Oss DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 456 of 2895

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........1REMOVAL.............................2

INSTALLATION..........................2

HORN SWITCH

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - HORN SWITCH . . . 2

HORN SYSTEM

DESCRIPTION

The dual-note horn system features dual electro-

magnetic horn units. The horn system includes the

following major components:

²Horn- The two horns are located on the left

side of the engine compartment below the Integrated

Power Module (IPM).

²Horn Switch- The horn switch is molded into

the driver airbag trim cover.

OPERATION

The horn system operates on battery current

received through a fuse in the Integrated Power

Module (IPM). The horn system circuit is designed so

that the system will remain operational, regardless

of the ignition switch position.

DIAGNOSIS AND TESTING - HORN SYSTEM

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn fuse from the Integrated Power Module

(IPM).WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

HORN

DIAGNOSIS AND TESTING - HORN

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DRHORN 8H - 1

Page 457 of 2895

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

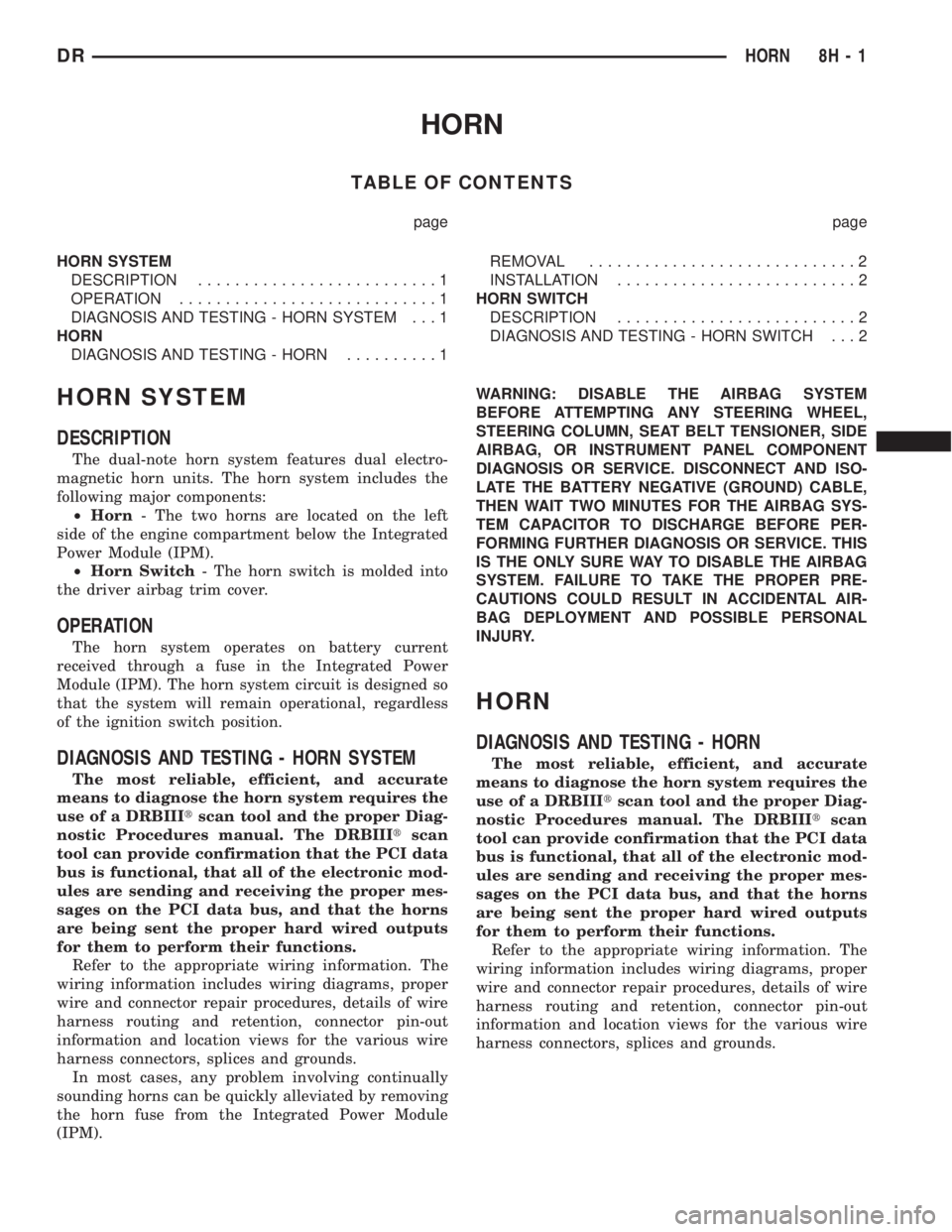

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connectors from

the horns (Fig. 1).

(3) Remove mounting bolt and remove horns.

INSTALLATION

(1) Position horns and install mounting bolt.

Tighten the bolt to 10 N´m (85 in. lbs.).

(2) Connect wire harness connectors.

(3) Connect battery negative cable.

HORN SWITCH

DESCRIPTION

The horn switch is molded into the driver airbag.

The horn switch can not be serviced separately. For

service procedures, (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

DIAGNOSIS AND TESTING - HORN SWITCH

The most reliable, efficient, and accurate

means to diagnose the horn system requires the

use of a DRBIIItscan tool and the proper Diag-

nostic Procedures manual. The DRBIIItscan

tool can provide confirmation that the PCI data

bus is functional, that all of the electronic mod-

ules are sending and receiving the proper mes-

sages on the PCI data bus, and that the horns

are being sent the proper hard wired outputs

for them to perform their functions.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 1 HORN

1 - WIRE HARNESS CONNECTORS

2 - HORNS

3 - MOUNTING BOLT

8H - 2 HORNDR

HORN (Continued)

