brake light switch DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1805 of 2895

KEY CYLINDER

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal.

(1) Disconnect negative cable from battery.

(2) Remove upper and lower covers (shrouds) from

steering column.

(3) Place shifter in PARK position.

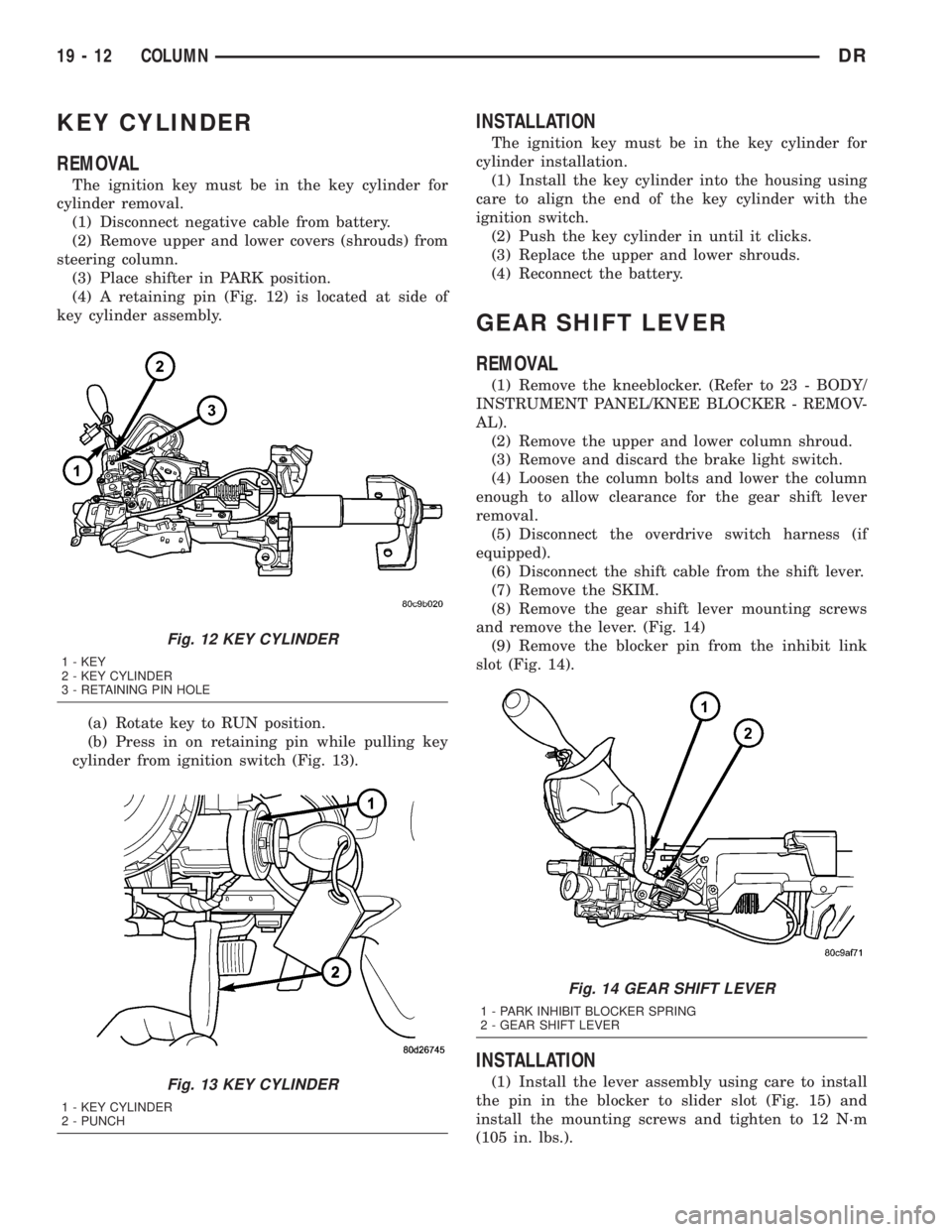

(4) A retaining pin (Fig. 12) is located at side of

key cylinder assembly.

