DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2051 of 2895

OIL PUMP

DESCRIPTION

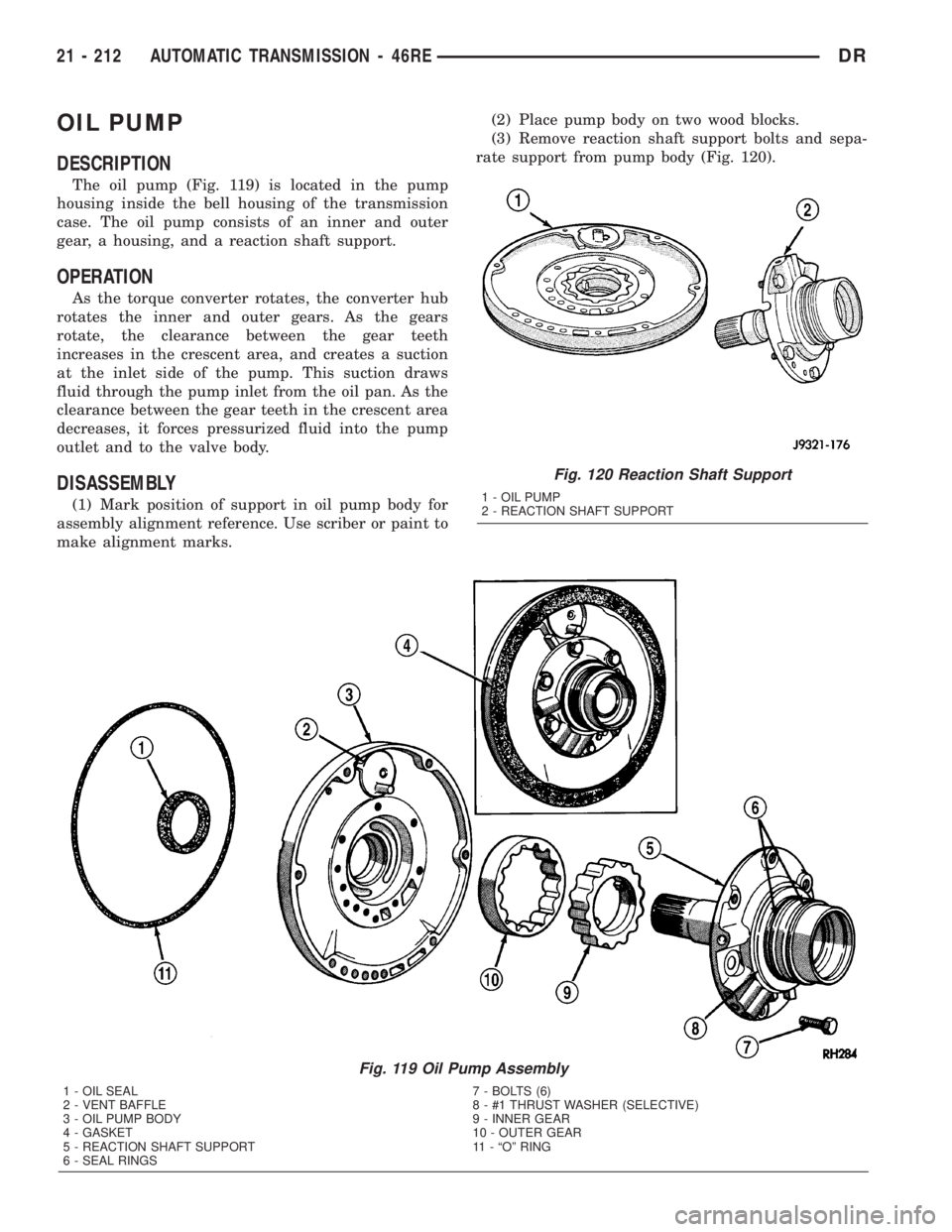

The oil pump (Fig. 119) is located in the pump

housing inside the bell housing of the transmission

case. The oil pump consists of an inner and outer

gear, a housing, and a reaction shaft support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

