brake DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 220 of 2895

ASSEMBLY

NOTE: Install all component in their original loca-

tions.

(1) Lubricate all gears and differential bores with

differential lubricant.

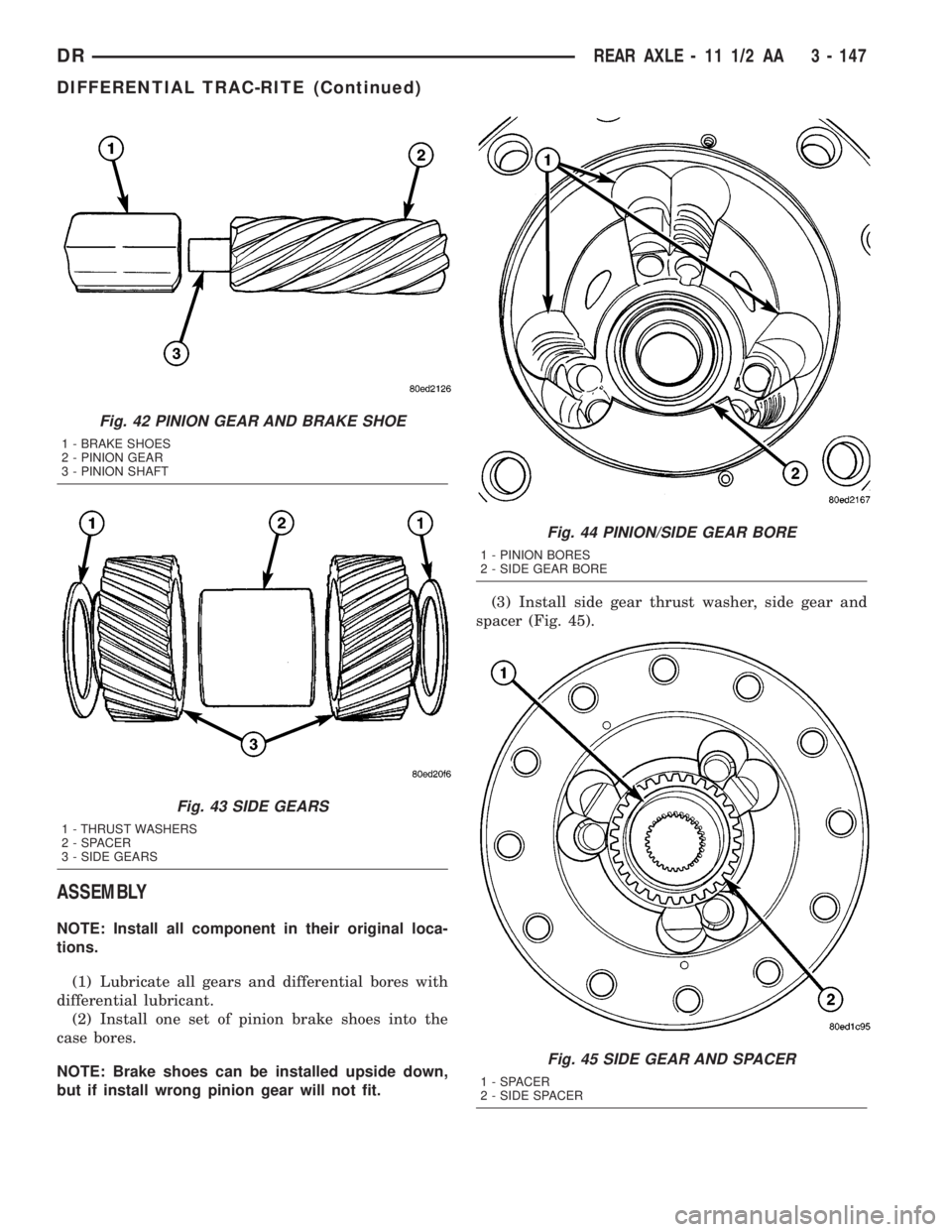

(2) Install one set of pinion brake shoes into the

case bores.

NOTE: Brake shoes can be installed upside down,

but if install wrong pinion gear will not fit.(3) Install side gear thrust washer, side gear and

spacer (Fig. 45).

