display DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2102 of 2895

tank. The valve prevents fluid drainback when the

vehicle is parked for lengthy periods. The valve check

ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not repair-

able. Do not clean the valve if restricted, or contami-

nated by sludge, or debris. If the valve fails, or if a

transmission malfunction occurs that generates signifi-

cant amounts of sludge and/or clutch particles and

metal shavings, the valve must be replaced.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow

device. It must be properly oriented in terms of flow

direction for the cooler to function properly. The

valve must be installed in the pressure line. Other-

wise flow will be blocked and would cause an over-

heating condition and eventual transmission failure.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

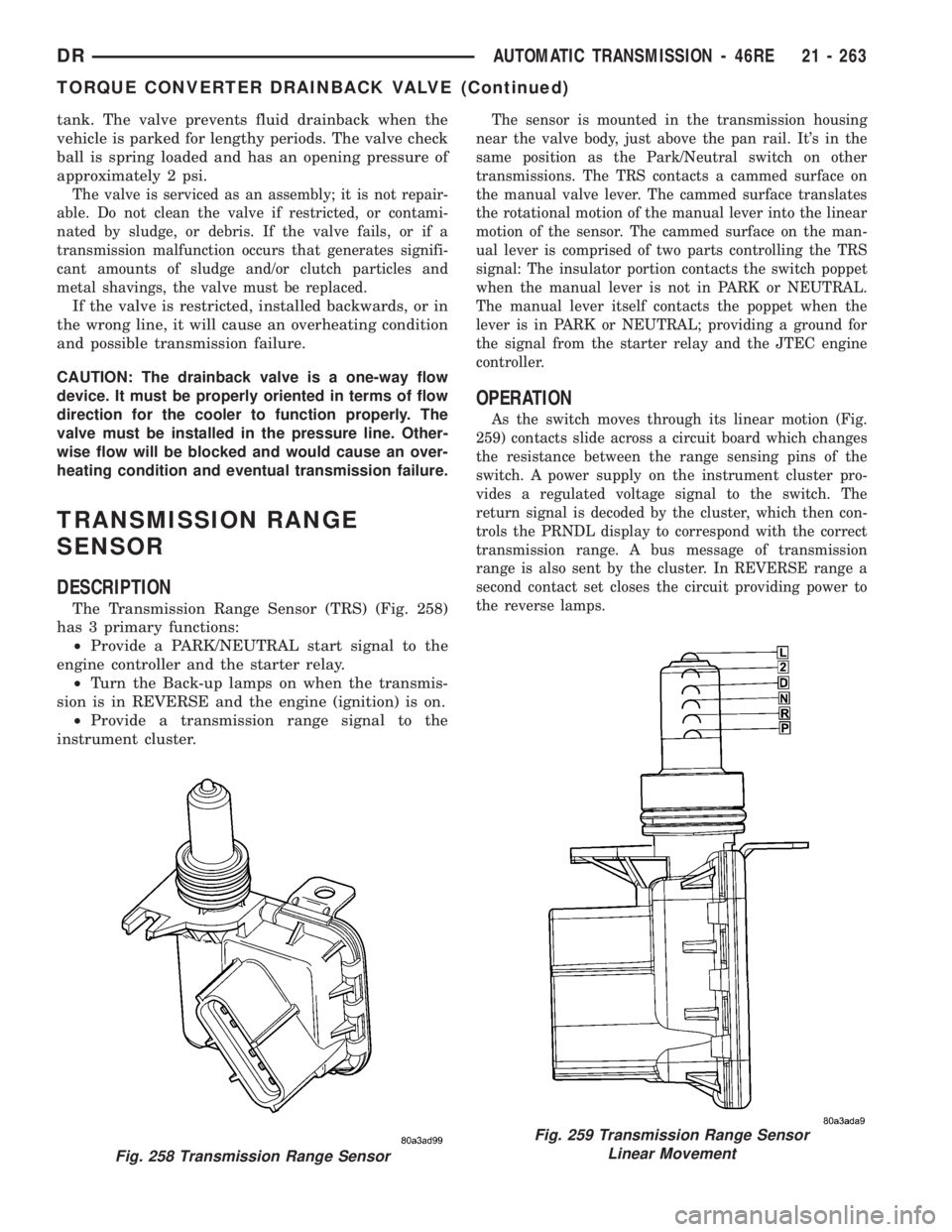

The Transmission Range Sensor (TRS) (Fig. 258)

has 3 primary functions:

²Provide a PARK/NEUTRAL start signal to the

engine controller and the starter relay.

²Turn the Back-up lamps on when the transmis-

sion is in REVERSE and the engine (ignition) is on.

²Provide a transmission range signal to the

instrument cluster.

The sensor is mounted in the transmission housing

near the valve body, just above the pan rail. It's in the

same position as the Park/Neutral switch on other

transmissions. The TRS contacts a cammed surface on

the manual valve lever. The cammed surface translates

the rotational motion of the manual lever into the linear

motion of the sensor. The cammed surface on the man-

ual lever is comprised of two parts controlling the TRS

signal: The insulator portion contacts the switch poppet

when the manual lever is not in PARK or NEUTRAL.

The manual lever itself contacts the poppet when the

lever is in PARK or NEUTRAL; providing a ground for

the signal from the starter relay and the JTEC engine

controller.