DISASSEMBLY

(1) Mark position of support in oil pump body for

assembly alignment reference. Use scriber or paint to

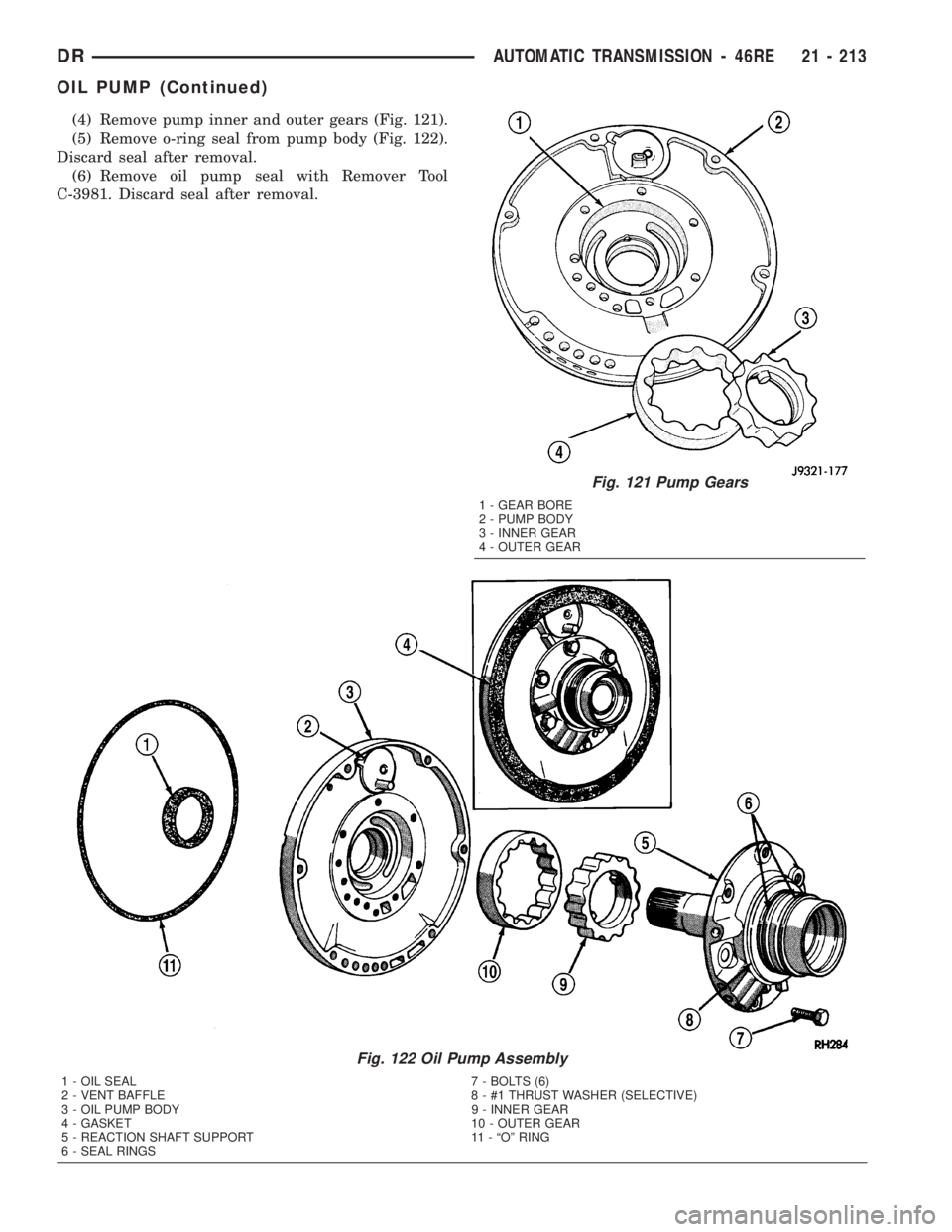

make alignment marks.(2) Place pump body on two wood blocks.

(3) Remove reaction shaft support bolts and sepa-

rate support from pump body (Fig. 120).

Fig. 119 Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - ªOº RING

6 - SEAL RINGS

Fig. 120 Reaction Shaft Support

1 - OIL PUMP

2 - REACTION SHAFT SUPPORT

21 - 212 AUTOMATIC TRANSMISSION - 46REDR

Page 2052 of 2895

(4) Remove pump inner and outer gears (Fig. 121).

(5) Remove o-ring seal from pump body (Fig. 122).

Discard seal after removal.

(6) Remove oil pump seal with Remover Tool

C-3981. Discard seal after removal.

Fig. 121 Pump Gears

1 - GEAR BORE

2 - PUMP BODY

3 - INNER GEAR

4 - OUTER GEAR

Fig. 122 Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - ªOº RING

6 - SEAL RINGS

DRAUTOMATIC TRANSMISSION - 46RE 21 - 213

OIL PUMP (Continued)

Page 2053 of 2895

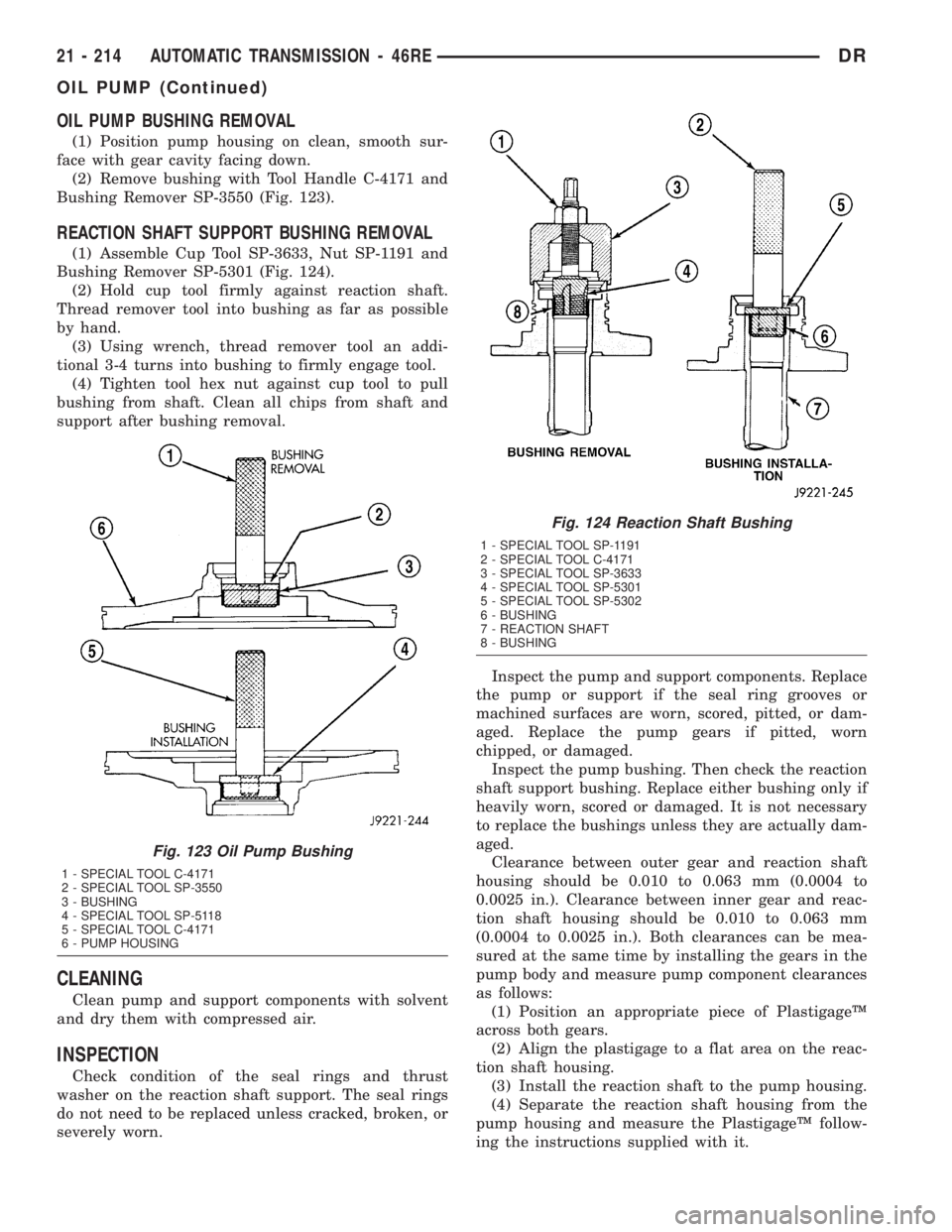

OIL PUMP BUSHING REMOVAL

(1) Position pump housing on clean, smooth sur-

face with gear cavity facing down.

(2) Remove bushing with Tool Handle C-4171 and

Bushing Remover SP-3550 (Fig. 123).

REACTION SHAFT SUPPORT BUSHING REMOVAL

(1) Assemble Cup Tool SP-3633, Nut SP-1191 and

Bushing Remover SP-5301 (Fig. 124).

(2) Hold cup tool firmly against reaction shaft.

Thread remover tool into bushing as far as possible

by hand.

(3) Using wrench, thread remover tool an addi-

tional 3-4 turns into bushing to firmly engage tool.

(4) Tighten tool hex nut against cup tool to pull

bushing from shaft. Clean all chips from shaft and

support after bushing removal.

CLEANING

Clean pump and support components with solvent

and dry them with compressed air.