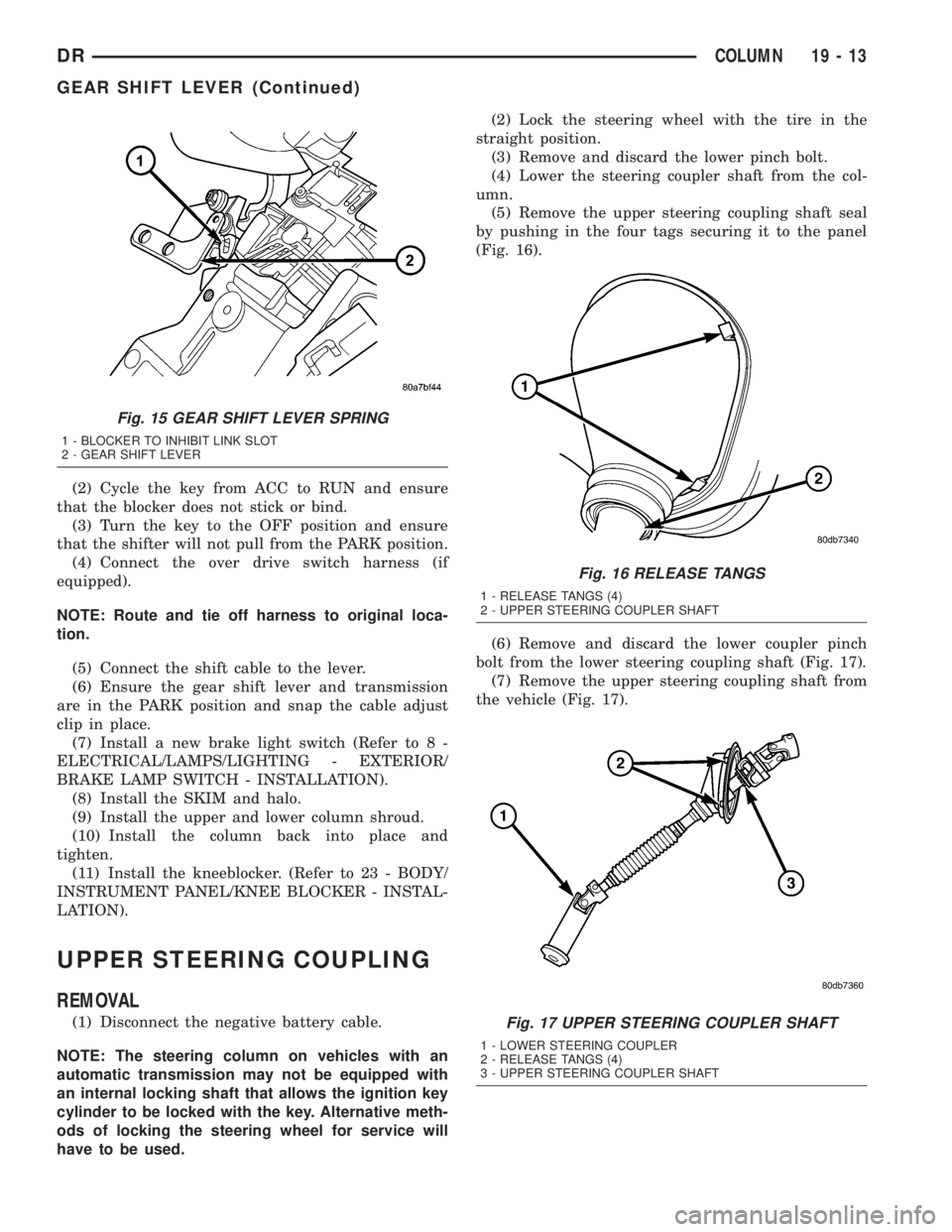

(a) Rotate key to RUN position.

(b) Press in on retaining pin while pulling key

cylinder from ignition switch (Fig. 13).

INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation.

(1) Install the key cylinder into the housing using

care to align the end of the key cylinder with the

ignition switch.

(2) Push the key cylinder in until it clicks.

(3) Replace the upper and lower shrouds.

(4) Reconnect the battery.

GEAR SHIFT LEVER

REMOVAL

(1) Remove the kneeblocker. (Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - REMOV-

AL).

(2) Remove the upper and lower column shroud.

(3) Remove and discard the brake light switch.

(4) Loosen the column bolts and lower the column

enough to allow clearance for the gear shift lever

removal.

(5) Disconnect the overdrive switch harness (if

equipped).

(6) Disconnect the shift cable from the shift lever.

(7) Remove the SKIM.

(8) Remove the gear shift lever mounting screws

and remove the lever. (Fig. 14)

(9) Remove the blocker pin from the inhibit link

slot (Fig. 14).

INSTALLATION

(1) Install the lever assembly using care to install

the pin in the blocker to slider slot (Fig. 15) and

install the mounting screws and tighten to 12 N´m

(105 in. lbs.).

Fig. 12 KEY CYLINDER

1 - KEY

2 - KEY CYLINDER

3 - RETAINING PIN HOLE

Fig. 13 KEY CYLINDER

1 - KEY CYLINDER

2 - PUNCH

Fig. 14 GEAR SHIFT LEVER

1 - PARK INHIBIT BLOCKER SPRING

2 - GEAR SHIFT LEVER

19 - 12 COLUMNDR

Page 1806 of 2895

(2) Cycle the key from ACC to RUN and ensure

that the blocker does not stick or bind.

(3) Turn the key to the OFF position and ensure

that the shifter will not pull from the PARK position.

(4) Connect the over drive switch harness (if

equipped).

NOTE: Route and tie off harness to original loca-

tion.

(5) Connect the shift cable to the lever.

(6) Ensure the gear shift lever and transmission

are in the PARK position and snap the cable adjust

clip in place.

(7) Install a new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION).

(8) Install the SKIM and halo.

(9) Install the upper and lower column shroud.

(10) Install the column back into place and

tighten.

(11) Install the kneeblocker. (Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

UPPER STEERING COUPLING

REMOVAL

(1) Disconnect the negative battery cable.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.(2) Lock the steering wheel with the tire in the

straight position.

(3) Remove and discard the lower pinch bolt.

(4) Lower the steering coupler shaft from the col-

umn.

(5) Remove the upper steering coupling shaft seal

by pushing in the four tags securing it to the panel

(Fig. 16).

(6) Remove and discard the lower coupler pinch

bolt from the lower steering coupling shaft (Fig. 17).

(7) Remove the upper steering coupling shaft from

the vehicle (Fig. 17).

Fig. 15 GEAR SHIFT LEVER SPRING

1 - BLOCKER TO INHIBIT LINK SLOT

2 - GEAR SHIFT LEVER

Fig. 16 RELEASE TANGS

1 - RELEASE TANGS (4)

2 - UPPER STEERING COUPLER SHAFT

Fig. 17 UPPER STEERING COUPLER SHAFT

1 - LOWER STEERING COUPLER

2 - RELEASE TANGS (4)

3 - UPPER STEERING COUPLER SHAFT

DRCOLUMN 19 - 13

GEAR SHIFT LEVER (Continued)

Page 2632 of 2895

(11) Install the right a-pillar trim panel. (Refer to

23 - BODY/INTERIOR/A-PILLAR TRIM - INSTAL-

LATION)

(12) Position the right end cap and seat the

attachment clips fully.

(13) Install the one HVAC mounting screw.

(14) Connect the radio antenna.

(15) Connect the two electrical connectors at the

right cowl panel.

(16) Install the right cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(17) Connect the air bag control module electrical

connector.

(18) Install the center bracket bolts and tighten to

12 N´m (9 ft. lbs.).

(19) Install the floor console, if equipped. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE - INSTAL-

LATION)

(20) Install the air bag control module cover, if

equipped.

(21) Connect the park brake release handle actua-

tor rod.

(22) Install the hood release handle and tighten

the screws.

(23) Install the two bolts at the column support

bracket and tighten to 14 N´m (10 ft. lbs.).

(24) Install the steering column. (Refer to 19 -

STEERING/COLUMN - INSTALLATION)

(25) Connect the wire harness electrical connectors

above the brake pedal.

(26) Install the two top instrument panel bolts and

tighten to 12 N´m (9 ft. lbs.).

(27) Install the four top instrument panel screws.

