jump cable DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 26 of 2895

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

DRLUBRICATION & MAINTENANCE 0 - 13

Page 418 of 2895

WARNING: ALWAYS WEAR APPROPRIATE EYE

PROTECTION AND USE EXTREME CAUTION WHEN

WORKING WITH BATTERIES.

BATTERY TESTING

(1) If testing the battery OUT-OF-VEHICLE, clean

the battery terminals with a wire brush before test-

ing. If the battery is equipped with side post termi-

nals, install and tighten the supplied lead terminal

stud adapters. Do not use steel bolts. Failure to prop-

erly install the stud adapters, or using stud adapters

that are dirty or worn-out may result in false test

readings.

(2) If testing the battery IN-THE-VEHICLE, make

certain all of the vehicle accessory loads are OFF,

including the ignition.The preferred test position

is at the battery terminal. If the battery is not

accessible, you may test using both the positive and

negative jumper posts. Select TESTING AT JUMPER

POST when connecting to that location.

(3) Connect the tester (Fig. 9) to the battery or

jumper posts, the red clamp to positive (+) and the

black clamp to negative (±).

NOTE: Multiple batteries connected in parallel must

have the ground cable disconnected to perform a

battery test. Failure to disconnect may result in

false battery test readings.

(4) Using the ARROW key selectinoroutof vehi-

cle testing and press ENTER to make a selection.

(5) If not selected, choose the Cold Cranking Amp

(CCA) battery rating. Or select the appropriate bat-

tery rating for your area (see menu). The tester will

then run its self programmed test of the battery and

display the results. Refer to the test result table

noted below.

CAUTION: If REPLACE BATTERY is the result of the

test, this may mean a poor connection between the

vehicle's cables and battery exists. After discon-

necting the vehicle's battery cables from the bat-

tery, retest the battery using the OUT-OF-VEHICLE

test before replacing.

(6) While viewing the battery test result, press the

CODE button and the tester will prompt you for the

last 4 digits of the VIN. Use the UP/DOWN arrow

buttons to scroll to the correct character; then press

ENTER to select and move to the next digit. Then

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

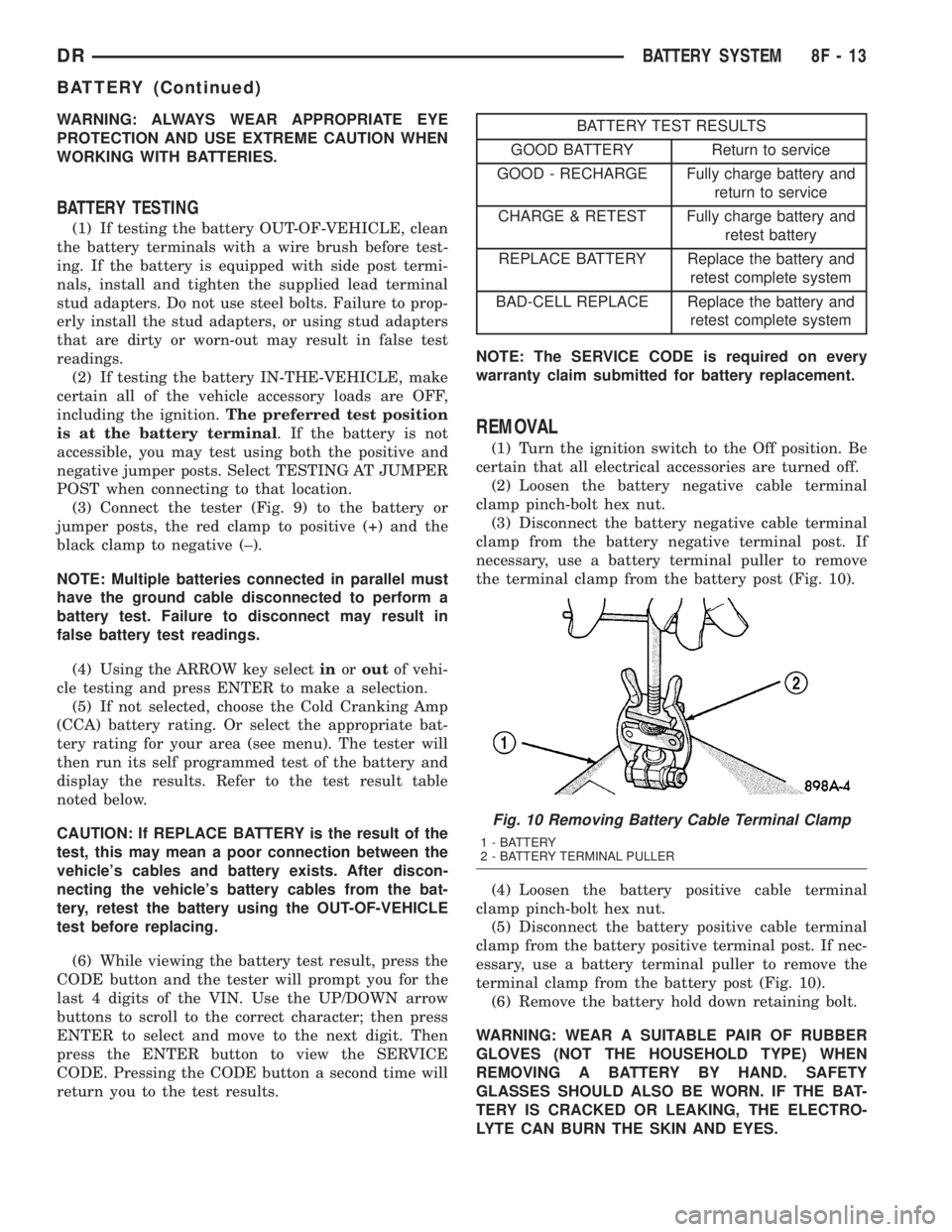

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 10).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post (Fig. 10).

(6) Remove the battery hold down retaining bolt.

