Output speed sensor DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1173 of 2895

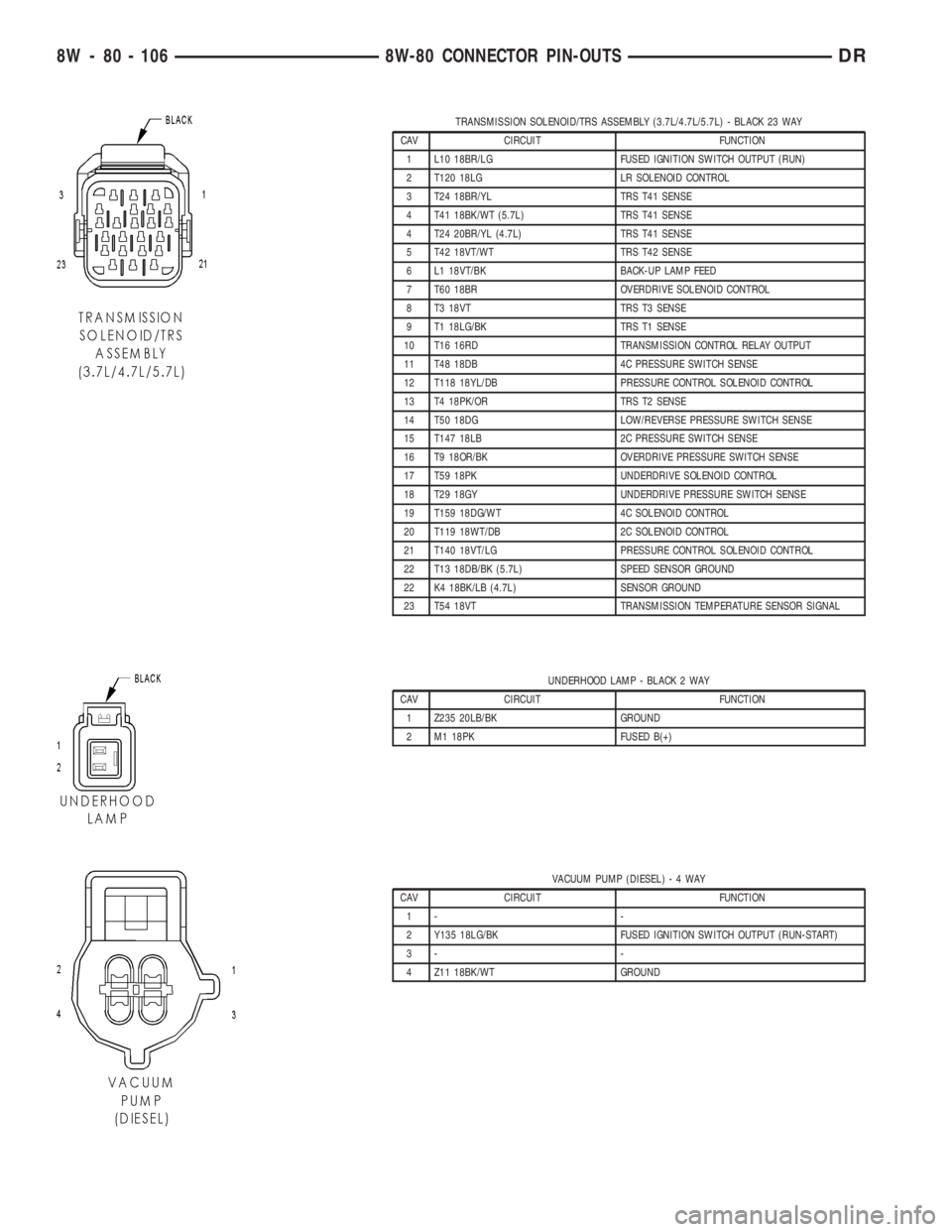

TRANSMISSION SOLENOID/TRS ASSEMBLY (3.7L/4.7L/5.7L) - BLACK 23 WAY

CAV CIRCUIT FUNCTION

1 L10 18BR/LG FUSED IGNITION SWITCH OUTPUT (RUN)

2 T120 18LG LR SOLENOID CONTROL

3 T24 18BR/YL TRS T41 SENSE

4 T41 18BK/WT (5.7L) TRS T41 SENSE

4 T24 20BR/YL (4.7L) TRS T41 SENSE

5 T42 18VT/WT TRS T42 SENSE

6 L1 18VT/BK BACK-UP LAMP FEED

7 T60 18BR OVERDRIVE SOLENOID CONTROL

8 T3 18VT TRS T3 SENSE

9 T1 18LG/BK TRS T1 SENSE

10 T16 16RD TRANSMISSION CONTROL RELAY OUTPUT

11 T48 18DB 4C PRESSURE SWITCH SENSE

12 T118 18YL/DB PRESSURE CONTROL SOLENOID CONTROL

13 T4 18PK/OR TRS T2 SENSE

14 T50 18DG LOW/REVERSE PRESSURE SWITCH SENSE

15 T147 18LB 2C PRESSURE SWITCH SENSE

16 T9 18OR/BK OVERDRIVE PRESSURE SWITCH SENSE

17 T59 18PK UNDERDRIVE SOLENOID CONTROL

18 T29 18GY UNDERDRIVE PRESSURE SWITCH SENSE

19 T159 18DG/WT 4C SOLENOID CONTROL

20 T119 18WT/DB 2C SOLENOID CONTROL

21 T140 18VT/LG PRESSURE CONTROL SOLENOID CONTROL

22 T13 18DB/BK (5.7L) SPEED SENSOR GROUND

22 K4 18BK/LB (4.7L) SENSOR GROUND

23 T54 18VT TRANSMISSION TEMPERATURE SENSOR SIGNAL

UNDERHOOD LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z235 20LB/BK GROUND