INSPECTION

Check condition of the seal rings and thrust

washer on the reaction shaft support. The seal rings

do not need to be replaced unless cracked, broken, or

severely worn.Inspect the pump and support components. Replace

the pump or support if the seal ring grooves or

machined surfaces are worn, scored, pitted, or dam-

aged. Replace the pump gears if pitted, worn

chipped, or damaged.

Inspect the pump bushing. Then check the reaction

shaft support bushing. Replace either bushing only if

heavily worn, scored or damaged. It is not necessary

to replace the bushings unless they are actually dam-

aged.

Clearance between outer gear and reaction shaft

housing should be 0.010 to 0.063 mm (0.0004 to

0.0025 in.). Clearance between inner gear and reac-

tion shaft housing should be 0.010 to 0.063 mm

(0.0004 to 0.0025 in.). Both clearances can be mea-

sured at the same time by installing the gears in the

pump body and measure pump component clearances

as follows:

(1) Position an appropriate piece of PlastigageŸ

across both gears.

(2) Align the plastigage to a flat area on the reac-

tion shaft housing.

(3) Install the reaction shaft to the pump housing.

(4) Separate the reaction shaft housing from the

pump housing and measure the PlastigageŸ follow-

ing the instructions supplied with it.

Fig. 123 Oil Pump Bushing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL SP-3550

3 - BUSHING

4 - SPECIAL TOOL SP-5118

5 - SPECIAL TOOL C-4171

6 - PUMP HOUSING

Fig. 124 Reaction Shaft Bushing

1 - SPECIAL TOOL SP-1191

2 - SPECIAL TOOL C-4171

3 - SPECIAL TOOL SP-3633

4 - SPECIAL TOOL SP-5301

5 - SPECIAL TOOL SP-5302

6 - BUSHING

7 - REACTION SHAFT

8 - BUSHING

21 - 214 AUTOMATIC TRANSMISSION - 46REDR

OIL PUMP (Continued)

Page 2054 of 2895

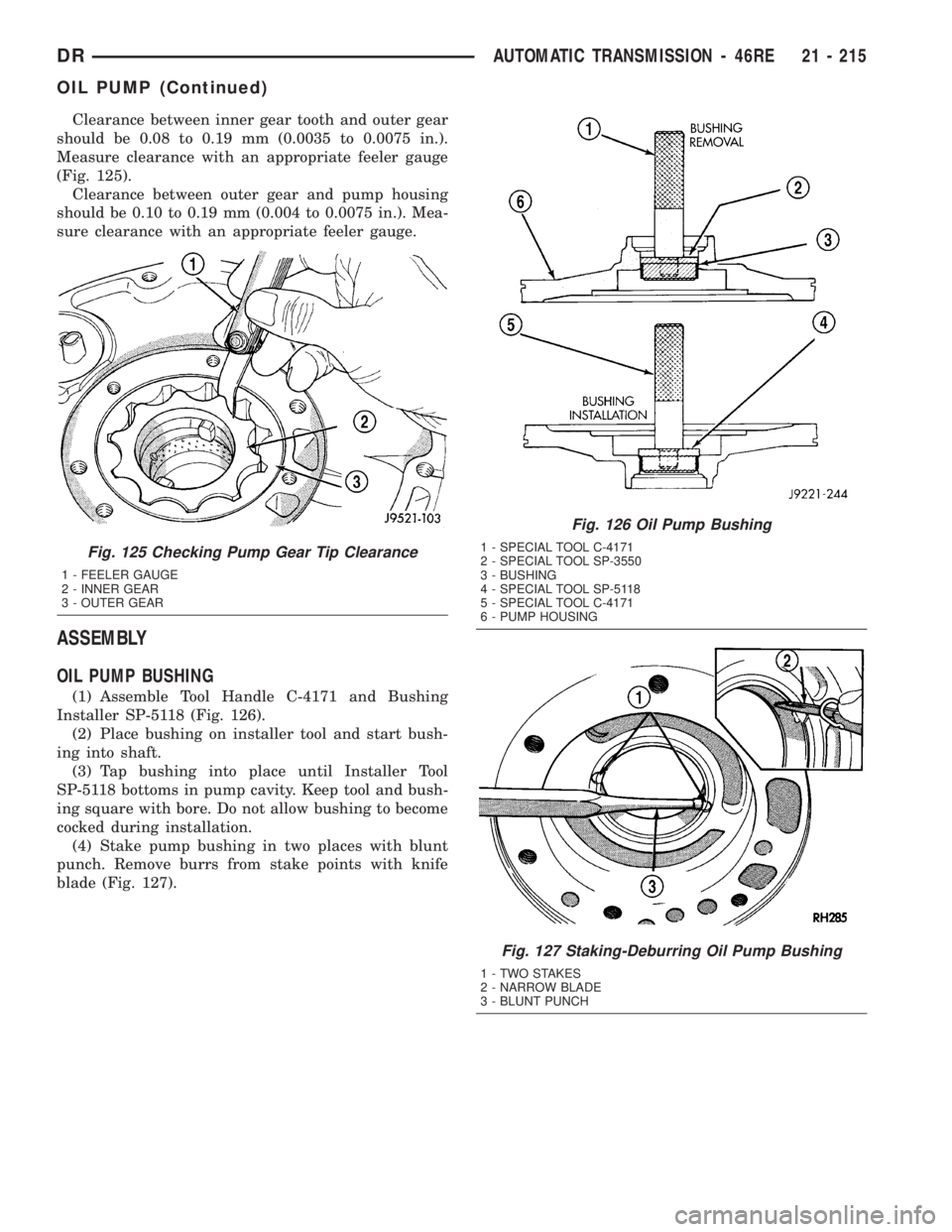

Clearance between inner gear tooth and outer gear

should be 0.08 to 0.19 mm (0.0035 to 0.0075 in.).

Measure clearance with an appropriate feeler gauge

(Fig. 125).

Clearance between outer gear and pump housing

should be 0.10 to 0.19 mm (0.004 to 0.0075 in.). Mea-

sure clearance with an appropriate feeler gauge.

ASSEMBLY

OIL PUMP BUSHING

(1) Assemble Tool Handle C-4171 and Bushing

Installer SP-5118 (Fig. 126).

(2) Place bushing on installer tool and start bush-

ing into shaft.

(3) Tap bushing into place until Installer Tool

SP-5118 bottoms in pump cavity. Keep tool and bush-

ing square with bore. Do not allow bushing to become

cocked during installation.

(4) Stake pump bushing in two places with blunt

punch. Remove burrs from stake points with knife

blade (Fig. 127).

