hood open DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 687 of 2895

WASHER NOZZLE

DESCRIPTION

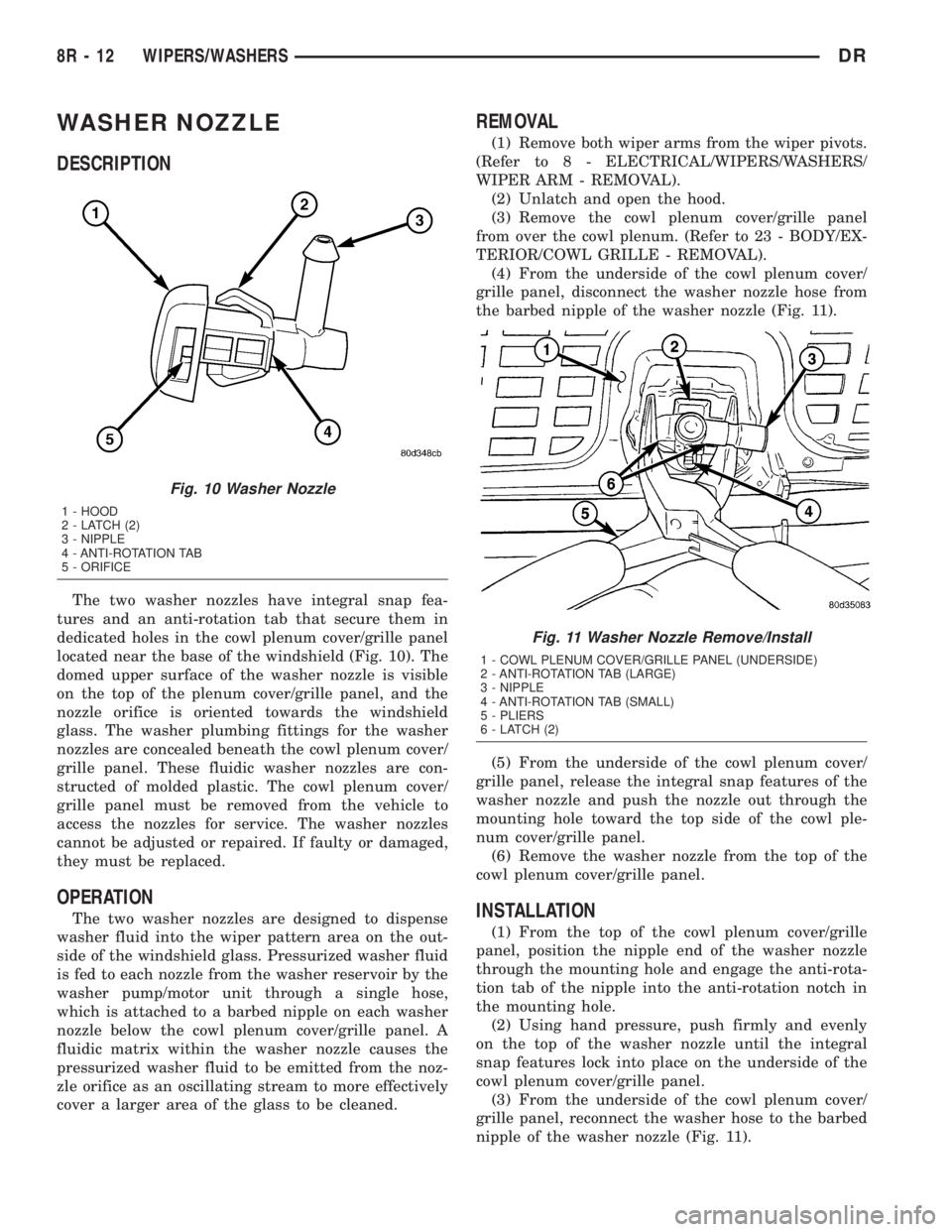

The two washer nozzles have integral snap fea-

tures and an anti-rotation tab that secure them in

dedicated holes in the cowl plenum cover/grille panel

located near the base of the windshield (Fig. 10). The

domed upper surface of the washer nozzle is visible

on the top of the plenum cover/grille panel, and the

nozzle orifice is oriented towards the windshield

glass. The washer plumbing fittings for the washer

nozzles are concealed beneath the cowl plenum cover/

grille panel. These fluidic washer nozzles are con-

structed of molded plastic. The cowl plenum cover/

grille panel must be removed from the vehicle to

access the nozzles for service. The washer nozzles

cannot be adjusted or repaired. If faulty or damaged,

they must be replaced.

OPERATION

The two washer nozzles are designed to dispense

washer fluid into the wiper pattern area on the out-

side of the windshield glass. Pressurized washer fluid

is fed to each nozzle from the washer reservoir by the

washer pump/motor unit through a single hose,

which is attached to a barbed nipple on each washer

nozzle below the cowl plenum cover/grille panel. A

fluidic matrix within the washer nozzle causes the

pressurized washer fluid to be emitted from the noz-

zle orifice as an oscillating stream to more effectively

cover a larger area of the glass to be cleaned.

REMOVAL

(1) Remove both wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

(2) Unlatch and open the hood.

(3) Remove the cowl plenum cover/grille panel

from over the cowl plenum. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - REMOVAL).

