steering DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 266 of 2895

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................39

OPERATION...........................39

STANDARD PROCEDURE - ABS BRAKE

BLEEDING...........................40

SPECIFICATIONS

TORQUE CHART......................40

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................42

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK...........................42

REMOVAL.............................42

INSTALLATION.........................43

TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR......................43HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............43

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............43

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................44

INSTALLATION.........................44

R WA L VA LV E

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................45

INSTALLATION.........................45

BRAKES - ABS

DESCRIPTION

The antilock brake system (ABS) is an electroni-

cally operated, three channel brake control system.

The vehicle has Electronic Variable Brake Propor-

tioning (EVBP) designed into the system which elim-

inates the combination/proportioning valve.

The system is designed to prevent wheel lockup

and maintain steering control during braking. Pre-

venting lockup is accomplished by modulating fluid

pressure to the wheel brake units.

The hydraulic system is a three channel design.

The front wheel brakes are controlled individually

and the rear wheel brakes in tandem. The ABS elec-

trical system is separate from other electrical circuits

in the vehicle. A specially programmed controller

antilock brake unit operates the system components.

ABS system major components include:

²Controller Antilock Brakes (CAB)

²Hydraulic Control Unit (HCU)

²Wheel Speed Sensors (WSS)

²ABS Warning Light

OPERATION

Battery voltage is supplied to the CAB. The CAB

performs a system initialization procedure at start

up. A check of the ABS motor is performed at 15

miles per hour. Initialization consists of a static and

dynamic self check of system electrical components.

The static and dynamic checks occurs at ignition

start up. During the dynamic check, the CAB briefly

cycles solenoids to verify operation. An audible noise

may be heard during this self check. This noise

should be considered normal. The ABS motor and

pump are then checked at a speed of 15 mile per

hour.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

The CAB monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the CAB will not activate any ABS components as

long as sensor inputs indicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

DRBRAKES - ABS 5 - 39

Page 267 of 2895

The purpose of the antilock system is to prevent

wheel lockup. Preventing lockup helps maintain vehi-

cle braking action and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip.

The antilock system prevents lockup during a

wheel slip condition by modulating fluid apply pres-

sure to the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve is energized

which acts to prevent further pressure build-up tothe calipers. Then the Dump valve dumps off pres-

sure until the wheel unlocks. This will continue until

the wheels quit slipping altogether.

STANDARD PROCEDURE - ABS BRAKE

BLEEDING

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time,(Re-

fer to 5 - BRAKES - STANDARD PROCEDURE) OR

(Refer to 5 - BRAKES - STANDARD PROCEDURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

ABS Assembly

Mounting Bolts15 11 Ð

ABS Assembly

CAB Screws3.5 Ð 31

ABS Assembly

Brake Line Fittings19 Ð 170

Wheel Speed Sensors

Front Sensor Bolt21 Ð 190

Wheel Speed Sensors

Bracket To Knuckle6.7 Ð 60

Wheel Speed Sensors

Rear Sensor Stud22.5 Ð 200

Controller

Mounting Screws6Ð53

RWAL Module

Mounting Bolts15 11 Ð

5 - 40 BRAKES - ABSDR

BRAKES - ABS (Continued)

Page 268 of 2895

DESCRIPTION N´m Ft. Lbs. In. Lbs.

RWAL Valve

Brake Line Fittings19 Ð 170

Rear Wheel Speed Sensor

Mounting Bolt24 Ð 200

FRONT WHEEL SPEED

SENSOR

DESCRIPTION

The ABS brake system uses 3 wheel speed sensors.

A sensor is mounted to each front hub/bearings. The

third sensor is mounted on top of the rear axle dif-

ferential housing.