(28) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

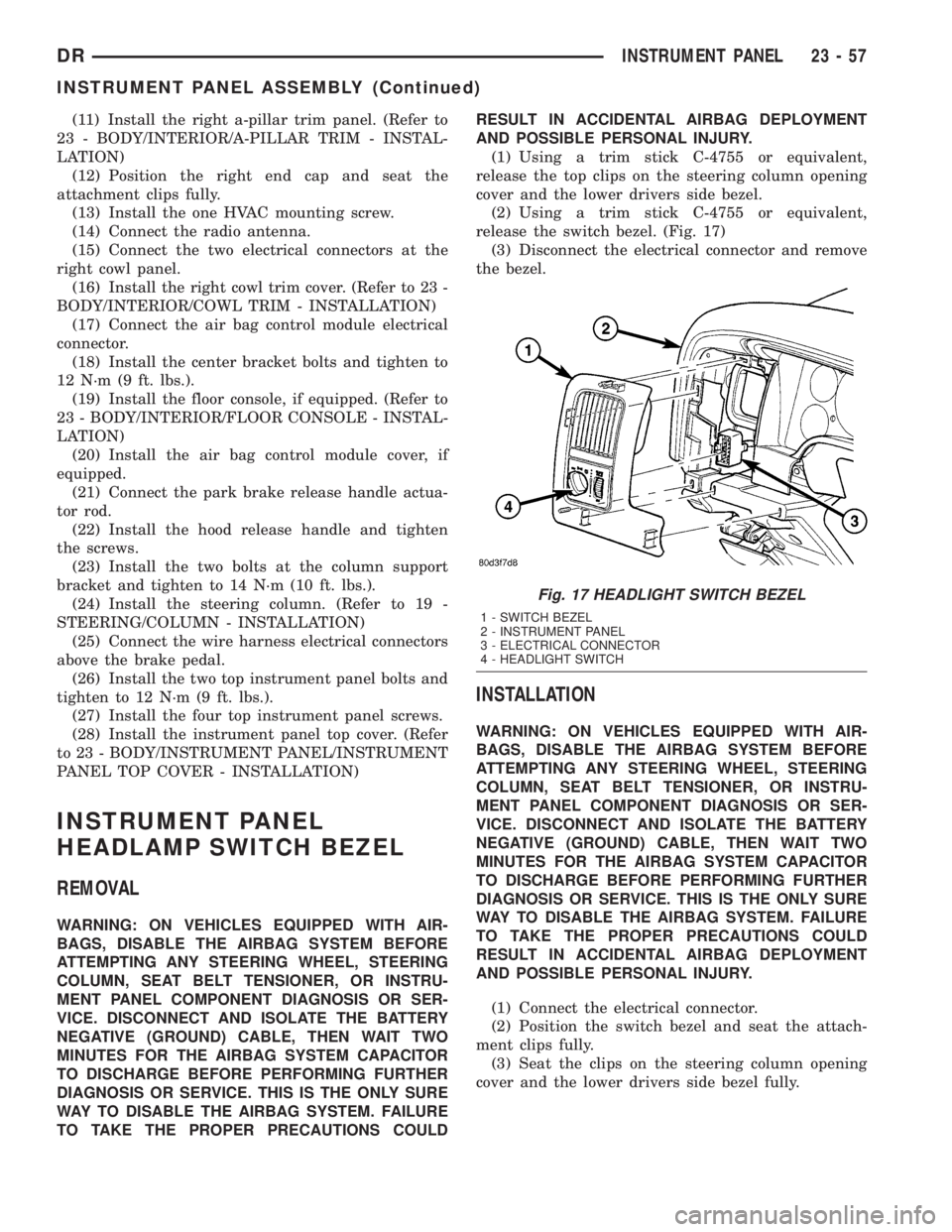

INSTRUMENT PANEL

HEADLAMP SWITCH BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Using a trim stick C-4755 or equivalent,

release the top clips on the steering column opening

cover and the lower drivers side bezel.

(2) Using a trim stick C-4755 or equivalent,

release the switch bezel. (Fig. 17)

(3) Disconnect the electrical connector and remove

the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Connect the electrical connector.

(2) Position the switch bezel and seat the attach-

ment clips fully.

(3) Seat the clips on the steering column opening

cover and the lower drivers side bezel fully.

Fig. 17 HEADLIGHT SWITCH BEZEL

1 - SWITCH BEZEL

2 - INSTRUMENT PANEL

3 - ELECTRICAL CONNECTOR

4 - HEADLIGHT SWITCH

DRINSTRUMENT PANEL 23 - 57

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2868 of 2895

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

ETC INDICATOR - DESCRIPTION.........8J-24

ETC INDICATOR - OPERATION..........8J-25

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM..........24-35,24-51

EVAP SYSTEM - DESCRIPTION..........25-10

EVAP SYSTEM - TORQUE..............25-12

EVAPORATOR - DESCRIPTION, A/C.......24-47

EVAPORATOR - INSTALLATION, A/C......24-47

EVAPORATOR - OPERATION, A/C........24-47

EVAPORATOR - REMOVAL, A/C..........24-47

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-12

EVAP/PURGE SOLENOID - INSTALLATION . 25-13

EVAP/PURGE SOLENOID - OPERATION....25-12

EVAP/PURGE SOLENOID - REMOVAL.....25-13

EXCEPT 4X4 HD - INSTALLATION, ALL

LD & HD ...........................19-15

EXCEPT 4X4 HD - REMOVAL, ALL LD &

HD................................19-14

EXCEPT DIESEL - INSTALLATION........14-22

EXCEPT DIESEL - REMOVAL............14-20

EXCEPT HYDROBOOST - INSTALLATION,

ALL ................................5-22

EXCEPT HYDROBOOST - REMOVAL, ALL . . . 5-21

EXCEPT V-10 OR DIESEL ENGINE -

INSTALLATION......................8R-17

EXCEPT V-10 OR DIESEL ENGINE -

REMOVAL............................8R-16

EXHAUST MANIFOLD - CLEANING . . 9-161,9-220,

9-277,9-347,9-404

EXHAUST MANIFOLD - DESCRIPTION....9-159,

9-220,9-277,9-403,9-73

EXHAUST MANIFOLD - INSPECTION.....9-161,

9-220,9-277,9-347,9-404

EXHAUST MANIFOLD - INSTALLATION . . . 9-162,

9-220,9-277,9-347,9-404,9-74

EXHAUST MANIFOLD - OPERATION . 9-220,9-277,

9-403

EXHAUST MANIFOLD - REMOVAL . . 9-159,9-220,

9-277,9-347,9-404,9-73

EXHAUST PIPE - INSPECTION...........11-7

EXHAUST PIPE - INSTALLATION..........11-7

EXHAUST PIPE - REMOVAL.............11-7

EXTENSION HOUSING BUSHING -

INSTALLATION......................21-200

EXTENSION HOUSING BUSHING -

REMOVAL.........................21-200

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION..........21-616,21-682

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL.............21-616,21-682

EXTENSION HOUSING SEAL -

INSTALLATION.....21-127,21-200,21-380,21-83

EXTENSION HOUSING SEAL - REMOVAL . 21-127,

21-200,21-380,21-83

EXTENSION HOUSING SEAL AND DUST

BOOT - INSTALLATION.........21-652,21-716

EXTENSION HOUSING SEAL AND DUST

BOOT - REMOVAL.............21-652,21-716

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-3

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR HANDLE - INSTALLATION.....23-20,