Page 463 of 2895

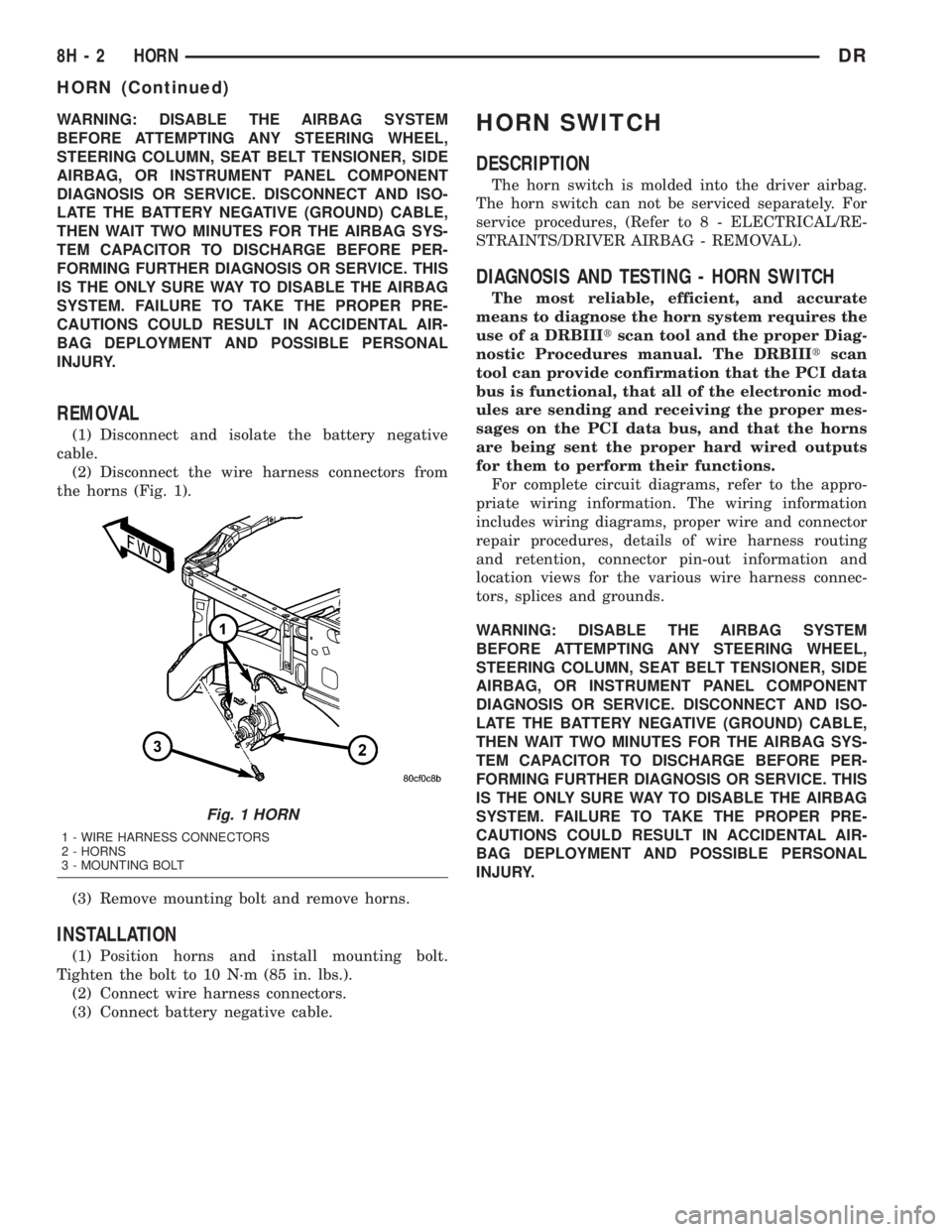

IGNITION COIL RESISTANCE - 3.7L V-6

PRIMARY RESISTANCE

21-27ÉC (70-80ÉF)SECONDARY

RESISTANCE 21-27ÉC

(70-80ÉF)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

IGNITION COIL RESISTANCE - 4.7L V-8

PRIMARY

RESISTANCE 21-27ÉC

(70-80ÉF)SECONDARY

RESISTANCE 21-27ÉC

(70-80ÉF)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

IGNITION COIL RESISTANCE - 5.7L V-8

PRIMARY RESISTANCE @ 21-27ÉC (70-80ÉF)

0.558 - 0.682 Ohms

(Plus or Minus 10% @ 70-80É F)

IGNITION COIL RESISTANCE - 5.9L

COIL MANUFACTURERPRIMARY RESISTANCE

21-27ÉC (70-80ÉF)SECONDARY RESISTANCE 21-27ÉC

(70-80ÉF)

Diamond 0.97 - 1.18 Ohms 11,300 - 15,300 Ohms

Toyodenso 0.95 - 1.20 Ohms 11,300 - 13,300 Ohms

IGNITION COIL RESISTANCE ± 8.0L V-10

ENGINE

Primary Resistance: 0.53-0.65 Ohms. Test across the

primary connector. Refer to text for test procedures.

Secondary Resistance: 10.9-14.7K Ohms. Test across

the individual coil towers. Refer to text for test

procedures.

IGNITION TIMING

Ignition timing is not adjustable on any engine.

AUTOMATIC SHUT DOWN

RELAY

DESCRIPTION - PCM OUTPUT

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements.The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if:

²the ignition key is left in the ON position. This

is if the engine has not been running for approxi-

mately 1.8 seconds.

²there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

8I - 6 IGNITION CONTROLDR

IGNITION CONTROL (Continued)

Page 472 of 2895

8.0L V±10

If Replacing Old Sensor With Original

The camshaft position sensor is located on the tim-

ing chain case/cover on the left-front side of the

engine (Fig. 18).

When installing a used camshaft position sensor,

the sensor depth must be adjusted to prevent contact

with the camshaft gear (sprocket).

(1) Observe the face of the sensor. If any of the

original rib material remains (Fig. 19), it must be cut

down flush to the face of the sensor with a razor

knife. Remove only enough of the rib material until

the face of the sensor is flat. Do not remove more

material than necessary as damage to sensor may

result. Due to a high magnetic field and possible elec-

trical damage to the sensor, never use an electric

grinder to remove material from sensor.

(2) From the parts department, obtain a peel-and-

stick paper spacer (Fig. 19). These special paper

spacers are of a certain thickness and are to be used

as a tool to set sensor depth.

(3) Clean the face of sensor and apply paper

spacer (Fig. 19).

(4) Apply a small amount of engine oil to the sen-

sor o-ring (Fig. 20).

