tow DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 123 of 2895

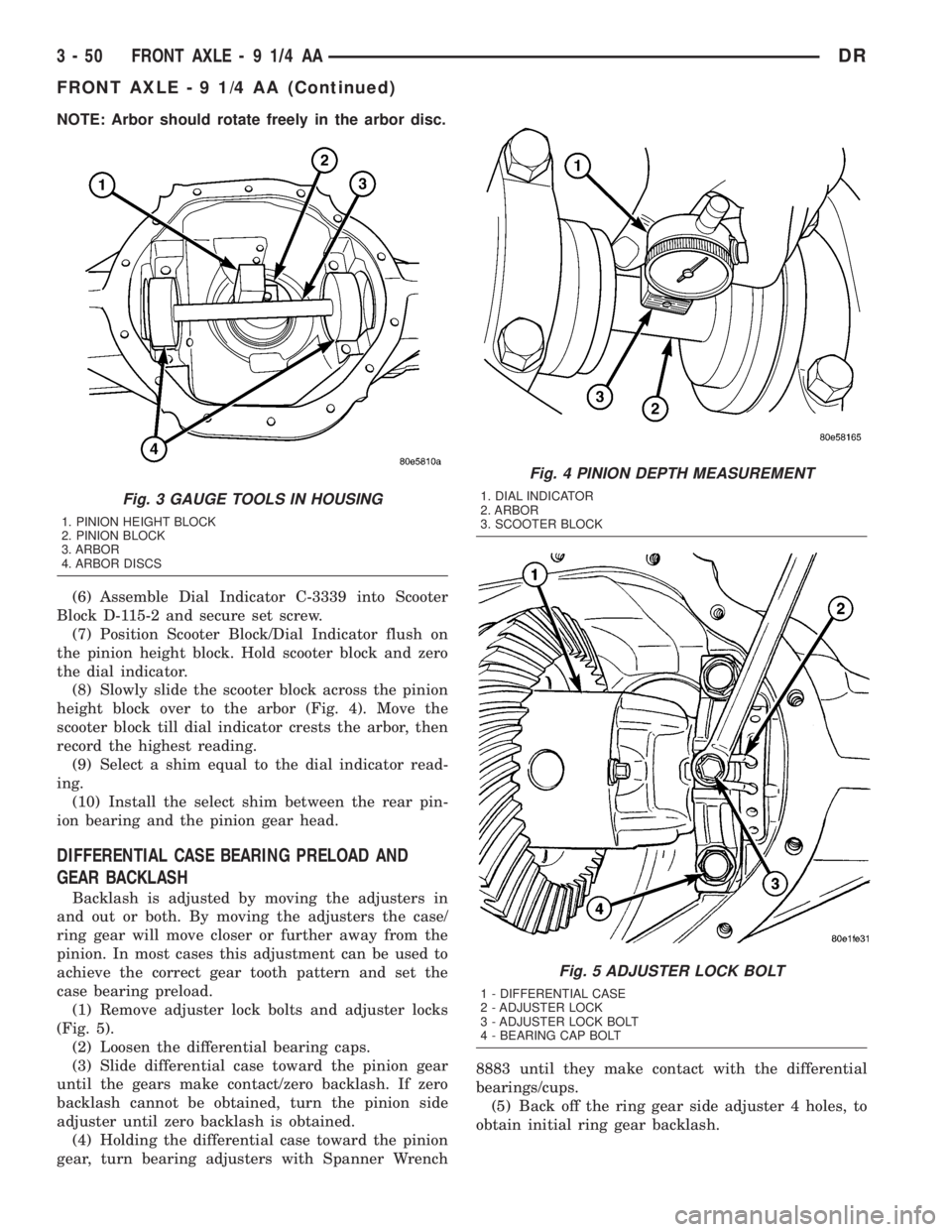

NOTE: Arbor should rotate freely in the arbor disc.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 4). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