Fig. 125 Checking Pump Gear Tip Clearance

1 - FEELER GAUGE

2 - INNER GEAR

3 - OUTER GEAR

Fig. 126 Oil Pump Bushing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL SP-3550

3 - BUSHING

4 - SPECIAL TOOL SP-5118

5 - SPECIAL TOOL C-4171

6 - PUMP HOUSING

Fig. 127 Staking-Deburring Oil Pump Bushing

1 - TWO STAKES

2 - NARROW BLADE

3 - BLUNT PUNCH

DRAUTOMATIC TRANSMISSION - 46RE 21 - 215

OIL PUMP (Continued)

Page 2055 of 2895

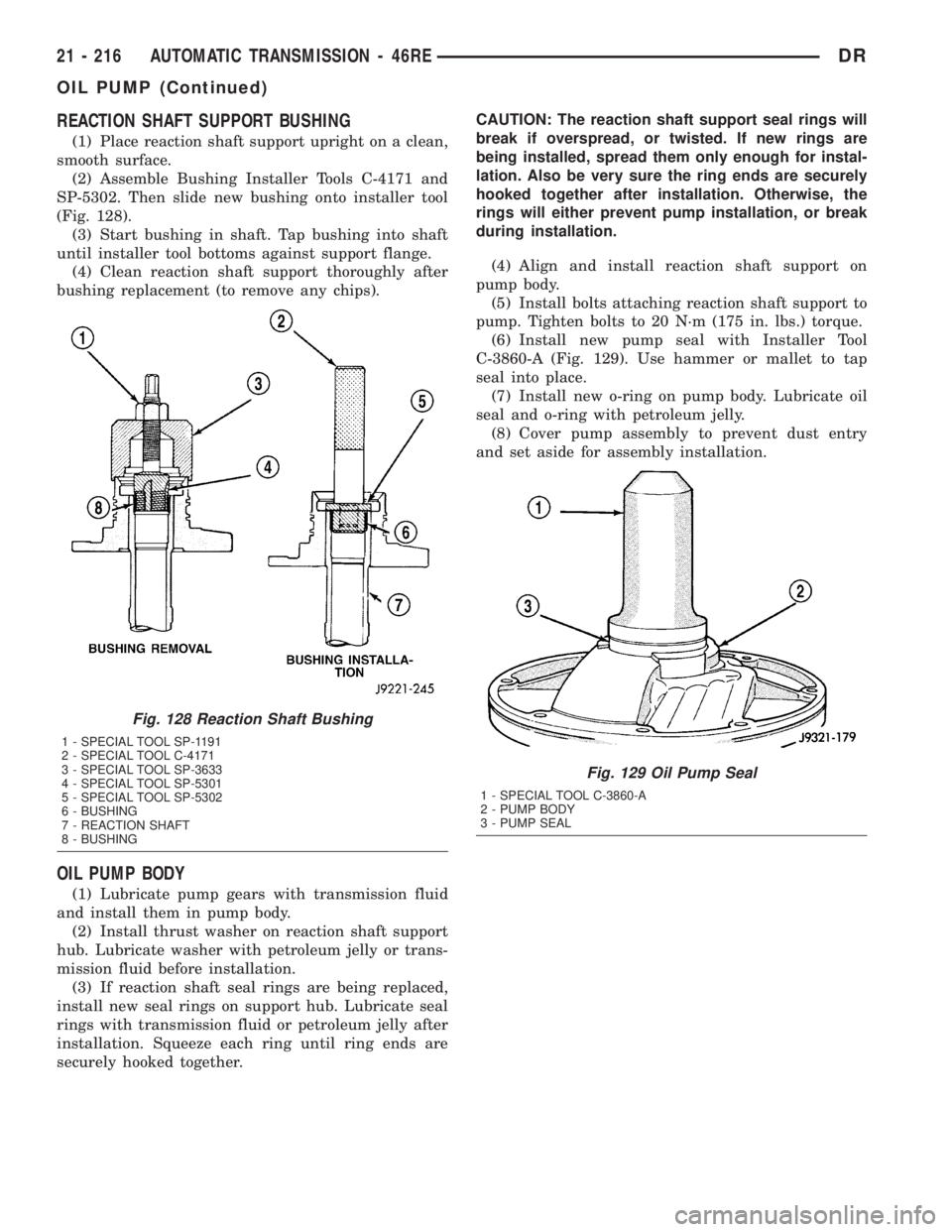

REACTION SHAFT SUPPORT BUSHING

(1) Place reaction shaft support upright on a clean,

smooth surface.

(2) Assemble Bushing Installer Tools C-4171 and

SP-5302. Then slide new bushing onto installer tool

(Fig. 128).

(3) Start bushing in shaft. Tap bushing into shaft

until installer tool bottoms against support flange.

(4) Clean reaction shaft support thoroughly after

bushing replacement (to remove any chips).

OIL PUMP BODY

(1) Lubricate pump gears with transmission fluid

and install them in pump body.

(2) Install thrust washer on reaction shaft support

hub. Lubricate washer with petroleum jelly or trans-

mission fluid before installation.

(3) If reaction shaft seal rings are being replaced,

install new seal rings on support hub. Lubricate seal

rings with transmission fluid or petroleum jelly after

installation. Squeeze each ring until ring ends are

securely hooked together.CAUTION: The reaction shaft support seal rings will

break if overspread, or twisted. If new rings are

being installed, spread them only enough for instal-

lation. Also be very sure the ring ends are securely

hooked together after installation. Otherwise, the

rings will either prevent pump installation, or break

during installation.

