig. 1).

OPERATION

The coolant reserve/overflow system works in con-

junction with the radiator pressure cap. It utilizes

thermal expansion and contraction of coolant to keep

coolant free of trapped air. It provides a volume for

expansion and contraction of coolant. It also providesa convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure.

This is done without removing the radiator pressure

cap. The system also provides some reserve coolant

to the radiator to cover minor leaks and evaporation

or boiling losses.

As the engine cools, a vacuum is formed in the

cooling system of both the radiator and engine. Cool-

ant will then be drawn from the coolant tank and

returned to a proper level in the radiator.

REMOVAL

(1) Remove recovery hose from radiator.

(2) Remove the coolant container to fan shroud

mounting bolt.

(3) Tilt the container backward towards the engine

to disengage the mounting pin locking features and

lift the container away from the fan shroud (Fig. 1).

INSTALLATION

(1) Align the coolant container mounting pins into

the slots on the fan shroud and push the container

onto the fan shroud.

(2) Secure the container to the fan shroud with the

bolt. Tighten to 8.5N´m (75 in-lbs).

NOTE: Ensure that the locking feature on the

mounting pins has engaged.

(3) Connect the recovery hose to the radiator (Fig.

1).

COOLANT DEGAS

CONTAINER-3.7L/4.7L

DESCRIPTION

The coolant degas container is mounted on top of

the fan shroud and is made of high temperatyre plas-

tic (Fig. 2).

OPERATION

The coolant degas system works in parallel with

the radiator. It is fed through a vent line connected

to the top of the radiator inlet tank and returns to

the engine/coolant pump via the heater return hoses.

This plumbing arrangement, together with the inlet

thermostat, provides for constant flow through the

degas container whenever the engine is running. The

air space in the top of the degas container serves sev-

eral functions. It provides a volume for the expansion

of coolant during engine operation. It provides a

space for quick de-aeration of the coolant. Since the

container is the highest point in the cooling system,

any air trapped in the coolant will quickly be trans-

ported to the degas container and be separated out.

Fig. 1 Coolant Recovery Bottle Ð 5.9L

1 - SCREW

2 - COOLANT RECOVERY CONTAINER

3 - RADIATOR/RADIATOR CAP

4 - FAN SHROUD

7 - 38 ENGINEDR

COOLANT (Continued)

