relay DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1428 of 2895

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)ÐPERFORMANCE and (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)ÐMECHANICAL for

possible causes and corrections of malfunctions.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

DIAGNOSIS AND TESTING) and (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION - DIAGNOSIS

AND TESTING) for the fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following diagnosis:²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING).

²Engine Cylinder Head Gasket Failure Diagnosis

(Refer to 9 - ENGINE/CYLINDER HEAD - DIAGNO-

SIS AND TESTING).

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

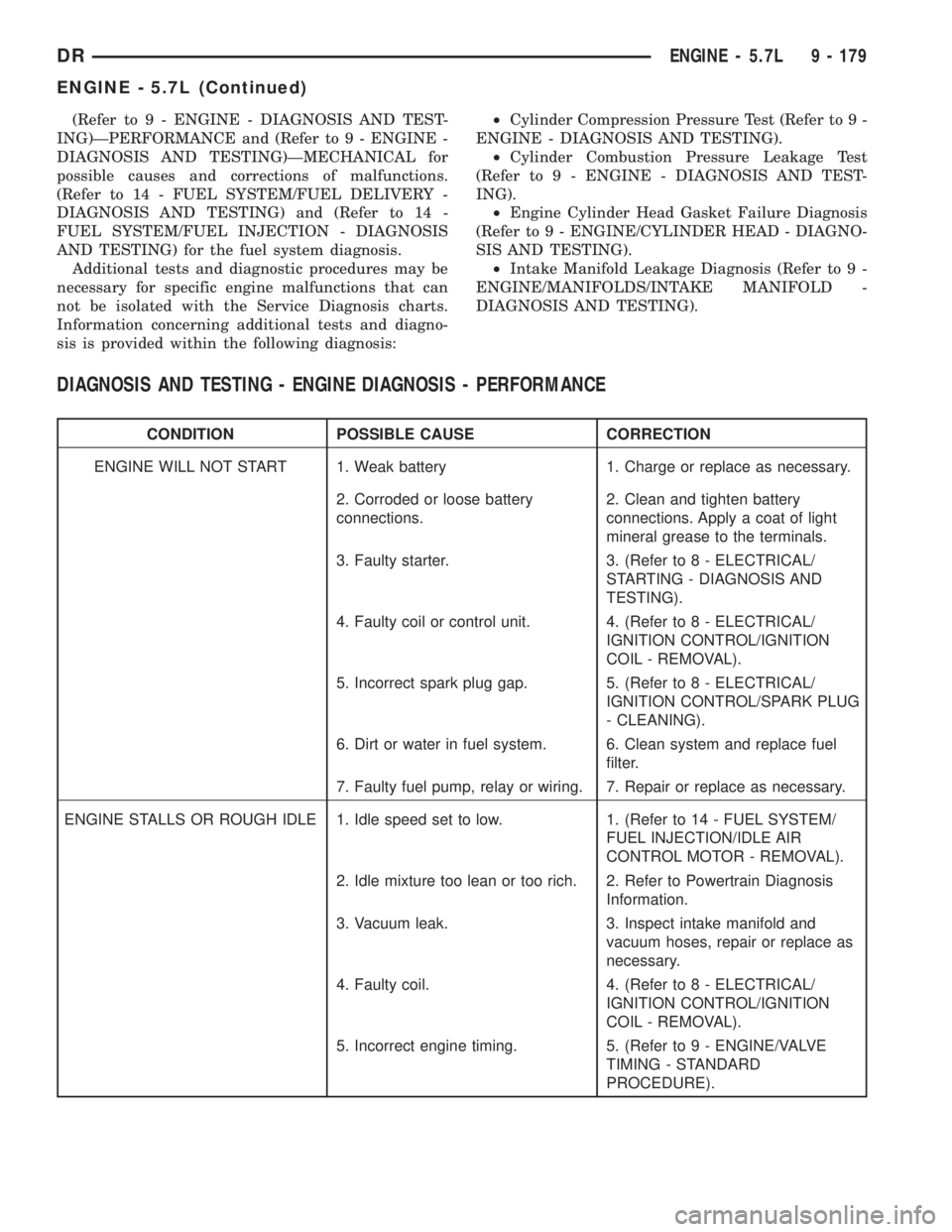

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

6. Dirt or water in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump, relay or wiring. 7. Repair or replace as necessary.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/IDLE AIR

CONTROL MOTOR - REMOVAL).

2. Idle mixture too lean or too rich. 2. Refer to Powertrain Diagnosis

Information.

3. Vacuum leak. 3. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect engine timing. 5. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD

PROCEDURE).

DRENGINE - 5.7L 9 - 179

ENGINE - 5.7L (Continued)

Page 1431 of 2895

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs.

(3) Secure the throttle in the wide-open position.

(4) Disable the fuel system (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DESCRIPTION).

(5) Remove the ASD relay (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/AUTO SHUT DOWN

RELAY - REMOVAL).

