Fuel system DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1474 of 2895

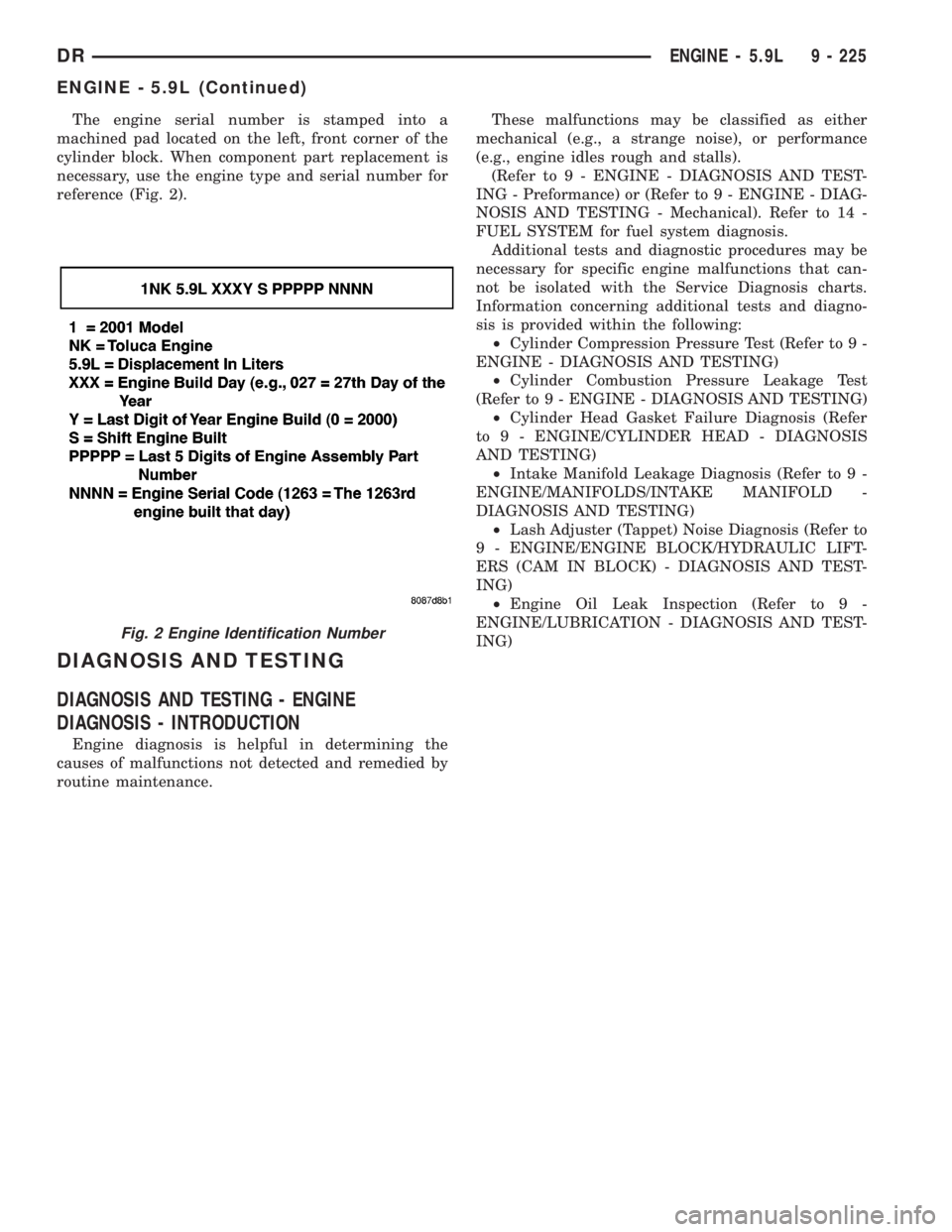

The engine serial number is stamped into a

machined pad located on the left, front corner of the

cylinder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 2).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Head Gasket Failure Diagnosis (Refer

to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS

AND TESTING)

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING)

²Lash Adjuster (Tappet) Noise Diagnosis (Refer to

9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - DIAGNOSIS AND TEST-

ING)

²Engine Oil Leak Inspection (Refer to 9 -

ENGINE/LUBRICATION - DIAGNOSIS AND TEST-

ING)

Fig. 2 Engine Identification Number

DRENGINE - 5.9L 9 - 225

ENGINE - 5.9L (Continued)

