sensor DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1741 of 2895

Downstream Sensor - Federal Emissions

Package :The downstream oxygen sensor (1/2) is

also used to determine the correct air-fuel ratio. As

the oxygen content changes at the downstream sen-

sor, the PCM calculates how much air-fuel ratio

change is required. The PCM then looks at the

upstream oxygen sensor voltage and changes fuel

delivery until the upstream sensor voltage changes

enough to correct the downstream sensor voltage

(oxygen content).

The downstream oxygen sensor also provides an

input to determine catalytic convertor efficiency.

Upstream Sensors - California Emissions

Package :Two upstream sensors are used (1/1 and

2/1). The 1/1 sensor is the first sensor to receive

exhaust gases from the #1 cylinder. They provide an

input voltage to the PCM. The input tells the PCM

the oxygen content of the exhaust gas. The PCM uses

this information to fine tune fuel delivery to main-

tain the correct oxygen content at the downstream

oxygen sensors. The PCM will change the air/fuel

ratio until the upstream sensors input a voltage that

the PCM has determined will make the downstream

sensors output (oxygen content) correct.

The upstream oxygen sensors also provide an input

to determine mini-catalyst efficiency. Main catalytic

convertor efficiency is not calculated with this pack-

age.

Downstream Sensors - California Emissions

Package :Two downstream sensors are used (1/2

and 2/2). The downstream sensors are used to deter-

mine the correct air-fuel ratio. As the oxygen content

changes at the downstream sensor, the PCM calcu-

lates how much air-fuel ratio change is required. The

PCM then looks at the upstream oxygen sensor volt-

age, and changes fuel delivery until the upstream

sensor voltage changes enough to correct the down-

stream sensor voltage (oxygen content).

The downstream oxygen sensors also provide an

input to determine mini-catalyst efficiency. Main cat-

alytic convertor efficiency is not calculated with this

package.

Engines equipped with either a downstream sen-

sor(s), or a post-catalytic sensor, will monitor cata-

lytic convertor efficiency. If efficiency is below

emission standards, the Malfunction Indicator Lamp

(MIL) will be illuminated and a Diagnostic Trouble

Code (DTC) will be set. Refer to Monitored Systems

in Emission Control Systems for additional informa-

tion.

REMOVAL

CAUTION: Never apply any type of grease to the

oxygen sensor electrical connector, or attempt any

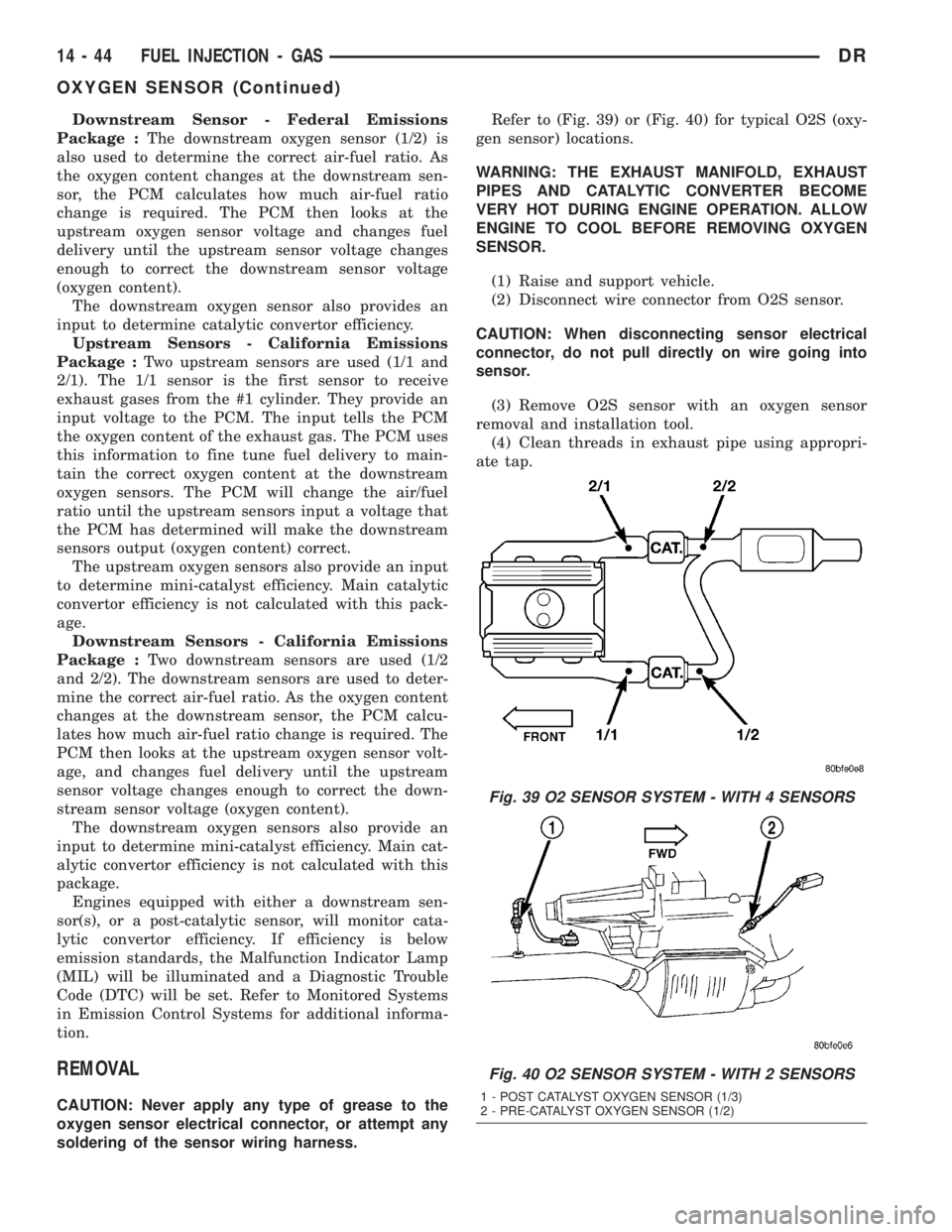

soldering of the sensor wiring harness.Refer to (Fig. 39) or (Fig. 40) for typical O2S (oxy-

gen sensor) locations.

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

(1) Raise and support vehicle.

(2) Disconnect wire connector from O2S sensor.

CAUTION: When disconnecting sensor electrical

connector, do not pull directly on wire going into

sensor.

(3) Remove O2S sensor with an oxygen sensor

removal and installation tool.

(4) Clean threads in exhaust pipe using appropri-

ate tap.

Fig. 39 O2 SENSOR SYSTEM - WITH 4 SENSORS

Fig. 40 O2 SENSOR SYSTEM - WITH 2 SENSORS

1 - POST CATALYST OXYGEN SENSOR (1/3)

2 - PRE-CATALYST OXYGEN SENSOR (1/2)

14 - 44 FUEL INJECTION - GASDR

OXYGEN SENSOR (Continued)

Page 1742 of 2895

INSTALLATION

Threads of new oxygen sensors are factory coated

with anti-seize compound to aid in removal.DO

NOT add any additional anti-seize compound to

threads of a new oxygen sensor.