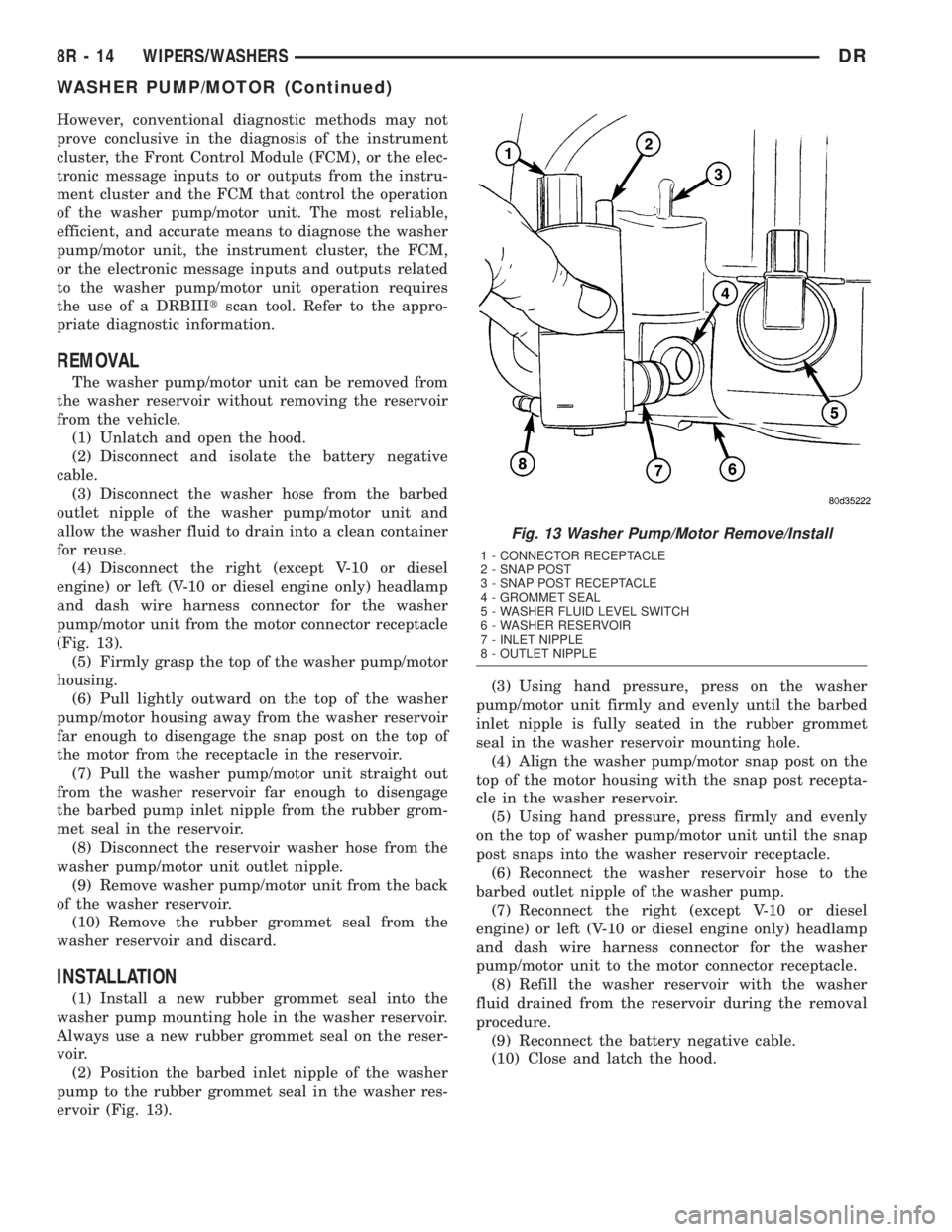

(4) From the underside of the cowl plenum cover/

grille panel, disconnect the washer nozzle hose from

the barbed nipple of the washer nozzle (Fig. 11).

(5) From the underside of the cowl plenum cover/

grille panel, release the integral snap features of the

washer nozzle and push the nozzle out through the

mounting hole toward the top side of the cowl ple-

num cover/grille panel.

(6) Remove the washer nozzle from the top of the

cowl plenum cover/grille panel.

INSTALLATION

(1) From the top of the cowl plenum cover/grille

panel, position the nipple end of the washer nozzle

through the mounting hole and engage the anti-rota-

tion tab of the nipple into the anti-rotation notch in

the mounting hole.

(2) Using hand pressure, push firmly and evenly

on the top of the washer nozzle until the integral

snap features lock into place on the underside of the

cowl plenum cover/grille panel.

(3) From the underside of the cowl plenum cover/

grille panel, reconnect the washer hose to the barbed

nipple of the washer nozzle (Fig. 11).

Fig. 10 Washer Nozzle

1 - HOOD

2 - LATCH (2)

3 - NIPPLE

4 - ANTI-ROTATION TAB

5 - ORIFICE

Fig. 11 Washer Nozzle Remove/Install

1 - COWL PLENUM COVER/GRILLE PANEL (UNDERSIDE)

2 - ANTI-ROTATION TAB (LARGE)

3 - NIPPLE

4 - ANTI-ROTATION TAB (SMALL)

5 - PLIERS

6 - LATCH (2)

8R - 12 WIPERS/WASHERSDR

Page 689 of 2895

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the instrument

cluster, the Front Control Module (FCM), or the elec-

tronic message inputs to or outputs from the instru-

ment cluster and the FCM that control the operation

of the washer pump/motor unit. The most reliable,

efficient, and accurate means to diagnose the washer

pump/motor unit, the instrument cluster, the FCM,

or the electronic message inputs and outputs related

to the washer pump/motor unit operation requires

the use of a DRBIIItscan tool. Refer to the appro-

priate diagnostic information.

REMOVAL

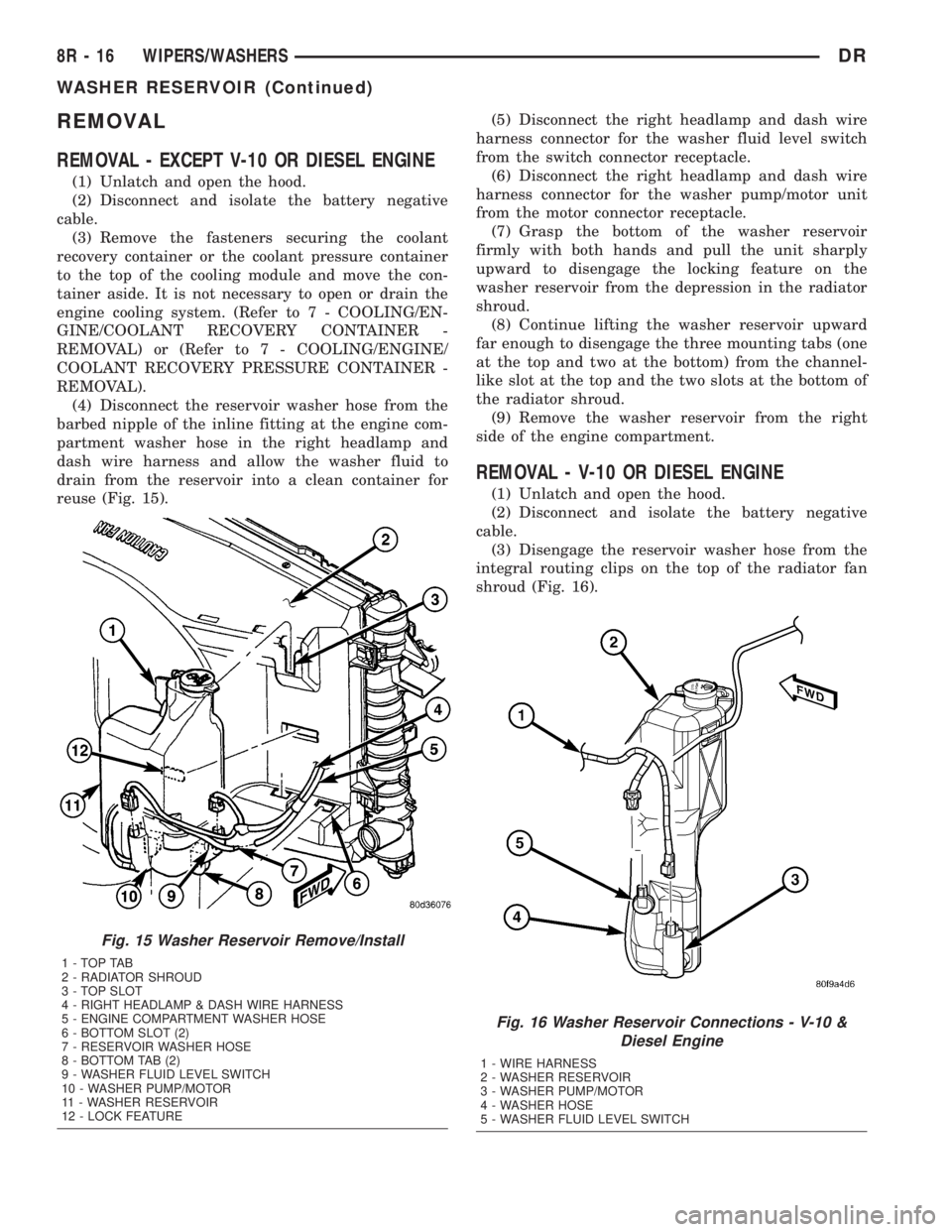

The washer pump/motor unit can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor unit and

allow the washer fluid to drain into a clean container

for reuse.

(4) Disconnect the right (except V-10 or diesel

engine) or left (V-10 or diesel engine only) headlamp

and dash wire harness connector for the washer

pump/motor unit from the motor connector receptacle

(Fig. 13).

(5) Firmly grasp the top of the washer pump/motor

housing.

(6) Pull lightly outward on the top of the washer

pump/motor housing away from the washer reservoir

far enough to disengage the snap post on the top of

the motor from the receptacle in the reservoir.

(7) Pull the washer pump/motor unit straight out

from the washer reservoir far enough to disengage

the barbed pump inlet nipple from the rubber grom-

met seal in the reservoir.