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

Fig. 10 Removing Battery Cable Terminal Clamp

1 - BATTERY

2 - BATTERY TERMINAL PULLER

DRBATTERY SYSTEM 8F - 13

BATTERY (Continued)

Page 439 of 2895

SPECIFICATIONS - TORQUE - STARTING

SYSTEM

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Battery Cable Eyelet Nut at

Solenoid (large nut - gas engines)25 19 221

Battery Cable Eyelet Nut at

Solenoid (large nut - diesel engine)14 - 120

Starter Solenoid Nut (small nut -

diesel engine)6-55

Starter Mounting Bolts - Gas

Engines68 50 -

Starter Mounting Nut - Gas Engines 68 50 -

Starter Mounting Bolts - Diesel 43 32 -

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with starter motor

removed from vehicle. Refer to Specifications for

starter motor specifications.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Mount starter motor securely in a soft-jawed

bench vise. The vise jaws should be clamped on the

mounting flange of starter motor. Never clamp on

starter motor by field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to starter motor in series, and set

ammeter to 100 ampere scale. See instructions pro-

vided by manufacturer of volt-ampere tester being

used.

(4) Install jumper wire from solenoid terminal to

solenoid battery terminal. The starter motor should

operate. If starter motor fails to operate, replace

faulty starter motor assembly.

(5) Adjust carbon pile load of tester to obtain free

running test voltage. Refer to Specifications for

starter motor free running test voltage specifications.

(6) Note reading on ammeter and compare reading

to free running test maximum amperage draw. Refer

to Specifications for starter motor free running test

maximum amperage draw specifications.

(7) If ammeter reading exceeds maximum amper-

age draw specification, replace faulty starter motor

assembly.

STARTER SOLENOID

This test can only be performed with starter motor

removed from vehicle.(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Disconnect wire from solenoid field coil termi-

nal.

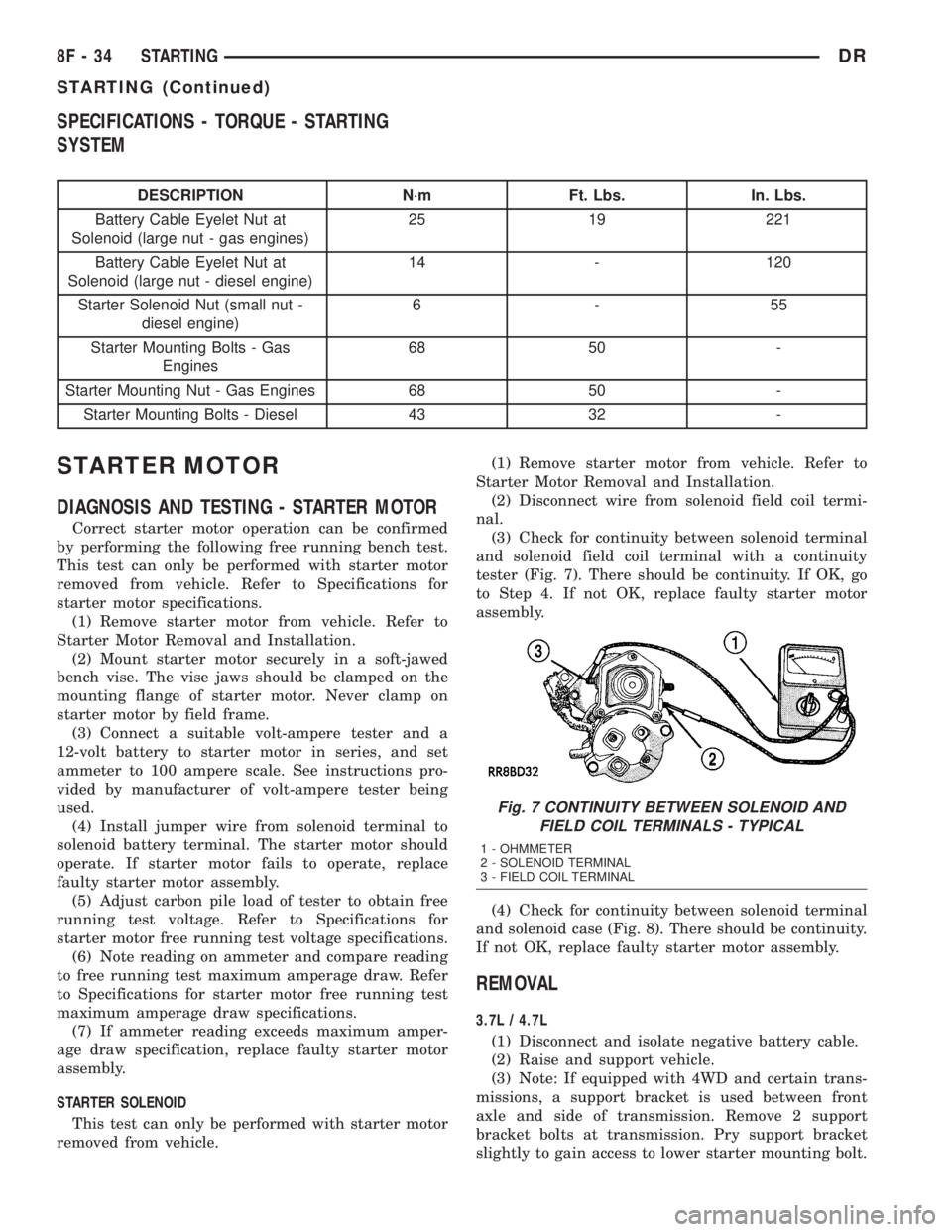

(3) Check for continuity between solenoid terminal

and solenoid field coil terminal with a continuity

tester (Fig. 7). There should be continuity. If OK, go

to Step 4. If not OK, replace faulty starter motor

assembly.

(4) Check for continuity between solenoid terminal

and solenoid case (Fig. 8). There should be continuity.

If not OK, replace faulty starter motor assembly.

REMOVAL

3.7L / 4.7L

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Note: If equipped with 4WD and certain trans-

missions, a support bracket is used between front

axle and side of transmission. Remove 2 support

bracket bolts at transmission. Pry support bracket

slightly to gain access to lower starter mounting bolt.