Page 1475 of 2895

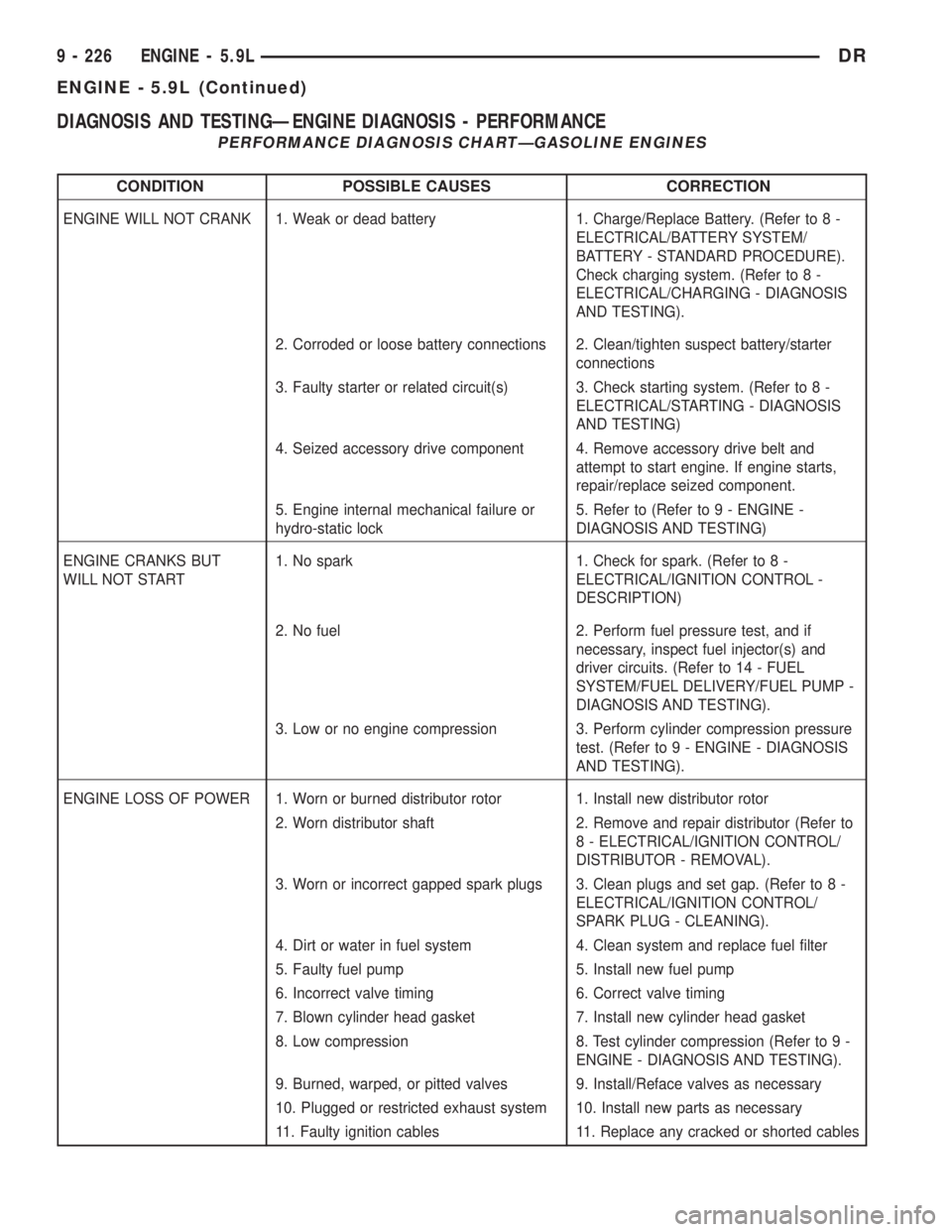

DIAGNOSIS AND TESTINGÐENGINE DIAGNOSIS - PERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE).

Check charging system. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS

AND TESTING).

2. Corroded or loose battery connections 2. Clean/tighten suspect battery/starter

connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine starts,

repair/replace seized component.

5. Engine internal mechanical failure or

hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT

WILL NOT START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL PUMP -

DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression pressure

test. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING).

ENGINE LOSS OF POWER 1. Worn or burned distributor rotor 1. Install new distributor rotor

2. Worn distributor shaft 2. Remove and repair distributor (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

DISTRIBUTOR - REMOVAL).

3. Worn or incorrect gapped spark plugs 3. Clean plugs and set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG - CLEANING).

4. Dirt or water in fuel system 4. Clean system and replace fuel filter

5. Faulty fuel pump 5. Install new fuel pump

6. Incorrect valve timing 6. Correct valve timing

7. Blown cylinder head gasket 7. Install new cylinder head gasket

8. Low compression 8. Test cylinder compression (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

9. Burned, warped, or pitted valves 9. Install/Reface valves as necessary

10. Plugged or restricted exhaust system 10. Install new parts as necessary

11. Faulty ignition cables 11. Replace any cracked or shorted cables

9 - 226 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1476 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

12. Faulty ignition coil 12. Test and replace, as necessary (Refer

to 8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL).

ENGINE STALLS OR

ROUGH IDLE1. Carbon build-up on throttle plate 1. Remove throttle body and de-carbon.

(Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/THROTTLE BODY -

REMOVAL).