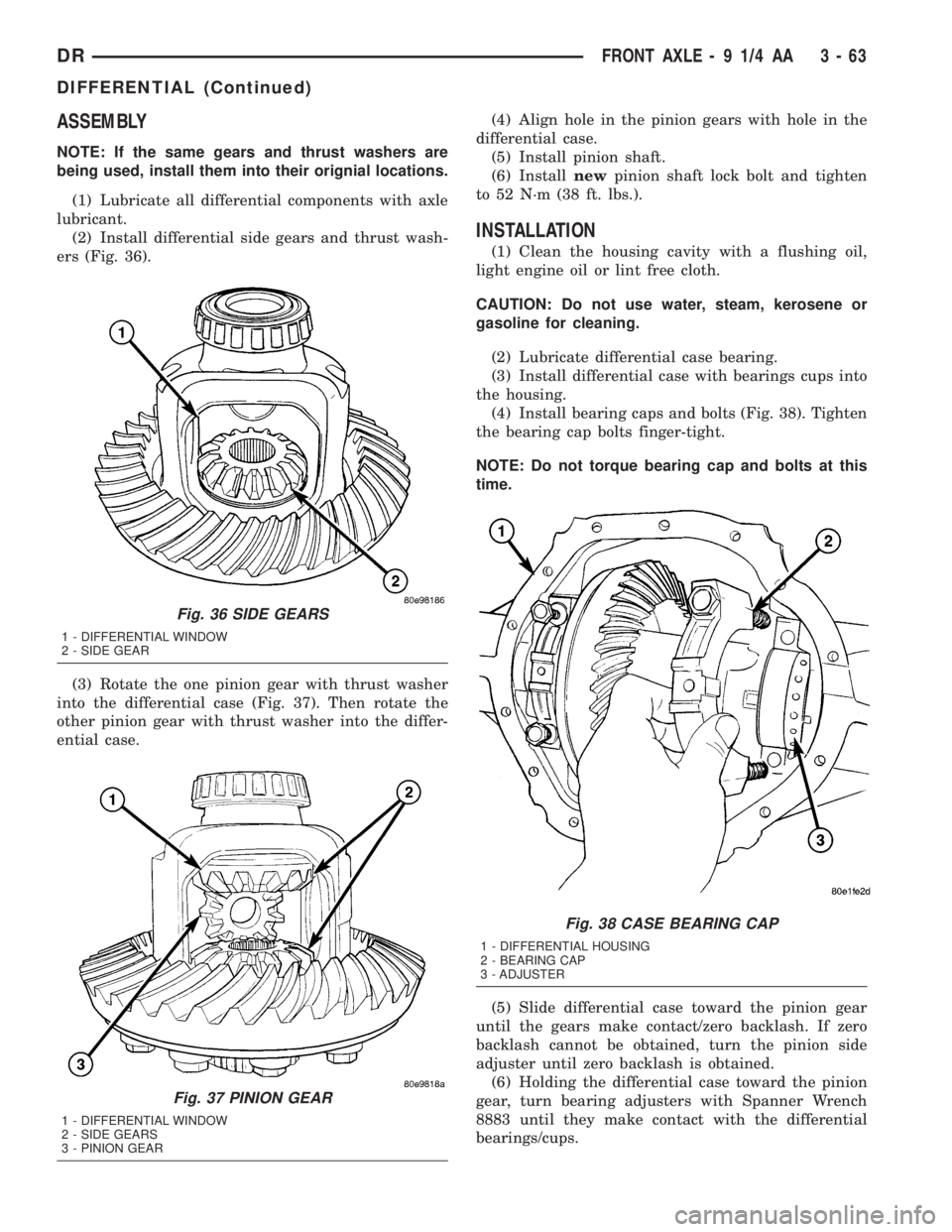

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 5).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench8883 until they make contact with the differential

bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 3 GAUGE TOOLS IN HOUSING

1. PINION HEIGHT BLOCK

2. PINION BLOCK

3. ARBOR

4. ARBOR DISCS

Fig. 4 PINION DEPTH MEASUREMENT

1. DIAL INDICATOR

2. ARBOR

3. SCOOTER BLOCK

Fig. 5 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 50 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 136 of 2895

ASSEMBLY

NOTE: If the same gears and thrust washers are

being used, install them into their orignial locations.

(1) Lubricate all differential components with axle

lubricant.

(2) Install differential side gears and thrust wash-

ers (Fig. 36).

(3) Rotate the one pinion gear with thrust washer

into the differential case (Fig. 37). Then rotate the

other pinion gear with thrust washer into the differ-

ential case.(4) Align hole in the pinion gears with hole in the

differential case.

(5) Install pinion shaft.

(6) Installnewpinion shaft lock bolt and tighten

to 52 N´m (38 ft. lbs.).

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

(4) Install bearing caps and bolts (Fig. 38). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

Fig. 36 SIDE GEARS

1 - DIFFERENTIAL WINDOW

2 - SIDE GEAR

Fig. 37 PINION GEAR

1 - DIFFERENTIAL WINDOW

2 - SIDE GEARS

3 - PINION GEAR

Fig. 38 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTER

DRFRONT AXLE - 9 1/4 AA 3 - 63

DIFFERENTIAL (Continued)