2 M1 18PK FUSED B(+)

VACUUM PUMP (DIESEL)-4WAY

CAV CIRCUIT FUNCTION

1- -

2 Y135 18LG/BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

3- -

4 Z11 18BK/WT GROUND

8W - 80 - 106 8W-80 CONNECTOR PIN-OUTSDR

Page 1174 of 2895

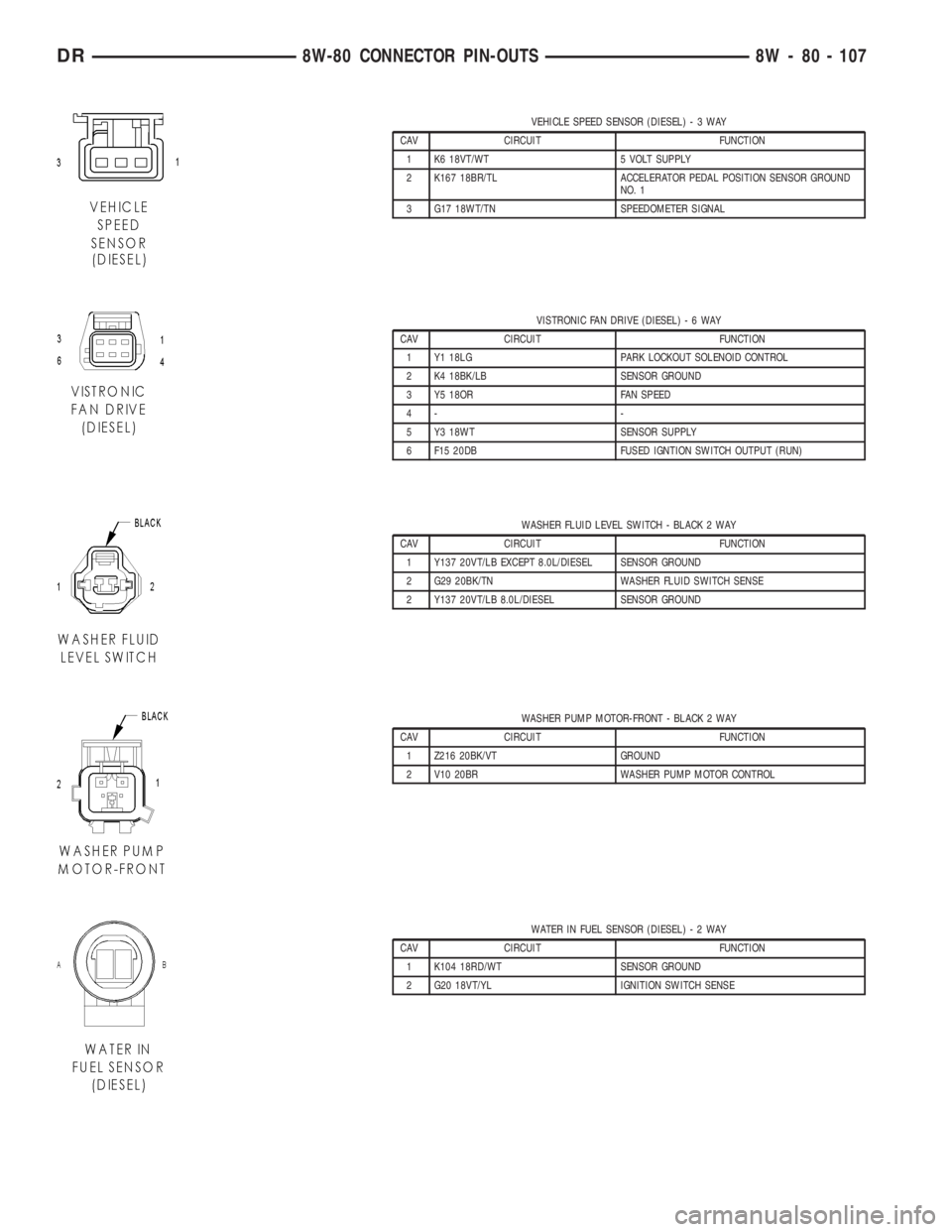

VEHICLE SPEED SENSOR (DIESEL)-3WAY

CAV CIRCUIT FUNCTION

1 K6 18VT/WT 5 VOLT SUPPLY

2 K167 18BR/TL ACCELERATOR PEDAL POSITION SENSOR GROUND

NO. 1

3 G17 18WT/TN SPEEDOMETER SIGNAL

VISTRONIC FAN DRIVE (DIESEL)-6WAY

CAV CIRCUIT FUNCTION

1 Y1 18LG PARK LOCKOUT SOLENOID CONTROL

2 K4 18BK/LB SENSOR GROUND

3 Y5 18OR FAN SPEED

4- -

5 Y3 18WT SENSOR SUPPLY

6 F15 20DB FUSED IGNTION SWITCH OUTPUT (RUN)

WASHER FLUID LEVEL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Y137 20VT/LB EXCEPT 8.0L/DIESEL SENSOR GROUND

2 G29 20BK/TN WASHER FLUID SWITCH SENSE

2 Y137 20VT/LB 8.0L/DIESEL SENSOR GROUND

WASHER PUMP MOTOR-FRONT - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z216 20BK/VT GROUND