23-30

EXTERIOR HANDLE - REMOVAL

....23-20,23-30

EXTERIOR LAMPS, SPECIFICATIONS

......8L-7

EXTERIOR NAME PLATES -

INSTALLATION

.......................23-38

EXTERIOR NAME PLATES - REMOVAL

....23-38

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET

....9-194,9-243,9-370

FAN - 5.9L DIESEL - CLEANING,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR

...........................7-41

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR

...........................7-41

FAN - CLEANING, RADIATOR

............7-40

FAN - INSPECTION, RADIATOR

...........7-40

FAN - INSTALLATION, RADIATOR

.........7-40

FAN - REMOVAL, RADIATOR

.............7-39FAN DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICLY CONTOLLED VISCOUS.....7-56

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-54

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-55

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-55

FAN DRIVE VISCOUS CLUTCH -

DESCRIPTION........................7-54

FAN DRIVE VISCOUS CLUTCH -

OPERATION..........................7-54

FAN (GAS ENGINE ONLY - 3.7, 4.7 &

5.7L) - INSTALLATION, CONDENSER.....24-43

FAN (GAS ENGINE ONLY - 3.7, 4.7 &

5.7L) - REMOVAL, CONDENSER.........24-43

FASCIA - INSTALLATION, FRONT.........13-3

FASCIA - REMOVAL, FRONT.............13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-6

FASTENER USAGE - DESCRIPTION......Intro.-9

FENDER - INSTALLATION, FRONT........23-39

FENDER - INSTALLATION, REAR.........23-44

FENDER - REMOVAL, FRONT...........23-39

FENDER - REMOVAL, REAR............23-44

FENDER RAIL REPAIR - STANDARD

PROCEDURE, HYDROFORM............13-12

FILL - STANDARD PROCEDURE,

TRANSMISSION.........21-203,21-383,21-544

FILL DOOR - INSTALLATION, FUEL.......23-39

FILL DOOR - REMOVAL, FUEL............23-39

FILLER CAP - DESCRIPTION, FUEL.......25-13

FILLER CAP - OPERATION, FUEL........25-13

FILTER - INSTALLATION, INLET..........14-23

FILTER - INSTALLATION, OIL . 9-153,9-217,9-270,

9-342,9-397,9-70

FILTER - REMOVAL, INLET.............14-23

FILTER - REMOVAL, OIL.....9-152,9-216,9-270,

9-342,9-397,9-69

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-57

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-61

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-62

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-61

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-61

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID.....21-203,21-383,21-542

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-6

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-6

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION............23-75

FINISH - DESCRIPTION, BASECOAT/

CLEARCOAT.........................23-74

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, 5.9L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-60

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING . 9-128,9-251,9-382

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING..........9-253

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-133,9-202

FITTING - STANDARD PROCEDURE,

PISTON.........9-137,9-205,9-260,9-389,9-50

FITTING - STANDARD PROCEDURE,

PISTON RING....9-140,9-207,9-262,9-333,9-52

FITTING CRANKSHAFT MAIN BEARINGS

- STANDARD PROCEDURE

.............9-383

FITTING PISTON RINGS - STANDARD

PROCEDURE

........................9-390

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING

............9-48

FITTING, STANDARD PROCEDURE -

MAIN BEARING

.......................9-43

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT

......................14-8FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-48

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-7

FLARING - STANDARD PROCEDURE, ISO....5-7

FLEX PLATE - INSTALLATION . . 9-137,9-205,9-47

FLEX PLATE - REMOVAL......9-137,9-205,9-47

FLOOR - DEFROST DOOR -

INSTALLATION.......................24-30

FLOOR - DEFROST DOOR - REMOVAL....24-30

FLOOR - DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-20

FLOOR - DEFROST DOOR ACTUATOR -

REMOVAL..........................24-19

FLOOR - INSTALLATION, LOAD..........23-73

FLOOR - REMOVAL, LOAD.............23-73

FLOOR CONSOLE - INSTALLATION.......23-68

FLOOR CONSOLE - REMOVAL...........23-68

FLOOR DISTRIBUTION DUCTS -

INSTALLATION.......................24-27

FLOOR DISTRIBUTION DUCTS -

REMOVAL..........................24-27

FLOOR MATS - INSTALLATION, CARPETS . 23-66

FLOOR MATS - REMOVAL, CARPETS.....23-66

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-64

FLOOR SHIFT BOOT - REMOVAL, 4WD.....23-63

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-73

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-73

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-2

FLOW - 5.9L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-57,7-59

FLOW 3.7L/4.7L ENGINE - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-42

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT......21-201,21-381,21-541

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE . . 21-203,21-383,21-542

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING..........21-201,21-381,21-541

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-18

FLUID COOLER - INSTALLATION.........19-42

FLUID COOLER - REMOVAL............19-42

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-617,21-652,21-682,21-716

FLUID INDICATOR - DESCRIPTION,

WASHER...........................8J-42

FLUID INDICATOR - OPERATION,

WASHER...........................8J-42

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING . . . 21-143,21-324,21-495

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT.....21-201,

21-381,21-541

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE..............................5-18