OPERATION

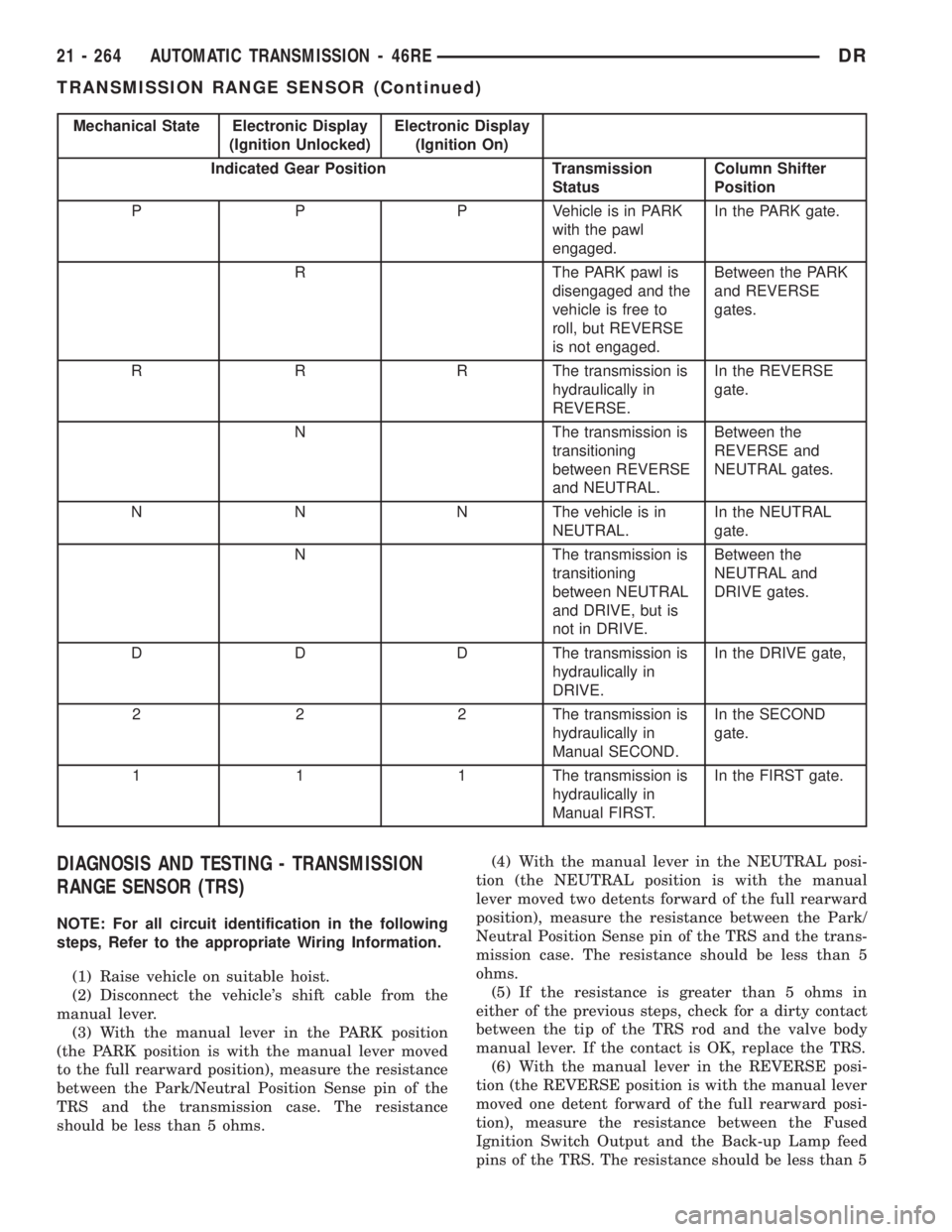

As the switch moves through its linear motion (Fig.

259) contacts slide across a circuit board which changes

the resistance between the range sensing pins of the

switch. A power supply on the instrument cluster pro-

vides a regulated voltage signal to the switch. The

return signal is decoded by the cluster, which then con-

trols the PRNDL display to correspond with the correct

transmission range. A bus message of transmission

range is also sent by the cluster. In REVERSE range a

second contact set closes the circuit providing power to

the reverse lamps.

Fig. 258 Transmission Range Sensor

Fig. 259 Transmission Range Sensor

Linear Movement

DRAUTOMATIC TRANSMISSION - 46RE 21 - 263

TORQUE CONVERTER DRAINBACK VALVE (Continued)

Page 2103 of 2895

Mechanical State Electronic Display

(Ignition Unlocked)Electronic Display

(Ignition On)

Indicated Gear Position Transmission

StatusColumn Shifter

Position

P P P Vehicle is in PARK

with the pawl

engaged.In the PARK gate.

R The PARK pawl is

disengaged and the

vehicle is free to

roll, but REVERSE

is not engaged.Between the PARK

and REVERSE

gates.

R R R The transmission is

hydraulically in

REVERSE.In the REVERSE

gate.

N The transmission is

transitioning

between REVERSE

and NEUTRAL.Between the

REVERSE and

NEUTRAL gates.

N N N The vehicle is in

NEUTRAL.In the NEUTRAL

gate.

N The transmission is

transitioning

between NEUTRAL

and DRIVE, but is

not in DRIVE.Between the

NEUTRAL and

DRIVE gates.