Fig. 42 PINION GEAR AND BRAKE SHOE

1 - BRAKE SHOES

2 - PINION GEAR

3 - PINION SHAFT

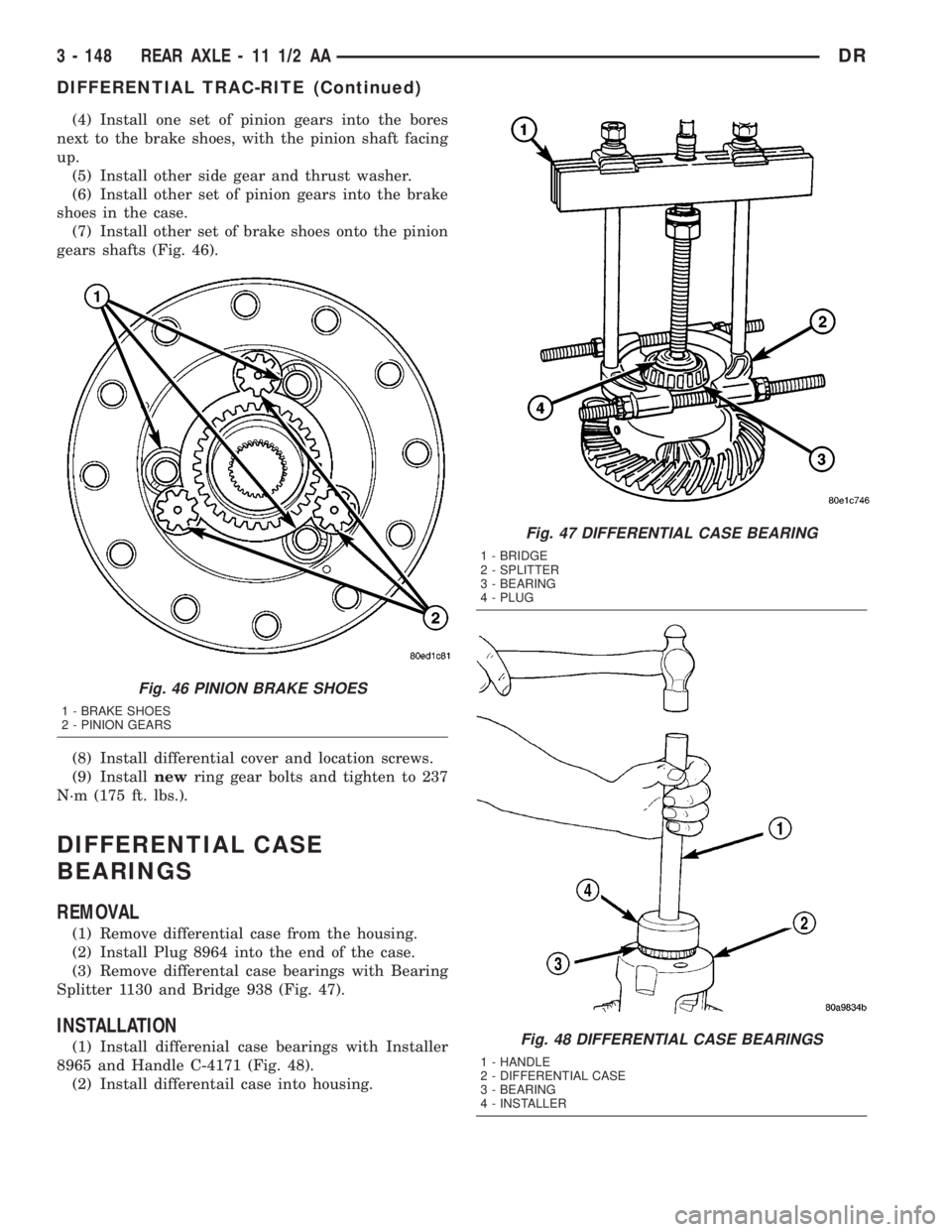

Fig. 43 SIDE GEARS

1 - THRUST WASHERS

2 - SPACER

3 - SIDE GEARS

Fig. 44 PINION/SIDE GEAR BORE

1 - PINION BORES

2 - SIDE GEAR BORE

Fig. 45 SIDE GEAR AND SPACER

1 - SPACER

2 - SIDE SPACER

DRREAR AXLE - 11 1/2 AA 3 - 147

DIFFERENTIAL TRAC-RITE (Continued)

Page 221 of 2895

(4) Install one set of pinion gears into the bores

next to the brake shoes, with the pinion shaft facing

up.

(5) Install other side gear and thrust washer.

(6) Install other set of pinion gears into the brake

shoes in the case.

(7) Install other set of brake shoes onto the pinion

gears shafts (Fig. 46).

(8) Install differential cover and location screws.

(9) Installnewring gear bolts and tighten to 237

N´m (175 ft. lbs.).

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential case from the housing.

(2) Install Plug 8964 into the end of the case.

(3) Remove differental case bearings with Bearing

Splitter 1130 and Bridge 938 (Fig. 47).

INSTALLATION

(1) Install differenial case bearings with Installer

8965 and Handle C-4171 (Fig. 48).

(2) Install differentail case into housing.

