POWER STEERING DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 315 of 2895

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

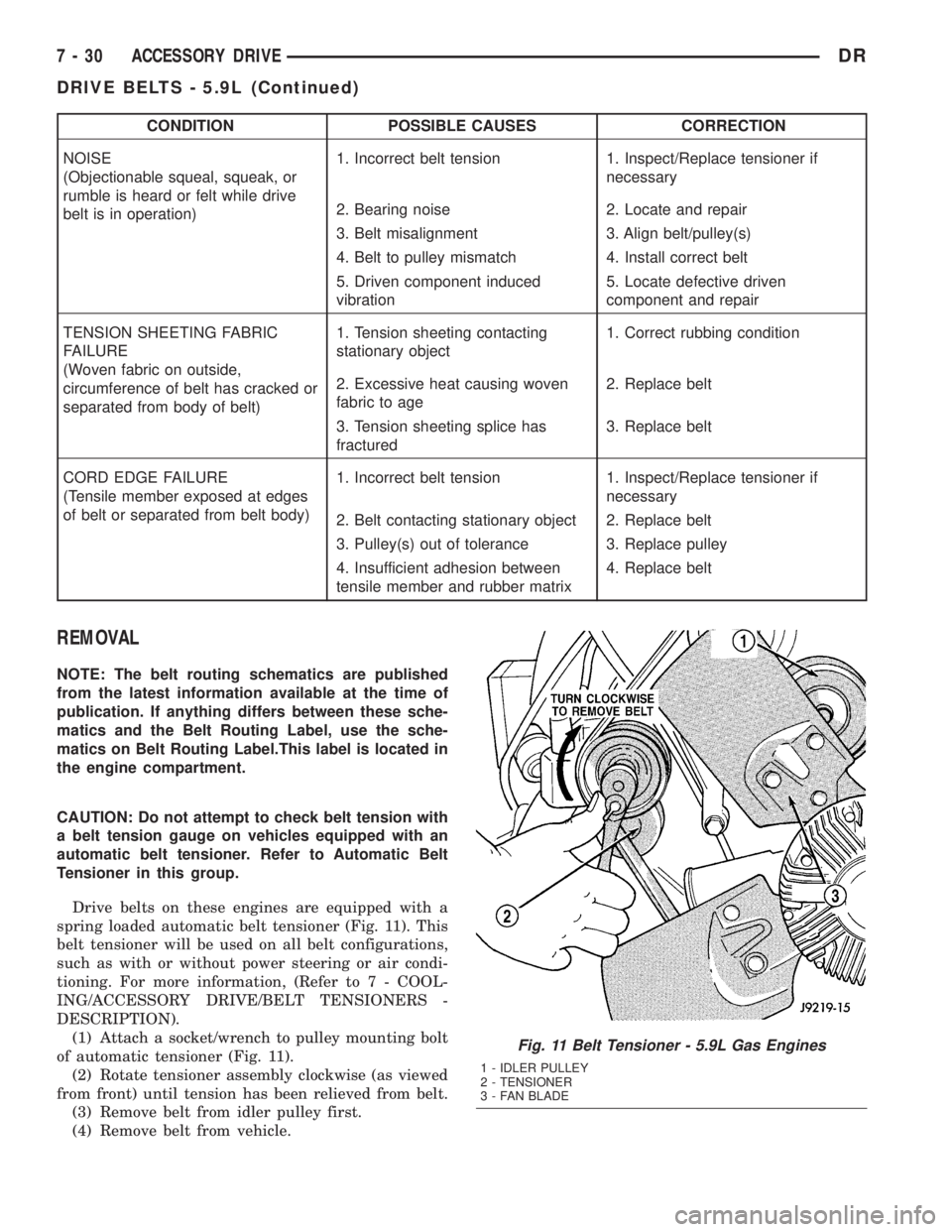

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 10), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 10). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for alignment, glazing, or excessive end

play.

