dead battery DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 408 of 2895

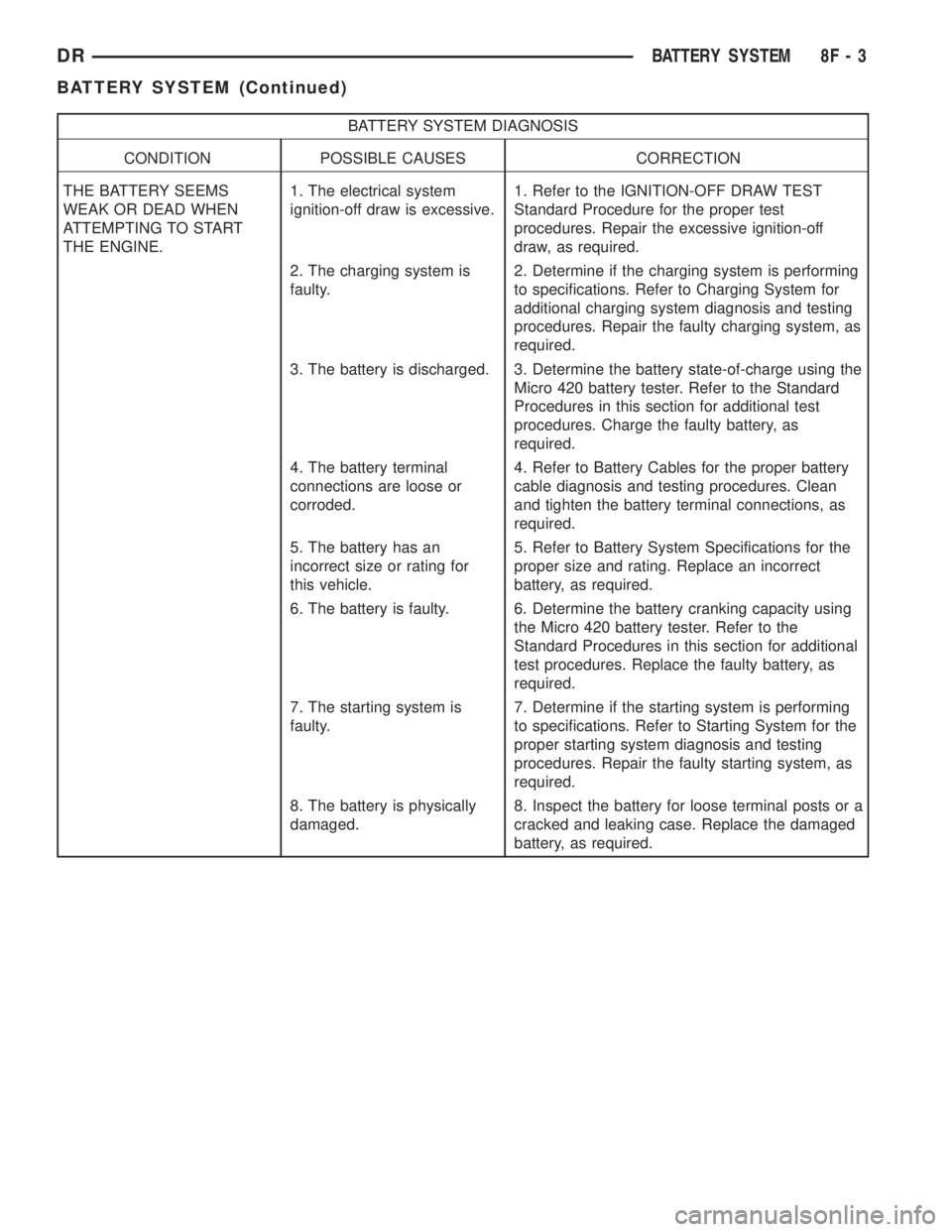

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY SEEMS

WEAK OR DEAD WHEN

ATTEMPTING TO START

THE ENGINE.1. The electrical system

ignition-off draw is excessive.1. Refer to the IGNITION-OFF DRAW TEST

Standard Procedure for the proper test

procedures. Repair the excessive ignition-off

draw, as required.

2. The charging system is

faulty.2. Determine if the charging system is performing

to specifications. Refer to Charging System for

additional charging system diagnosis and testing

procedures. Repair the faulty charging system, as

required.

3. The battery is discharged. 3. Determine the battery state-of-charge using the

Micro 420 battery tester. Refer to the Standard

Procedures in this section for additional test

procedures. Charge the faulty battery, as

required.

4. The battery terminal

connections are loose or

corroded.4. Refer to Battery Cables for the proper battery

cable diagnosis and testing procedures. Clean

and tighten the battery terminal connections, as

required.

5. The battery has an

incorrect size or rating for

this vehicle.5. Refer to Battery System Specifications for the

proper size and rating. Replace an incorrect

battery, as required.

6. The battery is faulty. 6. Determine the battery cranking capacity using

the Micro 420 battery tester. Refer to the

Standard Procedures in this section for additional

test procedures. Replace the faulty battery, as

required.