FLUID LEVEL CHECK - STANDARD

PROCEDURE...........21-201,21-381,21-542

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-42

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER

............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER

...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER

............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER

...........................8R-10

FLUID RESERVOIR - INSTALLATION

.......5-19

DRINDEX 13

Description Group-Page Description Group-Page Description Group-Page

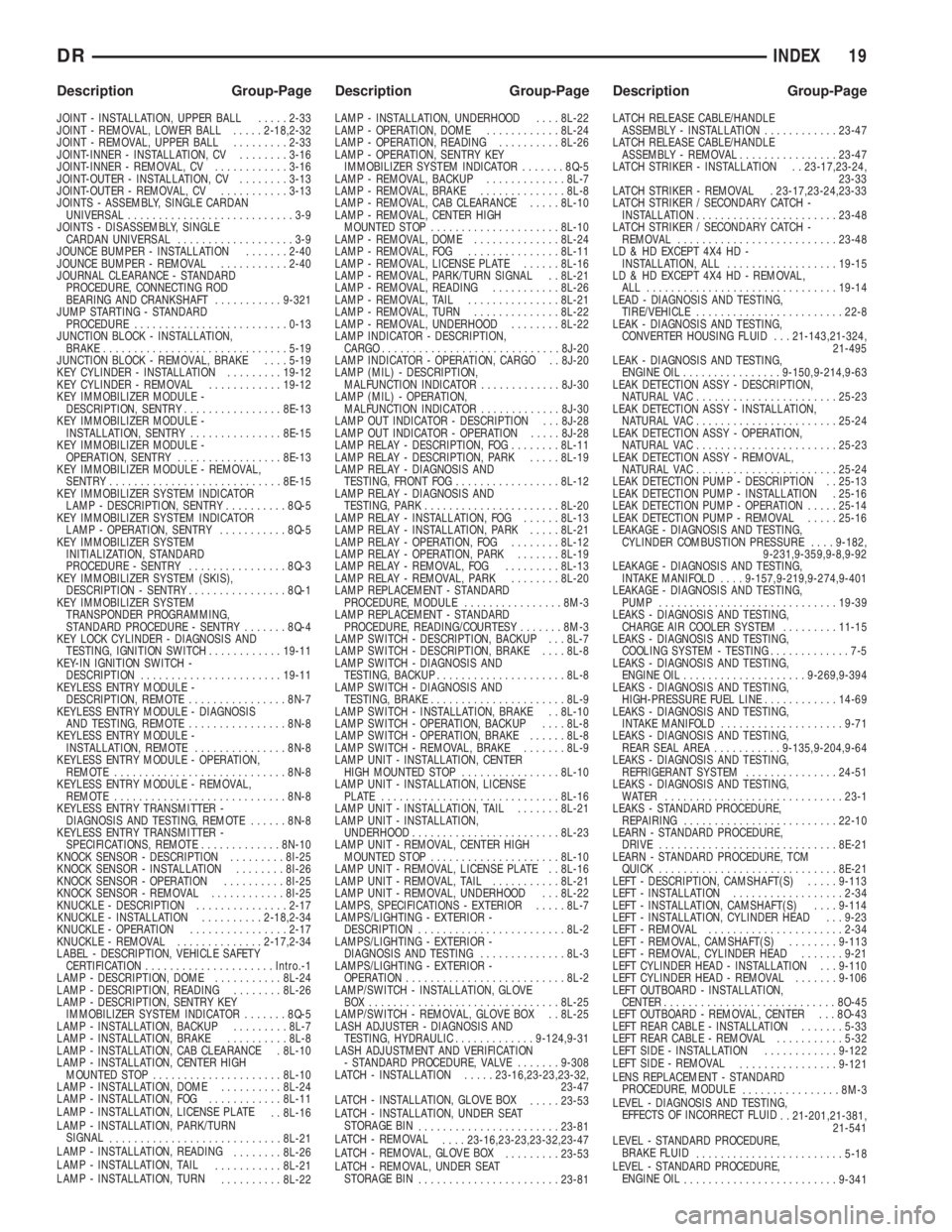

Page 2874 of 2895

JOINT - INSTALLATION, UPPER BALL.....2-33

JOINT - REMOVAL, LOWER BALL.....2-18,2-32

JOINT - REMOVAL, UPPER BALL.........2-33

JOINT-INNER - INSTALLATION, CV........3-16

JOINT-INNER - REMOVAL, CV............3-16

JOINT-OUTER - INSTALLATION, CV........3-13

JOINT-OUTER - REMOVAL, CV...........3-13

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-9

JOUNCE BUMPER - INSTALLATION.......2-40

JOUNCE BUMPER - REMOVAL...........2-40

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-321

JUMP STARTING - STANDARD

PROCEDURE.........................0-13

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-19

JUNCTION BLOCK - REMOVAL, BRAKE....5-19

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS),

DESCRIPTION - SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-8

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-8

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-8

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE.............8N-10

KNOCK SENSOR - DESCRIPTION.........8I-25

KNOCK SENSOR - INSTALLATION........8I-26

KNOCK SENSOR - OPERATION..........8I-25

KNOCK SENSOR - REMOVAL............8I-25

KNUCKLE - DESCRIPTION...............2-17

KNUCKLE - INSTALLATION..........2-18,2-34

KNUCKLE - OPERATION................2-17

KNUCKLE - REMOVAL..............2-17,2-34

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-1

LAMP - DESCRIPTION, DOME...........8L-24

LAMP - DESCRIPTION, READING........8L-26

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, BACKUP.........8L-7

LAMP - INSTALLATION, BRAKE..........8L-8

LAMP - INSTALLATION, CAB CLEARANCE . 8L-10

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - INSTALLATION, DOME..........8L-24

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-16

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-26

LAMP - INSTALLATION, TAIL

...........8L-21

LAMP - INSTALLATION, TURN

..........8L-22LAMP - INSTALLATION, UNDERHOOD....8L-22

LAMP - OPERATION, DOME............8L-24

LAMP - OPERATION, READING..........8L-26

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, BACKUP.............8L-7

LAMP - REMOVAL, BRAKE..............8L-8

LAMP - REMOVAL, CAB CLEARANCE.....8L-10

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP - REMOVAL, DOME..............8L-24

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-16

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-26

LAMP - REMOVAL, TAIL...............8L-21

LAMP - REMOVAL, TURN..............8L-22

LAMP - REMOVAL, UNDERHOOD........8L-22

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-30

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-30

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-28

LAMP OUT INDICATOR - OPERATION.....8J-28

LAMP RELAY - DESCRIPTION, FOG........8L-11

LAMP RELAY - DESCRIPTION, PARK.....8L-19

LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT FOG.................8L-12

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-12

LAMP RELAY - OPERATION, PARK.......8L-19

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-20

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-7

LAMP SWITCH - DESCRIPTION, BRAKE....8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-9

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-10

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-8

LAMP SWITCH - REMOVAL, BRAKE.......8L-9

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-10

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-16

LAMP UNIT - INSTALLATION, TAIL.......8L-21

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-23

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-10

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-16

LAMP UNIT - REMOVAL, TAIL...........8L-21

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-22

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-25

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-25

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-124,9-31

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-308

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX

.....23-53

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN

.......................23-81

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-53

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-81LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL................23-47

