Engine DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1553 of 2895

(40) Install wire harness P-clip to top of bracket.

(41) Install fan support and torque to 32 N´m (24

ft. lbs.).

(42) Install cooling fan/drive and torque to 33 N´m

(24 ft. lbs.).

(43) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(44) Install exhaust manifold/turbocharger assem-

bly, using new gaskets. Start all bolts/spacers by

hand. Torque bolts to 43 N´m (32 ft. lbs.).

(45) Install exhaust manifold heat shield. Torque

to 24 N´m (18 ft. lbs.).

(46) Install exhaust bolt retention straps across

cylinders5&6.

(47) Connect turbocharger oil drain tube. Torque to

8 N´m (71 in. lbs.).

(48) Perform the turbocharger pre-lube procedure.

Refer to Group 11, Exhaust System and Turbo-

charger for the correct procedure.

(49) Connect the turbocharger oil supply line.

Torque to 24 N´m (18 ft. lbs.).

(50) Install air cleaner housing and duct.

(51) Connect air inlet temperature/pressure sensor.

(52) Raise vehicle on hoist.

(53) Install exhaust pipe to turbocharger elbow.

Torque bolts to 8 N´m (72 in. lbs.).

(54) Lower vehicle.

(55) Fill engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(56) Start engine and check for leaks.

CYLINDER HEAD COVER(S)

REMOVAL

REMOVALÐCYLINDER HEAD COVER

(1) Disconnect both battery negative cables.

(2) Remove oil fill cap.

(3) Remove the breather cover.

(4) Disconnect the breather hose and breather

drain tube from the breather housing.

(5) Remove cylinder head cover bolts.

(6) Remove the cylinder head cover.

REMOVALÐROCKER HOUSING

(1) Remove cylinder head cover as outlined in this

section.

(2) Disconnect rocker housing injector harness con-

nectors.

(3) Remove injector harness nuts from injectors.

(4) Remove rocker housing bolts.

(5) Remove rocker housing and gasket.

CLEANING

Using a suitable solvent, Clean and dry gasket

mating surfaces on cylinder head and rocker housing.

Wipe gasket dry and inspect for re-use.

INSPECTION

The cylinder head cover gasket, rocker hous-

ing gasket, are reusable.However, should cracks,

nicks, or tears be present in the rubber/silicone con-

struction, the defective components should be

replaced. Also replace gasket if it is no longer flexi-

ble. Inspect o-rings on cylinder head cover bolts.

INSTALLATION

INSTALLATIONÐCYLINDER HEAD COVER

(1) Inspect cylinder head cover gasket for cuts and

proper installation in groove. Replace if damaged.

(2) Position cylinder cover on top of rocker hous-

ing.

(3) Install bolts.

(4) Starting with the center bolt, torque to 24 N´m

(18 ft. lbs.).

(5) Install breather hose to breather.

(6) Install breather drain hose to breather.

(7) Install breather cover and wire harness clip.

Torque to 24 N´m (18 ft. lbs.).

INSTALLATIONÐROCKER HOUSING

(1) Inspect rocker housing gasket for cuts, nicks,

or tears. Replace if damaged or if gasket has come

out of groove.

(2) Inspect rocker housing gasket for proper instal-

lation in groove. Gasket bead must be centered in

groove. A gasket bead that is tilted to the side will

cause an oil leak.

(3) Install ToolXXXXguide pins (or equivalent)

into the cylinder head at rocker housing bolt loca-

tions #1 and #5.

(4) Install the rocker hoiusing over the guide pins.

Carefully gyide the rocker housing evenly down onto

the cylinder head.

(5) With guide pins in place, install remaining

rocker housing bolts and tighten finger tight.

(6) Remove guide pins and install remaining

rocker housing bolts finger tight.

(7) Install rocker housing and bolts. Torque bolts,

working from center out, to 24 Nm (18ft. lbs.).

(8) Install injector harness nuts to injector sole-

noid. Torque to 1.5 Nm (13 in. lbs.).

(9) Connect rocker housing injector harness con-

nections.

9 - 304 ENGINE 5.9L DIESELDR

CYLINDER HEAD (Continued)

Page 1554 of 2895

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel, and

have chrome plated stems to prevent scuffing. The

intake and exhaust valves are both similar in head

diameter and overall length, but they have unique

face angles which makes them non-interchangeable.

The valves are distinguished by unique dimples on

the exhaust valve head (Fig. 21).

The exhaust valve springs are made from high

strength, chrome silicon steel. The exhaust valve

springs are also exhaust brake compatible.

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES, GUIDES

AND SPRINGS

REMOVAL

(1) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(2) Support cylinder head on stands, or install

head bolts upside down (through combustion surface

side) to protect injector tips from damage from work

bench.

(3) Install the valve spring compressor mounting

base as shown in (Fig. 22).

(4) Install the compressor top plate, washer, and

nut. Using a suitable wrench, tighten the nut (clock-

wise) to compress the valve springs (Fig. 23) and

remove the locks.

