jump start DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 14 of 2895

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

INTERNATIONAL SYMBOLS

DESCRIPTION..........................1

FLUID TYPES

DESCRIPTION

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE.......................1

DESCRIPTION - ENGINE OIL AND

LUBRICANTS.........................2

DESCRIPTION - POWER STEERING FLUID . . 3

DESCRIPTION - ENGINE COOLANT........3

DESCRIPTION - TRANSFER CASE - NV241

GENII...............................4

DESCRIPTION - TRANSFER CASE - NV271 . . 4

DESCRIPTION - TRANSFER CASE - NV243 . . 4

DESCRIPTION - TRANSFER CASE - NV273 . . 4

DESCRIPTION - AXLE...................4DESCRIPTION - MANUAL TRANSMISSION . . . 4

DESCRIPTION - AUTOMATIC

TRANSMISSION FLUID..................4

OPERATION - AUTOMATIC TRANSMISSION

FLUID...............................5

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES.....................5

MAINTENANCE SCHEDULES

DESCRIPTION..........................6

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING...13

HOISTING

STANDARD PROCEDURE - HOISTING.......14

TOWING

STANDARD PROCEDURE - TOWING........15

INTERNATIONAL SYMBOLS

DESCRIPTION

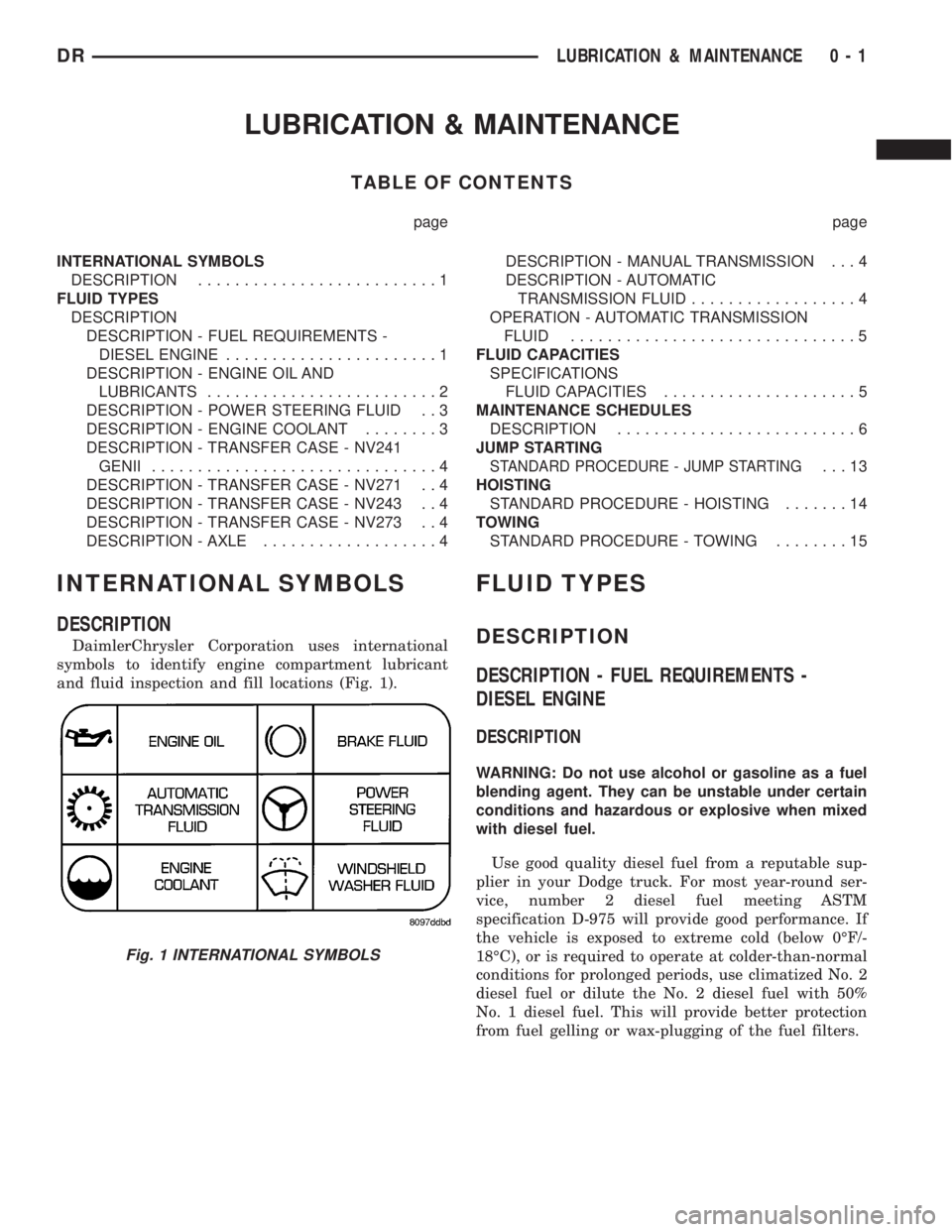

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 1).

FLUID TYPES

DESCRIPTION

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

DESCRIPTION

WARNING: Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed

with diesel fuel.