2. Engine idle speed too low 2. Check Idle Air Control circuit. (Refer to

14 - FUEL SYSTEM/FUEL INJECTION/

IDLE AIR CONTROL MOTOR -

DESCRIPTION)

3. Worn or incorrectly gapped spark plugs 3. Replace or clean and re-gap spark

plugs (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING)

4. Worn or burned distributor rotor 4. Install new distributor rotor

5. Spark plug cables defective or crossed 5. Check for correct firing order or replace

spark plug cables. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG CABLE - DIAGNOSIS AND

TESTING)

6. Faulty coil 6. Test and replace, if necessary (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL)

7. Intake manifold vacuum leak 7. Inspect intake manifold gasket and

vacuum hoses (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark plugs 1. Replace spark plugs or clean and set

gap. (Refer to 8 - ELECTRICAL/IGNITION

CONTROL/SPARK PLUG - CLEANING)

2. Spark plug cables defective or crossed 2. Replace or rewire secondary ignition

cables. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

CABLE - REMOVAL)

3. Dirt in fuel system 3. Clean fuel system

4. Burned, warped or pitted valves 4. Install new valves

5. Faulty coil 5. Test and replace as necessary (Refer to

8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL)

DRENGINE - 5.9L 9 - 227

ENGINE - 5.9L (Continued)

Page 1482 of 2895

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

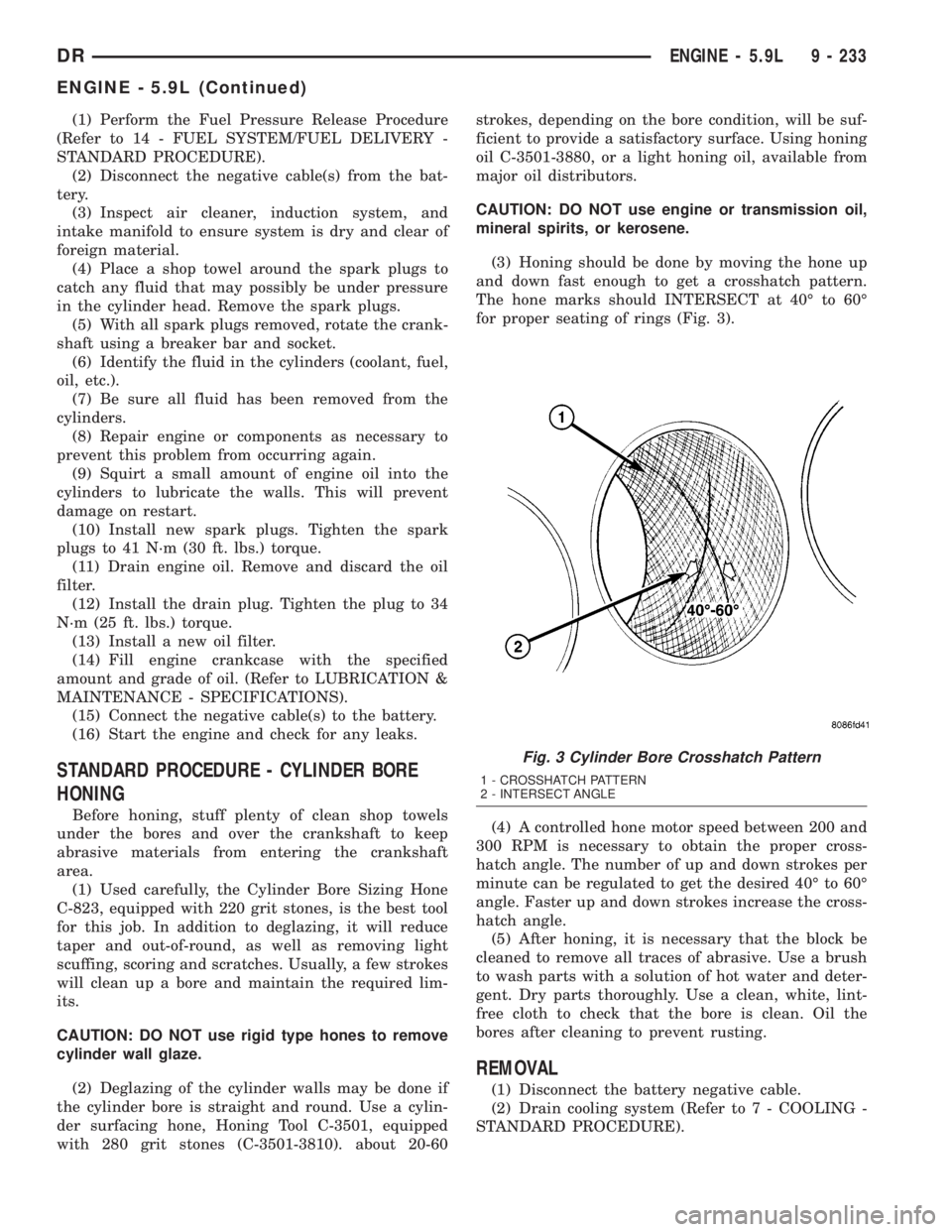

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

DRENGINE - 5.9L 9 - 233

ENGINE - 5.9L (Continued)

Page 1483 of 2895

(3) Recover refrigerant from a/c system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(4) Remove the a/c condenser, if equipped (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the washer bottle from the fan shroud.