Fig. 46 PINION BRAKE SHOES

1 - BRAKE SHOES

2 - PINION GEARS

Fig. 47 DIFFERENTIAL CASE BEARING

1 - BRIDGE

2 - SPLITTER

3 - BEARING

4 - PLUG

Fig. 48 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

3 - 148 REAR AXLE - 11 1/2 AADR

DIFFERENTIAL TRAC-RITE (Continued)

Page 228 of 2895

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 39

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM.............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................5

STANDARD PROCEDURE - PRESSURE

BLEEDING............................5

SPECIAL TOOLS

BASE BRAKES........................5

ADJUSTABLE PEDAL SWITCH

REMOVAL.............................6

INSTALLATION..........................6

HYDRAULIC/MECHANICAL

SPECIFICATIONS

SPECIFICATIONS - TORQUE CHART.......6

BASE BRAKE.........................7

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING....................7

STANDARD PROCEDURE - ISO FLARING . . . 7

REMOVAL

REMOVAL - REAR BRAKE HOSE..........8

REMOVAL - REAR TUBE / HOSE

ASSEMBLY...........................8

REMOVAL - FRONT HOSE...............9

INSTALLATION

INSTALLATION - REAR BRAKE HOSE......9

INSTALLATION - REAR TUBE / HOSE

ASSEMBLY...........................9

INSTALLATION - FRONT BRAKE HOSE.....9

BRAKE PADS/SHOES

REMOVAL.............................10

INSTALLATION.........................10

DISC BRAKE CALIPERS

DESCRIPTION.........................11OPERATION...........................12

REMOVAL

REMOVAL - REAR.....................12

REMOVAL - FRONT....................12

DISASSEMBLY.........................13

INSPECTION..........................14

ASSEMBLY............................15

INSTALLATION

INSTALLATION - REAR.................16

INSTALLATION - FRONT................16

DISC BRAKE CALIPER ADAPTER

REMOVAL

REMOVAL - REAR.....................16

REMOVAL - FRONT....................16

INSTALLATION

INSTALLATION - REAR.................17

INSTALLATION - FRONT................17

DISC BRAKE CALIPER ADAPTER MOUNT

REMOVAL - REAR......................17

INSTALLATION.........................17

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................18

STANDARD PROCEDURE - BRAKE FLUID

LEVEL..............................18

SPECIFICATIONS

BRAKE FLUID........................18

FLUID RESERVOIR

REMOVAL.............................19

INSTALLATION.........................19

BRAKE JUNCTION BLOCK

REMOVAL.............................19

INSTALLATION.........................19

MASTER CYLINDER

DESCRIPTION.........................19

OPERATION...........................20

DRBRAKES 5 - 1

Page 229 of 2895

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER...........20

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING..................20

REMOVAL

REMOVAL - ALL EXCEPT HYDROBOOST . . . 21

REMOVAL - HYDROBOOST.............21

INSTALLATION

INSTALLATION - ALL EXCEPT

HYDROBOOST.......................22

INSTALLATION - HYDROBOOST..........22

PEDAL

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................23

INSTALLATION.........................23

ADJUSTABLE PEDAL MOTOR

DESCRIPTION.........................24

REMOVAL.............................24

INSTALLATION.........................24

POWER BRAKE BOOSTER

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................25

HYDRO-BOOST BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER...........................25

STANDARD PROCEDURE - BLEEDING......27

REMOVAL.............................27

INSTALLATION.........................27

ROTORS

REMOVAL

REMOVAL - REAR.....................28

REMOVAL - FRONT....................28

INSTALLATION

INSTALLATION - REAR.................28

INSTALLATION - FRONT................29SUPPORT PLATE

REMOVAL.............................29

INSTALLATION.........................29

PARKING BRAKE

DESCRIPTION.........................30

OPERATION...........................30

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE

CABLE..............................31

REMOVAL - REAR PARK BRAKE CABLE . . . 31

REMOVAL - RIGHT REAR CABLE.........31

REMOVAL - LEFT REAR CABLE..........32

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE..............................32

INSTALLATION - REAR PARK BRAKE

CABLE..............................32

INSTALLATION - RIGHT REAR CABLE.....32

INSTALLATION - LEFT REAR CABLE......33

SHOES

REMOVAL.............................33

CLEANING - REAR DRUM IN HAT BRAKE....33

INSPECTION - REAR DRUM IN HAT BRAKE . . 33

INSTALLATION.........................34

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES . . 34

ADJUSTMENT - WITH ADJUSTING TOOL . . . 36

PEDAL

REMOVAL.............................36

INSTALLATION.........................36

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT........................37

RELEASE HANDLE

REMOVAL.............................38

INSTALLATION.........................38

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, wheel cylinders, brake drums, rotors, brake

lines, master cylinder, booster, and parking brake

components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

5 - 2 BRAKES - BASEDR

Page 230 of 2895

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn, damaged

tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

²Seized or improperly adjusted parking brake

cables.