LATCH STRIKER - INSTALLATION . . 23-17,23-24,

23-33

LATCH STRIKER - REMOVAL . 23-17,23-24,23-33

LATCH STRIKER / SECONDARY CATCH -

INSTALLATION.......................23-48

LATCH STRIKER / SECONDARY CATCH -

REMOVAL..........................23-48

LD & HD EXCEPT 4X4 HD -

INSTALLATION, ALL..................19-15

LD & HD EXCEPT 4X4 HD - REMOVAL,

ALL ...............................19-14

LEAD - DIAGNOSIS AND TESTING,

TIRE/VEHICLE........................22-8

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID . . . 21-143,21-324,

21-495

LEAK - DIAGNOSIS AND TESTING,

ENGINE OIL................9-150,9-214,9-63

LEAK DETECTION ASSY - DESCRIPTION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - INSTALLATION,

NATURAL VAC.......................25-24

LEAK DETECTION ASSY - OPERATION,

NATURAL VAC.......................25-23

LEAK DETECTION ASSY - REMOVAL,

NATURAL VAC.......................25-24

LEAK DETECTION PUMP - DESCRIPTION . . 25-13

LEAK DETECTION PUMP - INSTALLATION . 25-16

LEAK DETECTION PUMP - OPERATION.....25-14

LEAK DETECTION PUMP - REMOVAL.....25-16

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE....9-182,

9-231,9-359,9-8,9-92

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....9-157,9-219,9-274,9-401

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-39

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM.........11-15

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM - TESTING.............7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL....................9-269,9-394

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-69

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD....................9-71

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA...........9-135,9-204,9-64