(7) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(8) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(9) Remove the upper crossmember and top core

support.

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(12) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(13) Remove the air cleaner resonator and duct

work as an assembly.

(14) Disconnect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL).

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(21) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(22) On Manual Transmission vehicles, remove the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - REMOVAL).

(23) Raise and support the vehicle on a hoist and

drain the engine oil.

(24) Remove engine front mount thru-bolt nuts.

(25) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(26) Disconnect exhaust pipe at manifolds.(27) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(28) Remove the dust shield and transmission

inspection cover.

(29) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).

(30) Remove transmission bell housing to engine

block bolts.

(31) Lower the vehicle.

(32) Install an engine lifting fixture.

(33) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install engine lifting device.

(3) Lower engine into compartment and align

engine with transmission:

²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Lower engine assembly until engine mount

through bolts rest in mount perches.

(5) Install remaining transmission to engine block

mounting bolts and tighten.

(6) Tighten engine mount through bolts.

(7) Install drive plate to torque converter bolts.

(Automatic transmission models)

(8) Install the dust shield and transmission cover.

(9) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(10) Install exhaust pipe to manifold.

(11) Install the transmission cooler line brackets to

the oil pan.

(12) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(13) Lower the vehicle.

(14) Remove engine lifting fixture.

(15) On Manual Transmission vehicles, install the

shift lever (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/SHIFT COVER - INSTALLATION).

(16) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(17) Connect the power steering hoses, if equipped.

(18) Connect the heater hoses.

9 - 234 ENGINE - 5.9LDR

ENGINE - 5.9L (Continued)

Page 1484 of 2895

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(21) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(22) Connect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION).

(23) Install the air cleaner resonator and duct

work..

(24) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(25) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

(26) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(27) Install upper radiator support crossmember.

(28) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(29) Connect the radiator lower hose.

(30) Connect the transmission oil cooler lines to

the radiator.

(31) Install the fan shroud.

(32) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(33) Connect the radiator upper hose.

(34) Install the washer bottle.

(35) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(36) Connect the transmission cooler lines.

(37) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(38) Evacuate and charge the air conditioning sys-

tem, if equipped (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(39) Add engine oil to crankcase (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES - SPEC-

IFICATIONS).

(40) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(41) Connect battery negative cable.

(42) Start engine and inspect for leaks.

(43) Road test vehicle.SPECIFICATIONS

5.9L ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 101.6 x 90.9 mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure Feed ± Full

Flow

Filtration

Cooling System Liquid Cooled ± Forced

Circulation

Cylinder Block Cast Iron

Cylinder Head Cast Iron

Crankshaft Nodular Iron

Camshaft Nodular Cast Iron

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Compression Pressure 689.5 kPa (100 psi)

(Min.)

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

DRENGINE - 5.9L 9 - 235

ENGINE - 5.9L (Continued)

Page 1493 of 2895

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(9) Remove distributor cap and wires.

(10) Disconnect the coil wires.

(11) Disconnect heat indicator sending unit wire.

(12) Disconnect heater hoses and bypass hose.

(13) Remove the master cylinder and booster

assembly. Refer to section 5 brakes.

(14) Remove cylinder head covers and gaskets

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(15) Remove intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL) and throttle body as an assembly. Dis-

card the flange side gaskets and the front and rear

cross-over gaskets.(16) Remove exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

REMOVAL).

(17) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(18) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(19) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075mm/mm (0.0001in/in.) times the span

length in any direction, either replace head or lightly

machine the head surface.

FOR EXAMPLE:ÐA 305 mm (12 in.) span is

0.102 mm (0.004 in.) out-of-flat. The allowable out-of-

flat is 305 x 0.00075 (12 x 0.00075) equals 0.23 mm

(0.009 in.). This amount of out-of-flat is acceptable.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

(3) Position new cylinder head gaskets onto the

cylinder block.

(4) Position cylinder heads onto head gaskets and

cylinder block.

