Speedometer DODGE RAM 2003 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2036 of 2895

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absence

of sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to pro-

duce governor pressure. The average current sup-

plied to the solenoid controls governor pressure. One

amp current produces zero kPa/psi governor pres-

sure. Zero amps sets the maximum governor pres-

sure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higherthan normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-

tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 197

ELECTRONIC GOVERNOR (Continued)

Page 2162 of 2895

(3) Have helper start and run engine at 1600 rpm

for test.

(4) Move transmission shift lever four detents

rearward from full forward position. This is Reverse

range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotat-

ing.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7) Compare results of pressure test with analysis

chart.

Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

(1) Remove tachometer; it is not needed for this

test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 524-565 kPa (76-82 psi)

with closed throttle and increase to 690-896 kPa

(100-130 psi) at 1/2 to 3/4 throttle. Note that pres-

sure can increase to around 965 kPa (140 psi) at full

throttle.

(9) Return to shop or move vehicle off chassis

dyno.

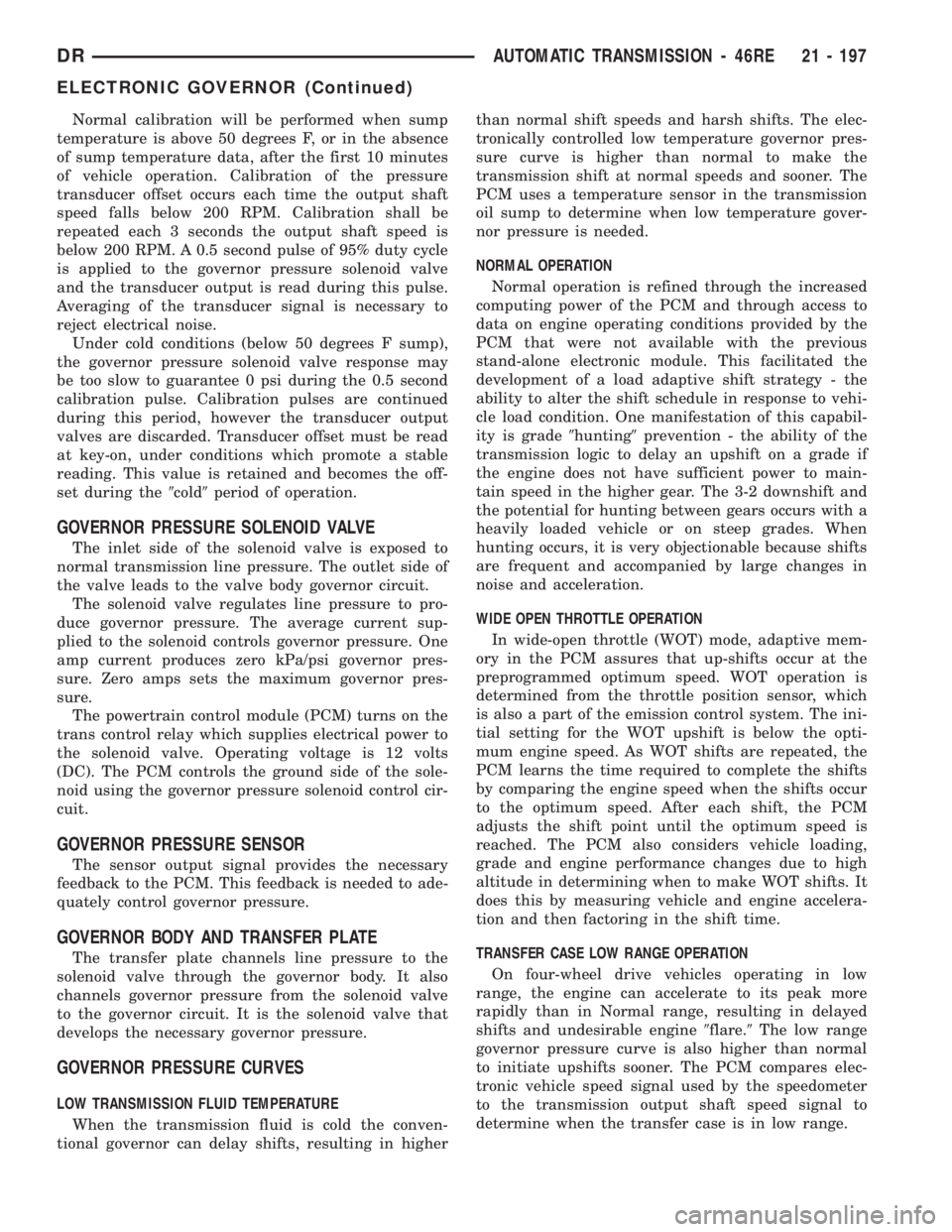

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one testPump and regulator valve