(1) Install O2S sensor. Tighten to 30 N´m (22 ft.

lbs.) torque.

(2) Connect O2S sensor wire connector.

(3) Lower vehicle.

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold.

Fuel does not enter the intake manifold through the

throttle body. Fuel is sprayed into the manifold by

the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle body

contains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

5.7L V-8 Engine:

The throttle body on the 5.7L engine is an electri-

cally controlled unit. A mechanical cable is not used

to connect the throttle body to the accelerator pedal.

The Accelerator Pedal Position Sensor (APPS) along

with inputs from other sensors sets the throttle blade

to pre-determined positions.

Except 5.7L V-8 Engine:

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable and

transmission control cable (when equipped) are con-

nected to the throttle body linkage arm.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

3.7L V-6

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Remove air cleaner tube at throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS.(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section for removal/installation procedures.

(4) Disconnect necessary vacuum lines at throttle

body.

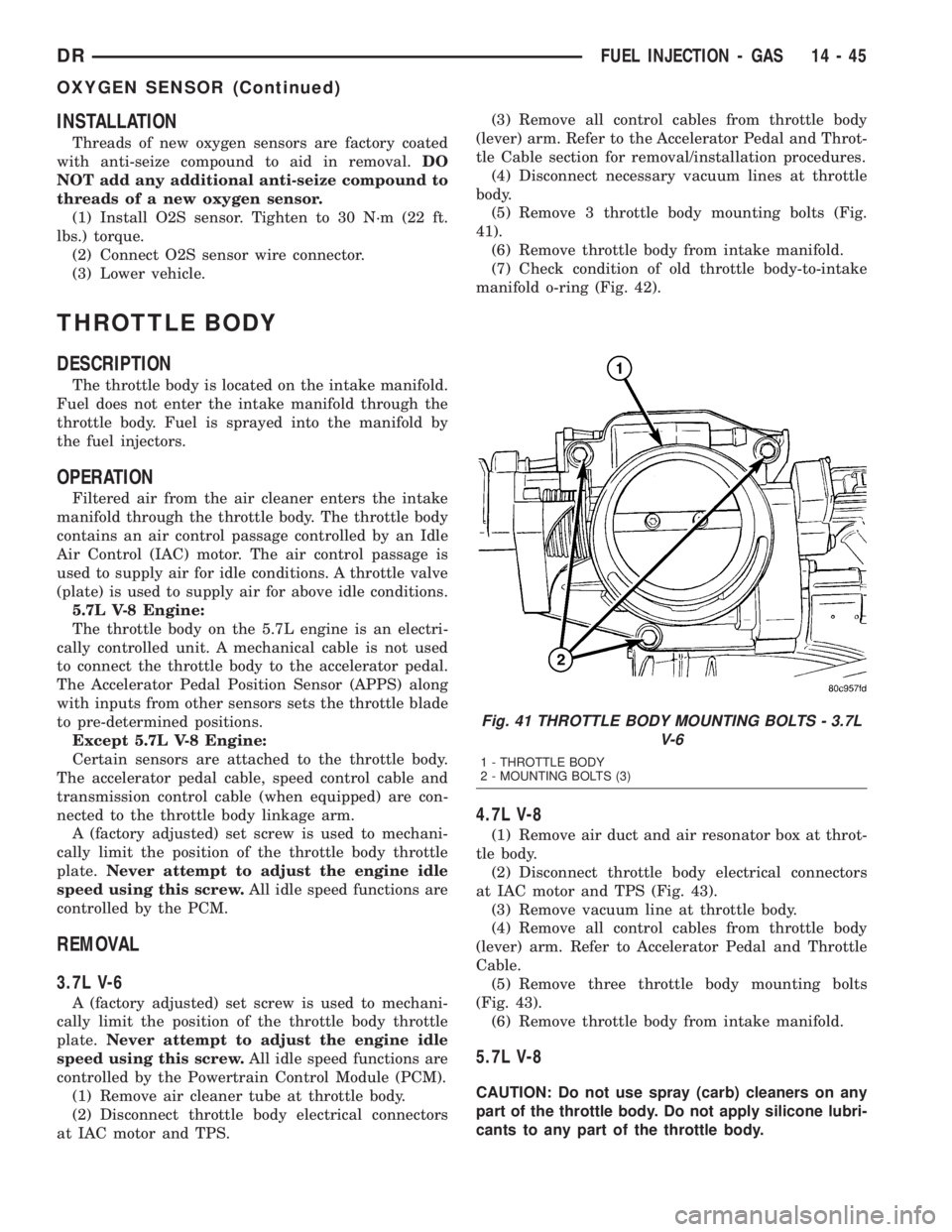

(5) Remove 3 throttle body mounting bolts (Fig.

41).

(6) Remove throttle body from intake manifold.

(7) Check condition of old throttle body-to-intake

manifold o-ring (Fig. 42).

4.7L V-8

(1) Remove air duct and air resonator box at throt-

tle body.