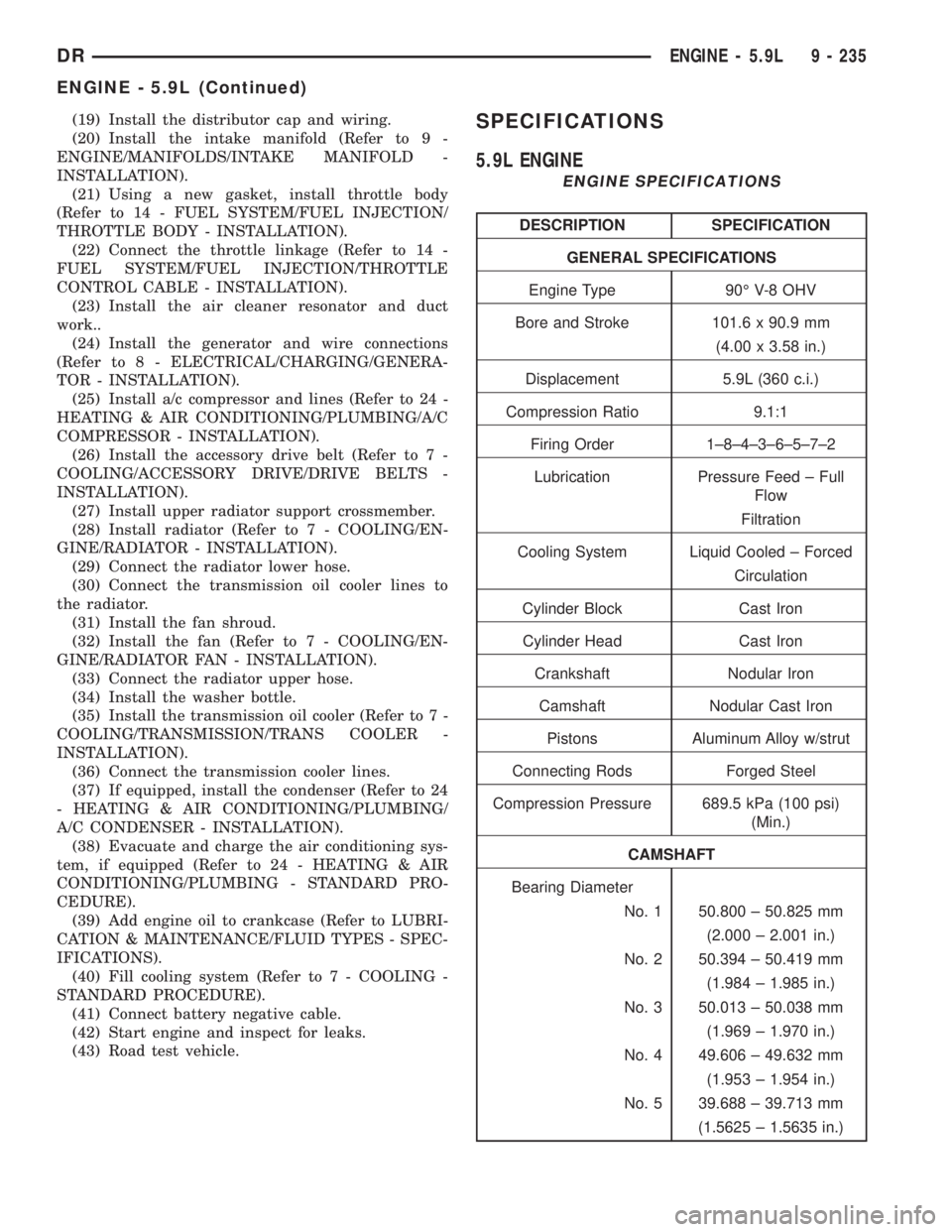

(5) Starting at top center, tighten all cylinder head

bolts, in sequence (Fig. 8).

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(6) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

(7) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION) and throttle body assembly.

(8) Install exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION).

9 - 244 ENGINE - 5.9LDR

CYLINDER HEAD (Continued)

Page 1494 of 2895

(9) If required, adjust spark plugs to specifications.

Install the plugs and tighten to 41 N´m (30 ft. lbs.)

torque.

(10) Install coil wire.

(11) Connect heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(15) Install the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(16) Install the generator and drive belt (Refer to 7

- COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION). Tighten generator mounting bolt

to 41 N´m (30 ft. lbs.) torque. Tighten the adjusting

strap bolt to 23 N´m (200 in. lbs.) torque.

(17) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts.

(18) Place the cylinder head cover gaskets in posi-

tion and install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(19) Install closed crankcase ventilation system.

(20) Connect the evaporation control system.

(21) Reinstall the master cylinder and booster

assembly. Refer to section 5 brakes.

(22) Install the air cleaner.

(23) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(24) Connect the negative cable to the battery.

(25) Start engine check for leaks.

CYLINDER HEAD COVER(S)