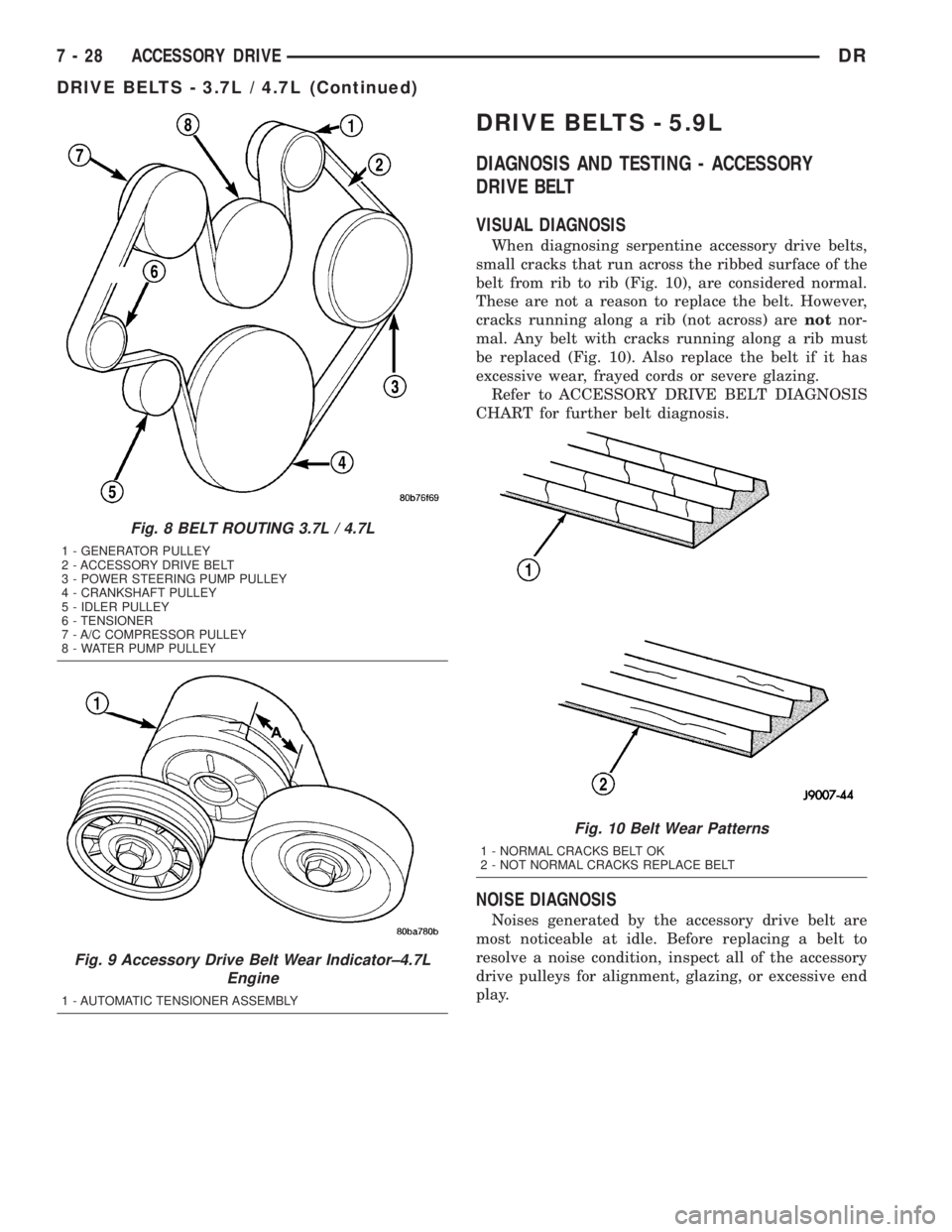

Fig. 8 BELT ROUTING 3.7L / 4.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

Fig. 9 Accessory Drive Belt Wear Indicator±4.7L

Engine

1 - AUTOMATIC TENSIONER ASSEMBLY

Fig. 10 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 28 ACCESSORY DRIVEDR

DRIVE BELTS - 3.7L / 4.7L (Continued)

Page 317 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

NOISE

(Objectionable squeal, squeak, or

rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

REMOVAL

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

Drive belts on these engines are equipped with a

spring loaded automatic belt tensioner (Fig. 11). This

belt tensioner will be used on all belt configurations,

such as with or without power steering or air condi-

tioning. For more information, (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELT TENSIONERS -

DESCRIPTION).

(1) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 11).

(2) Rotate tensioner assembly clockwise (as viewed

from front) until tension has been relieved from belt.

(3) Remove belt from idler pulley first.

(4) Remove belt from vehicle.

Fig. 11 Belt Tensioner - 5.9L Gas Engines

1 - IDLER PULLEY

2 - TENSIONER

3 - FAN BLADE

7 - 30 ACCESSORY DRIVEDR

DRIVE BELTS - 5.9L (Continued)

Page 318 of 2895

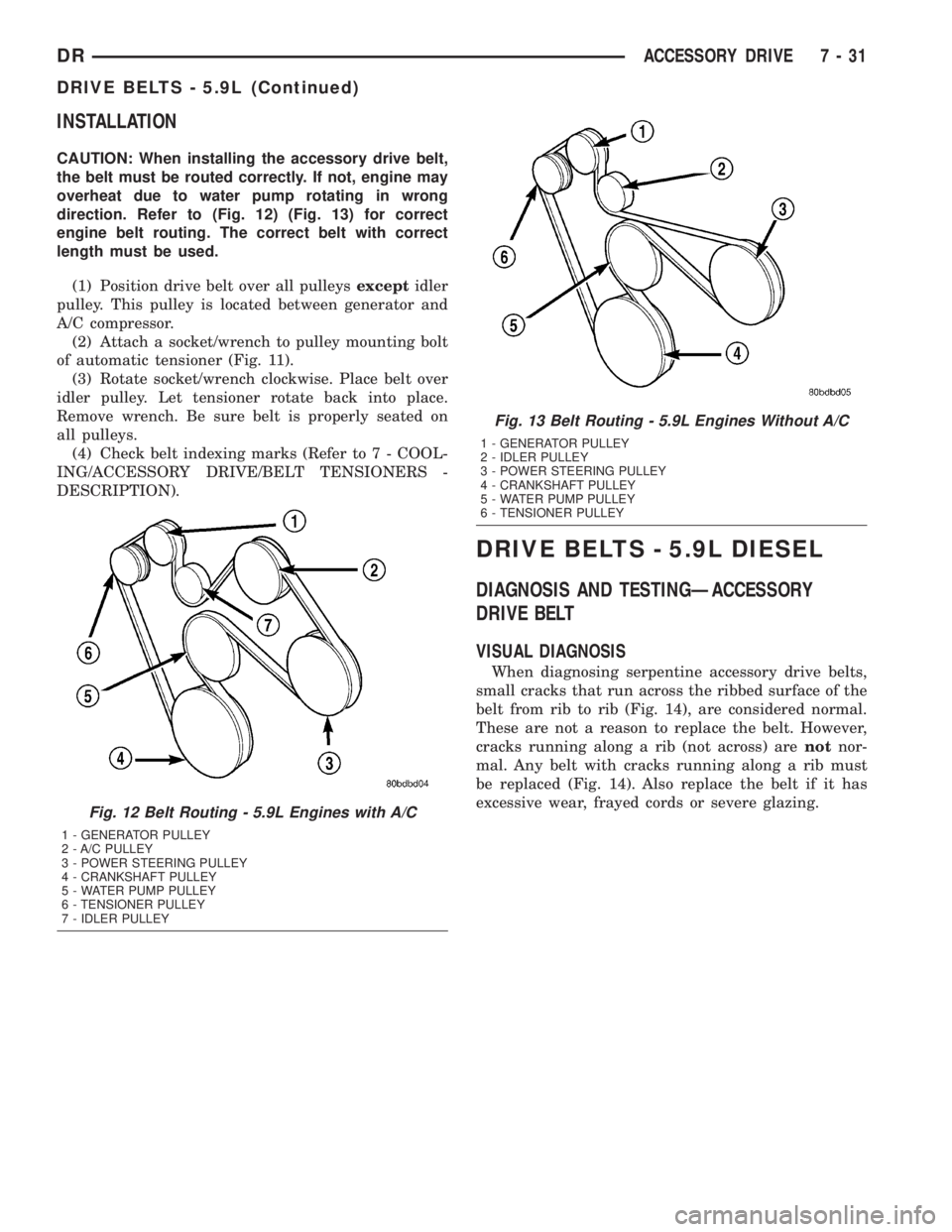

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 12) (Fig. 13) for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexceptidler

pulley. This pulley is located between generator and

A/C compressor.

(2) Attach a socket/wrench to pulley mounting bolt

of automatic tensioner (Fig. 11).

(3) Rotate socket/wrench clockwise. Place belt over

idler pulley. Let tensioner rotate back into place.

Remove wrench. Be sure belt is properly seated on

all pulleys.