Fig. 7 CONTINUITY BETWEEN SOLENOID AND

FIELD COIL TERMINALS - TYPICAL

1 - OHMMETER

2 - SOLENOID TERMINAL

3 - FIELD COIL TERMINAL

8F - 34 STARTINGDR

STARTING (Continued)

Page 491 of 2895

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

Except 5.7L V-8 :With the engine running,

remove spark plug cable from spark plug (one at a

time) and hold next to a good engine ground. If the

cable and spark plug are in good condition, the

engine rpm should drop and the engine will run

poorly. If engine rpm does not drop, the cable and/or

spark plug may not be operating properly and should

be replaced. Also check engine cylinder compression.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run

the other end of the test probe along the entire

length of all spark plug cables. If cables are cracked

or punctured, there will be a noticeable spark jump

from the damaged area to the test probe. The cable

running from the ignition coil to the distributor cap

can be checked in the same manner. Cracked, dam-

aged or faulty cables should be replaced with resis-

tance type cable. This can be identified by the words

ELECTRONIC SUPPRESSION printed on the cable

jacket.Use an ohmmeter to test for open circuits, exces-

sive resistance or loose terminals. If equipped,

remove the distributor cap from the distributor.Do

not remove cables from cap.Remove cable from

spark plug. Connect ohmmeter to spark plug termi-

nal end of cable and to corresponding electrode in

distributor cap. Resistance should be 250 to 1000

Ohms per inch of cable. If not, remove cable from dis-

tributor cap tower and connect ohmmeter to the ter-

minal ends of cable. If resistance is not within

specifications as found in the SPARK PLUG CABLE

RESISTANCE chart, replace the cable. Test all spark

plug cables in this manner.

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

To test ignition coil-to-distributor cap cable (if

applicaple), do not remove the cable from the cap.

Connect ohmmeter to rotor button (center contact) of

distributor cap and terminal at ignition coil end of

cable. If resistance is not within specifications as

found in the Spark Plug Cable Resistance chart,

remove the cable from the distributor cap. Connect

the ohmmeter to the terminal ends of the cable. If

resistance is not within specifications as found in the

Spark Plug Cable Resistance chart, replace the cable.

Inspect the ignition coil tower for cracks, burns or

corrosion.

REMOVAL

5.9L V-8 / 8.0L V-10

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 54). Grasp the boot (not the cable) and pull it

off with a steady, even force.

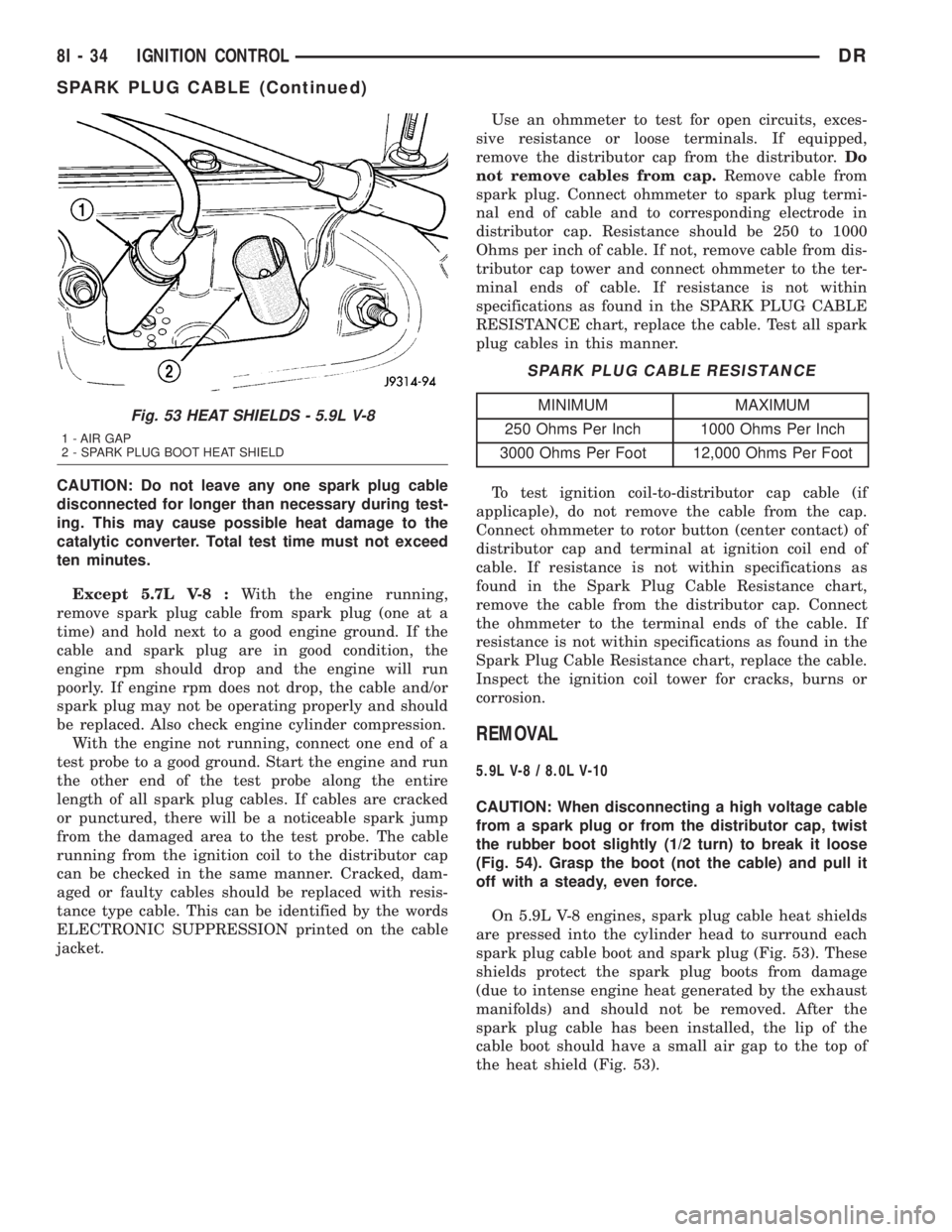

On 5.9L V-8 engines, spark plug cable heat shields

are pressed into the cylinder head to surround each

spark plug cable boot and spark plug (Fig. 53). These

shields protect the spark plug boots from damage

(due to intense engine heat generated by the exhaust

manifolds) and should not be removed. After the

spark plug cable has been installed, the lip of the

cable boot should have a small air gap to the top of

the heat shield (Fig. 53).