OK

Line pressure OK in R but

low in D, 2, 1Leakage in rear clutch

area (seal rings, clutch

seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball

problem

Pressure OK in 1, 2 but

low in D3 and RLeakage in front clutch

area

Pressure OK in 2 but low

in R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked

servo piston

Pressure low in all

positionsClogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too

high at idle speedGovernor pressure

solenoid valve system

fault. Refer to diagnostic

book.

Governor pressure low at

all mph figuresFaulty governor pressure

solenoid, transmission

control module, or

governor pressure sensor

Lubrication pressure low

at all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged,

sticky regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

DRAUTOMATIC TRANSMISSION - 48RE 21 - 323

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2217 of 2895

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higher

than normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

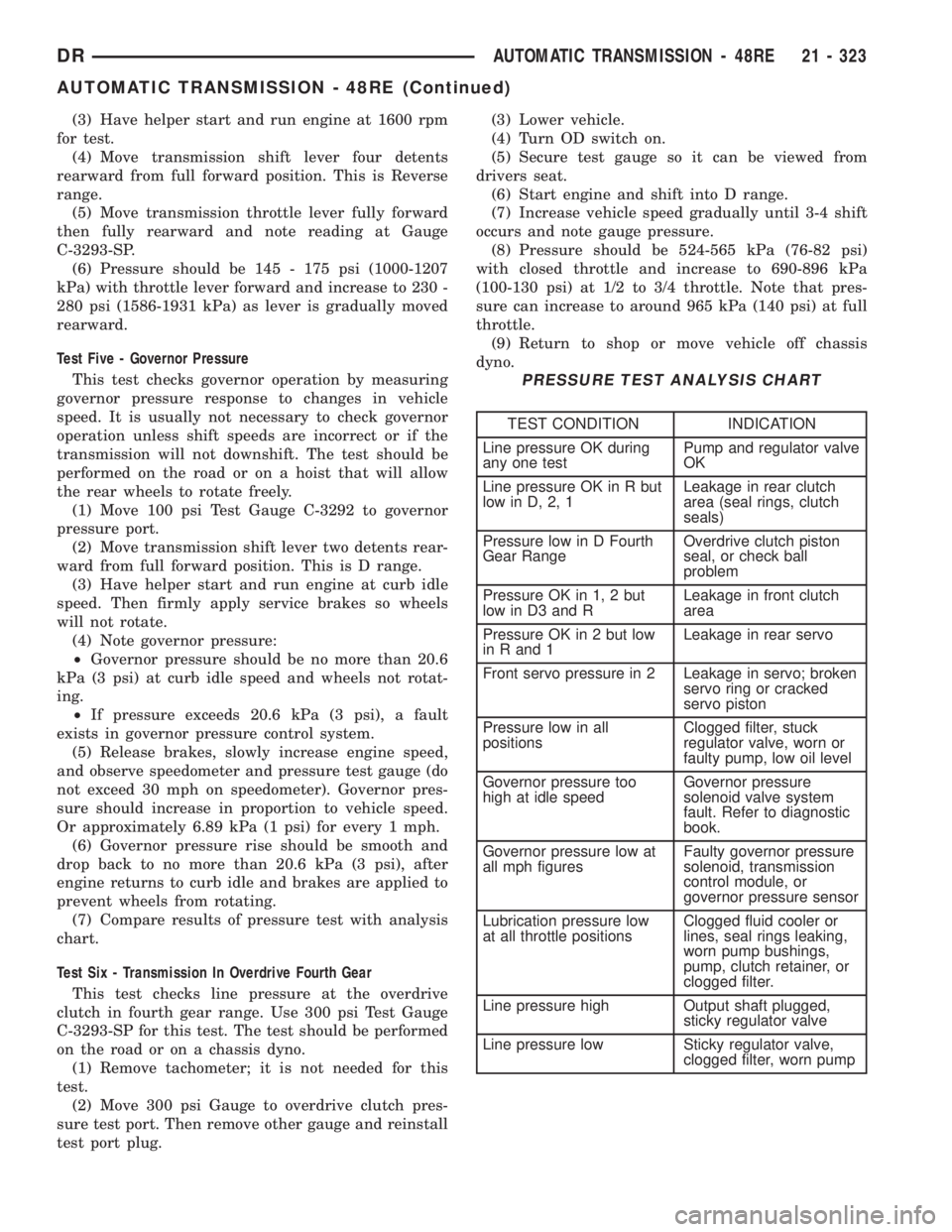

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove transmission fluid pan and filter.

(3) Disengage wire connectors from pressure sen-

sor and solenoid (Fig. 80).

Fig. 80 Governor Solenoid And Pressure Sensor

1 - PRESSURE SENSOR

2 - PRESSURE SOLENOID

3 - GOVERNOR

21 - 378 AUTOMATIC TRANSMISSION - 48REDR

ELECTRONIC GOVERNOR (Continued)

Page 2887 of 2895

SIDE - REMOVAL, LEFT................9-121

SIDE - REMOVAL, RIGHT..............9-121

SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL DRIVER...........23-59

SIDE BEZEL - REMOVAL, INSTRUMENT

PANEL DRIVER......................23-58

SIDE CURTAIN AIRBAG - DESCRIPTION . . . 8O-51

SIDE CURTAIN AIRBAG - INSTALLATION . . 8O-53

SIDE CURTAIN AIRBAG - OPERATION....8O-51

SIDE CURTAIN AIRBAG - REMOVAL......8O-52

SIDE IMPACT AIRBAG CONTROL

MODULE - DESCRIPTION..............8O-53

SIDE IMPACT AIRBAG CONTROL

MODULE - OPERATION................8O-54

SIDE MOLDINGS - INSTALLATION, BODY . . 23-36

SIDE MOLDINGS - REMOVAL, BODY.....23-36

SIDE VIEW MIRROR - INSTALLATION.....23-41

SIDE VIEW MIRROR - REMOVAL........23-41

SIDE VIEW MIRROR FLAG -

INSTALLATION.......................23-27

SIDE VIEW MIRROR FLAG - REMOVAL . . . 23-27

SIDE VIEW MIRROR GLASS -

INSTALLATION.......................23-44

SIDE VIEW MIRROR GLASS - REMOVAL . . 23-42

SIDEVIEW MIRROR - REMOVAL.........8N-13

SIGNAL INDICATOR - DESCRIPTION,

TURN..............................8J-39

SIGNAL INDICATOR - OPERATION, TURN . . 8J-39

SIGNAL LAMP - INSTALLATION,

PARK/TURN.........................8L-21

SIGNAL LAMP - REMOVAL, PARK/TURN . . 8L-21

SIGNAL SYSTEM - DESCRIPTION, TURN . . 8L-17

SIGNAL SYSTEM - OPERATION, TURN....8L-18

SILL TRIM COVER - INSTALLATION,

REAR DOOR........................23-72

SILL TRIM COVER - REMOVAL, REAR

DOOR.............................23-72

SINGLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY...........................3-9

SINGLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY.........................3-9