Use good quality diesel fuel from a reputable sup-

plier in your Dodge truck. For most year-round ser-

vice, number 2 diesel fuel meeting ASTM

specification D-975 will provide good performance. If

the vehicle is exposed to extreme cold (below 0ÉF/-

18ÉC), or is required to operate at colder-than-normal

conditions for prolonged periods, use climatized No. 2

diesel fuel or dilute the No. 2 diesel fuel with 50%

No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

Fig. 1 INTERNATIONAL SYMBOLS

DRLUBRICATION & MAINTENANCE 0 - 1

Page 26 of 2895

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.

²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

DRLUBRICATION & MAINTENANCE 0 - 13

Page 407 of 2895

For battery system maintenance schedules and

jump starting procedures, see the owner's manual in

the vehicle glove box. Optionally, refer to the Lubri-

cation and Maintenance section of this manual for

the proper battery jump starting procedure. While

battery charging can be considered a maintenance

procedure, the battery charging procedure and

related information are located later in this section of

the service manual. This was done because the bat-

tery must be fully-charged before any battery system

diagnosis or testing procedures can be performed.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important thatthe battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failure

must be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester), a 12-volt test lamp and/or special service

tools may be required. All OBD-sensed systems are

monitored by the PCM. Each monitored circuit is

assigned a Diagnostic Trouble Code (DTC). The PCM

will store a DTC in electronic memory for any failure

it detects. Always check the PCM for stored trouble

codes before returning the vehicle to service. Refer to

Charging System for the proper charging system test

procedures. Refer to Starting System for the proper

starting system test procedures.

MICRO 420 BATTERY TESTER

The Micro 420 automotive battery tester is

designed to help the dealership technician diagnose a

defective battery. Follow the instruction manual sup-

plied with the tester to properly diagnose a battery.

If the instruction manual is not available, refer to

the standard procedure in this section, which

includes the directions for using the Micro 420 bat-

tery tester.

8F - 2 BATTERY SYSTEMDR

BATTERY SYSTEM (Continued)

Page 439 of 2895

SPECIFICATIONS - TORQUE - STARTING

SYSTEM

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Battery Cable Eyelet Nut at

Solenoid (large nut - gas engines)25 19 221

Battery Cable Eyelet Nut at

Solenoid (large nut - diesel engine)14 - 120

Starter Solenoid Nut (small nut -

diesel engine)6-55

Starter Mounting Bolts - Gas

Engines68 50 -

Starter Mounting Nut - Gas Engines 68 50 -

Starter Mounting Bolts - Diesel 43 32 -

STARTER MOTOR

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with starter motor

removed from vehicle. Refer to Specifications for

starter motor specifications.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Mount starter motor securely in a soft-jawed

bench vise. The vise jaws should be clamped on the

mounting flange of starter motor. Never clamp on

starter motor by field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to starter motor in series, and set

ammeter to 100 ampere scale. See instructions pro-

vided by manufacturer of volt-ampere tester being

used.

(4) Install jumper wire from solenoid terminal to

solenoid battery terminal. The starter motor should

operate. If starter motor fails to operate, replace

faulty starter motor assembly.

(5) Adjust carbon pile load of tester to obtain free

running test voltage. Refer to Specifications for

starter motor free running test voltage specifications.

(6) Note reading on ammeter and compare reading

to free running test maximum amperage draw. Refer

to Specifications for starter motor free running test

maximum amperage draw specifications.

(7) If ammeter reading exceeds maximum amper-

age draw specification, replace faulty starter motor

assembly.