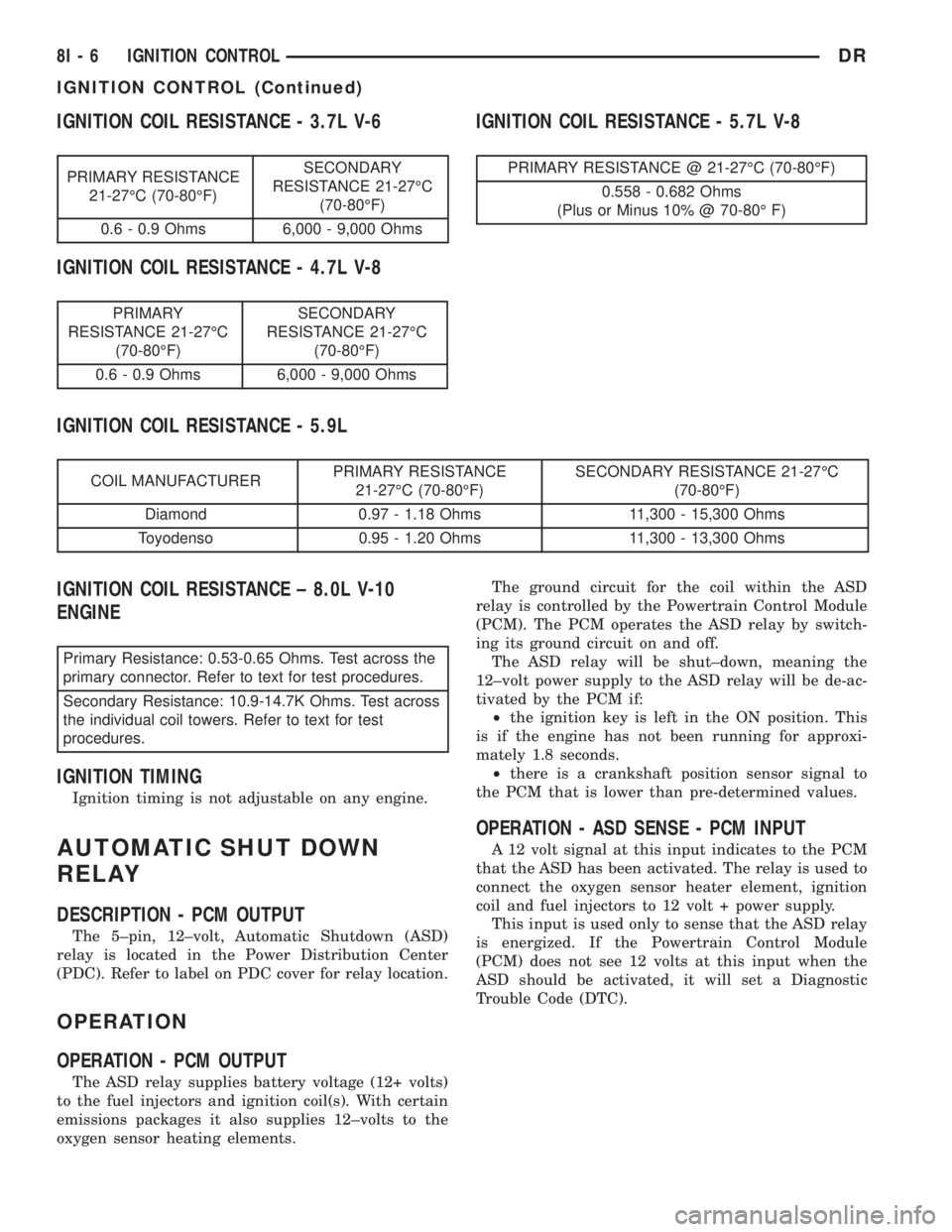

A low and high area are machined into the cam-

shaft drive gear (Fig. 21). The sensor is positioned in

the timing gear cover so that a small air gap (Fig.

21) exists between the face of sensor and the high

machined area of cam gear.

Before the sensor is installed, the cam gear may

have to be rotated. This is to allow the high

machined area on the gear to be directly in front of

the sensor mounting hole opening on the timing gear

cover.

Do not install sensor with gear positioned at

low area (Fig. 22) or (Fig. 21). When the engine

is started, the sensor will be broken.

(5) Using a 1/2 in. wide metal ruler, measure the

distance from the cam gear to the face of the sensor

mounting hole opening on the timing gear cover (Fig.

22).

(6) If the dimension is approximately 1.818 inches,

it is OK to install sensor. Proceed to step Step 9.

(7) If the dimension is approximately 2.018 inches,

the cam gear will have to be rotated.

(8) Attach a socket to the vibration damper mount-

ing bolt and rotate engine until the 1.818 inch

dimension is attained.

(9) Install the sensor into the timing case/cover

with a slight rocking action until the paper spacer

contacts the camshaft gear. Do not install the sensor

mounting bolt. Do not twist the sensor into position

as damage to the o-ring or tearing of the paper

spacer may result.(10) Scratch a scribe line into the timing chain

case/cover to indicate depth of sensor (Fig. 20).

(11) Remove the sensor from timing chain case/

cover.

(12) Remove paper spacer from sensor. This step

must be followed to prevent the paper spacer from

getting into the engine lubrication system.

(13) Again, apply a small amount of engine oil to

sensor o-ring.

(14) Again, install the sensor into the timing case/

cover with a slight rocking action until the sensor is

aligned to scribe line.

(15) Install sensor mounting bolt and tighten to 6

N´m (50 in. lbs.) torque.

(16) Connect engine wiring harness to sensor.

Replacing With a New Sensor

(1) Apply a small amount of engine oil to the sen-

sor o-ring (Fig. 20).

A low and high area are machined into the cam-

shaft drive gear (Fig. 21). The sensor is positioned in

the timing gear cover so that a small air gap (Fig.

21) exists between the face of sensor and the high

machined area of cam gear.

Before the sensor is installed, the cam gear may

have to be rotated. This is to allow the high

machined area on the gear to be directly in front of

the sensor mounting hole opening on the timing gear

cover.

Fig. 21 SENSOR OPERATION ± 8.0L V-10 ENGINE

1 - CAM DRIVE GEAR

2 - LOW MACHINED AREA

3 - HIGH MACHINED AREA

4 - CAMSHAFT POSITION SENSOR

5 - AIR GAP

DRIGNITION CONTROL 8I - 15

CAMSHAFT POSITION SENSOR (Continued)

Page 475 of 2895

INSTALLATION

If engine has been cranked while distributor is

removed, establish the relationship between distribu-

tor shaft and number one piston position as follows:

Rotate crankshaft in a clockwise direction, as

viewed from front, until number one cylinder piston

is at top of compression stroke (compression should

be felt on finger with number one spark plug

removed). Then continue to slowly rotate engine

clockwise until indicating mark (Fig. 24) is aligned to

0 degree (TDC) mark on timing chain cover.

(1) Clean top of cylinder block for a good seal

between distributor base and block.

(2) Lightly oil the rubber o-ring seal on the distrib-

utor housing.

(3) Install rotor to distributor shaft.

(4) Position distributor into engine to its original

position. Engage tongue of distributor shaft with slot

in distributor oil pump drive gear. Position rotor to

the number one spark plug cable position.

(5) Install distributor holddown clamp and clamp

bolt. Do not tighten bolt at this time.

(6) Rotate the distributor housing until rotor is

aligned to CYL. NO. 1 alignment mark on the cam-

shaft position sensor (Fig. 25).

(7) Tighten clamp holddown bolt (Fig. 26) to 22.5

N´m (200 in. lbs.) torque.

(8) Connect camshaft position sensor wiring har-

ness to main engine harness.

(9) Install distributor cap. Tighten mounting

screws.

(10) Refer to the following, Checking Distributor

Position.

Checking Distributor Position

To verify correct distributor rotational position, the

DRB scan tool must be used.

WARNING: WHEN PERFORMING THE FOLLOWING

TEST, THE ENGINE WILL BE RUNNING. BE CARE-

FUL NOT TO STAND IN LINE WITH THE FAN

BLADES OR FAN BELT. DO NOT WEAR LOOSE

CLOTHING.

(1) Connect DRB scan tool to data link connector.

The data link connector is located in passenger com-

partment, below and to left of steering column.

(2) Gain access to SET SYNC screen on DRB.

(3) Follow directions on DRB screen and start

engine. Bring to operating temperature (engine must

be in ªclosed loopº mode).

(4) With engine running atidle speed, the words

IN RANGE should appear on screen along with 0É.

This indicates correct distributor position.(5) If a plus (+) or a minus (-) is displayed next to

degree number, and/or the degree displayed is not

zero, loosen but do not remove distributor holddown

clamp bolt. Rotate distributor until IN RANGE

appears on screen. Continue to rotate distributor

until achieving as close to 0É as possible. After

adjustment, tighten clamp bolt to 22.5 N´m (200 in.

lbs.) torque.

Do not attempt to adjust ignition timing using this

method. Rotating distributor will have no effect on

ignition timing. All ignition timing values are con-

trolled by Powertrain Control Module (PCM).

After testing, install air cleaner tubing.