SIZE, SPARE WHEEL WITH MATCHING

TIRE - DESCRIPTION, FULL............22-15

SKID PLATE - INSTALLATION, FRONT.....13-24

SKID PLATE - INSTALLATION, TRANSFER

CASE..............................13-26

SKID PLATE - REMOVAL, FRONT........13-24

SKID PLATE - REMOVAL, TRANSFER

CASE..............................13-26

SLEEVE - INSTALLATION, HEADREST.....23-82

SLEEVE - REMOVAL, HEADREST........23-82

SMOKE DIAGNOSIS CHARTS -

DIAGNOSIS AND TESTING.............9-285

SOLENOID - DESCRIPTION......21-253,21-431

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-12

SOLENOID - INSTALLATION, EVAP/

PURGE.............................25-13

SOLENOID - OPERATION........21-254,21-431

SOLENOID - OPERATION, EVAP/PURGE . . . 25-12

SOLENOID - REMOVAL, EVAP/PURGE.....25-13

SOLENOID SWITCH VALVE -

DESCRIPTION......................21-574

SOLENOID SWITCH VALVE - OPERATION . 21-574

SOLENOIDS - DESCRIPTION...........21-574

SOLENOIDS - OPERATION.............21-575

SOLENOID/TRS ASSEMBLY -

DESCRIPTION, TRANSMISSION........21-582

SOLENOID/TRS ASSEMBLY -

INSTALLATION, TRANSMISSION........21-583

SOLENOID/TRS ASSEMBLY -

OPERATION, TRANSMISSION..........21-582

SOLENOID/TRS ASSEMBLY - REMOVAL,

TRANSMISSION.....................21-583

SOLID LIFTERS/TAPPETS - CLEANING....9-328

SOLID LIFTERS/TAPPETS - INSPECTION . . 9-328

SOLID LIFTERS/TAPPETS -

INSTALLATION.......................9-328

SOLID LIFTERS/TAPPETS - REMOVAL....9-327

SPARE / TEMPORARY TIRE -

DESCRIPTION.......................22-15

SPARE TIRE / TEMPORARY -

DESCRIPTION........................22-5

SPARE WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE

..............22-15

SPARK PLUG - DESCRIPTION

...........8I-27

SPARK PLUG - REMOVAL

..............8I-30

SPARK PLUG CABLE - DESCRIPTION

.....8I-33

SPARK PLUG CABLE - INSTALLATION

.....8I-35SPARK PLUG CABLE - OPERATION.......8I-33

SPARK PLUG CABLE - REMOVAL........8I-34

SPARK PLUG CABLE ORDER, 8.0L V-10

ENGINE..............................8I-5

SPARK PLUG CABLE RESISTANCE,

SPECIFICATIONS......................8I-5

SPARK PLUG CABLES - DIAGNOSIS AND

TESTING............................8I-33

SPARK PLUG CONDITIONS - DIAGNOSIS

AND TESTING........................8I-27

SPARK PLUGS, SPECIFICATIONS..........8I-5

SPEAKER - DESCRIPTION..............8A-12

SPEAKER - DIAGNOSIS AND TESTING....8A-13

SPEAKER - INSTALLATION.............8A-15

SPEAKER - OPERATION...............8A-12

SPEAKER - REMOVAL.................8A-13

SPECIFICATIONS......................7-20

SPEED CONTROL - DESCRIPTION........8P-1

SPEED CONTROL - OPERATION..........8P-2

SPEED CONTROL - TORQUE.............8P-3

SPEED SENSOR - DESCRIPTION . . 21-254,21-431

SPEED SENSOR - DESCRIPTION, FRONT

WHEEL.............................5-41

SPEED SENSOR - DESCRIPTION, INPUT . 21-558

SPEED SENSOR - DESCRIPTION,

OUTPUT...........................21-567

SPEED SENSOR - DIAGNOSIS AND

TESTING, REAR WHEEL................5-43

SPEED SENSOR - INSTALLATION, FRONT

WHEEL.............................5-42

SPEED SENSOR - INSTALLATION, INPUT . 21-559

SPEED SENSOR - INSTALLATION,

OUTPUT...........................21-567

SPEED SENSOR - INSTALLATION, REAR

WHEEL.............................5-43

SPEED SENSOR - OPERATION . . . 21-254,21-431

SPEED SENSOR - OPERATION, FRONT

WHEEL.............................5-41

SPEED SENSOR - OPERATION, INPUT . . . 21-558

SPEED SENSOR - OPERATION, OUTPUT . . 21-567

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-41

SPEED SENSOR - REMOVAL, INPUT.....21-559

SPEED SENSOR - REMOVAL, OUTPUT . . . 21-567

SPEED SENSOR - REMOVAL, REAR

WHEEL.............................5-42

SPEEDOMETER - DESCRIPTION.........8J-36

SPEEDOMETER - OPERATION...........8J-36

SPEEDS - DESCRIPTION, TIRE

PRESSURE FOR HIGH..................22-6

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE.................23-41

SPLASH SHIELD - INSTALLATION, REAR

WHEELHOUSE.......................23-41

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE.......................23-40