OPERATION

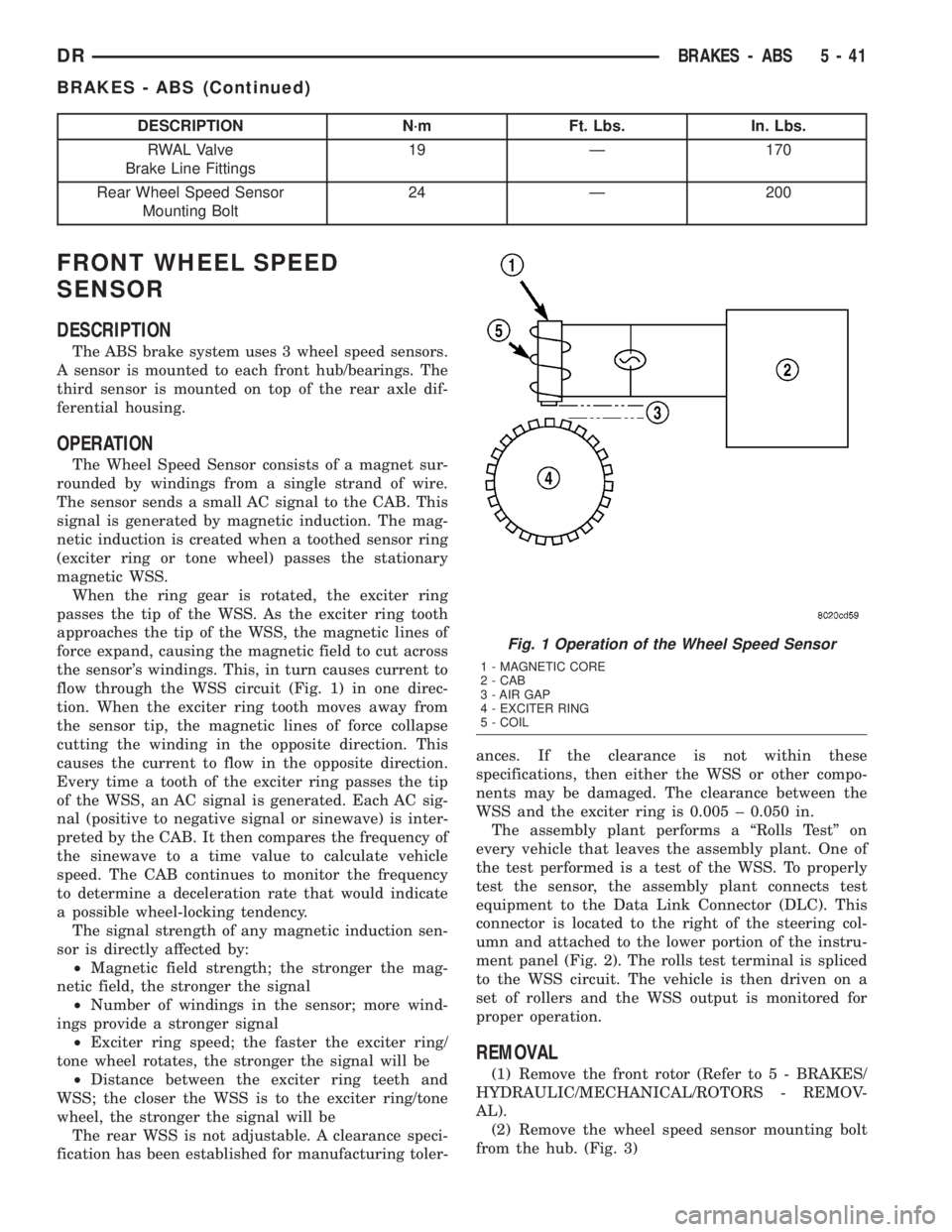

The Wheel Speed Sensor consists of a magnet sur-

rounded by windings from a single strand of wire.

The sensor sends a small AC signal to the CAB. This

signal is generated by magnetic induction. The mag-

netic induction is created when a toothed sensor ring

(exciter ring or tone wheel) passes the stationary

magnetic WSS.

When the ring gear is rotated, the exciter ring

passes the tip of the WSS. As the exciter ring tooth

approaches the tip of the WSS, the magnetic lines of

force expand, causing the magnetic field to cut across

the sensor's windings. This, in turn causes current to

flow through the WSS circuit (Fig. 1) in one direc-

tion. When the exciter ring tooth moves away from

the sensor tip, the magnetic lines of force collapse

cutting the winding in the opposite direction. This

causes the current to flow in the opposite direction.

Every time a tooth of the exciter ring passes the tip

of the WSS, an AC signal is generated. Each AC sig-

nal (positive to negative signal or sinewave) is inter-

preted by the CAB. It then compares the frequency of

the sinewave to a time value to calculate vehicle

speed. The CAB continues to monitor the frequency

to determine a deceleration rate that would indicate

a possible wheel-locking tendency.

The signal strength of any magnetic induction sen-

sor is directly affected by:

²Magnetic field strength; the stronger the mag-

netic field, the stronger the signal

²Number of windings in the sensor; more wind-

ings provide a stronger signal

²Exciter ring speed; the faster the exciter ring/

tone wheel rotates, the stronger the signal will be

²Distance between the exciter ring teeth and

WSS; the closer the WSS is to the exciter ring/tone

wheel, the stronger the signal will be

The rear WSS is not adjustable. A clearance speci-

fication has been established for manufacturing toler-ances. If the clearance is not within these

specifications, then either the WSS or other compo-

nents may be damaged. The clearance between the

WSS and the exciter ring is 0.005 ± 0.050 in.

The assembly plant performs a ªRolls Testº on

every vehicle that leaves the assembly plant. One of

the test performed is a test of the WSS. To properly

test the sensor, the assembly plant connects test

equipment to the Data Link Connector (DLC). This

connector is located to the right of the steering col-

umn and attached to the lower portion of the instru-

ment panel (Fig. 2). The rolls test terminal is spliced

to the WSS circuit. The vehicle is then driven on a

set of rollers and the WSS output is monitored for

proper operation.

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - REMOV-

AL).

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

Fig. 1 Operation of the Wheel Speed Sensor

1 - MAGNETIC CORE

2 - CAB

3 - AIR GAP

4 - EXCITER RING

5 - COIL

DRBRAKES - ABS 5 - 41

BRAKES - ABS (Continued)

Page 307 of 2895

WARNING: DO NOT REMOVE OR LOOSEN THE

RADIATOR CAP WITH THE COOLING SYSTEM HOT

AND UNDER PRESSURE. SERIOUS BURNS FROM

THE COOLANT OR HIGH PRESSURE STEAM CAN

OCCUR.