7. The starting system is

faulty.7. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

8. The battery is physically

damaged.8. Inspect the battery for loose terminal posts or a

cracked and leaking case. Replace the damaged

battery, as required.

DRBATTERY SYSTEM 8F - 3

BATTERY SYSTEM (Continued)

Page 474 of 2895

REMOVAL

CAUTION: Base ignition timing is not adjustable on

any engine. Distributors do not have built in centrif-

ugal or vacuum assisted advance. Base ignition

timing and timing advance are controlled by the

Powertrain Control Module (PCM). Because a con-

ventional timing light can not be used to adjust dis-

tributor position after installation, note position of

distributor before removal.

(1) Disconnect negative cable from battery.

(2) Remove air cleaner tubing.

(3) Remove distributor cap from distributor (two

screws).

(4) Mark the position of distributor housing in

relationship to engine or dash panel. This is done to

aid in installation.

(5) Before distributor is removed, the number one

cylinder must be brought to the Top Dead Center

(TDC) firing position.

(6) Attach a socket to the Crankshaft Vibration

Damper mounting bolt.

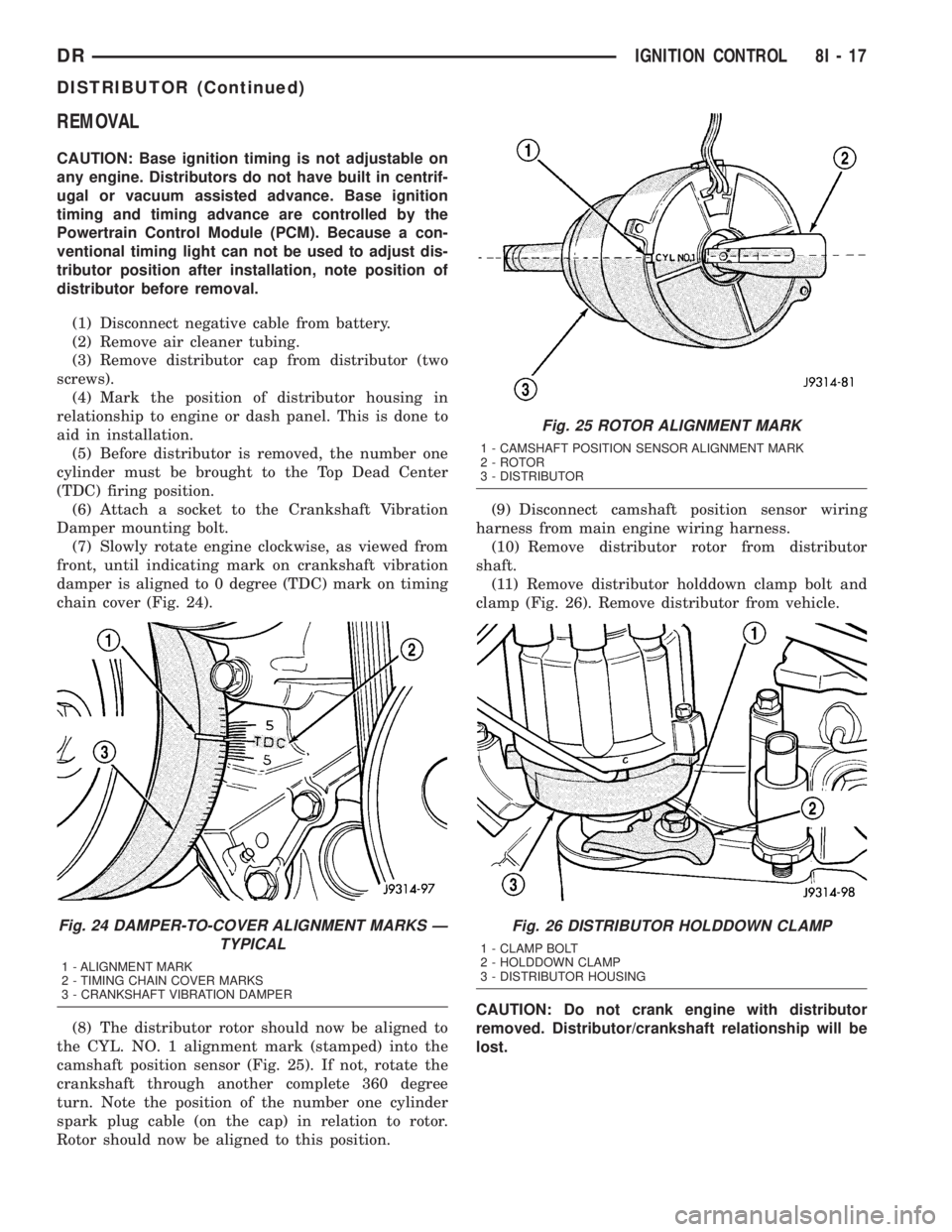

(7) Slowly rotate engine clockwise, as viewed from

front, until indicating mark on crankshaft vibration

damper is aligned to 0 degree (TDC) mark on timing

chain cover (Fig. 24).