Fig. 53 HEAT SHIELDS - 5.9L V-8

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

8I - 34 IGNITION CONTROLDR

SPARK PLUG CABLE (Continued)

Page 574 of 2895

then sends the proper ambient temperature mes-

sages to the EVIC, CMTC over the PCI J1850 data

bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Front Control Module, the Programmable Communi-

cations Interface (PCI) data bus, and a portion of the

Electronics module. If any portion of the ambient

temperature sensor circuit fails, the Front Control

Module will self-diagnose the circuit.

For complete circuit diagrams, refer toWiring.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At 24É C (75É F), the sensor resistance

should be approximately 10.3 kilohms. At 30É C (86É

F), the sensor resistance should be approximately

7.57 kilohms. The sensor resistance should decrease

as the temperature rises. If OK, refer toDiagnosis

and Testing - Ambient Temperature Sensor Cir-

cuitin this group. If not OK, replace the faulty

ambient temperature sensor.

NOTE: The ambient temperature sensor is a very

sensitive device. When testing, be certain the tem-

perature sensor has had time to stabilize (room

temperature) before attempting to read the sensor

resistance. Failure to let the ambient temperature

sensor temperature stabilize could result in a mis-

leading test.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Front Control Module wire

harness connector.

(2) Connect a jumper wire between the two termi-

nals of the ambient temperature sensor wire harness

connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the Front Control Module wire har-

ness connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return or

signal circuit as required.(4) Remove the jumper wire from the ambient tem-

perature sensor wire harness connector. Check for

continuity between the sensor return circuit cavity of

the Front Control Module wire harness connector

and a good ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted sen-

sor return circuit as required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the Front

Control Module wire harness connector and a good

ground. There should be no continuity. If OK, refer to

Diagnosis and Testing - Overhead Consolein

this group. If not OK, repair the shorted ambient

temperature sensor signal circuit as required.

REMOVAL

(1) Open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Working on the underside of the hood, remove

screw holding sensor to hood panel.

(4) Disconnect the sensor electrical connector and

remove sensor from vehicle.

INSTALLATION

(1) Connect the sensor electrical connector.

(2) Working on the underside of the hood, install

screw holding sensor to hood panel.

(3) Connect the battery negative cable.

(4) Close the hood.

UNIVERSAL TRANSMITTER

DESCRIPTION

Some DR models are equipped with a universal

transmitter transceiver. The universal transmitter is

integral to the Electronic Vehicle Information Center

(EVIC) and the Compass Mini-Trip Computer

(CMTC), which is located in the overhead console.

The only visible component of the universal transmit-

ter are the three transmitter push buttons centered

between the modules push buttons located just rear-

ward of the display screen in the overhead console.

The three universal transmitter push buttons are

identified with one, two or three light indicators so

that they be easily identified.

Each of the three universal transmitter push but-

tons control an independent radio transmitter chan-

nel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-

tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

DRMESSAGE SYSTEMS 8M - 11

AMBIENT TEMP SENSOR (Continued)

Page 599 of 2895

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WINDOW MOTOR

REMOVAL

The window motor is serviced with the window reg-

ulator (Refer to 23 - BODY/DOOR - FRONT/WINDOW

REGULATOR - REMOVAL) or (Refer to 23 - BODY/

DOORS - REAR/WINDOW REGULATOR - REMOVAL).

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

junction block. If all of the LEDs are inoperative in

both the power window and lock switch units and the

power windows are inoperative, (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS - DIAGNOSIS AND

TESTING). If the power windows operate, but any or

all of the LEDs are inoperative, the power window

and lock switch units with the inoperative LED(s) is

faulty and must be replaced. For complete circuit dia-

grams, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.(1) Check the fuse in the Integrated Power Module

(IPM) and the circuit breaker located near the park

brake pedal. If OK, go to Step 2. If not OK, replace

the faulty fuse or circuit breaker.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the Inte-

grated Power Module (IPM). If OK, turn the ignition

switch to the Off position and go to Step 3. If not OK,

check circuit breaker and repair the circuit to the

ignition switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window switch unit from

the door trim panel (passenger doors). The drivers

door switch is included with the Driver Door Module

(Refer to 8 - ELECTRICAL/POWER LOCKS/DOOR

MODULE - DIAGNOSIS AND TESTING) for service

procedures. Unplug the wire harness connector from

the switch unit.