(6) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(7) Record the compression pressure on the 3rd

revolution. Continue the test for the remaining cylin-

ders.

(8) (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct engine compression pressures.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

(1) Check the coolant level and fill as required. DO

NOT install the radiator cap.

(2) Start and operate the engine until it attains

normal operating temperature, then turn the engine

OFF.

(3) Remove the spark plugs.

(4) Remove the oil filler cap.

(5) Remove the air cleaner hose.

(6) Calibrate the tester according to the manufac-

turer's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

(7) Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

Set piston of cylinder to be tested at TDC compres-

sion,While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to CYLINDER COMBUSTION PRESSURE

LEAKAGE DIAGNOSIS CHART.

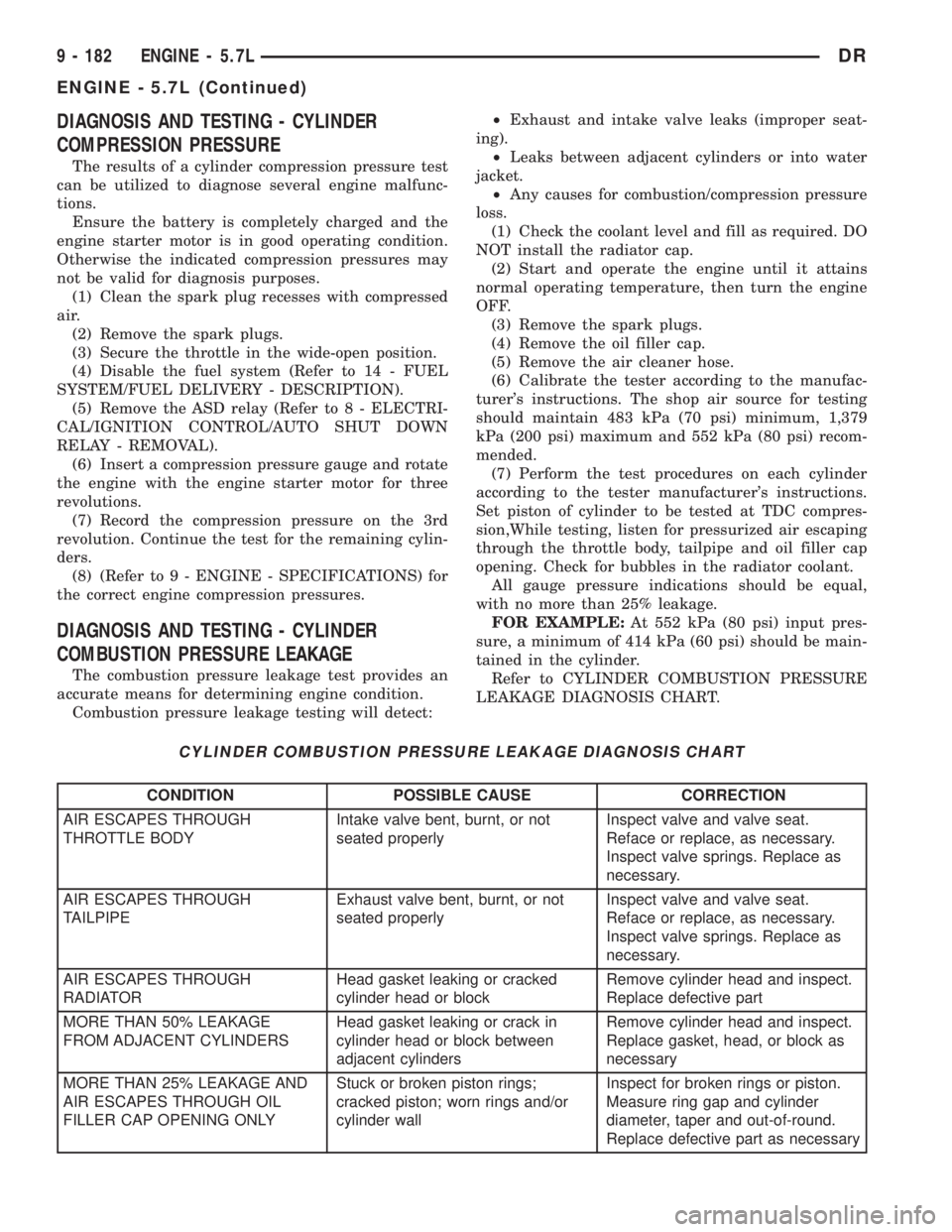

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

9 - 182 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1539 of 2895

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Disconnect the negative cable(s) from the bat-

tery.

(2) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(3) Place a shop towel around the fuel injectors to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the fuel injectors (Refer

to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL

INJECTOR - REMOVAL).

(4) With all injectors removed, rotate the crank-

shaft using the crankshaft barring tool (PN 7471±B).

(5) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(6) Be sure all fluid has been removed from the

cylinders.

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

(8) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(9) Install fuel injectors (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

REMOVAL

REMOVALÐENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(9) Remove radiator upper hose.