REMOVAL

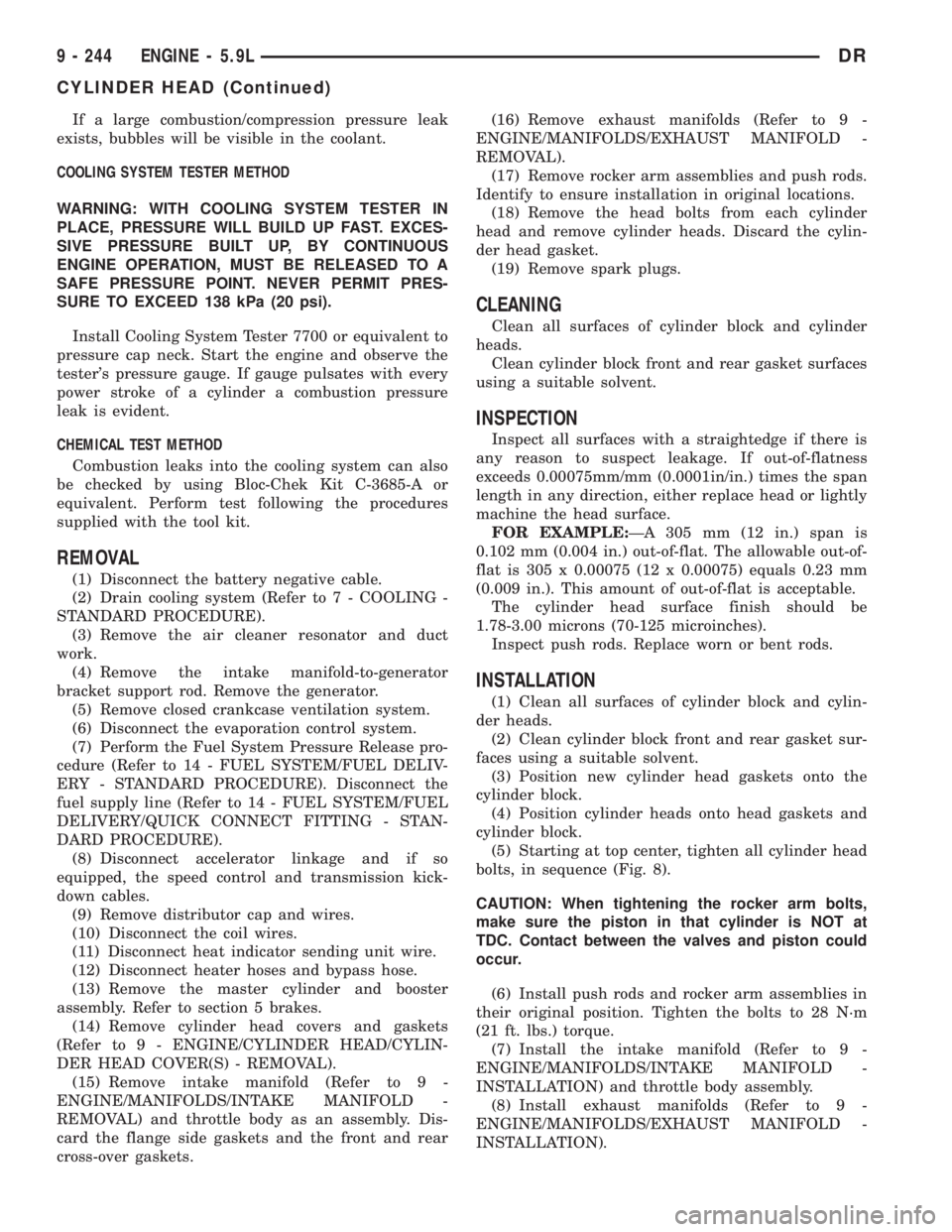

NOTE: A steel backed silicon gasket is used with

the cylinder head cover (Fig. 9). This gasket can be

used again.

(1) Disconnect the negative cable from the battery.

(2) Disconnect the spark plug wires form the spark

plugs and set aside.

(3) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

(4) Remove cylinder head cover and gasket.

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

INSTALLATION

(1) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.

(2) Position the cylinder head cover onto the gas-

ket. Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Connect the spark plug wires to the spark

plugs.

(5) Connect the negative cable to the battery.

Fig. 8 Cylinder Head Bolt Tightening Sequence

Fig. 9 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

DRENGINE - 5.9L 9 - 245

CYLINDER HEAD (Continued)

Page 1524 of 2895

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPMs occur, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

(4) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner.

(7) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel lines (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect the accelerator linkage (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL) and if so equipped,

the speed control and transmission kickdown cables.

(9) Remove the return spring.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the heat indicator sending unit

wire.

(13) Disconnect the heater hoses and bypass hose.

(14) Remove the closed crankcase ventilation and

evaporation control systems.

(15) Remove intake manifold bolts.

(16) Lift the intake manifold and throttle body out

of the engine compartment as an assembly.

(17) Remove and discard the flange side gaskets

and the front and rear end seals.