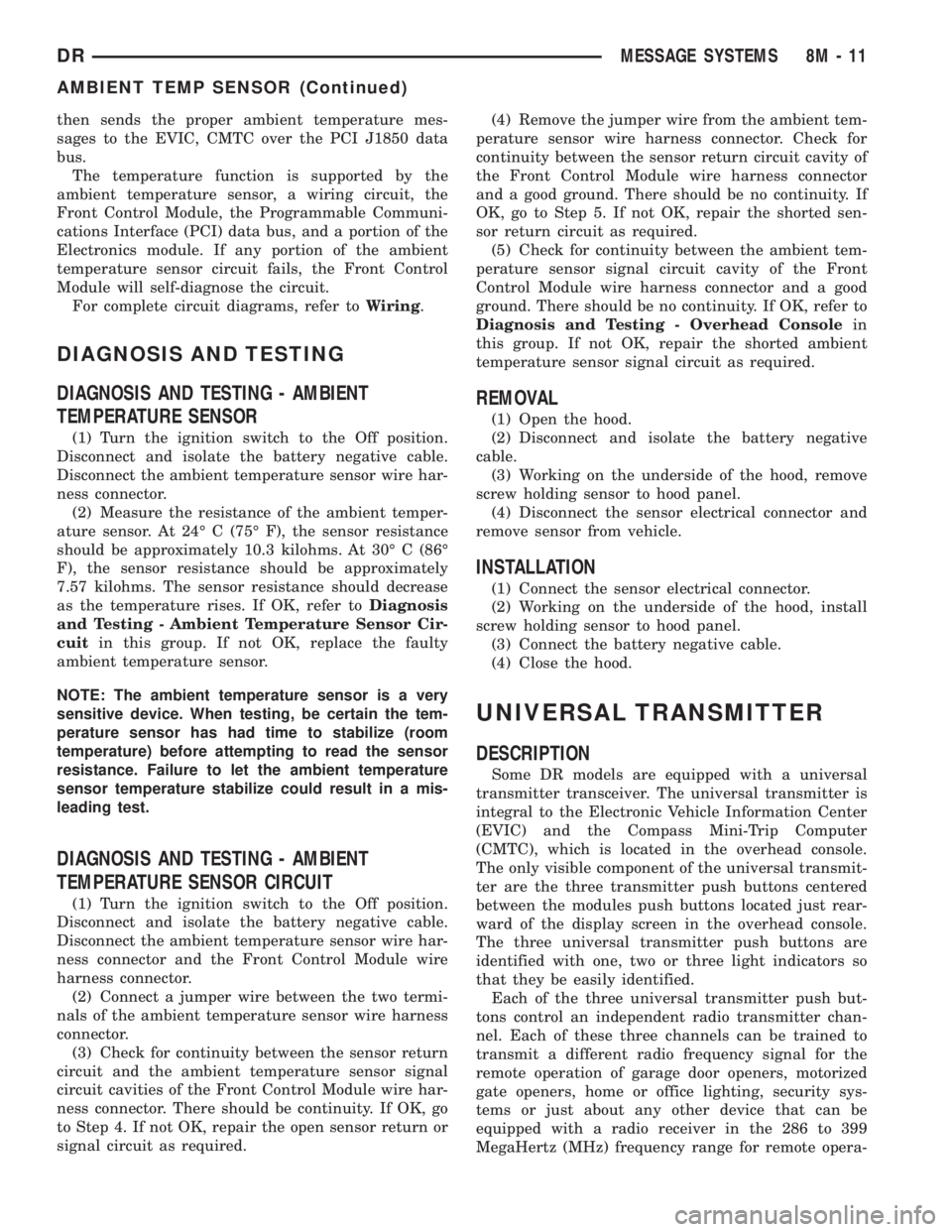

(4) Test the power window switch continuity. See

the Power Window Switch Continuity charts to deter-

mine if the continuity is correct in the Off, Up and

Down switch positions (Fig. 1). If OK, (Refer to 8 -

ELECTRICAL/POWER WINDOWS - DIAGNOSIS

AND TESTING). If not OK, replace the faulty switch.

POWER WINDOW SWITCH CONTINUITY

CHART

SWITCH POSITION CONTINUITY BETWEEN

NEUTRAL PIN 2 AND 5, PIN 4 AND 1

UP (FRONT

PASSENGER)PIN 6 AND 5

UP (REAR

PASSENGER)PIN 6 AND 1

DOWN (FRONT

PASSENGER)PIN 6 AND 1

DOWN (REAR

PASSENGER)PIN 6 AND 5

Fig. 1 PASSENGER DOOR SWITCH

8N - 22 POWER WINDOWSDR

POWER WINDOWS (Continued)

Page 2820 of 2895

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

LIQUID LINE

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

NOTE: Removal of the second battery and battery

tray is required on the diesel equipped vehicles.

(2) Remove rightside battery(Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/BATTERY - REMOV-

AL).

(3) Remove rightside battery tray(Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - REMOV-

AL).

(4) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(5) Disconnect the liquid line refrigerant line cou-

plers at the condenser outlet the mid point connec-

tion and the evaporator inlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

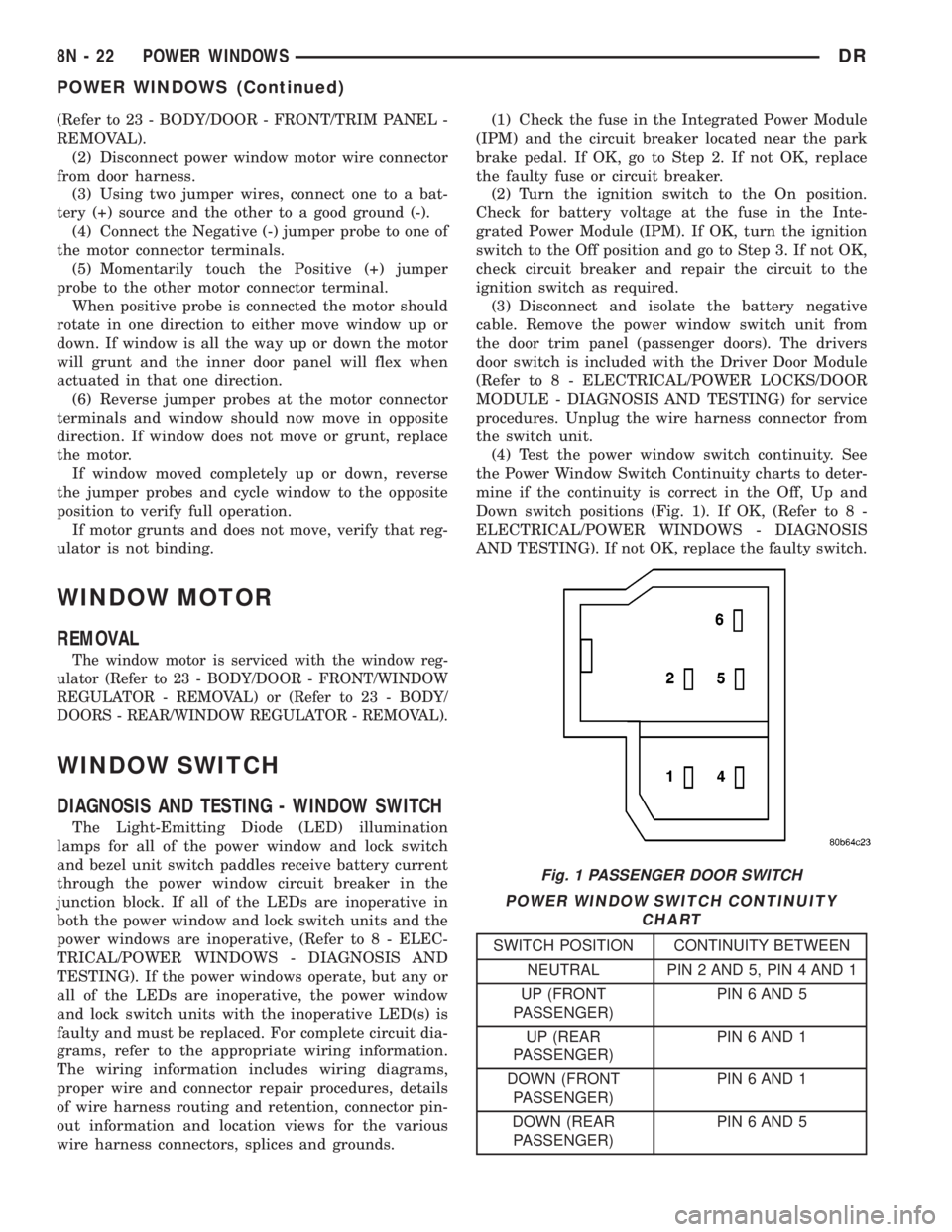

(6) Disengage any clips that secure the liquid line

to the inner fender shield or cross brace. (Fig. 11).