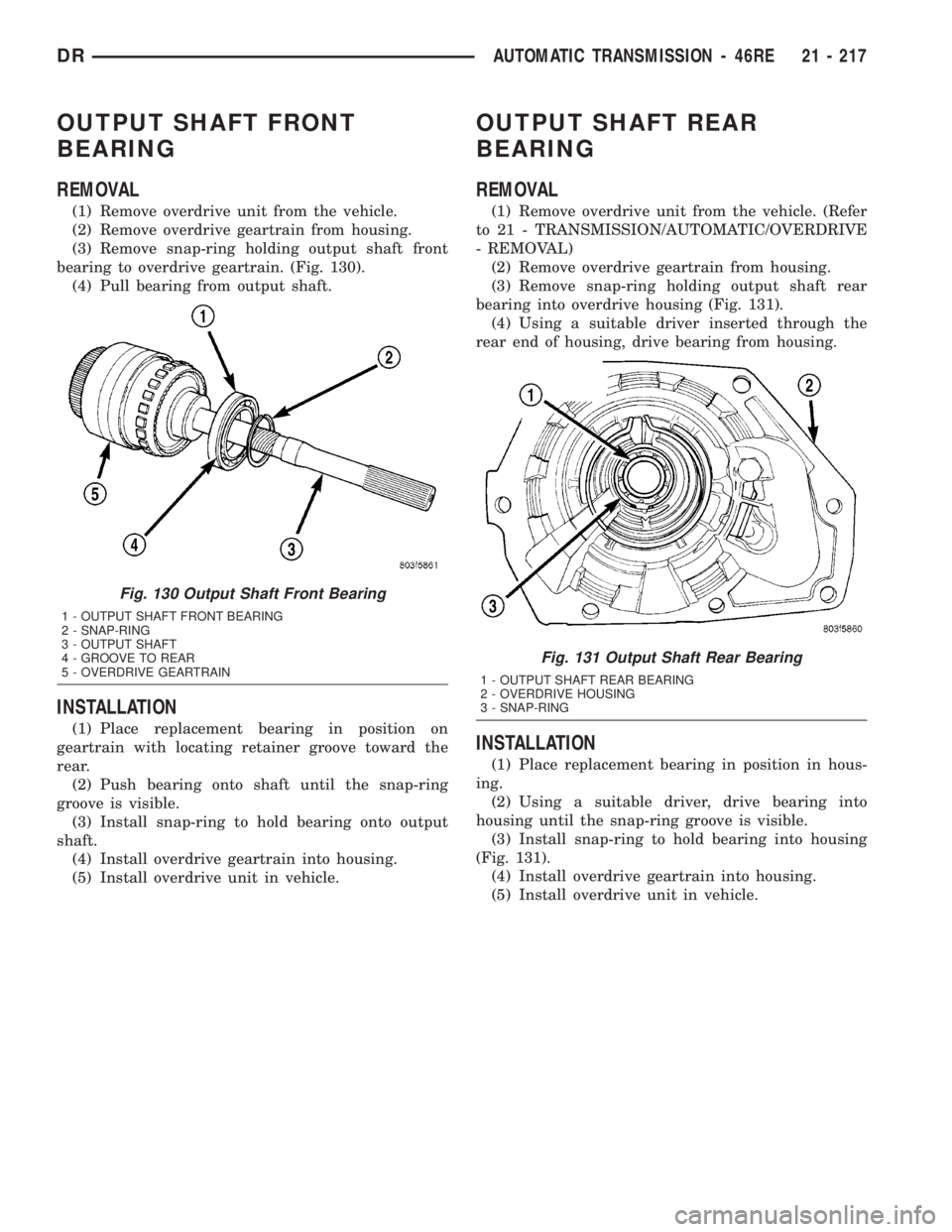

(4) Align and install reaction shaft support on

pump body.

(5) Install bolts attaching reaction shaft support to

pump. Tighten bolts to 20 N´m (175 in. lbs.) torque.

(6) Install new pump seal with Installer Tool

C-3860-A (Fig. 129). Use hammer or mallet to tap

seal into place.

(7) Install new o-ring on pump body. Lubricate oil

seal and o-ring with petroleum jelly.

(8) Cover pump assembly to prevent dust entry

and set aside for assembly installation.

Fig. 128 Reaction Shaft Bushing

1 - SPECIAL TOOL SP-1191

2 - SPECIAL TOOL C-4171

3 - SPECIAL TOOL SP-3633

4 - SPECIAL TOOL SP-5301

5 - SPECIAL TOOL SP-5302

6 - BUSHING

7 - REACTION SHAFT

8 - BUSHING

Fig. 129 Oil Pump Seal

1 - SPECIAL TOOL C-3860-A

2 - PUMP BODY

3 - PUMP SEAL

21 - 216 AUTOMATIC TRANSMISSION - 46REDR

OIL PUMP (Continued)

Page 2056 of 2895

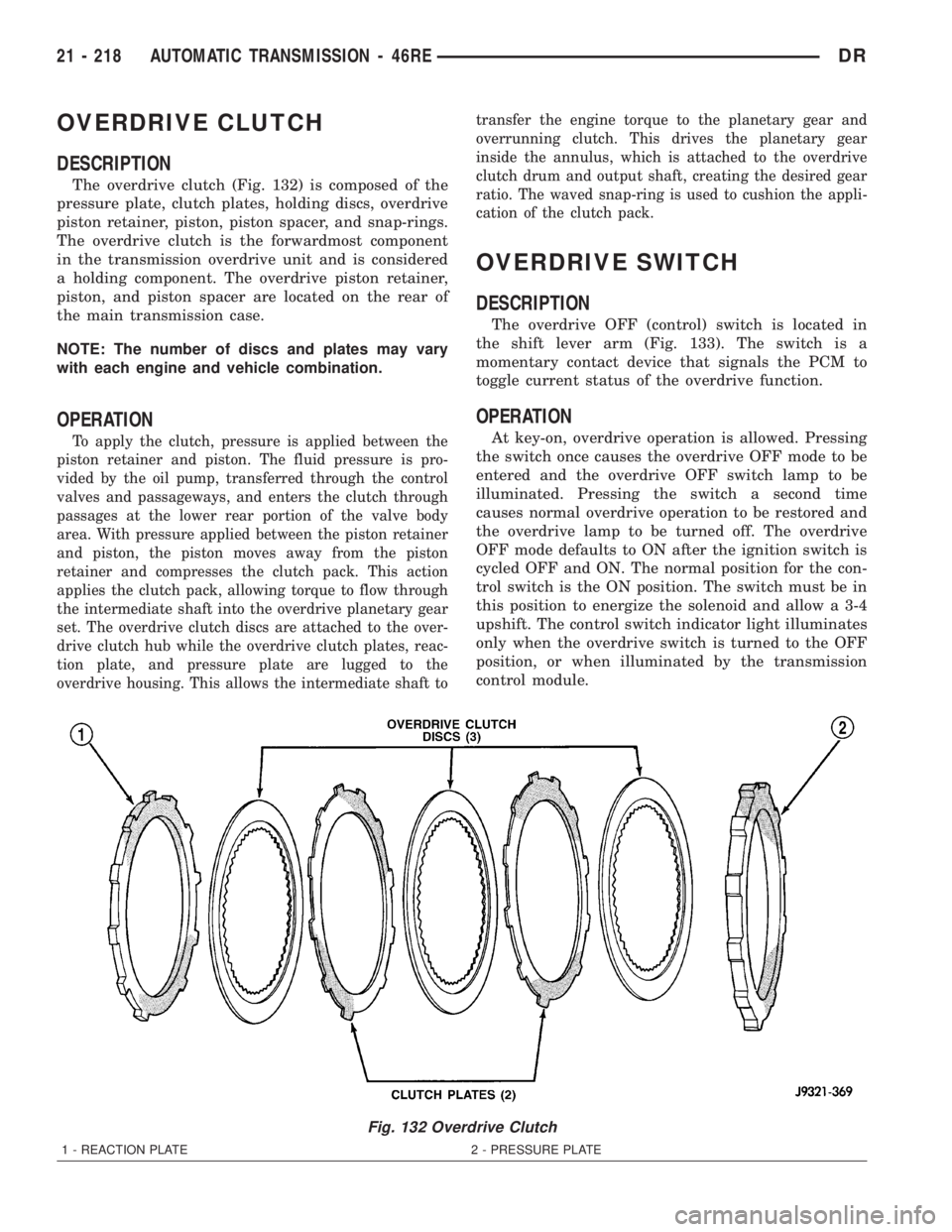

OUTPUT SHAFT FRONT

BEARING

REMOVAL

(1) Remove overdrive unit from the vehicle.