Page 178 of 2895

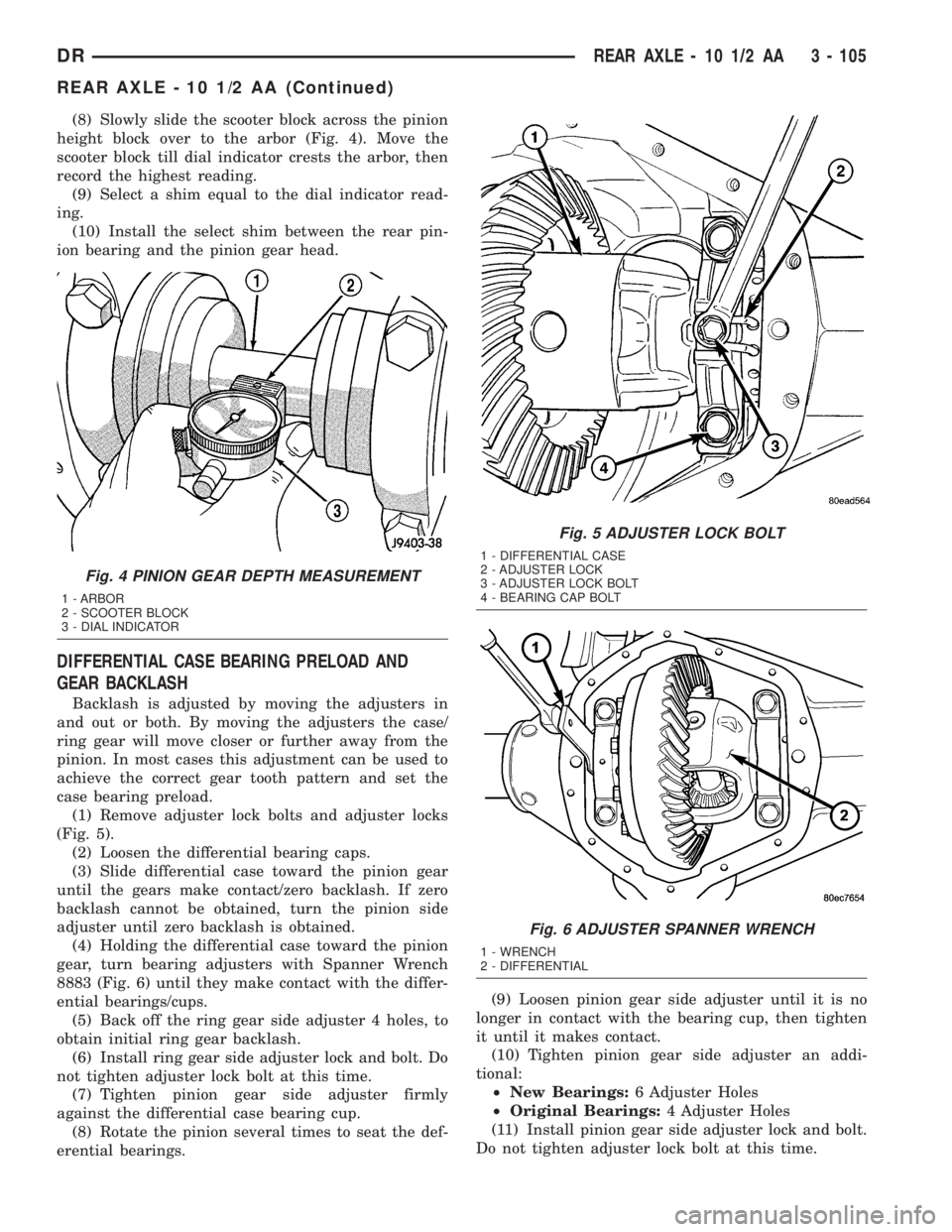

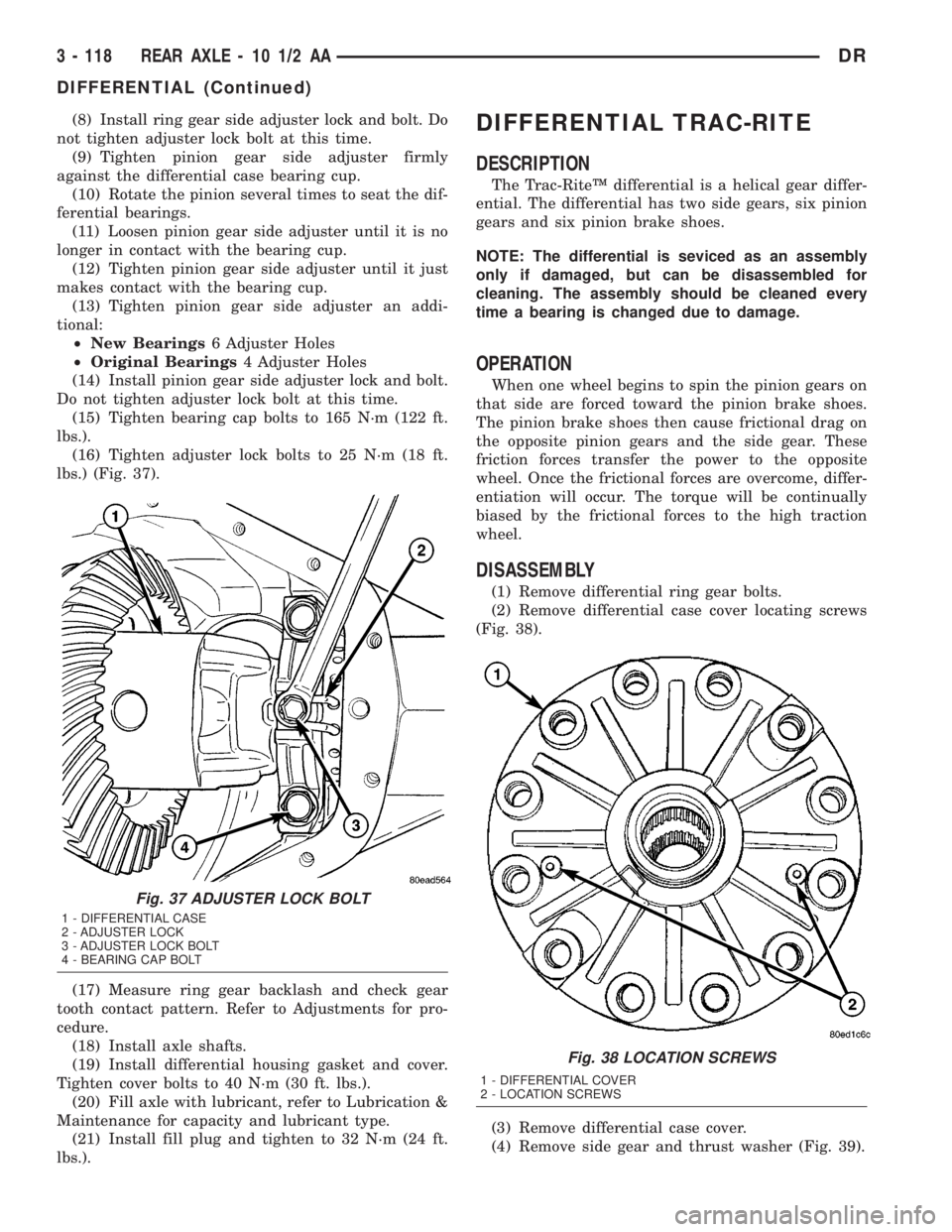

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 4). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