D D D The transmission is

hydraulically in

DRIVE.In the DRIVE gate,

2 2 2 The transmission is

hydraulically in

Manual SECOND.In the SECOND

gate.

1 1 1 The transmission is

hydraulically in

Manual FIRST.In the FIRST gate.

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS)

NOTE: For all circuit identification in the following

steps, Refer to the appropriate Wiring Information.

(1) Raise vehicle on suitable hoist.

(2) Disconnect the vehicle's shift cable from the

manual lever.

(3) With the manual lever in the PARK position

(the PARK position is with the manual lever moved

to the full rearward position), measure the resistance

between the Park/Neutral Position Sense pin of the

TRS and the transmission case. The resistance

should be less than 5 ohms.(4) With the manual lever in the NEUTRAL posi-

tion (the NEUTRAL position is with the manual

lever moved two detents forward of the full rearward

position), measure the resistance between the Park/

Neutral Position Sense pin of the TRS and the trans-

mission case. The resistance should be less than 5

ohms.

(5) If the resistance is greater than 5 ohms in

either of the previous steps, check for a dirty contact

between the tip of the TRS rod and the valve body

manual lever. If the contact is OK, replace the TRS.

(6) With the manual lever in the REVERSE posi-

tion (the REVERSE position is with the manual lever

moved one detent forward of the full rearward posi-

tion), measure the resistance between the Fused

Ignition Switch Output and the Back-up Lamp feed

pins of the TRS. The resistance should be less than 5

21 - 264 AUTOMATIC TRANSMISSION - 46REDR

TRANSMISSION RANGE SENSOR (Continued)

Page 2280 of 2895

TRANSMISSION RANGE

SENSOR

DESCRIPTION

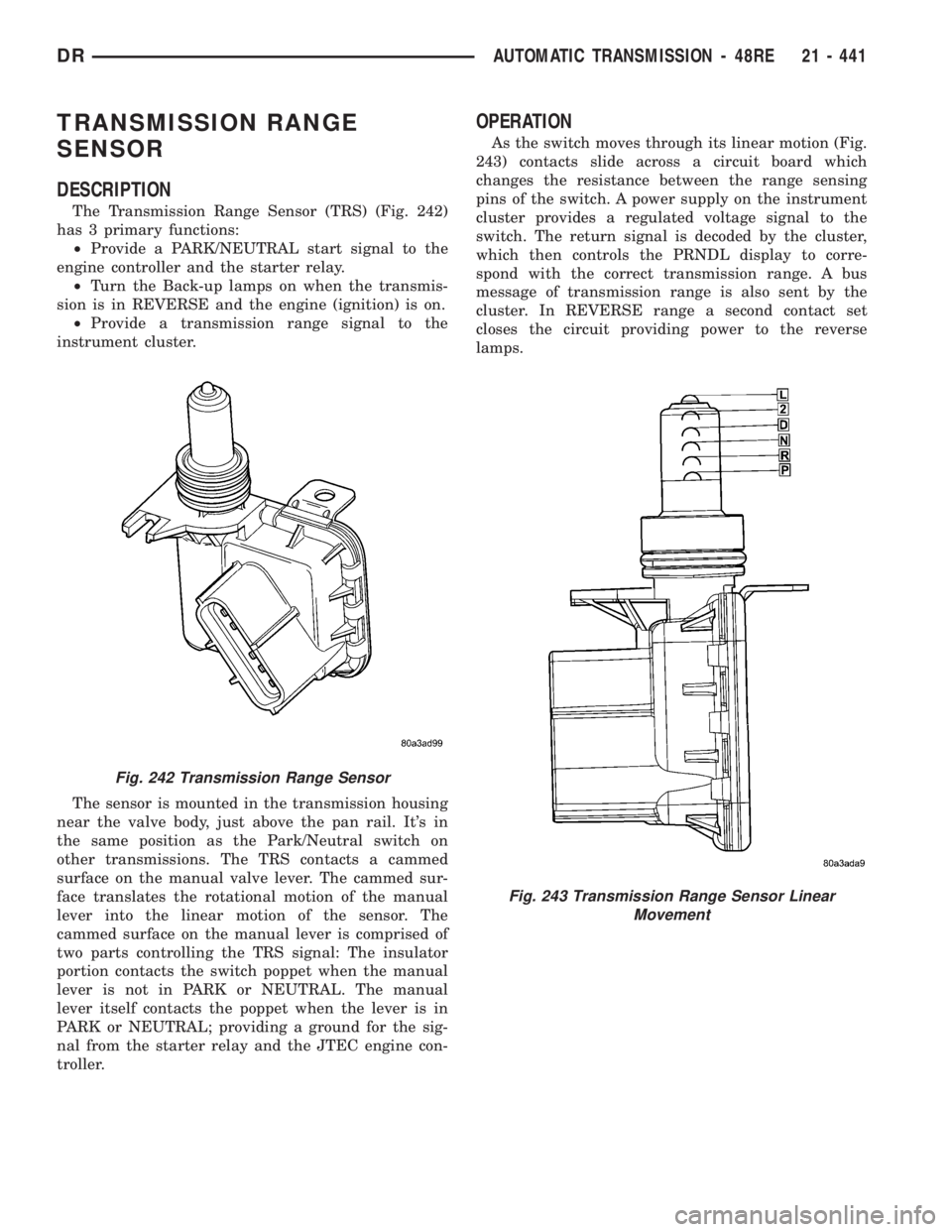

The Transmission Range Sensor (TRS) (Fig. 242)

has 3 primary functions:

²Provide a PARK/NEUTRAL start signal to the

engine controller and the starter relay.