(8) The distributor rotor should now be aligned to

the CYL. NO. 1 alignment mark (stamped) into the

camshaft position sensor (Fig. 25). If not, rotate the

crankshaft through another complete 360 degree

turn. Note the position of the number one cylinder

spark plug cable (on the cap) in relation to rotor.

Rotor should now be aligned to this position.(9) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(10) Remove distributor rotor from distributor

shaft.

(11) Remove distributor holddown clamp bolt and

clamp (Fig. 26). Remove distributor from vehicle.

CAUTION: Do not crank engine with distributor

removed. Distributor/crankshaft relationship will be

lost.

Fig. 24 DAMPER-TO-COVER ALIGNMENT MARKS Ð

TYPICAL

1 - ALIGNMENT MARK

2 - TIMING CHAIN COVER MARKS

3 - CRANKSHAFT VIBRATION DAMPER

Fig. 25 ROTOR ALIGNMENT MARK

1 - CAMSHAFT POSITION SENSOR ALIGNMENT MARK

2 - ROTOR

3 - DISTRIBUTOR

Fig. 26 DISTRIBUTOR HOLDDOWN CLAMP

1 - CLAMP BOLT

2 - HOLDDOWN CLAMP

3 - DISTRIBUTOR HOUSING

DRIGNITION CONTROL 8I - 17

DISTRIBUTOR (Continued)

Page 1270 of 2895

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the master cylinder and booster assem-

bly(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/POWER BRAKE BOOSTER - REMOVAL).

(8) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(9) Remove the fan shroud and fan blade assem-

bly(Refer to 7 - COOLING/ENGINE/RADIATOR FAN

- REMOVAL).

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the power steering pump and set

aside.

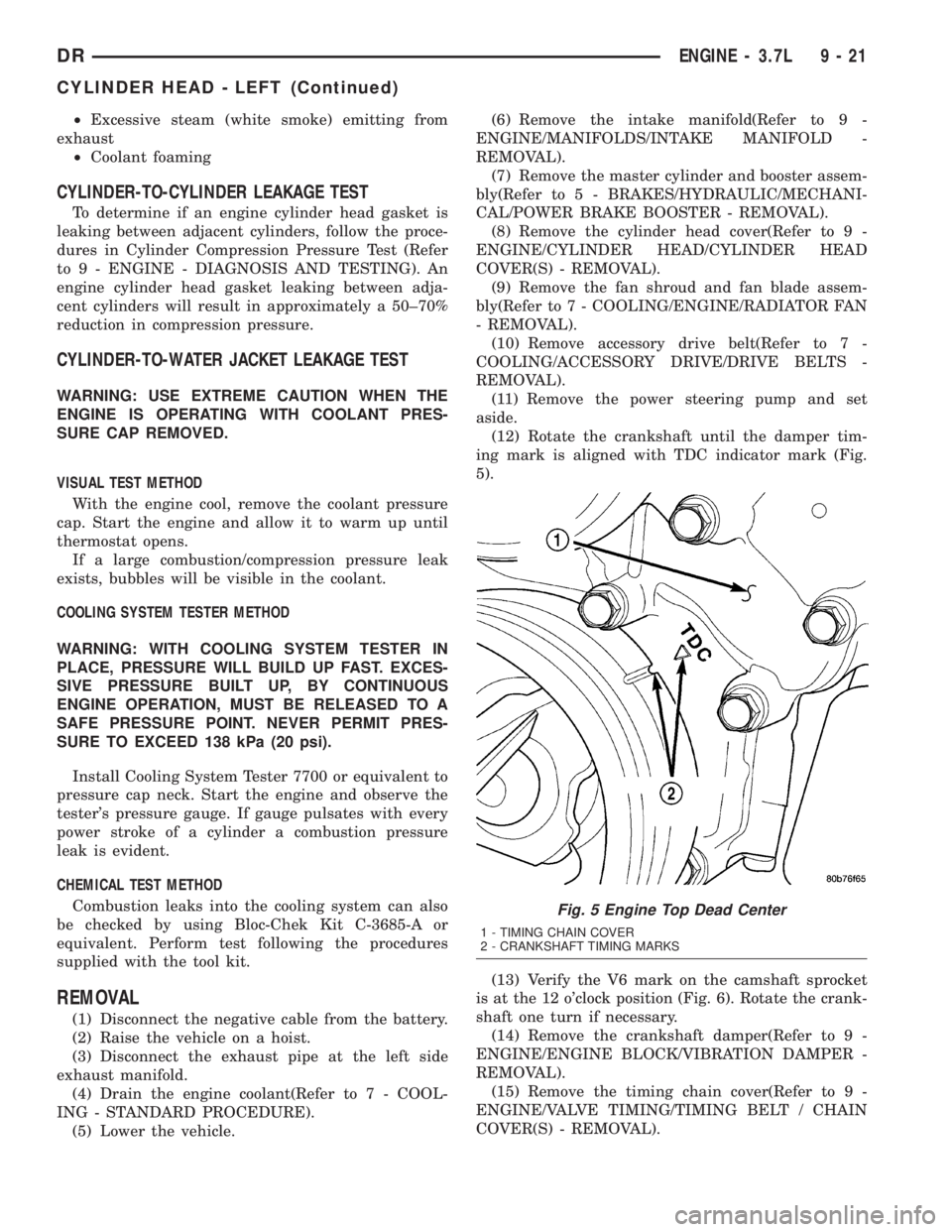

(12) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

5).

