Amplifier DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 364 of 2895

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - AUDIO..........2

AMPLIFIER

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................4

ANTENNA BODY & CABLE

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................4

REMOVAL.............................6

INSTALLATION..........................6

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................6

INSTALLATION..........................7

RADIO

DESCRIPTION..........................7OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................8

RADIO NOISE SUPPRESSION GROUND STRAP

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................9

INSTALLATION.........................10

REMOTE SWITCHES

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................11

REMOVAL.............................12

INSTALLATION.........................12

SPEAKER

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - SPEAKER......13

REMOVAL.............................13

INSTALLATION.........................15

AUDIO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model. Several combinations of

radio receivers and speaker systems are offered. The

audio system uses an ignition switched source of bat-

tery current so that the system will only operate

when the ignition switch is in the RUN or ACCES-

SORY positions.

The audio system includes the following compo-

nents:

²Antenna

²Power amplifier (with premium speaker system

only)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (if equipped)

²Speakers

Certain functions and features of the audio system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munication Interface (PCI) bus network. The data

bus network allows the sharing of sensor informa-

tion. For diagnosis of these electronic modules or of

the data bus network, the use of a DRB IIItscan tooland the proper Diagnostic Procedures manual are

recommended.

Refer to the appropriate wiring information for

complete standard and premium audio system circuit

diagrams. The wiring information includes proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

OPERATION

The audio system components are designed to pro-

vide audio entertainment and information through

the reception, tuning and amplification of locally

broadcast radio signals in both the Amplitude Modu-

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges.

The audio system components operate on battery

current received through a fuse in the Integrated

Power Module (IPM) on a fused ignition switch out-

put (run-acc) circuit so that the system will only

operate when the ignition switch is in the Run or

Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the Instrument Cluster

receives hard wired resistor multiplexed inputs from

the remote radio switches. The programming in the

DRAUDIO 8A - 1

Page 365 of 2895

Instrument Cluster allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.

Refer to the owner's manual for more information

on the features, use and operation of each of the

available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wireharness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in the Integrated Power Module (IPM).

Replace fuses, if required.

2. Radio/amplifier (if

equipped) connector faulty.2. Check for loose or corroded radio/amplifier

connector. Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio/amplifier (if

equipped) ground faulty.4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio/amplifier (if

equipped) faulty.5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Integrated Power Module (IPM). Replace

fuses, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

8A - 2 AUDIODR

AUDIO (Continued)

Page 366 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

CLOCK WILL NOT KEEP

SET TIME1. Fuse faulty. 1. Check Ignition-Off Draw (IOD) fuse in the

Integrated Power Module (IPM). Replace fuse, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

POOR RADIO RECEPTION 1. Antenna faulty. 1. (Refer to 8 - ELECTRICAL/AUDIO/ANTENNA

BODY & CABLE - DIAGNOSIS AND TESTING).

2. Radio ground faulty. 2. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

3. Radio noise suppression

faulty.3. Repair or replace ground strap as necessary.

4. Radio faulty. 4. Refer to appropriate Diagnostic Service

Manual.

NO/POOR TAPE

OPERATION1. Faulty tape. 1. Insert known good tape and test operation.

2. Foreign objects behind

tape door.2. Remove foreign objects and test operation.

3. Dirty cassette tape head. 3. Clean head with Mopar Cassette Head

Cleaner.

4. Faulty tape deck. 4. Exchange or replace radio, if required.

NO COMPACT DISC

OPERATION1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on CD. 2. Clean CD and test operation.

3. Condensation on CD or

optics.3. Allow temperature of vehicle interior to stabilize

and test operation.

4. Faulty CD player. 4. Refer to appropriate Diagnostic Service

Manual.

AMPLIFIER

DESCRIPTION

The optional Infinity premium speaker system

includes a separate Infinity audio power amplifier.

The amplifier is a six channel unit and is rated at

240 total output watts. The amplifier is located

behind the glove box.

OPERATION

The power amplifier electronically increases the

frequency response of the normal audio signal output

from the radio amplifier in order to improve the

acoustic performance of the speakers. On vehiclesequipped with an amplifier, the amplifier section of

the radio becomes a pre-amplifier.