²Loose/worn wheel bearing.

²Seized caliper or wheel cylinder piston.

²Caliper binding on corroded bushings or rusted

slide surfaces.

²Loose caliper mounting.

²Drum brake shoes binding on worn/damaged

support plates.

²Mis-assembled components.

²Long booster output rod.

If brake drag occurs at all wheels, the problem

may be related to a blocked master cylinder return

port, or faulty power booster (binds-does not release).

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

DRBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 231 of 2895

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake shoes

²Damaged rotor

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE GRAB OR PULL

Rear grab or pull is usually caused by improperly

adjusted or seized parking brake cables, contami-

nated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is

involved. However, when both rear wheels are

affected, the master cylinder or proportioning valve

could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or wheel cylinders, worn seals, driv-

ing through deep water puddles, or lining that hasbecome covered with grease and grit during repair.

Contaminated lining should be replaced to avoid fur-

ther brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors and drums can become so scored that replace-

ment is necessary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brake shoes can also produce a thump noise.

5 - 4 BRAKES - BASEDR

BRAKES - BASE (Continued)

Page 232 of 2895

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

(1) Remove reservoir filler caps and fill reservoir.

(2) If calipers, or wheel cylinders were overhauled,

open all caliper and wheel cylinder bleed screws.

Then close each bleed screw as fluid starts to drip

from it. Top off master cylinder reservoir once more

before proceeding.