²Turn the Back-up lamps on when the transmis-

sion is in REVERSE and the engine (ignition) is on.

²Provide a transmission range signal to the

instrument cluster.

The sensor is mounted in the transmission housing

near the valve body, just above the pan rail. It's in

the same position as the Park/Neutral switch on

other transmissions. The TRS contacts a cammed

surface on the manual valve lever. The cammed sur-

face translates the rotational motion of the manual

lever into the linear motion of the sensor. The

cammed surface on the manual lever is comprised of

two parts controlling the TRS signal: The insulator

portion contacts the switch poppet when the manual

lever is not in PARK or NEUTRAL. The manual

lever itself contacts the poppet when the lever is in

PARK or NEUTRAL; providing a ground for the sig-

nal from the starter relay and the JTEC engine con-

troller.

OPERATION

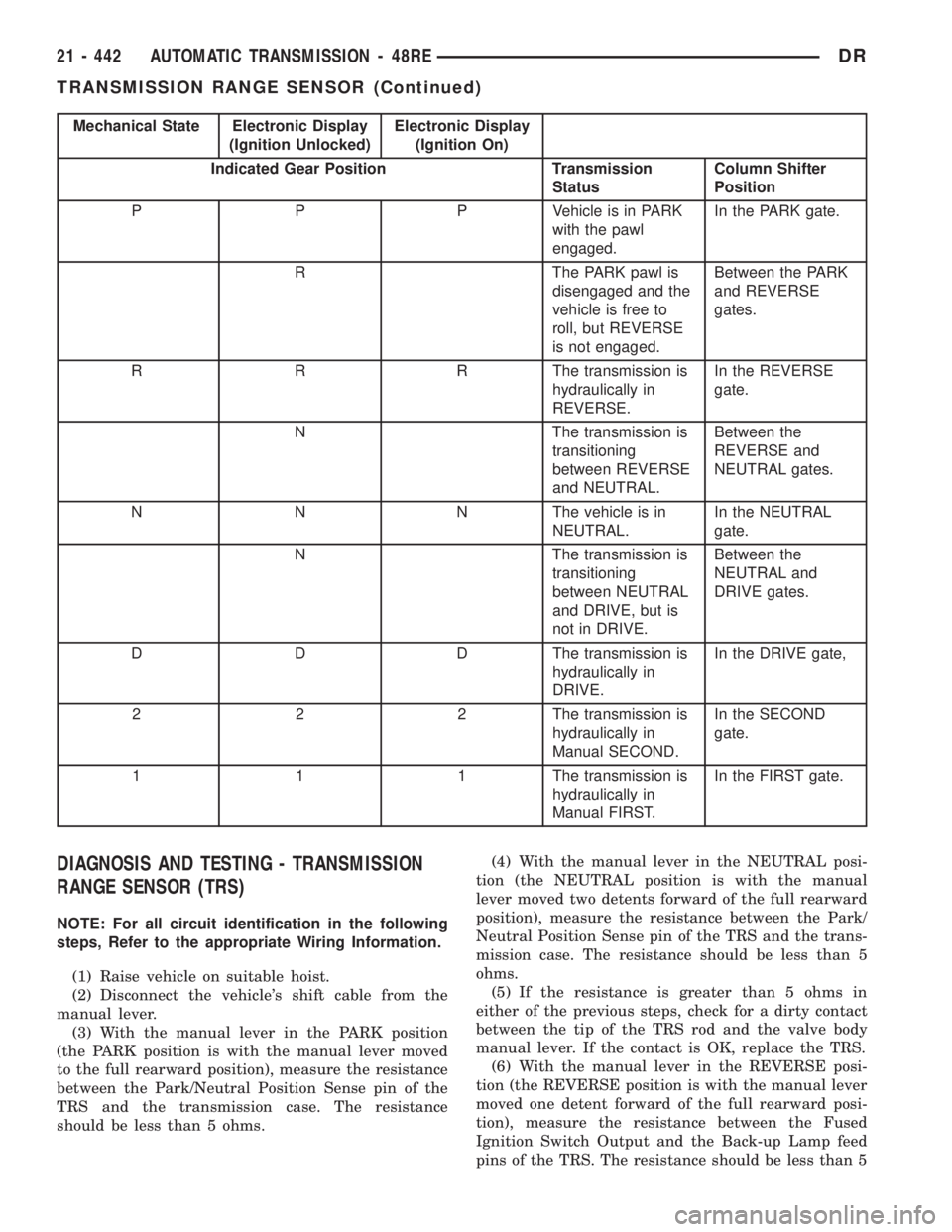

As the switch moves through its linear motion (Fig.

243) contacts slide across a circuit board which

changes the resistance between the range sensing

pins of the switch. A power supply on the instrument

cluster provides a regulated voltage signal to the

switch. The return signal is decoded by the cluster,

which then controls the PRNDL display to corre-

spond with the correct transmission range. A bus

message of transmission range is also sent by the

cluster. In REVERSE range a second contact set

closes the circuit providing power to the reverse

lamps.