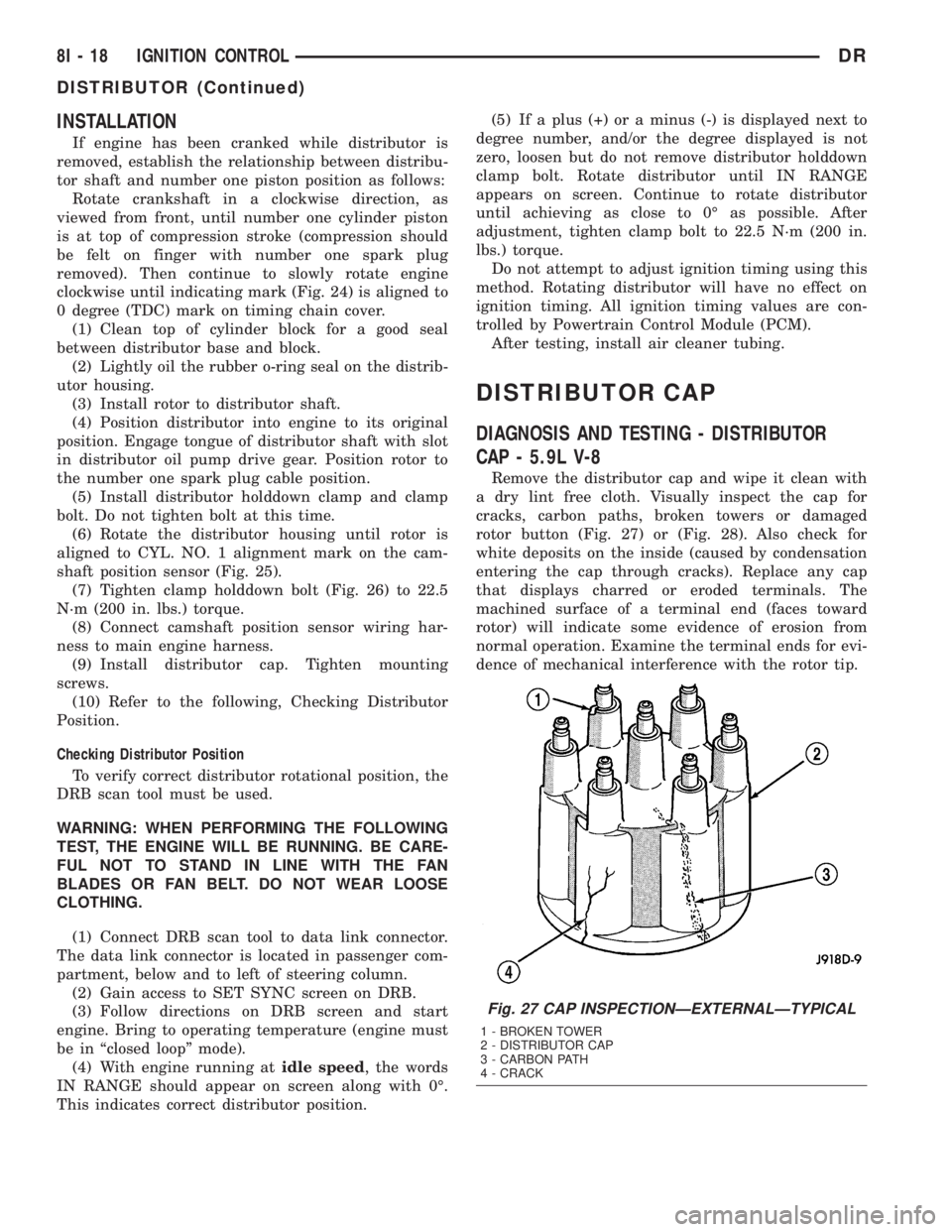

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING - DISTRIBUTOR

CAP - 5.9L V-8

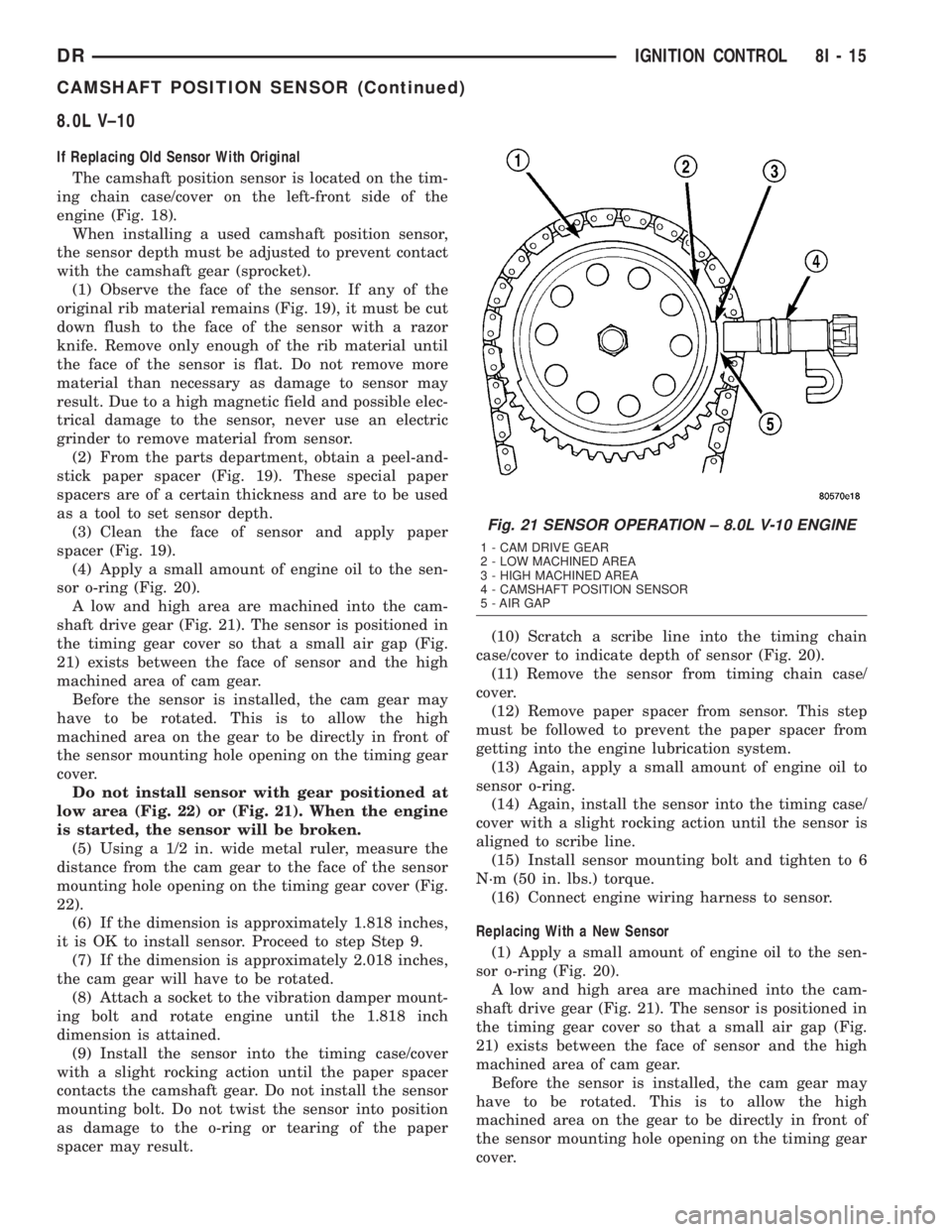

Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers or damaged

rotor button (Fig. 27) or (Fig. 28). Also check for

white deposits on the inside (caused by condensation

entering the cap through cracks). Replace any cap

that displays charred or eroded terminals. The

machined surface of a terminal end (faces toward

rotor) will indicate some evidence of erosion from

normal operation. Examine the terminal ends for evi-

dence of mechanical interference with the rotor tip.