(10) Remove upper fan shroud mounting bolts.

(11) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(12) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(13) Remove cooling fan and shroud together.

(14) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(15) Raise vehicle on a hoist.

(16) Remove transmission and transfer case (if

equipped).

(17) Disconnect exhaust pipe from turbocharger

extension pipe.

(18) Disconnect engine harness to vehicle harness

connectors.

(19) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(20) Remove flywheel/flexplate.

(21) Remove transmission adapter

(22) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(23) Lower vehicle.

(24) Disconnect lower radiator hose from radiator

outlet.

(25) Automatic transmission models:

(26) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(27) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(28) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(29) Disconnect charge air cooler piping.

(30) Remove charge air cooler mounting bolts.

(31) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(32) Remove damper and speed indicator ring from

front of engine.

(33) Disconnect engine block heater connector.

(34) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

9 - 290 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)

Page 1541 of 2895

(2) Lower engine into the engine compartment and

install the engine the engine mount through bolts

and nuts.

(3) Tighten the mount through bolts and nuts to

88 N-m (65 ft-lbs) torque.

(4) Remove the engine lifting device (Tool 9009).

(5) Check cylinder head capscrew length and

install into cylinder head.

(6) Torque alternately to 70 N-m (52 ft-lbs). Torque

alternately to 105 N-m (77 ft-lbs). Rotate 90 degrees.

(7) Install rocker housing. Torque to 24 N-m (18 ft-

lbs). Refer to Section 9 Rocker Housing Installation

(8) Replace injector o-ring and sealing washer on

injectors #5 and #6. Install injectors and alternately

tighten hold-down capscrews to 10 N-m (89 in-lbs).

(9) Install fuel connector tube and fuel connector

tube nut. Torque to 50 N-m (37 ft-lb). 10.

(10) Install #5 and #6 high pressure fuel lines. Fol-

low correct torque sequence per section 14. Torque

fuel line fittings to 30 N-m (22 ft-lb). Torque brace

capscrew to 24 N-m (18 ft-lb).

(11) Install rear engine lift bracket. Torque to 77

N-m (57 ft-lb).

(12) Install push tubes, rocker arms, and pedestals

for cylinders #4, #5, and #6. Torque the mounting

bolts to 36 N-m (27 ft-lbs).

(13) Reset valve lash on cylinders #4, #5, and #6.

Torque adjusting nuts to 24 N-m (18 ft-lbs).

(14) Install cylinder head cover. Torque to 24 N-m

(18 ft-lbs).(Refer to 9 - ENGINE/CYLINDER HEAD -

INSTALLATION).

(15) Connect breather tube and lube oil drain tube

to breather housing. Install breather housing. Torque

capscrews to 24 N-m (18 ft-lbs)

(16) Connect fuel supply and return hoses.

(17) Connect ECM ground to hydroform screw.

Connect ECM power connector.

(18) Install the APPS cable(s) to the APPS. Install

the throttle linkage cover.

(19) Install the power steering pump.

(20) Install the damper and speed indicator ring.

Torque to 40 N-m (30 ft-lb) plus 60 degrees.

(21) Connect the engine block heater connection.

(22) Connect the A/C compressor and pressure sen-

sor connectors

(23) Install the charge air cooler and a/c condenser

(if equipped). Install and tighten the charge air

cooler mounting bolts to 2 N-m (17 in-lbs).

(24) Connect the charge air cooler piping. Torque

all clamps to 8 N-m (72 in-lbs).

(25) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(26) Install the radiator upper support panel.

(27) Install radiator.

(28) Connect the transmission quick-connect oil

cooler lines.(29) Raise vehicle.

(30) Connect a/c compressor suction/discharge hose

(if equipped).

(31) Install the radiator lower hose and clamps.

(32) Install the battery negative cables to the

engine block on the driver and passenger side.

(33) Install the transmission adapter with a new

camshaft rectangular ring seal. Torque to 77 N-m (57

ft-lb).

(34) Install the flywheel/flexplate. Torque to 137

N-m (101 ft-lb).

(35) Install the starter motor. Torque to 43 N-m

(32 ft-lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(36) Connect engine to vehicle harness connectors.

(37) Install transmission and transfer case (if

equipped).

(38) Connect the exhaust pipe to the turbocharger

elbow.

(39) Connect the transmission auxiliary oil cooler

lines (if equipped).

(40) Lower the vehicle.

(41)

Connect the heater core supply and return hoses.

(42) Install the cooling fan and upper fan shroud

at the same time. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

(43) Install the coolant recovery bottle.

(44) Install the windshield washer bottle.

(45) Install the upper radiator hose and clamps.

(46) Raise vehicle.

(47) Connect electronically controlled fan drive

wire harness. Install lower radiator fan shroud.

(48) Change oil filter and install new engine oil.

(49) Fill the cooling system with coolant. (Refer to

7 - COOLING - STANDARD PROCEDURE).

(50) Connect grid heater harness at grid heater

relays.

(51) Connect electrical connections to rear of alter-

nator.