2 V10 20BR WASHER PUMP MOTOR CONTROL

WATER IN FUEL SENSOR (DIESEL)-2WAY

CAV CIRCUIT FUNCTION

1 K104 18RD/WT SENSOR GROUND

2 G20 18VT/YL IGNITION SWITCH SENSE

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 107

Page 1175 of 2895

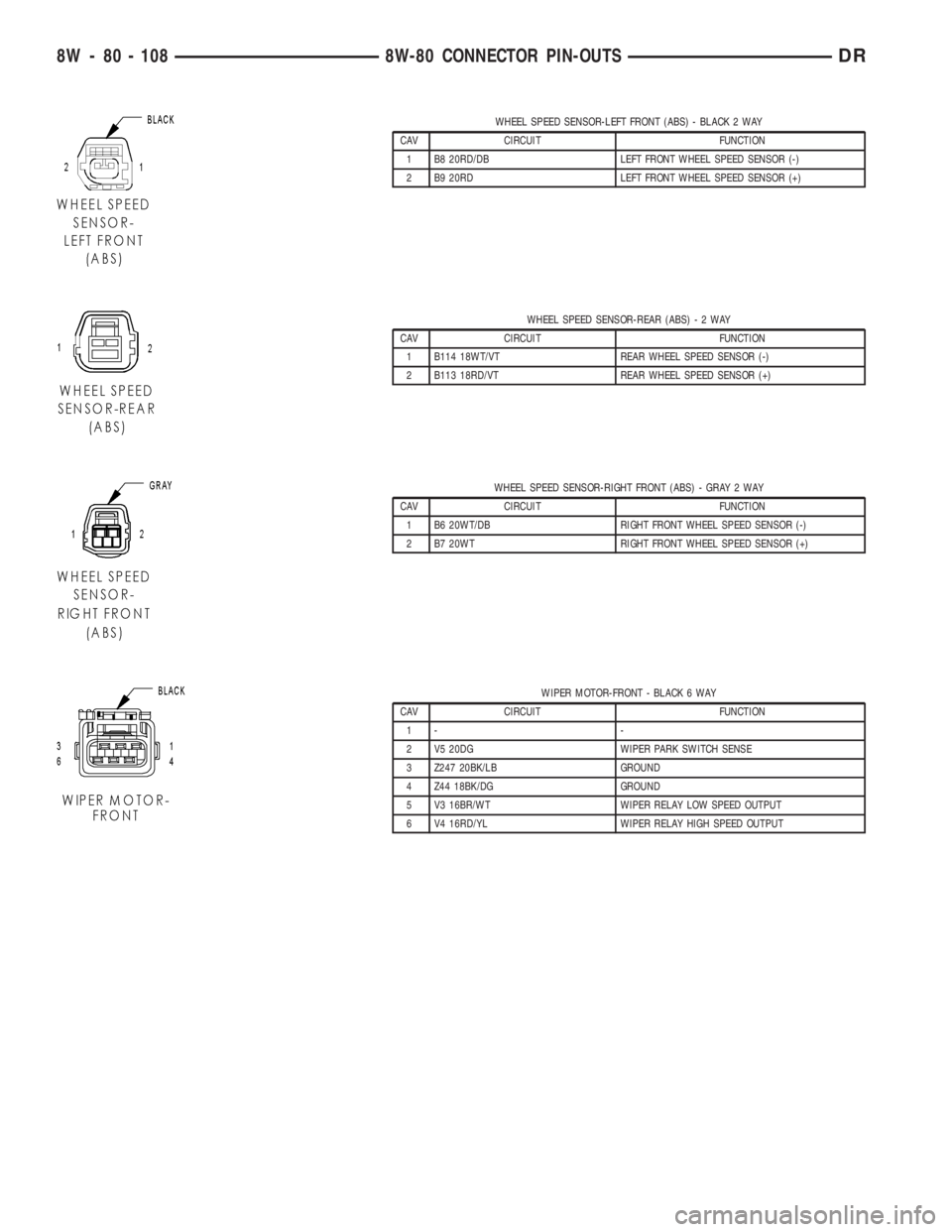

WHEEL SPEED SENSOR-LEFT FRONT (ABS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B8 20RD/DB LEFT FRONT WHEEL SPEED SENSOR (-)

2 B9 20RD LEFT FRONT WHEEL SPEED SENSOR (+)

WHEEL SPEED SENSOR-REAR (ABS)-2WAY

CAV CIRCUIT FUNCTION

1 B114 18WT/VT REAR WHEEL SPEED SENSOR (-)

2 B113 18RD/VT REAR WHEEL SPEED SENSOR (+)

WHEEL SPEED SENSOR-RIGHT FRONT (ABS) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 B6 20WT/DB RIGHT FRONT WHEEL SPEED SENSOR (-)

2 B7 20WT RIGHT FRONT WHEEL SPEED SENSOR (+)

WIPER MOTOR-FRONT - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 V5 20DG WIPER PARK SWITCH SENSE

3 Z247 20BK/LB GROUND

4 Z44 18BK/DG GROUND

5 V3 16BR/WT WIPER RELAY LOW SPEED OUTPUT

6 V4 16RD/YL WIPER RELAY HIGH SPEED OUTPUT

8W - 80 - 108 8W-80 CONNECTOR PIN-OUTSDR

Page 1177 of 2895

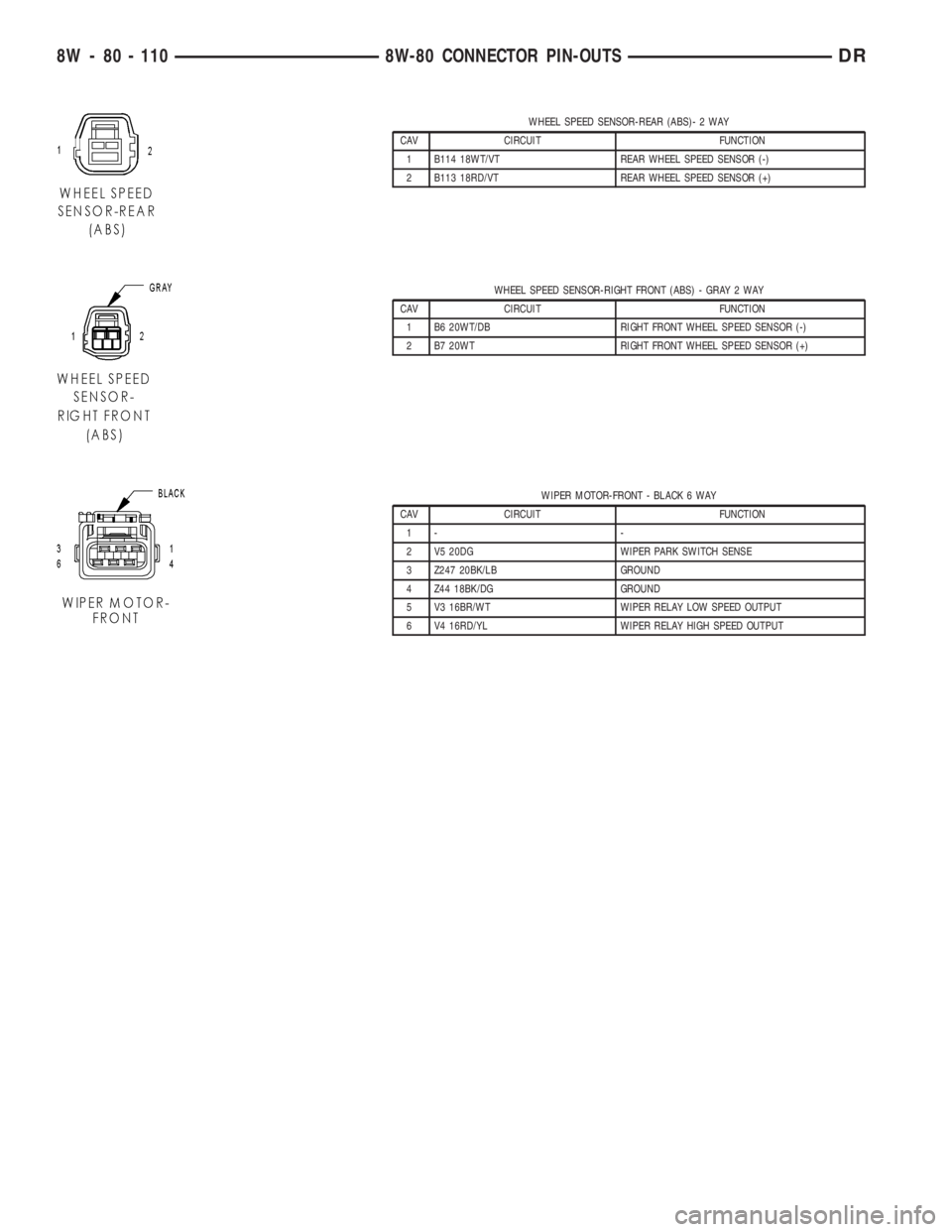

WHEEL SPEED SENSOR-REAR (ABS)- 2 WAY

CAV CIRCUIT FUNCTION

1 B114 18WT/VT REAR WHEEL SPEED SENSOR (-)

2 B113 18RD/VT REAR WHEEL SPEED SENSOR (+)

WHEEL SPEED SENSOR-RIGHT FRONT (ABS) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 B6 20WT/DB RIGHT FRONT WHEEL SPEED SENSOR (-)