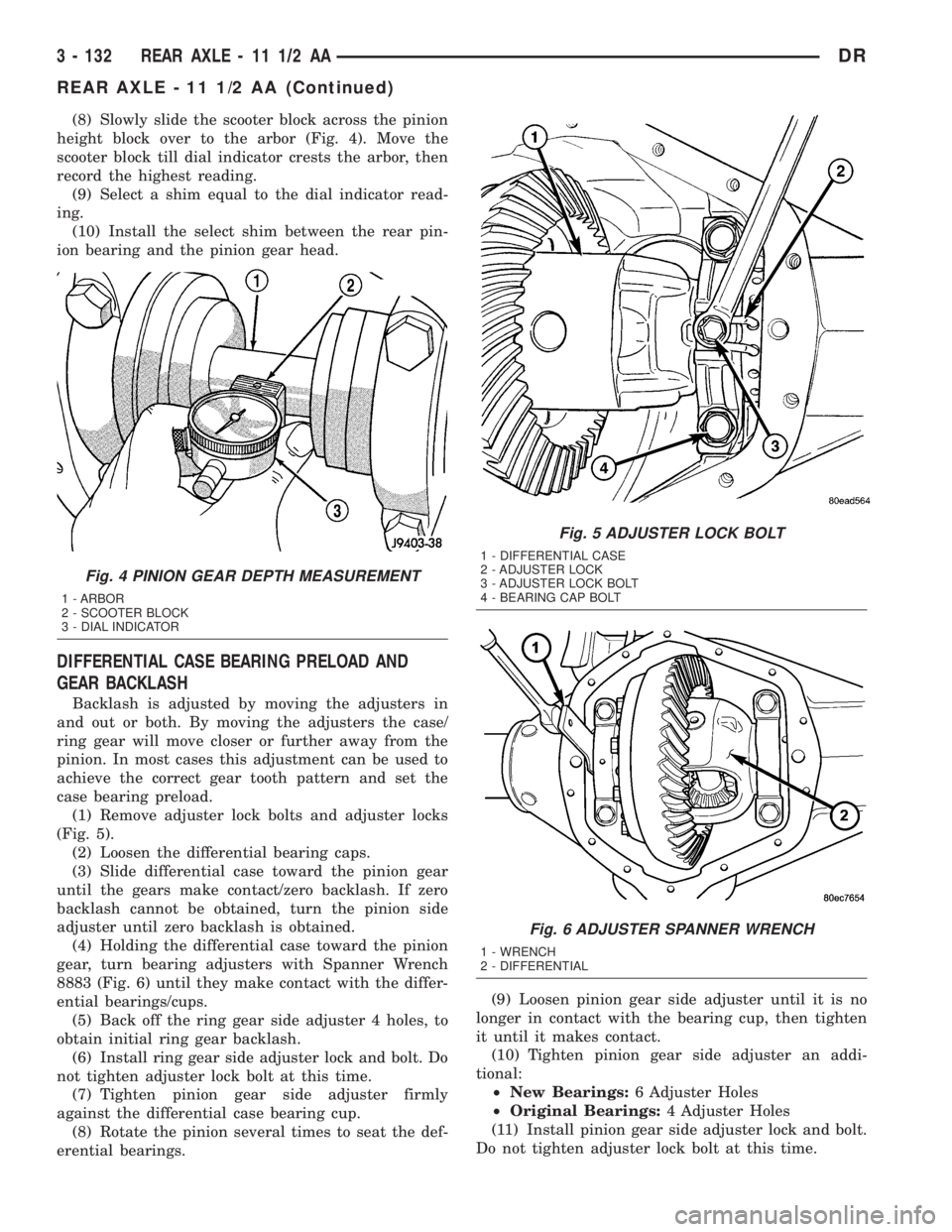

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 5).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 6) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

Fig. 4 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 5 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 6 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 10 1/2 AA 3 - 105

REAR AXLE - 10 1/2 AA (Continued)