(52) Start the engine and inspect for engine oil,

coolant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

(1) Install a new o-ring onto the breather element.

(2) Lubricate o-ring and install into cylinder head

cover. Torque capscrews to 10 N´m (89 in. lbs.).

(3) Connect breather tube and lube oil drain tube.

(4) Install breather cover (Fig. 4). Torque to 24

N´m (18 ft. lbs.)

(5) Install oil fill cap.

9 - 292 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)

Page 1700 of 2895

(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa +/- 34 kPa (49.2 psi +/- 2 psi).

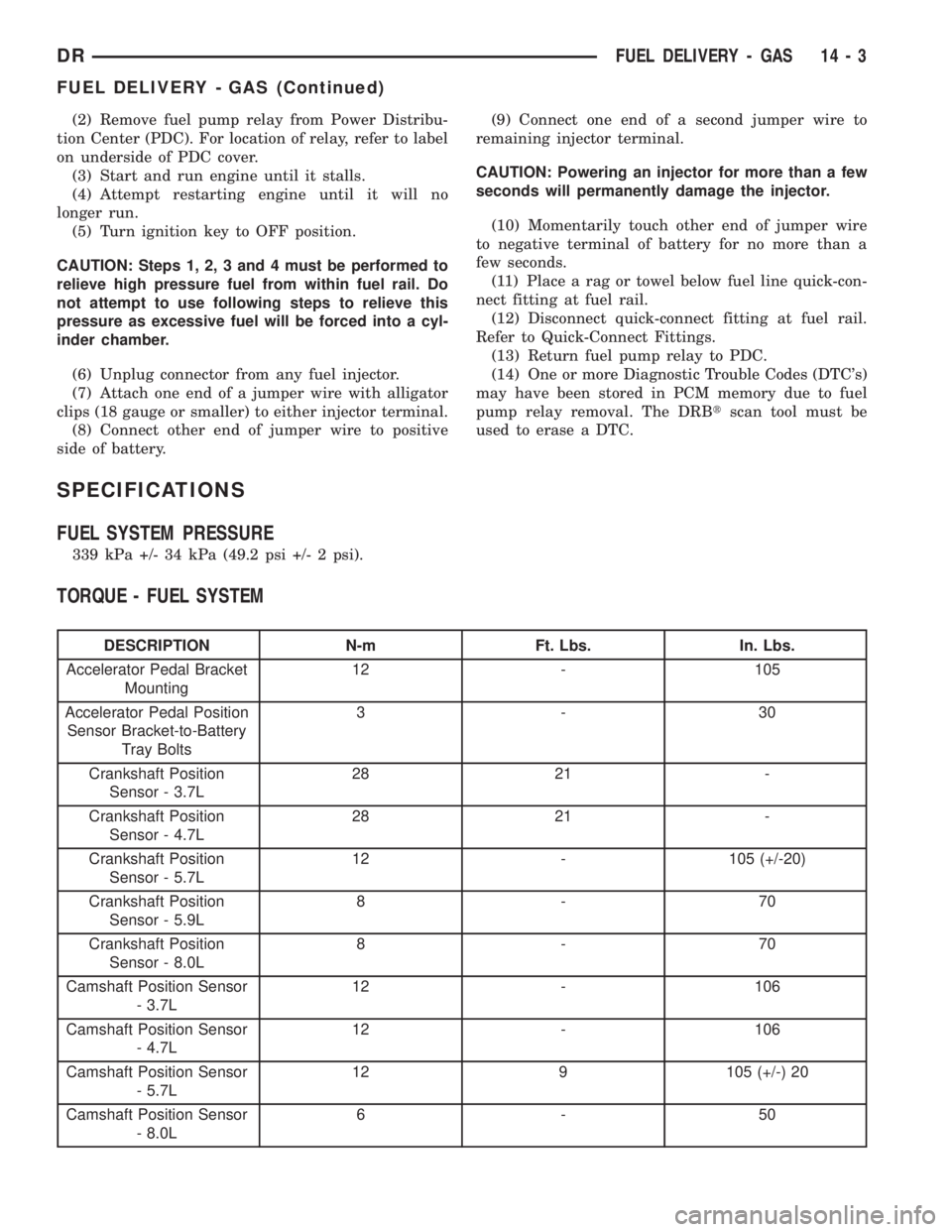

TORQUE - FUEL SYSTEM

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting12 - 105

Accelerator Pedal Position

Sensor Bracket-to-Battery

Tray Bolts3-30

Crankshaft Position

Sensor - 3.7L28 21 -

Crankshaft Position

Sensor - 4.7L28 21 -

Crankshaft Position

Sensor - 5.7L12 - 105 (+/-20)

Crankshaft Position

Sensor - 5.9L8-70

Crankshaft Position

Sensor - 8.0L8-70

Camshaft Position Sensor

- 3.7L12 - 106

Camshaft Position Sensor

- 4.7L12 - 106

Camshaft Position Sensor

- 5.7L12 9 105 (+/-) 20

Camshaft Position Sensor

- 8.0L6-50

DRFUEL DELIVERY - GAS 14 - 3

FUEL DELIVERY - GAS (Continued)

Page 1709 of 2895

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.

Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation:The bottom section of

the fuel pump module contains a one-way check

valve to prevent fuel flow back into the tank and to

maintain fuel supply line pressure (engine warm)

when pump is not operational. It is also used to keep

the fuel supply line full of gasoline when pump is not

operational. After the vehicle has cooled down, fuel

pressure may drop to 0 psi (cold fluid contracts), but

liquid gasoline will remain in fuel supply line

between the check valve and fuel injectors.Fuel

pressure that has dropped to 0 psi on a cooled

down vehicle (engine off) is a normal condition.

The electric fuel pump is not a separate, service-

able component.

FUEL PUMP MODULE

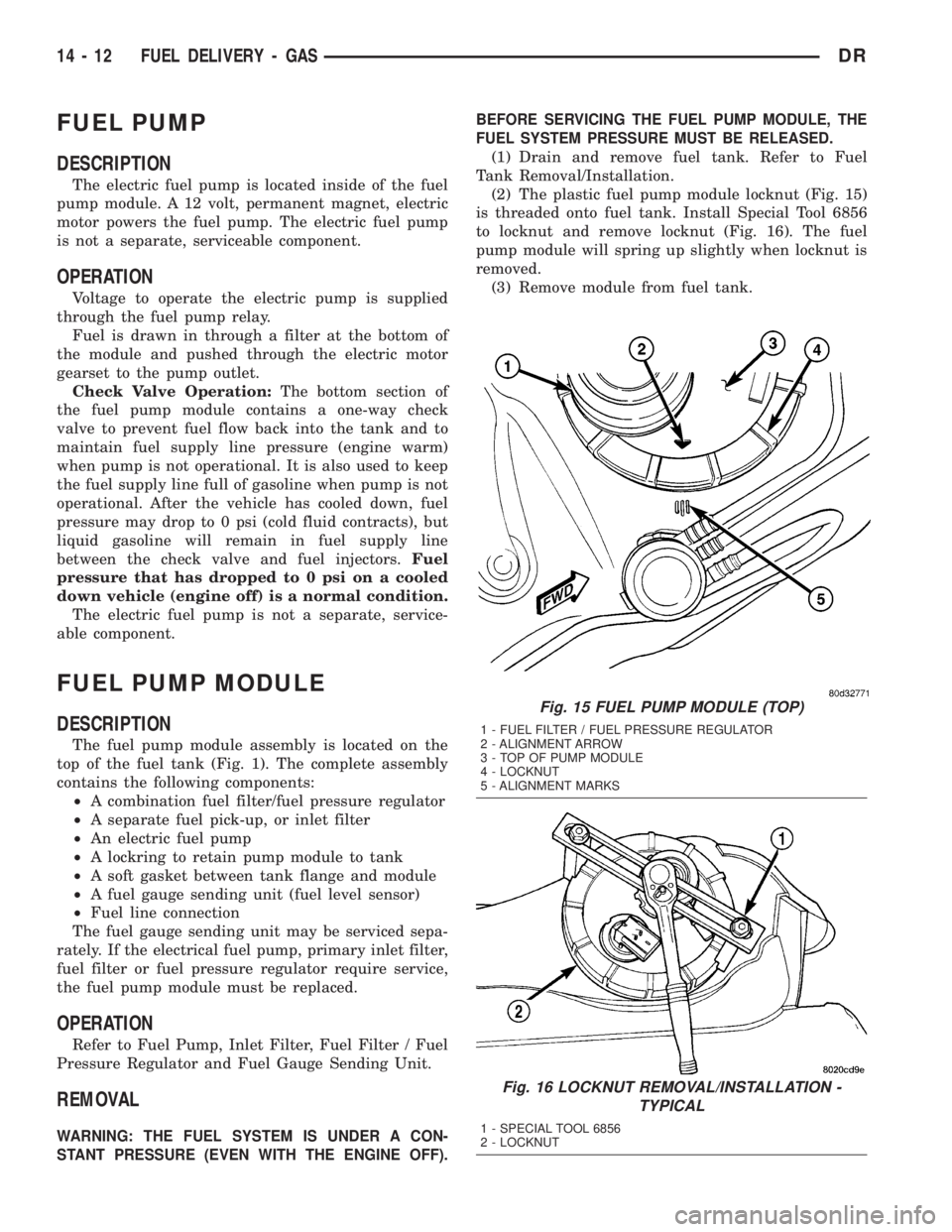

DESCRIPTION

The fuel pump module assembly is located on the

top of the fuel tank (Fig. 1). The complete assembly

contains the following components:

²A combination fuel filter/fuel pressure regulator

²A separate fuel pick-up, or inlet filter

²An electric fuel pump

²A lockring to retain pump module to tank

²A soft gasket between tank flange and module

²A fuel gauge sending unit (fuel level sensor)

²Fuel line connection

The fuel gauge sending unit may be serviced sepa-

rately. If the electrical fuel pump, primary inlet filter,

fuel filter or fuel pressure regulator require service,

the fuel pump module must be replaced.