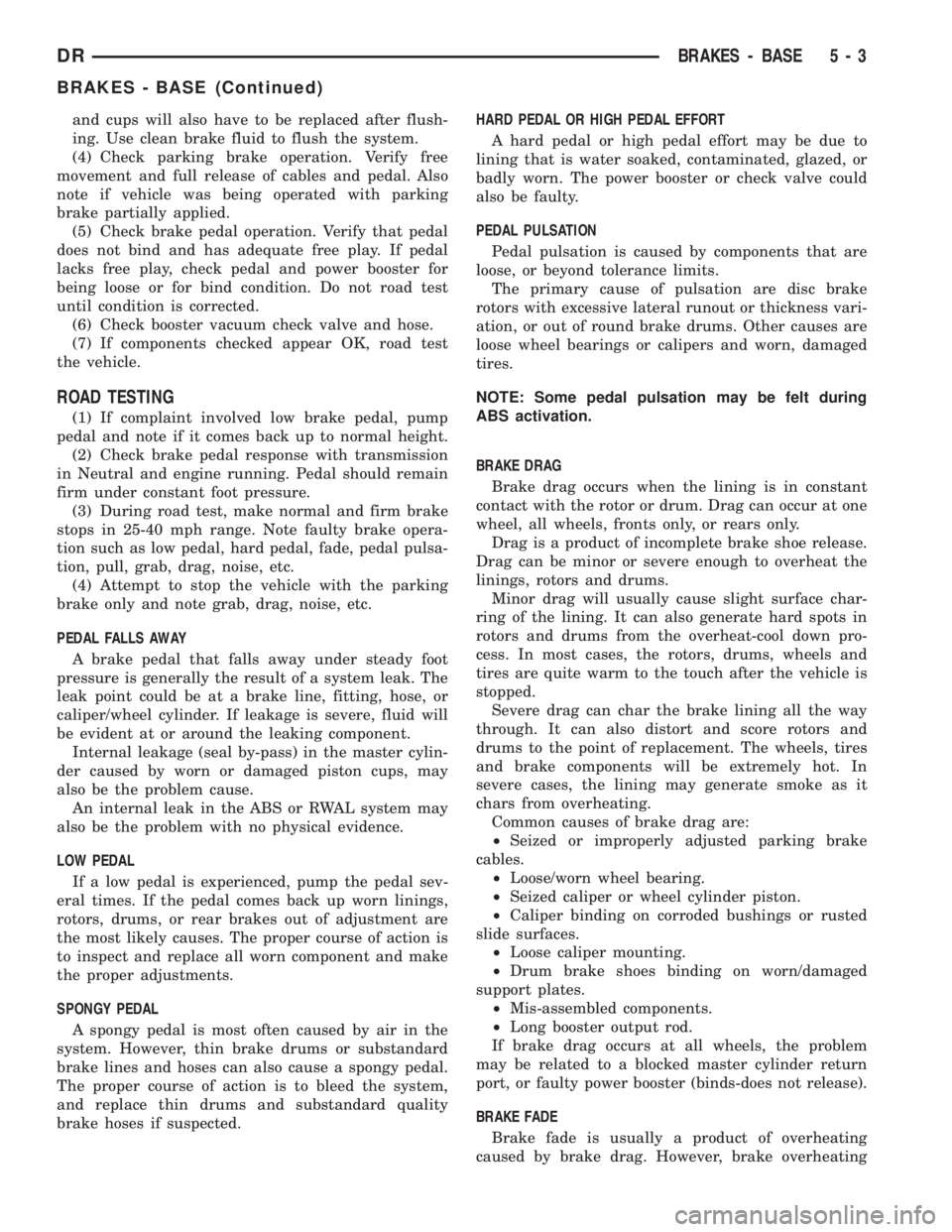

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

(4) Open up bleeder, then have a helper press

down the brake pedal. Once the pedal is down close

the bleeder. Repeat bleeding until fluid stream is

clear and free of bubbles. Then move to the next

wheel.

STANDARD PROCEDURE - PRESSURE

BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

Follow the manufacturers instructions carefully

when using pressure equipment. Do not exceed thetank manufacturers pressure recommendations. Gen-

erally, a tank pressure of 15-20 psi is sufficient for

bleeding.

Fill the bleeder tank with recommended fluid and

purge air from the tank lines before bleeding.

Do not pressure bleed without a proper master cyl-

inder adapter. The wrong adapter can lead to leak-

age, or drawing air back into the system.

SPECIAL TOOLS

BASE BRAKES

Fig. 1 Bleed Hose Setup

1 - BLEED HOSE

2 - FLUID CONTAINER PARTIALLY FILLED WITH FLUID

INSTALLER, BRAKE CALIPER DUST BOOT C-4340

INSTALLER, BRAKE CALIPER DUST BOOT

C-3716-A

HANDLE C-4171

DRBRAKES - BASE 5 - 5

BRAKES - BASE (Continued)