(8) Disconnect the reservoir washer hose from the

washer pump/motor unit outlet nipple.

(9) Remove washer pump/motor unit from the back

of the washer reservoir.

(10) Remove the rubber grommet seal from the

washer reservoir and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reser-

voir.

(2) Position the barbed inlet nipple of the washer

pump to the rubber grommet seal in the washer res-

ervoir (Fig. 13).(3) Using hand pressure, press on the washer

pump/motor unit firmly and evenly until the barbed

inlet nipple is fully seated in the rubber grommet

seal in the washer reservoir mounting hole.

(4) Align the washer pump/motor snap post on the

top of the motor housing with the snap post recepta-

cle in the washer reservoir.

(5) Using hand pressure, press firmly and evenly

on the top of washer pump/motor unit until the snap

post snaps into the washer reservoir receptacle.

(6) Reconnect the washer reservoir hose to the

barbed outlet nipple of the washer pump.

(7) Reconnect the right (except V-10 or diesel

engine) or left (V-10 or diesel engine only) headlamp

and dash wire harness connector for the washer

pump/motor unit to the motor connector receptacle.

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

(10) Close and latch the hood.

Fig. 13 Washer Pump/Motor Remove/Install

1 - CONNECTOR RECEPTACLE

2 - SNAP POST

3 - SNAP POST RECEPTACLE

4 - GROMMET SEAL

5 - WASHER FLUID LEVEL SWITCH

6 - WASHER RESERVOIR

7 - INLET NIPPLE

8 - OUTLET NIPPLE

8R - 14 WIPERS/WASHERSDR

WASHER PUMP/MOTOR (Continued)

Page 691 of 2895

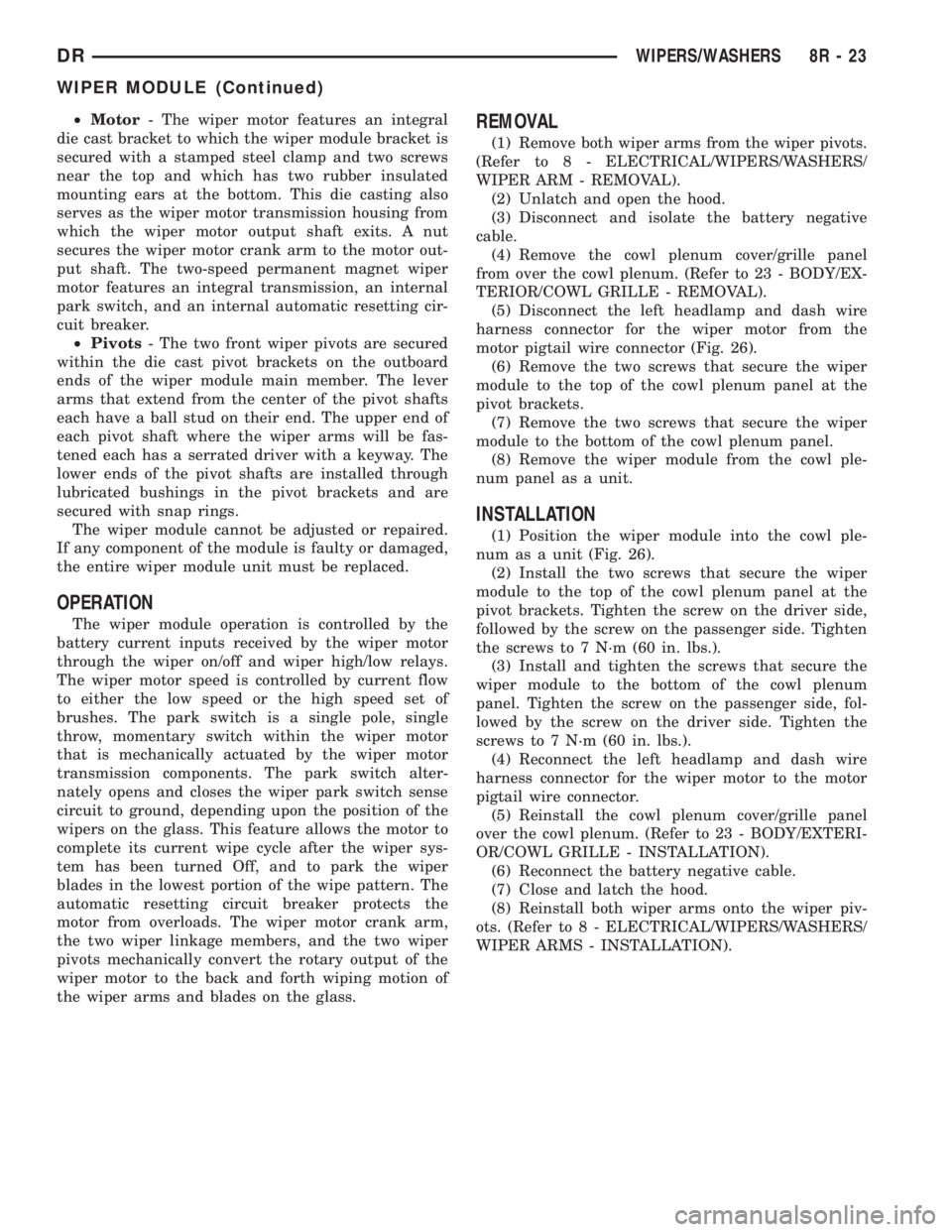

REMOVAL

REMOVAL - EXCEPT V-10 OR DIESEL ENGINE

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the fasteners securing the coolant

recovery container or the coolant pressure container

to the top of the cooling module and move the con-

tainer aside. It is not necessary to open or drain the

engine cooling system. (Refer to 7 - COOLING/EN-

GINE/COOLANT RECOVERY CONTAINER -

REMOVAL) or (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESSURE CONTAINER -

REMOVAL).

(4) Disconnect the reservoir washer hose from the

barbed nipple of the inline fitting at the engine com-

partment washer hose in the right headlamp and

dash wire harness and allow the washer fluid to

drain from the reservoir into a clean container for

reuse (Fig. 15).(5) Disconnect the right headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

(6) Disconnect the right headlamp and dash wire

harness connector for the washer pump/motor unit

from the motor connector receptacle.

(7) Grasp the bottom of the washer reservoir

firmly with both hands and pull the unit sharply

upward to disengage the locking feature on the

washer reservoir from the depression in the radiator

shroud.

(8) Continue lifting the washer reservoir upward

far enough to disengage the three mounting tabs (one

at the top and two at the bottom) from the channel-

like slot at the top and the two slots at the bottom of

the radiator shroud.

(9) Remove the washer reservoir from the right

side of the engine compartment.

REMOVAL - V-10 OR DIESEL ENGINE

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disengage the reservoir washer hose from the

integral routing clips on the top of the radiator fan

shroud (Fig. 16).

Fig. 15 Washer Reservoir Remove/Install

1-TOPTAB

2 - RADIATOR SHROUD

3 - TOP SLOT

4 - RIGHT HEADLAMP & DASH WIRE HARNESS

5 - ENGINE COMPARTMENT WASHER HOSE

6 - BOTTOM SLOT (2)

7 - RESERVOIR WASHER HOSE

8 - BOTTOM TAB (2)

9 - WASHER FLUID LEVEL SWITCH

10 - WASHER PUMP/MOTOR

11 - WASHER RESERVOIR

12 - LOCK FEATURE

Fig. 16 Washer Reservoir Connections - V-10 &

Diesel Engine

1 - WIRE HARNESS

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - WASHER HOSE

5 - WASHER FLUID LEVEL SWITCH

8R - 16 WIPERS/WASHERSDR

WASHER RESERVOIR (Continued)

Page 698 of 2895

²Motor- The wiper motor features an integral

die cast bracket to which the wiper module bracket is

secured with a stamped steel clamp and two screws

near the top and which has two rubber insulated

mounting ears at the bottom. This die casting also

serves as the wiper motor transmission housing from

which the wiper motor output shaft exits. A nut

secures the wiper motor crank arm to the motor out-

put shaft. The two-speed permanent magnet wiper

motor features an integral transmission, an internal

park switch, and an internal automatic resetting cir-

cuit breaker.