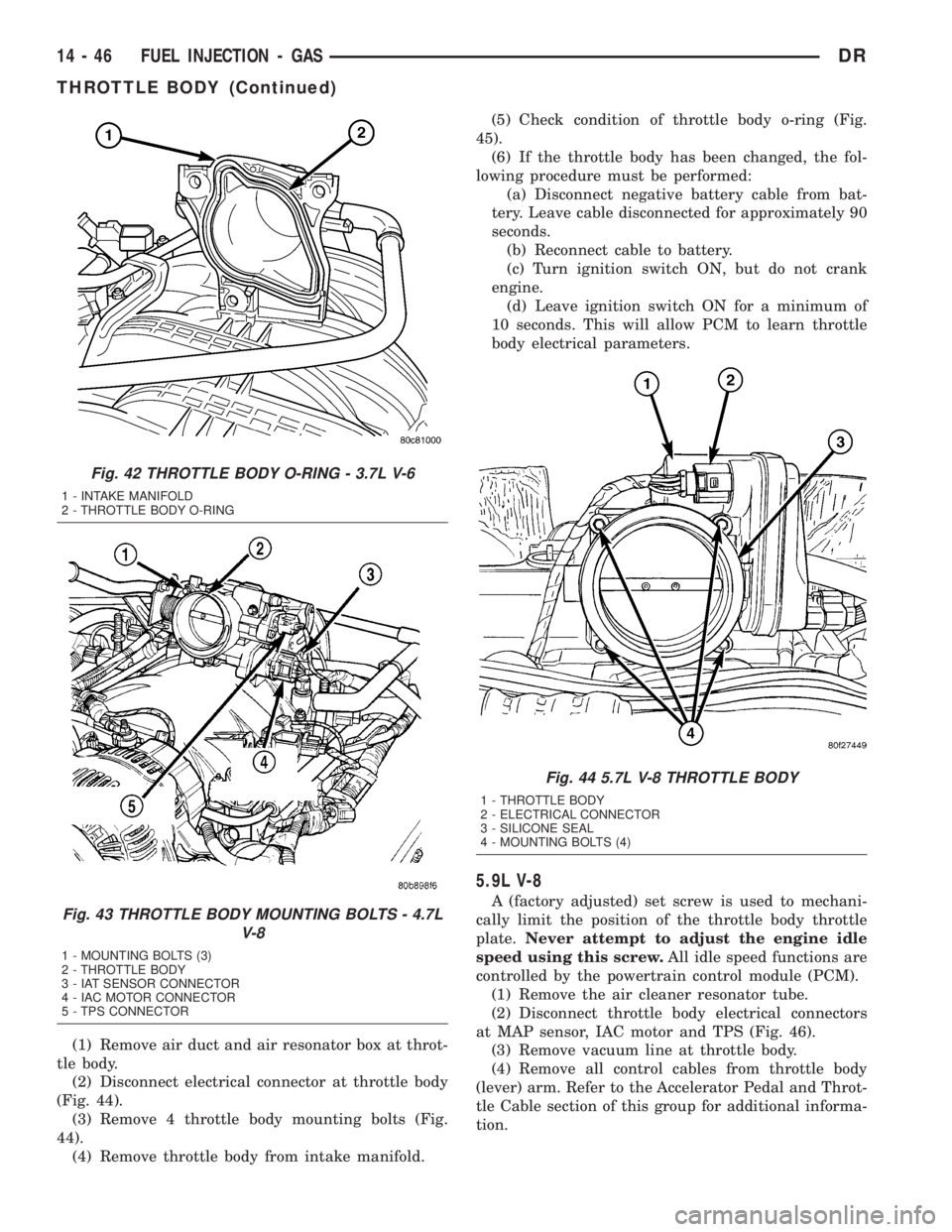

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS (Fig. 43).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(5) Remove three throttle body mounting bolts

(Fig. 43).

(6) Remove throttle body from intake manifold.

5.7L V-8

CAUTION: Do not use spray (carb) cleaners on any

part of the throttle body. Do not apply silicone lubri-

cants to any part of the throttle body.

Fig. 41 THROTTLE BODY MOUNTING BOLTS - 3.7L

V-6

1 - THROTTLE BODY

2 - MOUNTING BOLTS (3)

DRFUEL INJECTION - GAS 14 - 45

OXYGEN SENSOR (Continued)

Page 1743 of 2895

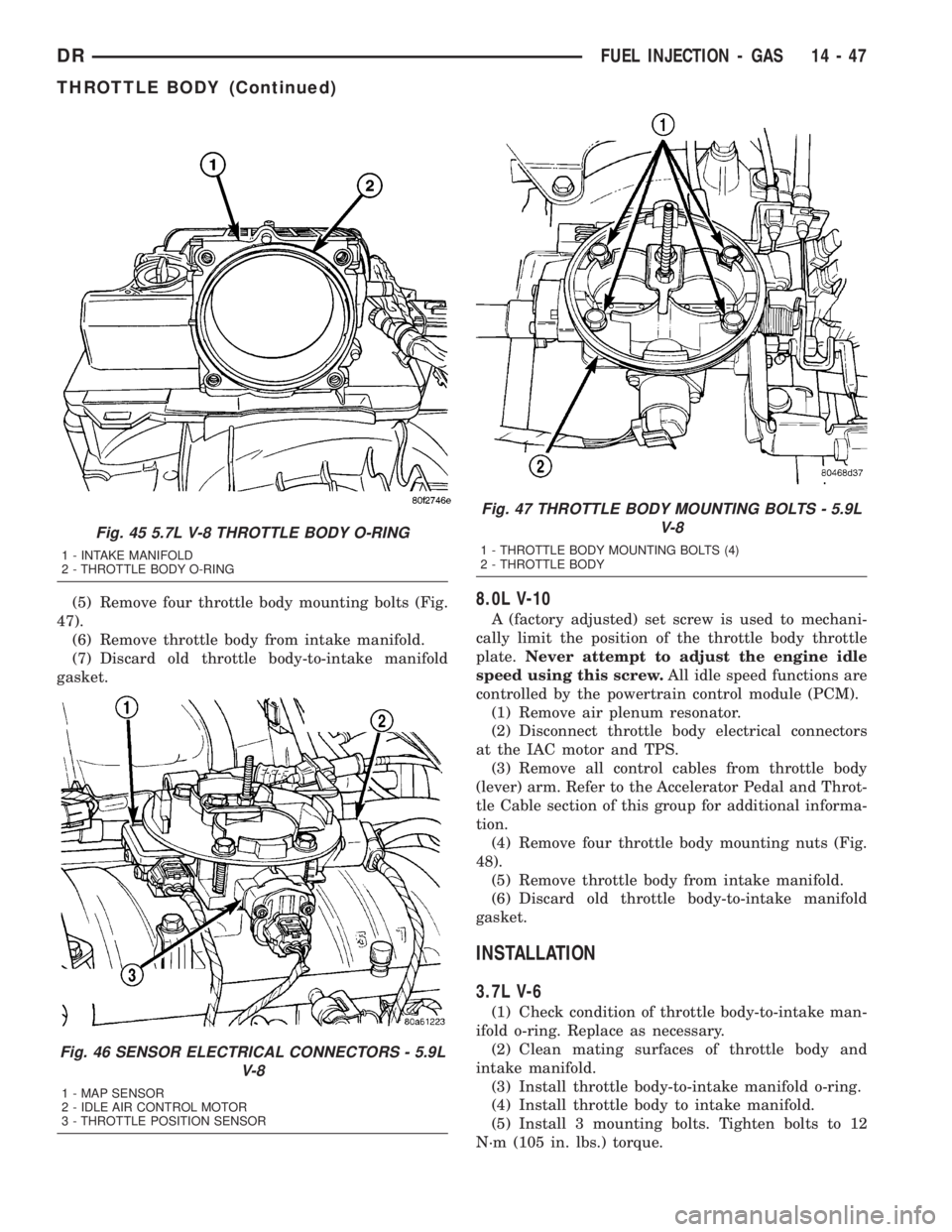

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect electrical connector at throttle body

(Fig. 44).

(3) Remove 4 throttle body mounting bolts (Fig.

44).

(4) Remove throttle body from intake manifold.(5) Check condition of throttle body o-ring (Fig.

45).

(6) If the throttle body has been changed, the fol-

lowing procedure must be performed:

(a) Disconnect negative battery cable from bat-

tery. Leave cable disconnected for approximately 90

seconds.

(b) Reconnect cable to battery.

(c) Turn ignition switch ON, but do not crank

engine.

(d) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn throttle

body electrical parameters.

5.9L V-8

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove the air cleaner resonator tube.

(2) Disconnect throttle body electrical connectors

at MAP sensor, IAC motor and TPS (Fig. 46).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section of this group for additional informa-

tion.