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-51

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-1

LEAKS - STANDARD PROCEDURE,

REPAIRING.........................22-10

LEARN - STANDARD PROCEDURE,

DRIVE.............................8E-21

LEARN - STANDARD PROCEDURE, TCM

QUICK.............................8E-21

LEFT - DESCRIPTION, CAMSHAFT(S).....9-113

LEFT - INSTALLATION..................2-34

LEFT - INSTALLATION, CAMSHAFT(S)....9-114

LEFT - INSTALLATION, CYLINDER HEAD . . . 9-23

LEFT - REMOVAL......................2-34

LEFT - REMOVAL, CAMSHAFT(S)........9-113

LEFT - REMOVAL, CYLINDER HEAD.......9-21

LEFT CYLINDER HEAD - INSTALLATION . . . 9-110

LEFT CYLINDER HEAD - REMOVAL.......9-106

LEFT OUTBOARD - INSTALLATION,

CENTER............................8O-45

LEFT OUTBOARD - REMOVAL, CENTER . . . 8O-43

LEFT REAR CABLE - INSTALLATION.......5-33

LEFT REAR CABLE - REMOVAL...........5-32

LEFT SIDE - INSTALLATION............9-122

LEFT SIDE - REMOVAL

................9-121

LENS REPLACEMENT - STANDARD

PROCEDURE, MODULE

................8M-3

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID

. . 21-201,21-381,

21-541

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID

........................5-18

LEVEL - STANDARD PROCEDURE,

ENGINE OIL

.........................9-341

DRINDEX 19

Description Group-Page Description Group-Page Description Group-Page

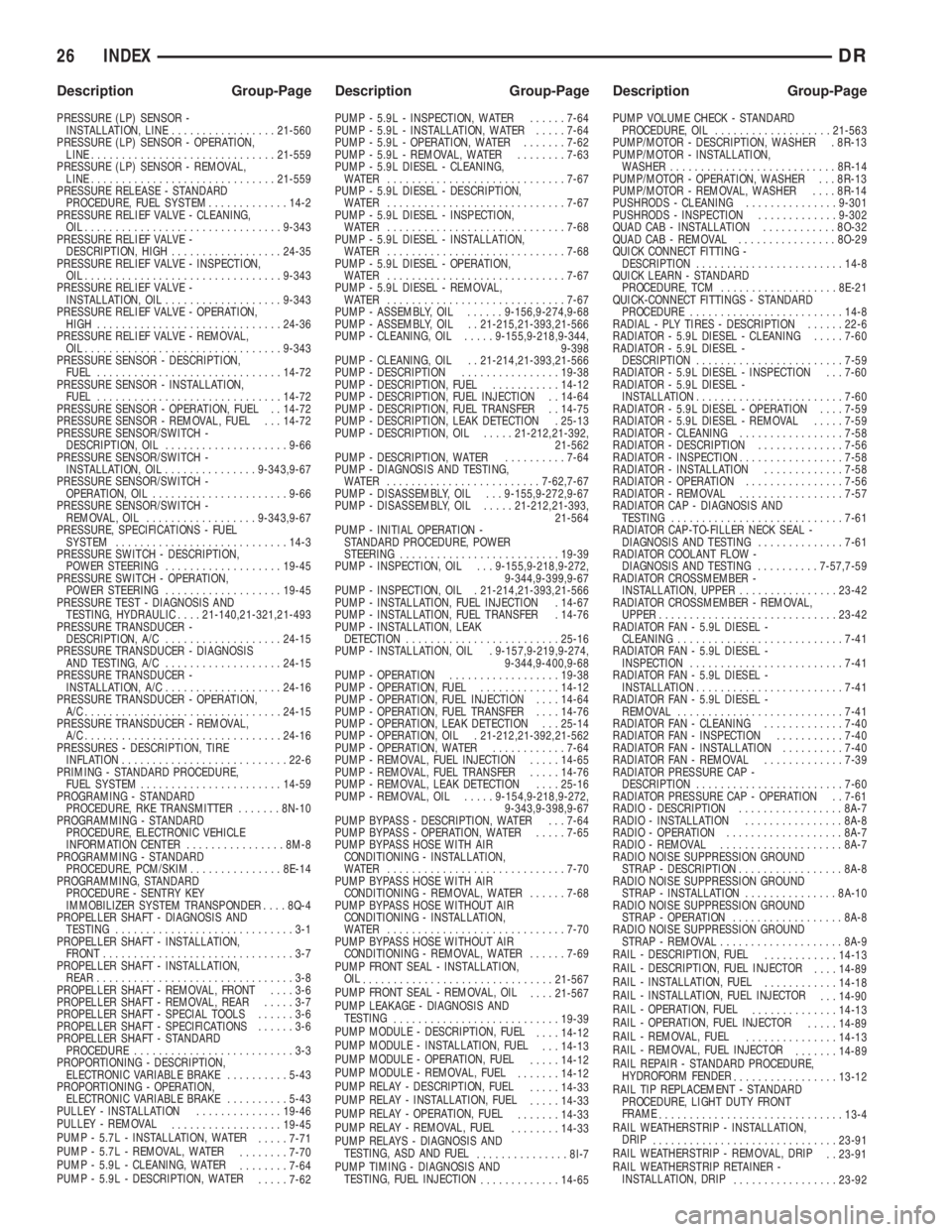

Page 2881 of 2895

PRESSURE (LP) SENSOR -

INSTALLATION, LINE.................21-560

PRESSURE (LP) SENSOR - OPERATION,

LINE..............................21-559

PRESSURE (LP) SENSOR - REMOVAL,

LINE..............................21-559

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-2

PRESSURE RELIEF VALVE - CLEANING,

OIL................................9-343

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH..................24-35

PRESSURE RELIEF VALVE - INSPECTION,

OIL................................9-343

PRESSURE RELIEF VALVE -

INSTALLATION, OIL...................9-343

PRESSURE RELIEF VALVE - OPERATION,

HIGH..............................24-36

PRESSURE RELIEF VALVE - REMOVAL,

OIL................................9-343

PRESSURE SENSOR - DESCRIPTION,

FUEL..............................14-72

PRESSURE SENSOR - INSTALLATION,

FUEL..............................14-72

PRESSURE SENSOR - OPERATION, FUEL . . 14-72

PRESSURE SENSOR - REMOVAL, FUEL . . . 14-72

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-66

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL...............9-343,9-67

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-66

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL..................9-343,9-67