²Pivots- The two front wiper pivots are secured

within the die cast pivot brackets on the outboard

ends of the wiper module main member. The lever

arms that extend from the center of the pivot shafts

each have a ball stud on their end. The upper end of

each pivot shaft where the wiper arms will be fas-

tened each has a serrated driver with a keyway. The

lower ends of the pivot shafts are installed through

lubricated bushings in the pivot brackets and are

secured with snap rings.

The wiper module cannot be adjusted or repaired.

If any component of the module is faulty or damaged,

the entire wiper module unit must be replaced.

OPERATION

The wiper module operation is controlled by the

battery current inputs received by the wiper motor

through the wiper on/off and wiper high/low relays.

The wiper motor speed is controlled by current flow

to either the low speed or the high speed set of

brushes. The park switch is a single pole, single

throw, momentary switch within the wiper motor

that is mechanically actuated by the wiper motor

transmission components. The park switch alter-

nately opens and closes the wiper park switch sense

circuit to ground, depending upon the position of the

wipers on the glass. This feature allows the motor to

complete its current wipe cycle after the wiper sys-

tem has been turned Off, and to park the wiper

blades in the lowest portion of the wipe pattern. The

automatic resetting circuit breaker protects the

motor from overloads. The wiper motor crank arm,

the two wiper linkage members, and the two wiper

pivots mechanically convert the rotary output of the

wiper motor to the back and forth wiping motion of

the wiper arms and blades on the glass.

REMOVAL

(1) Remove both wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

(2) Unlatch and open the hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Remove the cowl plenum cover/grille panel

from over the cowl plenum. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - REMOVAL).

(5) Disconnect the left headlamp and dash wire

harness connector for the wiper motor from the

motor pigtail wire connector (Fig. 26).

(6) Remove the two screws that secure the wiper

module to the top of the cowl plenum panel at the

pivot brackets.

(7) Remove the two screws that secure the wiper

module to the bottom of the cowl plenum panel.

(8) Remove the wiper module from the cowl ple-

num panel as a unit.

INSTALLATION

(1) Position the wiper module into the cowl ple-

num as a unit (Fig. 26).

(2) Install the two screws that secure the wiper

module to the top of the cowl plenum panel at the

pivot brackets. Tighten the screw on the driver side,

followed by the screw on the passenger side. Tighten

the screws to 7 N´m (60 in. lbs.).

(3) Install and tighten the screws that secure the

wiper module to the bottom of the cowl plenum

panel. Tighten the screw on the passenger side, fol-

lowed by the screw on the driver side. Tighten the

screws to 7 N´m (60 in. lbs.).

(4) Reconnect the left headlamp and dash wire

harness connector for the wiper motor to the motor

pigtail wire connector.

(5) Reinstall the cowl plenum cover/grille panel

over the cowl plenum. (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

(6) Reconnect the battery negative cable.

(7) Close and latch the hood.

(8) Reinstall both wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARMS - INSTALLATION).

DRWIPERS/WASHERS 8R - 23

WIPER MODULE (Continued)

Page 2524 of 2895

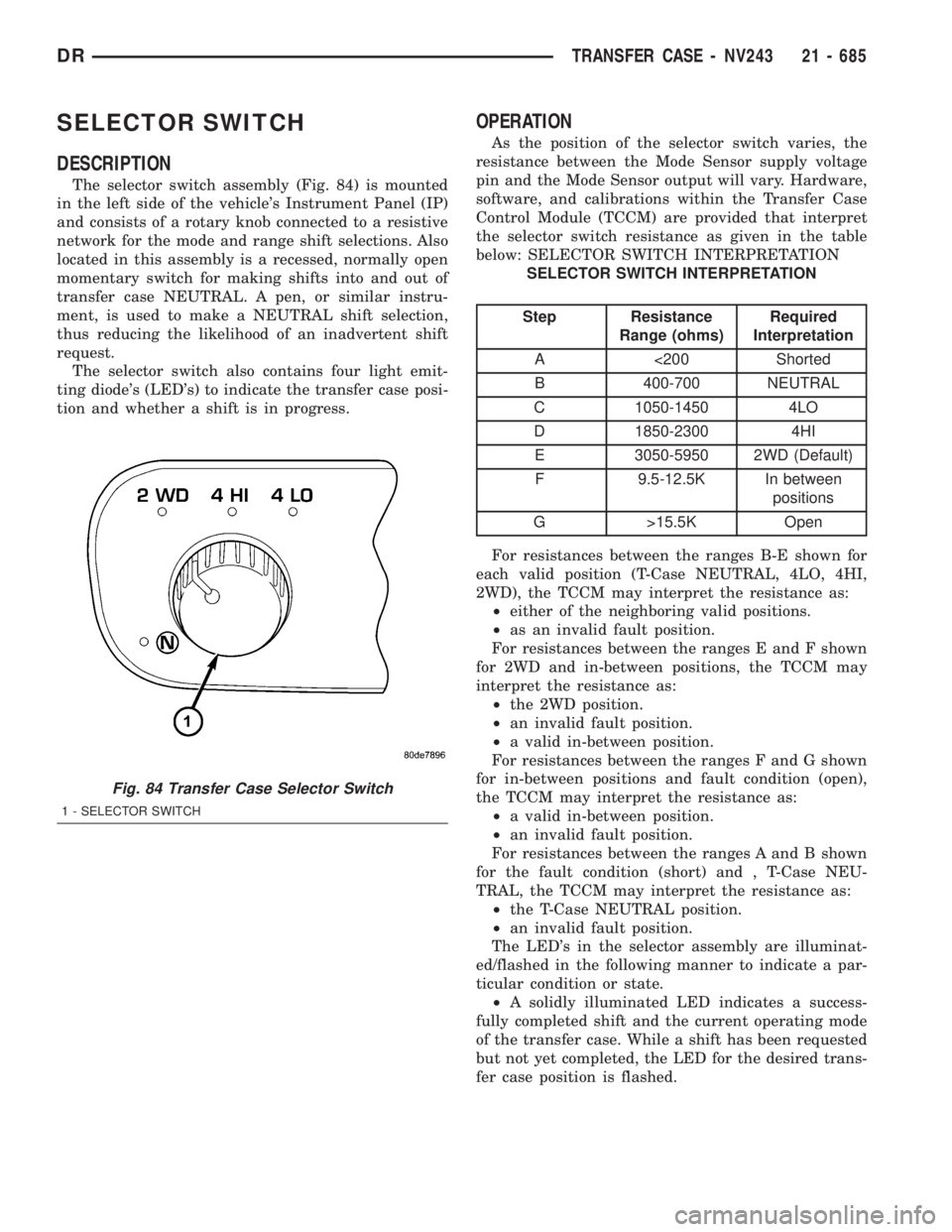

SELECTOR SWITCH

DESCRIPTION

The selector switch assembly (Fig. 84) is mounted

in the left side of the vehicle's Instrument Panel (IP)

and consists of a rotary knob connected to a resistive

network for the mode and range shift selections. Also

located in this assembly is a recessed, normally open

momentary switch for making shifts into and out of

transfer case NEUTRAL. A pen, or similar instru-

ment, is used to make a NEUTRAL shift selection,

thus reducing the likelihood of an inadvertent shift

request.