Fig. 42 THROTTLE BODY O-RING - 3.7L V-6

1 - INTAKE MANIFOLD

2 - THROTTLE BODY O-RING

Fig. 43 THROTTLE BODY MOUNTING BOLTS - 4.7L

V-8

1 - MOUNTING BOLTS (3)

2 - THROTTLE BODY

3 - IAT SENSOR CONNECTOR

4 - IAC MOTOR CONNECTOR

5 - TPS CONNECTOR

Fig. 44 5.7L V-8 THROTTLE BODY

1 - THROTTLE BODY

2 - ELECTRICAL CONNECTOR

3 - SILICONE SEAL

4 - MOUNTING BOLTS (4)

14 - 46 FUEL INJECTION - GASDR

THROTTLE BODY (Continued)

Page 1744 of 2895

(5) Remove four throttle body mounting bolts (Fig.

47).

(6) Remove throttle body from intake manifold.

(7) Discard old throttle body-to-intake manifold

gasket.8.0L V-10

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the powertrain control module (PCM).

(1) Remove air plenum resonator.

(2) Disconnect throttle body electrical connectors

at the IAC motor and TPS.

(3) Remove all control cables from throttle body

(lever) arm. Refer to the Accelerator Pedal and Throt-

tle Cable section of this group for additional informa-

tion.

(4) Remove four throttle body mounting nuts (Fig.

48).

(5) Remove throttle body from intake manifold.

(6) Discard old throttle body-to-intake manifold

gasket.

INSTALLATION

3.7L V-6

(1) Check condition of throttle body-to-intake man-

ifold o-ring. Replace as necessary.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body-to-intake manifold o-ring.

(4) Install throttle body to intake manifold.

(5) Install 3 mounting bolts. Tighten bolts to 12

N´m (105 in. lbs.) torque.

Fig. 45 5.7L V-8 THROTTLE BODY O-RING

1 - INTAKE MANIFOLD

2 - THROTTLE BODY O-RING

Fig. 46 SENSOR ELECTRICAL CONNECTORS - 5.9L

V-8

1 - MAP SENSOR

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

Fig. 47 THROTTLE BODY MOUNTING BOLTS - 5.9L

V-8

1 - THROTTLE BODY MOUNTING BOLTS (4)

2 - THROTTLE BODY

DRFUEL INJECTION - GAS 14 - 47

THROTTLE BODY (Continued)

Page 1747 of 2895

5.7L V-8

The Throttle Control Cable on the 5.7L V-8 engine

connects the accelerator pedal to the Accelerator

Pedal Position Sensor (APPS). A separate mechanical

cable is not routed to the throttle body.

CAUTION: Be careful not to damage or kink cable

core wire (within cable sheathing) while servicing

accelerator pedal, cables or APPS.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 1). The plas-

tic cable retainer snaps into pedal arm.

(2) Remove cable core wire at pedal arm.

(3) Remove APPS. Refer to Accelerator Pedal Posi-

tion Sensor (APPS) Removal / Installation.

(4) From inside vehicle, remove cable clip (Fig. 1).

(5) Remove cable housing from dash panel and

pull cable into engine compartment.

(6) Remove cable housing at APPS bracket by

pressing on release tab with a small screwdriver.To

prevent cable housing breakage, press on tab

only enough to release cable from APPS

bracket.

5.9L V-8

CAUTION: Be careful not to damage or kink cable

core wire (within cable sheathing) while servicing

accelerator pedal or cables.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 1). The plas-

tic cable retainer snaps into pedal arm.

(2) Remove cable core wire at pedal arm.

(3) Remove air resonator at throttle body.

(4) From inside vehicle, remove cable clip (Fig. 1).

(5) Remove cable housing from dash panel and

pull cable into engine compartment.

(6) Disconnect cable from routing/holddown clip.

(7) Slip cable end rearward from pin on throttle

body (Fig. 53).

(8) Remove cable housing at throttle body mount-

ing bracket by pressing on release tab with a small

screwdriver (Fig. 54).To prevent cable housing

breakage, press on tab only enough to release

cable from bracket.Lift cable housing straight up

from bracket while pressing on release tab. Remove

throttle cable from vehicle.