Fig. 242 Transmission Range Sensor

Fig. 243 Transmission Range Sensor Linear

Movement

DRAUTOMATIC TRANSMISSION - 48RE 21 - 441

Page 2281 of 2895

Mechanical State Electronic Display

(Ignition Unlocked)Electronic Display

(Ignition On)

Indicated Gear Position Transmission

StatusColumn Shifter

Position

P P P Vehicle is in PARK

with the pawl

engaged.In the PARK gate.

R The PARK pawl is

disengaged and the

vehicle is free to

roll, but REVERSE

is not engaged.Between the PARK

and REVERSE

gates.

R R R The transmission is

hydraulically in

REVERSE.In the REVERSE

gate.

N The transmission is

transitioning

between REVERSE

and NEUTRAL.Between the

REVERSE and

NEUTRAL gates.

N N N The vehicle is in

NEUTRAL.In the NEUTRAL

gate.

N The transmission is

transitioning

between NEUTRAL

and DRIVE, but is

not in DRIVE.Between the

NEUTRAL and

DRIVE gates.

D D D The transmission is

hydraulically in

DRIVE.In the DRIVE gate,

2 2 2 The transmission is

hydraulically in

Manual SECOND.In the SECOND

gate.

1 1 1 The transmission is

hydraulically in

Manual FIRST.In the FIRST gate.

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS)

NOTE: For all circuit identification in the following

steps, Refer to the appropriate Wiring Information.

(1) Raise vehicle on suitable hoist.

(2) Disconnect the vehicle's shift cable from the

manual lever.

(3) With the manual lever in the PARK position

(the PARK position is with the manual lever moved

to the full rearward position), measure the resistance

between the Park/Neutral Position Sense pin of the

TRS and the transmission case. The resistance

should be less than 5 ohms.(4) With the manual lever in the NEUTRAL posi-

tion (the NEUTRAL position is with the manual

lever moved two detents forward of the full rearward

position), measure the resistance between the Park/

Neutral Position Sense pin of the TRS and the trans-

mission case. The resistance should be less than 5

ohms.

(5) If the resistance is greater than 5 ohms in

either of the previous steps, check for a dirty contact

between the tip of the TRS rod and the valve body

manual lever. If the contact is OK, replace the TRS.

(6) With the manual lever in the REVERSE posi-

tion (the REVERSE position is with the manual lever

moved one detent forward of the full rearward posi-

tion), measure the resistance between the Fused

Ignition Switch Output and the Back-up Lamp feed

pins of the TRS. The resistance should be less than 5

21 - 442 AUTOMATIC TRANSMISSION - 48REDR

TRANSMISSION RANGE SENSOR (Continued)

Page 2830 of 2895

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - STATE DISPLAY TEST

MODE...............................1

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE...............................1

DESCRIPTION - DIAGNOSTIC TROUBLE

CODES..............................1

DESCRIPTION - TASK MANAGER..........1DESCRIPTION - MONITORED SYSTEMS....1

DESCRIPTION - TRIP DEFINITION.........4

DESCRIPTION - COMPONENT MONITORS . . 4

OPERATION

OPERATION..........................4

OPERATION - TASK MANAGER...........5

OPERATION - NON-MONITORED CIRCUITS . . 8

EVAPORATIVE EMISSIONS................10

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Obtain the applicable Powertrain Diagnostic

Manual.

(2) Obtain the DRB Scan Tool.

(3) Connect the DRB Scan Tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(4) Turn the ignition switch on and access the

ªRead Faultº screen.

(5) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(6) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

DESCRIPTION - TASK MANAGER

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is call the 'Task Manager'.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

DREMISSIONS CONTROL 25 - 1

Page 2831 of 2895

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator Lamp

(MIL) will be illuminated. These monitors generate

Diagnostic Trouble Codes that can be displayed with

the MIL or a scan tool.

The following is a list of the system monitors:

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Leak Detection Pump Monitor (if equipped)

All these system monitors require two consecutive

trips with the malfunction present to set a fault.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

The following is an operation and description of

each system monitor :

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

Catalyst and Fuel Monitors.

The O2S can fail in any or all of the following

manners:

²slow response rate

²reduced output voltage

²dynamic shift

²shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer todetect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to volt-

age DTC, as well as a O2S heater DTC, the O2S

fault MUST be repaired first. Before checking the

O2S fault, verify that the heater circuit is operating

correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S sensor

are very temperature sensitive. The readings are not

accurate below 300ÉC. Heating of the O2S sensor is

done to allow the engine controller to shift to closed

loop control as soon as possible. The heating element

used to heat the O2S sensor must be tested to ensure

that it is heating the sensor properly.

The O2S sensor circuit is monitored for a drop in

voltage. The sensor output is used to test the heater

by isolating the effect of the heater element on the

O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

25 - 2 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2834 of 2895

problem is repaired or ceases to exist, the PCM can-

cels the code after 40 warm-up cycles. Diagnostic

trouble codes that affect vehicle emissions illuminate

the Malfunction Indicator Lamp (MIL). The MIL is

displayed as an engine icon (graphic) on the instru-

ment panel. Refer to Malfunction Indicator Lamp in

this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example,assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