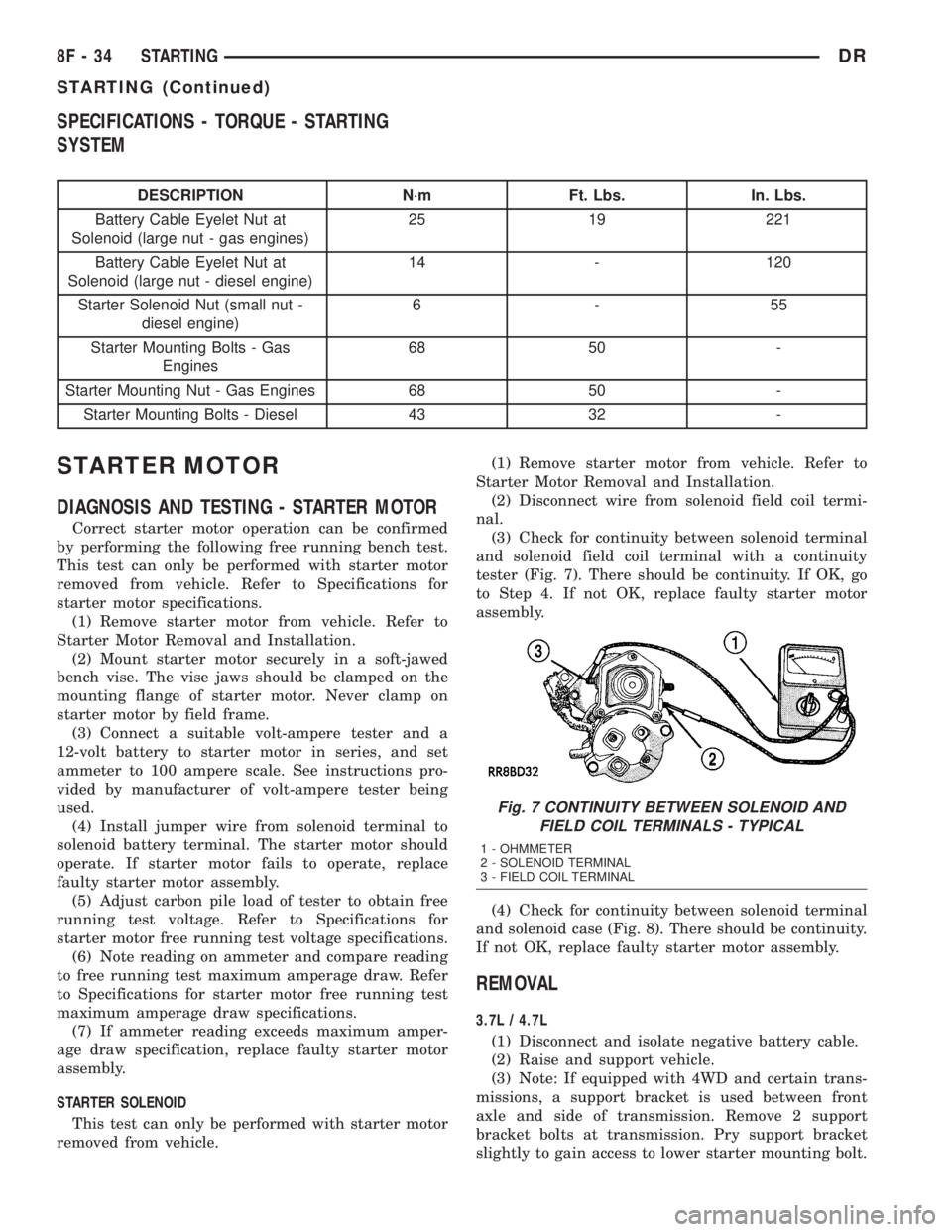

STARTER SOLENOID

This test can only be performed with starter motor

removed from vehicle.(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2) Disconnect wire from solenoid field coil termi-

nal.

(3) Check for continuity between solenoid terminal

and solenoid field coil terminal with a continuity

tester (Fig. 7). There should be continuity. If OK, go

to Step 4. If not OK, replace faulty starter motor

assembly.

(4) Check for continuity between solenoid terminal

and solenoid case (Fig. 8). There should be continuity.

If not OK, replace faulty starter motor assembly.

REMOVAL

3.7L / 4.7L

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Note: If equipped with 4WD and certain trans-

missions, a support bracket is used between front

axle and side of transmission. Remove 2 support

bracket bolts at transmission. Pry support bracket

slightly to gain access to lower starter mounting bolt.

Fig. 7 CONTINUITY BETWEEN SOLENOID AND

FIELD COIL TERMINALS - TYPICAL

1 - OHMMETER

2 - SOLENOID TERMINAL

3 - FIELD COIL TERMINAL

8F - 34 STARTINGDR

STARTING (Continued)

Page 491 of 2895

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

Except 5.7L V-8 :With the engine running,

remove spark plug cable from spark plug (one at a

time) and hold next to a good engine ground. If the

cable and spark plug are in good condition, the

engine rpm should drop and the engine will run

poorly. If engine rpm does not drop, the cable and/or

spark plug may not be operating properly and should

be replaced. Also check engine cylinder compression.

With the engine not running, connect one end of a

test probe to a good ground. Start the engine and run

the other end of the test probe along the entire

length of all spark plug cables. If cables are cracked

or punctured, there will be a noticeable spark jump

from the damaged area to the test probe. The cable

running from the ignition coil to the distributor cap

can be checked in the same manner. Cracked, dam-

aged or faulty cables should be replaced with resis-

tance type cable. This can be identified by the words

ELECTRONIC SUPPRESSION printed on the cable

jacket.Use an ohmmeter to test for open circuits, exces-

sive resistance or loose terminals. If equipped,

remove the distributor cap from the distributor.Do

not remove cables from cap.Remove cable from

spark plug. Connect ohmmeter to spark plug termi-

nal end of cable and to corresponding electrode in

distributor cap. Resistance should be 250 to 1000

Ohms per inch of cable. If not, remove cable from dis-

tributor cap tower and connect ohmmeter to the ter-

minal ends of cable. If resistance is not within

specifications as found in the SPARK PLUG CABLE

RESISTANCE chart, replace the cable. Test all spark

plug cables in this manner.

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

To test ignition coil-to-distributor cap cable (if

applicaple), do not remove the cable from the cap.

Connect ohmmeter to rotor button (center contact) of

distributor cap and terminal at ignition coil end of

cable. If resistance is not within specifications as

found in the Spark Plug Cable Resistance chart,

remove the cable from the distributor cap. Connect

the ohmmeter to the terminal ends of the cable. If

resistance is not within specifications as found in the

Spark Plug Cable Resistance chart, replace the cable.

Inspect the ignition coil tower for cracks, burns or

corrosion.

REMOVAL

5.9L V-8 / 8.0L V-10

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 54). Grasp the boot (not the cable) and pull it

off with a steady, even force.