(7) Remove the both sections of the liquid line

from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install both sections of the liquid line into any

clips on the inner fender shield and the dash panel.

(2) Remove the tape or plugs from the refrigerant

line fittings on the liquid line, the condenser outlet,

and the evaporator inlet. Connect the liquid line

pieces together and to the condenser and the evapo-

rator. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE - A/C

LINE COUPLERS)

NOTE: Installation of the second battery and battery

tray is required on the diesel equipped vehicles.

(3) Install the rightside battery tray(Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/TRAY - INSTAL-

LATION).

(4) Install the rightside battery(Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/BATTERY - INSTAL-

LATION).

(5) Connect the battery positive cables.

(6) Connect the battery negative cables.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

Fig. 11 A/C Liquid Line - Gas Engine shown

1 - A/C Line Retainer Clip

2 - A/C Line Retention Clip

3 - A/C Line Retainer Clip

4 - Liquid Line to Evaporator

5 - A/C Line Retention Clip

6 - Evaporator Ports

7 - A/C Condensor Modular

8 - A/C Jumper Line Retainer Nut

9 - A/C Line Retainer Clip

10 - A/C Liquid Jumper Line

DRPLUMBING 24 - 45

A/C DISCHARGE LINE (Continued)

Page 2874 of 2895

JOINT - INSTALLATION, UPPER BALL.....2-33

JOINT - REMOVAL, LOWER BALL.....2-18,2-32

JOINT - REMOVAL, UPPER BALL.........2-33

JOINT-INNER - INSTALLATION, CV........3-16

JOINT-INNER - REMOVAL, CV............3-16

JOINT-OUTER - INSTALLATION, CV........3-13

JOINT-OUTER - REMOVAL, CV...........3-13

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-9

JOUNCE BUMPER - INSTALLATION.......2-40

JOUNCE BUMPER - REMOVAL...........2-40

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-321

JUMP STARTING - STANDARD

PROCEDURE.........................0-13

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-19

JUNCTION BLOCK - REMOVAL, BRAKE....5-19

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS),

DESCRIPTION - SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-8

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-8

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-8

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE.............8N-10

KNOCK SENSOR - DESCRIPTION.........8I-25

KNOCK SENSOR - INSTALLATION........8I-26

KNOCK SENSOR - OPERATION..........8I-25

KNOCK SENSOR - REMOVAL............8I-25

KNUCKLE - DESCRIPTION...............2-17

KNUCKLE - INSTALLATION..........2-18,2-34

KNUCKLE - OPERATION................2-17

KNUCKLE - REMOVAL..............2-17,2-34

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-1

LAMP - DESCRIPTION, DOME...........8L-24

LAMP - DESCRIPTION, READING........8L-26

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, BACKUP.........8L-7

LAMP - INSTALLATION, BRAKE..........8L-8

LAMP - INSTALLATION, CAB CLEARANCE . 8L-10

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - INSTALLATION, DOME..........8L-24

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-16

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-26

LAMP - INSTALLATION, TAIL

...........8L-21

LAMP - INSTALLATION, TURN

..........8L-22LAMP - INSTALLATION, UNDERHOOD....8L-22

LAMP - OPERATION, DOME............8L-24

LAMP - OPERATION, READING..........8L-26

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, BACKUP.............8L-7

LAMP - REMOVAL, BRAKE..............8L-8

LAMP - REMOVAL, CAB CLEARANCE.....8L-10

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - REMOVAL, DOME..............8L-24

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-16

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-26

LAMP - REMOVAL, TAIL...............8L-21

LAMP - REMOVAL, TURN..............8L-22

LAMP - REMOVAL, UNDERHOOD........8L-22

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-30

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-30

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-28

LAMP OUT INDICATOR - OPERATION.....8J-28

LAMP RELAY - DESCRIPTION, FOG........8L-11

LAMP RELAY - DESCRIPTION, PARK.....8L-19

LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-12

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-12

LAMP RELAY - OPERATION, PARK.......8L-19

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-20

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-7

LAMP SWITCH - DESCRIPTION, BRAKE....8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-9

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-10

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-8

LAMP SWITCH - REMOVAL, BRAKE.......8L-9

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-10

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-16

LAMP UNIT - INSTALLATION, TAIL.......8L-21

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-23

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-16

LAMP UNIT - REMOVAL, TAIL...........8L-21

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-22

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-25

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-25

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-124,9-31

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-308

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX

.....23-53

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN

.......................23-81

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-53

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-81LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL................23-47

LATCH STRIKER - INSTALLATION . . 23-17,23-24,

23-33

LATCH STRIKER - REMOVAL . 23-17,23-24,23-33

LATCH STRIKER / SECONDARY CATCH -

INSTALLATION.......................23-48

LATCH STRIKER / SECONDARY CATCH -

REMOVAL..........................23-48

LD & HD EXCEPT 4X4 HD -

INSTALLATION, ALL..................19-15

LD & HD EXCEPT 4X4 HD - REMOVAL,

ALL ...............................19-14

LEAD - DIAGNOSIS AND TESTING,

TIRE/VEHICLE........................22-8

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID . . . 21-143,21-324,

21-495

LEAK - DIAGNOSIS AND TESTING,

ENGINE OIL................9-150,9-214,9-63

LEAK DETECTION ASSY - DESCRIPTION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - INSTALLATION,

NATURAL VAC.......................25-24

LEAK DETECTION ASSY - OPERATION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - REMOVAL,