(2) Remove overdrive geartrain from housing.

(3) Remove snap-ring holding output shaft front

bearing to overdrive geartrain. (Fig. 130).

(4) Pull bearing from output shaft.

INSTALLATION

(1) Place replacement bearing in position on

geartrain with locating retainer groove toward the

rear.

(2) Push bearing onto shaft until the snap-ring

groove is visible.

(3) Install snap-ring to hold bearing onto output

shaft.

(4) Install overdrive geartrain into housing.

(5) Install overdrive unit in vehicle.

OUTPUT SHAFT REAR

BEARING

REMOVAL

(1) Remove overdrive unit from the vehicle. (Refer

to 21 - TRANSMISSION/AUTOMATIC/OVERDRIVE

- REMOVAL)

(2) Remove overdrive geartrain from housing.

(3) Remove snap-ring holding output shaft rear

bearing into overdrive housing (Fig. 131).

(4) Using a suitable driver inserted through the

rear end of housing, drive bearing from housing.

INSTALLATION

(1) Place replacement bearing in position in hous-

ing.

(2) Using a suitable driver, drive bearing into

housing until the snap-ring groove is visible.

(3) Install snap-ring to hold bearing into housing

(Fig. 131).

(4) Install overdrive geartrain into housing.

(5) Install overdrive unit in vehicle.

Fig. 130 Output Shaft Front Bearing

1 - OUTPUT SHAFT FRONT BEARING

2 - SNAP-RING

3 - OUTPUT SHAFT

4 - GROOVE TO REAR

5 - OVERDRIVE GEARTRAIN

Fig. 131 Output Shaft Rear Bearing

1 - OUTPUT SHAFT REAR BEARING

2 - OVERDRIVE HOUSING

3 - SNAP-RING

DRAUTOMATIC TRANSMISSION - 46RE 21 - 217

Page 2057 of 2895

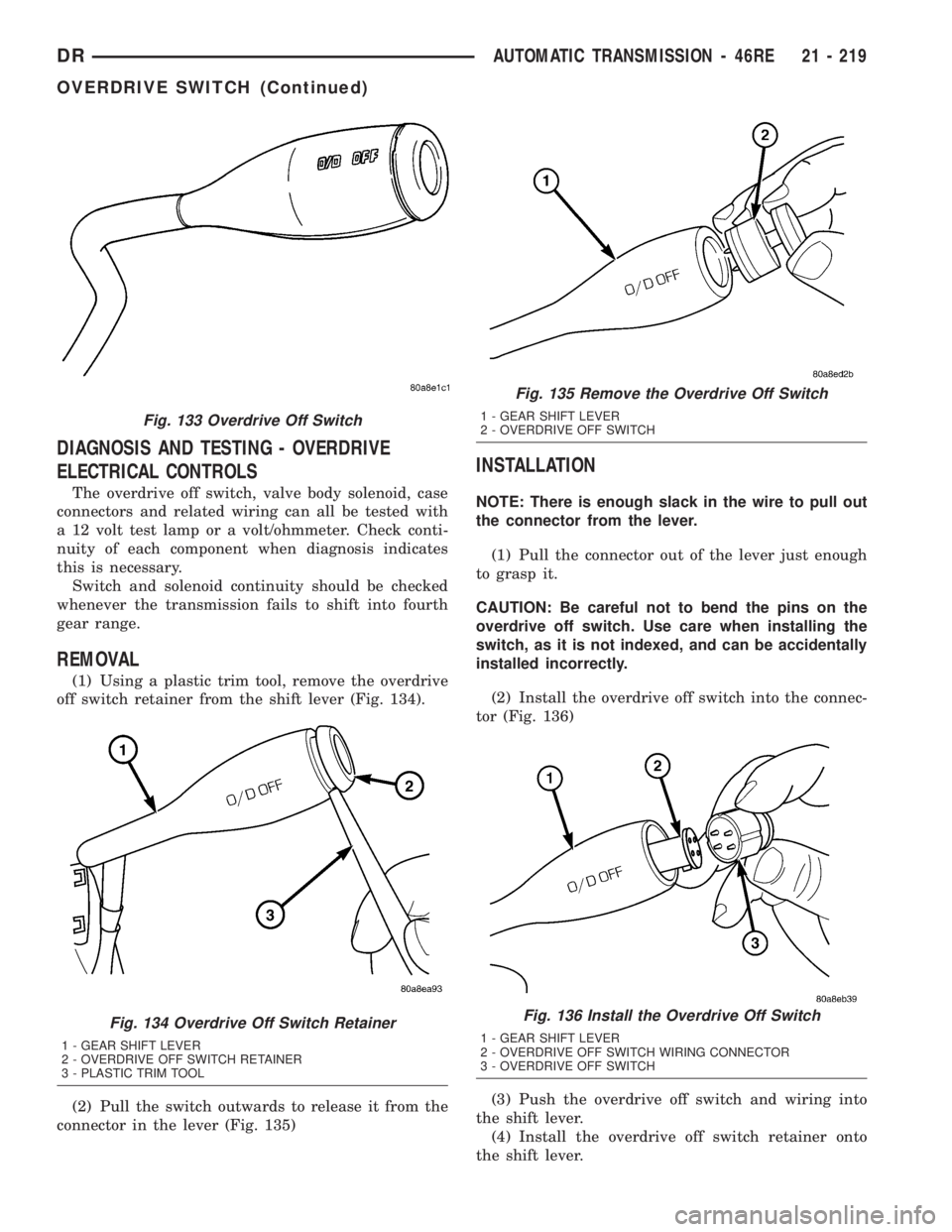

OVERDRIVE CLUTCH

DESCRIPTION

The overdrive clutch (Fig. 132) is composed of the

pressure plate, clutch plates, holding discs, overdrive

piston retainer, piston, piston spacer, and snap-rings.

The overdrive clutch is the forwardmost component

in the transmission overdrive unit and is considered

a holding component. The overdrive piston retainer,

piston, and piston spacer are located on the rear of

the main transmission case.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between the

piston retainer and piston. The fluid pressure is pro-

vided by the oil pump, transferred through the control

valves and passageways, and enters the clutch through

passages at the lower rear portion of the valve body

area. With pressure applied between the piston retainer

and piston, the piston moves away from the piston

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow through

the intermediate shaft into the overdrive planetary gear

set. The overdrive clutch discs are attached to the over-

drive clutch hub while the overdrive clutch plates, reac-

tion plate, and pressure plate are lugged to the

overdrive housing. This allows the intermediate shaft totransfer the engine torque to the planetary gear and

overrunning clutch. This drives the planetary gear

inside the annulus, which is attached to the overdrive

clutch drum and output shaft, creating the desired gear

ratio. The waved snap-ring is used to cushion the appli-

cation of the clutch pack.