Fig. 27 CAP INSPECTIONÐEXTERNALÐTYPICAL

1 - BROKEN TOWER

2 - DISTRIBUTOR CAP

3 - CARBON PATH

4 - CRACK

8I - 18 IGNITION CONTROLDR

DISTRIBUTOR (Continued)

Page 480 of 2895

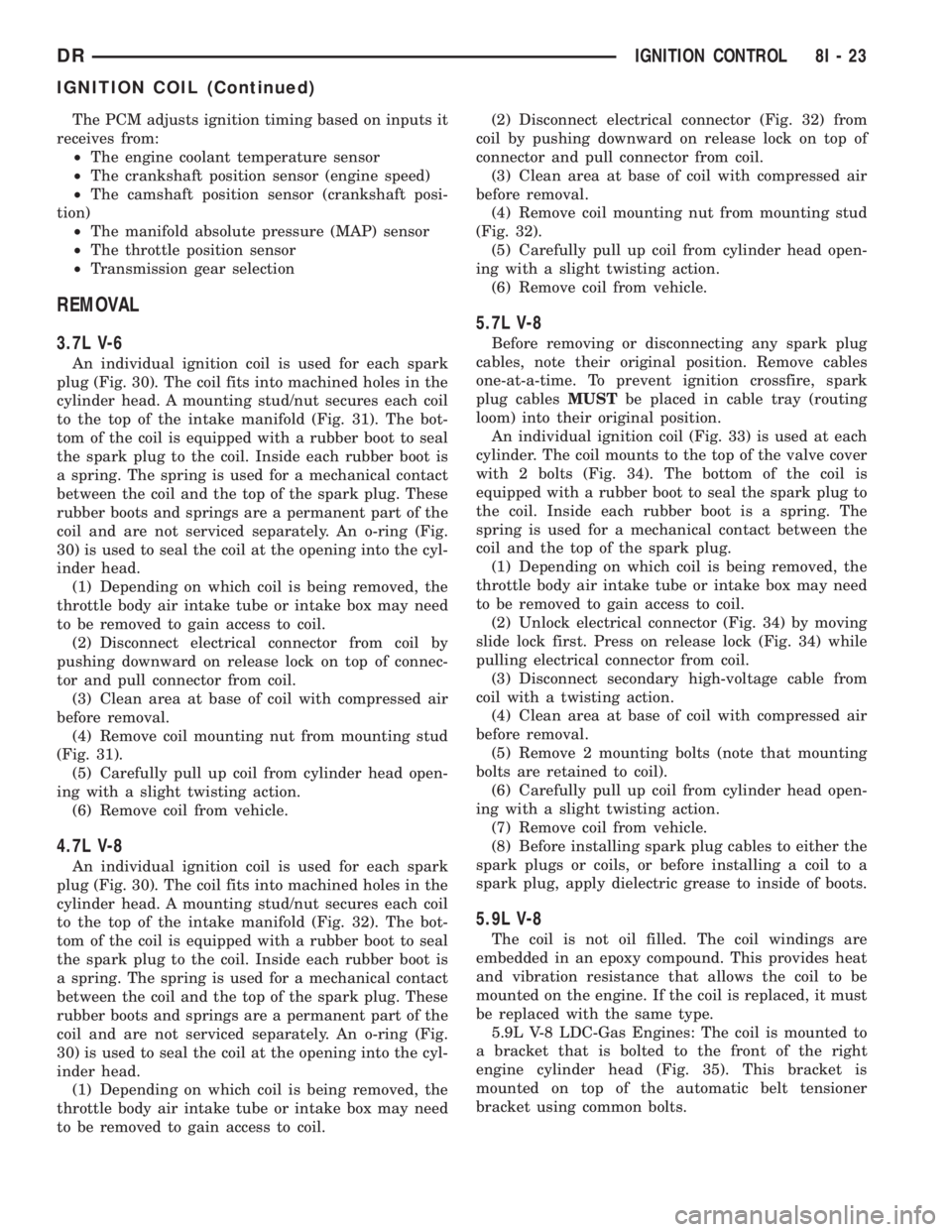

The PCM adjusts ignition timing based on inputs it

receives from:

²The engine coolant temperature sensor

²The crankshaft position sensor (engine speed)

²The camshaft position sensor (crankshaft posi-

tion)

²The manifold absolute pressure (MAP) sensor

²The throttle position sensor

²Transmission gear selection

REMOVAL

3.7L V-6

An individual ignition coil is used for each spark

plug (Fig. 30). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 31). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

30) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector from coil by

pushing downward on release lock on top of connec-

tor and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 31).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

4.7L V-8

An individual ignition coil is used for each spark

plug (Fig. 30). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 32). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

30) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.(2) Disconnect electrical connector (Fig. 32) from

coil by pushing downward on release lock on top of

connector and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 32).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

5.7L V-8

Before removing or disconnecting any spark plug

cables, note their original position. Remove cables

one-at-a-time. To prevent ignition crossfire, spark

plug cablesMUSTbe placed in cable tray (routing

loom) into their original position.

An individual ignition coil (Fig. 33) is used at each

cylinder. The coil mounts to the top of the valve cover

with 2 bolts (Fig. 34). The bottom of the coil is

equipped with a rubber boot to seal the spark plug to

the coil. Inside each rubber boot is a spring. The

spring is used for a mechanical contact between the

coil and the top of the spark plug.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Unlock electrical connector (Fig. 34) by moving

slide lock first. Press on release lock (Fig. 34) while

pulling electrical connector from coil.

(3) Disconnect secondary high-voltage cable from

coil with a twisting action.

(4) Clean area at base of coil with compressed air

before removal.

(5) Remove 2 mounting bolts (note that mounting

bolts are retained to coil).

(6) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(7) Remove coil from vehicle.

(8) Before installing spark plug cables to either the

spark plugs or coils, or before installing a coil to a

spark plug, apply dielectric grease to inside of boots.

5.9L V-8

The coil is not oil filled. The coil windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the coil to be

mounted on the engine. If the coil is replaced, it must

be replaced with the same type.

5.9L V-8 LDC-Gas Engines: The coil is mounted to

a bracket that is bolted to the front of the right

engine cylinder head (Fig. 35). This bracket is

mounted on top of the automatic belt tensioner

bracket using common bolts.

DRIGNITION CONTROL 8I - 23

IGNITION COIL (Continued)