The amplifier receives audio signal inputs for

speaker channels from the radio, then sends ampli-

fied audio outputs through six separate channels

with dedicated feed and return circuits to the indi-

vidual speakers.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

DRAUDIO 8A - 3

AUDIO (Continued)

Page 367 of 2895

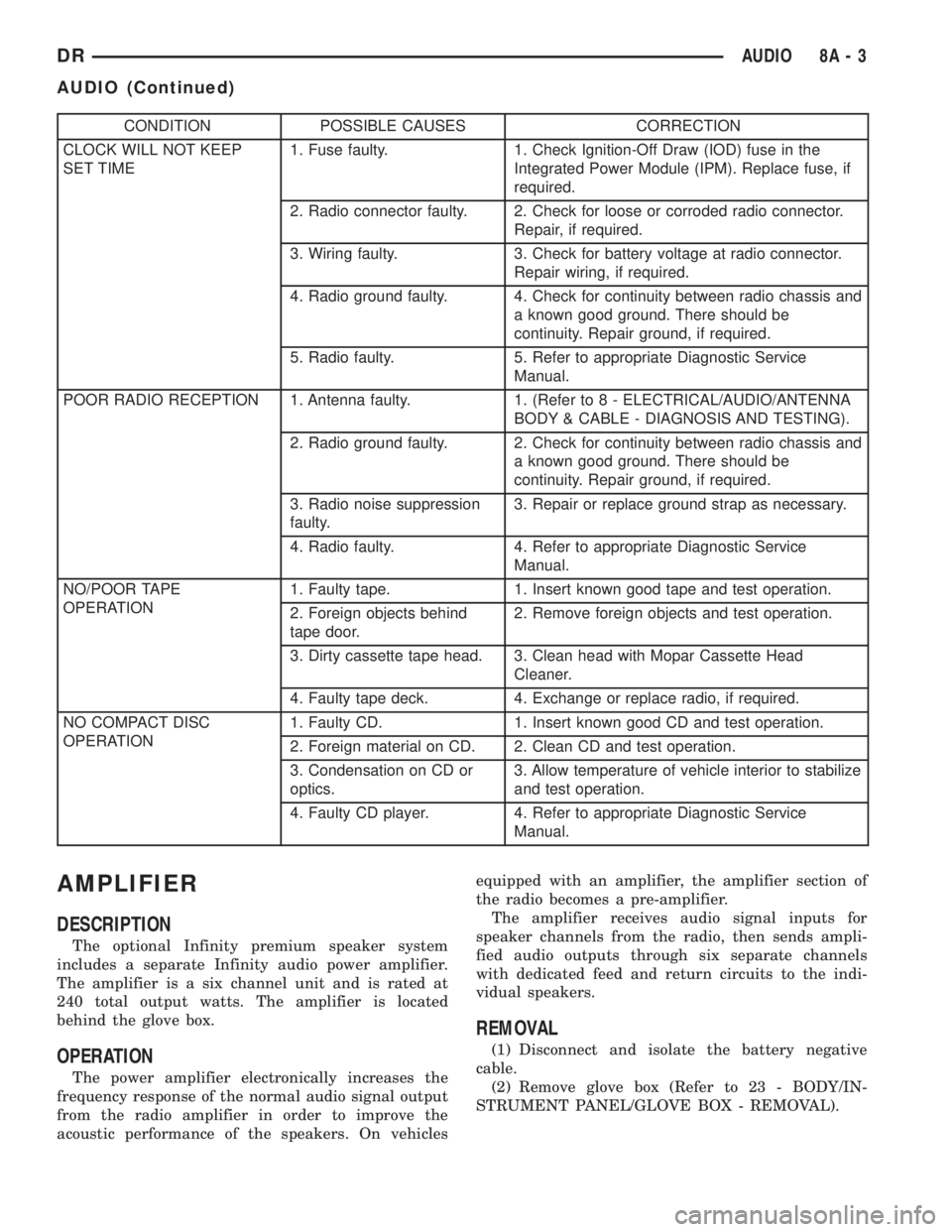

(3) Remove instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - REMOVAL).

(4) Remove instrument panel lower right center

bezel (Refer to 23 - BODY/INSTRUMENT PANEL/IP

LOWER RIGHT CENTER BEZEL - REMOVAL).