For 3.7L / 4.7L/5.9L engines, remove the radiator

cap from the coolant degas bottle to add coolant.

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Automatic Belt Tensioner to

BlockÐBolts 41 30 Ð

Automatic Belt Tensioner

PulleyÐBolt 61 45 Ð

Block HeaterÐBolt 2 Ð 17

Generator/Compressor

Mounting BracketÐBolts

# 1 and 2 54 40 Ð

# 3 40 30 Ð

Fan Shroud to Radiator

MountingÐBolts6Ð55

Radiator to Support - Bolts 8.5 Ð 75

Fan Blade to Viscous Fan

DriveÐBolts24 18 Ð

Idler PulleyÐBolt 54 40 Ð

Thermostat HousingÐBolts

- All Except 5.9L13 Ð 112

Thermostat HousingÐBolts

- 5.9L23 16 Ð

Power Steering Oil Cooler

Ð Bolts6Ð55

Transmission Auxiliary Oil

CoolerÐBolts 6 Ð 55

Transmission Oil Cooler

Tube Nuts31.5 24 Ð

Coolant Bottle Ð Bolts 8.5 Ð 75

Transmission Oil Cooler to

Transmission - 5.9L/46RE -

Tube Nuts 31.5 24 Ð

Transmission Oil Cooler to

Transmission - 3.7L/4.7L/

45RFE - Tube Nuts20 18 Ð

Water PumpÐBolts 24 18 Ð

Water Pump Ð Bolts - 4.7L 58 43 Ð

SPECIFICATIONS -

SPECIFICATIONS

DESCRIPTION SPECIFICATION

3.7/4.7L Engine 15.4L (16.2 qts.)- to the

middle of the cold fill

range

5.7L Engine 15.4L (16.2 qts.)- to the

middle of the cold fill

range

5.9L Engine 15.5L (16.3 qts.)- to the

MIN mark after 3 warm

up, cool down cycles

8.0L Engine 24L (25.3 qts.)

5.9L Diesel Engine 28L (29.5 qts.)

SPECIAL TOOLS

COOLING

Pliers Constant Pressure Hose Clamp - 6094

3/8º Quick Connect Release Tool - 6935

SPANNER WRENCHÐ6958

7 - 20 COOLINGDR

COOLING (Continued)

Page 309 of 2895

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

BELT TENSIONERS - 3.7L / 4.7L

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

BELT TENSIONERS - 5.9L

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................24

BELT TENSIONERS - 5.9L DIESEL

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................25

INSTALLATION.........................25DRIVE BELTS - 3.7L / 4.7L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................25

REMOVAL.............................27

INSTALLATION.........................27

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................28

REMOVAL.............................30

INSTALLATION.........................31

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT.........................31