(5) Rotate the compressor nut counter-clockwise to

relieve tension on the springs. Remove the spring

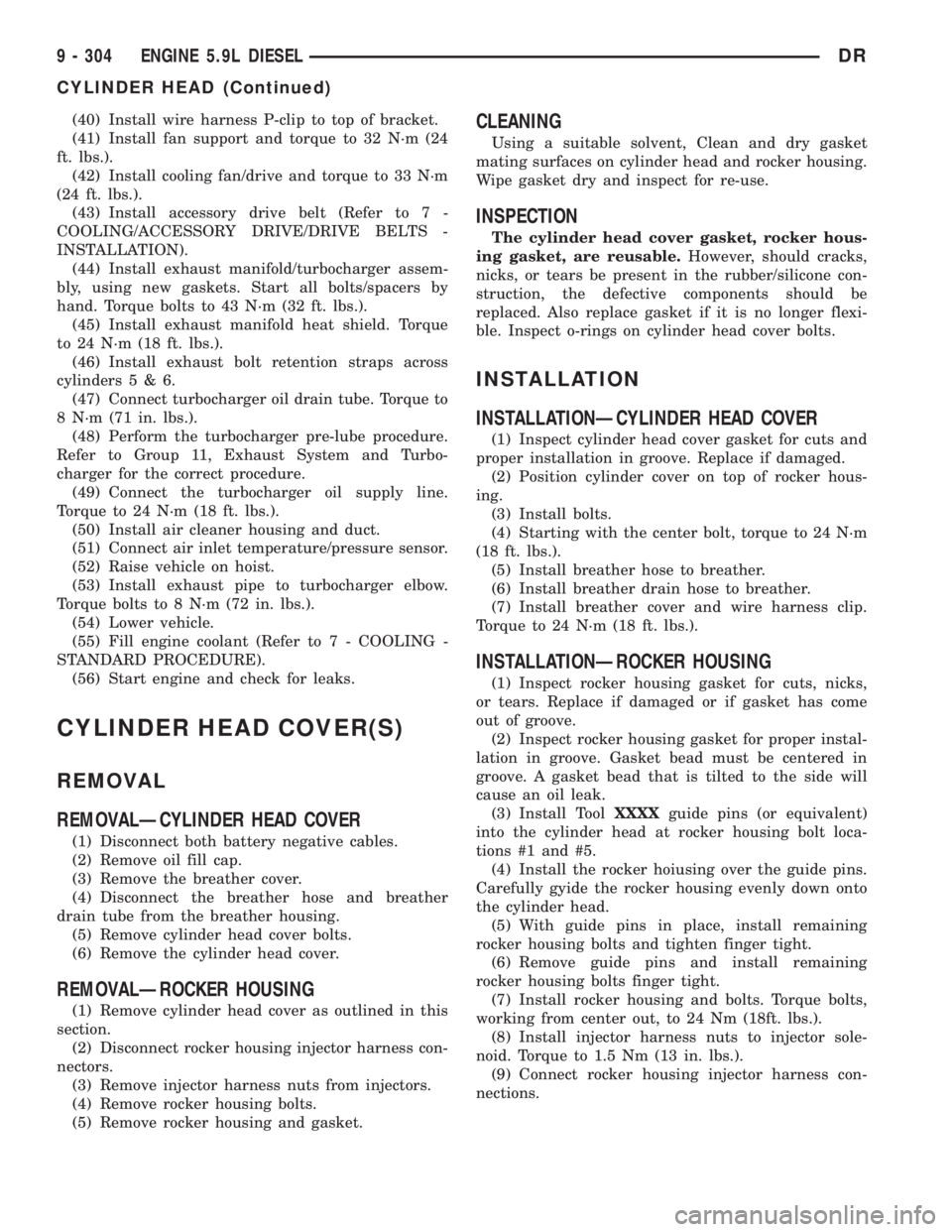

compressor.(6) Remove the retainers, springs, valve seals (if

necessary), and valves (Fig. 24). Arrange or number

all components so they can be installed in their orig-

inal locations.

(7) Repeat the procedure on all cylinders to be ser-

viced.

CLEANING

Clean the valve stems with crocus cloth or a

Scotch-BriteŸ pad. Remove carbon with a soft wire

brush. Clean valves, springs, retainers, and valve

retaining locks in a suitable solvent. Rinse in hot

water and blow dry with compressed air.

Fig. 21 Valve Identification

1 - INTAKE VALVES

2 - EXHAUST VALVES

Fig. 22 Spring Compressor Mounting BaseÐPart of

Tool 8319±A

1 - COMPRESSOR MOUNTING BASE

Fig. 23 Compressing Valve Springs with Tool

8319±A

1 - SPECIAL TOOL 8319

DRENGINE 5.9L DIESEL 9 - 305

Page 1555 of 2895

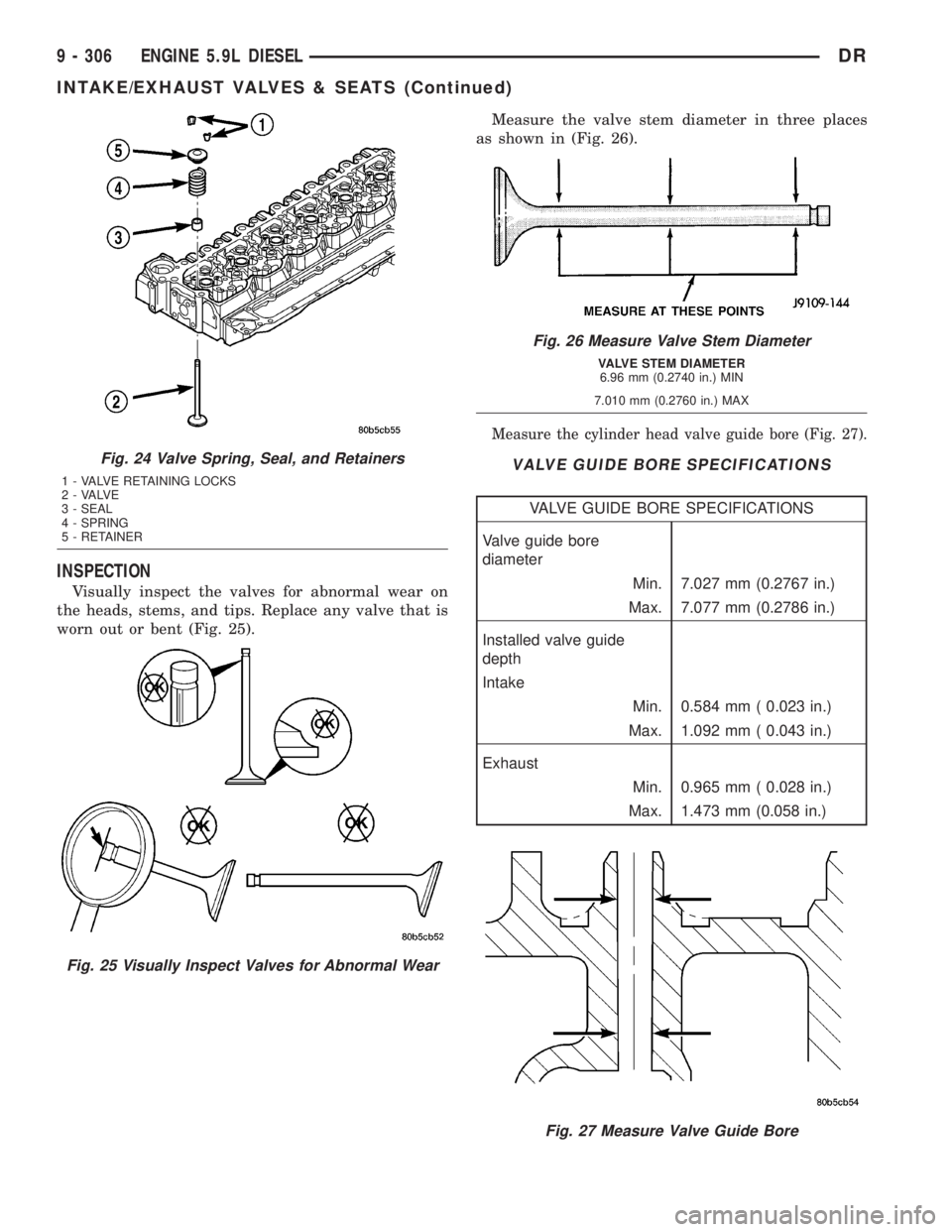

INSPECTION

Visually inspect the valves for abnormal wear on

the heads, stems, and tips. Replace any valve that is

worn out or bent (Fig. 25).Measure the valve stem diameter in three places

as shown in (Fig. 26).

Measure the cylinder head valve guide bore (Fig. 27).

VALVE GUIDE BORE SPECIFICATIONS

VALVE GUIDE BORE SPECIFICATIONS

Valve guide bore

diameter

Min. 7.027 mm (0.2767 in.)

Max. 7.077 mm (0.2786 in.)

Installed valve guide

depth

Intake

Min. 0.584 mm ( 0.023 in.)

Max. 1.092 mm ( 0.043 in.)

Exhaust

Min. 0.965 mm ( 0.028 in.)

Max. 1.473 mm (0.058 in.)