(5) Disconnect electrical harness connector from

amplifier (Fig. 1).

(6) Remove mounting bolts.

INSTALLATION

(1) Connect electrical harness connector and

install amplifier.

(2) Install mounting bolts. Tighten to 10 N´m (90

in. lbs.).

(3) Install instrument panel lower right center

bezel (Refer to 23 - BODY/INSTRUMENT PANEL/IP

LOWER RIGHT CENTER BEZEL - INSTALLA-

TION).

(4) Install instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - INSTALLATION).

(5) Install glove box (Refer to 23 - BODY/INSTRU-

MENT PANEL/GLOVE BOX - INSTALLATION).

(6) Connect battery negative cable.

ANTENNA BODY & CABLE

DESCRIPTION

The antenna body and cable is secured below the

fender panel by the antenna cap nut through a

mounting hole in the right front fender. The primary

coaxial antenna cable is then routed beneath the

fender sheet metal and through a entry hole in theright cowl side panel into the interior of the vehicle.

Inside the vehicle, the primary coaxial cable is con-

nected to a secondary instrument panel antenna

coaxial cable with an in-line connector that is located

behind the right kick panel. The secondary coaxial

cable is then routed behind the instrument panel to

the back of the radio.

OPERATION

The antenna body and cable connects the antenna

mast to the radio. The radio antenna is an electro-

magnetic circuit component used to capture radio fre-

quency signals that are broadcast by local

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to antenna coaxial cable

shield test.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The ohmmeter test lead connections for each test

are shown in the illustration (Fig. 2).

Fig. 1 AMPLIFIER MOUNTING

1 - INSTRUMENT PANEL

2 - AMPLIFIER

3 - MOUNTING BOLTS

4 - ELECTRICAL CONNECTOR

8A - 4 AUDIODR

AMPLIFIER (Continued)