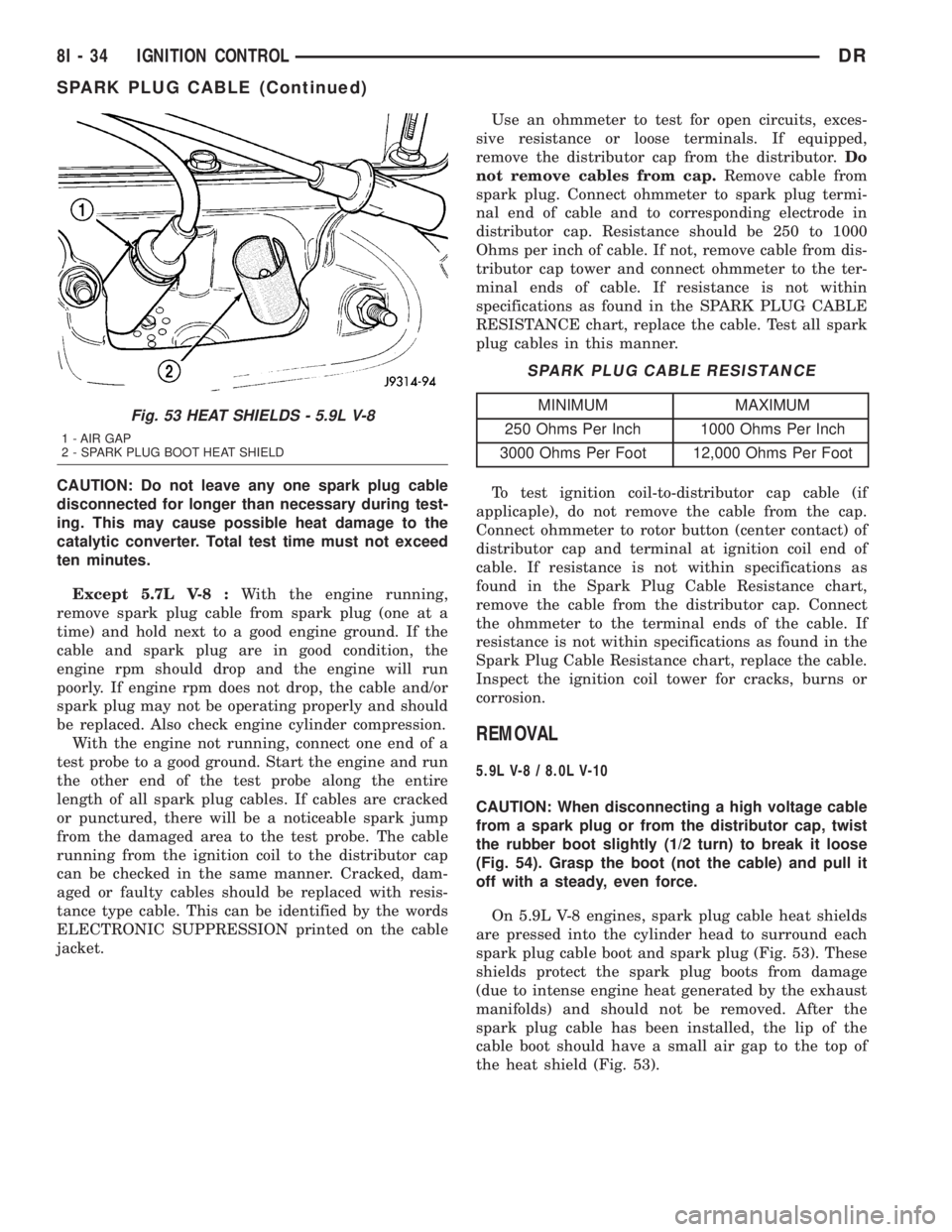

On 5.9L V-8 engines, spark plug cable heat shields

are pressed into the cylinder head to surround each

spark plug cable boot and spark plug (Fig. 53). These

shields protect the spark plug boots from damage

(due to intense engine heat generated by the exhaust

manifolds) and should not be removed. After the

spark plug cable has been installed, the lip of the

cable boot should have a small air gap to the top of

the heat shield (Fig. 53).

Fig. 53 HEAT SHIELDS - 5.9L V-8

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

8I - 34 IGNITION CONTROLDR

SPARK PLUG CABLE (Continued)