(4) Check belt indexing marks (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELT TENSIONERS -

DESCRIPTION).

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 14), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 14). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Fig. 12 Belt Routing - 5.9L Engines with A/C

1 - GENERATOR PULLEY

2 - A/C PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

7 - IDLER PULLEY

Fig. 13 Belt Routing - 5.9L Engines Without A/C

1 - GENERATOR PULLEY

2 - IDLER PULLEY

3 - POWER STEERING PULLEY

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - TENSIONER PULLEY

DRACCESSORY DRIVE 7 - 31

DRIVE BELTS - 5.9L (Continued)

Page 321 of 2895

NOTE: The engine speed sensor face is very close

to the accessory drive belt. Inspect engine speed

sensor and wire harness for damage when acces-

sory drive belt has been replaced due to failure or

abnormal conditions.

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner.displays the

tensioner for vehicles without air conditioning.

This belt tensioner will be used on all belt config-

urations, such as with or without air conditioning.

For more information, (Refer to 7 - COOLING/AC-

CESSORY DRIVE/BELT TENSIONERS - DESCRIP-

TION).

(1) A 1/2 inch square hole is provided in the auto-

matic belt tensioner. Attach a 1/2 inch drive-long

handle ratchet to this hole.

(2) Rotate ratchet and tensioner assembly clock-

wise (as viewed from front) until tension has been

relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

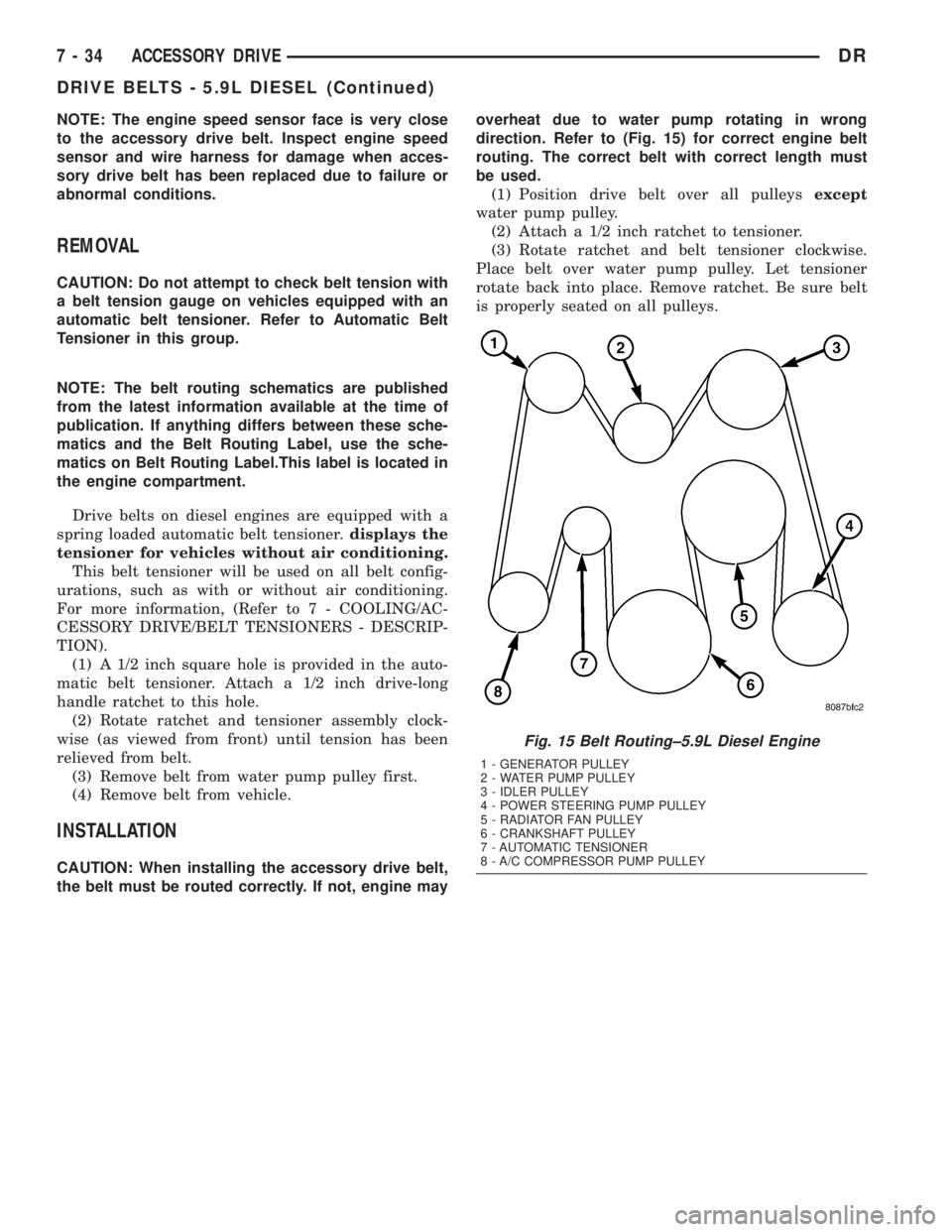

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine mayoverheat due to water pump rotating in wrong

direction. Refer to (Fig. 15) for correct engine belt

routing. The correct belt with correct length must

be used.

(1) Position drive belt over all pulleysexcept

water pump pulley.

(2) Attach a 1/2 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner clockwise.

Place belt over water pump pulley. Let tensioner

rotate back into place. Remove ratchet. Be sure belt

is properly seated on all pulleys.

Fig. 15 Belt Routing±5.9L Diesel Engine

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR PUMP PULLEY

7 - 34 ACCESSORY DRIVEDR

DRIVE BELTS - 5.9L DIESEL (Continued)

Page 337 of 2895

(6) Install the radiator upper hose to the thermo-

stat housing.