Page 481 of 2895

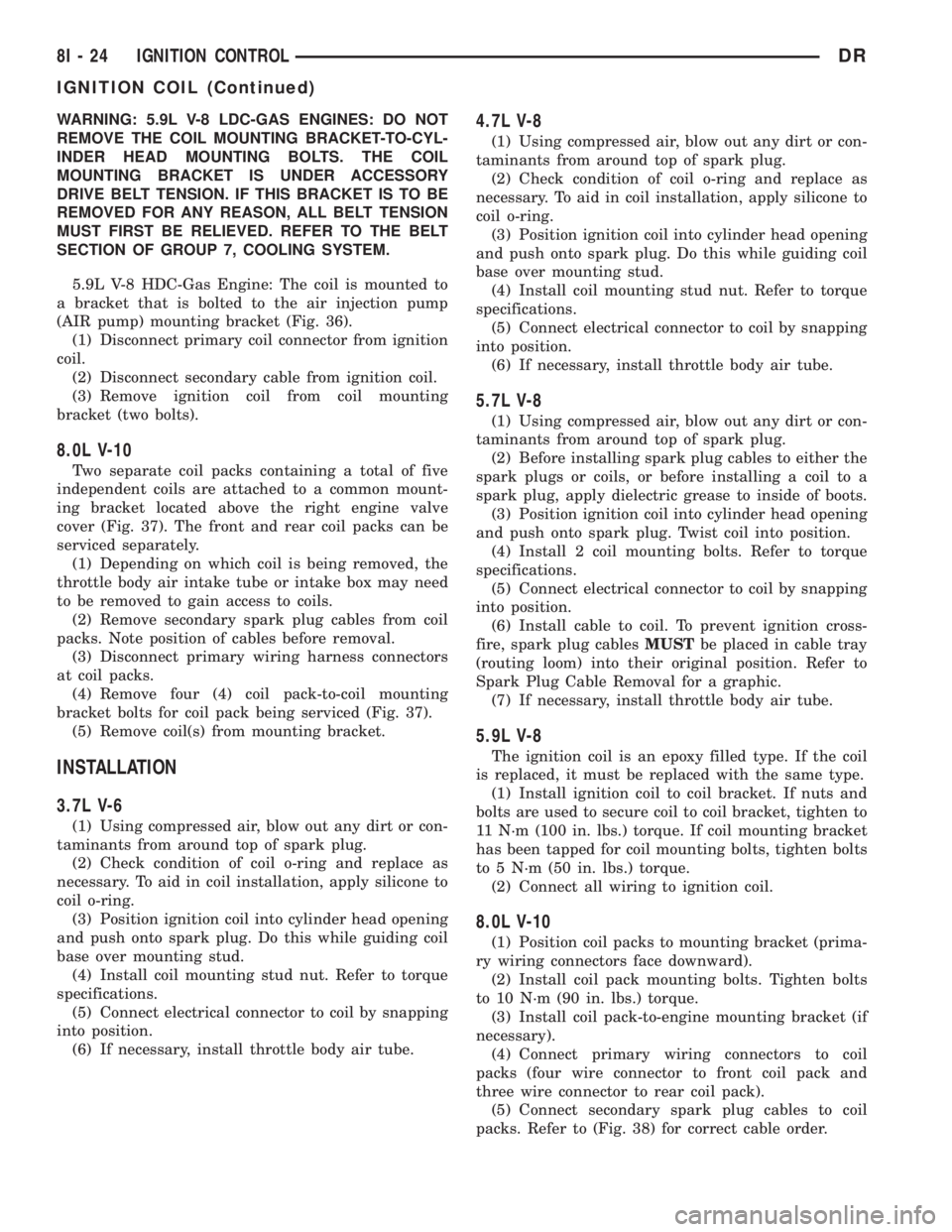

WARNING: 5.9L V-8 LDC-GAS ENGINES: DO NOT

REMOVE THE COIL MOUNTING BRACKET-TO-CYL-

INDER HEAD MOUNTING BOLTS. THE COIL

MOUNTING BRACKET IS UNDER ACCESSORY

DRIVE BELT TENSION. IF THIS BRACKET IS TO BE

REMOVED FOR ANY REASON, ALL BELT TENSION

MUST FIRST BE RELIEVED. REFER TO THE BELT

SECTION OF GROUP 7, COOLING SYSTEM.

5.9L V-8 HDC-Gas Engine: The coil is mounted to

a bracket that is bolted to the air injection pump

(AIR pump) mounting bracket (Fig. 36).

(1) Disconnect primary coil connector from ignition

coil.

(2) Disconnect secondary cable from ignition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts).

8.0L V-10

Two separate coil packs containing a total of five

independent coils are attached to a common mount-

ing bracket located above the right engine valve

cover (Fig. 37). The front and rear coil packs can be

serviced separately.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coils.

(2) Remove secondary spark plug cables from coil

packs. Note position of cables before removal.

(3) Disconnect primary wiring harness connectors

at coil packs.

(4) Remove four (4) coil pack-to-coil mounting

bracket bolts for coil pack being serviced (Fig. 37).

(5) Remove coil(s) from mounting bracket.

INSTALLATION

3.7L V-6

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install coil mounting stud nut. Refer to torque

specifications.

(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube.

4.7L V-8

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install coil mounting stud nut. Refer to torque

specifications.

(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube.

5.7L V-8

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Before installing spark plug cables to either the

spark plugs or coils, or before installing a coil to a

spark plug, apply dielectric grease to inside of boots.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Twist coil into position.

(4) Install 2 coil mounting bolts. Refer to torque

specifications.

(5) Connect electrical connector to coil by snapping

into position.

(6) Install cable to coil. To prevent ignition cross-

fire, spark plug cablesMUSTbe placed in cable tray

(routing loom) into their original position. Refer to

Spark Plug Cable Removal for a graphic.

(7) If necessary, install throttle body air tube.

5.9L V-8

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

(1) Install ignition coil to coil bracket. If nuts and

bolts are used to secure coil to coil bracket, tighten to

11 N´m (100 in. lbs.) torque. If coil mounting bracket

has been tapped for coil mounting bolts, tighten bolts

to 5 N´m (50 in. lbs.) torque.

(2) Connect all wiring to ignition coil.

8.0L V-10

(1) Position coil packs to mounting bracket (prima-

ry wiring connectors face downward).

(2) Install coil pack mounting bolts. Tighten bolts

to 10 N´m (90 in. lbs.) torque.

(3) Install coil pack-to-engine mounting bracket (if

necessary).

(4) Connect primary wiring connectors to coil

packs (four wire connector to front coil pack and

three wire connector to rear coil pack).

(5) Connect secondary spark plug cables to coil

packs. Refer to (Fig. 38) for correct cable order.

8I - 24 IGNITION CONTROLDR

IGNITION COIL (Continued)

Page 484 of 2895

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts. Refer to

torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor wiring harness to engine

harness at rear of intake manifold.

5.7L V-8

(1) Thoroughly clean knock sensor mounting hole.

(2) Install sensor into cylinder block.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolt. Refer to

torque specification.

(4) Install electrical connector to sensor.