Page 1700 of 2895

(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

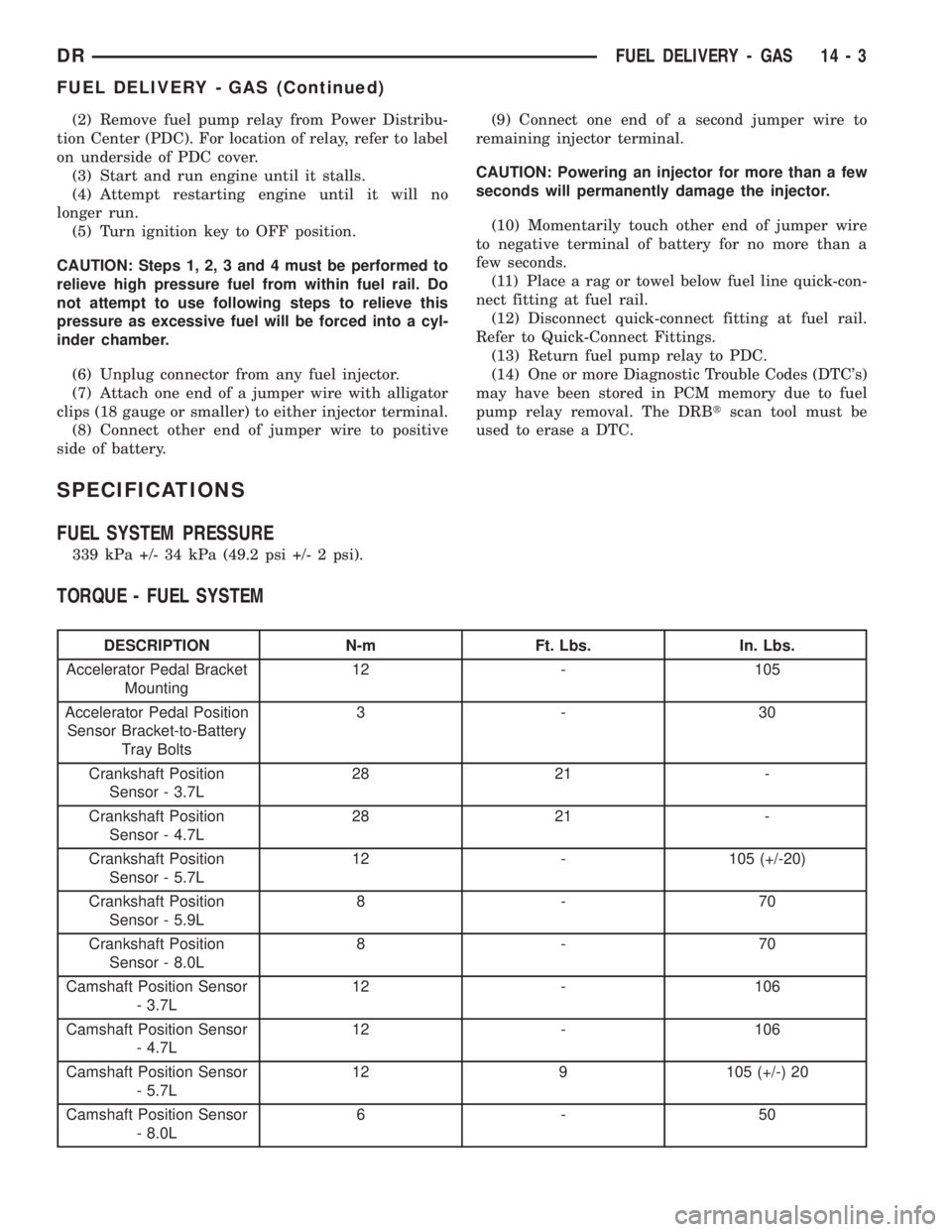

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa +/- 34 kPa (49.2 psi +/- 2 psi).

TORQUE - FUEL SYSTEM

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting12 - 105

Accelerator Pedal Position

Sensor Bracket-to-Battery

Tray Bolts3-30

Crankshaft Position

Sensor - 3.7L28 21 -

Crankshaft Position

Sensor - 4.7L28 21 -

Crankshaft Position

Sensor - 5.7L12 - 105 (+/-20)

Crankshaft Position

Sensor - 5.9L8-70

Crankshaft Position

Sensor - 8.0L8-70

Camshaft Position Sensor

- 3.7L12 - 106

Camshaft Position Sensor

- 4.7L12 - 106

Camshaft Position Sensor

- 5.7L12 9 105 (+/-) 20

Camshaft Position Sensor

- 8.0L6-50

DRFUEL DELIVERY - GAS 14 - 3

FUEL DELIVERY - GAS (Continued)

Page 2874 of 2895

JOINT - INSTALLATION, UPPER BALL.....2-33

JOINT - REMOVAL, LOWER BALL.....2-18,2-32

JOINT - REMOVAL, UPPER BALL.........2-33

JOINT-INNER - INSTALLATION, CV........3-16

JOINT-INNER - REMOVAL, CV............3-16

JOINT-OUTER - INSTALLATION, CV........3-13

JOINT-OUTER - REMOVAL, CV...........3-13

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-9

JOUNCE BUMPER - INSTALLATION.......2-40

JOUNCE BUMPER - REMOVAL...........2-40

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-321

JUMP STARTING - STANDARD

PROCEDURE.........................0-13

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-19

JUNCTION BLOCK - REMOVAL, BRAKE....5-19

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS),

DESCRIPTION - SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-8

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-8

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-8

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE.............8N-10

KNOCK SENSOR - DESCRIPTION.........8I-25

KNOCK SENSOR - INSTALLATION........8I-26

KNOCK SENSOR - OPERATION..........8I-25

KNOCK SENSOR - REMOVAL............8I-25

KNUCKLE - DESCRIPTION...............2-17

KNUCKLE - INSTALLATION..........2-18,2-34

KNUCKLE - OPERATION................2-17

KNUCKLE - REMOVAL..............2-17,2-34

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-1

LAMP - DESCRIPTION, DOME...........8L-24

LAMP - DESCRIPTION, READING........8L-26

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, BACKUP.........8L-7

LAMP - INSTALLATION, BRAKE..........8L-8

LAMP - INSTALLATION, CAB CLEARANCE . 8L-10

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - INSTALLATION, DOME..........8L-24