(13) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 6). Rotate the crank-

shaft one turn if necessary.

(14) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(15) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 5 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

DRENGINE - 3.7L 9 - 21

CYLINDER HEAD - LEFT (Continued)

Page 1355 of 2895

(3) Pry up 4 spring clips (Fig. 7) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

DESCRIPTION

DESCRIPTION - CYLINDER HEAD

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylin-

der heads.

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

REMOVAL

REMOVAL - LEFT CYLINDER HEAD

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant. Refer to COOLING

SYSTEM.

(5) Lower the vehicle.

(6) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the master cylinder and booster assem-

bly. Refer to section 5 brakes.

(8) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(9) Remove the fan shroud and fan blade assembly

(Refer to 7 - COOLING/ENGINE/FAN DRIVE VIS-

COUS CLUTCH - REMOVAL).

(10) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the power steering pump and set

aside.

(12) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

9).

Fig. 8 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

Fig. 9 Engine Top Dead Center (TDC) Indicator Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 106 ENGINE - 4.7LDR

AIR CLEANER ELEMENT (Continued)

Page 1357 of 2895

NOTE: The cylinder head is attached to the cylinder

block with fourteen bolts.

(22) Remove the cylinder head retaining bolts.

(23) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, due to the design of the cylin-

der head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

REMOVAL - RIGHT CYLINDER HEAD

(1) Disconnect battery negitive cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(8) Remove the fan shroud (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark (Fig. 13).(12) Verify the V8 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 14). Rotate the

crankshaft one turn if necessary.

(13) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(14) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (Fig. 15).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive gear

(Fig. 14).