Fig. 24 Valve Spring, Seal, and Retainers

1 - VALVE RETAINING LOCKS

2 - VALVE

3 - SEAL

4 - SPRING

5 - RETAINER

Fig. 25 Visually Inspect Valves for Abnormal Wear

Fig. 26 Measure Valve Stem Diameter

VALVE STEM DIAMETER

6.96 mm (0.2740 in.) MIN

7.010 mm (0.2760 in.) MAX

Fig. 27 Measure Valve Guide Bore

9 - 306 ENGINE 5.9L DIESELDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1556 of 2895

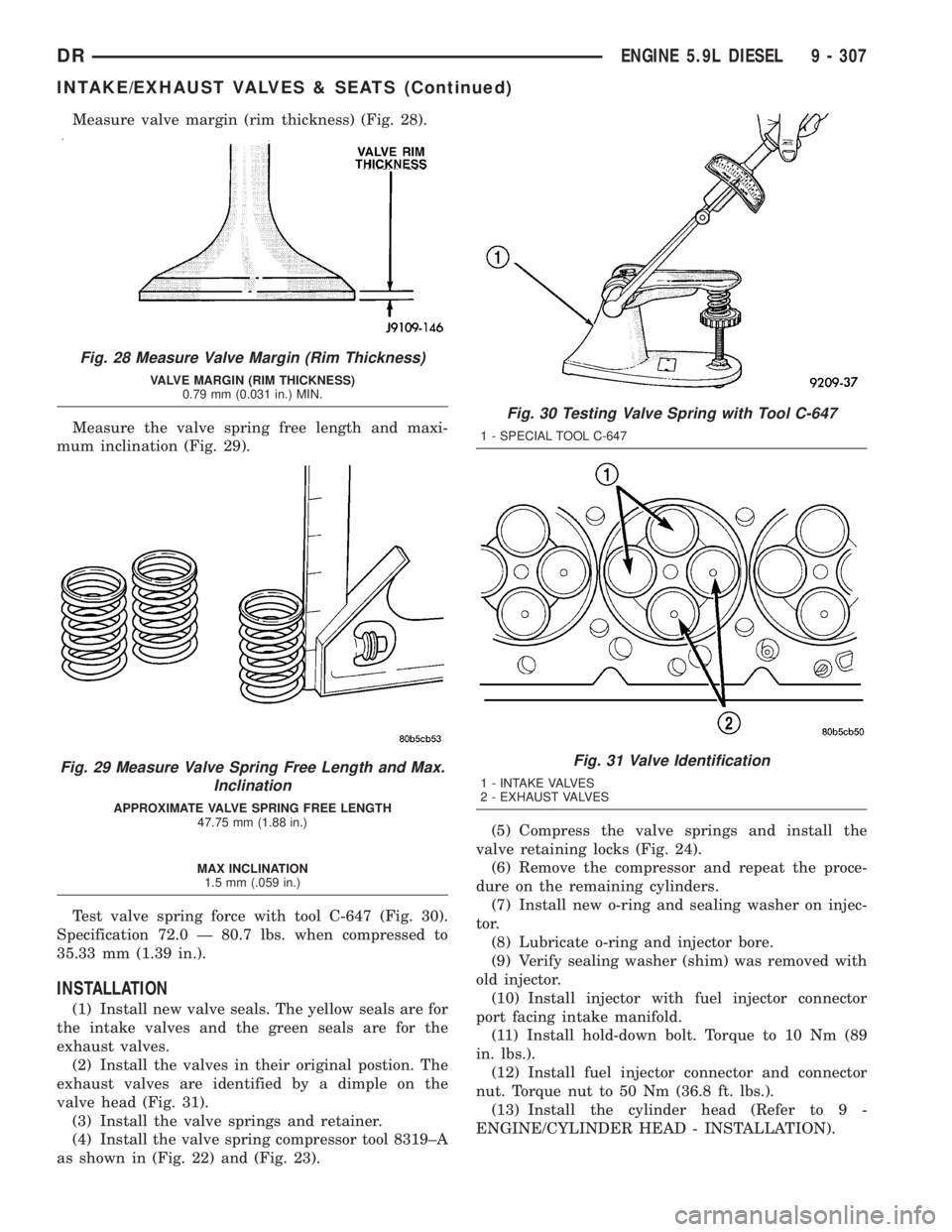

Measure valve margin (rim thickness) (Fig. 28).

Measure the valve spring free length and maxi-

mum inclination (Fig. 29).

Test valve spring force with tool C-647 (Fig. 30).

Specification 72.0 Ð 80.7 lbs. when compressed to

35.33 mm (1.39 in.).

INSTALLATION

(1) Install new valve seals. The yellow seals are for

the intake valves and the green seals are for the

exhaust valves.

(2) Install the valves in their original postion. The

exhaust valves are identified by a dimple on the

valve head (Fig. 31).

(3) Install the valve springs and retainer.

(4) Install the valve spring compressor tool 8319±A

as shown in (Fig. 22) and (Fig. 23).(5) Compress the valve springs and install the

valve retaining locks (Fig. 24).

(6) Remove the compressor and repeat the proce-

dure on the remaining cylinders.

(7) Install new o-ring and sealing washer on injec-

tor.

(8) Lubricate o-ring and injector bore.

(9) Verify sealing washer (shim) was removed with

old injector.

(10) Install injector with fuel injector connector

port facing intake manifold.

(11) Install hold-down bolt. Torque to 10 Nm (89

in. lbs.).

(12) Install fuel injector connector and connector

nut. Torque nut to 50 Nm (36.8 ft. lbs.).

(13) Install the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION).

Fig. 28 Measure Valve Margin (Rim Thickness)

VALVE MARGIN (RIM THICKNESS)

0.79 mm (0.031 in.) MIN.

Fig. 29 Measure Valve Spring Free Length and Max.

Inclination

APPROXIMATE VALVE SPRING FREE LENGTH

47.75 mm (1.88 in.)

MAX INCLINATION

1.5 mm (.059 in.)