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-16

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-26

LAMP - INSTALLATION, TAIL

...........8L-21

LAMP - INSTALLATION, TURN

..........8L-22LAMP - INSTALLATION, UNDERHOOD....8L-22

LAMP - OPERATION, DOME............8L-24

LAMP - OPERATION, READING..........8L-26

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, BACKUP.............8L-7

LAMP - REMOVAL, BRAKE..............8L-8

LAMP - REMOVAL, CAB CLEARANCE.....8L-10

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - REMOVAL, DOME..............8L-24

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-16

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-26

LAMP - REMOVAL, TAIL...............8L-21

LAMP - REMOVAL, TURN..............8L-22

LAMP - REMOVAL, UNDERHOOD........8L-22

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-30

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-30

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-28

LAMP OUT INDICATOR - OPERATION.....8J-28

LAMP RELAY - DESCRIPTION, FOG........8L-11

LAMP RELAY - DESCRIPTION, PARK.....8L-19

LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-12

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-12

LAMP RELAY - OPERATION, PARK.......8L-19

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-20

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-7

LAMP SWITCH - DESCRIPTION, BRAKE....8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-9

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-10

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-8

LAMP SWITCH - REMOVAL, BRAKE.......8L-9

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-10

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-16

LAMP UNIT - INSTALLATION, TAIL.......8L-21

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-23

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-16

LAMP UNIT - REMOVAL, TAIL...........8L-21

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-22

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-25

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-25

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-124,9-31

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-308

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX

.....23-53

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN

.......................23-81

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-53

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-81LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL................23-47

LATCH STRIKER - INSTALLATION . . 23-17,23-24,

23-33

LATCH STRIKER - REMOVAL . 23-17,23-24,23-33

LATCH STRIKER / SECONDARY CATCH -

INSTALLATION.......................23-48

LATCH STRIKER / SECONDARY CATCH -

REMOVAL..........................23-48

LD & HD EXCEPT 4X4 HD -

INSTALLATION, ALL..................19-15

LD & HD EXCEPT 4X4 HD - REMOVAL,

ALL ...............................19-14

LEAD - DIAGNOSIS AND TESTING,

TIRE/VEHICLE........................22-8

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID . . . 21-143,21-324,

21-495

LEAK - DIAGNOSIS AND TESTING,

ENGINE OIL................9-150,9-214,9-63

LEAK DETECTION ASSY - DESCRIPTION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - INSTALLATION,

NATURAL VAC.......................25-24

LEAK DETECTION ASSY - OPERATION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - REMOVAL,

NATURAL VAC.......................25-24

LEAK DETECTION PUMP - DESCRIPTION . . 25-13

LEAK DETECTION PUMP - INSTALLATION . 25-16

LEAK DETECTION PUMP - OPERATION.....25-14

LEAK DETECTION PUMP - REMOVAL.....25-16

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE....9-182,

9-231,9-359,9-8,9-92

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....9-157,9-219,9-274,9-401

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-39

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM.........11-15

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM - TESTING.............7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL....................9-269,9-394

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-69

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-71

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA...........9-135,9-204,9-64