SPLASH SHIELD - REMOVAL, REAR

WHEELHOUSE.......................23-41

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-15

SPRING - DESCRIPTION................2-41

SPRING - INSTALLATION.......2-22,2-36,2-41

SPRING - OPERATION..................2-41

SPRING - REMOVAL...........2-21,2-36,2-41

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-38

SPRING BUMPERS (3500) -

INSTALLATION, AUXILIARY..............2-40

SPRING BUMPERS (3500) - REMOVAL,

AUXILIARY..........................2-40

SPRING TIP INSERTS - INSTALLATION....2-42

SPRING TIP INSERTS - REMOVAL........2-41

SPRINGS - DESCRIPTION, VALVE . . . 9-125,9-31,

9-36

SPRINGS - INSTALLATION, VALVE . . 9-126,9-199,

9-31,9-37

SPRINGS - INSTALLATION, VALVES AND

VALVE

.............................9-379

SPRINGS - REMOVAL, VALVE

. 9-125,9-199,9-31,

9-37

SPRINGS - REMOVAL, VALVES AND

VALVE

.............................9-377

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES

................9-246,9-305

SPRINGS AND SEALS - REMOVAL,

VALVE

.............................9-308SPROCKETS - INSPECTION, TIMING

BELT/CHAIN.....................9-171,9-83

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN...........9-172,9-279,9-406,9-84

SPROCKETS - INSTALLATION,

TIMING/CHAIN.......................9-222

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN...........9-169,9-279,9-405,9-81

SPROCKETS - REMOVAL, TIMING/CHAIN . . 9-221

SQUEAK & RATTLE - STANDARD

PROCEDURE, BUZZ...................23-11

STABILIZER BAR - DESCRIPTION.........2-24

STABILIZER BAR - INSTALLATION....2-24,2-37

STABILIZER BAR - OPERATION...........2-24

STABILIZER BAR - REMOVAL........2-24,2-37

STAKING - STANDARD PROCEDURE,

HEAT ...............................23-3

STANDARD CAB - INSTALLATION........8O-31

STANDARD CAB - REMOVAL...........8O-28

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-34

STARTER MOTOR - INSTALLATION.......8F-37

STARTER MOTOR - REMOVAL..........8F-34

STARTER MOTOR RELAY - DESCRIPTION . 8F-38

STARTER MOTOR RELAY -

INSTALLATION.......................8F-39

STARTER MOTOR RELAY - OPERATION . . . 8F-38

STARTER MOTOR RELAY - REMOVAL.....8F-39

STARTER RELAY - DIAGNOSIS AND

TESTING.............................8F-38

STARTING - DESCRIPTION.............8F-28

STARTING - OPERATION...............8F-28

STARTING - STANDARD PROCEDURE,

JUMP...............................0-13

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-29

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-34

STARTING SYSTEM, SPECIFICATIONS.....8F-33

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING COLUMN - DIAGNOSIS AND

TESTING............................19-7

STEERING COLUMN OPENING COVER -

INSTALLATION.......................23-61

STEERING COLUMN OPENING COVER -

REMOVAL..........................23-61

STEERING COLUMN OPENING SUPPORT

BRACKET - INSTALLATION.............23-62

STEERING COLUMN OPENING SUPPORT

BRACKET - REMOVAL.................23-61

STEERING COUPLING - INSTALLATION,

UPPER.............................19-14

STEERING COUPLING - REMOVAL,

UPPER.............................19-13

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING FLUID - DESCRIPTION,

POWER..............................0-3

STEERING FLUID LEVEL CHECKING -

STANDARD PROCEDURE, POWER.......19-42

STEERING GEAR INPUT SHAFT SEAL -

INSTALLATION.......................19-28

STEERING GEAR INPUT SHAFT SEAL -

REMOVAL..........................19-25

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-22

STEERING GEAR, SPECIFICATIONS -

POWER............................19-21

STEERING LINKAGE, SPECIAL TOOLS....19-35

STEERING PRESSURE SWITCH -

DESCRIPTION, POWER................19-45

STEERING PRESSURE SWITCH -

OPERATION, POWER..................19-45

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-39

STEERING, SPECIAL TOOLS.............19-5

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER

........19-39

STEERING WHEEL - INSTALLATION

......19-15

STEERING WHEEL - REMOVAL

..........19-15

STEM SEAL - INSTALLATION, VALVE

.....9-378

STEM SEALS - DESCRIPTION, VALVE

....9-126,

9-198

32 INDEXDR

Description Group-Page Description Group-Page Description Group-Page