The selector switch also contains four light emit-

ting diode's (LED's) to indicate the transfer case posi-

tion and whether a shift is in progress.

OPERATION

As the position of the selector switch varies, the

resistance between the Mode Sensor supply voltage

pin and the Mode Sensor output will vary. Hardware,

software, and calibrations within the Transfer Case

Control Module (TCCM) are provided that interpret

the selector switch resistance as given in the table

below: SELECTOR SWITCH INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance

Range (ohms)Required

Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4HI

E 3050-5950 2WD (Default)

F 9.5-12.5K In between

positions

G >15.5K Open

For resistances between the ranges B-E shown for

each valid position (T-Case NEUTRAL, 4LO, 4HI,

2WD), the TCCM may interpret the resistance as:

²either of the neighboring valid positions.

²as an invalid fault position.

For resistances between the ranges E and F shown

for 2WD and in-between positions, the TCCM may

interpret the resistance as:

²the 2WD position.

²an invalid fault position.

²a valid in-between position.

For resistances between the ranges F and G shown

for in-between positions and fault condition (open),

the TCCM may interpret the resistance as:

²a valid in-between position.

²an invalid fault position.

For resistances between the ranges A and B shown

for the fault condition (short) and , T-Case NEU-

TRAL, the TCCM may interpret the resistance as:

²the T-Case NEUTRAL position.

²an invalid fault position.

The LED's in the selector assembly are illuminat-

ed/flashed in the following manner to indicate a par-

ticular condition or state.

²A solidly illuminated LED indicates a success-

fully completed shift and the current operating mode

of the transfer case. While a shift has been requested

but not yet completed, the LED for the desired trans-

fer case position is flashed.

Fig. 84 Transfer Case Selector Switch

1 - SELECTOR SWITCH

DRTRANSFER CASE - NV243 21 - 685

Page 2558 of 2895

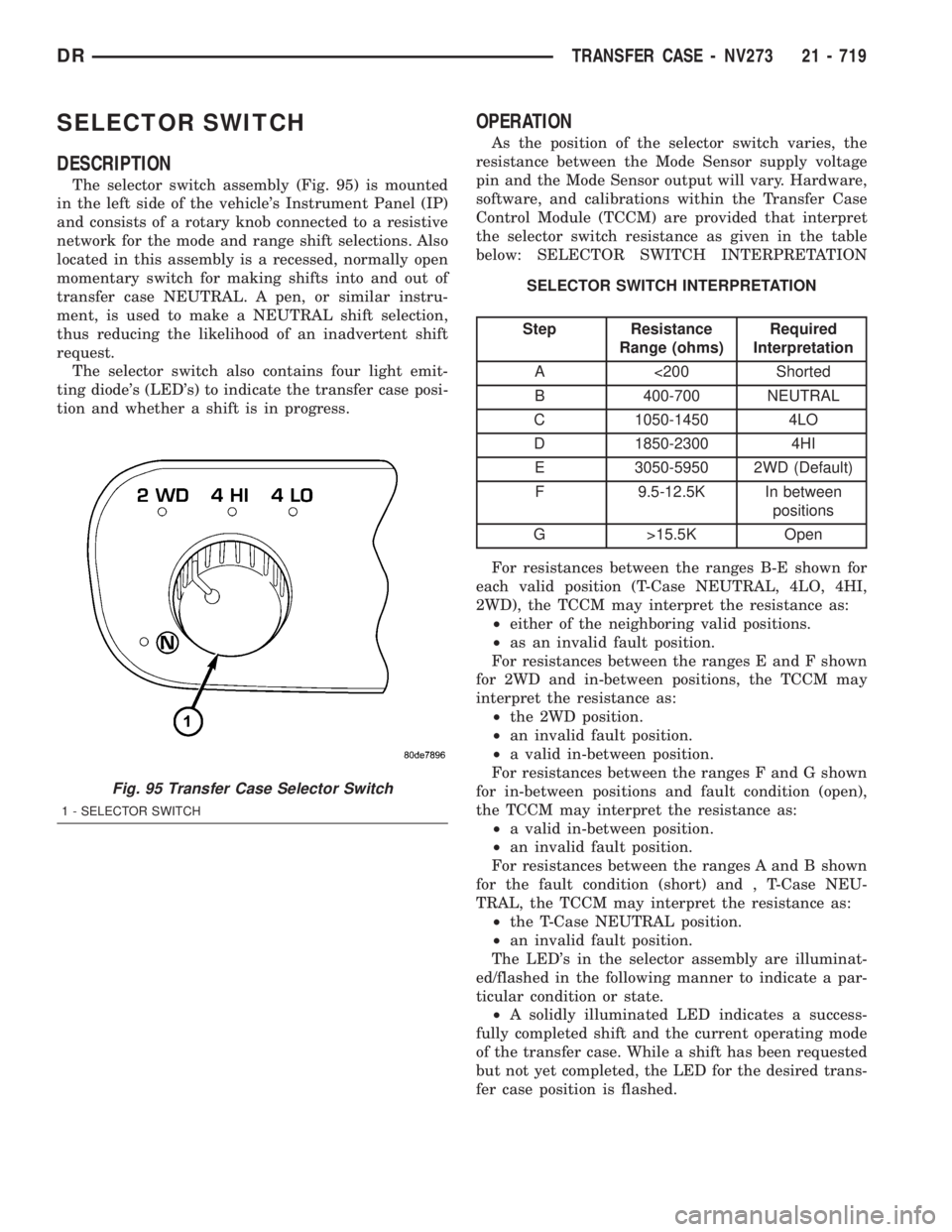

SELECTOR SWITCH

DESCRIPTION

The selector switch assembly (Fig. 95) is mounted

in the left side of the vehicle's Instrument Panel (IP)

and consists of a rotary knob connected to a resistive

network for the mode and range shift selections. Also

located in this assembly is a recessed, normally open

momentary switch for making shifts into and out of

transfer case NEUTRAL. A pen, or similar instru-

ment, is used to make a NEUTRAL shift selection,

thus reducing the likelihood of an inadvertent shift

request.

The selector switch also contains four light emit-

ting diode's (LED's) to indicate the transfer case posi-

tion and whether a shift is in progress.

OPERATION

As the position of the selector switch varies, the

resistance between the Mode Sensor supply voltage

pin and the Mode Sensor output will vary. Hardware,

software, and calibrations within the Transfer Case

Control Module (TCCM) are provided that interpret

the selector switch resistance as given in the table

below: SELECTOR SWITCH INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance

Range (ohms)Required

Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4HI

E 3050-5950 2WD (Default)

F 9.5-12.5K In between

positions

G >15.5K Open

For resistances between the ranges B-E shown for

each valid position (T-Case NEUTRAL, 4LO, 4HI,

2WD), the TCCM may interpret the resistance as:

²either of the neighboring valid positions.

²as an invalid fault position.

For resistances between the ranges E and F shown

for 2WD and in-between positions, the TCCM may

interpret the resistance as:

²the 2WD position.

²an invalid fault position.

²a valid in-between position.

For resistances between the ranges F and G shown

for in-between positions and fault condition (open),

the TCCM may interpret the resistance as:

²a valid in-between position.

²an invalid fault position.

For resistances between the ranges A and B shown

for the fault condition (short) and , T-Case NEU-

TRAL, the TCCM may interpret the resistance as:

²the T-Case NEUTRAL position.

²an invalid fault position.

The LED's in the selector assembly are illuminat-

ed/flashed in the following manner to indicate a par-

ticular condition or state.