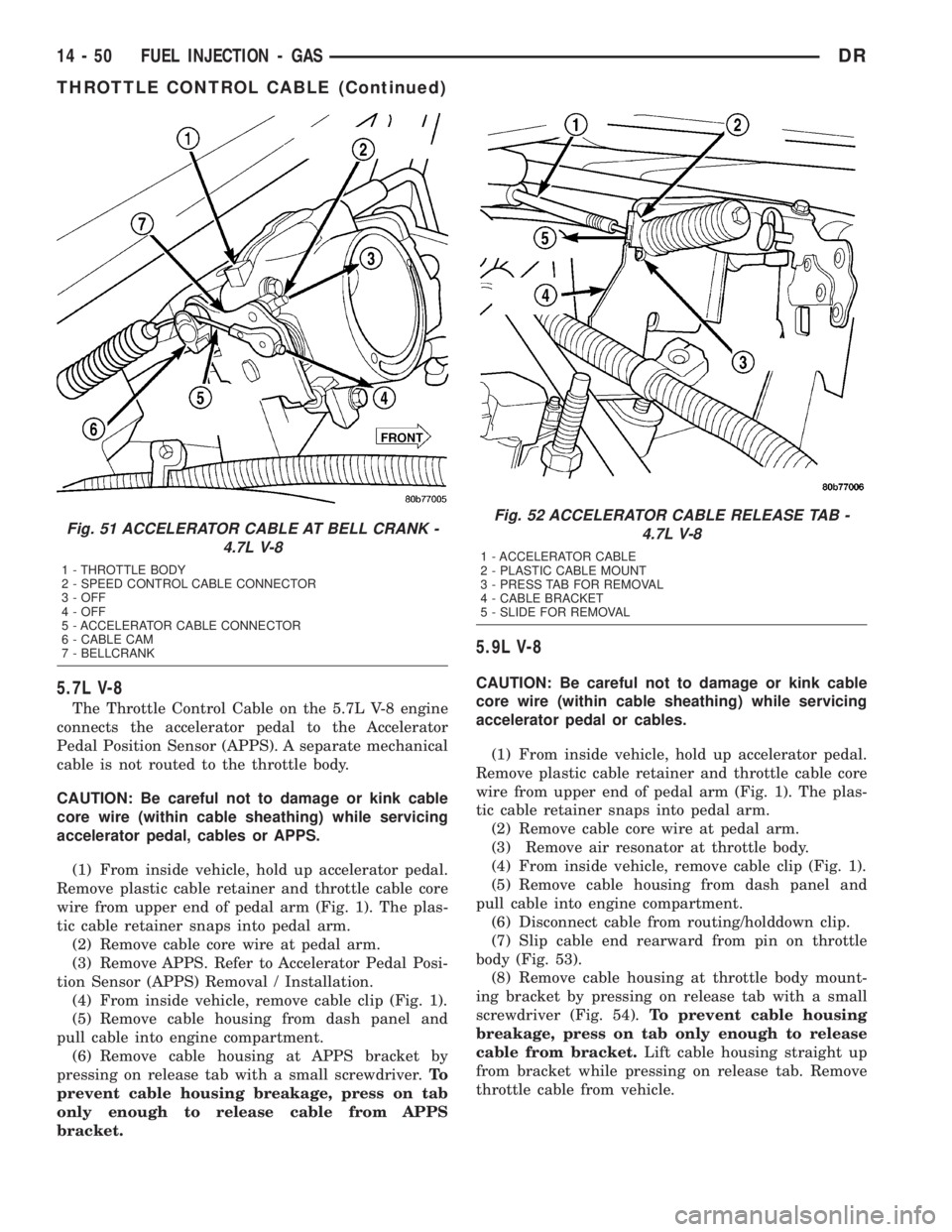

Fig. 51 ACCELERATOR CABLE AT BELL CRANK -

4.7L V-8

1 - THROTTLE BODY

2 - SPEED CONTROL CABLE CONNECTOR

3 - OFF

4 - OFF

5 - ACCELERATOR CABLE CONNECTOR

6 - CABLE CAM

7 - BELLCRANK

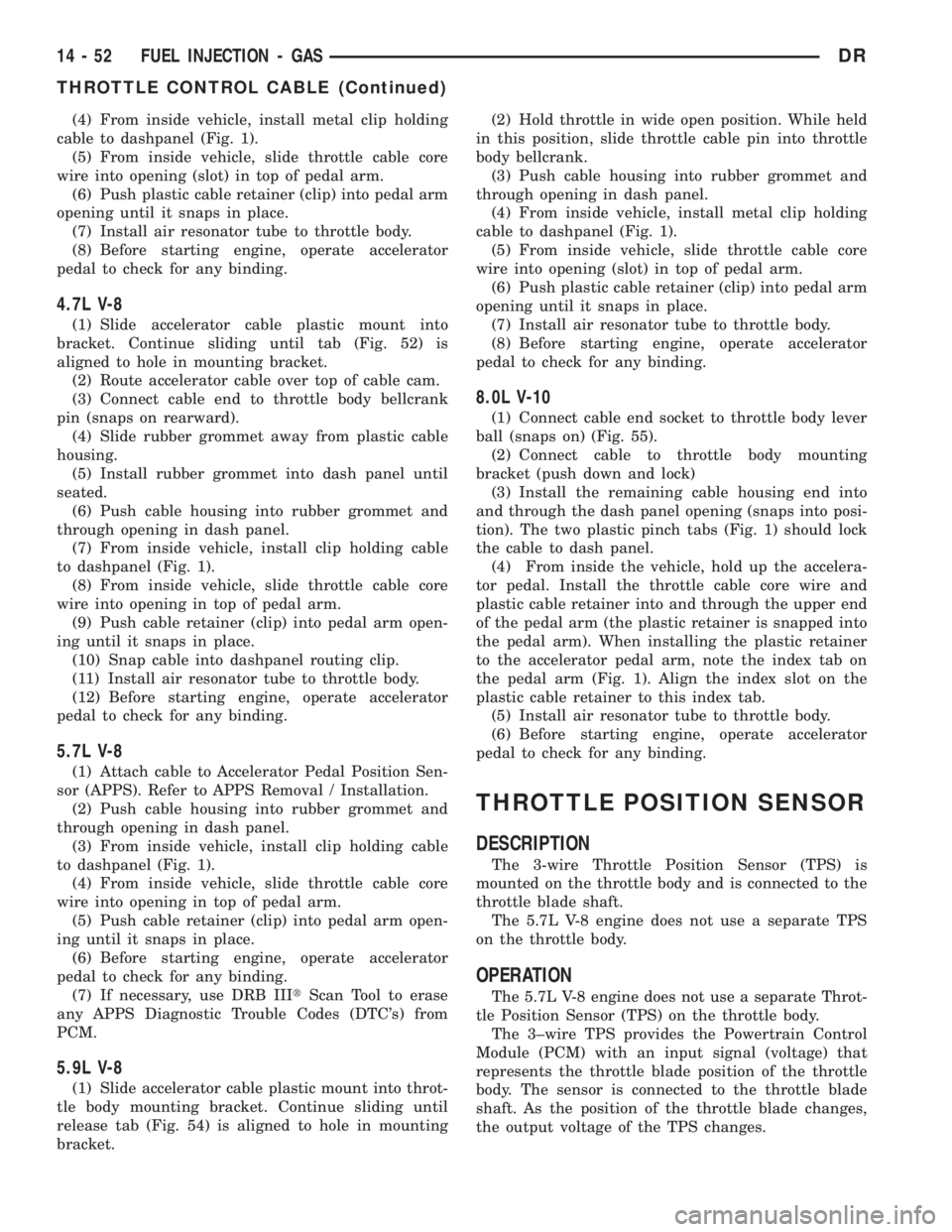

Fig. 52 ACCELERATOR CABLE RELEASE TAB -

4.7L V-8

1 - ACCELERATOR CABLE

2 - PLASTIC CABLE MOUNT

3 - PRESS TAB FOR REMOVAL

4 - CABLE BRACKET

5 - SLIDE FOR REMOVAL

14 - 50 FUEL INJECTION - GASDR

THROTTLE CONTROL CABLE (Continued)

Page 1749 of 2895

(4) From inside vehicle, install metal clip holding

cable to dashpanel (Fig. 1).

(5) From inside vehicle, slide throttle cable core

wire into opening (slot) in top of pedal arm.

(6) Push plastic cable retainer (clip) into pedal arm

opening until it snaps in place.

(7) Install air resonator tube to throttle body.

(8) Before starting engine, operate accelerator

pedal to check for any binding.

4.7L V-8

(1) Slide accelerator cable plastic mount into

bracket. Continue sliding until tab (Fig. 52) is

aligned to hole in mounting bracket.

(2) Route accelerator cable over top of cable cam.

(3) Connect cable end to throttle body bellcrank

pin (snaps on rearward).

(4) Slide rubber grommet away from plastic cable

housing.

(5) Install rubber grommet into dash panel until

seated.

(6) Push cable housing into rubber grommet and

through opening in dash panel.

(7) From inside vehicle, install clip holding cable

to dashpanel (Fig. 1).

(8) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(9) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(10) Snap cable into dashpanel routing clip.

(11) Install air resonator tube to throttle body.

(12) Before starting engine, operate accelerator

pedal to check for any binding.

5.7L V-8

(1) Attach cable to Accelerator Pedal Position Sen-

sor (APPS). Refer to APPS Removal / Installation.

(2) Push cable housing into rubber grommet and

through opening in dash panel.

(3) From inside vehicle, install clip holding cable

to dashpanel (Fig. 1).

(4) From inside vehicle, slide throttle cable core

wire into opening in top of pedal arm.

(5) Push cable retainer (clip) into pedal arm open-

ing until it snaps in place.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) If necessary, use DRB IIItScan Tool to erase

any APPS Diagnostic Trouble Codes (DTC's) from

PCM.

5.9L V-8

(1) Slide accelerator cable plastic mount into throt-

tle body mounting bracket. Continue sliding until

release tab (Fig. 54) is aligned to hole in mounting

bracket.(2) Hold throttle in wide open position. While held

in this position, slide throttle cable pin into throttle

body bellcrank.