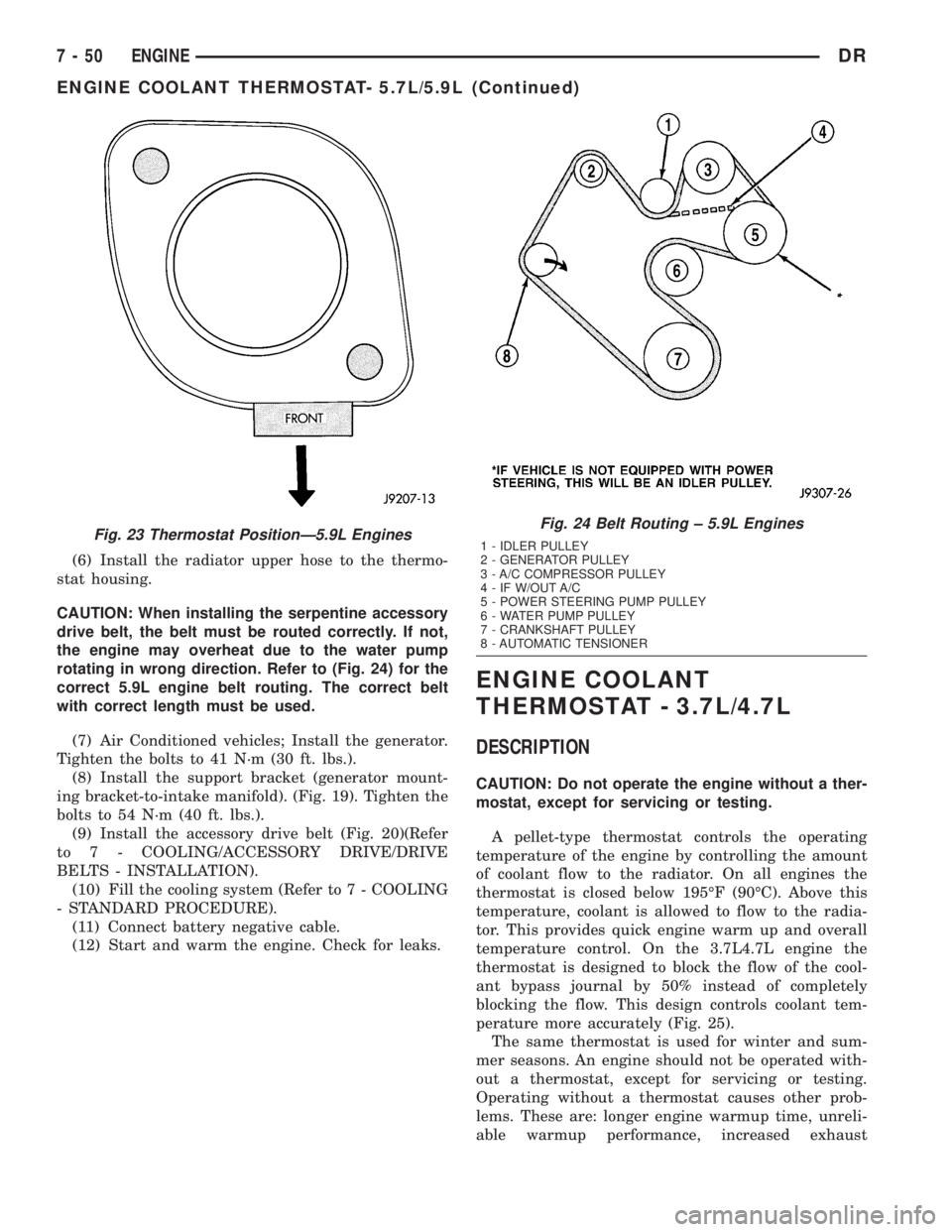

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in wrong direction. Refer to (Fig. 24) for the

correct 5.9L engine belt routing. The correct belt

with correct length must be used.

(7) Air Conditioned vehicles; Install the generator.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(8) Install the support bracket (generator mount-

ing bracket-to-intake manifold). (Fig. 19). Tighten the

bolts to 54 N´m (40 ft. lbs.).

(9) Install the accessory drive belt (Fig. 20)(Refer

to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(10) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(11) Connect battery negative cable.

(12) Start and warm the engine. Check for leaks.

ENGINE COOLANT

THERMOSTAT - 3.7L/4.7L

DESCRIPTION

CAUTION: Do not operate the engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L4.7L engine the

thermostat is designed to block the flow of the cool-

ant bypass journal by 50% instead of completely

blocking the flow. This design controls coolant tem-

perature more accurately (Fig. 25).

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

Fig. 23 Thermostat PositionÐ5.9L EnginesFig. 24 Belt Routing ± 5.9L Engines

1 - IDLER PULLEY

2 - GENERATOR PULLEY

3 - A/C COMPRESSOR PULLEY

4 - IF W/OUT A/C

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP PULLEY

7 - CRANKSHAFT PULLEY

8 - AUTOMATIC TENSIONER

7 - 50 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L/5.9L (Continued)