REMOVAL.............................34

INSTALLATION.........................34

BELT TENSIONERS - 3.7L /

4.7L

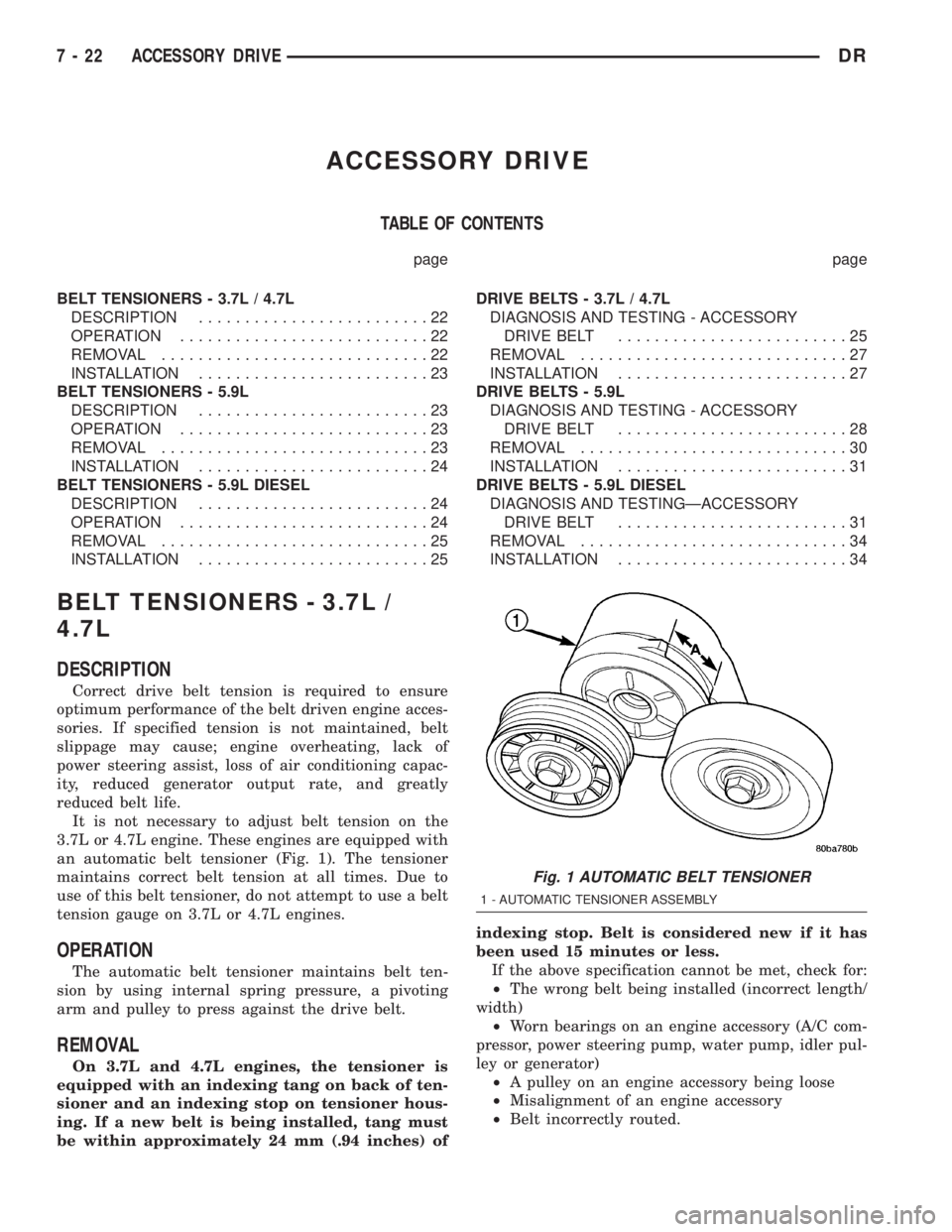

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

It is not necessary to adjust belt tension on the

3.7L or 4.7L engine. These engines are equipped with

an automatic belt tensioner (Fig. 1). The tensioner

maintains correct belt tension at all times. Due to

use of this belt tensioner, do not attempt to use a belt

tension gauge on 3.7L or 4.7L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

On 3.7L and 4.7L engines, the tensioner is

equipped with an indexing tang on back of ten-

sioner and an indexing stop on tensioner hous-

ing. If a new belt is being installed, tang must

be within approximately 24 mm (.94 inches) ofindexing stop. Belt is considered new if it has

been used 15 minutes or less.

If the above specification cannot be met, check for:

²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

Fig. 1 AUTOMATIC BELT TENSIONER

1 - AUTOMATIC TENSIONER ASSEMBLY

7 - 22 ACCESSORY DRIVEDR

Page 310 of 2895

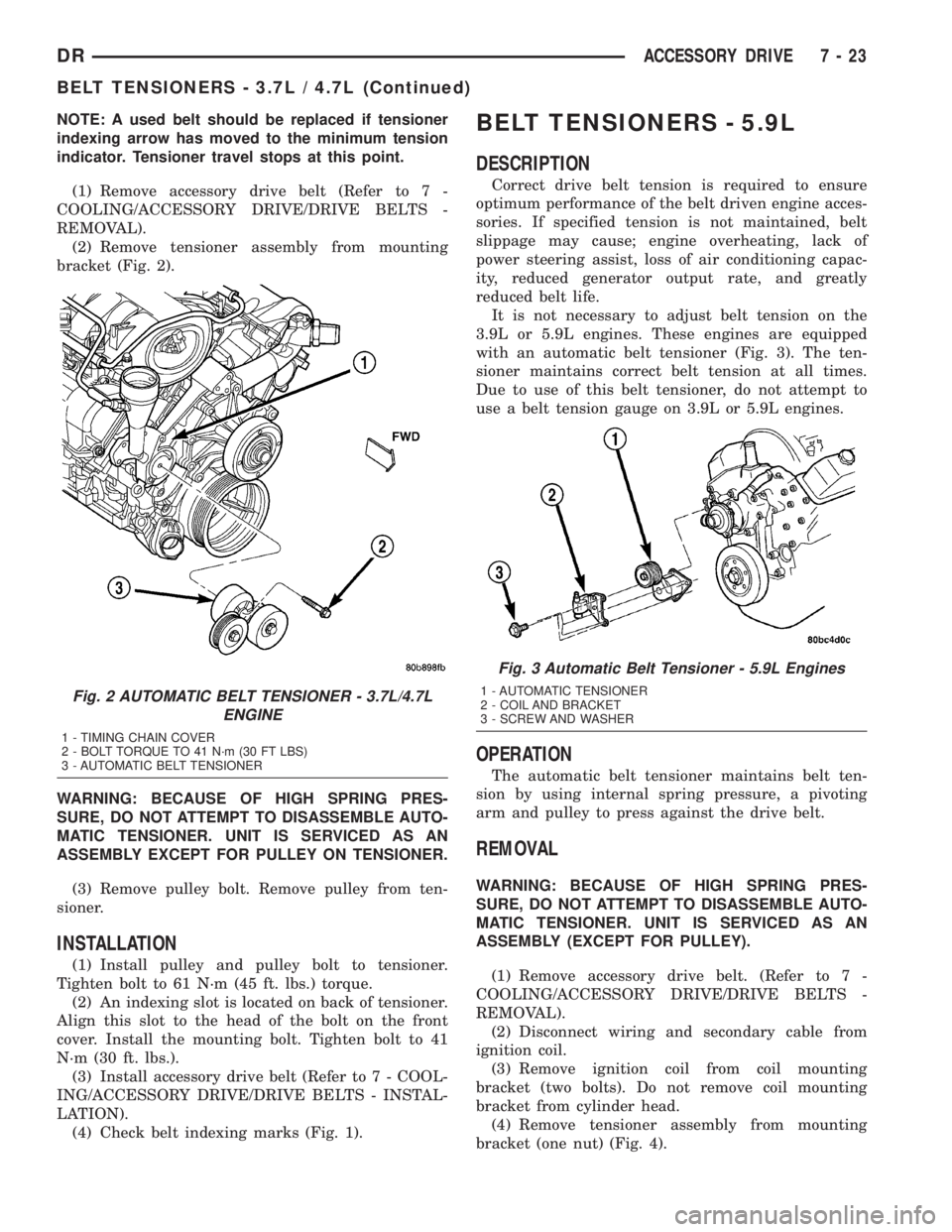

NOTE: A used belt should be replaced if tensioner

indexing arrow has moved to the minimum tension

indicator. Tensioner travel stops at this point.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner assembly from mounting

bracket (Fig. 2).

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY EXCEPT FOR PULLEY ON TENSIONER.

(3) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) An indexing slot is located on back of tensioner.

Align this slot to the head of the bolt on the front

cover. Install the mounting bolt. Tighten bolt to 41

N´m (30 ft. lbs.).

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Check belt indexing marks (Fig. 1).

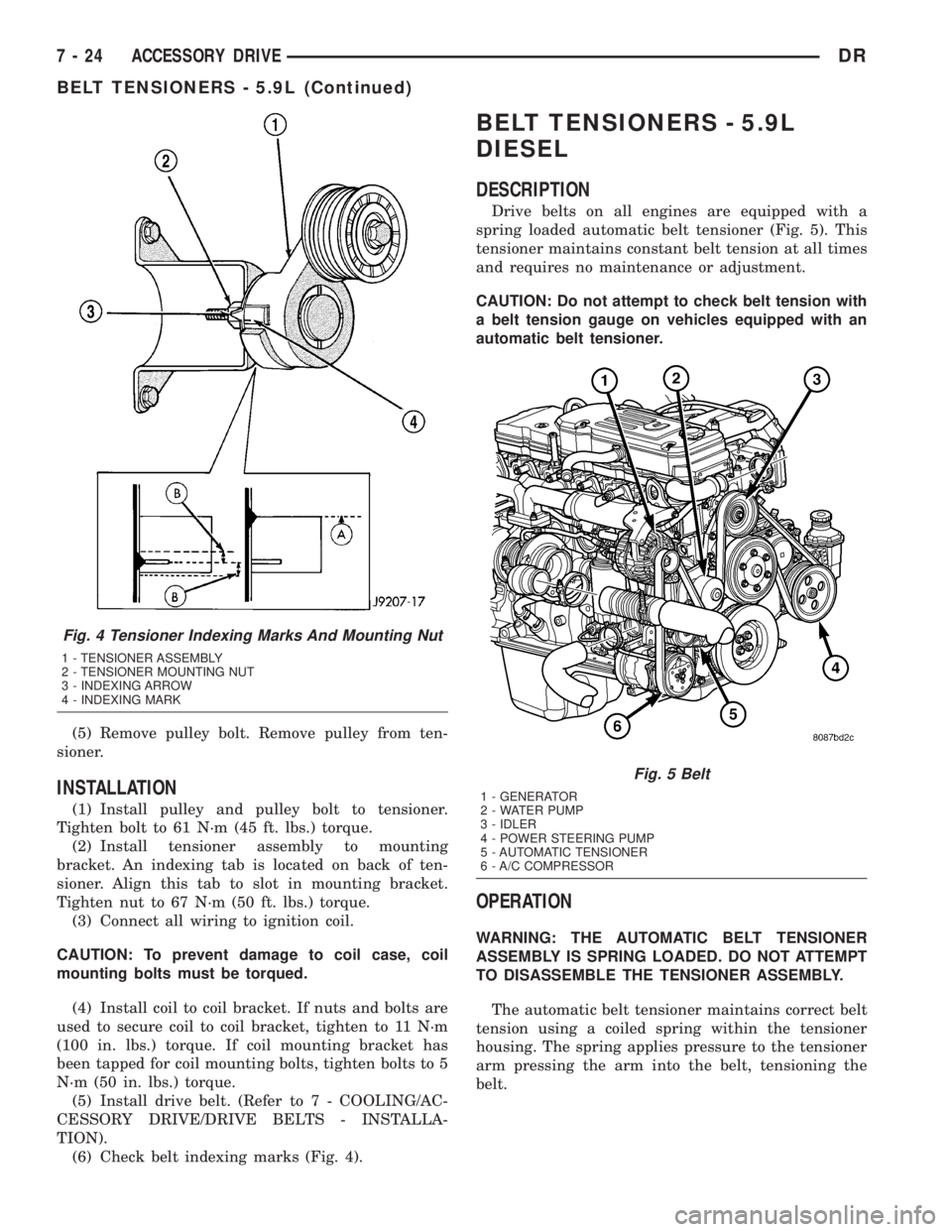

BELT TENSIONERS - 5.9L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

It is not necessary to adjust belt tension on the

3.9L or 5.9L engines. These engines are equipped

with an automatic belt tensioner (Fig. 3). The ten-

sioner maintains correct belt tension at all times.