OVERDRIVE SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shift lever arm (Fig. 133). The switch is a

momentary contact device that signals the PCM to

toggle current status of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing

the switch once causes the overdrive OFF mode to be

entered and the overdrive OFF switch lamp to be

illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow a 3-4

upshift. The control switch indicator light illuminates

only when the overdrive switch is turned to the OFF

position, or when illuminated by the transmission

control module.

Fig. 132 Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

21 - 218 AUTOMATIC TRANSMISSION - 46REDR

Page 2058 of 2895

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS

The overdrive off switch, valve body solenoid, case

connectors and related wiring can all be tested with

a 12 volt test lamp or a volt/ohmmeter. Check conti-

nuity of each component when diagnosis indicates

this is necessary.

Switch and solenoid continuity should be checked

whenever the transmission fails to shift into fourth

gear range.

REMOVAL

(1) Using a plastic trim tool, remove the overdrive

off switch retainer from the shift lever (Fig. 134).

(2) Pull the switch outwards to release it from the

connector in the lever (Fig. 135)

INSTALLATION

NOTE: There is enough slack in the wire to pull out

the connector from the lever.

(1) Pull the connector out of the lever just enough

to grasp it.

CAUTION: Be careful not to bend the pins on the

overdrive off switch. Use care when installing the

switch, as it is not indexed, and can be accidentally

installed incorrectly.

(2) Install the overdrive off switch into the connec-

tor (Fig. 136)

(3) Push the overdrive off switch and wiring into

the shift lever.

(4) Install the overdrive off switch retainer onto

the shift lever.

Fig. 133 Overdrive Off Switch

Fig. 134 Overdrive Off Switch Retainer

1 - GEAR SHIFT LEVER

2 - OVERDRIVE OFF SWITCH RETAINER

3 - PLASTIC TRIM TOOL

Fig. 135 Remove the Overdrive Off Switch

1 - GEAR SHIFT LEVER

2 - OVERDRIVE OFF SWITCH

Fig. 136 Install the Overdrive Off Switch

1 - GEAR SHIFT LEVER

2 - OVERDRIVE OFF SWITCH WIRING CONNECTOR

3 - OVERDRIVE OFF SWITCH

DRAUTOMATIC TRANSMISSION - 46RE 21 - 219

OVERDRIVE SWITCH (Continued)

Page 2059 of 2895

OVERDRIVE UNIT

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Remove transfer case, if equipped.

(4) Mark propeller shaft universal joint(s) and axle

pinion yoke, or the companion flange and flange

yoke, for alignment reference at installation, if neces-

sary.

(5) Disconnect and remove the rear propeller shaft,

if necessary. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(6) Remove transmission oil pan, remove gasket,

drain oil and reinstall pan.

(7) If overdrive unit had malfunctioned, or if fluid

is contaminated, remove entire transmission. If diag-

nosis indicated overdrive problems only, remove just

the overdrive unit.

(8) Support transmission with transmission jack.

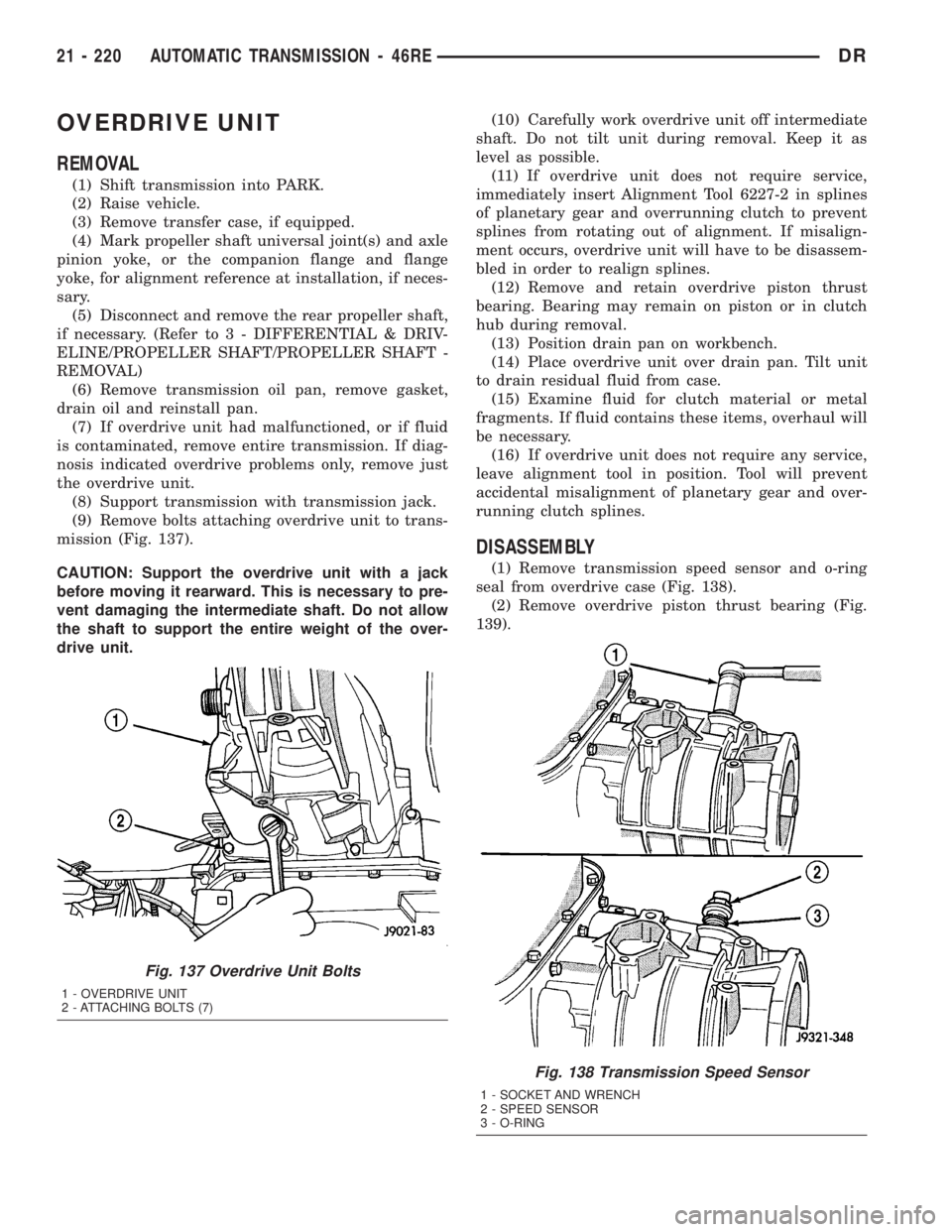

(9) Remove bolts attaching overdrive unit to trans-

mission (Fig. 137).