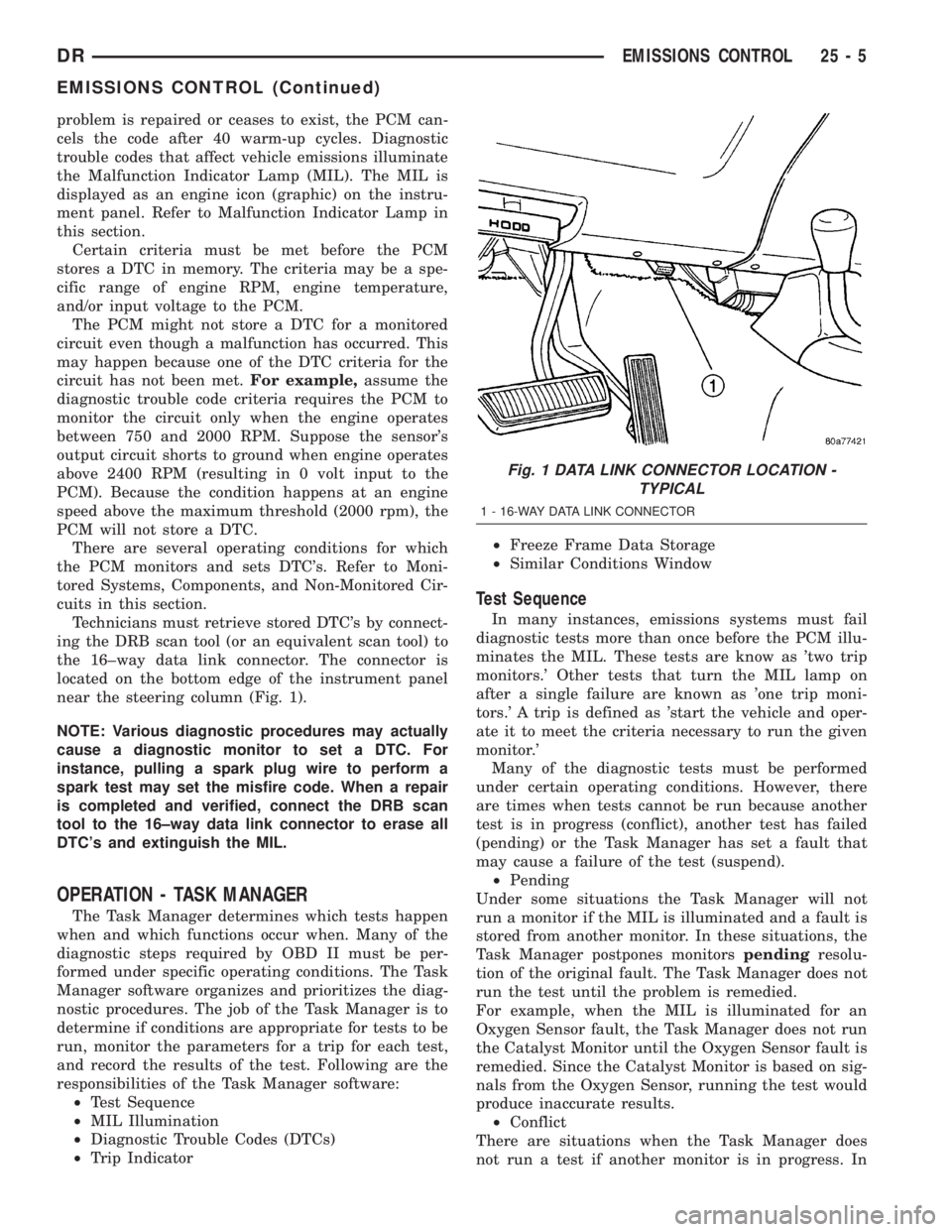

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector. The connector is

located on the bottom edge of the instrument panel

near the steering column (Fig. 1).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL.

OPERATION - TASK MANAGER

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The Task

Manager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

determine if conditions are appropriate for tests to be

run, monitor the parameters for a trip for each test,

and record the results of the test. Following are the

responsibilities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are know as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will not

run a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

Fig. 1 DATA LINK CONNECTOR LOCATION -

TYPICAL

1 - 16-WAY DATA LINK CONNECTOR

DREMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 2835 of 2895

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

25 - 6 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2836 of 2895

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC andFreeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

DREMISSIONS CONTROL 25 - 7

EMISSIONS CONTROL (Continued)

Page 2866 of 2895

DIESEL ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-7

DIESEL ENGINE - INSTALLATION, 5.9L . . . 24-39,

24-42,24-44

DIESEL ENGINE - INSTALLATION,

EXCEPT V-10 OR.....................8R-17

DIESEL ENGINE - INSTALLATION, V-10

OR................................8R-17

DIESEL ENGINE - REMOVAL, 5.9L . . 24-37,24-40,

24-43,24-46

DIESEL ENGINE - REMOVAL, EXCEPT

V-10 OR ...........................8R-16

DIESEL ENGINE - REMOVAL, V-10 OR....8R-16

DIESEL ENGINE - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM 5.9L........................7-19

DIESEL ENGINE - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM 5.9L........................7-19