Page 233 of 2895

ADJUSTABLE PEDAL SWITCH

REMOVAL

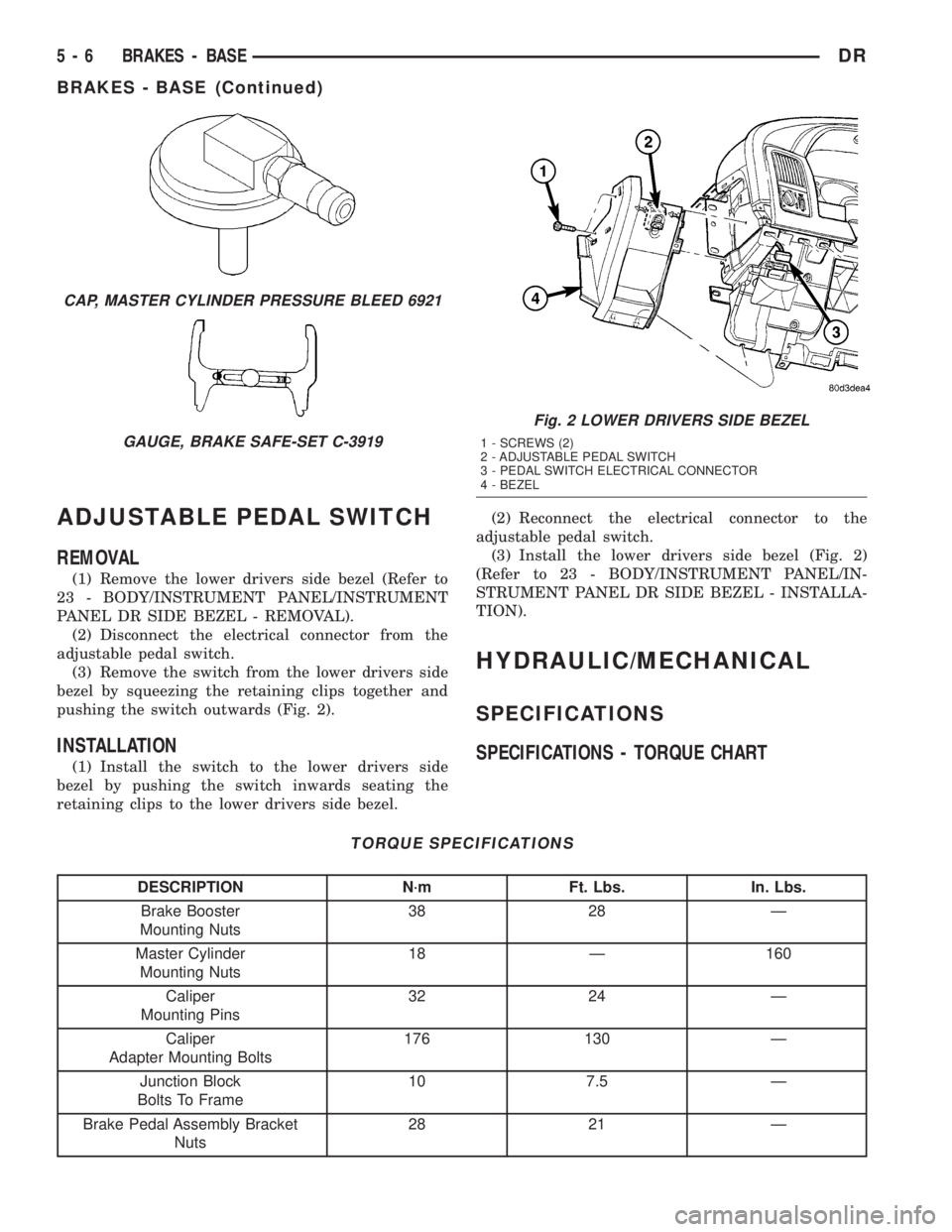

(1) Remove the lower drivers side bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL DR SIDE BEZEL - REMOVAL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the lower drivers side

bezel by squeezing the retaining clips together and

pushing the switch outwards (Fig. 2).

INSTALLATION

(1) Install the switch to the lower drivers side

bezel by pushing the switch inwards seating the

retaining clips to the lower drivers side bezel.(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the lower drivers side bezel (Fig. 2)

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL DR SIDE BEZEL - INSTALLA-

TION).

HYDRAULIC/MECHANICAL

SPECIFICATIONS

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Brake Booster

Mounting Nuts38 28 Ð

Master Cylinder

Mounting Nuts18 Ð 160

Caliper

Mounting Pins32 24 Ð

Caliper

Adapter Mounting Bolts176 130 Ð

Junction Block

Bolts To Frame10 7.5 Ð

Brake Pedal Assembly Bracket

Nuts28 21 Ð

CAP, MASTER CYLINDER PRESSURE BLEED 6921

GAUGE, BRAKE SAFE-SET C-3919

Fig. 2 LOWER DRIVERS SIDE BEZEL

1 - SCREWS (2)

2 - ADJUSTABLE PEDAL SWITCH

3 - PEDAL SWITCH ELECTRICAL CONNECTOR

4 - BEZEL

5 - 6 BRAKES - BASEDR

BRAKES - BASE (Continued)

Page 234 of 2895

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Support Plate

Mounting Bolts/Nuts64 47 Ð

Brake Line Fittings

Master Cylinder19 14 170

Brake Line Fittings

Junction Block19 14 170

Caliper

Brake Line Banjo Bolt27 20 245

Brake Hose

Front Bolts To Frame10 7.5 Ð

Brake Hose

Front Fitting19 14 250

Brake Hose

Rear Fitting19 14 250

Parking Brake Pedal Assembly 19 14 250

Hub/Bearing

Bolts163 120 Ð

BASE BRAKE

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Front Disc Brake Caliper

TypeDual Piston Sliding

Rear Disc Brake Caliper

TypeSingle Piston Sliding

Front Disc Brake Caliper 54 mm (2.00 in.)

Front Disc Brake Rotor 336ý28 mm (13.2ý1.1

in.)

Front/Rear Disc Brake

Rotor

Max. Runout0.127 mm (0.005 in.)

Front/Rear Disc Brake

Rotor

Max. Thickness Variation0.025 mm (0.001 in.)

Minimum Front Rotor

Thickness26.4 mm (1.039 in.)

Mininium Rear Rotor

Thickness28.39 mm (1.117 in)

Rear Disc Brake Caliper 1x54 mm (2.12 in)

Rear Disc Brake Rotor 350x22 mm (.86 in)