Page 344 of 2895

DIAGNOSIS AND TESTINGÐRADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

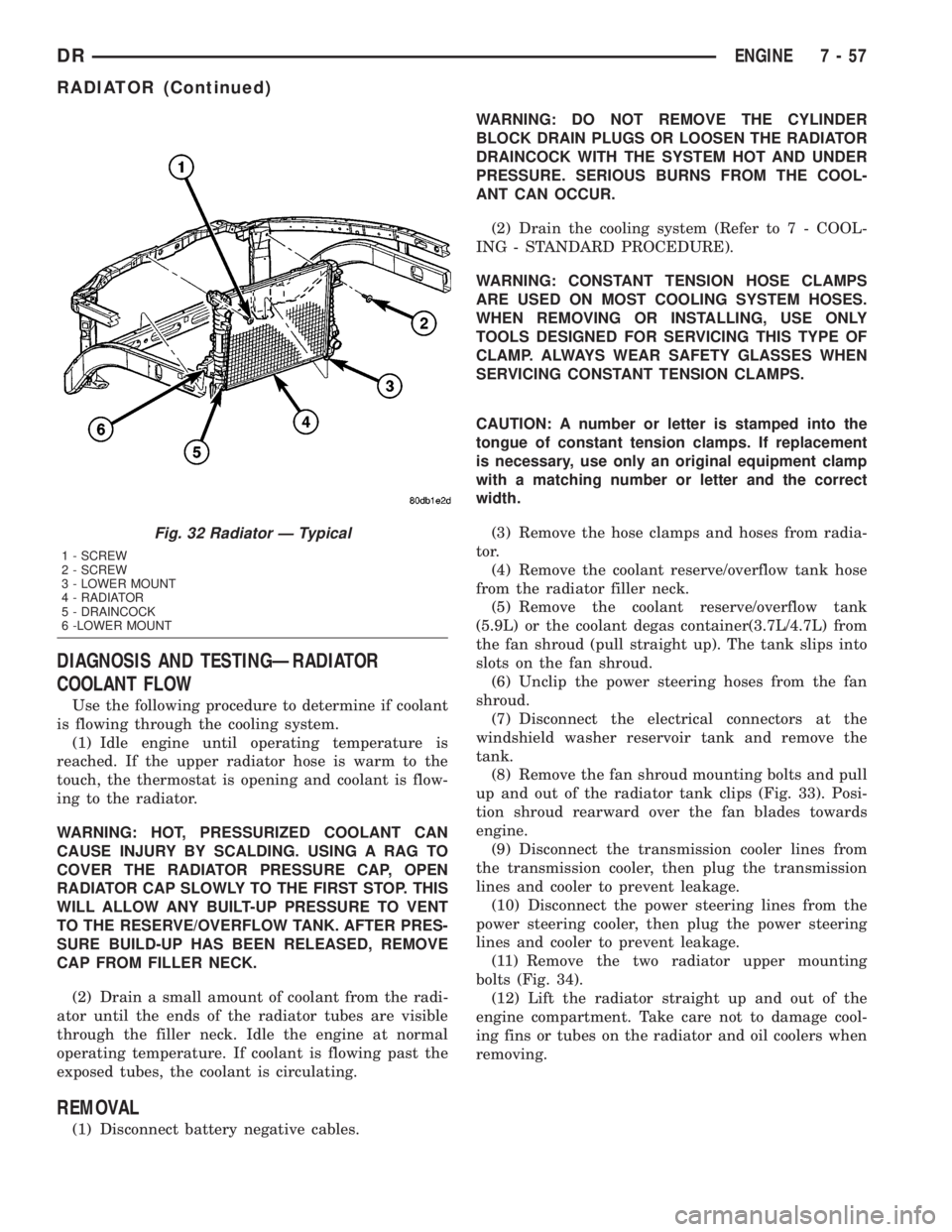

REMOVAL

(1) Disconnect battery negative cables.WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter and the correct

width.

(3) Remove the hose clamps and hoses from radia-

tor.

(4) Remove the coolant reserve/overflow tank hose

from the radiator filler neck.

(5) Remove the coolant reserve/overflow tank

(5.9L) or the coolant degas container(3.7L/4.7L) from

the fan shroud (pull straight up). The tank slips into

slots on the fan shroud.

(6) Unclip the power steering hoses from the fan

shroud.

(7) Disconnect the electrical connectors at the

windshield washer reservoir tank and remove the

tank.

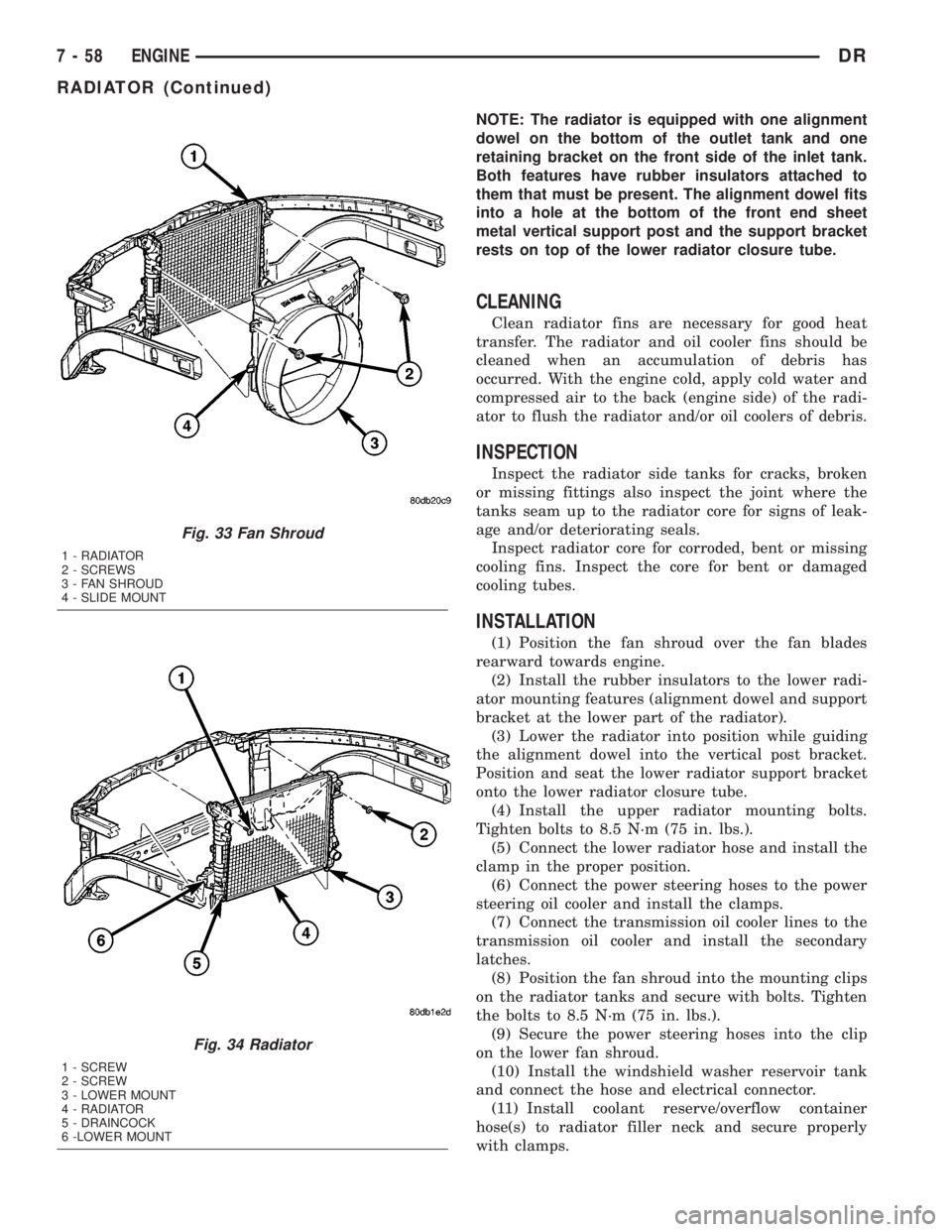

(8) Remove the fan shroud mounting bolts and pull

up and out of the radiator tank clips (Fig. 33). Posi-

tion shroud rearward over the fan blades towards

engine.

(9) Disconnect the transmission cooler lines from

the transmission cooler, then plug the transmission

lines and cooler to prevent leakage.

(10) Disconnect the power steering lines from the

power steering cooler, then plug the power steering

lines and cooler to prevent leakage.

(11) Remove the two radiator upper mounting

bolts (Fig. 34).