(3) Push cable housing into rubber grommet and

through opening in dash panel.

(4) From inside vehicle, install metal clip holding

cable to dashpanel (Fig. 1).

(5) From inside vehicle, slide throttle cable core

wire into opening (slot) in top of pedal arm.

(6) Push plastic cable retainer (clip) into pedal arm

opening until it snaps in place.

(7) Install air resonator tube to throttle body.

(8) Before starting engine, operate accelerator

pedal to check for any binding.

8.0L V-10

(1) Connect cable end socket to throttle body lever

ball (snaps on) (Fig. 55).

(2) Connect cable to throttle body mounting

bracket (push down and lock)

(3) Install the remaining cable housing end into

and through the dash panel opening (snaps into posi-

tion). The two plastic pinch tabs (Fig. 1) should lock

the cable to dash panel.

(4) From inside the vehicle, hold up the accelera-

tor pedal. Install the throttle cable core wire and

plastic cable retainer into and through the upper end

of the pedal arm (the plastic retainer is snapped into

the pedal arm). When installing the plastic retainer

to the accelerator pedal arm, note the index tab on

the pedal arm (Fig. 1). Align the index slot on the

plastic cable retainer to this index tab.

(5) Install air resonator tube to throttle body.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

THROTTLE POSITION SENSOR

DESCRIPTION

The 3-wire Throttle Position Sensor (TPS) is

mounted on the throttle body and is connected to the

throttle blade shaft.

The 5.7L V-8 engine does not use a separate TPS

on the throttle body.

OPERATION

The 5.7L V-8 engine does not use a separate Throt-

tle Position Sensor (TPS) on the throttle body.

The 3±wire TPS provides the Powertrain Control

Module (PCM) with an input signal (voltage) that

represents the throttle blade position of the throttle

body. The sensor is connected to the throttle blade

shaft. As the position of the throttle blade changes,

the output voltage of the TPS changes.

14 - 52 FUEL INJECTION - GASDR

THROTTLE CONTROL CABLE (Continued)

Page 1750 of 2895

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from .26

volts at minimum throttle opening (idle), to 4.49 volts

at wide open throttle. Along with inputs from other

sensors, the PCM uses the TPS input to determine

current engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.

The PCM needs to identify the actions and position

of the throttle blade at all times. This information is

needed to assist in performing the following calcula-

tions:

²Ignition timing advance

²Fuel injection pulse-width

²Idle (learned value or minimum TPS)

²Off-idle (0.06 volt)

²Wide Open Throttle (WOT) open loop (2.608

volts above learned idle voltage)

²Deceleration fuel lean out

²Fuel cutoff during cranking at WOT (2.608 volts

above learned idle voltage)

²A/C WOT cutoff (certain automatic transmis-

sions only)

REMOVAL

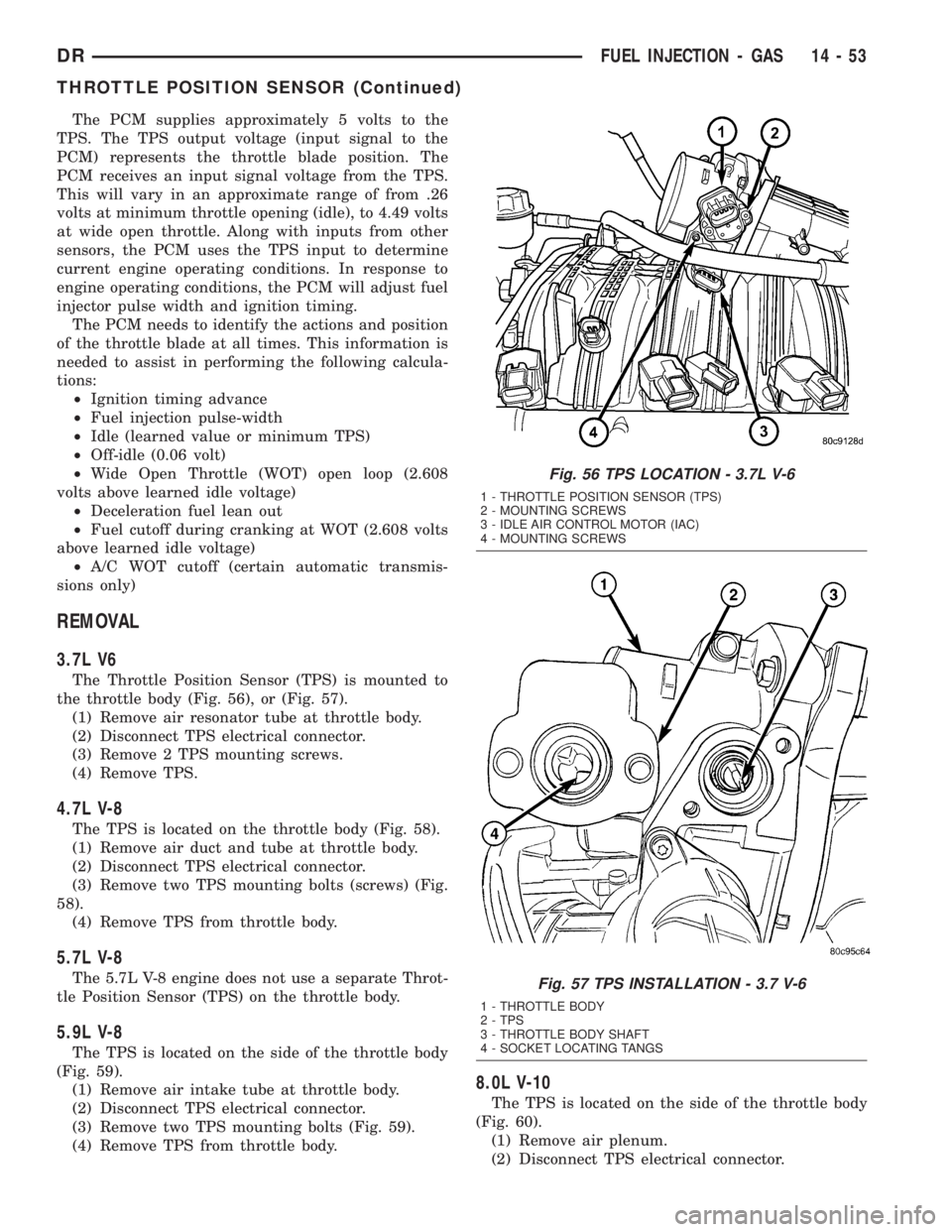

3.7L V6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 56), or (Fig. 57).

(1) Remove air resonator tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove 2 TPS mounting screws.

(4) Remove TPS.