OPERATION

Refer to Fuel Pump, Inlet Filter, Fuel Filter / Fuel

Pressure Regulator and Fuel Gauge Sending Unit.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).BEFORE SERVICING THE FUEL PUMP MODULE, THE

FUEL SYSTEM PRESSURE MUST BE RELEASED.

(1) Drain and remove fuel tank. Refer to Fuel

Tank Removal/Installation.

(2) The plastic fuel pump module locknut (Fig. 15)

is threaded onto fuel tank. Install Special Tool 6856

to locknut and remove locknut (Fig. 16). The fuel

pump module will spring up slightly when locknut is

removed.

(3) Remove module from fuel tank.

Fig. 15 FUEL PUMP MODULE (TOP)

1 - FUEL FILTER / FUEL PRESSURE REGULATOR

2 - ALIGNMENT ARROW

3 - TOP OF PUMP MODULE

4 - LOCKNUT

5 - ALIGNMENT MARKS

Fig. 16 LOCKNUT REMOVAL/INSTALLATION -

TYPICAL

1 - SPECIAL TOOL 6856

2 - LOCKNUT

14 - 12 FUEL DELIVERY - GASDR

Page 1721 of 2895

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................24

INSTALLATION.........................24

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................25

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................29

INSTALLATION.........................30

FUEL INJECTOR

DESCRIPTION.........................32

OPERATION

OPERATION - FUEL INJECTOR..........32

OPERATION - PCM OUTPUT............32

REMOVAL.............................32

INSTALLATION.........................33

FUEL PUMP RELAY

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................34INSTALLATION.........................35