²A solidly illuminated LED indicates a success-

fully completed shift and the current operating mode

of the transfer case. While a shift has been requested

but not yet completed, the LED for the desired trans-

fer case position is flashed.

Fig. 95 Transfer Case Selector Switch

1 - SELECTOR SWITCH

DRTRANSFER CASE - NV273 21 - 719

Page 2614 of 2895

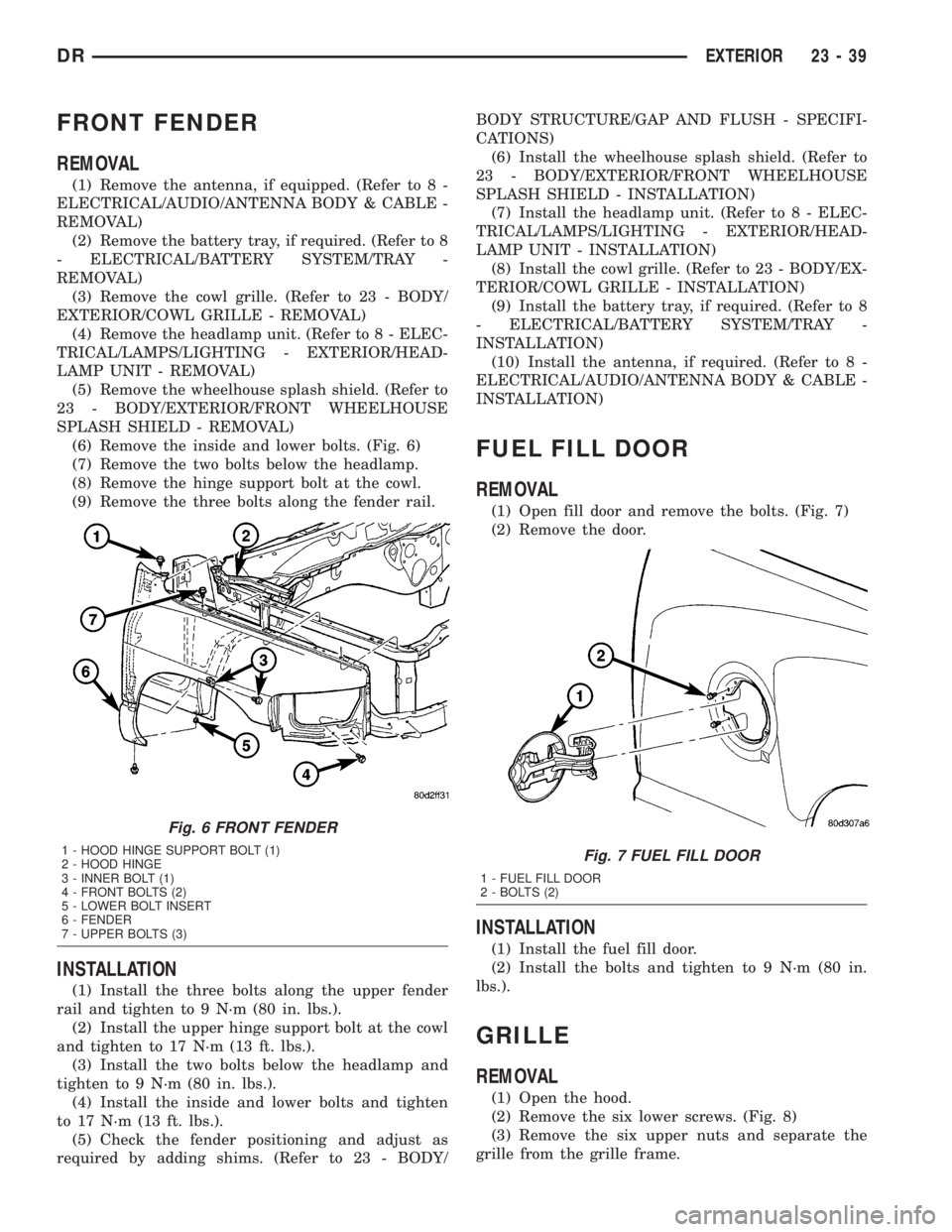

FRONT FENDER

REMOVAL

(1) Remove the antenna, if equipped. (Refer to 8 -

ELECTRICAL/AUDIO/ANTENNA BODY & CABLE -

REMOVAL)

(2) Remove the battery tray, if required. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/TRAY -

REMOVAL)

(3) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(4) Remove the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(5) Remove the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(6) Remove the inside and lower bolts. (Fig. 6)

(7) Remove the two bolts below the headlamp.

(8) Remove the hinge support bolt at the cowl.

(9) Remove the three bolts along the fender rail.

INSTALLATION

(1) Install the three bolts along the upper fender

rail and tighten to 9 N´m (80 in. lbs.).

(2) Install the upper hinge support bolt at the cowl

and tighten to 17 N´m (13 ft. lbs.).

(3) Install the two bolts below the headlamp and

tighten to 9 N´m (80 in. lbs.).

(4) Install the inside and lower bolts and tighten

to 17 N´m (13 ft. lbs.).

(5) Check the fender positioning and adjust as

required by adding shims. (Refer to 23 - BODY/BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS)

(6) Install the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - INSTALLATION)

(7) Install the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(8) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

(9) Install the battery tray, if required. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/TRAY -

INSTALLATION)

(10) Install the antenna, if required. (Refer to 8 -

ELECTRICAL/AUDIO/ANTENNA BODY & CABLE -

INSTALLATION)

FUEL FILL DOOR

REMOVAL

(1) Open fill door and remove the bolts. (Fig. 7)

(2) Remove the door.

INSTALLATION

(1) Install the fuel fill door.

(2) Install the bolts and tighten to 9 N´m (80 in.

lbs.).

GRILLE

REMOVAL

(1) Open the hood.

(2) Remove the six lower screws. (Fig. 8)

(3) Remove the six upper nuts and separate the

grille from the grille frame.

Fig. 6 FRONT FENDER

1 - HOOD HINGE SUPPORT BOLT (1)

2 - HOOD HINGE

3 - INNER BOLT (1)

4 - FRONT BOLTS (2)

5 - LOWER BOLT INSERT

6 - FENDER

7 - UPPER BOLTS (3)Fig. 7 FUEL FILL DOOR

1 - FUEL FILL DOOR

2 - BOLTS (2)