DIESEL ENGINE, SPECIAL TOOLS - 5.9L . . 9-294

DIESEL FUEL SYSTEM - DESCRIPTION . . . 14-57

DIESEL FUEL SYSTEM, SPECIAL TOOLS . . 14-60

DIESEL, SPECIFICATIONS - 5.9L.........9-293

DIFFERENTIAL - ASSEMBLY . . . 3-116,3-143,3-38,

3-63,3-88

DIFFERENTIAL - DESCRIPTION....3-114,3-141,

3-36,3-61,3-86

DIFFERENTIAL - DISASSEMBLY....3-115,3-142,

3-37,3-62,3-88

DIFFERENTIAL - INSTALLATION....3-117,3-144,

3-38,3-63,3-88

DIFFERENTIAL - OPERATION . . 3-114,3-141,3-36,

3-61,3-86

DIFFERENTIAL - REMOVAL . . . 3-115,3-142,3-36,

3-61,3-86

DIFFERENTIAL CASE BEARINGS -

INSTALLATION.....3-121,3-148,3-39,3-65,3-94

DIFFERENTIAL CASE BEARINGS -

REMOVAL.........3-121,3-148,3-39,3-64,3-93

DIFFERENTIAL TRAC-RITE - ASSEMBLY . . 3-120,

3-147

DIFFERENTIAL TRAC-RITE - CLEANING . . . 3-119,

3-146

DIFFERENTIAL TRAC-RITE -

DESCRIPTION..................3-118,3-145

DIFFERENTIAL TRAC-RITE -

DISASSEMBLY..................3-118,3-145

DIFFERENTIAL TRAC-RITE - INSPECTION . 3-119,

3-146

DIFFERENTIAL TRAC-RITE - OPERATION . . 3-118,

3-145

DIFFERENTIAL-TRAC-LOK - ASSEMBLY....3-92

DIFFERENTIAL-TRAC-LOK -

DESCRIPTION........................3-89

DIFFERENTIAL-TRAC-LOK - DIAGNOSIS

AND TESTING........................3-89

DIFFERENTIAL-TRAC-LOK -

DISASSEMBLY........................3-90

DIFFERENTIAL-TRAC-LOK - OPERATION....3-89

DIMENSIONS - SPECIFICATIONS, BODY

OPENING...........................23-99

DIMENSIONS - SPECIFICATIONS, FRAME . . 13-17

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DIODE REPLACEMENT - STANDARD

PROCEDURE.........................24-7

DISC - INSTALLATION, CLUTCH...........6-6

DISC - REMOVAL, CLUTCH...............6-6

DISC BRAKE CALIPER ADAPTER MOUNT

- INSTALLATION......................5-17

DISC BRAKE CALIPERS - DESCRIPTION....5-11

DISC BRAKE CALIPERS - OPERATION.....5-12

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-1

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION DUCTS - INSTALLATION,

FLOOR.............................24-27

DISTRIBUTION DUCTS - REMOVAL,

FLOOR

.............................24-27

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER

...................8W-97-2

DISTRIBUTOR - DESCRIPTION

..........8I-16

DISTRIBUTOR - INSTALLATION

..........8I-18

DISTRIBUTOR - OPERATION

............8I-16DISTRIBUTOR - REMOVAL..............8I-17

DISTRIBUTOR BUSHING - INSTALLATION . 9-258

DISTRIBUTOR BUSHING - REMOVAL.....9-258

DISTRIBUTOR CAP - 5.9L V-8 -

DIAGNOSIS AND TESTING..............8I-18

DISTRIBUTOR ROTOR - 5.9L V-8 -

DIAGNOSIS AND TESTING..............8I-19

DOME LAMP - DESCRIPTION...........8L-24

DOME LAMP - INSTALLATION..........8L-24

DOME LAMP - OPERATION.............8L-24

DOME LAMP - REMOVAL..............8L-24

DOOR - INSTALLATION...........23-18,23-28

DOOR - INSTALLATION, BLEND.........24-25

DOOR - INSTALLATION, DEFROST.......24-27

DOOR - INSTALLATION, FLOOR -

DEFROST...........................24-30

DOOR - INSTALLATION, FUEL FILL.......23-39

DOOR - INSTALLATION, RECIRC.........24-30

DOOR - REMOVAL...............23-18,23-28

DOOR - REMOVAL, BLEND.............24-24

DOOR - REMOVAL, DEFROST...........24-27

DOOR - REMOVAL, FLOOR - DEFROST....24-30

DOOR - REMOVAL, FUEL FILL..........23-39

DOOR - REMOVAL, RECIRC............24-30

DOOR ACTUATOR - DESCRIPTION,

BLEND.............................24-16

DOOR ACTUATOR - DESCRIPTION,

MODE...............................24-20

DOOR ACTUATOR - DESCRIPTION,

RECIRCULATION.....................24-22

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-17

DOOR ACTUATOR - INSTALLATION,

FLOOR - DEFROST...................24-20

DOOR ACTUATOR - INSTALLATION,

MODE.............................24-22

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-23

DOOR ACTUATOR - OPERATION, BLEND . . 24-16

DOOR ACTUATOR - OPERATION, MODE . . . 24-21

DOOR ACTUATOR - OPERATION,

RECIRCULATION.....................24-22

DOOR ACTUATOR - REMOVAL, BLEND....24-17

DOOR ACTUATOR - REMOVAL, FLOOR -

DEFROST...........................24-19

DOOR ACTUATOR - REMOVAL, MODE....24-21

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-22

DOOR AJAR INDICATOR - DESCRIPTION . . 8J-23

DOOR AJAR INDICATOR - OPERATION....8J-23

DOOR AJAR SWITCH - DESCRIPTION....8L-25

DOOR AJAR SWITCH - OPERATION......8L-25

DOOR GLASS - INSTALLATION.....23-20,23-30

DOOR GLASS - REMOVAL........23-20,23-30

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT................23-92

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR.................23-93

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT....................23-92

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, REAR.....................23-93