Page 371 of 2895

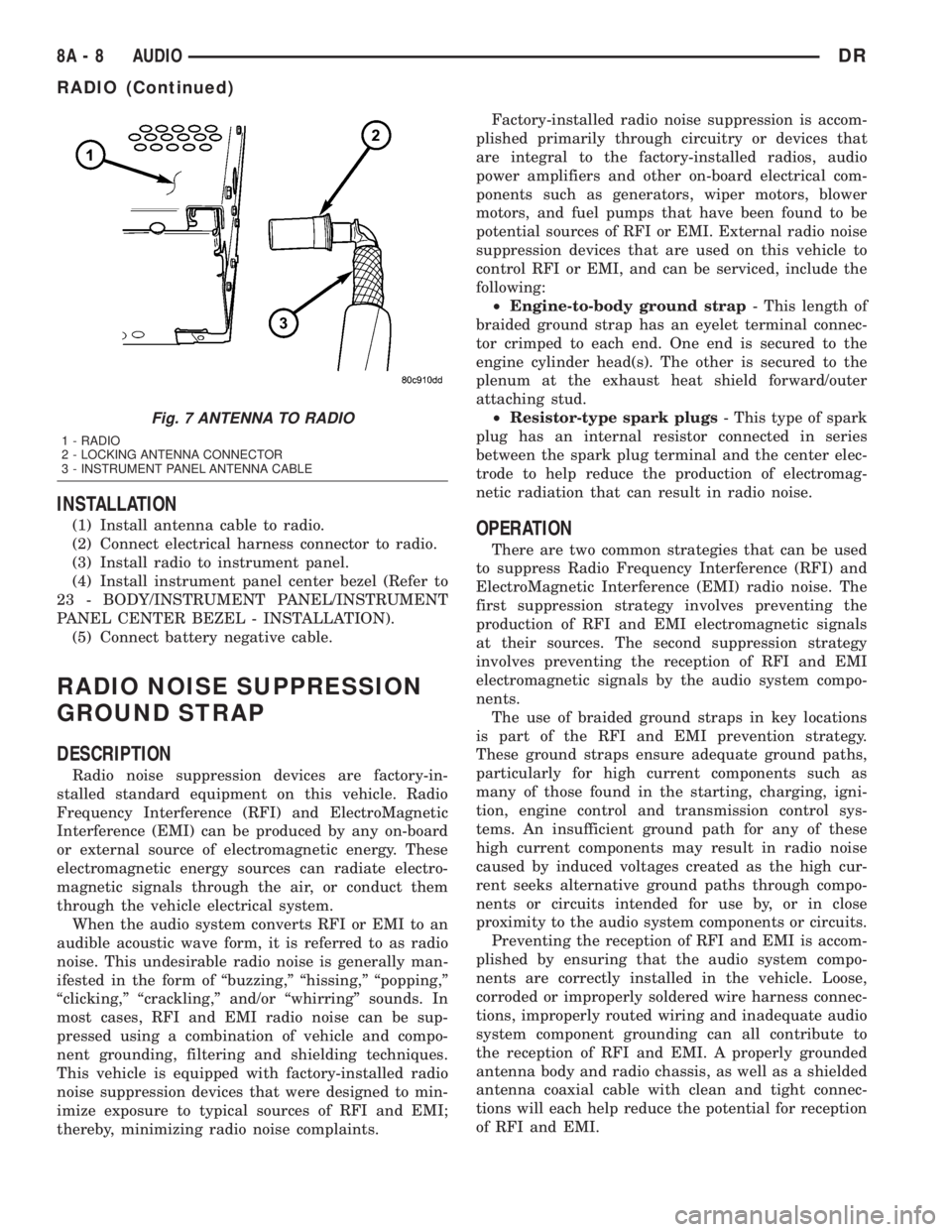

INSTALLATION

(1) Install antenna cable to radio.

(2) Connect electrical harness connector to radio.

(3) Install radio to instrument panel.

(4) Install instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - INSTALLATION).

(5) Connect battery negative cable.

RADIO NOISE SUPPRESSION

GROUND STRAP

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.

When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI. External radio noise

suppression devices that are used on this vehicle to

control RFI or EMI, and can be serviced, include the

following:

²Engine-to-body ground strap- This length of

braided ground strap has an eyelet terminal connec-

tor crimped to each end. One end is secured to the

engine cylinder head(s). The other is secured to the

plenum at the exhaust heat shield forward/outer

attaching stud.

²Resistor-type spark plugs- This type of spark

plug has an internal resistor connected in series

between the spark plug terminal and the center elec-

trode to help reduce the production of electromag-

netic radiation that can result in radio noise.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

Fig. 7 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

8A - 8 AUDIODR

RADIO (Continued)