DREXTERIOR 23 - 39

Page 2622 of 2895

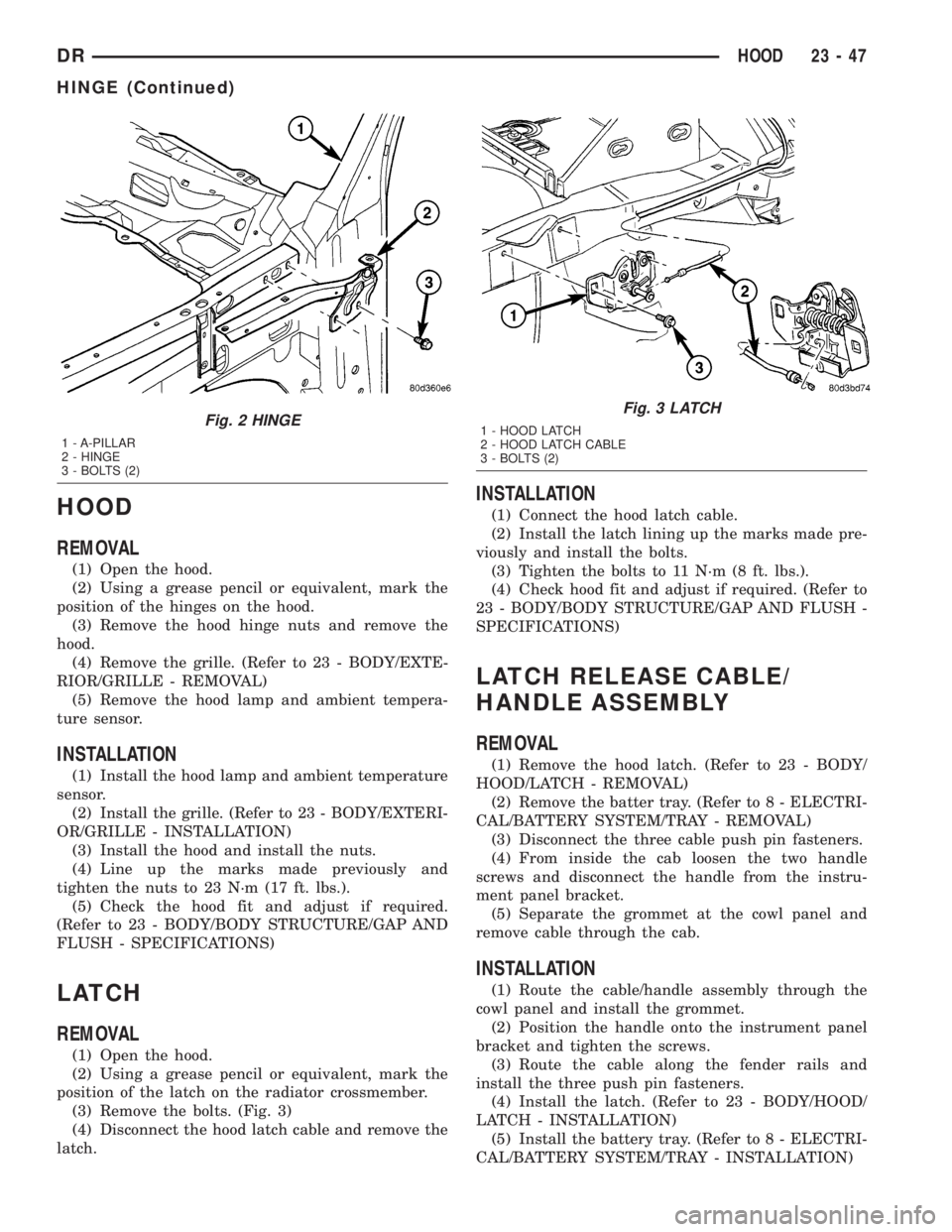

HOOD

REMOVAL

(1) Open the hood.

(2) Using a grease pencil or equivalent, mark the

position of the hinges on the hood.

(3) Remove the hood hinge nuts and remove the

hood.

(4) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(5) Remove the hood lamp and ambient tempera-

ture sensor.

INSTALLATION

(1) Install the hood lamp and ambient temperature

sensor.

(2) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

(3) Install the hood and install the nuts.

(4) Line up the marks made previously and

tighten the nuts to 23 N´m (17 ft. lbs.).

(5) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

LATCH

REMOVAL

(1) Open the hood.

(2) Using a grease pencil or equivalent, mark the

position of the latch on the radiator crossmember.

(3) Remove the bolts. (Fig. 3)

(4) Disconnect the hood latch cable and remove the

latch.

INSTALLATION

(1) Connect the hood latch cable.

(2) Install the latch lining up the marks made pre-

viously and install the bolts.

(3) Tighten the bolts to 11 N´m (8 ft. lbs.).

(4) Check hood fit and adjust if required. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

LATCH RELEASE CABLE/

HANDLE ASSEMBLY

REMOVAL

(1) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)

(2) Remove the batter tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL)

(3) Disconnect the three cable push pin fasteners.

(4) From inside the cab loosen the two handle

screws and disconnect the handle from the instru-

ment panel bracket.

(5) Separate the grommet at the cowl panel and

remove cable through the cab.

INSTALLATION

(1) Route the cable/handle assembly through the

cowl panel and install the grommet.

(2) Position the handle onto the instrument panel

bracket and tighten the screws.

(3) Route the cable along the fender rails and

install the three push pin fasteners.

(4) Install the latch. (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION)

(5) Install the battery tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION)

Fig. 2 HINGE

1 - A-PILLAR

2 - HINGE

3 - BOLTS (2)

Fig. 3 LATCH

1 - HOOD LATCH

2 - HOOD LATCH CABLE

3 - BOLTS (2)

DRHOOD 23 - 47

HINGE (Continued)

Page 2623 of 2895

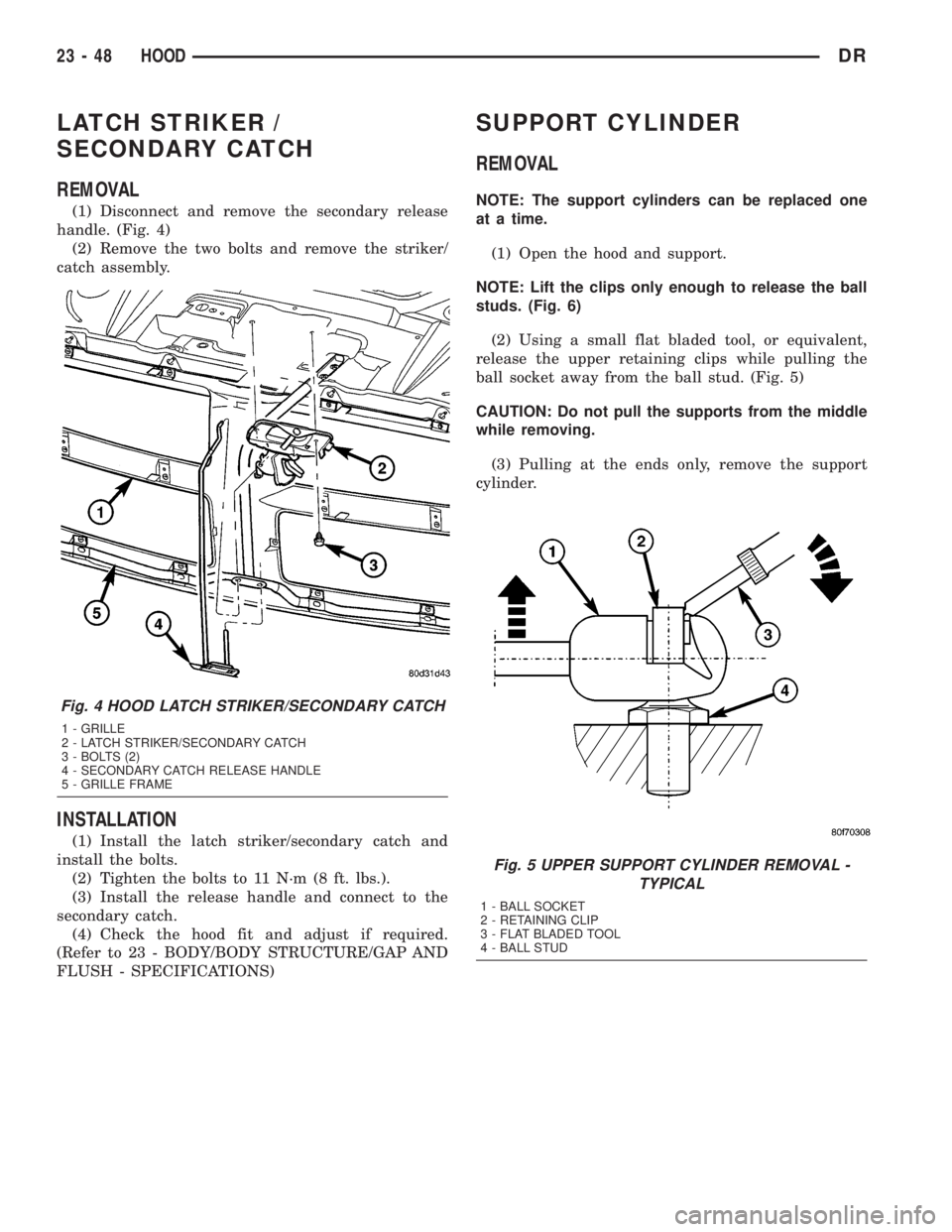

LATCH STRIKER /

SECONDARY CATCH

REMOVAL

(1) Disconnect and remove the secondary release

handle. (Fig. 4)

(2) Remove the two bolts and remove the striker/

catch assembly.