Due to use of this belt tensioner, do not attempt to

use a belt tension gauge on 3.9L or 5.9L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

(1) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Disconnect wiring and secondary cable from

ignition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts). Do not remove coil mounting

bracket from cylinder head.

(4) Remove tensioner assembly from mounting

bracket (one nut) (Fig. 4).

Fig. 2 AUTOMATIC BELT TENSIONER - 3.7L/4.7L

ENGINE

1 - TIMING CHAIN COVER

2 - BOLT TORQUE TO 41 N´m (30 FT LBS)

3 - AUTOMATIC BELT TENSIONER

Fig. 3 Automatic Belt Tensioner - 5.9L Engines

1 - AUTOMATIC TENSIONER

2 - COIL AND BRACKET

3 - SCREW AND WASHER

DRACCESSORY DRIVE 7 - 23

BELT TENSIONERS - 3.7L / 4.7L (Continued)

Page 311 of 2895

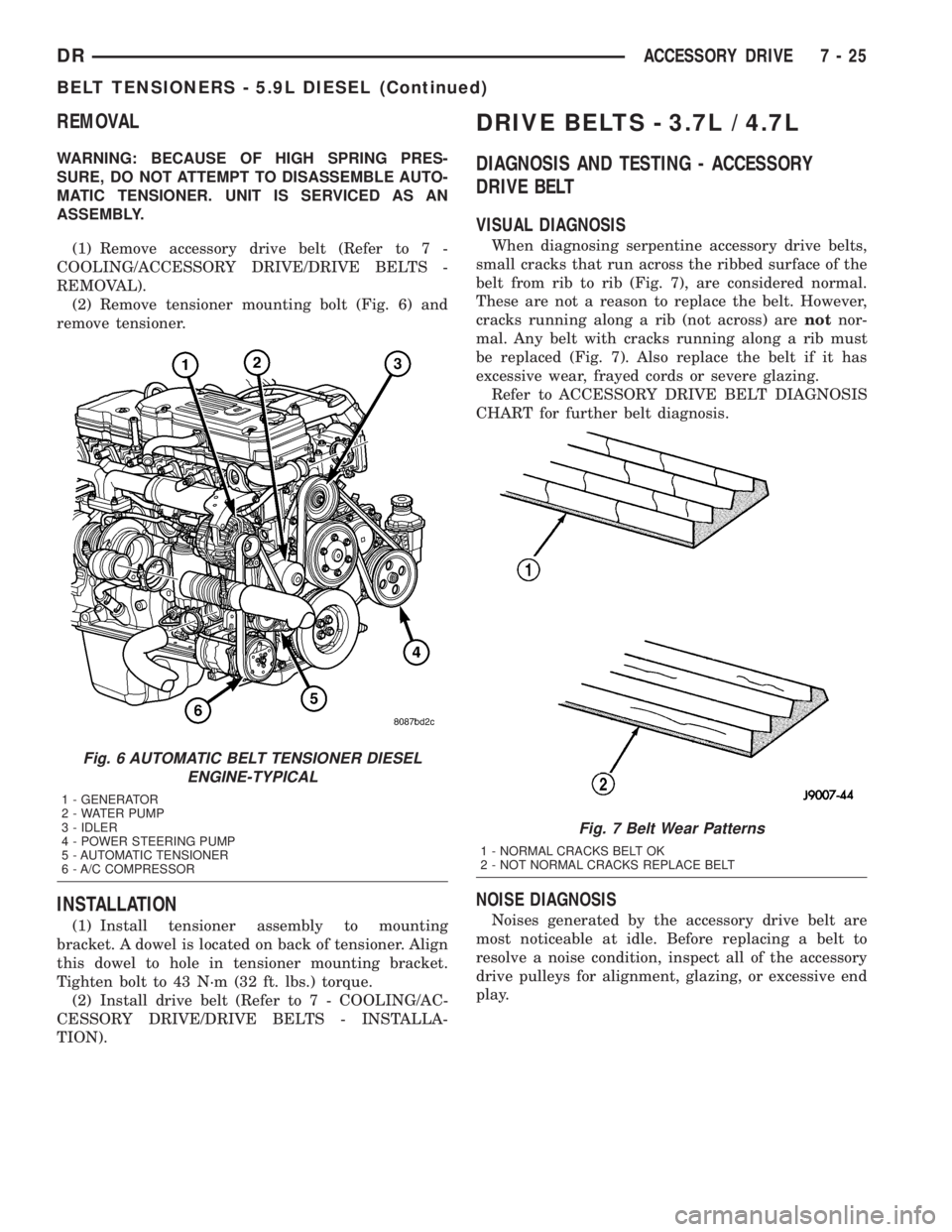

(5) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) Install tensioner assembly to mounting

bracket. An indexing tab is located on back of ten-

sioner. Align this tab to slot in mounting bracket.

Tighten nut to 67 N´m (50 ft. lbs.) torque.