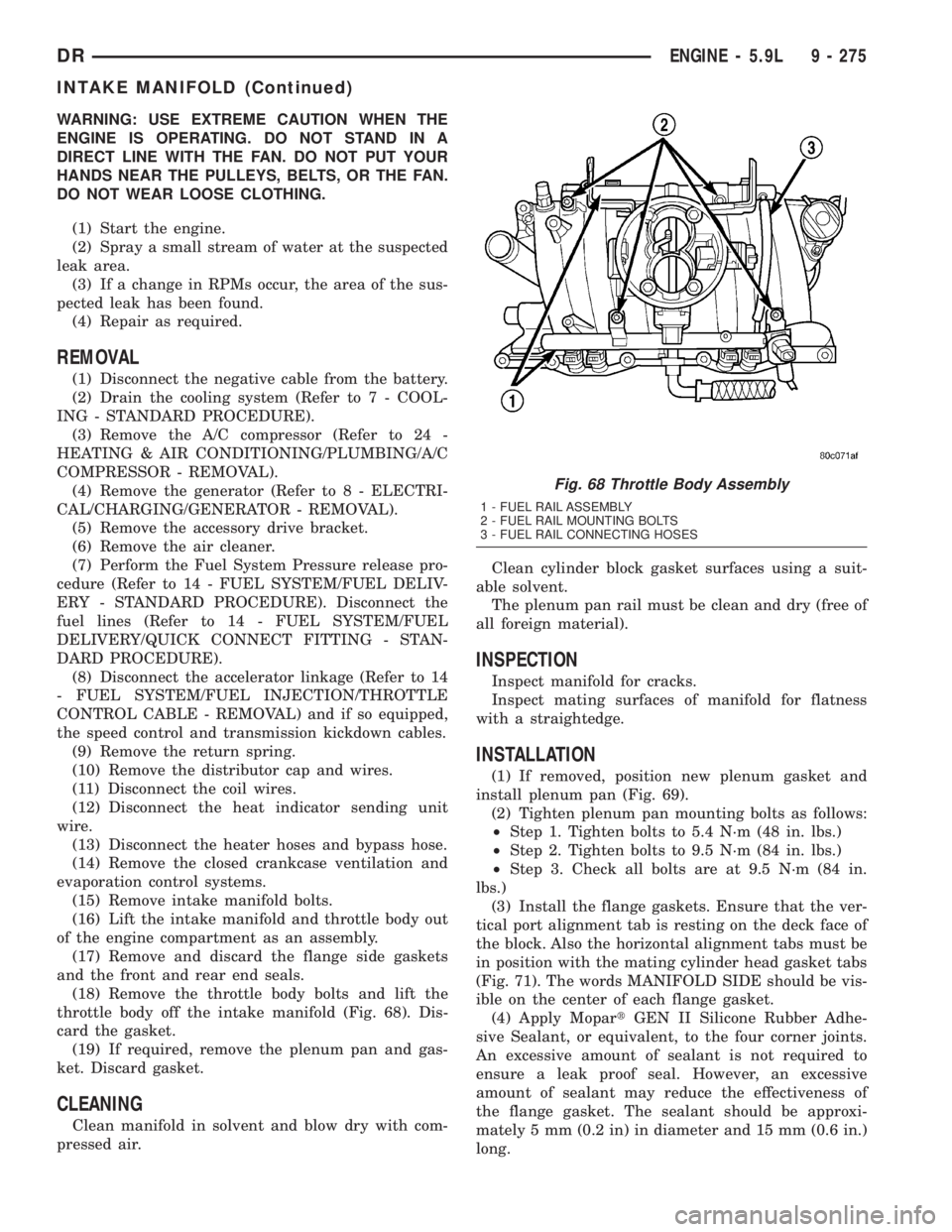

(18) Remove the throttle body bolts and lift the

throttle body off the intake manifold (Fig. 68). Dis-

card the gasket.