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-51

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-1

LEAKS - STANDARD PROCEDURE,

REPAIRING.........................22-10

LEARN - STANDARD PROCEDURE,

DRIVE.............................8E-21

LEARN - STANDARD PROCEDURE, TCM

QUICK.............................8E-21

LEFT - DESCRIPTION, CAMSHAFT(S).....9-113

LEFT - INSTALLATION..................2-34

LEFT - INSTALLATION, CAMSHAFT(S)....9-114

LEFT - INSTALLATION, CYLINDER HEAD . . . 9-23

LEFT - REMOVAL......................2-34

LEFT - REMOVAL, CAMSHAFT(S)........9-113

LEFT - REMOVAL, CYLINDER HEAD.......9-21

LEFT CYLINDER HEAD - INSTALLATION . . . 9-110

LEFT CYLINDER HEAD - REMOVAL.......9-106

LEFT OUTBOARD - INSTALLATION,

CENTER............................8O-45

LEFT OUTBOARD - REMOVAL, CENTER . . . 8O-43

LEFT REAR CABLE - INSTALLATION.......5-33

LEFT REAR CABLE - REMOVAL...........5-32

LEFT SIDE - INSTALLATION............9-122

LEFT SIDE - REMOVAL

................9-121

LENS REPLACEMENT - STANDARD

PROCEDURE, MODULE

................8M-3

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID

. . 21-201,21-381,

21-541

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID

........................5-18

LEVEL - STANDARD PROCEDURE,

ENGINE OIL

.........................9-341

DRINDEX 19

Description Group-Page Description Group-Page Description Group-Page

Page 2887 of 2895

SIDE - REMOVAL, LEFT................9-121

SIDE - REMOVAL, RIGHT..............9-121

SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL DRIVER...........23-59

SIDE BEZEL - REMOVAL, INSTRUMENT

PANEL DRIVER......................23-58

SIDE CURTAIN AIRBAG - DESCRIPTION . . . 8O-51

SIDE CURTAIN AIRBAG - INSTALLATION . . 8O-53

SIDE CURTAIN AIRBAG - OPERATION....8O-51

SIDE CURTAIN AIRBAG - REMOVAL......8O-52

SIDE IMPACT AIRBAG CONTROL

MODULE - DESCRIPTION..............8O-53

SIDE IMPACT AIRBAG CONTROL

MODULE - OPERATION................8O-54

SIDE MOLDINGS - INSTALLATION, BODY . . 23-36

SIDE MOLDINGS - REMOVAL, BODY.....23-36

SIDE VIEW MIRROR - INSTALLATION.....23-41

SIDE VIEW MIRROR - REMOVAL........23-41

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-27

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-27

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-44

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-42

SIDEVIEW MIRROR - REMOVAL.........8N-13

SIGNAL INDICATOR - DESCRIPTION,

TURN..............................8J-39

SIGNAL INDICATOR - OPERATION, TURN . . 8J-39

SIGNAL LAMP - INSTALLATION,

PARK/TURN.........................8L-21

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-21

SIGNAL SYSTEM - DESCRIPTION, TURN . . 8L-17

SIGNAL SYSTEM - OPERATION, TURN....8L-18

SILL TRIM COVER - INSTALLATION,

REAR DOOR........................23-72

SILL TRIM COVER - REMOVAL, REAR

DOOR.............................23-72

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-9

SIZE, SPARE WHEEL WITH MATCHING

TIRE - DESCRIPTION, FULL............22-15

SKID PLATE - INSTALLATION, FRONT.....13-24

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-26

SKID PLATE - REMOVAL, FRONT........13-24

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-26

SLEEVE - INSTALLATION, HEADREST.....23-82

SLEEVE - REMOVAL, HEADREST........23-82

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-285

SOLENOID - DESCRIPTION......21-253,21-431

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-12

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-13

SOLENOID - OPERATION........21-254,21-431

SOLENOID - OPERATION, EVAP/PURGE . . . 25-12

SOLENOID - REMOVAL, EVAP/PURGE.....25-13

SOLENOID SWITCH VALVE -

DESCRIPTION......................21-574

SOLENOID SWITCH VALVE - OPERATION . 21-574

SOLENOIDS - DESCRIPTION...........21-574

SOLENOIDS - OPERATION.............21-575

SOLENOID/TRS ASSEMBLY -

DESCRIPTION, TRANSMISSION........21-582

SOLENOID/TRS ASSEMBLY -

INSTALLATION, TRANSMISSION........21-583

SOLENOID/TRS ASSEMBLY -

OPERATION, TRANSMISSION..........21-582

SOLENOID/TRS ASSEMBLY - REMOVAL,

TRANSMISSION.....................21-583

SOLID LIFTERS/TAPPETS - CLEANING....9-328

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-328

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-328

SOLID LIFTERS/TAPPETS - REMOVAL....9-327

SPARE / TEMPORARY TIRE -

DESCRIPTION.......................22-15

SPARE TIRE / TEMPORARY -

DESCRIPTION........................22-5

SPARE WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE

..............22-15

SPARK PLUG - DESCRIPTION

...........8I-27

SPARK PLUG - REMOVAL

..............8I-30

SPARK PLUG CABLE - DESCRIPTION

.....8I-33

SPARK PLUG CABLE - INSTALLATION

.....8I-35SPARK PLUG CABLE - OPERATION.......8I-33

SPARK PLUG CABLE - REMOVAL........8I-34

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-5

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-5

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-33

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-27

SPARK PLUGS, SPECIFICATIONS..........8I-5

SPEAKER - DESCRIPTION..............8A-12

SPEAKER - DIAGNOSIS AND TESTING....8A-13

SPEAKER - INSTALLATION.............8A-15

SPEAKER - OPERATION...............8A-12

SPEAKER - REMOVAL.................8A-13

SPECIFICATIONS......................7-20

SPEED CONTROL - DESCRIPTION........8P-1

SPEED CONTROL - OPERATION..........8P-2

SPEED CONTROL - TORQUE.............8P-3

SPEED SENSOR - DESCRIPTION . . 21-254,21-431

SPEED SENSOR - DESCRIPTION, FRONT

WHEEL.............................5-41

SPEED SENSOR - DESCRIPTION, INPUT . 21-558

SPEED SENSOR - DESCRIPTION,

OUTPUT...........................21-567

SPEED SENSOR - DIAGNOSIS AND

TESTING, REAR WHEEL................5-43

SPEED SENSOR - INSTALLATION, FRONT

WHEEL.............................5-42

SPEED SENSOR - INSTALLATION, INPUT . 21-559

SPEED SENSOR - INSTALLATION,

OUTPUT...........................21-567

SPEED SENSOR - INSTALLATION, REAR

WHEEL.............................5-43

SPEED SENSOR - OPERATION . . . 21-254,21-431

SPEED SENSOR - OPERATION, FRONT

WHEEL.............................5-41

SPEED SENSOR - OPERATION, INPUT . . . 21-558

SPEED SENSOR - OPERATION, OUTPUT . . 21-567

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-41

SPEED SENSOR - REMOVAL, INPUT.....21-559

SPEED SENSOR - REMOVAL, OUTPUT . . . 21-567

SPEED SENSOR - REMOVAL, REAR

WHEEL.............................5-42

SPEEDOMETER - DESCRIPTION.........8J-36

SPEEDOMETER - OPERATION...........8J-36

SPEEDS - DESCRIPTION, TIRE

PRESSURE FOR HIGH..................22-6

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE.................23-41

SPLASH SHIELD - INSTALLATION, REAR

WHEELHOUSE.......................23-41

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE.......................23-40