NATURAL VAC.......................25-24

LEAK DETECTION PUMP - DESCRIPTION . . 25-13

LEAK DETECTION PUMP - INSTALLATION . 25-16

LEAK DETECTION PUMP - OPERATION.....25-14

LEAK DETECTION PUMP - REMOVAL.....25-16

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE....9-182,

9-231,9-359,9-8,9-92

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....9-157,9-219,9-274,9-401

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-39

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM.........11-15

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM - TESTING.............7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL....................9-269,9-394

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-69

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-71

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA...........9-135,9-204,9-64

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-51

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-1

LEAKS - STANDARD PROCEDURE,

REPAIRING.........................22-10

LEARN - STANDARD PROCEDURE,

DRIVE.............................8E-21

LEARN - STANDARD PROCEDURE, TCM

QUICK.............................8E-21

LEFT - DESCRIPTION, CAMSHAFT(S).....9-113

LEFT - INSTALLATION..................2-34

LEFT - INSTALLATION, CAMSHAFT(S)....9-114

LEFT - INSTALLATION, CYLINDER HEAD . . . 9-23

LEFT - REMOVAL......................2-34

LEFT - REMOVAL, CAMSHAFT(S)........9-113

LEFT - REMOVAL, CYLINDER HEAD.......9-21

LEFT CYLINDER HEAD - INSTALLATION . . . 9-110

LEFT CYLINDER HEAD - REMOVAL.......9-106

LEFT OUTBOARD - INSTALLATION,

CENTER............................8O-45

LEFT OUTBOARD - REMOVAL, CENTER . . . 8O-43

LEFT REAR CABLE - INSTALLATION.......5-33

LEFT REAR CABLE - REMOVAL...........5-32

LEFT SIDE - INSTALLATION............9-122

LEFT SIDE - REMOVAL

................9-121

LENS REPLACEMENT - STANDARD

PROCEDURE, MODULE

................8M-3

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID

. . 21-201,21-381,

21-541

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID

........................5-18

LEVEL - STANDARD PROCEDURE,

ENGINE OIL

.........................9-341

DRINDEX 19

Description Group-Page Description Group-Page Description Group-Page

Page 2887 of 2895

SIDE - REMOVAL, LEFT................9-121

SIDE - REMOVAL, RIGHT..............9-121

SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL DRIVER...........23-59

SIDE BEZEL - REMOVAL, INSTRUMENT

PANEL DRIVER......................23-58

SIDE CURTAIN AIRBAG - DESCRIPTION . . . 8O-51

SIDE CURTAIN AIRBAG - INSTALLATION . . 8O-53

SIDE CURTAIN AIRBAG - OPERATION....8O-51

SIDE CURTAIN AIRBAG - REMOVAL......8O-52

SIDE IMPACT AIRBAG CONTROL

MODULE - DESCRIPTION..............8O-53

SIDE IMPACT AIRBAG CONTROL

MODULE - OPERATION................8O-54

SIDE MOLDINGS - INSTALLATION, BODY . . 23-36

SIDE MOLDINGS - REMOVAL, BODY.....23-36

SIDE VIEW MIRROR - INSTALLATION.....23-41

SIDE VIEW MIRROR - REMOVAL........23-41

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-27

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-27

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-44

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-42

SIDEVIEW MIRROR - REMOVAL.........8N-13

SIGNAL INDICATOR - DESCRIPTION,

TURN..............................8J-39

SIGNAL INDICATOR - OPERATION, TURN . . 8J-39

SIGNAL LAMP - INSTALLATION,

PARK/TURN.........................8L-21

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-21

SIGNAL SYSTEM - DESCRIPTION, TURN . . 8L-17

SIGNAL SYSTEM - OPERATION, TURN....8L-18

SILL TRIM COVER - INSTALLATION,

REAR DOOR........................23-72

SILL TRIM COVER - REMOVAL, REAR

DOOR.............................23-72

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-9

SIZE, SPARE WHEEL WITH MATCHING

TIRE - DESCRIPTION, FULL............22-15

SKID PLATE - INSTALLATION, FRONT.....13-24

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-26

SKID PLATE - REMOVAL, FRONT........13-24

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-26

SLEEVE - INSTALLATION, HEADREST.....23-82

SLEEVE - REMOVAL, HEADREST........23-82

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-285

SOLENOID - DESCRIPTION......21-253,21-431

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-12

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-13

SOLENOID - OPERATION........21-254,21-431

SOLENOID - OPERATION, EVAP/PURGE . . . 25-12

SOLENOID - REMOVAL, EVAP/PURGE.....25-13

SOLENOID SWITCH VALVE -

DESCRIPTION......................21-574

SOLENOID SWITCH VALVE - OPERATION . 21-574

SOLENOIDS - DESCRIPTION...........21-574

SOLENOIDS - OPERATION.............21-575

SOLENOID/TRS ASSEMBLY -

DESCRIPTION, TRANSMISSION........21-582

SOLENOID/TRS ASSEMBLY -

INSTALLATION, TRANSMISSION........21-583

SOLENOID/TRS ASSEMBLY -

OPERATION, TRANSMISSION..........21-582

SOLENOID/TRS ASSEMBLY - REMOVAL,

TRANSMISSION.....................21-583

SOLID LIFTERS/TAPPETS - CLEANING....9-328

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-328

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-328

SOLID LIFTERS/TAPPETS - REMOVAL....9-327

SPARE / TEMPORARY TIRE -

DESCRIPTION.......................22-15

SPARE TIRE / TEMPORARY -

DESCRIPTION........................22-5

SPARE WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE

..............22-15

SPARK PLUG - DESCRIPTION

...........8I-27

SPARK PLUG - REMOVAL

..............8I-30

SPARK PLUG CABLE - DESCRIPTION

.....8I-33

SPARK PLUG CABLE - INSTALLATION

.....8I-35SPARK PLUG CABLE - OPERATION.......8I-33

SPARK PLUG CABLE - REMOVAL........8I-34

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-5

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-5

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-33

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-27

SPARK PLUGS, SPECIFICATIONS..........8I-5