(3) Connect all wiring to ignition coil.

CAUTION: To prevent damage to coil case, coil

mounting bolts must be torqued.

(4) Install coil to coil bracket. If nuts and bolts are

used to secure coil to coil bracket, tighten to 11 N´m

(100 in. lbs.) torque. If coil mounting bracket has

been tapped for coil mounting bolts, tighten bolts to 5

N´m (50 in. lbs.) torque.

(5) Install drive belt. (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(6) Check belt indexing marks (Fig. 4).

BELT TENSIONERS - 5.9L

DIESEL

DESCRIPTION

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 5). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

Fig. 4 Tensioner Indexing Marks And Mounting Nut

1 - TENSIONER ASSEMBLY

2 - TENSIONER MOUNTING NUT

3 - INDEXING ARROW

4 - INDEXING MARK

Fig. 5 Belt

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - AUTOMATIC TENSIONER

6 - A/C COMPRESSOR

7 - 24 ACCESSORY DRIVEDR

BELT TENSIONERS - 5.9L (Continued)

Page 312 of 2895

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner mounting bolt (Fig. 6) and

remove tensioner.

INSTALLATION

(1) Install tensioner assembly to mounting

bracket. A dowel is located on back of tensioner. Align

this dowel to hole in tensioner mounting bracket.

Tighten bolt to 43 N´m (32 ft. lbs.) torque.

(2) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

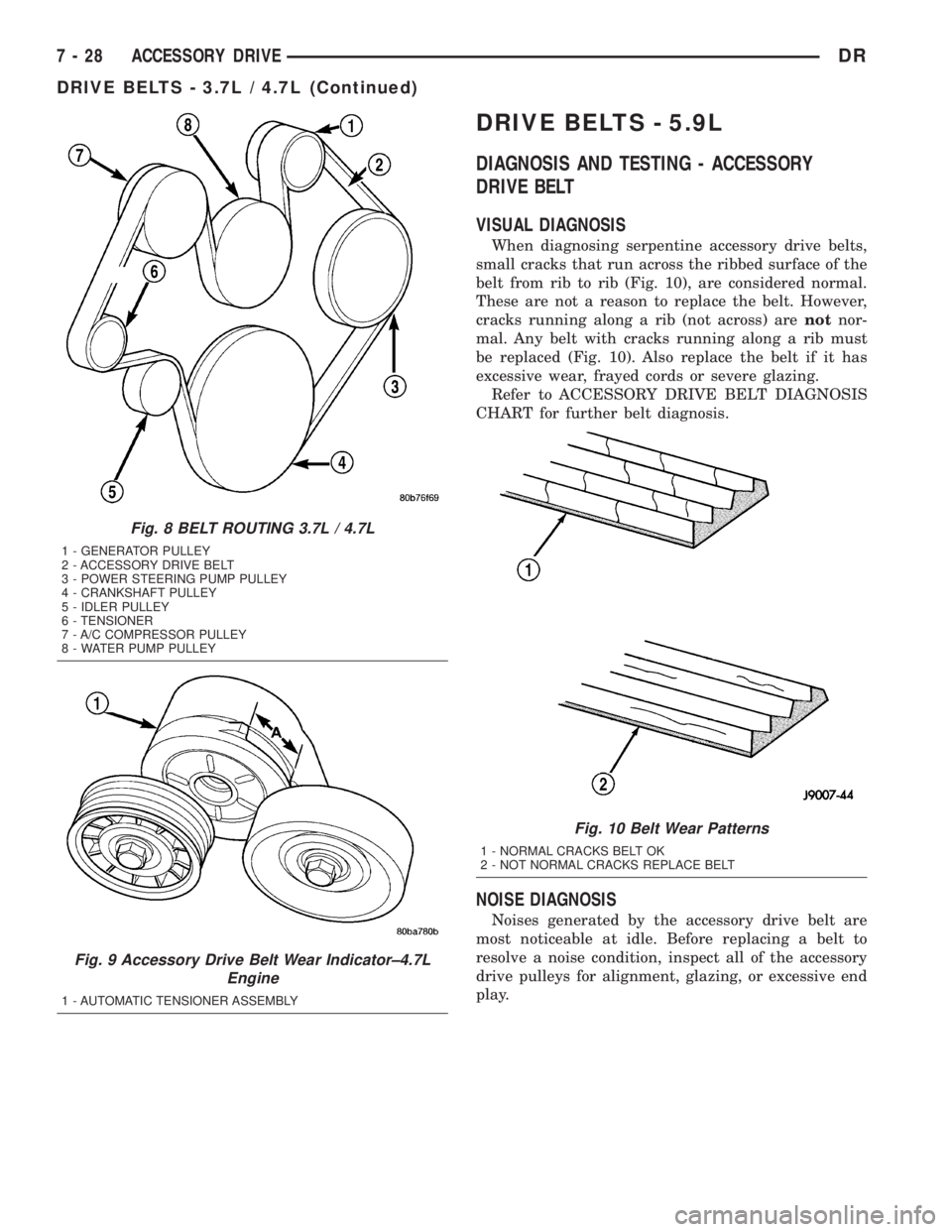

DRIVE BELTS - 3.7L / 4.7L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 7), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 7). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