Fig. 30 Testing Valve Spring with Tool C-647

1 - SPECIAL TOOL C-647

Fig. 31 Valve Identification

1 - INTAKE VALVES

2 - EXHAUST VALVES

DRENGINE 5.9L DIESEL 9 - 307

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1557 of 2895

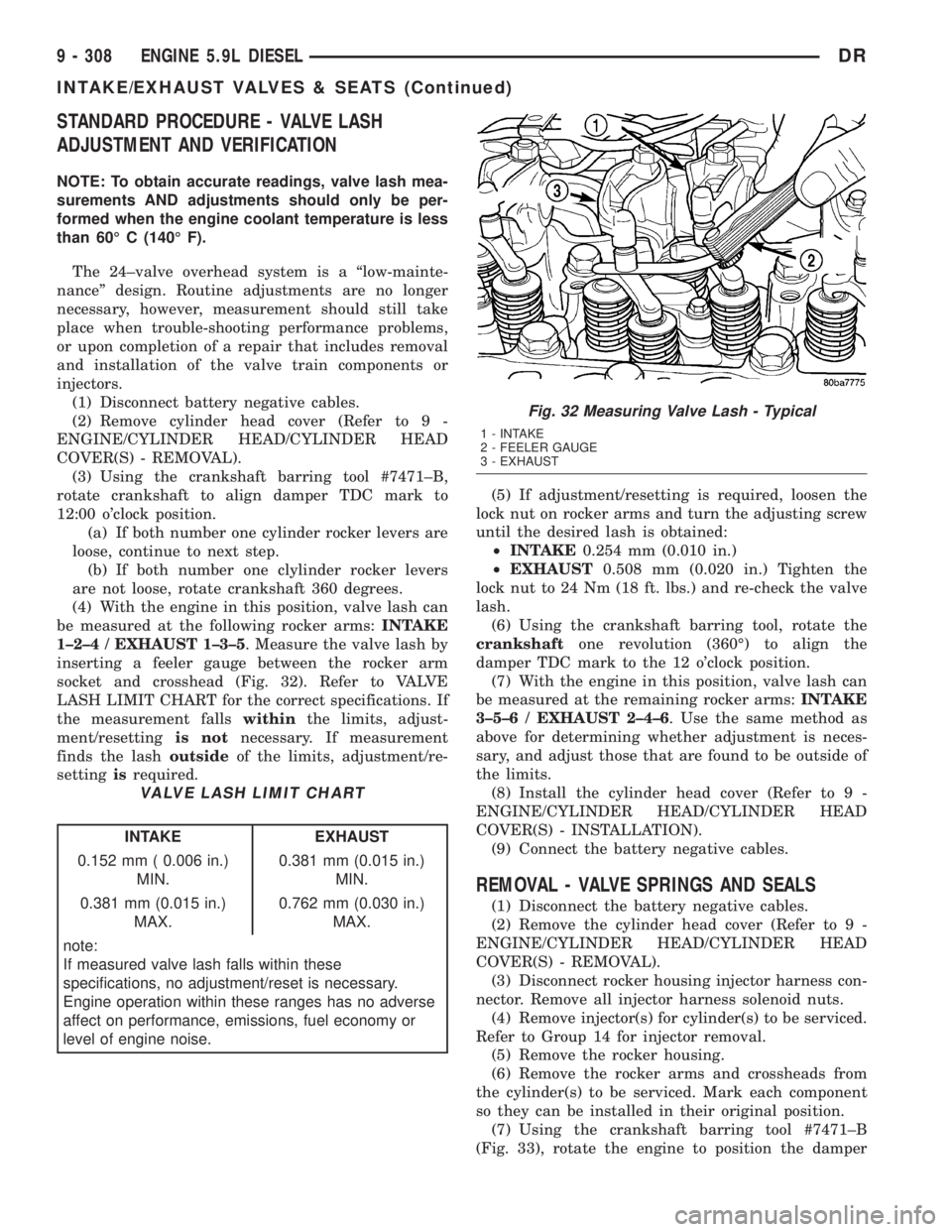

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION

NOTE: To obtain accurate readings, valve lash mea-

surements AND adjustments should only be per-

formed when the engine coolant temperature is less

than 60É C (140É F).

The 24±valve overhead system is a ªlow-mainte-

nanceº design. Routine adjustments are no longer

necessary, however, measurement should still take

place when trouble-shooting performance problems,

or upon completion of a repair that includes removal

and installation of the valve train components or

injectors.

(1) Disconnect battery negative cables.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Using the crankshaft barring tool #7471±B,

rotate crankshaft to align damper TDC mark to

12:00 o'clock position.

(a) If both number one cylinder rocker levers are

loose, continue to next step.

(b) If both number one clylinder rocker levers

are not loose, rotate crankshaft 360 degrees.

(4) With the engine in this position, valve lash can

be measured at the following rocker arms:INTAKE

1±2±4 / EXHAUST 1±3±5. Measure the valve lash by

inserting a feeler gauge between the rocker arm

socket and crosshead (Fig. 32). Refer to VALVE

LASH LIMIT CHART for the correct specifications. If

the measurement fallswithinthe limits, adjust-

ment/resettingis notnecessary. If measurement

finds the lashoutsideof the limits, adjustment/re-

settingisrequired.

VALVE LASH LIMIT CHART

INTAKE EXHAUST

0.152 mm ( 0.006 in.)

MIN.0.381 mm (0.015 in.)

MIN.

0.381 mm (0.015 in.)

MAX.0.762 mm (0.030 in.)

MAX.

note:

If measured valve lash falls within these

specifications, no adjustment/reset is necessary.

Engine operation within these ranges has no adverse

affect on performance, emissions, fuel economy or

level of engine noise.(5) If adjustment/resetting is required, loosen the

lock nut on rocker arms and turn the adjusting screw

until the desired lash is obtained:

²INTAKE0.254 mm (0.010 in.)

²EXHAUST0.508 mm (0.020 in.) Tighten the

lock nut to 24 Nm (18 ft. lbs.) and re-check the valve

lash.

(6) Using the crankshaft barring tool, rotate the

crankshaftone revolution (360É) to align the

damper TDC mark to the 12 o'clock position.

(7) With the engine in this position, valve lash can

be measured at the remaining rocker arms:INTAKE

3±5±6 / EXHAUST 2±4±6. Use the same method as

above for determining whether adjustment is neces-

sary, and adjust those that are found to be outside of

the limits.

(8) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(9) Connect the battery negative cables.

REMOVAL - VALVE SPRINGS AND SEALS

(1) Disconnect the battery negative cables.

(2) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Disconnect rocker housing injector harness con-

nector. Remove all injector harness solenoid nuts.

(4) Remove injector(s) for cylinder(s) to be serviced.

Refer to Group 14 for injector removal.

(5) Remove the rocker housing.

(6) Remove the rocker arms and crossheads from

the cylinder(s) to be serviced. Mark each component

so they can be installed in their original position.

(7) Using the crankshaft barring tool #7471±B

(Fig. 33), rotate the engine to position the damper

Fig. 32 Measuring Valve Lash - Typical

1 - INTAKE

2 - FEELER GAUGE

3 - EXHAUST

9 - 308 ENGINE 5.9L DIESELDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1558 of 2895