PRESSURE, SPECIFICATIONS - FUEL

SYSTEM............................14-3

PRESSURE SWITCH - DESCRIPTION,

POWER STEERING...................19-45

PRESSURE SWITCH - OPERATION,

POWER STEERING...................19-45

PRESSURE TEST - DIAGNOSIS AND

TESTING, HYDRAULIC....21-140,21-321,21-493

PRESSURE TRANSDUCER -

DESCRIPTION, A/C...................24-15

PRESSURE TRANSDUCER - DIAGNOSIS

AND TESTING, A/C...................24-15

PRESSURE TRANSDUCER -

INSTALLATION, A/C...................24-16

PRESSURE TRANSDUCER - OPERATION,

A/C................................24-15

PRESSURE TRANSDUCER - REMOVAL,

A/C................................24-16

PRESSURES - DESCRIPTION, TIRE

INFLATION...........................22-6

PRIMING - STANDARD PROCEDURE,

FUEL SYSTEM.......................14-59

PROGRAMING - STANDARD

PROCEDURE, RKE TRANSMITTER.......8N-10

PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC VEHICLE

INFORMATION CENTER................8M-8

PROGRAMMING - STANDARD

PROCEDURE, PCM/SKIM...............8E-14

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY

IMMOBILIZER SYSTEM TRANSPONDER....8Q-4

PROPELLER SHAFT - DIAGNOSIS AND

TESTING.............................3-1

PROPELLER SHAFT - INSTALLATION,

FRONT...............................3-7

PROPELLER SHAFT - INSTALLATION,

REAR................................3-8

PROPELLER SHAFT - REMOVAL, FRONT....3-6

PROPELLER SHAFT - REMOVAL, REAR.....3-7

PROPELLER SHAFT - SPECIAL TOOLS......3-6

PROPELLER SHAFT - SPECIFICATIONS......3-6

PROPELLER SHAFT - STANDARD

PROCEDURE..........................3-3

PROPORTIONING - DESCRIPTION,

ELECTRONIC VARIABLE BRAKE..........5-43

PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE BRAKE..........5-43

PULLEY - INSTALLATION..............19-46

PULLEY - REMOVAL

..................19-45

PUMP - 5.7L - INSTALLATION, WATER

.....7-71

PUMP - 5.7L - REMOVAL, WATER

........7-70

PUMP - 5.9L - CLEANING, WATER

........7-64

PUMP - 5.9L - DESCRIPTION, WATER

.....7-62PUMP - 5.9L - INSPECTION, WATER......7-64

PUMP - 5.9L - INSTALLATION, WATER.....7-64

PUMP - 5.9L - OPERATION, WATER.......7-62

PUMP - 5.9L - REMOVAL, WATER........7-63

PUMP - 5.9L DIESEL - CLEANING,

WATER .............................7-67

PUMP - 5.9L DIESEL - DESCRIPTION,

WATER .............................7-67

PUMP - 5.9L DIESEL - INSPECTION,

WATER .............................7-68

PUMP - 5.9L DIESEL - INSTALLATION,

WATER .............................7-68

PUMP - 5.9L DIESEL - OPERATION,

WATER .............................7-67

PUMP - 5.9L DIESEL - REMOVAL,

WATER .............................7-67

PUMP - ASSEMBLY, OIL......9-156,9-274,9-68

PUMP - ASSEMBLY, OIL . . 21-215,21-393,21-566

PUMP - CLEANING, OIL.....9-155,9-218,9-344,

9-398

PUMP - CLEANING, OIL . . 21-214,21-393,21-566

PUMP - DESCRIPTION................19-38

PUMP - DESCRIPTION, FUEL...........14-12

PUMP - DESCRIPTION, FUEL INJECTION . . 14-64

PUMP - DESCRIPTION, FUEL TRANSFER . . 14-75

PUMP - DESCRIPTION, LEAK DETECTION . 25-13

PUMP - DESCRIPTION, OIL.....21-212,21-392,

21-562

PUMP - DESCRIPTION, WATER..........7-64

PUMP - DIAGNOSIS AND TESTING,

WATER .........................7-62,7-67

PUMP - DISASSEMBLY, OIL . . . 9-155,9-272,9-67

PUMP - DISASSEMBLY, OIL.....21-212,21-393,

21-564

PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER

STEERING..........................19-39

PUMP - INSPECTION, OIL . . . 9-155,9-218,9-272,

9-344,9-399,9-67

PUMP - INSPECTION, OIL . 21-214,21-393,21-566

PUMP - INSTALLATION, FUEL INJECTION . 14-67

PUMP - INSTALLATION, FUEL TRANSFER . 14-76

PUMP - INSTALLATION, LEAK

DETECTION.........................25-16

PUMP - INSTALLATION, OIL . 9-157,9-219,9-274,

9-344,9-400,9-68

PUMP - OPERATION..................19-38

PUMP - OPERATION, FUEL.............14-12

PUMP - OPERATION, FUEL INJECTION....14-64

PUMP - OPERATION, FUEL TRANSFER....14-76

PUMP - OPERATION, LEAK DETECTION . . . 25-14

PUMP - OPERATION, OIL . 21-212,21-392,21-562

PUMP - OPERATION, WATER............7-64

PUMP - REMOVAL, FUEL INJECTION.....14-65

PUMP - REMOVAL, FUEL TRANSFER.....14-76

PUMP - REMOVAL, LEAK DETECTION....25-16

PUMP - REMOVAL, OIL.....9-154,9-218,9-272,

9-343,9-398,9-67

PUMP BYPASS - DESCRIPTION, WATER . . . 7-64

PUMP BYPASS - OPERATION, WATER.....7-65

PUMP BYPASS HOSE WITH AIR

CONDITIONING - INSTALLATION,

WATER .............................7-70

PUMP BYPASS HOSE WITH AIR

CONDITIONING - REMOVAL, WATER......7-68

PUMP BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER .............................7-70

PUMP BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER......7-69

PUMP FRONT SEAL - INSTALLATION,

OIL

...............................21-567

PUMP FRONT SEAL - REMOVAL, OIL

....21-567

PUMP LEAKAGE - DIAGNOSIS AND

TESTING

...........................19-39

PUMP MODULE - DESCRIPTION, FUEL

....14-12

PUMP MODULE - INSTALLATION, FUEL

. . . 14-13

PUMP MODULE - OPERATION, FUEL

.....14-12

PUMP MODULE - REMOVAL, FUEL

.......14-12

PUMP RELAY - DESCRIPTION, FUEL

.....14-33

PUMP RELAY - INSTALLATION, FUEL

.....14-33

PUMP RELAY - OPERATION, FUEL

.......14-33

PUMP RELAY - REMOVAL, FUEL

........14-33

PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD AND FUEL

...............8I-7

PUMP TIMING - DIAGNOSIS AND

TESTING, FUEL INJECTION

.............14-65PUMP VOLUME CHECK - STANDARD

PROCEDURE, OIL...................21-563

PUMP/MOTOR - DESCRIPTION, WASHER . 8R-13

PUMP/MOTOR - INSTALLATION,

WASHER...........................8R-14

PUMP/MOTOR - OPERATION, WASHER . . . 8R-13

PUMP/MOTOR - REMOVAL, WASHER....8R-14

PUSHRODS - CLEANING...............9-301

PUSHRODS - INSPECTION.............9-302

QUAD CAB - INSTALLATION............8O-32

QUAD CAB - REMOVAL................8O-29

QUICK CONNECT FITTING -

DESCRIPTION........................14-8

QUICK LEARN - STANDARD

PROCEDURE, TCM...................8E-21

QUICK-CONNECT FITTINGS - STANDARD

PROCEDURE.........................14-8

RADIAL - PLY TIRES - DESCRIPTION......22-6

RADIATOR - 5.9L DIESEL - CLEANING.....7-60

RADIATOR - 5.9L DIESEL -

DESCRIPTION........................7-59

RADIATOR - 5.9L DIESEL - INSPECTION . . . 7-60

RADIATOR - 5.9L DIESEL -

INSTALLATION........................7-60

RADIATOR - 5.9L DIESEL - OPERATION....7-59

RADIATOR - 5.9L DIESEL - REMOVAL.....7-59

RADIATOR - CLEANING.................7-58

RADIATOR - DESCRIPTION..............7-56

RADIATOR - INSPECTION.................7-58

RADIATOR - INSTALLATION.............7-58

RADIATOR - OPERATION................7-56

RADIATOR - REMOVAL.................7-57

RADIATOR CAP - DIAGNOSIS AND

TESTING............................7-61

RADIATOR CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING..............7-61

RADIATOR COOLANT FLOW -

DIAGNOSIS AND TESTING..........7-57,7-59

RADIATOR CROSSMEMBER -

INSTALLATION, UPPER................23-42

RADIATOR CROSSMEMBER - REMOVAL,

UPPER.............................23-42

RADIATOR FAN - 5.9L DIESEL -

CLEANING...........................7-41

RADIATOR FAN - 5.9L DIESEL -

INSPECTION.........................7-41

RADIATOR FAN - 5.9L DIESEL -

INSTALLATION........................7-41

RADIATOR FAN - 5.9L DIESEL -

REMOVAL...........................7-41

RADIATOR FAN - CLEANING.............7-40

RADIATOR FAN - INSPECTION...........7-40

RADIATOR FAN - INSTALLATION..........7-40

RADIATOR FAN - REMOVAL.............7-39

RADIATOR PRESSURE CAP -

DESCRIPTION........................7-60

RADIATOR PRESSURE CAP - OPERATION . . 7-61

RADIO - DESCRIPTION.................8A-7

RADIO - INSTALLATION................8A-8

RADIO - OPERATION...................8A-7

RADIO - REMOVAL....................8A-7

RADIO NOISE SUPPRESSION GROUND

STRAP - DESCRIPTION.................8A-8

RADIO NOISE SUPPRESSION GROUND

STRAP - INSTALLATION...............8A-10

RADIO NOISE SUPPRESSION GROUND

STRAP - OPERATION..................8A-8

RADIO NOISE SUPPRESSION GROUND

STRAP - REMOVAL....................8A-9

RAIL - DESCRIPTION, FUEL

............14-13

RAIL - DESCRIPTION, FUEL INJECTOR

....14-89

RAIL - INSTALLATION, FUEL

............14-18

RAIL - INSTALLATION, FUEL INJECTOR

. . . 14-90

RAIL - OPERATION, FUEL

..............14-13

RAIL - OPERATION, FUEL INJECTOR

.....14-89

RAIL - REMOVAL, FUEL

...............14-13

RAIL - REMOVAL, FUEL INJECTOR

.......14-89

RAIL REPAIR - STANDARD PROCEDURE,

HYDROFORM FENDER

.................13-12

RAIL TIP REPLACEMENT - STANDARD

PROCEDURE, LIGHT DUTY FRONT

FRAME

..............................13-4

RAIL WEATHERSTRIP - INSTALLATION,

DRIP

..............................23-91

RAIL WEATHERSTRIP - REMOVAL, DRIP

. . 23-91

RAIL WEATHERSTRIP RETAINER -

INSTALLATION, DRIP

.................23-92

26 INDEXDR

Description Group-Page Description Group-Page Description Group-Page