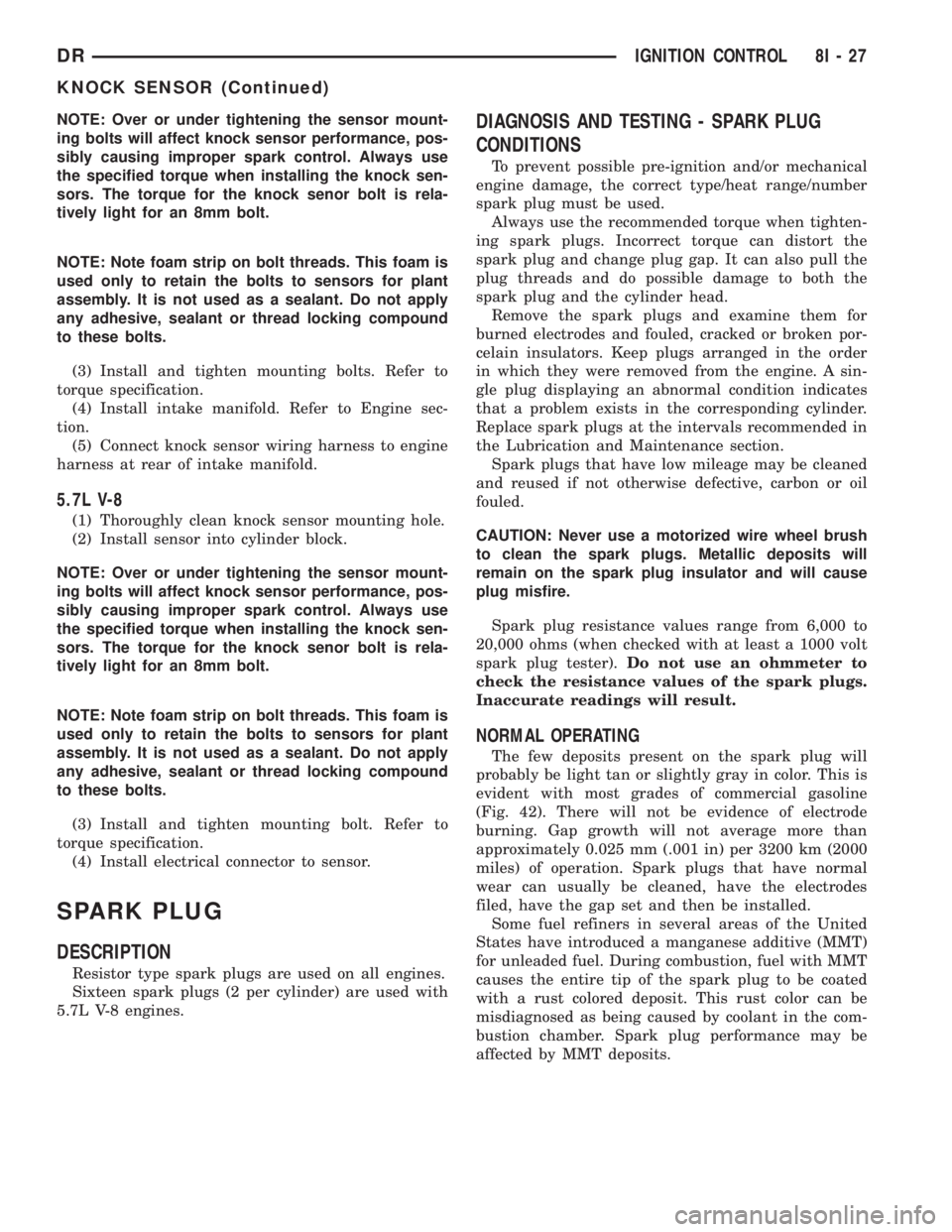

SPARK PLUG

DESCRIPTION

Resistor type spark plugs are used on all engines.

Sixteen spark plugs (2 per cylinder) are used with

5.7L V-8 engines.

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.

Always use the recommended torque when tighten-

ing spark plugs. Incorrect torque can distort the

spark plug and change plug gap. It can also pull the

plug threads and do possible damage to both the

spark plug and the cylinder head.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-

gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

the Lubrication and Maintenance section.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will

remain on the spark plug insulator and will cause

plug misfire.

Spark plug resistance values range from 6,000 to

20,000 ohms (when checked with at least a 1000 volt

spark plug tester).Do not use an ohmmeter to

check the resistance values of the spark plugs.

Inaccurate readings will result.

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 42). There will not be evidence of electrode

burning. Gap growth will not average more than

approximately 0.025 mm (.001 in) per 3200 km (2000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

causes the entire tip of the spark plug to be coated

with a rust colored deposit. This rust color can be

misdiagnosed as being caused by coolant in the com-

bustion chamber. Spark plug performance may be

affected by MMT deposits.

DRIGNITION CONTROL 8I - 27

KNOCK SENSOR (Continued)

Page 487 of 2895

REMOVAL

3.7L V-6

Each individual spark plug is located under each

ignition coil. Each individual ignition coil must be

removed to gain access to each spark plug. Refer to

Ignition Coil Removal/Installation.

(1) Remove necessary air filter tubing at throttle

body.

(2) Prior to removing ignition coil, spray com-

pressed air around coil base at cylinder head.

(3) Prior to removing spark plug, spray com-

pressed air into cylinder head opening. This will help

prevent foreign material from entering combustion

chamber.

(4) Remove spark plug from cylinder head using a

quality socket with a rubber or foam insert. Also

check condition of ignition coil o-ring and replace as

necessary.

(5) Inspect spark plug condition. Refer to Diagnos-

tics and Testing - Spark Plug Conditions.

4.7L V-8

Each individual spark plug is located under each

ignition coil. Each individual ignition coil must be

removed to gain access to each spark plug. Refer to

Ignition Coil Removal/Installation.

(1) Remove necessary air filter tubing at throttle

body.

(2) Prior to removing ignition coil, spray com-

pressed air around coil base at cylinder head.

(3) Prior to removing spark plug, spray com-

pressed air into cylinder head opening. This will help

prevent foreign material from entering combustion

chamber.

(4) Remove spark plug from cylinder head using a

quality socket with a rubber or foam insert. Also

check condition of ignition coil o-ring and replace as

necessary.

(5) Inspect spark plug condition. Refer to Diagnos-

tics and Testing - Spark Plug Conditions.

5.7L V-8

Eight of the 16 spark plugs are located under an

ignition coil; the other 8 are not. If spark plug being

removed is under coil, coil must be removed to gain

access to spark plug. Refer to Ignition Coil Removal/

Installation and observe all CAUTIONS and WARN-

INGS.

Before removing or disconnecting any spark plug

cables, note their original position. Remove cables

one-at-a-time. To prevent ignition crossfire, spark

plug cablesMUSTbe placed in cable tray (routing

loom) into their original position. Refer to Spark Plug

Cable Removal for a graphic.Before installing spark plug cables to either the

spark plugs or coils, apply dielectric grease to inside

of boots.

(1) Remove necessary air filter tubing at throttle

body.

(2) Prior to removing ignition coil (if coil removal

is necessary), spray compressed air around coil base

at cylinder head cover.

(3) Prior to removing spark plug, spray com-

pressed air into cylinder head opening. This will help

prevent foreign material from entering combustion

chamber.

(4) Remove spark plug from cylinder head using a

quality socket with a rubber or foam insert.

(5) Inspect spark plug condition. Refer to Diagnos-

tics and Testing - Spark Plug Conditions.