Fig. 6 AUTOMATIC BELT TENSIONER DIESEL

ENGINE-TYPICAL

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - AUTOMATIC TENSIONER

6 - A/C COMPRESSOR

Fig. 7 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

DRACCESSORY DRIVE 7 - 25

BELT TENSIONERS - 5.9L DIESEL (Continued)

Page 315 of 2895

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 10), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 10). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

Fig. 8 BELT ROUTING 3.7L / 4.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

Fig. 9 Accessory Drive Belt Wear Indicator±4.7L

Engine

1 - AUTOMATIC TENSIONER ASSEMBLY

Fig. 10 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 28 ACCESSORY DRIVEDR

DRIVE BELTS - 3.7L / 4.7L (Continued)

Page 317 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

NOISE

(Objectionable squeal, squeak, or

rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

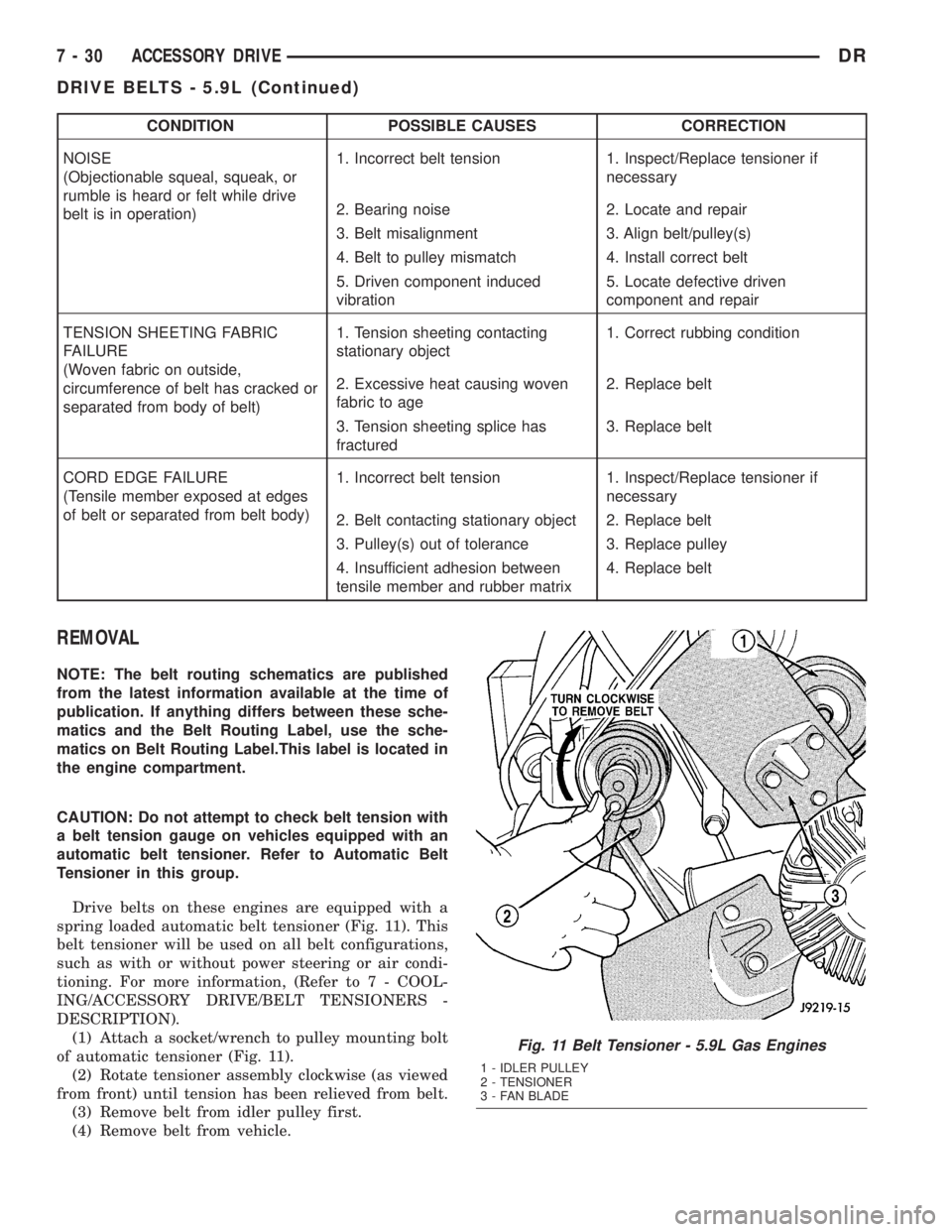

REMOVAL

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 11). This

belt tensioner will be used on all belt configurations,

such as with or without power steering or air condi-

tioning. For more information, (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELT TENSIONERS -

DESCRIPTION).

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 11).

(2) Rotate tensioner assembly clockwise (as viewed

from front) until tension has been relieved from belt.

(3) Remove belt from idler pulley first.

(4) Remove belt from vehicle.

Fig. 11 Belt Tensioner - 5.9L Gas Engines

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

7 - 30 ACCESSORY DRIVEDR

DRIVE BELTS - 5.9L (Continued)