(17) Remove the right side secondary chain ten-

sioner (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

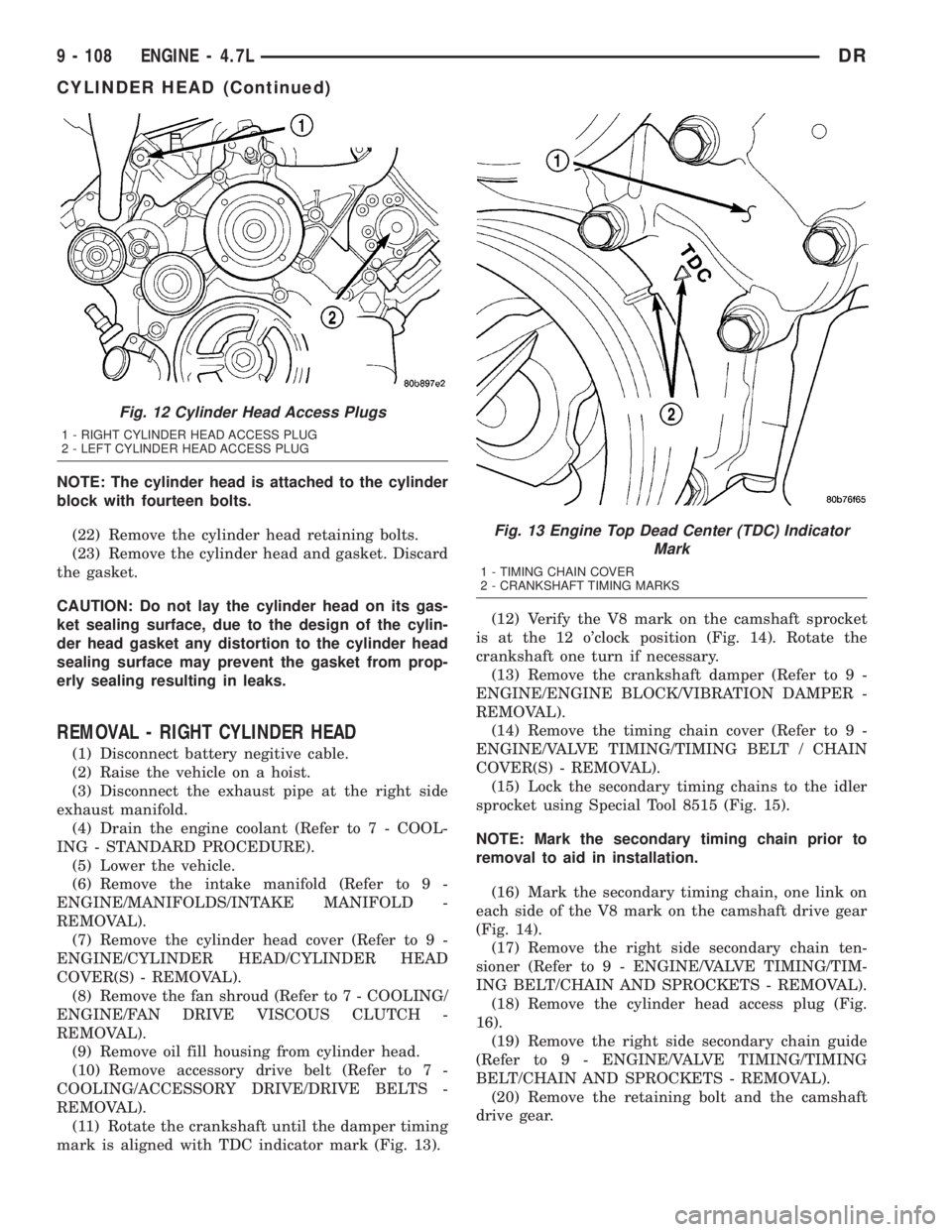

(18) Remove the cylinder head access plug (Fig.

16).

(19) Remove the right side secondary chain guide

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

(20) Remove the retaining bolt and the camshaft

drive gear.

Fig. 12 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

Fig. 13 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 108 ENGINE - 4.7LDR

CYLINDER HEAD (Continued)

Page 1418 of 2895

(8) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(9) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

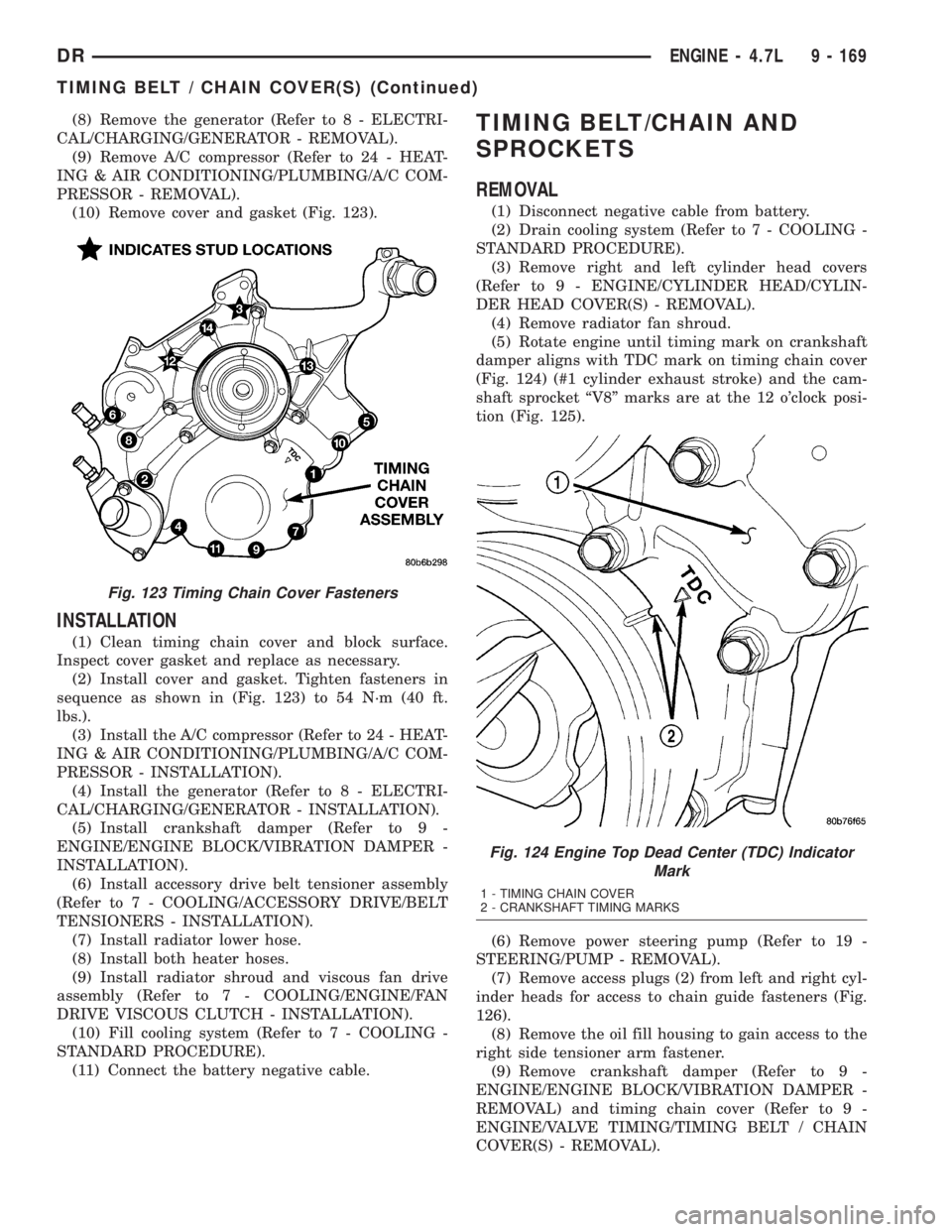

(10) Remove cover and gasket (Fig. 123).