DOOR INNER BELT MOLDING -

INSTALLATION, FRONT................23-93

DOOR INNER BELT MOLDING -

INSTALLATION, REAR.................23-94

DOOR INNER BELT MOLDING -

REMOVAL, FRONT....................23-93

DOOR INNER BELT MOLDING -

REMOVAL, REAR

.....................23-94

DOOR LOCK MOTOR - DESCRIPTION

......8N-5

DOOR LOCK MOTOR - DIAGNOSIS AND

TESTING

............................8N-5

DOOR LOCK MOTOR - OPERATION

.......8N-5

DOOR MODULE - DESCRIPTION, DRIVER

. . 8N-5

DOOR MODULE - DIAGNOSIS AND

TESTING, DRIVER

.....................8N-6

DOOR MODULE - INSTALLATION,

DRIVER

.............................8N-7

DOOR MODULE - OPERATION, DRIVER

....8N-5

DOOR MODULE - REMOVAL, DRIVER

.....8N-7

DOOR OPENING SEAL - INSTALLATION

. . . 23-92

DOOR OPENING SEAL - REMOVAL

.......23-92

DOOR OUTER BELT MOLDING -

INSTALLATION, FRONT

................23-93

DOOR OUTER BELT MOLDING -

INSTALLATION, REAR

.................23-94DOOR OUTER BELT MOLDING -

REMOVAL, FRONT....................23-93

DOOR OUTER BELT MOLDING -

REMOVAL, REAR.....................23-94

DOOR SILL TRIM COVER -

INSTALLATION, REAR.................23-72

DOOR SILL TRIM COVER - REMOVAL,

REAR..............................23-72

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE.................5-7

DRAG LINK - INSTALLATION............19-35

DRAG LINK - REMOVAL...............19-35

DRAIN AND REFILL - STANDARD

PROCEDURE, FLUID.....21-617,21-652,21-682,

21-716

DRAIN CIRCUIT - OPERATION, FUEL.....14-78

DRAINBACK VALVE - DESCRIPTION,

TORQUE CONVERTER..........21-262,21-440

DRAINBACK VALVE - OPERATION,

TORQUE CONVERTER..........21-262,21-440

DRAINBACK VALVE - STANDARD

PROCEDURE, TORQUE CONVERTER....21-262,

21-440

DRAINING AT FUEL FILTER - STANDARD

PROCEDURES, WATER................14-57

DRAINING COOLING SYSTEM

3.7L/4.7L/5.7L ENGINE - STANDARD

PROCEDURE.........................7-18

DRAINING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-19

DRAINING COOLING SYSTEM 5.9L/8.0L

ENGINE - STANDARD PROCEDURE........7-18

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-11

DRIP RAIL WEATHERSTRIP -

INSTALLATION.......................23-91

DRIP RAIL WEATHERSTRIP - REMOVAL . . 23-91

DRIP RAIL WEATHERSTRIP RETAINER -

INSTALLATION.......................23-92

DRIP RAIL WEATHERSTRIP RETAINER -

REMOVAL..........................23-92

DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICLY CONTOLLED VISCOUS

FAN ................................7-56

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN........................7-54

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY.................7-25,7-28,7-31

DRIVE BELTS - 3.7L / 4.7L -

INSTALLATION........................7-27

DRIVE BELTS - 3.7L / 4.7L - REMOVAL....7-27

DRIVE BELTS - 5.9L - INSTALLATION......7-31

DRIVE BELTS - 5.9L - REMOVAL.........7-30

DRIVE BELTS - 5.9L DIESEL -

INSTALLATION........................7-34

DRIVE BELTS - 5.9L DIESEL - REMOVAL . . . 7-34

DRIVE LEARN - STANDARD PROCEDURE . . 8E-21

DRIVE SYSTEM - DESCRIPTION, TIMING . . 9-164

DRIVE SYSTEM - OPERATION, TIMING....9-164

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- DESCRIPTION, FAN...................7-55

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- OPERATION, FAN....................7-55

DRIVE VISCOUS CLUTCH -

DESCRIPTION, FAN....................7-54

DRIVE VISCOUS CLUTCH - OPERATION,

FAN ................................7-54

DRIVER AIRBAG - DESCRIPTION........8O-22

DRIVER AIRBAG - INSTALLATION.......8O-24

DRIVER AIRBAG - OPERATION..........8O-23

DRIVER AIRBAG - REMOVAL...........8O-23

DRIVER DOOR MODULE - DESCRIPTION . . . 8N-5

DRIVER DOOR MODULE - DIAGNOSIS

AND TESTING........................8N-6

DRIVER DOOR MODULE - INSTALLATION . . 8N-7

DRIVER DOOR MODULE - OPERATION....8N-5

DRIVER DOOR MODULE - REMOVAL......8N-7

DRIVER SEAT SWITCH - DESCRIPTION . . . 8N-15

DRIVER SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8N-15

DRIVER SEAT SWITCH - INSTALLATION

. . 8N-16

DRIVER SEAT SWITCH - OPERATION

.....8N-15

DRIVER SEAT SWITCH - REMOVAL

......8N-16

DRIVER SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL

..................23-59

DRIVER SIDE BEZEL - REMOVAL,

INSTRUMENT PANEL

..................23-58

DRINDEX 11

Description Group-Page Description Group-Page Description Group-Page