Page 190 of 2895

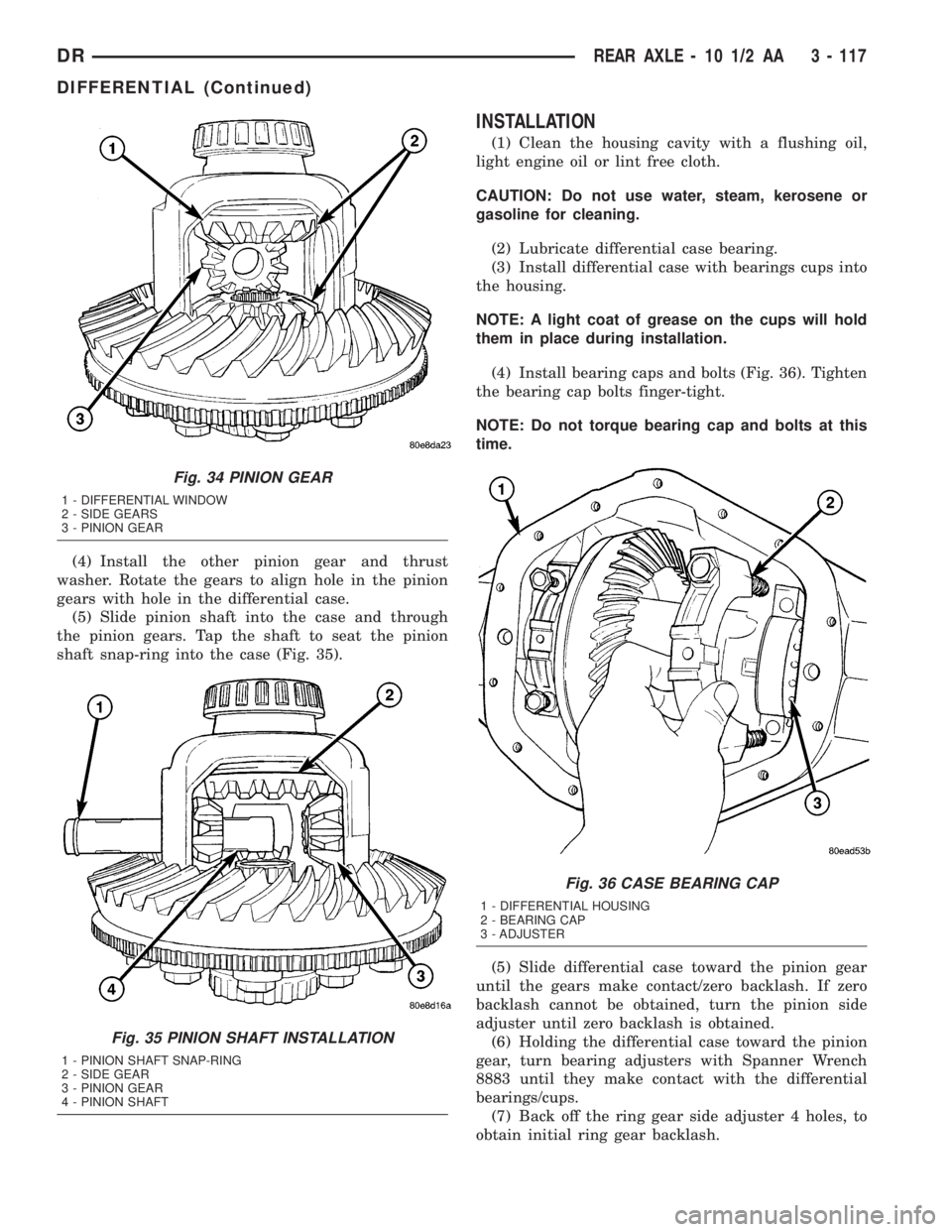

(4) Install the other pinion gear and thrust

washer. Rotate the gears to align hole in the pinion

gears with hole in the differential case.

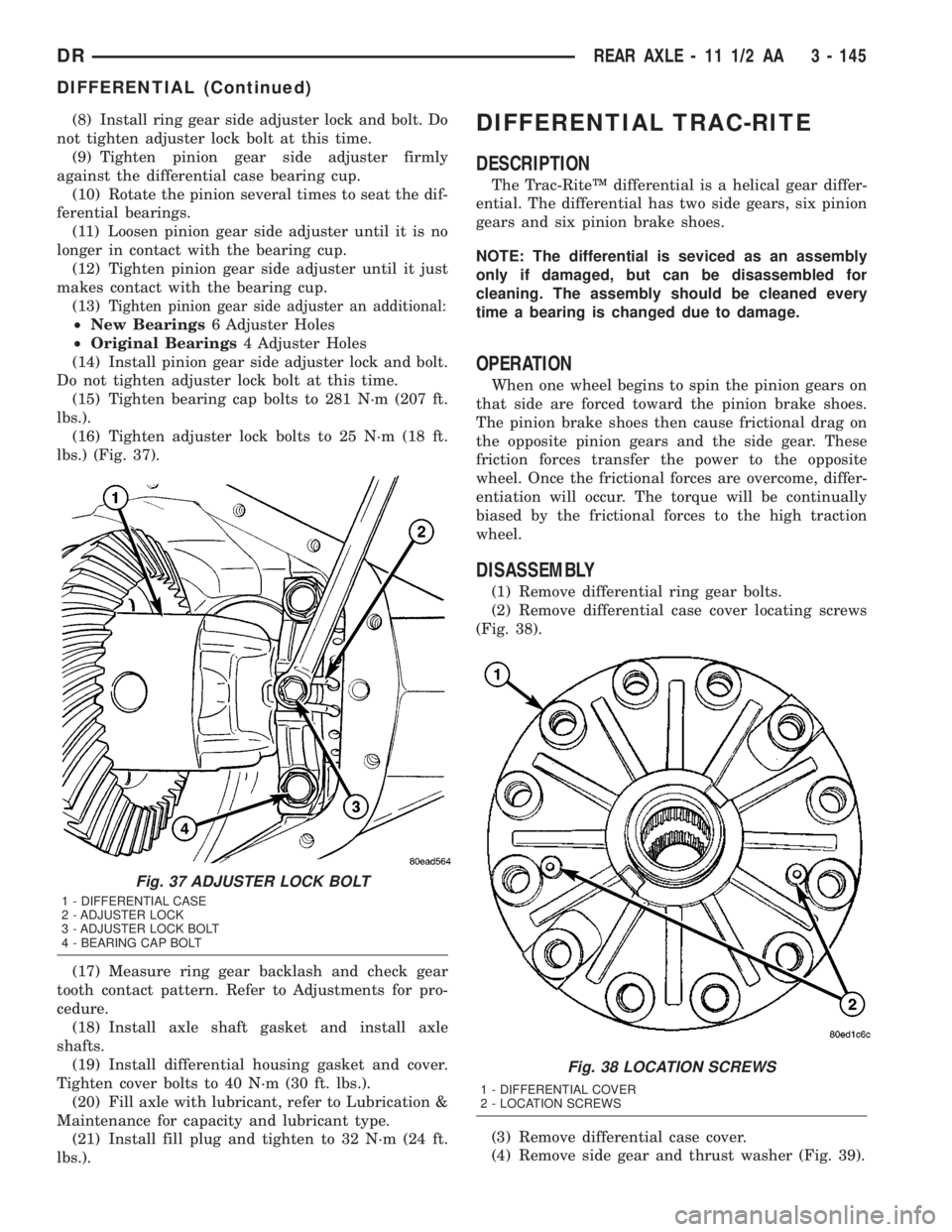

(5) Slide pinion shaft into the case and through

the pinion gears. Tap the shaft to seat the pinion

shaft snap-ring into the case (Fig. 35).