INSTALLATION

(1) Clean timing chain cover and block surface.

Inspect cover gasket and replace as necessary.

(2) Install cover and gasket. Tighten fasteners in

sequence as shown in (Fig. 123) to 54 N´m (40 ft.

lbs.).

(3) Install the A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(4) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION).

(5) Install crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(6) Install accessory drive belt tensioner assembly

(Refer to 7 - COOLING/ACCESSORY DRIVE/BELT

TENSIONERS - INSTALLATION).

(7) Install radiator lower hose.

(8) Install both heater hoses.

(9) Install radiator shroud and viscous fan drive

assembly (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH - INSTALLATION).

(10) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Connect the battery negative cable.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove right and left cylinder head covers

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(4) Remove radiator fan shroud.

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 124) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV8º marks are at the 12 o'clock posi-

tion (Fig. 125).

(6) Remove power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(7) Remove access plugs (2) from left and right cyl-

inder heads for access to chain guide fasteners (Fig.

126).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 123 Timing Chain Cover Fasteners

Fig. 124 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

DRENGINE - 4.7L 9 - 169

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1475 of 2895

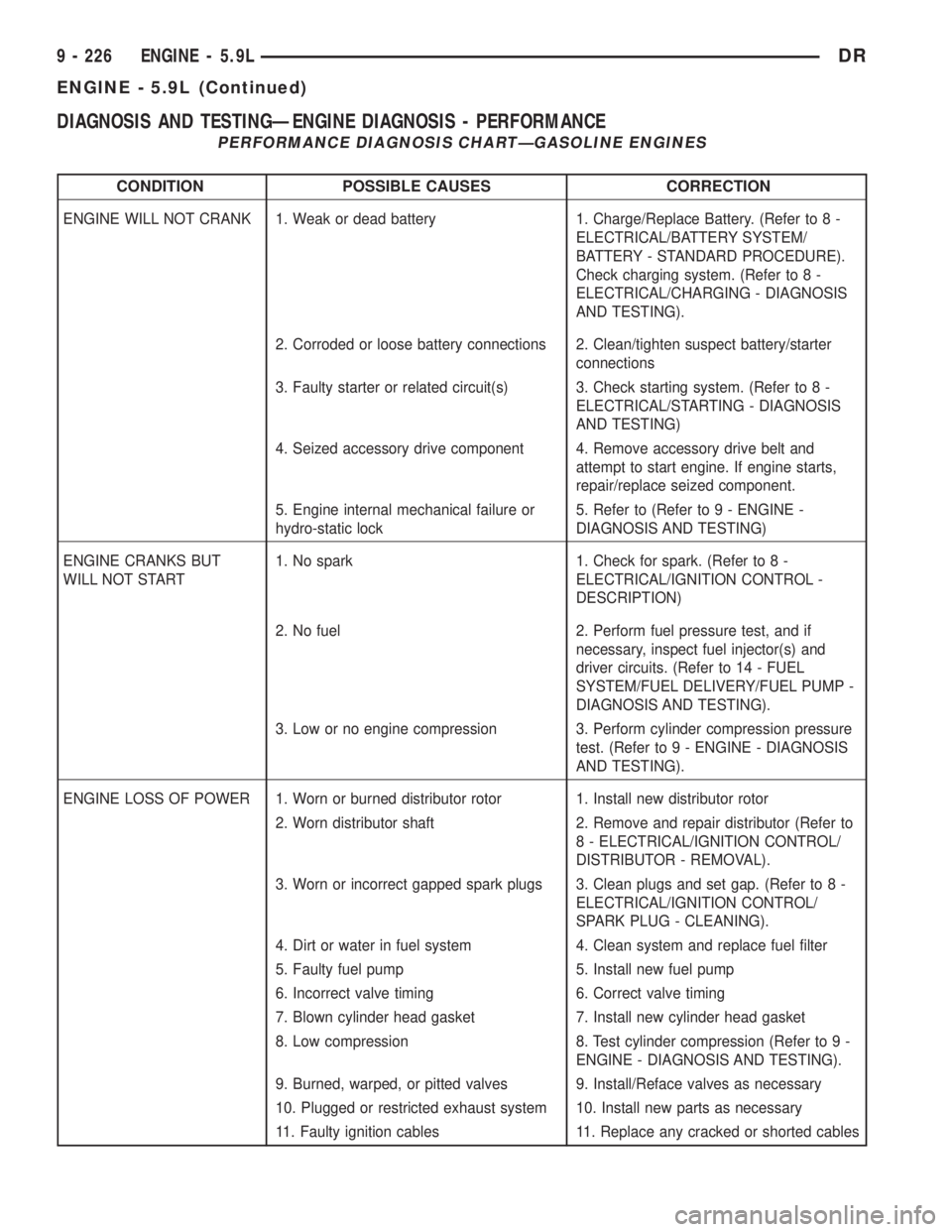

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE).