2 B7 20WT RIGHT FRONT WHEEL SPEED SENSOR (+)

WIPER MOTOR-FRONT - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 V5 20DG WIPER PARK SWITCH SENSE

3 Z247 20BK/LB GROUND

4 Z44 18BK/DG GROUND

5 V3 16BR/WT WIPER RELAY LOW SPEED OUTPUT

6 V4 16RD/YL WIPER RELAY HIGH SPEED OUTPUT

8W - 80 - 110 8W-80 CONNECTOR PIN-OUTSDR

Page 1183 of 2895

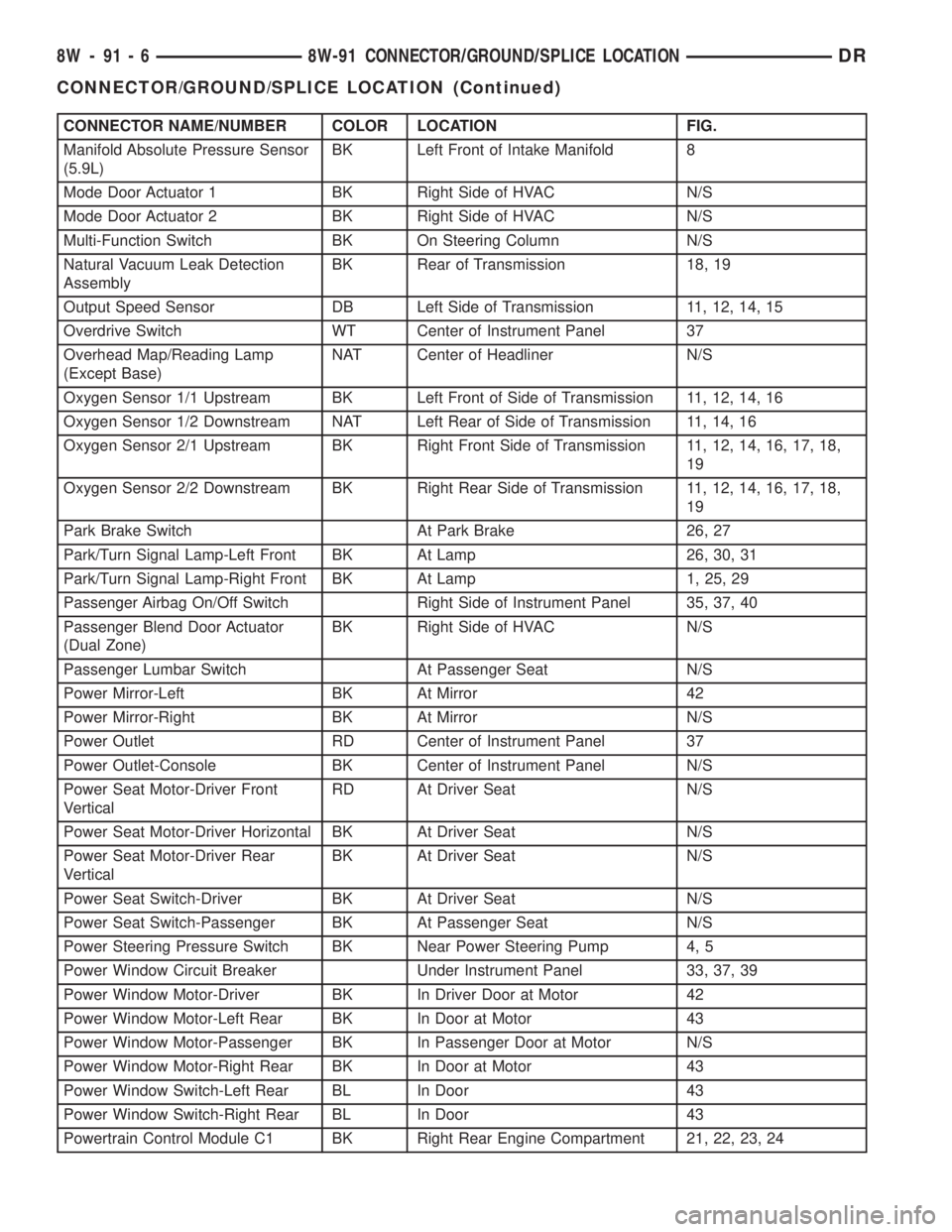

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Manifold Absolute Pressure Sensor

(5.9L)BK Left Front of Intake Manifold 8

Mode Door Actuator 1 BK Right Side of HVAC N/S

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column N/S

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 19

Output Speed Sensor DB Left Side of Transmission 11, 12, 14, 15

Overdrive Switch WT Center of Instrument Panel 37

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 11, 12, 14, 16

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 11, 14, 16

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 11, 12, 14, 16, 17, 18,

19

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 11, 12, 14, 16, 17, 18,

19

Park Brake Switch At Park Brake 26, 27

Park/Turn Signal Lamp-Left Front BK At Lamp 26, 30, 31

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 25, 29

Passenger Airbag On/Off Switch Right Side of Instrument Panel 35, 37, 40

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 42

Power Mirror-Right BK At Mirror N/S

Power Outlet RD Center of Instrument Panel 37

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 4, 5

Power Window Circuit Breaker Under Instrument Panel 33, 37, 39

Power Window Motor-Driver BK In Driver Door at Motor 42

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor N/S

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 21, 22, 23, 24

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1736 of 2895

(1) Install sensor to intake manifold. Tighten to

12±15 N´m (110±130 in. lbs.) torque.

(2) Install electrical connector.