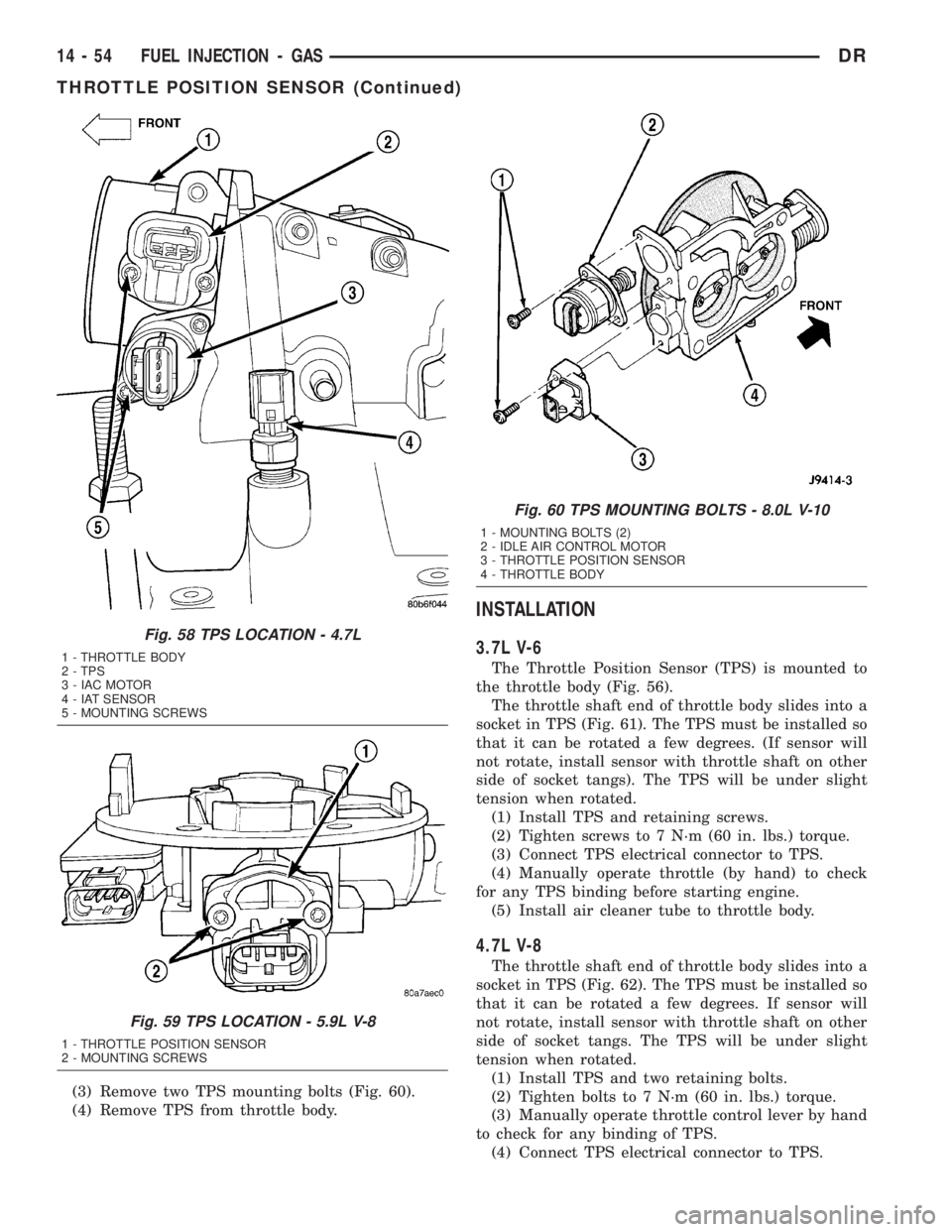

4.7L V-8

The TPS is located on the throttle body (Fig. 58).

(1) Remove air duct and tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove two TPS mounting bolts (screws) (Fig.

58).

(4) Remove TPS from throttle body.

5.7L V-8

The 5.7L V-8 engine does not use a separate Throt-

tle Position Sensor (TPS) on the throttle body.

5.9L V-8

The TPS is located on the side of the throttle body

(Fig. 59).

(1) Remove air intake tube at throttle body.

(2) Disconnect TPS electrical connector.

(3) Remove two TPS mounting bolts (Fig. 59).

(4) Remove TPS from throttle body.

8.0L V-10

The TPS is located on the side of the throttle body

(Fig. 60).

(1) Remove air plenum.

(2) Disconnect TPS electrical connector.

Fig. 56 TPS LOCATION - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

Fig. 57 TPS INSTALLATION - 3.7 V-6

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

DRFUEL INJECTION - GAS 14 - 53

THROTTLE POSITION SENSOR (Continued)

Page 1751 of 2895

(3) Remove two TPS mounting bolts (Fig. 60).

(4) Remove TPS from throttle body.