Check charging system. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS

AND TESTING).

2. Corroded or loose battery connections 2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT

WILL NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression pressure

test. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark plugs 3. Clean plugs and set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust system 10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted cables

9 - 226 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1603 of 2895

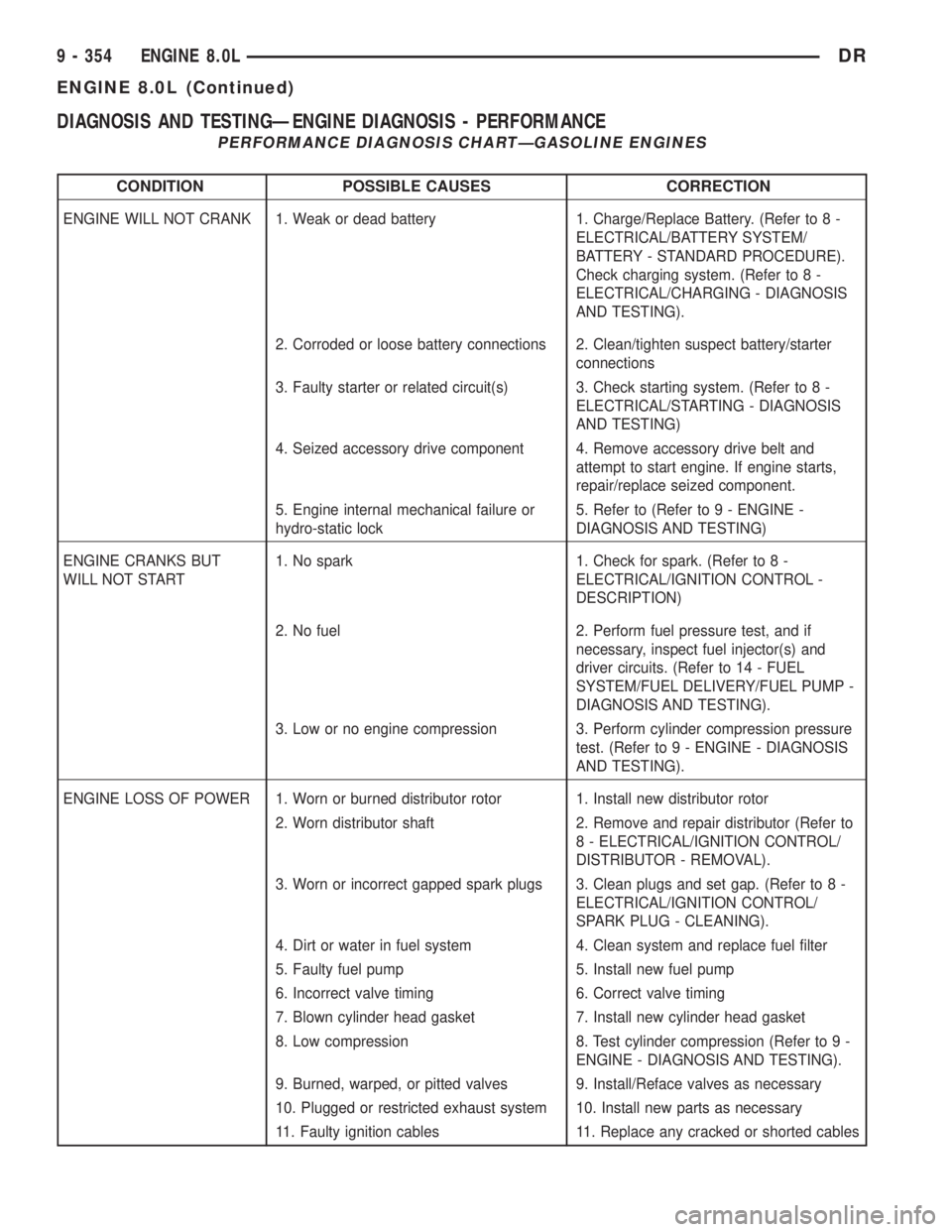

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE).

Check charging system. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS

AND TESTING).

2. Corroded or loose battery connections 2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT

WILL NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression pressure

test. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark plugs 3. Clean plugs and set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust system 10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted cables

9 - 354 ENGINE 8.0LDR

ENGINE 8.0L (Continued)