Page 328 of 2895

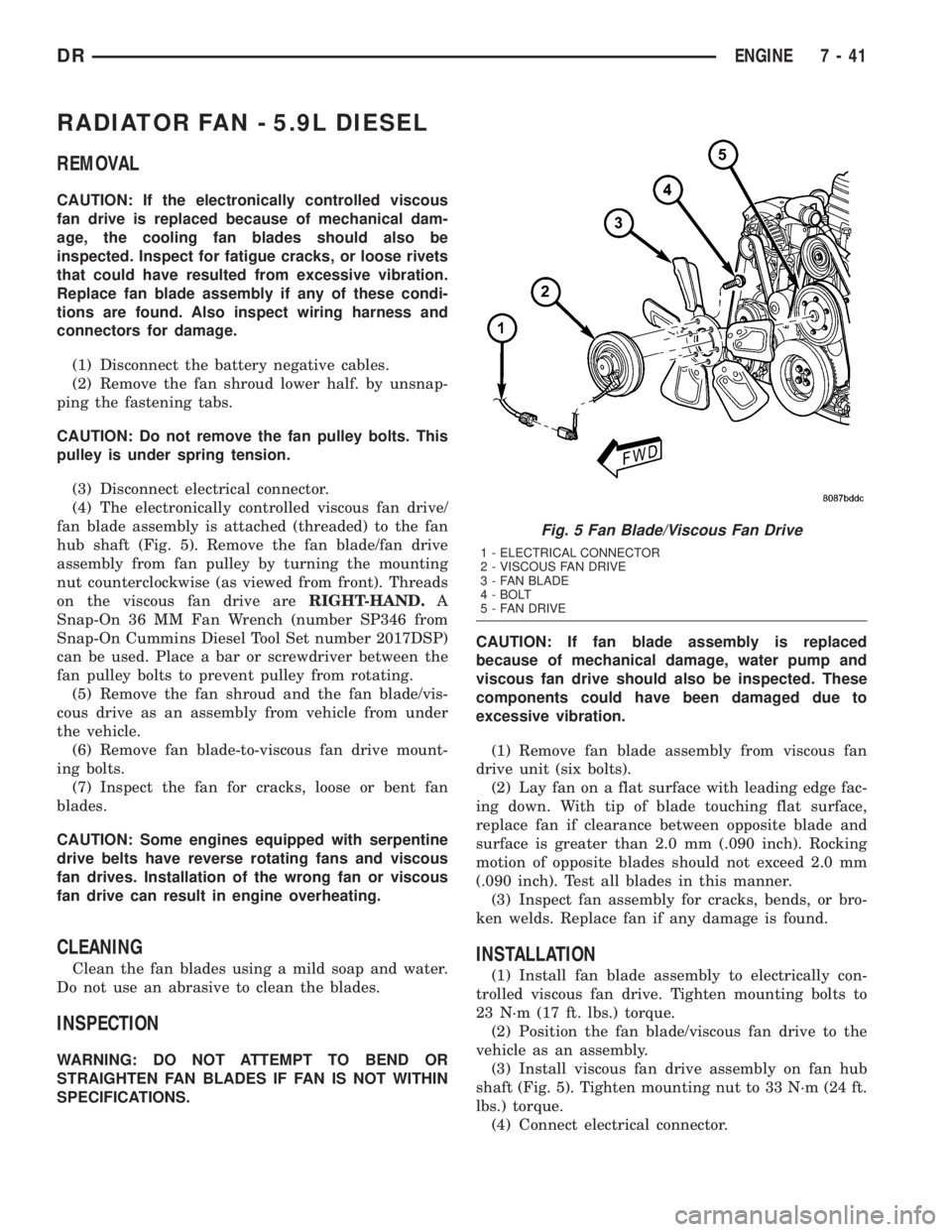

RADIATOR FAN - 5.9L DIESEL

REMOVAL

CAUTION: If the electronically controlled viscous

fan drive is replaced because of mechanical dam-

age, the cooling fan blades should also be

inspected. Inspect for fatigue cracks, or loose rivets

that could have resulted from excessive vibration.

Replace fan blade assembly if any of these condi-

tions are found. Also inspect wiring harness and

connectors for damage.

(1) Disconnect the battery negative cables.

(2) Remove the fan shroud lower half. by unsnap-

ping the fastening tabs.

CAUTION: Do not remove the fan pulley bolts. This

pulley is under spring tension.

(3) Disconnect electrical connector.

(4) The electronically controlled viscous fan drive/

fan blade assembly is attached (threaded) to the fan

hub shaft (Fig. 5). Remove the fan blade/fan drive

assembly from fan pulley by turning the mounting

nut counterclockwise (as viewed from front). Threads

on the viscous fan drive areRIGHT-HAND.A

Snap-On 36 MM Fan Wrench (number SP346 from

Snap-On Cummins Diesel Tool Set number 2017DSP)

can be used. Place a bar or screwdriver between the

fan pulley bolts to prevent pulley from rotating.

(5) Remove the fan shroud and the fan blade/vis-

cous drive as an assembly from vehicle from under

the vehicle.

(6) Remove fan blade-to-viscous fan drive mount-

ing bolts.

(7) Inspect the fan for cracks, loose or bent fan

blades.

CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. Installation of the wrong fan or viscous

fan drive can result in engine overheating.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (six bolts).

(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, or bro-

ken welds. Replace fan if any damage is found.

INSTALLATION

(1) Install fan blade assembly to electrically con-

trolled viscous fan drive. Tighten mounting bolts to

23 N´m (17 ft. lbs.) torque.

(2) Position the fan blade/viscous fan drive to the

vehicle as an assembly.

(3) Install viscous fan drive assembly on fan hub

shaft (Fig. 5). Tighten mounting nut to 33 N´m (24 ft.

lbs.) torque.

(4) Connect electrical connector.

Fig. 5 Fan Blade/Viscous Fan Drive

1 - ELECTRICAL CONNECTOR

2 - VISCOUS FAN DRIVE

3 - FAN BLADE

4 - BOLT

5 - FAN DRIVE

DRENGINE 7 - 41