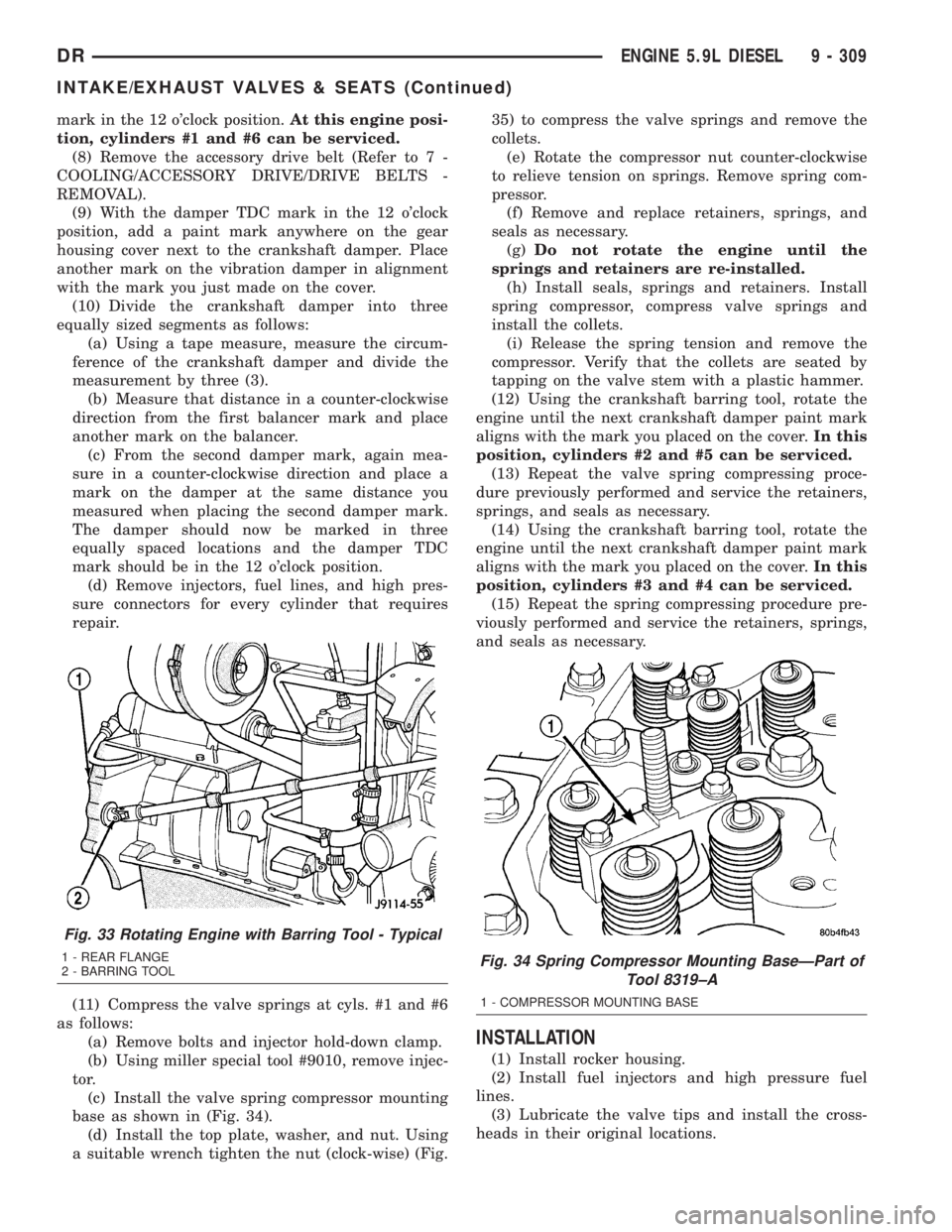

mark in the 12 o'clock position.At this engine posi-

tion, cylinders #1 and #6 can be serviced.

(8) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(9) With the damper TDC mark in the 12 o'clock

position, add a paint mark anywhere on the gear

housing cover next to the crankshaft damper. Place

another mark on the vibration damper in alignment

with the mark you just made on the cover.

(10) Divide the crankshaft damper into three

equally sized segments as follows:

(a) Using a tape measure, measure the circum-

ference of the crankshaft damper and divide the

measurement by three (3).

(b) Measure that distance in a counter-clockwise

direction from the first balancer mark and place

another mark on the balancer.

(c) From the second damper mark, again mea-

sure in a counter-clockwise direction and place a

mark on the damper at the same distance you

measured when placing the second damper mark.

The damper should now be marked in three

equally spaced locations and the damper TDC

mark should be in the 12 o'clock position.

(d) Remove injectors, fuel lines, and high pres-

sure connectors for every cylinder that requires

repair.

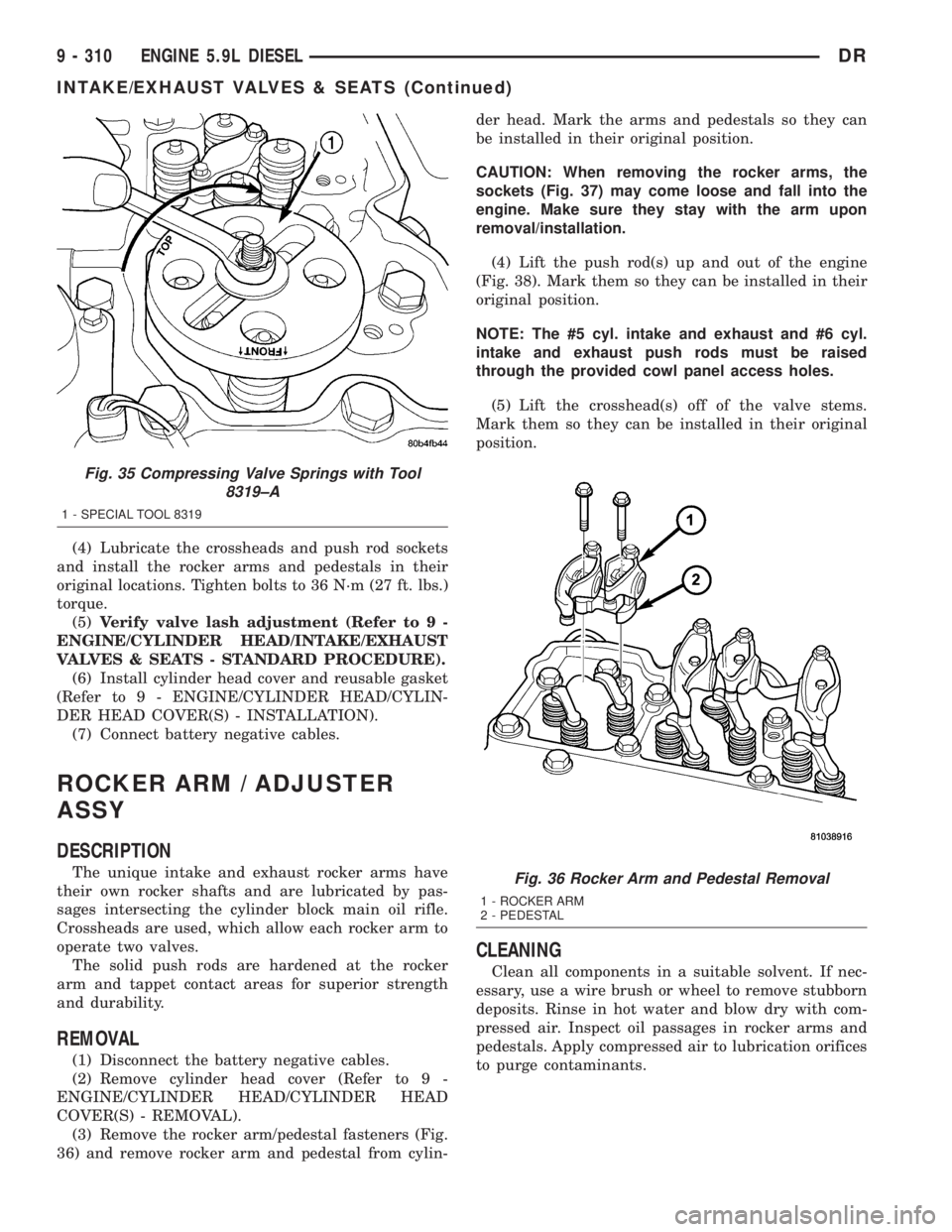

(11) Compress the valve springs at cyls. #1 and #6

as follows:

(a) Remove bolts and injector hold-down clamp.