Page 1626 of 2895

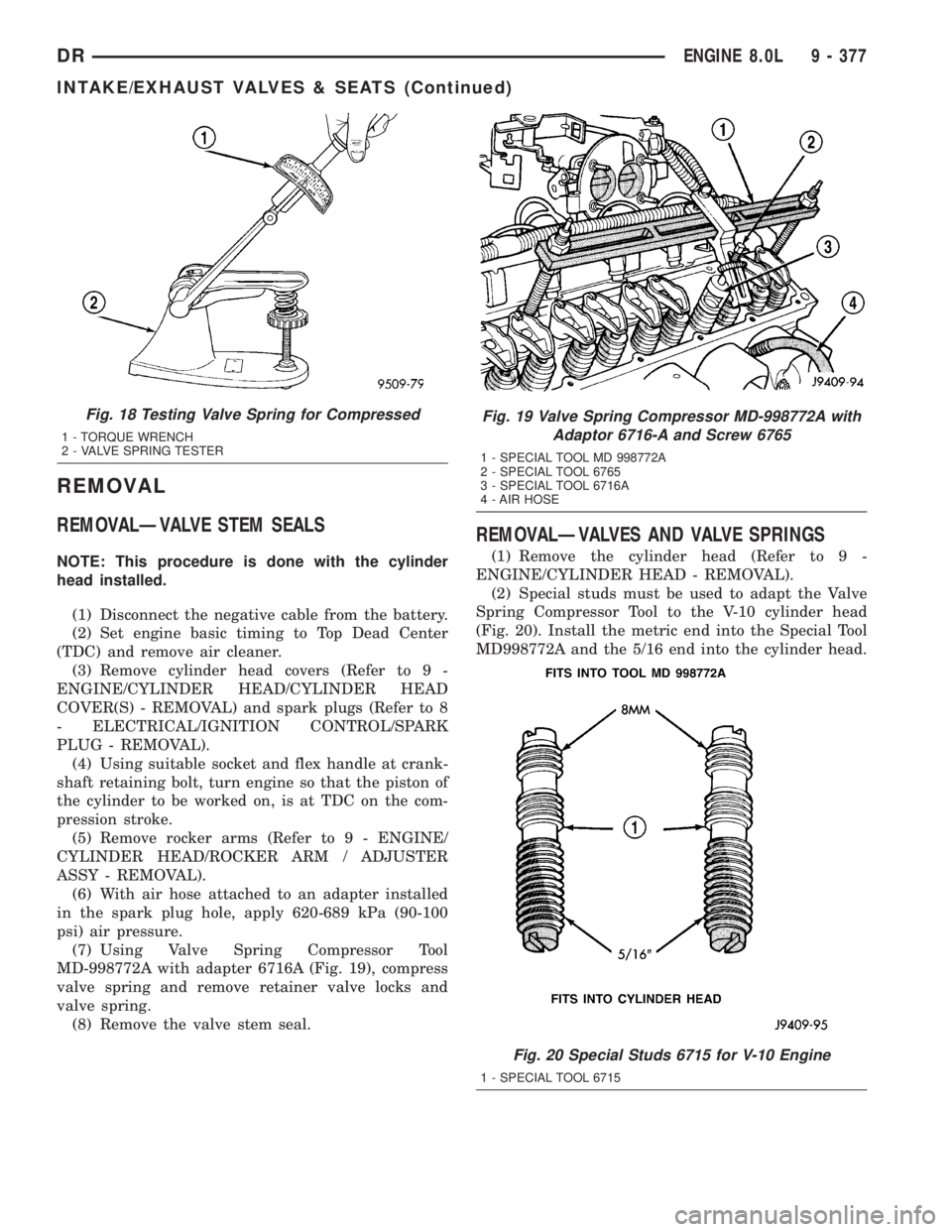

REMOVAL

REMOVALÐVALVE STEM SEALS

NOTE: This procedure is done with the cylinder

head installed.

(1) Disconnect the negative cable from the battery.

(2) Set engine basic timing to Top Dead Center

(TDC) and remove air cleaner.

(3) Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL) and spark plugs (Refer to 8

- ELECTRICAL/IGNITION CONTROL/SPARK

PLUG - REMOVAL).

(4) Using suitable socket and flex handle at crank-

shaft retaining bolt, turn engine so that the piston of

the cylinder to be worked on, is at TDC on the com-

pression stroke.

(5) Remove rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - REMOVAL).

(6) With air hose attached to an adapter installed

in the spark plug hole, apply 620-689 kPa (90-100

psi) air pressure.

(7) Using Valve Spring Compressor Tool

MD-998772A with adapter 6716A (Fig. 19), compress

valve spring and remove retainer valve locks and

valve spring.

(8) Remove the valve stem seal.

REMOVALÐVALVES AND VALVE SPRINGS

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Special studs must be used to adapt the Valve

Spring Compressor Tool to the V-10 cylinder head

(Fig. 20). Install the metric end into the Special Tool

MD998772A and the 5/16 end into the cylinder head.

Fig. 18 Testing Valve Spring for Compressed

1 - TORQUE WRENCH

2 - VALVE SPRING TESTER

Fig. 19 Valve Spring Compressor MD-998772A with

Adaptor 6716-A and Screw 6765

1 - SPECIAL TOOL MD 998772A

2 - SPECIAL TOOL 6765

3 - SPECIAL TOOL 6716A

4 - AIR HOSE

Fig. 20 Special Studs 6715 for V-10 Engine

1 - SPECIAL TOOL 6715

DRENGINE 8.0L 9 - 377

INTAKE/EXHAUST VALVES & SEATS (Continued)