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

NOTE: A light coat of grease on the cups will hold

them in place during installation.

(4) Install bearing caps and bolts (Fig. 36). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

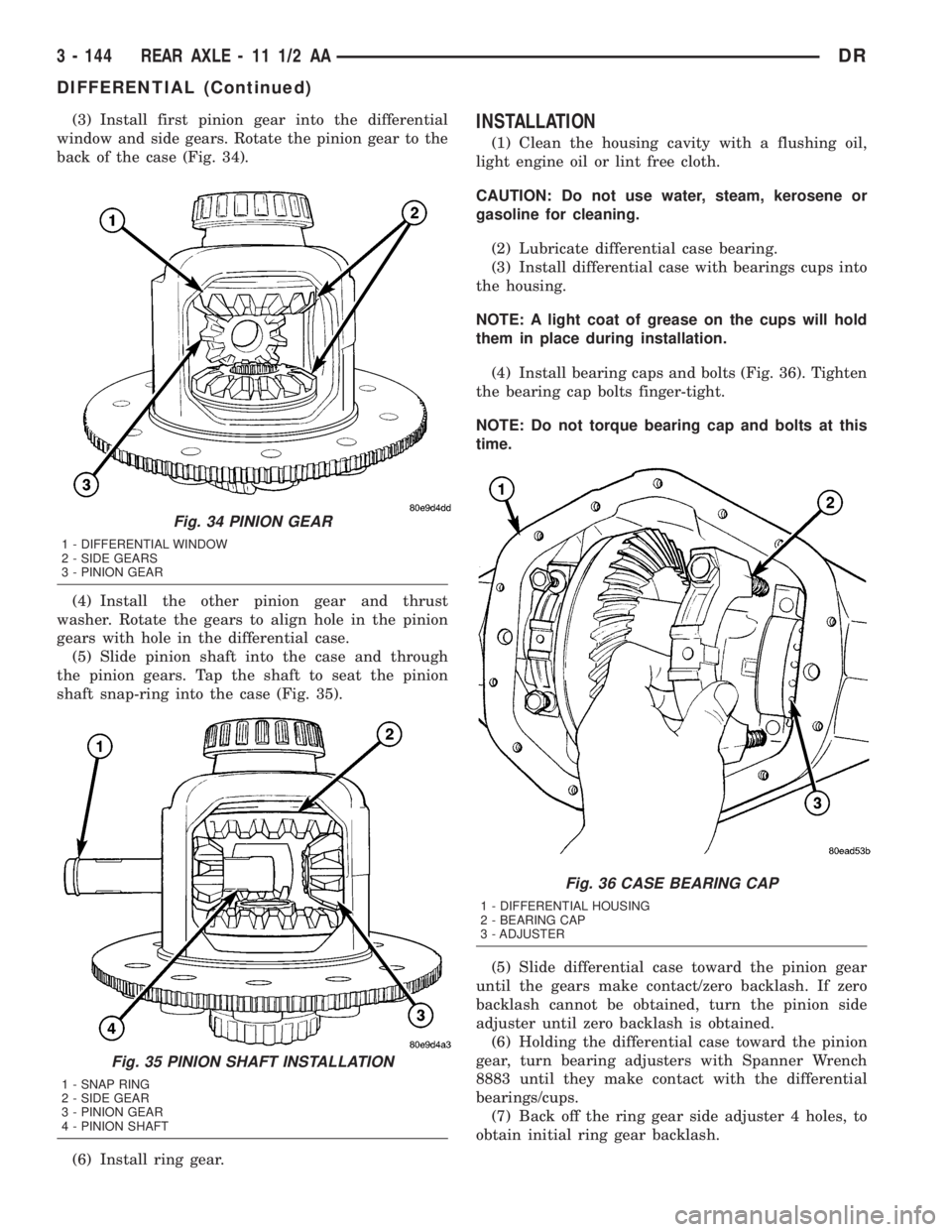

Fig. 34 PINION GEAR

1 - DIFFERENTIAL WINDOW

2 - SIDE GEARS

3 - PINION GEAR

Fig. 35 PINION SHAFT INSTALLATION

1 - PINION SHAFT SNAP-RING

2 - SIDE GEAR

3 - PINION GEAR

4 - PINION SHAFT

Fig. 36 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTER

DRREAR AXLE - 10 1/2 AA 3 - 117

DIFFERENTIAL (Continued)

Page 191 of 2895

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 165 N´m (122 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

3 - 118 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL (Continued)

Page 205 of 2895

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 4). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 5).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 6) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

Fig. 4 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 5 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 6 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

3 - 132 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)

Page 217 of 2895

(3) Install first pinion gear into the differential

window and side gears. Rotate the pinion gear to the

back of the case (Fig. 34).

(4) Install the other pinion gear and thrust

washer. Rotate the gears to align hole in the pinion

gears with hole in the differential case.

(5) Slide pinion shaft into the case and through

the pinion gears. Tap the shaft to seat the pinion

shaft snap-ring into the case (Fig. 35).

(6) Install ring gear.INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

NOTE: A light coat of grease on the cups will hold

them in place during installation.