CAUTION: Support the overdrive unit with a jack

before moving it rearward. This is necessary to pre-

vent damaging the intermediate shaft. Do not allow

the shaft to support the entire weight of the over-

drive unit.(10) Carefully work overdrive unit off intermediate

shaft. Do not tilt unit during removal. Keep it as

level as possible.

(11) If overdrive unit does not require service,

immediately insert Alignment Tool 6227-2 in splines

of planetary gear and overrunning clutch to prevent

splines from rotating out of alignment. If misalign-

ment occurs, overdrive unit will have to be disassem-

bled in order to realign splines.

(12) Remove and retain overdrive piston thrust

bearing. Bearing may remain on piston or in clutch

hub during removal.

(13) Position drain pan on workbench.

(14) Place overdrive unit over drain pan. Tilt unit

to drain residual fluid from case.

(15) Examine fluid for clutch material or metal

fragments. If fluid contains these items, overhaul will

be necessary.

(16) If overdrive unit does not require any service,

leave alignment tool in position. Tool will prevent

accidental misalignment of planetary gear and over-

running clutch splines.

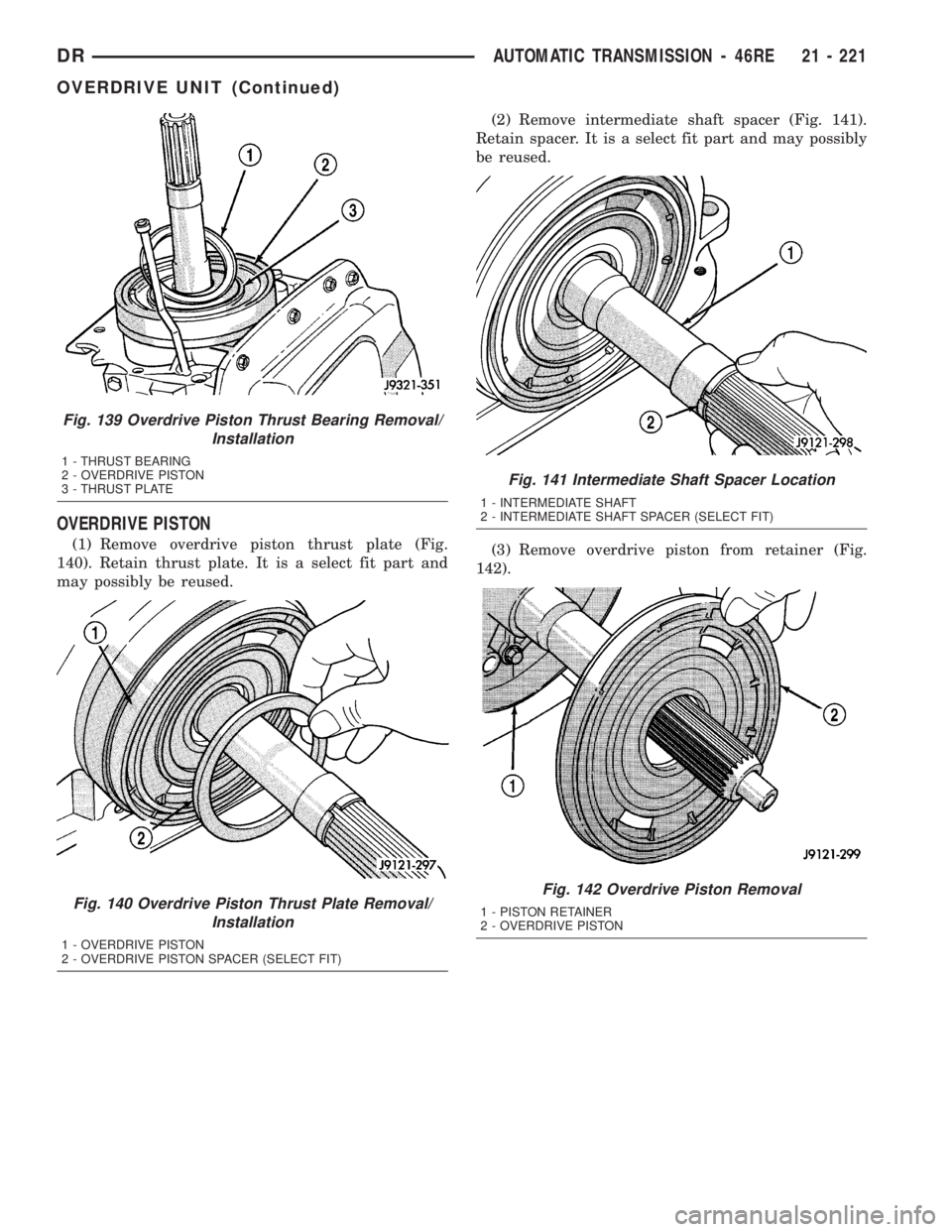

DISASSEMBLY

(1) Remove transmission speed sensor and o-ring

seal from overdrive case (Fig. 138).

(2) Remove overdrive piston thrust bearing (Fig.

139).

Fig. 137 Overdrive Unit Bolts

1 - OVERDRIVE UNIT

2 - ATTACHING BOLTS (7)

Fig. 138 Transmission Speed Sensor

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

21 - 220 AUTOMATIC TRANSMISSION - 46REDR

Page 2060 of 2895

OVERDRIVE PISTON

(1) Remove overdrive piston thrust plate (Fig.

140). Retain thrust plate. It is a select fit part and

may possibly be reused.(2) Remove intermediate shaft spacer (Fig. 141).

Retain spacer. It is a select fit part and may possibly

be reused.

(3) Remove overdrive piston from retainer (Fig.

142).

Fig. 139 Overdrive Piston Thrust Bearing Removal/

Installation

1 - THRUST BEARING

2 - OVERDRIVE PISTON

3 - THRUST PLATE

Fig. 140 Overdrive Piston Thrust Plate Removal/

Installation

1 - OVERDRIVE PISTON

2 - OVERDRIVE PISTON SPACER (SELECT FIT)

Fig. 141 Intermediate Shaft Spacer Location

1 - INTERMEDIATE SHAFT

2 - INTERMEDIATE SHAFT SPACER (SELECT FIT)

Fig. 142 Overdrive Piston Removal

1 - PISTON RETAINER

2 - OVERDRIVE PISTON

DRAUTOMATIC TRANSMISSION - 46RE 21 - 221

OVERDRIVE UNIT (Continued)