INSTALLATION

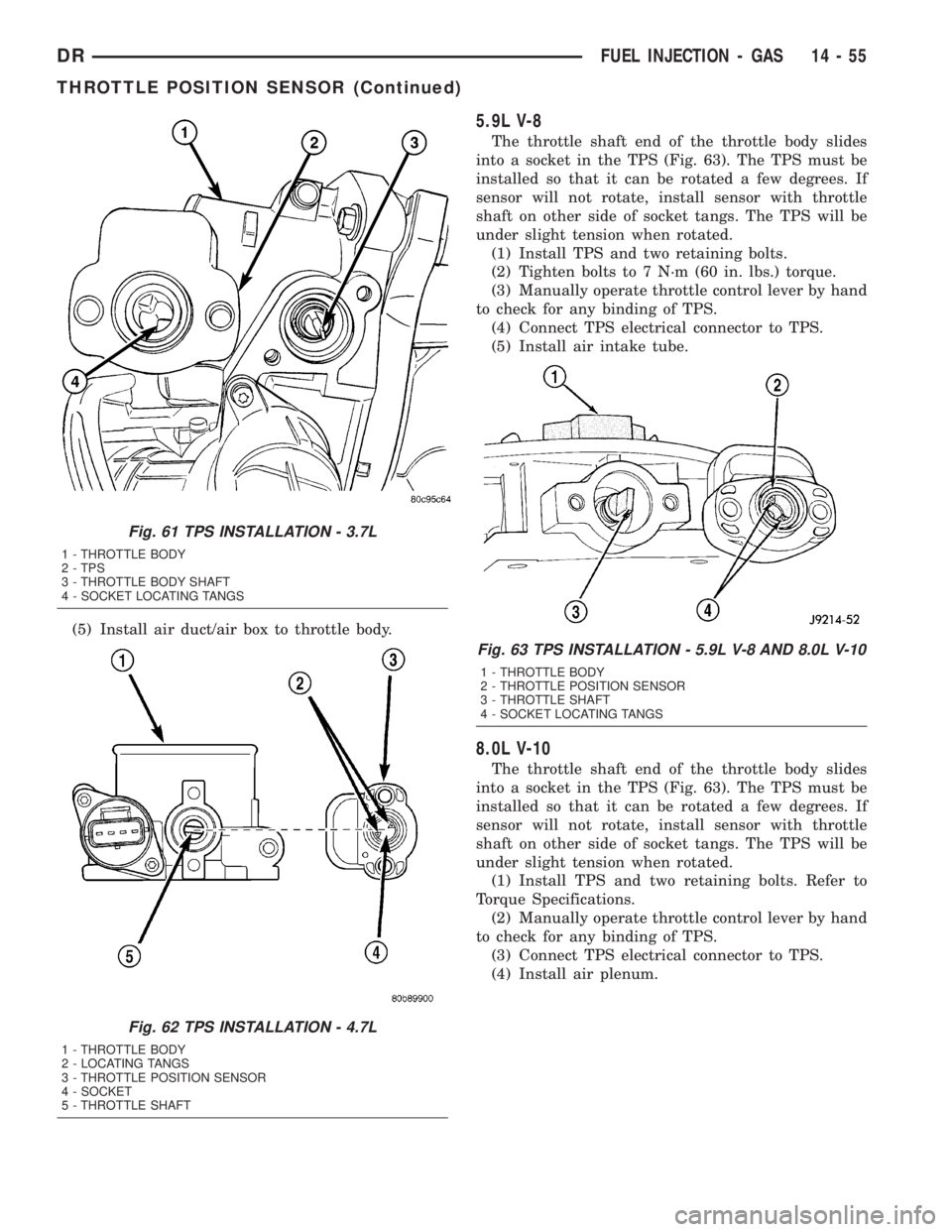

3.7L V-6

The Throttle Position Sensor (TPS) is mounted to

the throttle body (Fig. 56).

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 61). The TPS must be installed so

that it can be rotated a few degrees. (If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs). The TPS will be under slight

tension when rotated.

(1) Install TPS and retaining screws.

(2) Tighten screws to 7 N´m (60 in. lbs.) torque.

(3) Connect TPS electrical connector to TPS.

(4) Manually operate throttle (by hand) to check

for any TPS binding before starting engine.

(5) Install air cleaner tube to throttle body.

4.7L V-8

The throttle shaft end of throttle body slides into a

socket in TPS (Fig. 62). The TPS must be installed so

that it can be rotated a few degrees. If sensor will

not rotate, install sensor with throttle shaft on other

side of socket tangs. The TPS will be under slight

tension when rotated.

(1) Install TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate throttle control lever by hand

to check for any binding of TPS.

(4) Connect TPS electrical connector to TPS.

Fig. 58 TPS LOCATION - 4.7L

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

Fig. 59 TPS LOCATION - 5.9L V-8

1 - THROTTLE POSITION SENSOR

2 - MOUNTING SCREWS

Fig. 60 TPS MOUNTING BOLTS - 8.0L V-10

1 - MOUNTING BOLTS (2)

2 - IDLE AIR CONTROL MOTOR

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

14 - 54 FUEL INJECTION - GASDR

THROTTLE POSITION SENSOR (Continued)

Page 1752 of 2895

(5) Install air duct/air box to throttle body.

5.9L V-8

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 63). The TPS must be

installed so that it can be rotated a few degrees. If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs. The TPS will be

under slight tension when rotated.

(1) Install TPS and two retaining bolts.

(2) Tighten bolts to 7 N´m (60 in. lbs.) torque.

(3) Manually operate throttle control lever by hand

to check for any binding of TPS.

(4) Connect TPS electrical connector to TPS.

(5) Install air intake tube.

8.0L V-10

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 63). The TPS must be

installed so that it can be rotated a few degrees. If

sensor will not rotate, install sensor with throttle

shaft on other side of socket tangs. The TPS will be

under slight tension when rotated.

(1) Install TPS and two retaining bolts. Refer to

Torque Specifications.

(2) Manually operate throttle control lever by hand

to check for any binding of TPS.

(3) Connect TPS electrical connector to TPS.

(4) Install air plenum.

Fig. 61 TPS INSTALLATION - 3.7L

1 - THROTTLE BODY

2 - TPS

3 - THROTTLE BODY SHAFT

4 - SOCKET LOCATING TANGS

Fig. 62 TPS INSTALLATION - 4.7L

1 - THROTTLE BODY

2 - LOCATING TANGS

3 - THROTTLE POSITION SENSOR

4 - SOCKET

5 - THROTTLE SHAFT

Fig. 63 TPS INSTALLATION - 5.9L V-8 AND 8.0L V-10

1 - THROTTLE BODY

2 - THROTTLE POSITION SENSOR

3 - THROTTLE SHAFT

4 - SOCKET LOCATING TANGS

DRFUEL INJECTION - GAS 14 - 55

THROTTLE POSITION SENSOR (Continued)

Page 1753 of 2895

FUEL DELIVERY - DIESEL

TABLE OF CONTENTS

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM.....57

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER

DRAINING AT FUEL FILTER..............57

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM PARTS.................58

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING............................59

SPECIFICATIONS

FUEL SYSTEM PRESSURE - DIESEL......60

FUEL INJECTOR FIRING ORDER - DIESEL . 60

SPECIAL TOOLS

DIESEL FUEL SYSTEM.................60

FUEL FILTER / WATER SEPARATOR

DESCRIPTION.........................61

OPERATION...........................61

REMOVAL.............................61

INSTALLATION.........................62

FUEL HEATER

DESCRIPTION.........................63

OPERATION...........................63

DIAGNOSIS AND TESTING - FUEL HEATER . . . 63

REMOVAL

REMOVAL/INSTALLATION...............64

FUEL HEATER RELAY

DESCRIPTION.........................64

OPERATION...........................64

REMOVAL.............................64

INSTALLATION.........................64

FUEL INJECTION PUMP

DESCRIPTION.........................64

OPERATION...........................64

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING........................65

REMOVAL.............................65

INSTALLATION.........................67

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION.........................68

OPERATION...........................68

REMOVAL

REMOVAL/INSTALLATION...............68FUEL LINES

DESCRIPTION.........................69

OPERATION...........................69

DIAGNOSIS AND TESTING - HIGH-

PRESSURE FUEL LINE LEAKS...........69

REMOVAL.............................69

INSTALLATION.........................71

FUEL PRESSURE SENSOR

DESCRIPTION.........................72

OPERATION...........................72

REMOVAL.............................72

INSTALLATION.........................72

FUEL PRESSURE LIMITING VALVE

DESCRIPTION.........................72

OPERATION...........................72

REMOVAL.............................72

INSTALLATION.........................73

FUEL TANK

DESCRIPTION - DIESEL..................73

REMOVAL - DIESEL.....................73

INSTALLATION - DIESEL.................74

FUEL TANK MODULE

DESCRIPTION.........................75

OPERATION...........................75

REMOVAL.............................75

INSTALLATION.........................75

FUEL TRANSFER PUMP

DESCRIPTION.........................75

OPERATION...........................76

REMOVAL.............................76

INSTALLATION.........................76

CASCADE OVERFLOW VALVE

DESCRIPTION.........................77

OPERATION...........................77

REMOVAL

REMOVAL/INSTALLATION...............77

WATER IN FUEL SENSOR

DESCRIPTION.........................77

OPERATION...........................78

REMOVAL.............................78

FUEL DRAIN CIRCUIT

OPERATION...........................78

14 - 56 FUEL DELIVERY - DIESELDR