(12) Lift the radiator straight up and out of the

engine compartment. Take care not to damage cool-

ing fins or tubes on the radiator and oil coolers when

removing.

Fig. 32 Radiator Ð Typical

1 - SCREW

2 - SCREW

3 - LOWER MOUNT

4 - RADIATOR

5 - DRAINCOCK

6 -LOWER MOUNT

DRENGINE 7 - 57

RADIATOR (Continued)

Page 345 of 2895

NOTE: The radiator is equipped with one alignment

dowel on the bottom of the outlet tank and one

retaining bracket on the front side of the inlet tank.

Both features have rubber insulators attached to

them that must be present. The alignment dowel fits

into a hole at the bottom of the front end sheet

metal vertical support post and the support bracket

rests on top of the lower radiator closure tube.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position the fan shroud over the fan blades

rearward towards engine.

(2) Install the rubber insulators to the lower radi-

ator mounting features (alignment dowel and support

bracket at the lower part of the radiator).

(3) Lower the radiator into position while guiding

the alignment dowel into the vertical post bracket.

Position and seat the lower radiator support bracket

onto the lower radiator closure tube.

(4) Install the upper radiator mounting bolts.

Tighten bolts to 8.5 N´m (75 in. lbs.).

(5) Connect the lower radiator hose and install the

clamp in the proper position.

(6) Connect the power steering hoses to the power

steering oil cooler and install the clamps.

(7) Connect the transmission oil cooler lines to the

transmission oil cooler and install the secondary

latches.

(8) Position the fan shroud into the mounting clips

on the radiator tanks and secure with bolts. Tighten

the bolts to 8.5 N´m (75 in. lbs.).

(9) Secure the power steering hoses into the clip

on the lower fan shroud.

(10) Install the windshield washer reservoir tank

and connect the hose and electrical connector.

(11) Install coolant reserve/overflow container

hose(s) to radiator filler neck and secure properly

with clamps.

Fig. 33 Fan Shroud

1 - RADIATOR

2 - SCREWS

3 - FAN SHROUD

4 - SLIDE MOUNT

Fig. 34 Radiator

1 - SCREW

2 - SCREW

3 - LOWER MOUNT

4 - RADIATOR

5 - DRAINCOCK

6 -LOWER MOUNT

7 - 58 ENGINEDR

RADIATOR (Continued)

Page 347 of 2895

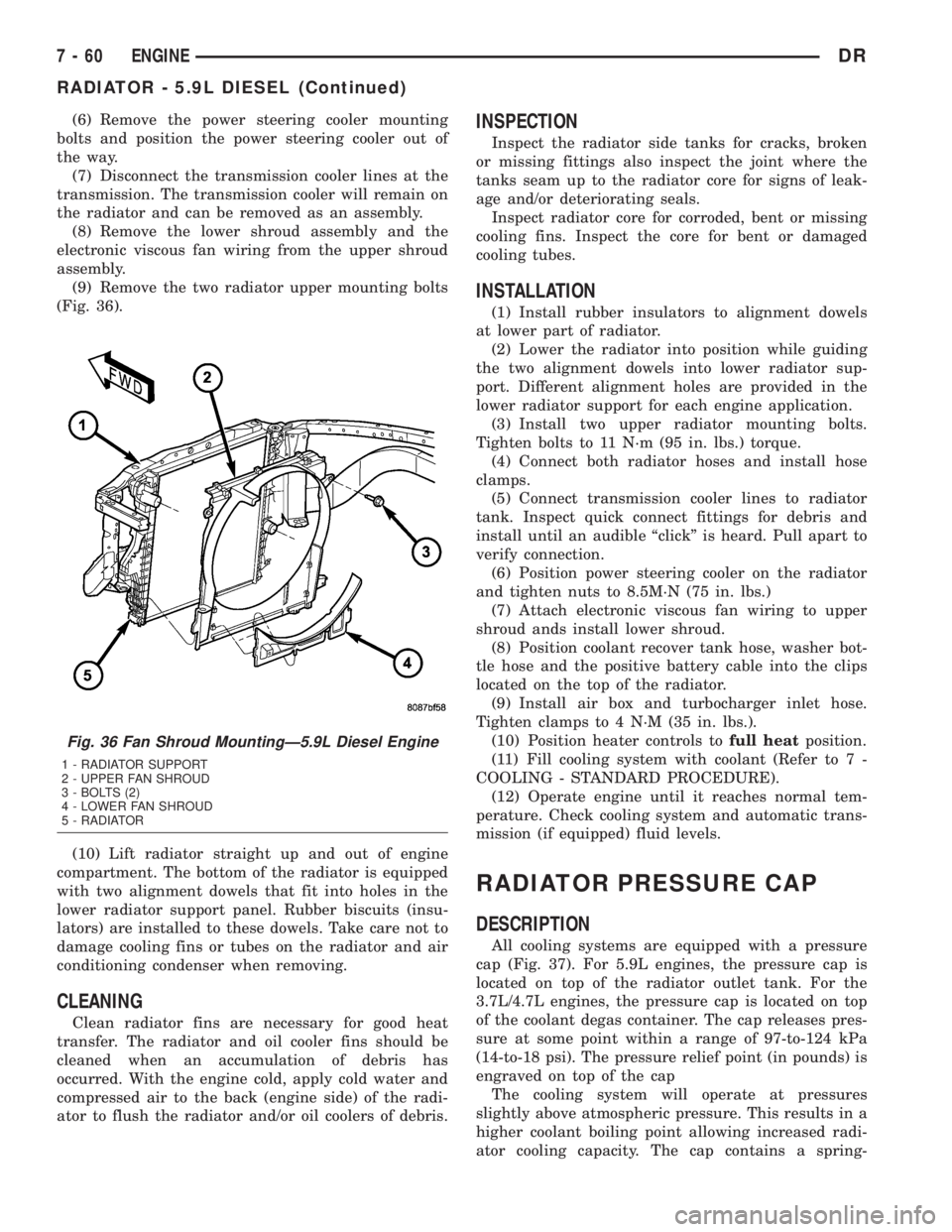

(6) Remove the power steering cooler mounting

bolts and position the power steering cooler out of

the way.

(7) Disconnect the transmission cooler lines at the

transmission. The transmission cooler will remain on

the radiator and can be removed as an assembly.

(8) Remove the lower shroud assembly and the

electronic viscous fan wiring from the upper shroud

assembly.

(9) Remove the two radiator upper mounting bolts

(Fig. 36).