INSTALLATION

(1) Install the latch striker/secondary catch and

install the bolts.

(2) Tighten the bolts to 11 N´m (8 ft. lbs.).

(3) Install the release handle and connect to the

secondary catch.

(4) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

SUPPORT CYLINDER

REMOVAL

NOTE: The support cylinders can be replaced one

at a time.

(1) Open the hood and support.

NOTE: Lift the clips only enough to release the ball

studs. (Fig. 6)

(2) Using a small flat bladed tool, or equivalent,

release the upper retaining clips while pulling the

ball socket away from the ball stud. (Fig. 5)

CAUTION: Do not pull the supports from the middle

while removing.

(3) Pulling at the ends only, remove the support

cylinder.

Fig. 4 HOOD LATCH STRIKER/SECONDARY CATCH

1 - GRILLE

2 - LATCH STRIKER/SECONDARY CATCH

3 - BOLTS (2)

4 - SECONDARY CATCH RELEASE HANDLE

5 - GRILLE FRAME

Fig. 5 UPPER SUPPORT CYLINDER REMOVAL -

TYPICAL

1 - BALL SOCKET

2 - RETAINING CLIP

3 - FLAT BLADED TOOL

4 - BALL STUD

23 - 48 HOODDR

Page 2632 of 2895

(11) Install the right a-pillar trim panel. (Refer to

23 - BODY/INTERIOR/A-PILLAR TRIM - INSTAL-

LATION)

(12) Position the right end cap and seat the

attachment clips fully.

(13) Install the one HVAC mounting screw.

(14) Connect the radio antenna.

(15) Connect the two electrical connectors at the

right cowl panel.

(16) Install the right cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(17) Connect the air bag control module electrical

connector.

(18) Install the center bracket bolts and tighten to

12 N´m (9 ft. lbs.).

(19) Install the floor console, if equipped. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE - INSTAL-

LATION)

(20) Install the air bag control module cover, if

equipped.

(21) Connect the park brake release handle actua-

tor rod.

(22) Install the hood release handle and tighten

the screws.

(23) Install the two bolts at the column support

bracket and tighten to 14 N´m (10 ft. lbs.).

(24) Install the steering column. (Refer to 19 -

STEERING/COLUMN - INSTALLATION)

(25) Connect the wire harness electrical connectors

above the brake pedal.

(26) Install the two top instrument panel bolts and

tighten to 12 N´m (9 ft. lbs.).

(27) Install the four top instrument panel screws.

(28) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

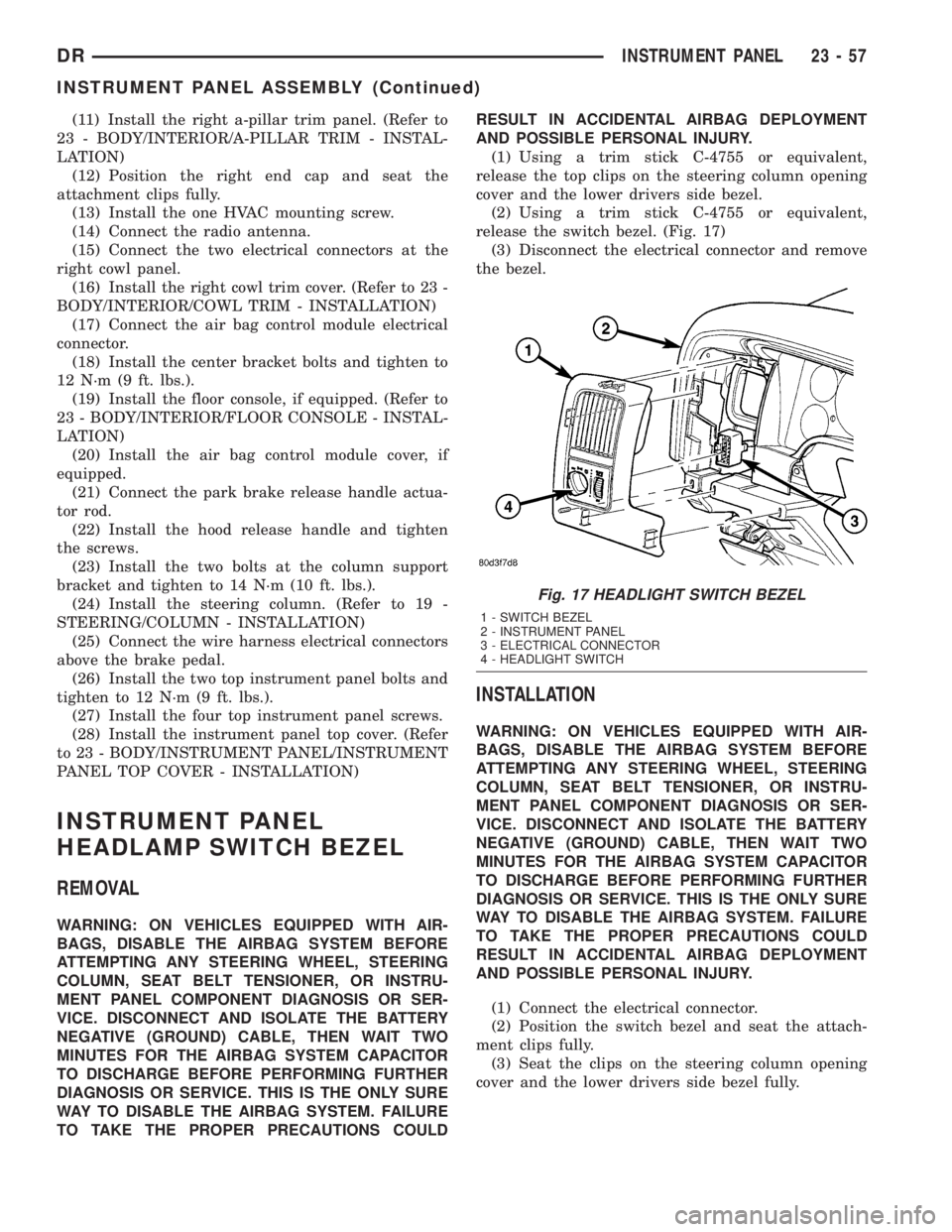

INSTRUMENT PANEL

HEADLAMP SWITCH BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Using a trim stick C-4755 or equivalent,

release the top clips on the steering column opening

cover and the lower drivers side bezel.

(2) Using a trim stick C-4755 or equivalent,

release the switch bezel. (Fig. 17)

(3) Disconnect the electrical connector and remove

the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Connect the electrical connector.

(2) Position the switch bezel and seat the attach-

ment clips fully.

(3) Seat the clips on the steering column opening

cover and the lower drivers side bezel fully.

Fig. 17 HEADLIGHT SWITCH BEZEL

1 - SWITCH BEZEL

2 - INSTRUMENT PANEL

3 - ELECTRICAL CONNECTOR

4 - HEADLIGHT SWITCH

DRINSTRUMENT PANEL 23 - 57

INSTRUMENT PANEL ASSEMBLY (Continued)