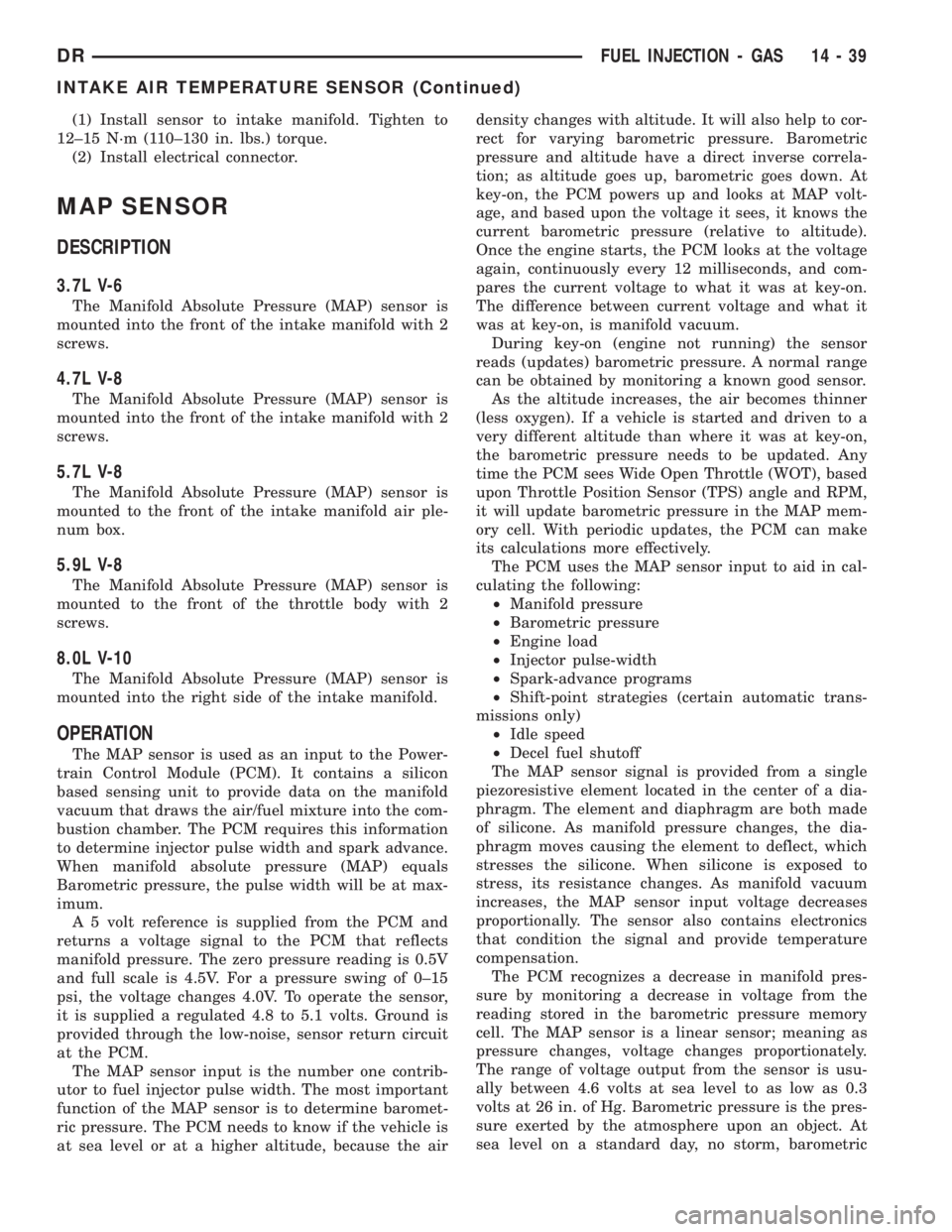

MAP SENSOR

DESCRIPTION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold with 2

screws.

4.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold with 2

screws.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the intake manifold air ple-

num box.

5.9L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the throttle body with 2

screws.

8.0L V-10

The Manifold Absolute Pressure (MAP) sensor is

mounted into the right side of the intake manifold.

OPERATION

The MAP sensor is used as an input to the Power-

train Control Module (PCM). It contains a silicon

based sensing unit to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When manifold absolute pressure (MAP) equals

Barometric pressure, the pulse width will be at max-

imum.

A 5 volt reference is supplied from the PCM and

returns a voltage signal to the PCM that reflects

manifold pressure. The zero pressure reading is 0.5V

and full scale is 4.5V. For a pressure swing of 0±15

psi, the voltage changes 4.0V. To operate the sensor,

it is supplied a regulated 4.8 to 5.1 volts. Ground is

provided through the low-noise, sensor return circuit

at the PCM.

The MAP sensor input is the number one contrib-

utor to fuel injector pulse width. The most important

function of the MAP sensor is to determine baromet-

ric pressure. The PCM needs to know if the vehicle is

at sea level or at a higher altitude, because the airdensity changes with altitude. It will also help to cor-

rect for varying barometric pressure. Barometric

pressure and altitude have a direct inverse correla-

tion; as altitude goes up, barometric goes down. At

key-on, the PCM powers up and looks at MAP volt-

age, and based upon the voltage it sees, it knows the

current barometric pressure (relative to altitude).

Once the engine starts, the PCM looks at the voltage

again, continuously every 12 milliseconds, and com-

pares the current voltage to what it was at key-on.

The difference between current voltage and what it

was at key-on, is manifold vacuum.

During key-on (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring a known good sensor.

As the altitude increases, the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key-on,

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open Throttle (WOT), based

upon Throttle Position Sensor (TPS) angle and RPM,

it will update barometric pressure in the MAP mem-

ory cell. With periodic updates, the PCM can make

its calculations more effectively.

The PCM uses the MAP sensor input to aid in cal-

culating the following:

²Manifold pressure

²Barometric pressure

²Engine load

²Injector pulse-width

²Spark-advance programs

²Shift-point strategies (certain automatic trans-

missions only)

²Idle speed

²Decel fuel shutoff

The MAP sensor signal is provided from a single

piezoresistive element located in the center of a dia-

phragm. The element and diaphragm are both made

of silicone. As manifold pressure changes, the dia-

phragm moves causing the element to deflect, which

stresses the silicone. When silicone is exposed to

stress, its resistance changes. As manifold vacuum

increases, the MAP sensor input voltage decreases

proportionally. The sensor also contains electronics

that condition the signal and provide temperature

compensation.

The PCM recognizes a decrease in manifold pres-

sure by monitoring a decrease in voltage from the

reading stored in the barometric pressure memory

cell. The MAP sensor is a linear sensor; meaning as

pressure changes, voltage changes proportionately.