(10) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel. Rubber biscuits (insu-

lators) are installed to these dowels. Take care not to

damage cooling fins or tubes on the radiator and air

conditioning condenser when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Install rubber insulators to alignment dowels

at lower part of radiator.

(2) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(3) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(4) Connect both radiator hoses and install hose

clamps.

(5) Connect transmission cooler lines to radiator

tank. Inspect quick connect fittings for debris and

install until an audible ªclickº is heard. Pull apart to

verify connection.

(6) Position power steering cooler on the radiator

and tighten nuts to 8.5M´N (75 in. lbs.)

(7) Attach electronic viscous fan wiring to upper

shroud ands install lower shroud.

(8) Position coolant recover tank hose, washer bot-

tle hose and the positive battery cable into the clips

located on the top of the radiator.

(9) Install air box and turbocharger inlet hose.

Tighten clamps to 4 N´M (35 in. lbs.).

(10) Position heater controls tofull heatposition.

(11) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(12) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

All cooling systems are equipped with a pressure

cap (Fig. 37). For 5.9L engines, the pressure cap is

located on top of the radiator outlet tank. For the

3.7L/4.7L engines, the pressure cap is located on top

of the coolant degas container. The cap releases pres-

sure at some point within a range of 97-to-124 kPa

(14-to-18 psi). The pressure relief point (in pounds) is

engraved on top of the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

Fig. 36 Fan Shroud MountingÐ5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - UPPER FAN SHROUD

3 - BOLTS (2)

4 - LOWER FAN SHROUD

5 - RADIATOR

7 - 60 ENGINEDR

RADIATOR - 5.9L DIESEL (Continued)

Page 354 of 2895

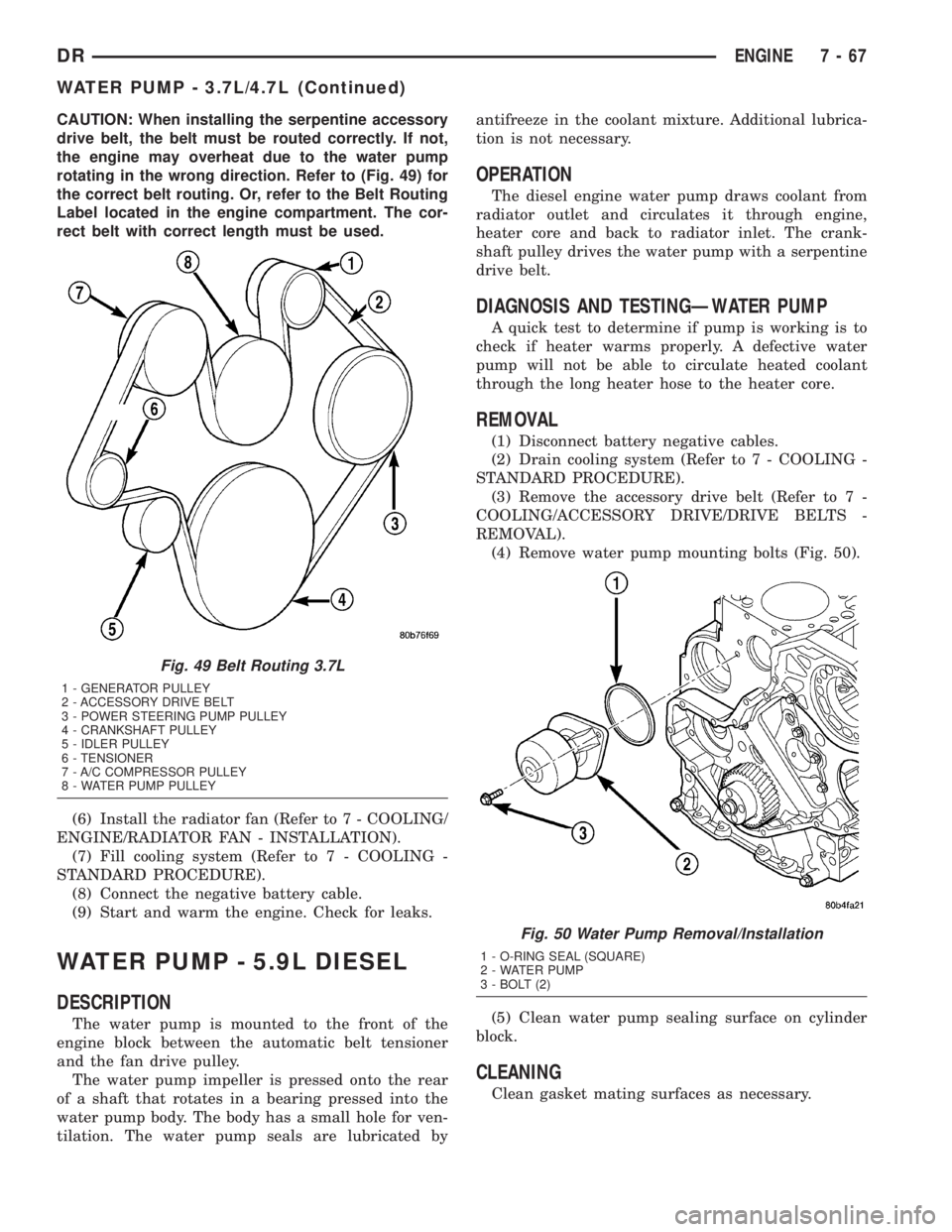

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. Refer to (Fig. 49) for

the correct belt routing. Or, refer to the Belt Routing

Label located in the engine compartment. The cor-

rect belt with correct length must be used.

(6) Install the radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(7) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect the negative battery cable.

(9) Start and warm the engine. Check for leaks.

WATER PUMP - 5.9L DIESEL

DESCRIPTION

The water pump is mounted to the front of the

engine block between the automatic belt tensioner

and the fan drive pulley.

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated byantifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

The diesel engine water pump draws coolant from

radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank-

shaft pulley drives the water pump with a serpentine

drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

(1) Disconnect battery negative cables.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove water pump mounting bolts (Fig. 50).

(5) Clean water pump sealing surface on cylinder

block.

CLEANING

Clean gasket mating surfaces as necessary.