SPLASH SHIELD - REMOVAL, REAR

WHEELHOUSE.......................23-41

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-15

SPRING - DESCRIPTION................2-41

SPRING - INSTALLATION.......2-22,2-36,2-41

SPRING - OPERATION..................2-41

SPRING - REMOVAL...........2-21,2-36,2-41

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-38

SPRING BUMPERS (3500) -

INSTALLATION, AUXILIARY..............2-40

SPRING BUMPERS (3500) - REMOVAL,

AUXILIARY..........................2-40

SPRING TIP INSERTS - INSTALLATION....2-42

SPRING TIP INSERTS - REMOVAL........2-41

SPRINGS - DESCRIPTION, VALVE . . . 9-125,9-31,

9-36

SPRINGS - INSTALLATION, VALVE . . 9-126,9-199,

9-31,9-37

SPRINGS - INSTALLATION, VALVES AND

VALVE

.............................9-379

SPRINGS - REMOVAL, VALVE

. 9-125,9-199,9-31,

9-37

SPRINGS - REMOVAL, VALVES AND

VALVE

.............................9-377

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES

................9-246,9-305

SPRINGS AND SEALS - REMOVAL,

VALVE

.............................9-308SPROCKETS - INSPECTION, TIMING

BELT/CHAIN.....................9-171,9-83

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN...........9-172,9-279,9-406,9-84

SPROCKETS - INSTALLATION,

TIMING/CHAIN.......................9-222

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN...........9-169,9-279,9-405,9-81

SPROCKETS - REMOVAL, TIMING/CHAIN . . 9-221

SQUEAK & RATTLE - STANDARD

PROCEDURE, BUZZ...................23-11

STABILIZER BAR - DESCRIPTION.........2-24

STABILIZER BAR - INSTALLATION....2-24,2-37

STABILIZER BAR - OPERATION...........2-24

STABILIZER BAR - REMOVAL........2-24,2-37

STAKING - STANDARD PROCEDURE,

HEAT ...............................23-3

STANDARD CAB - INSTALLATION........8O-31

STANDARD CAB - REMOVAL...........8O-28

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-34

STARTER MOTOR - INSTALLATION.......8F-37

STARTER MOTOR - REMOVAL..........8F-34

STARTER MOTOR RELAY - DESCRIPTION . 8F-38

STARTER MOTOR RELAY -

INSTALLATION.......................8F-39

STARTER MOTOR RELAY - OPERATION . . . 8F-38

STARTER MOTOR RELAY - REMOVAL.....8F-39

STARTER RELAY - DIAGNOSIS AND

TESTING.............................8F-38

STARTING - DESCRIPTION.............8F-28

STARTING - OPERATION...............8F-28

STARTING - STANDARD PROCEDURE,

JUMP...............................0-13

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-29

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-34

STARTING SYSTEM, SPECIFICATIONS.....8F-33

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING COLUMN - DIAGNOSIS AND

TESTING............................19-7

STEERING COLUMN OPENING COVER -

INSTALLATION.......................23-61

STEERING COLUMN OPENING COVER -

REMOVAL..........................23-61

STEERING COLUMN OPENING SUPPORT

BRACKET - INSTALLATION.............23-62

STEERING COLUMN OPENING SUPPORT

BRACKET - REMOVAL.................23-61

STEERING COUPLING - INSTALLATION,

UPPER.............................19-14

STEERING COUPLING - REMOVAL,

UPPER.............................19-13

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING FLUID - DESCRIPTION,

POWER..............................0-3

STEERING FLUID LEVEL CHECKING -

STANDARD PROCEDURE, POWER.......19-42

STEERING GEAR INPUT SHAFT SEAL -

INSTALLATION.......................19-28

STEERING GEAR INPUT SHAFT SEAL -

REMOVAL..........................19-25

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-22

STEERING GEAR, SPECIFICATIONS -

POWER............................19-21

STEERING LINKAGE, SPECIAL TOOLS....19-35

STEERING PRESSURE SWITCH -

DESCRIPTION, POWER................19-45

STEERING PRESSURE SWITCH -

OPERATION, POWER..................19-45

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-39

STEERING, SPECIAL TOOLS.............19-5

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER

........19-39

STEERING WHEEL - INSTALLATION

......19-15

STEERING WHEEL - REMOVAL

..........19-15

STEM SEAL - INSTALLATION, VALVE

.....9-378

STEM SEALS - DESCRIPTION, VALVE

....9-126,

9-198

32 INDEXDR

Description Group-Page Description Group-Page Description Group-Page