The range of voltage output from the sensor is usu-

ally between 4.6 volts at sea level to as low as 0.3

volts at 26 in. of Hg. Barometric pressure is the pres-

sure exerted by the atmosphere upon an object. At

sea level on a standard day, no storm, barometric

DRFUEL INJECTION - GAS 14 - 39

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1740 of 2895

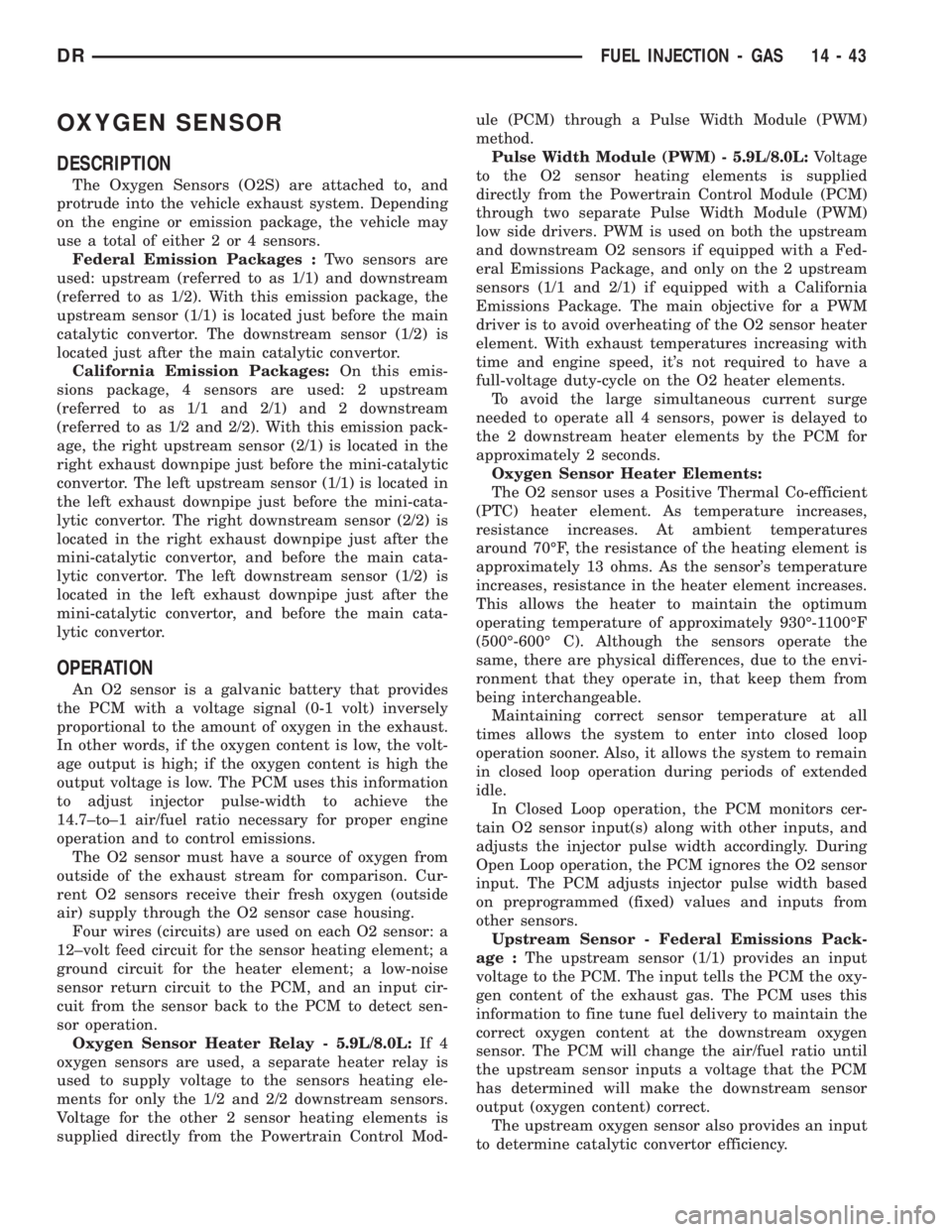

OXYGEN SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the engine or emission package, the vehicle may

use a total of either 2 or 4 sensors.

Federal Emission Packages :Two sensors are

used: upstream (referred to as 1/1) and downstream

(referred to as 1/2). With this emission package, the

upstream sensor (1/1) is located just before the main

catalytic convertor. The downstream sensor (1/2) is

located just after the main catalytic convertor.

California Emission Packages:On this emis-

sions package, 4 sensors are used: 2 upstream

(referred to as 1/1 and 2/1) and 2 downstream

(referred to as 1/2 and 2/2). With this emission pack-

age, the right upstream sensor (2/1) is located in the

right exhaust downpipe just before the mini-catalytic

convertor. The left upstream sensor (1/1) is located in

the left exhaust downpipe just before the mini-cata-

lytic convertor. The right downstream sensor (2/2) is

located in the right exhaust downpipe just after the

mini-catalytic convertor, and before the main cata-

lytic convertor. The left downstream sensor (1/2) is

located in the left exhaust downpipe just after the

mini-catalytic convertor, and before the main cata-

lytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the O2 sensor case housing.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heater Relay - 5.9L/8.0L:If 4

oxygen sensors are used, a separate heater relay is

used to supply voltage to the sensors heating ele-

ments for only the 1/2 and 2/2 downstream sensors.

Voltage for the other 2 sensor heating elements is

supplied directly from the Powertrain Control Mod-ule (PCM) through a Pulse Width Module (PWM)

method.

Pulse Width Module (PWM) - 5.9L/8.0L:Voltage

to the O2 sensor heating elements is supplied

directly from the Powertrain Control Module (PCM)

through two separate Pulse Width Module (PWM)

low side drivers. PWM is used on both the upstream

and downstream O2 sensors if equipped with a Fed-

eral Emissions Package, and only on the 2 upstream

sensors (1/1 and 2/1) if equipped with a California

Emissions Package. The main objective for a PWM

driver is to avoid overheating of the O2 sensor heater

element. With exhaust temperatures increasing with

time and engine speed, it's not required to have a

full-voltage duty-cycle on the O2 heater elements.

To avoid the large simultaneous current surge

needed to operate all 4 sensors, power is delayed to

the 2 downstream heater elements by the PCM for

approximately 2 seconds.

Oxygen Sensor Heater Elements:

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

around 70ÉF, the resistance of the heating element is

approximately 13 ohms. As the sensor's temperature

increases, resistance in the heater element increases.

This allows the heater to maintain the optimum

operating temperature of approximately 930É-1100ÉF

(500É-600É C). Although the sensors operate the

same, there are physical differences, due to the envi-

ronment that they operate in, that keep them from

being interchangeable.

Maintaining correct sensor temperature at all

times allows the system to enter into closed loop

operation sooner. Also, it allows the system to remain

in closed loop operation during periods of extended

idle.

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

on preprogrammed (fixed) values and inputs from

other sensors.

Upstream Sensor - Federal Emissions Pack-

age :The upstream sensor (1/1) provides an input

voltage to the PCM. The input tells the PCM the oxy-

gen content of the exhaust gas. The PCM uses this

information to fine tune fuel delivery to maintain the

correct oxygen content at the downstream oxygen

sensor. The PCM will change the air/fuel ratio until

the upstream sensor inputs a voltage that the PCM

has determined will make the downstream sensor

output (oxygen content) correct.

The upstream oxygen sensor also provides an input

to determine catalytic convertor efficiency.