Brake Booster

Type

Gasoline EnginesVacuum Dual Diaphragm

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE INVERTED

FLARING

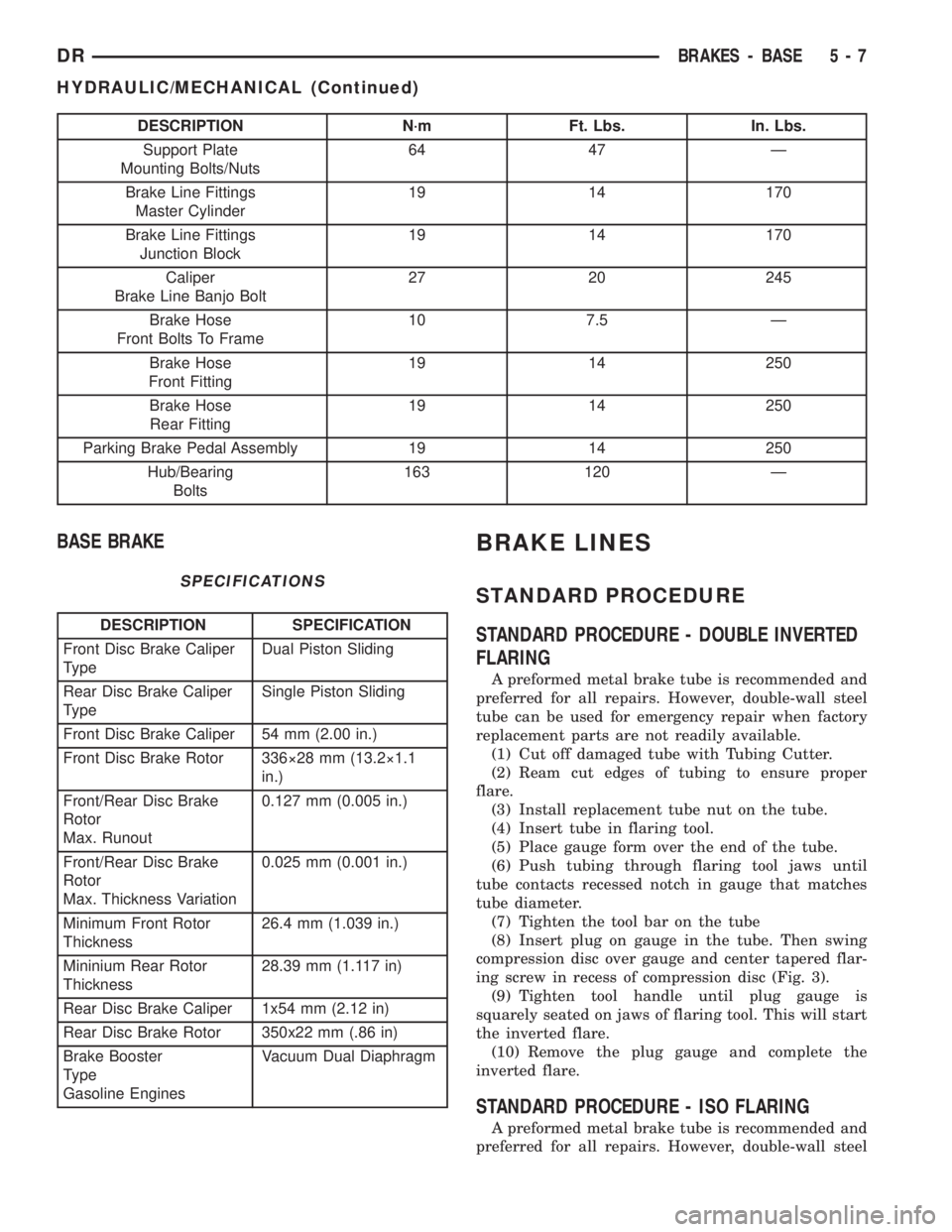

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

(1) Cut off damaged tube with Tubing Cutter.

(2) Ream cut edges of tubing to ensure proper

flare.

(3) Install replacement tube nut on the tube.

(4) Insert tube in flaring tool.

(5) Place gauge form over the end of the tube.

(6) Push tubing through flaring tool jaws until

tube contacts recessed notch in gauge that matches

tube diameter.

(7) Tighten the tool bar on the tube

(8) Insert plug on gauge in the tube. Then swing

compression disc over gauge and center tapered flar-

ing screw in recess of compression disc (Fig. 3).

(9) Tighten tool handle until plug gauge is

squarely seated on jaws of flaring tool. This will start

the inverted flare.

(10) Remove the plug gauge and complete the

inverted flare.

STANDARD PROCEDURE - ISO FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

DRBRAKES - BASE 5 - 7

HYDRAULIC/MECHANICAL (Continued)

Page 235 of 2895

tube can be used for emergency repair when factory

replacement parts are not readily available.