Fig. 49 Belt Routing 3.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

Fig. 50 Water Pump Removal/Installation

1 - O-RING SEAL (SQUARE)

2 - WATER PUMP

3 - BOLT (2)

DRENGINE 7 - 67

WATER PUMP - 3.7L/4.7L (Continued)

Page 359 of 2895

TRANSMISSION

TABLE OF CONTENTS

page page

TRANS COOLER

DESCRIPTION

DESCRIPTION........................72

DESCRIPTION........................72

OPERATION...........................72

REMOVAL.............................72

DISASSEMBLY - 5.9L ONLY...............73

ASSEMBLY - 5.9L ONLY..................73

INSTALLATION.........................73TRANS COOLER - 5.9L DIESEL

DESCRIPTION.........................73

OPERATION...........................74

REMOVAL

REMOVALÐAIR TO OIL COOLER.........74

REMOVALÐWATER TO OIL COOLER......74

INSTALLATION

INSTALLATIONÐAIR TO OIL COOLER.....75

INSTALLATION.......................75

TRANS COOLER

DESCRIPTION

DESCRIPTION

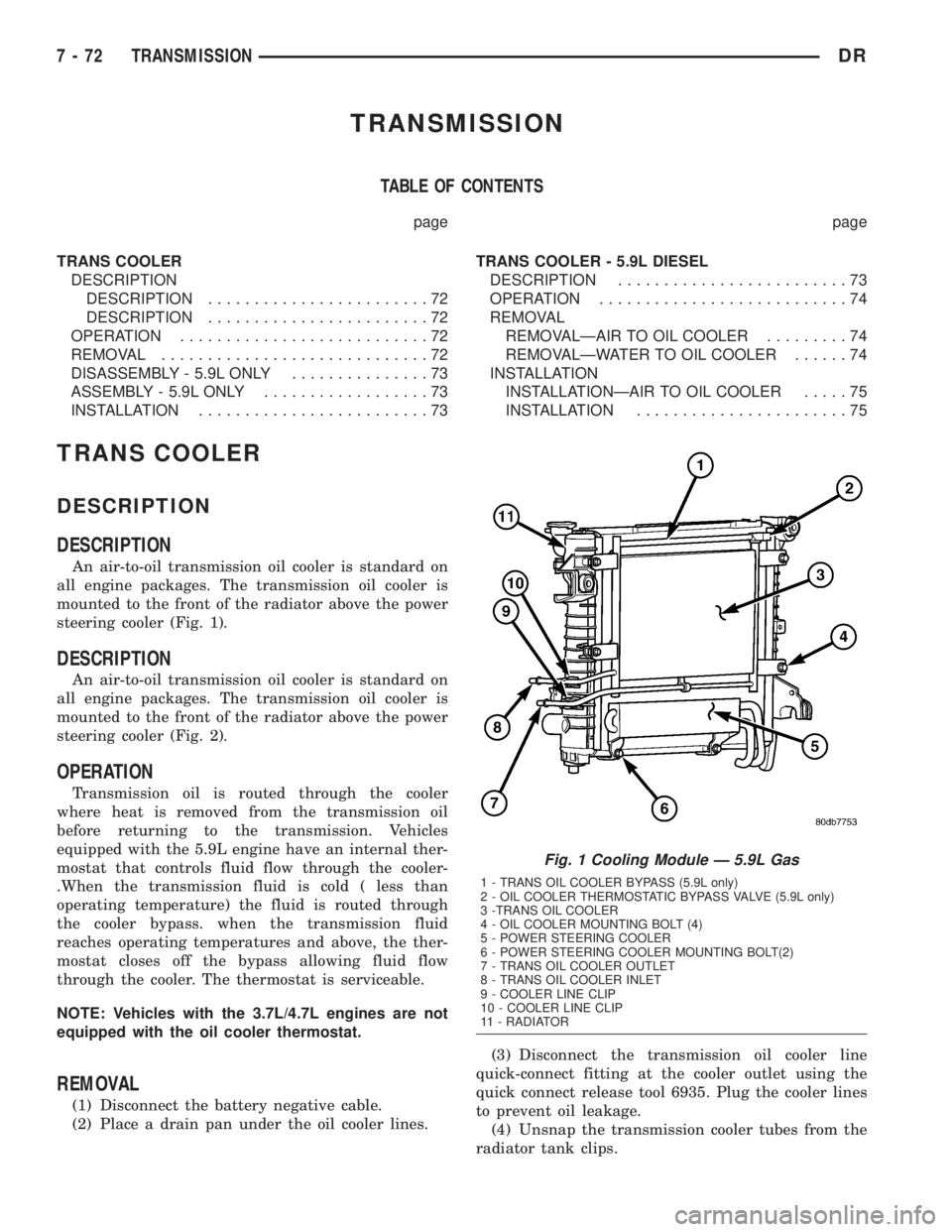

An air-to-oil transmission oil cooler is standard on

all engine packages. The transmission oil cooler is

mounted to the front of the radiator above the power

steering cooler (Fig. 1).

DESCRIPTION

An air-to-oil transmission oil cooler is standard on

all engine packages. The transmission oil cooler is

mounted to the front of the radiator above the power

steering cooler (Fig. 2).

OPERATION

Transmission oil is routed through the cooler

where heat is removed from the transmission oil

before returning to the transmission. Vehicles

equipped with the 5.9L engine have an internal ther-

mostat that controls fluid flow through the cooler-

.When the transmission fluid is cold ( less than

operating temperature) the fluid is routed through

the cooler bypass. when the transmission fluid

reaches operating temperatures and above, the ther-

mostat closes off the bypass allowing fluid flow

through the cooler. The thermostat is serviceable.

NOTE: Vehicles with the 3.7L/4.7L engines are not

equipped with the oil cooler thermostat.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Place a drain pan under the oil cooler lines.(3) Disconnect the transmission oil cooler line

quick-connect fitting at the cooler outlet using the

quick connect release tool 6935. Plug the cooler lines

to prevent oil leakage.

(4) Unsnap the transmission cooler tubes from the

radiator tank clips.

Fig. 1 Cooling Module Ð 5.9L Gas

1 - TRANS OIL COOLER BYPASS (5.9L only)

2 - OIL COOLER THERMOSTATIC BYPASS VALVE (5.9L only)

3 -TRANS OIL COOLER

4 - OIL COOLER MOUNTING BOLT (4)

5 - POWER STEERING COOLER

6 - POWER STEERING COOLER MOUNTING BOLT(2)

7 - TRANS OIL COOLER OUTLET

8 - TRANS OIL COOLER INLET

9 - COOLER LINE CLIP

10 - COOLER LINE CLIP

11 - RADIATOR

7 - 72 TRANSMISSIONDR