DRFUEL INJECTION - GAS 14 - 43

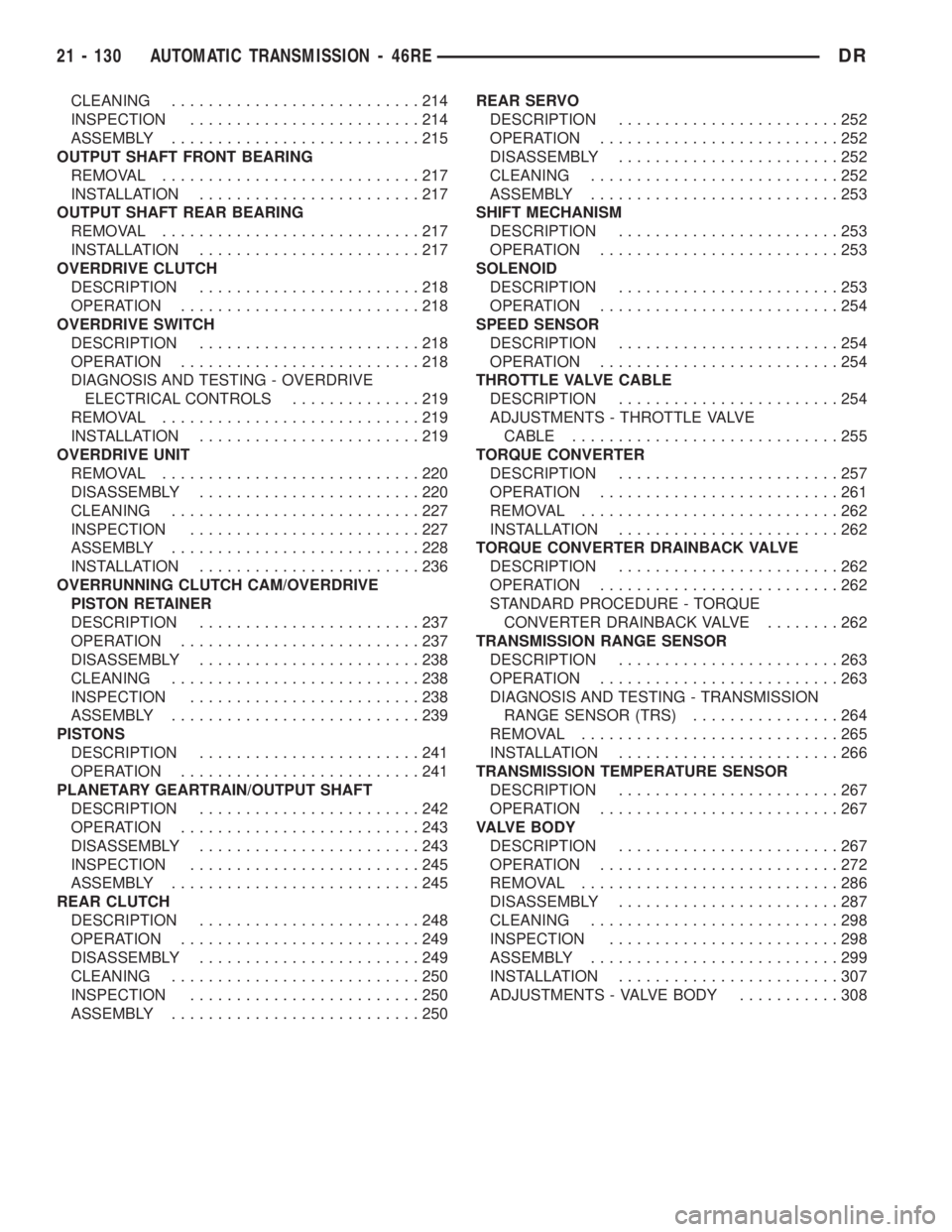

Page 1969 of 2895

CLEANING...........................214

INSPECTION.........................214

ASSEMBLY...........................215

OUTPUT SHAFT FRONT BEARING

REMOVAL............................217

INSTALLATION........................217

OUTPUT SHAFT REAR BEARING

REMOVAL............................217

INSTALLATION........................217

OVERDRIVE CLUTCH

DESCRIPTION........................218

OPERATION..........................218

OVERDRIVE SWITCH

DESCRIPTION........................218

OPERATION..........................218

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS..............219

REMOVAL............................219

INSTALLATION........................219

OVERDRIVE UNIT

REMOVAL............................220

DISASSEMBLY........................220

CLEANING...........................227

INSPECTION.........................227

ASSEMBLY...........................228

INSTALLATION........................236

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION........................237

OPERATION..........................237

DISASSEMBLY........................238

CLEANING...........................238

INSPECTION.........................238

ASSEMBLY...........................239

PISTONS

DESCRIPTION........................241

OPERATION..........................241

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION........................242

OPERATION..........................243

DISASSEMBLY........................243

INSPECTION.........................245

ASSEMBLY...........................245

REAR CLUTCH

DESCRIPTION........................248

OPERATION..........................249

DISASSEMBLY........................249

CLEANING...........................250

INSPECTION.........................250

ASSEMBLY...........................250REAR SERVO

DESCRIPTION........................252

OPERATION..........................252

DISASSEMBLY........................252

CLEANING...........................252

ASSEMBLY...........................253

SHIFT MECHANISM

DESCRIPTION........................253

OPERATION..........................253

SOLENOID

DESCRIPTION........................253

OPERATION..........................254

SPEED SENSOR

DESCRIPTION........................254

OPERATION..........................254

THROTTLE VALVE CABLE

DESCRIPTION........................254

ADJUSTMENTS - THROTTLE VALVE

CABLE.............................255

TORQUE CONVERTER

DESCRIPTION........................257

OPERATION..........................261

REMOVAL............................262

INSTALLATION........................262

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION........................262

OPERATION..........................262

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE........262

TRANSMISSION RANGE SENSOR

DESCRIPTION........................263

OPERATION..........................263

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS)................264

REMOVAL............................265

INSTALLATION........................266

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................267

OPERATION..........................267

VALVE BODY

DESCRIPTION........................267

OPERATION..........................272

REMOVAL............................286

DISASSEMBLY........................287

CLEANING...........................298

INSPECTION.........................298

ASSEMBLY...........................299

INSTALLATION........................307

ADJUSTMENTS - VALVE BODY...........308

21 - 130 AUTOMATIC TRANSMISSION - 46REDR

Page 1981 of 2895

Test Four - Transmission In Reverse

This test checks pump output, pressure regulation

and the front clutch and rear servo circuits. Use 300

psi Test Gauge C-3293-SP for this test.

(1) Leave vehicle on hoist and leave gauge C-3292

in place at accumulator port.

(2) Move 300 psi Gauge C-3293-SP back to rear

servo port.

(3) Have helper start and run engine at 1600 rpm

for test.

(4) Move transmission shift lever four detents

rearward from full forward position. This is Reverse

range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotat-

ing.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7) Compare results of pressure test with analysis

chart.Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

(1) Remove tachometer; it is not needed for this

test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 469-496 kPa (68-72 psi)

with closed throttle and increase to 620-827 kPa (90-

120 psi) at 1/2 to 3/4 throttle. Note that pressure can

increase to around 896 kPa (130 psi) at full throttle.

(9) Return to shop or move vehicle off chassis

dyno.

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during any

one testPump and regulator valve

OK

Line pressure OK in R but

low in D, 2, 1Leakage in rear clutch area

(seal rings, clutch seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball problem

Pressure OK in 1, 2 but low

in D3 and RLeakage in front clutch area

Pressure OK in 2 but low in

R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked servo

piston

Pressure low in all positions Clogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too high

at idle speedGovernor pressure solenoid

valve system fault. Refer to

diagnostic book.

Governor pressure low at all

mph figuresFaulty governor pressure

solenoid, transmission

control module, or governor

pressure sensor

Lubrication pressure low at

all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged, sticky

regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

21 - 142 AUTOMATIC TRANSMISSION - 46REDR

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2035 of 2895

(8) With shifter lever in the:

²PARK position - Apply upward force on the shift

arm and remove pressure. Engine starts must be

possible.

²PARK position - Apply downward force on the

shift arm and remove pressure. Engine starts must

be possible.

²NEUTRAL position - Normal position. Engine

starts must be possible.