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................38

MAP SENSOR

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................42

OXYGEN SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................44

INSTALLATION.........................45

THROTTLE BODY

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................47

THROTTLE CONTROL CABLE

REMOVAL.............................49

INSTALLATION.........................51

THROTTLE POSITION SENSOR

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................53

INSTALLATION.........................54

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

14 - 24 FUEL INJECTION - GASDR

Page 1729 of 2895

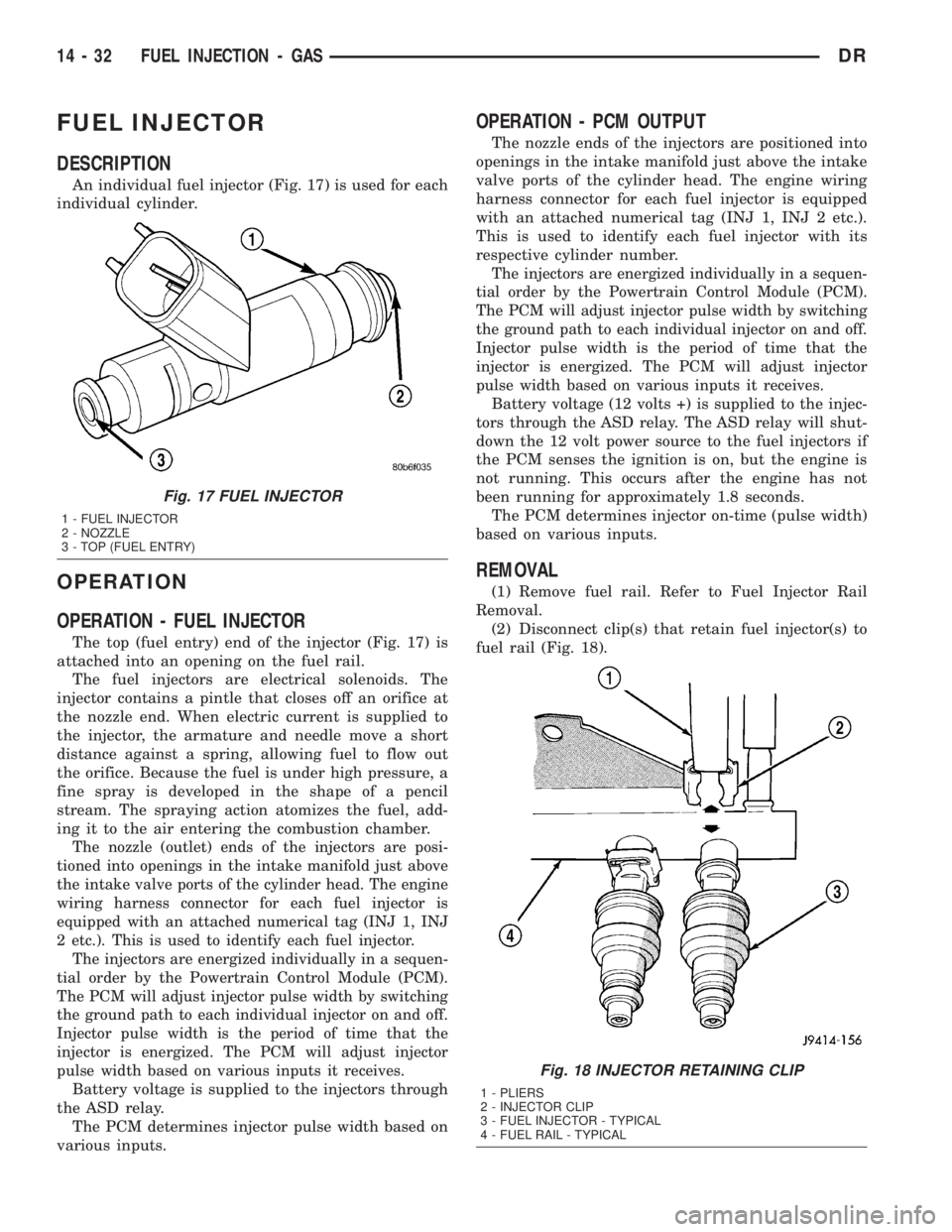

FUEL INJECTOR

DESCRIPTION

An individual fuel injector (Fig. 17) is used for each

individual cylinder.

OPERATION

OPERATION - FUEL INJECTOR

The top (fuel entry) end of the injector (Fig. 17) is

attached into an opening on the fuel rail.

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just above

the intake valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is

equipped with an attached numerical tag (INJ 1, INJ

2 etc.). This is used to identify each fuel injector.

The injectors are energized individually in a sequen-

tial order by the Powertrain Control Module (PCM).

The PCM will adjust injector pulse width by switching

the ground path to each individual injector on and off.

Injector pulse width is the period of time that the

injector is energized. The PCM will adjust injector

pulse width based on various inputs it receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a sequen-

tial order by the Powertrain Control Module (PCM).

The PCM will adjust injector pulse width by switching

the ground path to each individual injector on and off.

Injector pulse width is the period of time that the

injector is energized. The PCM will adjust injector

pulse width based on various inputs it receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 18).

Fig. 17 FUEL INJECTOR

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

Fig. 18 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

14 - 32 FUEL INJECTION - GASDR

Page 1730 of 2895

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).