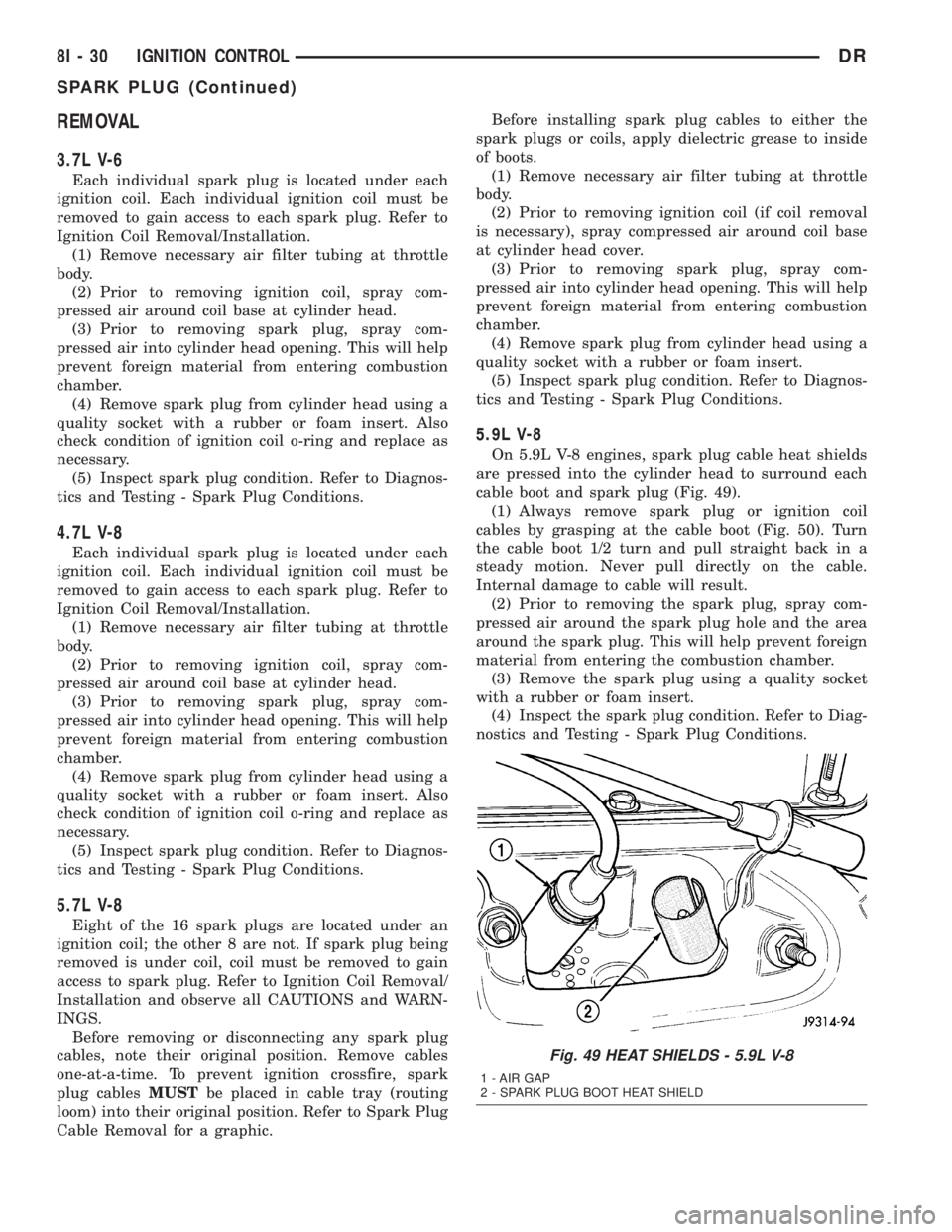

5.9L V-8

On 5.9L V-8 engines, spark plug cable heat shields

are pressed into the cylinder head to surround each

cable boot and spark plug (Fig. 49).

(1) Always remove spark plug or ignition coil

cables by grasping at the cable boot (Fig. 50). Turn

the cable boot 1/2 turn and pull straight back in a

steady motion. Never pull directly on the cable.

Internal damage to cable will result.

(2) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert.

(4) Inspect the spark plug condition. Refer to Diag-

nostics and Testing - Spark Plug Conditions.

Fig. 49 HEAT SHIELDS - 5.9L V-8

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

8I - 30 IGNITION CONTROLDR

SPARK PLUG (Continued)

Page 488 of 2895

8.0L V-10

(1) Always remove spark plug or ignition coil

cables by grasping at the cable boot (Fig. 50). Turn

the cable boot 1/2 turn and pull straight back in a

steady motion. Never pull directly on the cable.

Internal damage to cable will result.

(2) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert.

(4) Inspect the spark plug condition. Refer to Diag-

nostics and Testing - Spark Plug Conditions.

CLEANING

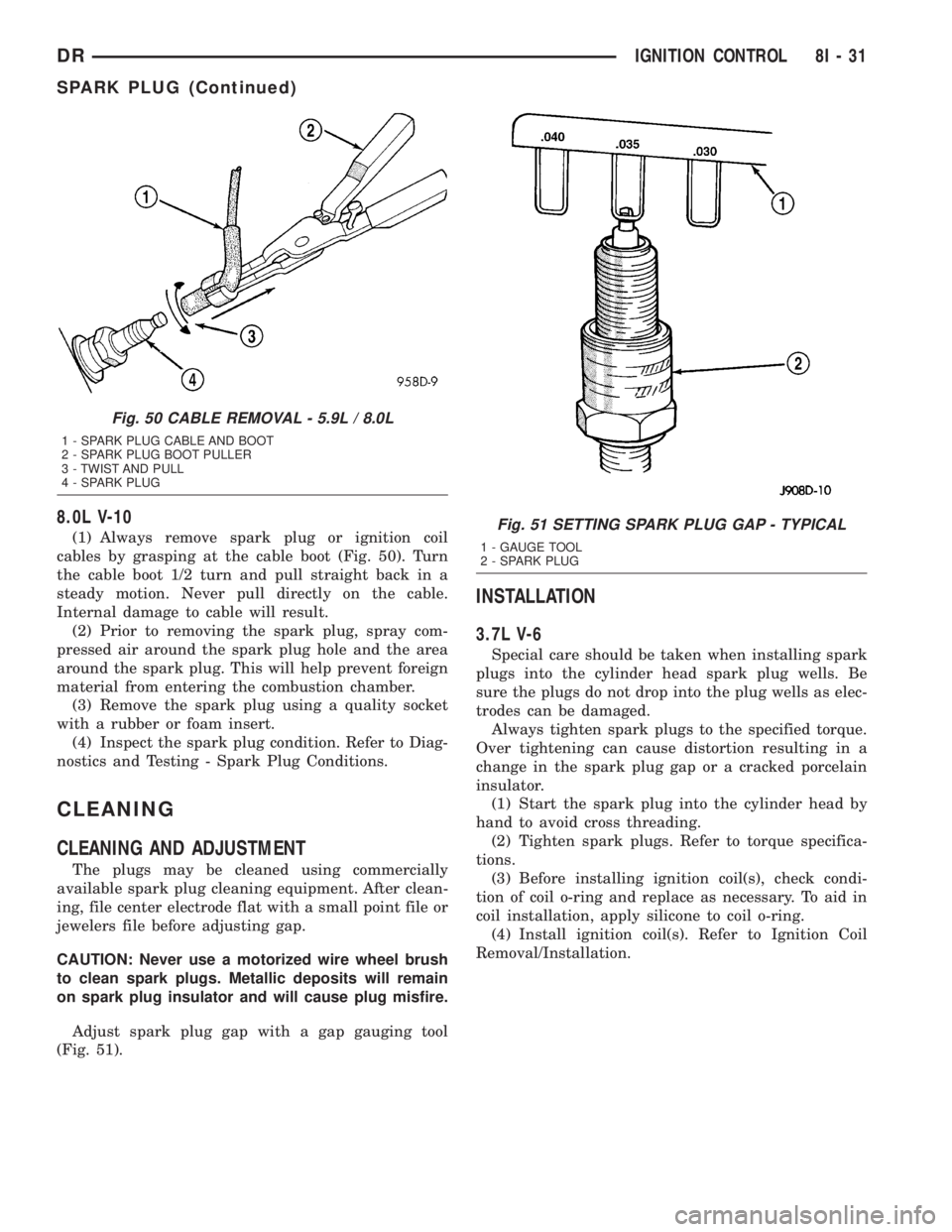

CLEANING AND ADJUSTMENT

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After clean-

ing, file center electrode flat with a small point file or

jewelers file before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean spark plugs. Metallic deposits will remain

on spark plug insulator and will cause plug misfire.

Adjust spark plug gap with a gap gauging tool

(Fig. 51).

INSTALLATION

3.7L V-6

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs. Refer to torque specifica-

tions.

(3) Before installing ignition coil(s), check condi-

tion of coil o-ring and replace as necessary. To aid in

coil installation, apply silicone to coil o-ring.

(4) Install ignition coil(s). Refer to Ignition Coil

Removal/Installation.

Fig. 50 CABLE REMOVAL - 5.9L / 8.0L

1 - SPARK PLUG CABLE AND BOOT

2 - SPARK PLUG BOOT PULLER

3 - TWIST AND PULL

4 - SPARK PLUG

Fig. 51 SETTING SPARK PLUG GAP - TYPICAL

1 - GAUGE TOOL

2 - SPARK PLUG

DRIGNITION CONTROL 8I - 31

SPARK PLUG (Continued)