(b) Using miller special tool #9010, remove injec-

tor.

(c) Install the valve spring compressor mounting

base as shown in (Fig. 34).

(d) Install the top plate, washer, and nut. Using

a suitable wrench tighten the nut (clock-wise) (Fig.35) to compress the valve springs and remove the

collets.

(e) Rotate the compressor nut counter-clockwise

to relieve tension on springs. Remove spring com-

pressor.

(f) Remove and replace retainers, springs, and

seals as necessary.

(g)Do not rotate the engine until the

springs and retainers are re-installed.

(h) Install seals, springs and retainers. Install

spring compressor, compress valve springs and

install the collets.

(i) Release the spring tension and remove the

compressor. Verify that the collets are seated by

tapping on the valve stem with a plastic hammer.

(12) Using the crankshaft barring tool, rotate the

engine until the next crankshaft damper paint mark

aligns with the mark you placed on the cover.In this

position, cylinders #2 and #5 can be serviced.

(13) Repeat the valve spring compressing proce-

dure previously performed and service the retainers,

springs, and seals as necessary.

(14) Using the crankshaft barring tool, rotate the

engine until the next crankshaft damper paint mark

aligns with the mark you placed on the cover.In this

position, cylinders #3 and #4 can be serviced.

(15) Repeat the spring compressing procedure pre-

viously performed and service the retainers, springs,

and seals as necessary.

INSTALLATION

(1) Install rocker housing.

(2) Install fuel injectors and high pressure fuel

lines.

(3) Lubricate the valve tips and install the cross-

heads in their original locations.

Fig. 33 Rotating Engine with Barring Tool - Typical

1 - REAR FLANGE

2 - BARRING TOOLFig. 34 Spring Compressor Mounting BaseÐPart of

Tool 8319±A

1 - COMPRESSOR MOUNTING BASE

DRENGINE 5.9L DIESEL 9 - 309

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1559 of 2895

(4) Lubricate the crossheads and push rod sockets

and install the rocker arms and pedestals in their

original locations. Tighten bolts to 36 N´m (27 ft. lbs.)

torque.

(5)Verify valve lash adjustment (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

(6) Install cylinder head cover and reusable gasket

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - INSTALLATION).

(7) Connect battery negative cables.

ROCKER ARM / ADJUSTER

ASSY

DESCRIPTION

The unique intake and exhaust rocker arms have

their own rocker shafts and are lubricated by pas-

sages intersecting the cylinder block main oil rifle.

Crossheads are used, which allow each rocker arm to

operate two valves.

The solid push rods are hardened at the rocker

arm and tappet contact areas for superior strength

and durability.

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

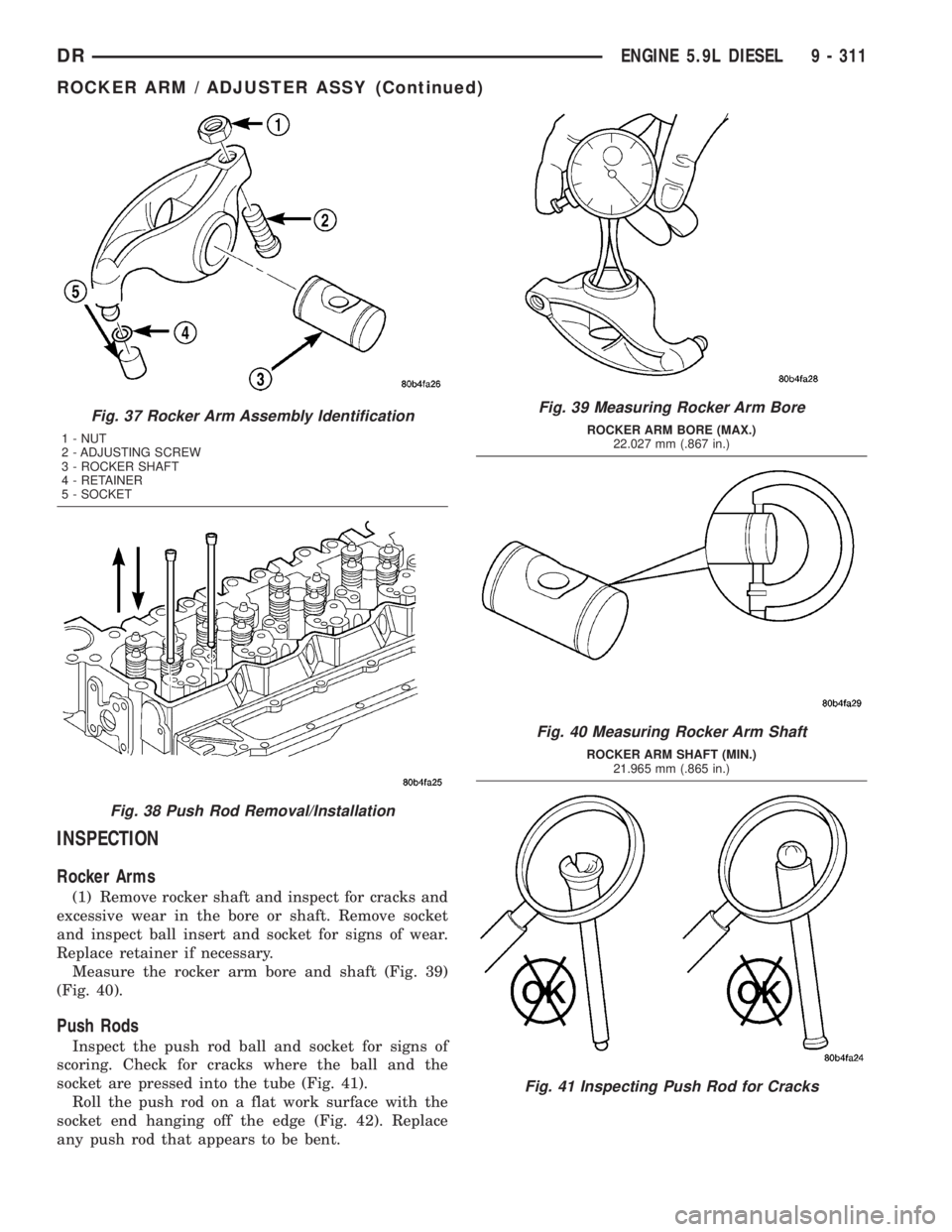

(3) Remove the rocker arm/pedestal fasteners (Fig.

36) and remove rocker arm and pedestal from cylin-der head. Mark the arms and pedestals so they can

be installed in their original position.

CAUTION: When removing the rocker arms, the

sockets (Fig. 37) may come loose and fall into the

engine. Make sure they stay with the arm upon

removal/installation.

(4) Lift the push rod(s) up and out of the engine

(Fig. 38). Mark them so they can be installed in their

original position.

NOTE: The #5 cyl. intake and exhaust and #6 cyl.

intake and exhaust push rods must be raised

through the provided cowl panel access holes.

(5) Lift the crosshead(s) off of the valve stems.