(19) If required, remove the plenum pan and gas-

ket. Discard gasket.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

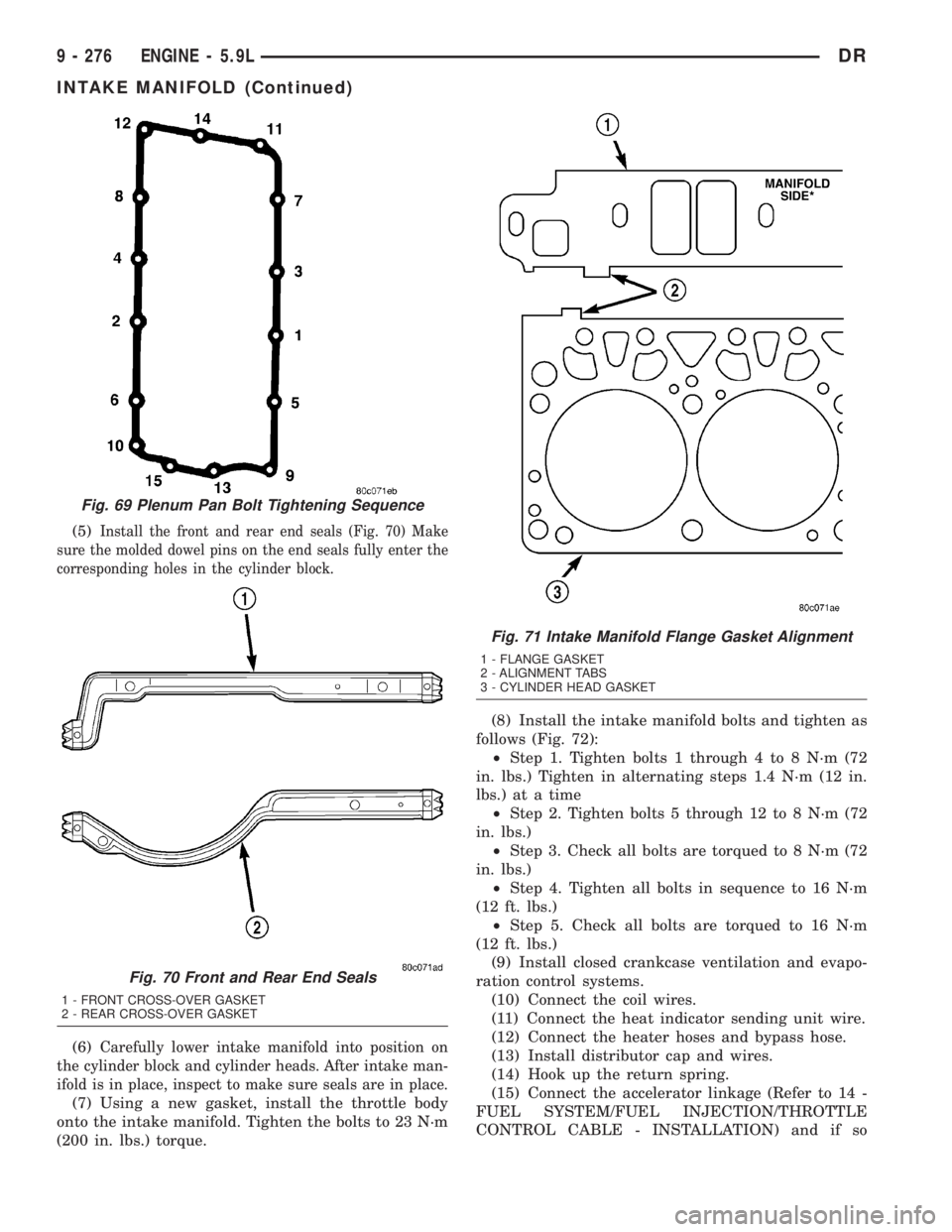

(1) If removed, position new plenum gasket and

install plenum pan (Fig. 69).

(2) Tighten plenum pan mounting bolts as follows:

²Step 1. Tighten bolts to 5.4 N´m (48 in. lbs.)

²Step 2. Tighten bolts to 9.5 N´m (84 in. lbs.)

²Step 3. Check all bolts are at 9.5 N´m (84 in.

lbs.)

(3) Install the flange gaskets. Ensure that the ver-

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must be

in position with the mating cylinder head gasket tabs

(Fig. 71). The words MANIFOLD SIDE should be vis-

ible on the center of each flange gasket.

(4) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, to the four corner joints.

An excessive amount of sealant is not required to

ensure a leak proof seal. However, an excessive

amount of sealant may reduce the effectiveness of

the flange gasket. The sealant should be approxi-

mately 5 mm (0.2 in) in diameter and 15 mm (0.6 in.)

long.

Fig. 68 Throttle Body Assembly

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

DRENGINE - 5.9L 9 - 275

INTAKE MANIFOLD (Continued)

Page 1525 of 2895

(5)Install the front and rear end seals (Fig. 70) Make

sure the molded dowel pins on the end seals fully enter the

corresponding holes in the cylinder block.

(6)Carefully lower intake manifold into position on

the cylinder block and cylinder heads. After intake man-

ifold is in place, inspect to make sure seals are in place.

(7) Using a new gasket, install the throttle body

onto the intake manifold. Tighten the bolts to 23 N´m

(200 in. lbs.) torque.(8) Install the intake manifold bolts and tighten as

follows (Fig. 72):

²Step 1. Tighten bolts 1 through 4 to 8 N´m (72

in. lbs.) Tighten in alternating steps 1.4 N´m (12 in.

lbs.) at a time

²Step 2. Tighten bolts 5 through 12 to 8 N´m (72

in. lbs.)

²Step 3. Check all bolts are torqued to 8 N´m (72

in. lbs.)

²Step 4. Tighten all bolts in sequence to 16 N´m

(12 ft. lbs.)

²Step 5. Check all bolts are torqued to 16 N´m

(12 ft. lbs.)

(9) Install closed crankcase ventilation and evapo-

ration control systems.

(10) Connect the coil wires.

(11) Connect the heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Hook up the return spring.

(15) Connect the accelerator linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION) and if so

Fig. 69 Plenum Pan Bolt Tightening Sequence

Fig. 70 Front and Rear End Seals

1 - FRONT CROSS-OVER GASKET

2 - REAR CROSS-OVER GASKET

Fig. 71 Intake Manifold Flange Gasket Alignment

1 - FLANGE GASKET

2 - ALIGNMENT TABS

3 - CYLINDER HEAD GASKET

9 - 276 ENGINE - 5.9LDR

INTAKE MANIFOLD (Continued)