(4) Install bearing caps and bolts (Fig. 36). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 34 PINION GEAR

1 - DIFFERENTIAL WINDOW

2 - SIDE GEARS

3 - PINION GEAR

Fig. 35 PINION SHAFT INSTALLATION

1 - SNAP RING

2 - SIDE GEAR

3 - PINION GEAR

4 - PINION SHAFT

Fig. 36 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTER

3 - 144 REAR AXLE - 11 1/2 AADR

DIFFERENTIAL (Continued)

Page 218 of 2895

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13)

Tighten pinion gear side adjuster an additional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 281 N´m (207 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shaft gasket and install axle

shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

DRREAR AXLE - 11 1/2 AA 3 - 145

DIFFERENTIAL (Continued)

Page 240 of 2895

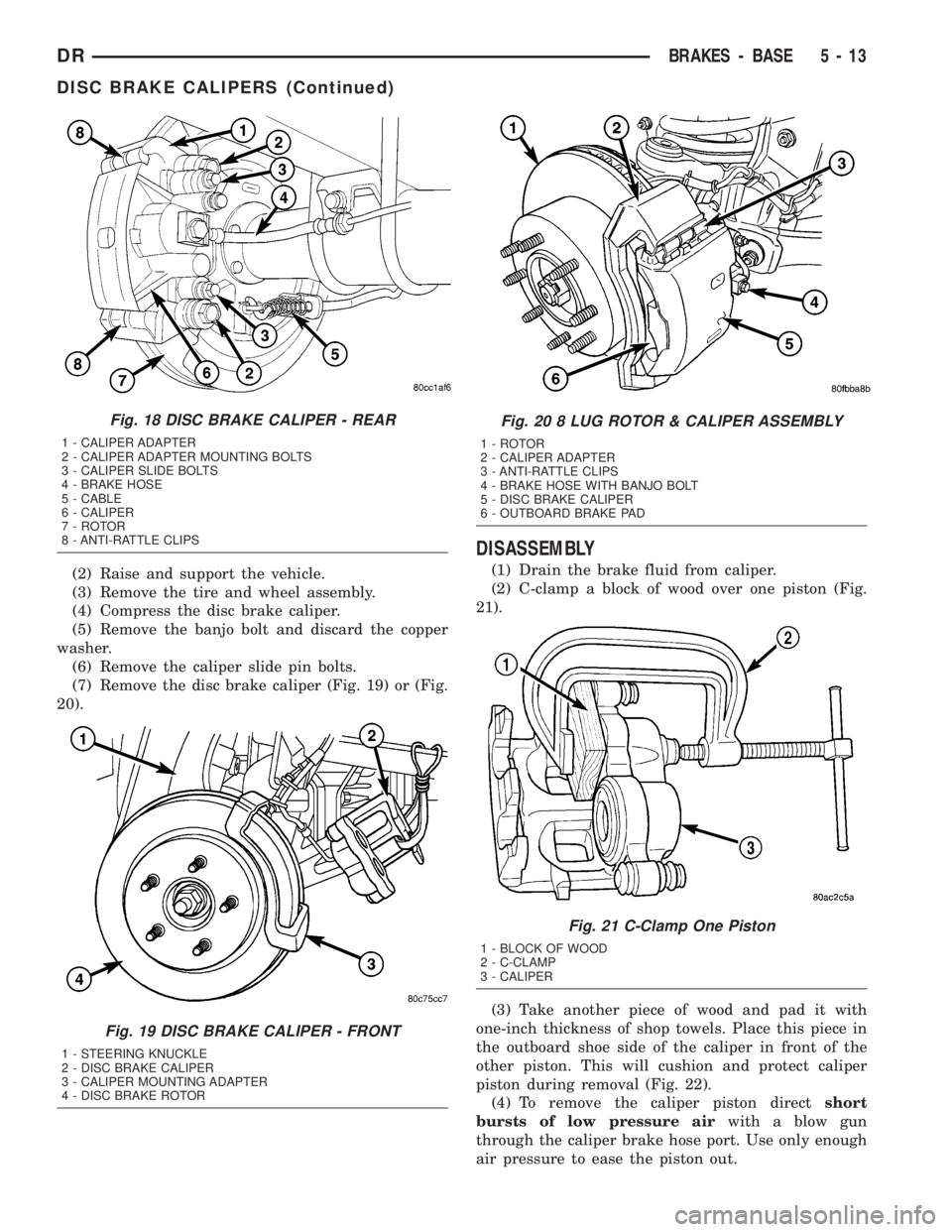

(2) Raise and support the vehicle.

(3) Remove the tire and wheel assembly.

(4) Compress the disc brake caliper.

(5) Remove the banjo bolt and discard the copper

washer.

(6) Remove the caliper slide pin bolts.

(7) Remove the disc brake caliper (Fig. 19) or (Fig.

20).

DISASSEMBLY

(1) Drain the brake fluid from caliper.

(2) C-clamp a block of wood over one piston (Fig.

21).

(3) Take another piece of wood and pad it with

one-inch thickness of shop towels. Place this piece in

the outboard shoe side of the caliper in front of the

other piston. This will cushion and protect caliper

piston during removal (Fig. 22).

(4) To remove the caliper piston directshort

bursts of low pressure airwith a blow gun

through the caliper brake hose port. Use only enough

air pressure to ease the piston out.