(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

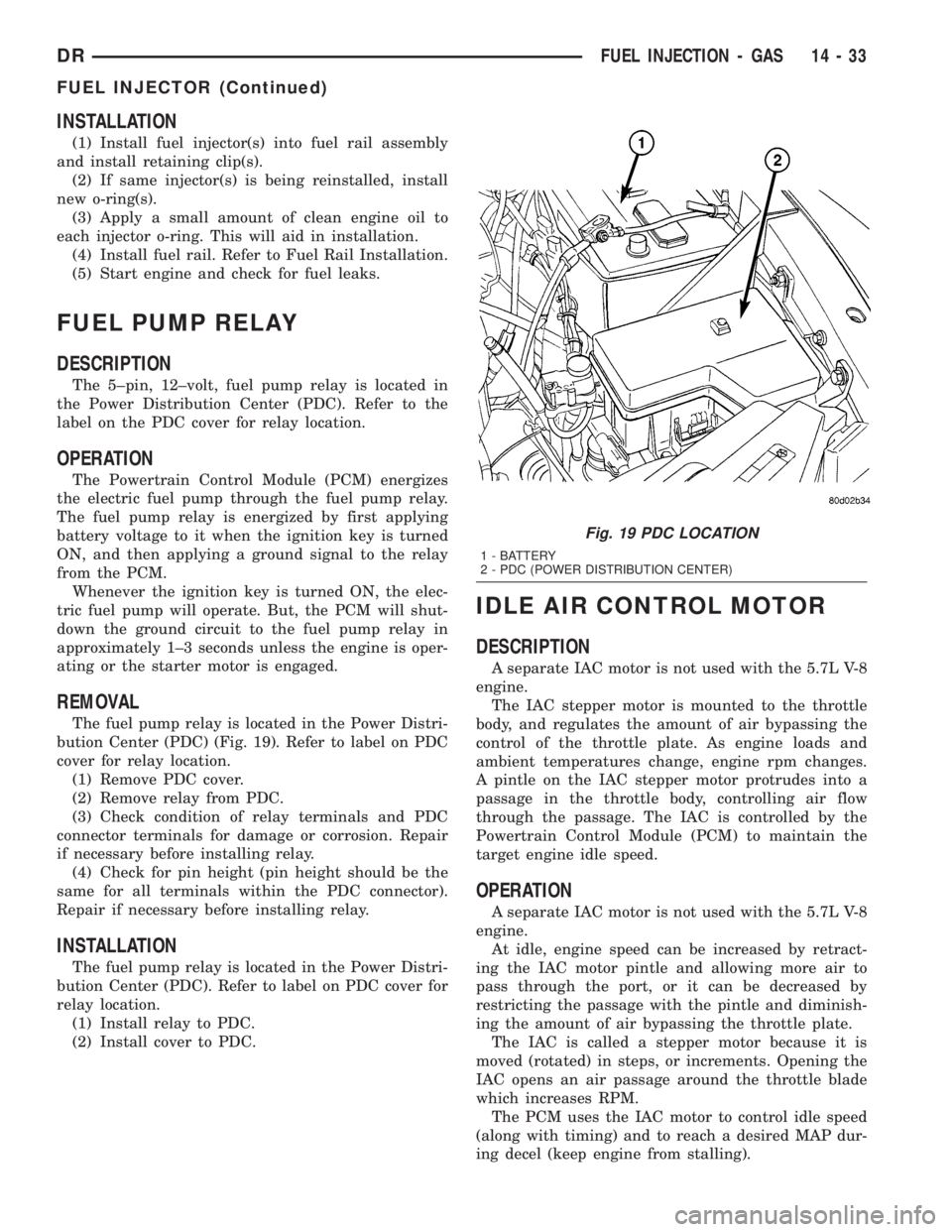

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 19). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC). Refer to label on PDC cover for

relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

A separate IAC motor is not used with the 5.7L V-8

engine.

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

A separate IAC motor is not used with the 5.7L V-8

engine.

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

Fig. 19 PDC LOCATION

1 - BATTERY

2 - PDC (POWER DISTRIBUTION CENTER)

DRFUEL INJECTION - GAS 14 - 33

FUEL INJECTOR (Continued)

Page 1740 of 2895

OXYGEN SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the engine or emission package, the vehicle may

use a total of either 2 or 4 sensors.

Federal Emission Packages :Two sensors are

used: upstream (referred to as 1/1) and downstream

(referred to as 1/2). With this emission package, the

upstream sensor (1/1) is located just before the main

catalytic convertor. The downstream sensor (1/2) is

located just after the main catalytic convertor.

California Emission Packages:On this emis-

sions package, 4 sensors are used: 2 upstream

(referred to as 1/1 and 2/1) and 2 downstream

(referred to as 1/2 and 2/2). With this emission pack-

age, the right upstream sensor (2/1) is located in the

right exhaust downpipe just before the mini-catalytic

convertor. The left upstream sensor (1/1) is located in

the left exhaust downpipe just before the mini-cata-

lytic convertor. The right downstream sensor (2/2) is

located in the right exhaust downpipe just after the

mini-catalytic convertor, and before the main cata-

lytic convertor. The left downstream sensor (1/2) is

located in the left exhaust downpipe just after the

mini-catalytic convertor, and before the main cata-

lytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the O2 sensor case housing.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heater Relay - 5.9L/8.0L:If 4

oxygen sensors are used, a separate heater relay is

used to supply voltage to the sensors heating ele-

ments for only the 1/2 and 2/2 downstream sensors.

Voltage for the other 2 sensor heating elements is

supplied directly from the Powertrain Control Mod-ule (PCM) through a Pulse Width Module (PWM)

method.

Pulse Width Module (PWM) - 5.9L/8.0L:Voltage

to the O2 sensor heating elements is supplied

directly from the Powertrain Control Module (PCM)

through two separate Pulse Width Module (PWM)

low side drivers. PWM is used on both the upstream

and downstream O2 sensors if equipped with a Fed-

eral Emissions Package, and only on the 2 upstream

sensors (1/1 and 2/1) if equipped with a California

Emissions Package. The main objective for a PWM

driver is to avoid overheating of the O2 sensor heater

element. With exhaust temperatures increasing with

time and engine speed, it's not required to have a

full-voltage duty-cycle on the O2 heater elements.

To avoid the large simultaneous current surge

needed to operate all 4 sensors, power is delayed to

the 2 downstream heater elements by the PCM for

approximately 2 seconds.

Oxygen Sensor Heater Elements:

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

around 70ÉF, the resistance of the heating element is

approximately 13 ohms. As the sensor's temperature

increases, resistance in the heater element increases.

This allows the heater to maintain the optimum

operating temperature of approximately 930É-1100ÉF

(500É-600É C). Although the sensors operate the

same, there are physical differences, due to the envi-

ronment that they operate in, that keep them from

being interchangeable.

Maintaining correct sensor temperature at all

times allows the system to enter into closed loop

operation sooner. Also, it allows the system to remain

in closed loop operation during periods of extended

idle.

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

on preprogrammed (fixed) values and inputs from

other sensors.

Upstream Sensor - Federal Emissions Pack-

age :The upstream sensor (1/1) provides an input

voltage to the PCM. The input tells the PCM the oxy-

gen content of the exhaust gas. The PCM uses this

information to fine tune fuel delivery to maintain the

correct oxygen content at the downstream oxygen

sensor. The PCM will change the air/fuel ratio until

the upstream sensor inputs a voltage that the PCM

has determined will make the downstream sensor

output (oxygen content) correct.

The upstream oxygen sensor also provides an input

to determine catalytic convertor efficiency.

DRFUEL INJECTION - GAS 14 - 43