²NEUTRAL position - Engine running and brakes

applied, apply upward force on the shift arm. Trans-

mission shall not be able to shift from neutral to

reverse.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

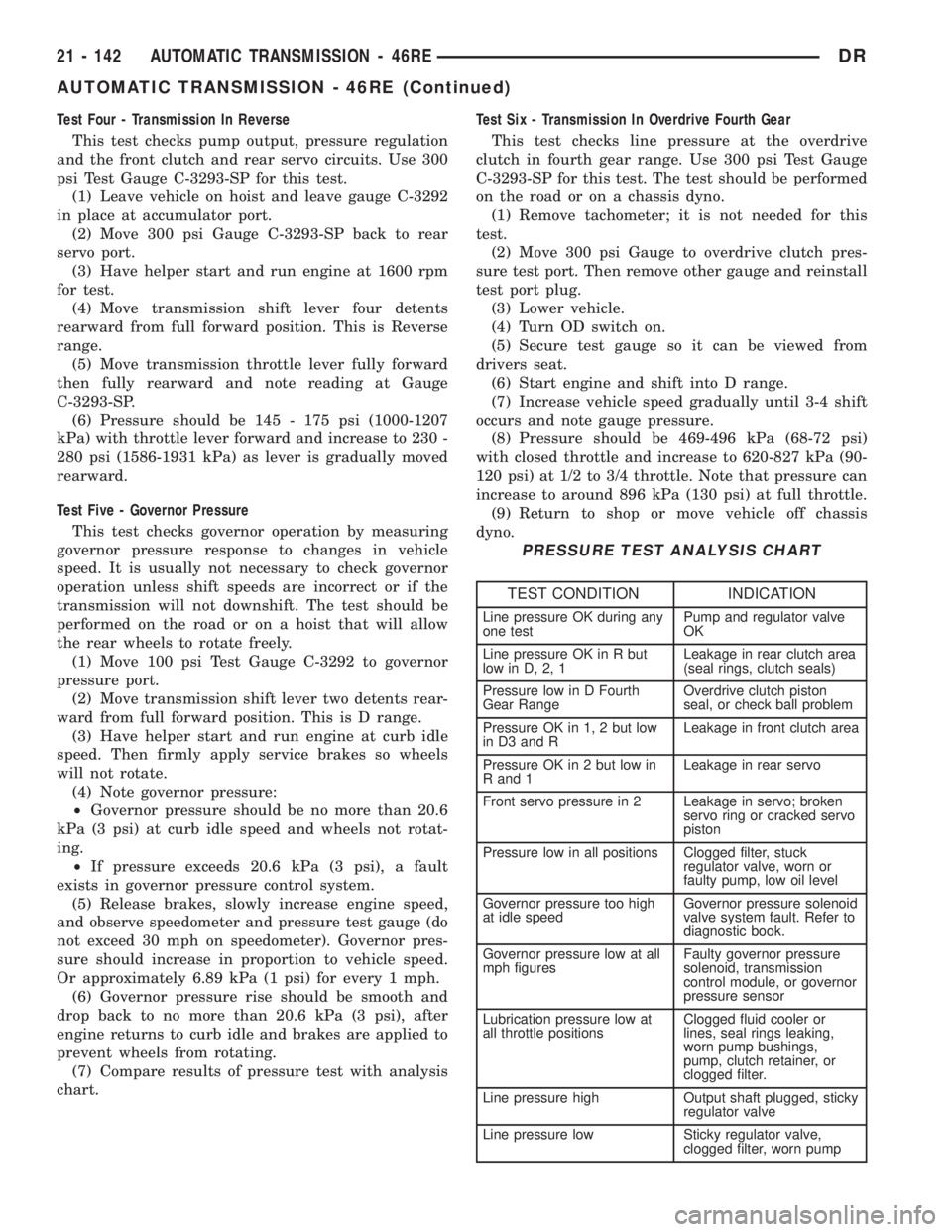

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 82).

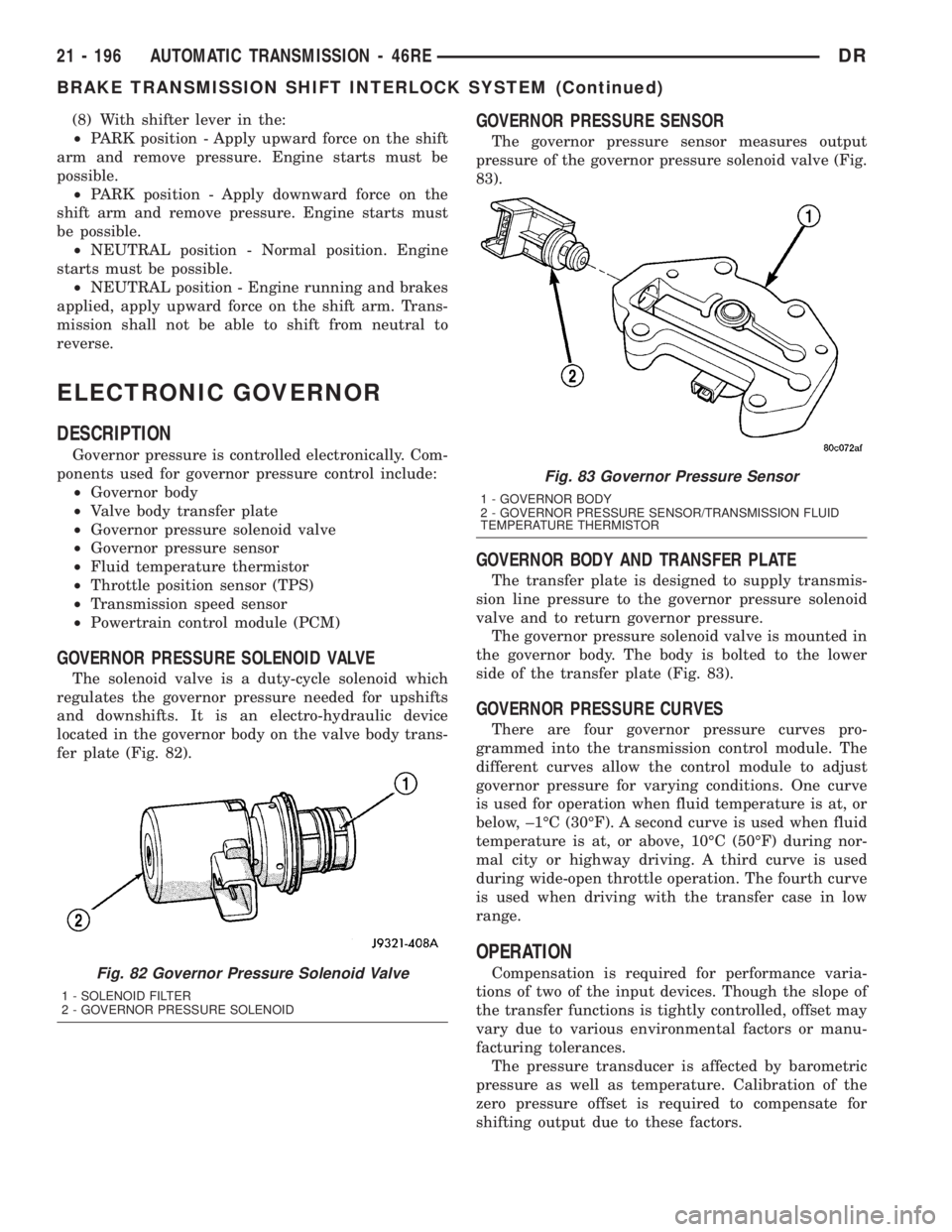

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

83).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 83).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.Fig. 82 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 83 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

21 - 196 AUTOMATIC TRANSMISSION - 46REDR

BRAKE TRANSMISSION SHIFT INTERLOCK SYSTEM (Continued)