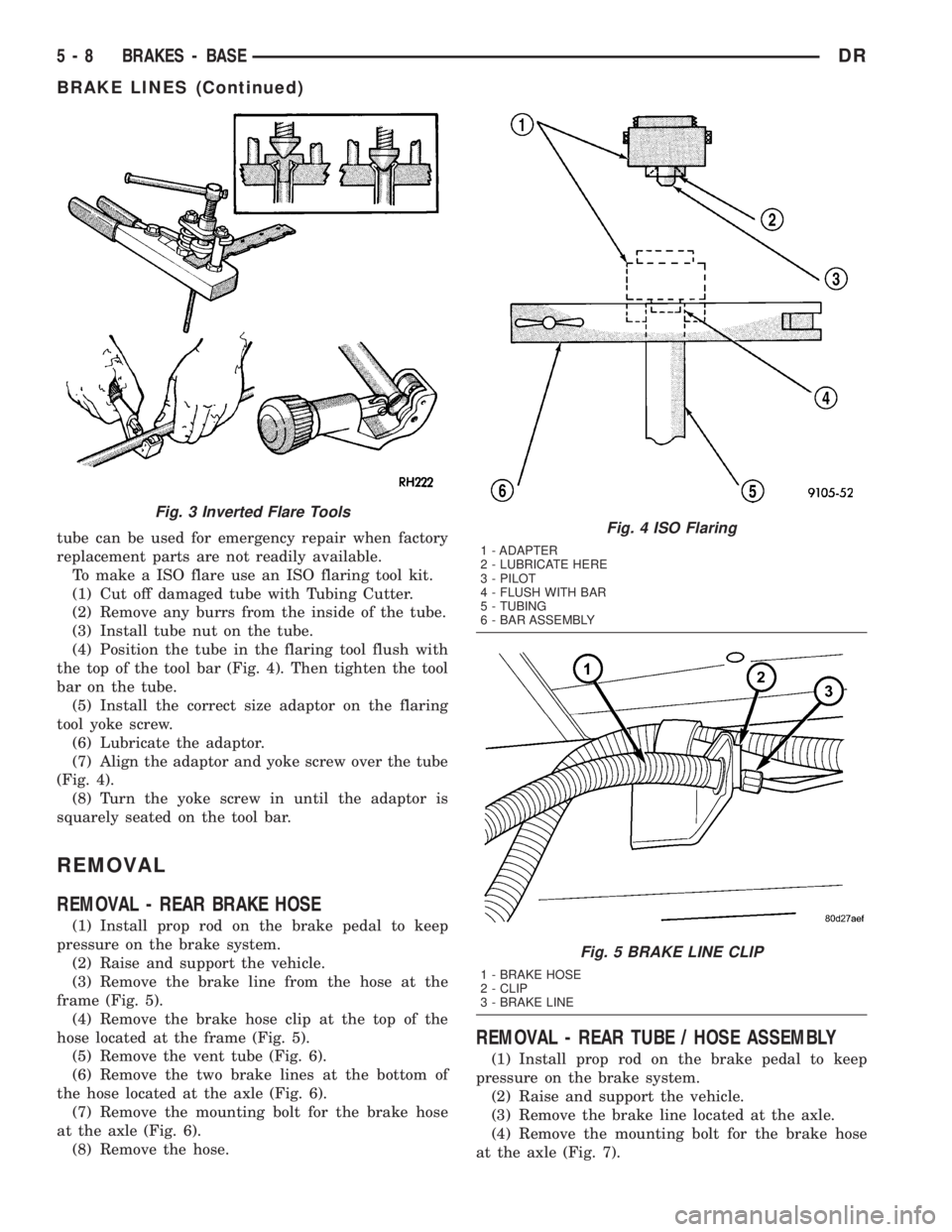

To make a ISO flare use an ISO flaring tool kit.

(1) Cut off damaged tube with Tubing Cutter.

(2) Remove any burrs from the inside of the tube.

(3) Install tube nut on the tube.

(4) Position the tube in the flaring tool flush with

the top of the tool bar (Fig. 4). Then tighten the tool

bar on the tube.

(5) Install the correct size adaptor on the flaring

tool yoke screw.

(6) Lubricate the adaptor.

(7) Align the adaptor and yoke screw over the tube

(Fig. 4).

(8) Turn the yoke screw in until the adaptor is

squarely seated on the tool bar.

REMOVAL

REMOVAL - REAR BRAKE HOSE

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.

(3) Remove the brake line from the hose at the

frame (Fig. 5).

(4) Remove the brake hose clip at the top of the

hose located at the frame (Fig. 5).

(5) Remove the vent tube (Fig. 6).

(6) Remove the two brake lines at the bottom of

the hose located at the axle (Fig. 6).

(7) Remove the mounting bolt for the brake hose

at the axle (Fig. 6).

(8) Remove the hose.

REMOVAL - REAR TUBE / HOSE ASSEMBLY

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.

(3) Remove the brake line located at the axle.

(4) Remove the mounting bolt for the brake hose

at the axle (Fig. 7).

Fig. 3 Inverted Flare Tools

Fig. 4 ISO Flaring

1 - ADAPTER

2 - LUBRICATE HERE

3 - PILOT

4 - FLUSH WITH BAR

5 - TUBING

6 - BAR ASSEMBLY

Fig. 5 BRAKE LINE CLIP

1 - BRAKE HOSE

2 - CLIP

3 - BRAKE LINE

5 - 8 BRAKES - BASEDR

BRAKE LINES (Continued)