SPEAKER - DESCRIPTION..............8A-12

SPEAKER - DIAGNOSIS AND TESTING....8A-13

SPEAKER - INSTALLATION.............8A-15

SPEAKER - OPERATION...............8A-12

SPEAKER - REMOVAL.................8A-13

SPECIFICATIONS......................7-20

SPEED CONTROL - DESCRIPTION........8P-1

SPEED CONTROL - OPERATION..........8P-2

SPEED CONTROL - TORQUE.............8P-3

SPEED SENSOR - DESCRIPTION . . 21-254,21-431

SPEED SENSOR - DESCRIPTION, FRONT

WHEEL.............................5-41

SPEED SENSOR - DESCRIPTION, INPUT . 21-558

SPEED SENSOR - DESCRIPTION,

OUTPUT...........................21-567

SPEED SENSOR - DIAGNOSIS AND

TESTING, REAR WHEEL................5-43

SPEED SENSOR - INSTALLATION, FRONT

WHEEL.............................5-42

SPEED SENSOR - INSTALLATION, INPUT . 21-559

SPEED SENSOR - INSTALLATION,

OUTPUT...........................21-567

SPEED SENSOR - INSTALLATION, REAR

WHEEL.............................5-43

SPEED SENSOR - OPERATION . . . 21-254,21-431

SPEED SENSOR - OPERATION, FRONT

WHEEL.............................5-41

SPEED SENSOR - OPERATION, INPUT . . . 21-558

SPEED SENSOR - OPERATION, OUTPUT . . 21-567

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-41

SPEED SENSOR - REMOVAL, INPUT.....21-559

SPEED SENSOR - REMOVAL, OUTPUT . . . 21-567

SPEED SENSOR - REMOVAL, REAR

WHEEL.............................5-42

SPEEDOMETER - DESCRIPTION.........8J-36

SPEEDOMETER - OPERATION...........8J-36

SPEEDS - DESCRIPTION, TIRE

PRESSURE FOR HIGH..................22-6

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE.................23-41

SPLASH SHIELD - INSTALLATION, REAR

WHEELHOUSE.......................23-41

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE.......................23-40

SPLASH SHIELD - REMOVAL, REAR

WHEELHOUSE.......................23-41

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-15

SPRING - DESCRIPTION................2-41

SPRING - INSTALLATION.......2-22,2-36,2-41

SPRING - OPERATION..................2-41

SPRING - REMOVAL...........2-21,2-36,2-41

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-38

SPRING BUMPERS (3500) -

INSTALLATION, AUXILIARY..............2-40

SPRING BUMPERS (3500) - REMOVAL,

AUXILIARY..........................2-40

SPRING TIP INSERTS - INSTALLATION....2-42

SPRING TIP INSERTS - REMOVAL........2-41

SPRINGS - DESCRIPTION, VALVE . . . 9-125,9-31,

9-36

SPRINGS - INSTALLATION, VALVE . . 9-126,9-199,

9-31,9-37

SPRINGS - INSTALLATION, VALVES AND

VALVE

.............................9-379

SPRINGS - REMOVAL, VALVE

. 9-125,9-199,9-31,

9-37

SPRINGS - REMOVAL, VALVES AND

VALVE

.............................9-377

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES

................9-246,9-305

SPRINGS AND SEALS - REMOVAL,

VALVE

.............................9-308SPROCKETS - INSPECTION, TIMING

BELT/CHAIN.....................9-171,9-83

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN...........9-172,9-279,9-406,9-84

SPROCKETS - INSTALLATION,

TIMING/CHAIN.......................9-222

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN...........9-169,9-279,9-405,9-81

SPROCKETS - REMOVAL, TIMING/CHAIN . . 9-221

SQUEAK & RATTLE - STANDARD

PROCEDURE, BUZZ...................23-11

STABILIZER BAR - DESCRIPTION.........2-24

STABILIZER BAR - INSTALLATION....2-24,2-37

STABILIZER BAR - OPERATION...........2-24

STABILIZER BAR - REMOVAL........2-24,2-37

STAKING - STANDARD PROCEDURE,

HEAT ...............................23-3

STANDARD CAB - INSTALLATION........8O-31

STANDARD CAB - REMOVAL...........8O-28

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-34

STARTER MOTOR - INSTALLATION.......8F-37

STARTER MOTOR - REMOVAL..........8F-34

STARTER MOTOR RELAY - DESCRIPTION . 8F-38

STARTER MOTOR RELAY -

INSTALLATION.......................8F-39

STARTER MOTOR RELAY - OPERATION . . . 8F-38

STARTER MOTOR RELAY - REMOVAL.....8F-39

STARTER RELAY - DIAGNOSIS AND

TESTING.............................8F-38

STARTING - DESCRIPTION.............8F-28

STARTING - OPERATION...............8F-28

STARTING - STANDARD PROCEDURE,

JUMP...............................0-13

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-29

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-34

STARTING SYSTEM, SPECIFICATIONS.....8F-33

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING COLUMN - DIAGNOSIS AND

TESTING............................19-7

STEERING COLUMN OPENING COVER -

INSTALLATION.......................23-61

STEERING COLUMN OPENING COVER -

REMOVAL..........................23-61

STEERING COLUMN OPENING SUPPORT

BRACKET - INSTALLATION.............23-62

STEERING COLUMN OPENING SUPPORT

BRACKET - REMOVAL.................23-61

STEERING COUPLING - INSTALLATION,

UPPER.............................19-14

STEERING COUPLING - REMOVAL,

UPPER.............................19-13

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING FLUID - DESCRIPTION,

POWER..............................0-3

STEERING FLUID LEVEL CHECKING -

STANDARD PROCEDURE, POWER.......19-42

STEERING GEAR INPUT SHAFT SEAL -

INSTALLATION.......................19-28

STEERING GEAR INPUT SHAFT SEAL -

REMOVAL..........................19-25

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-22

STEERING GEAR, SPECIFICATIONS -

POWER............................19-21

STEERING LINKAGE, SPECIAL TOOLS....19-35

STEERING PRESSURE SWITCH -

DESCRIPTION, POWER................19-45

STEERING PRESSURE SWITCH -

OPERATION, POWER..................19-45

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-39

STEERING, SPECIAL TOOLS.............19-5

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER

........19-39

STEERING WHEEL - INSTALLATION

......19-15

STEERING WHEEL - REMOVAL

..........19-15

STEM SEAL - INSTALLATION, VALVE

.....9-378

STEM SEALS - DESCRIPTION, VALVE

....9-126,

9-198

32 INDEXDR

Description Group-Page Description Group-Page Description Group-Page