Mark them so they can be installed in their original

position.

CLEANING

Clean all components in a suitable solvent. If nec-

essary, use a wire brush or wheel to remove stubborn

deposits. Rinse in hot water and blow dry with com-

pressed air. Inspect oil passages in rocker arms and

pedestals. Apply compressed air to lubrication orifices

to purge contaminants.

Fig. 35 Compressing Valve Springs with Tool

8319±A

1 - SPECIAL TOOL 8319

Fig. 36 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

9 - 310 ENGINE 5.9L DIESELDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1560 of 2895

INSPECTION

Rocker Arms

(1) Remove rocker shaft and inspect for cracks and

excessive wear in the bore or shaft. Remove socket

and inspect ball insert and socket for signs of wear.

Replace retainer if necessary.

Measure the rocker arm bore and shaft (Fig. 39)

(Fig. 40).

Push Rods

Inspect the push rod ball and socket for signs of

scoring. Check for cracks where the ball and the

socket are pressed into the tube (Fig. 41).

Roll the push rod on a flat work surface with the

socket end hanging off the edge (Fig. 42). Replace

any push rod that appears to be bent.

Fig. 37 Rocker Arm Assembly Identification

1 - NUT

2 - ADJUSTING SCREW

3 - ROCKER SHAFT

4 - RETAINER

5 - SOCKET

Fig. 38 Push Rod Removal/Installation

Fig. 39 Measuring Rocker Arm Bore

ROCKER ARM BORE (MAX.)

22.027 mm (.867 in.)

Fig. 40 Measuring Rocker Arm Shaft

ROCKER ARM SHAFT (MIN.)

21.965 mm (.865 in.)

Fig. 41 Inspecting Push Rod for Cracks

DRENGINE 5.9L DIESEL 9 - 311

ROCKER ARM / ADJUSTER ASSY (Continued)

Page 1561 of 2895

Crossheads

Inspect the crossheads for cracks and/or excessive

wear on rocker lever and valve tip mating surfaces

(Fig. 43).

INSTALLATION

(1) If previously removed, install the push rods in

their original location.Verify that they are seated

in the tappets.

(2) Lubricate the valve tips and install the cross-

heads in their original locations.

(3) Lubricate the crossheads and push rod sockets

and install the rocker arms and pedestals in their

original locations. Tighten bolts to 36 N´m (27 ft. lbs.)

torque.

(4)Verify valve lash adjustment (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

(5) Install cylinder head cover and reusable gasket

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - INSTALLATION).

(6) Connect battery negative cables.

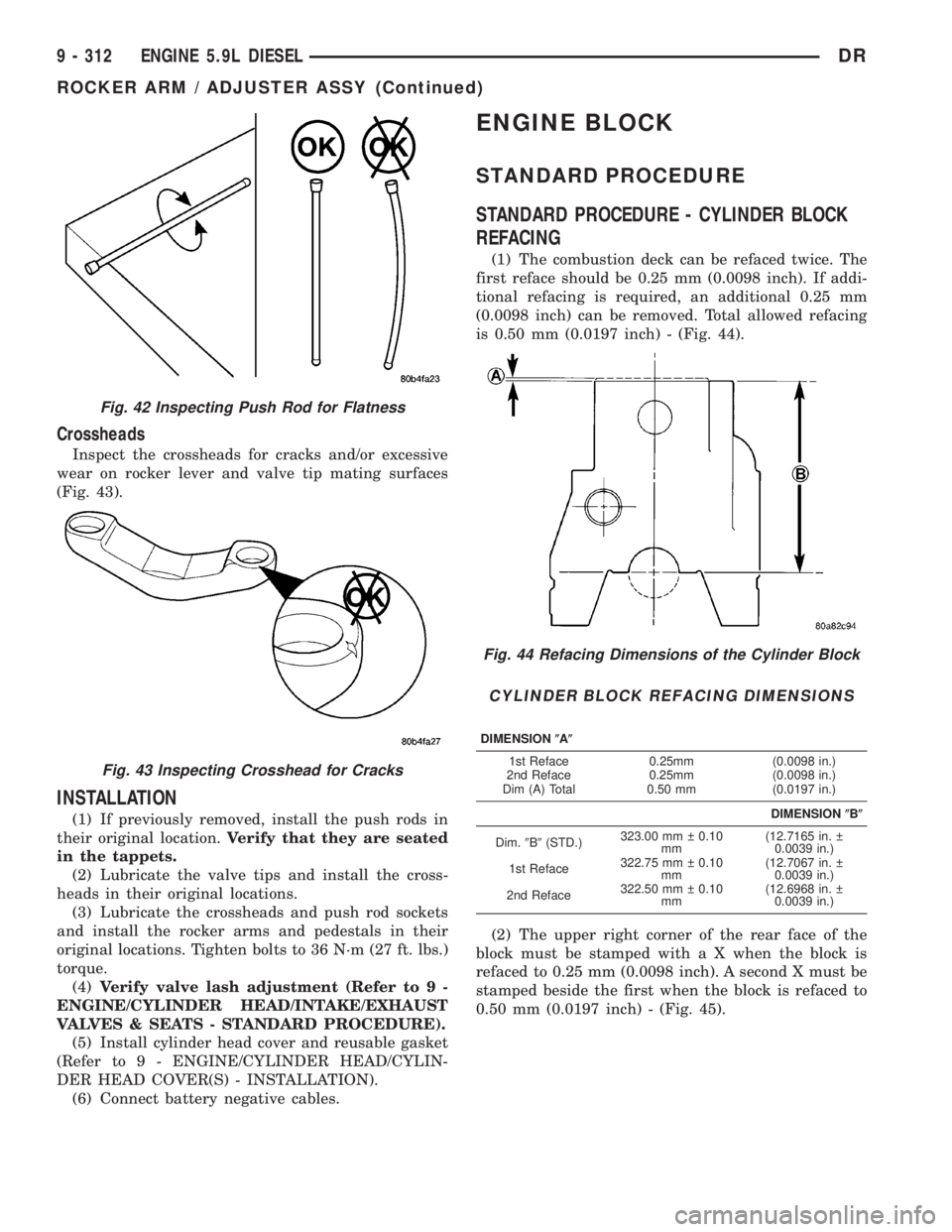

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER BLOCK

REFACING

(1) The combustion deck can be refaced twice. The

first reface should be 0.25 mm (0.0098 inch). If addi-

tional refacing is required, an additional 0.25 mm

(0.0098 inch) can be removed. Total allowed refacing

is 0.50 mm (0.0197 inch) - (Fig. 44).

(2) The upper right corner of the rear face of the

block must be stamped with a X when the block is

refaced to 0.25 mm (0.0098 inch). A second X must be

stamped beside the first when the block is refaced to

0.50 mm (0.0197 inch) - (Fig. 45).

Fig. 42 Inspecting Push Rod for Flatness

Fig. 43 Inspecting Crosshead for Cracks

Fig. 44 Refacing Dimensions of the Cylinder Block

CYLINDER BLOCK REFACING DIMENSIONS

DIMENSION(A(

1st Reface 0.25mm (0.0098 in.)

2nd Reface 0.25mm (0.0098 in.)