Fig. 18 DISC BRAKE CALIPER - REAR

1 - CALIPER ADAPTER

2 - CALIPER ADAPTER MOUNTING BOLTS

3 - CALIPER SLIDE BOLTS

4 - BRAKE HOSE

5 - CABLE

6 - CALIPER

7 - ROTOR

8 - ANTI-RATTLE CLIPS

Fig. 19 DISC BRAKE CALIPER - FRONT

1 - STEERING KNUCKLE

2 - DISC BRAKE CALIPER

3 - CALIPER MOUNTING ADAPTER

4 - DISC BRAKE ROTOR

Fig. 20 8 LUG ROTOR & CALIPER ASSEMBLY

1 - ROTOR

2 - CALIPER ADAPTER

3 - ANTI-RATTLE CLIPS

4 - BRAKE HOSE WITH BANJO BOLT

5 - DISC BRAKE CALIPER

6 - OUTBOARD BRAKE PAD

Fig. 21 C-Clamp One Piston

1 - BLOCK OF WOOD

2 - C-CLAMP

3 - CALIPER

DRBRAKES - BASE 5 - 13

DISC BRAKE CALIPERS (Continued)

Page 280 of 2895

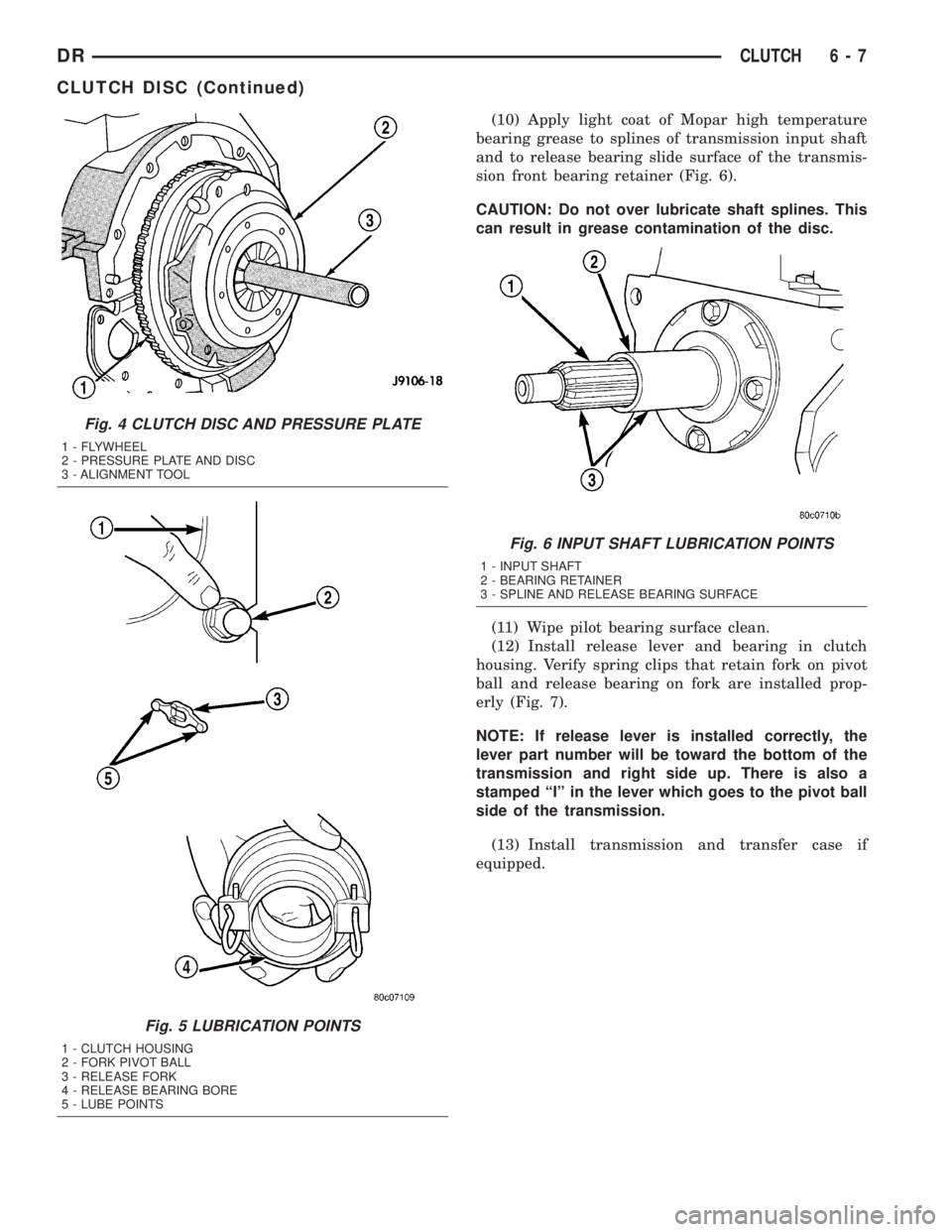

(10) Apply light coat of Mopar high temperature

bearing grease to splines of transmission input shaft

and to release bearing slide surface of the transmis-

sion front bearing retainer (Fig. 6).

CAUTION: Do not over lubricate shaft splines. This

can result in grease contamination of the disc.

(11) Wipe pilot bearing surface clean.

(12) Install release lever and bearing in clutch

housing. Verify spring clips that retain fork on pivot

ball and release bearing on fork are installed prop-

erly (Fig. 7).

NOTE: If release lever is installed correctly, the

lever part number will be toward the bottom of the

transmission and right side up. There is also a

stamped ªIº in the lever which goes to the pivot ball

side of the transmission.

(13) Install transmission and transfer case if

equipped.

Fig. 4 CLUTCH DISC AND PRESSURE PLATE

1 - FLYWHEEL

2 - PRESSURE PLATE AND DISC

3 - ALIGNMENT TOOL

Fig. 5 LUBRICATION POINTS

1 - CLUTCH HOUSING

2 - FORK PIVOT BALL

3 - RELEASE FORK

4 - RELEASE BEARING BORE

5 - LUBE POINTS

Fig. 6 INPUT SHAFT LUBRICATION POINTS

1 - INPUT SHAFT

2 - BEARING RETAINER

3 - SPLINE AND RELEASE BEARING SURFACE

DRCLUTCH 6 - 7

CLUTCH DISC (Continued)