Dim (A) Total 0.50 mm (0.0197 in.)

DIMENSION(B(

Dim.9B9(STD.)323.00 mm 0.10

mm(12.7165 in.

0.0039 in.)

1st Reface322.75 mm 0.10

mm(12.7067 in.

0.0039 in.)

2nd Reface322.50 mm 0.10

mm(12.6968 in.

0.0039 in.)

9 - 312 ENGINE 5.9L DIESELDR

ROCKER ARM / ADJUSTER ASSY (Continued)

Page 1562 of 2895

(3) Consult the parts catalog for the proper head

gaskets which must be used with refaced blocks to

ensure proper piston-to-valve clearance.

STANDARD PROCEDURE - CYLINDER BORE -

DE-GLAZE

(1) New piston rings may not seat in glazed cylin-

der bores.

(2) De-glazing gives the bore the correct surface

finish required to seat the rings. The size of the bore

is not changed by proper de-glazing.

(3) Cover the lube and tappet holes in the top of

the block with waterproof tape.

(4) It crankshaft is installed, wrap connecting rod

journals with clean cloth. Cover cloth with water-

proof tape.

(5) A correctly honed surface will have a cross-

hatch appearance with the lines at 15É to 25É angles

(Fig. 46). For the rough hone, use 80 grit honing

stones. To finish hone, use 280 grit honing stones.

(6) Use a drill, a fine grit Flex-hone and a mixture

of equal parts of mineral spirits and SAE 30W engine

oil to de-glaze the bores.

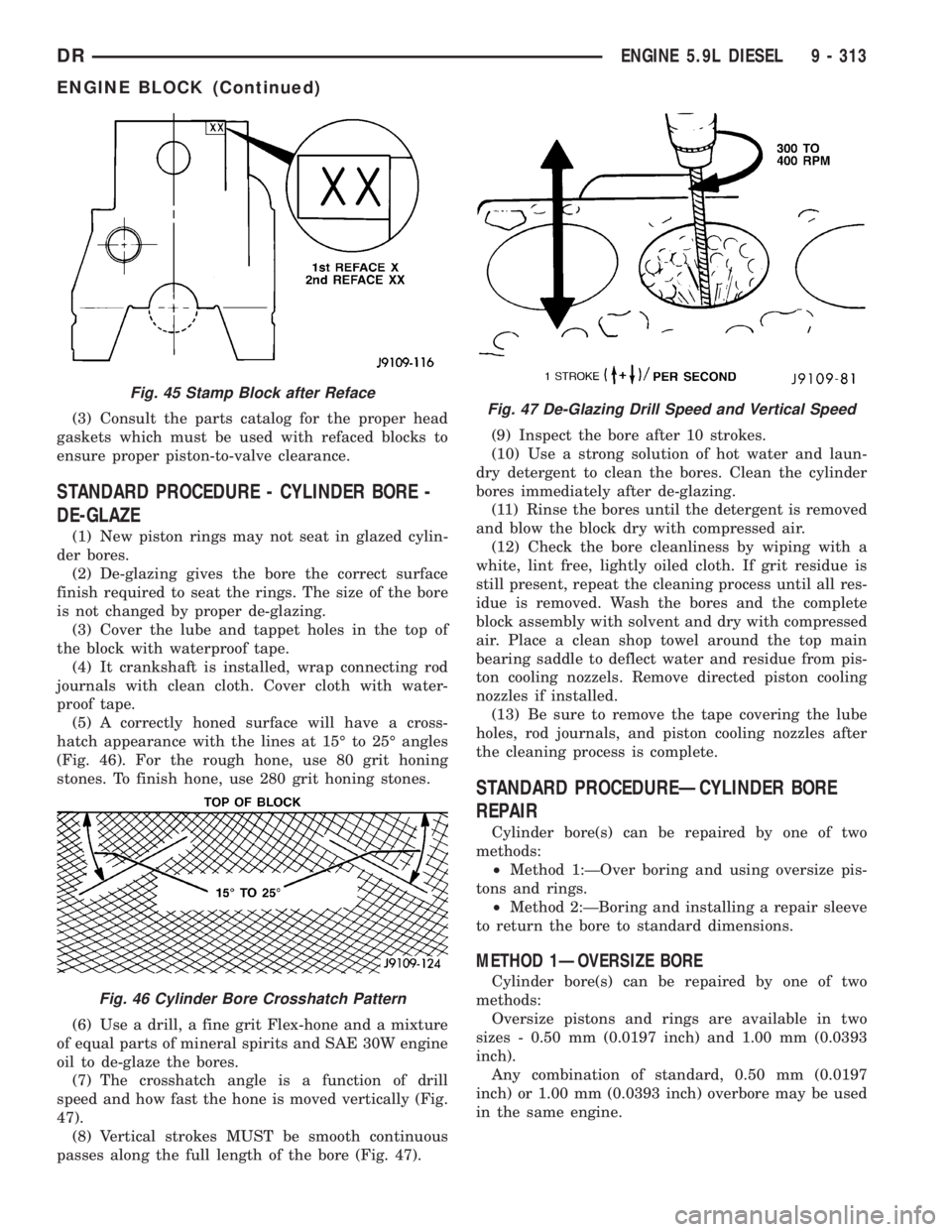

(7) The crosshatch angle is a function of drill

speed and how fast the hone is moved vertically (Fig.

47).

(8) Vertical strokes MUST be smooth continuous

passes along the full length of the bore (Fig. 47).(9) Inspect the bore after 10 strokes.

(10) Use a strong solution of hot water and laun-

dry detergent to clean the bores. Clean the cylinder

bores immediately after de-glazing.

(11) Rinse the bores until the detergent is removed

and blow the block dry with compressed air.

(12) Check the bore cleanliness by wiping with a

white, lint free, lightly oiled cloth. If grit residue is

still present, repeat the cleaning process until all res-

idue is removed. Wash the bores and the complete

block assembly with solvent and dry with compressed

air. Place a clean shop towel around the top main

bearing saddle to deflect water and residue from pis-

ton cooling nozzels. Remove directed piston cooling

nozzles if installed.

(13) Be sure to remove the tape covering the lube

holes, rod journals, and piston cooling nozzles after

the cleaning process is complete.

STANDARD PROCEDUREÐCYLINDER BORE

REPAIR

Cylinder bore(s) can be repaired by one of two

methods:

²Method 1:ÐOver boring and using oversize pis-

tons and rings.

²Method 2:ÐBoring and installing a repair sleeve

to return the bore to standard dimensions.

METHOD 1ÐOVERSIZE BORE

Cylinder bore(s) can be repaired by one of two

methods:

Oversize pistons and rings are available in two

sizes - 0.50 mm (0.0197 inch) and 1.00 mm (0.0393

inch).

Any combination of standard, 0.50 mm (0.0197

inch) or 1.00 mm (0.0393 inch) overbore may be used

in the same engine.

Fig. 45 Stamp Block after Reface

Fig. 46 Cylinder Bore Crosshatch Pattern

Fig. 47 De-Glazing Drill Speed and Vertical Speed

DRENGINE 5.9L DIESEL 9 - 313

ENGINE BLOCK (Continued)