Page 375 of 2895

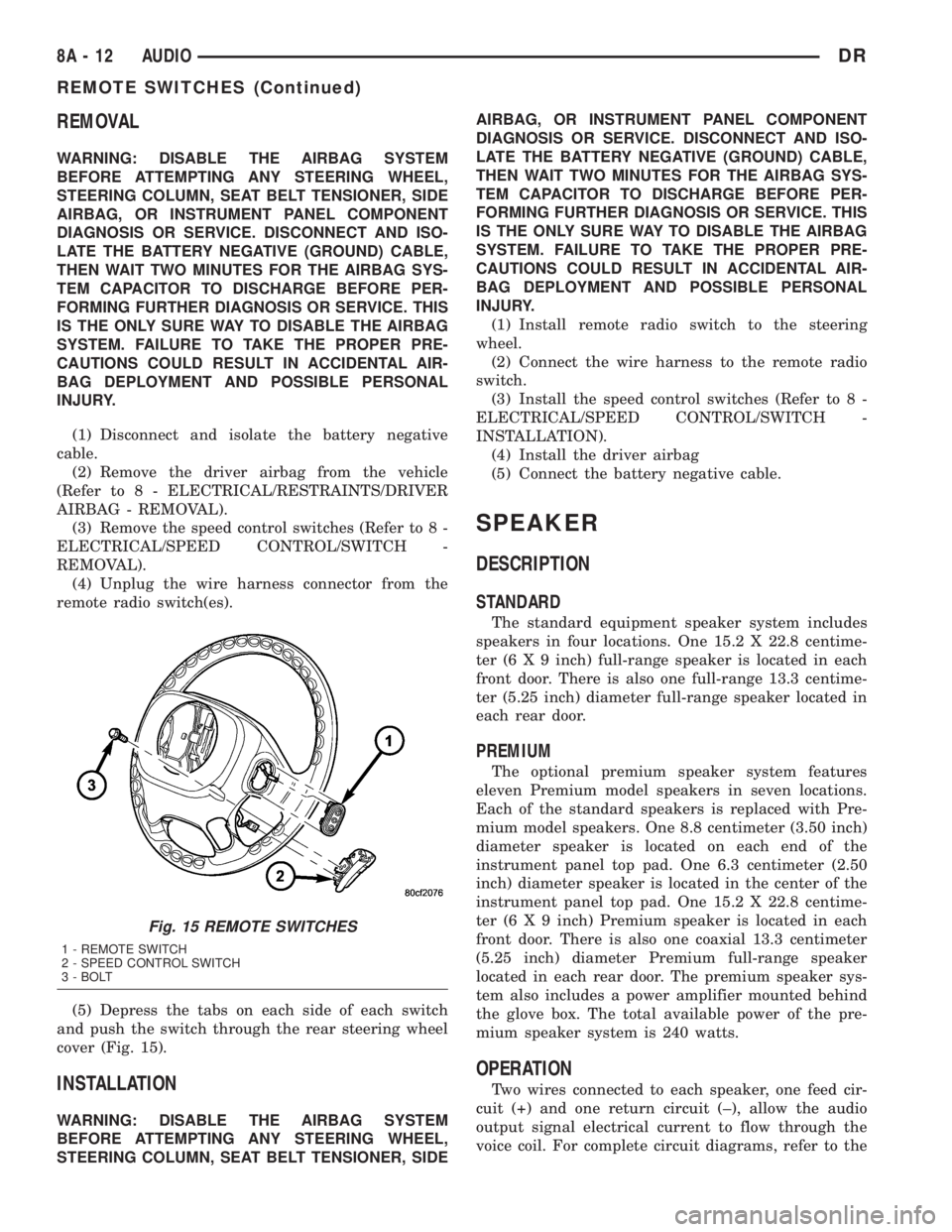

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver airbag from the vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(3) Remove the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

REMOVAL).

(4) Unplug the wire harness connector from the

remote radio switch(es).

(5) Depress the tabs on each side of each switch

and push the switch through the rear steering wheel

cover (Fig. 15).

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDEAIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Connect the wire harness to the remote radio

switch.

(3) Install the speed control switches (Refer to 8 -

ELECTRICAL/SPEED CONTROL/SWITCH -

INSTALLATION).

(4) Install the driver airbag

(5) Connect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in four locations. One 15.2 X 22.8 centime-

ter (6 X 9 inch) full-range speaker is located in each

front door. There is also one full-range 13.3 centime-

ter (5.25 inch) diameter full-range speaker located in

each rear door.

PREMIUM

The optional premium speaker system features

eleven Premium model speakers in seven locations.

Each of the standard speakers is replaced with Pre-

mium model speakers. One 8.8 centimeter (3.50 inch)

diameter speaker is located on each end of the

instrument panel top pad. One 6.3 centimeter (2.50

inch) diameter speaker is located in the center of the

instrument panel top pad. One 15.2 X 22.8 centime-

ter (6 X 9 inch) Premium speaker is located in each

front door. There is also one coaxial 13.3 centimeter

(5.25 inch) diameter Premium full-range speaker

located in each rear door. The premium speaker sys-

tem also includes a power amplifier mounted behind

the glove box. The total available power of the pre-

mium speaker system is 240 watts.

OPERATION

Two wires connected to each speaker, one feed cir-

cuit (+) and one return circuit (±), allow the audio

output signal electrical current to flow through the

voice coil. For complete circuit diagrams, refer to the

Fig. 15 REMOTE SWITCHES

1 - REMOTE SWITCH

2 - SPEED CONTROL SWITCH

3 - BOLT

8A - 12 AUDIODR

REMOTE SWITCHES (Continued)

Page 376 of 2895

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

and/or amplifier may result.

(1) If all speakers are inoperative, check the fuses

in the Integrated Power Module (IPM). If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Check the amplifier fuse (if equipped) in the

IPM. If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 4.

(4) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negativecable. If vehicle isnotequipped with a amplifier,

remove the radio receiver. If vehicle is equipped with

an amplifier. disconnect wire harness connector at

output side of amplifier. Go to Step 5.

(5) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 6. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(6) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector or if equipped, the amplifier

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

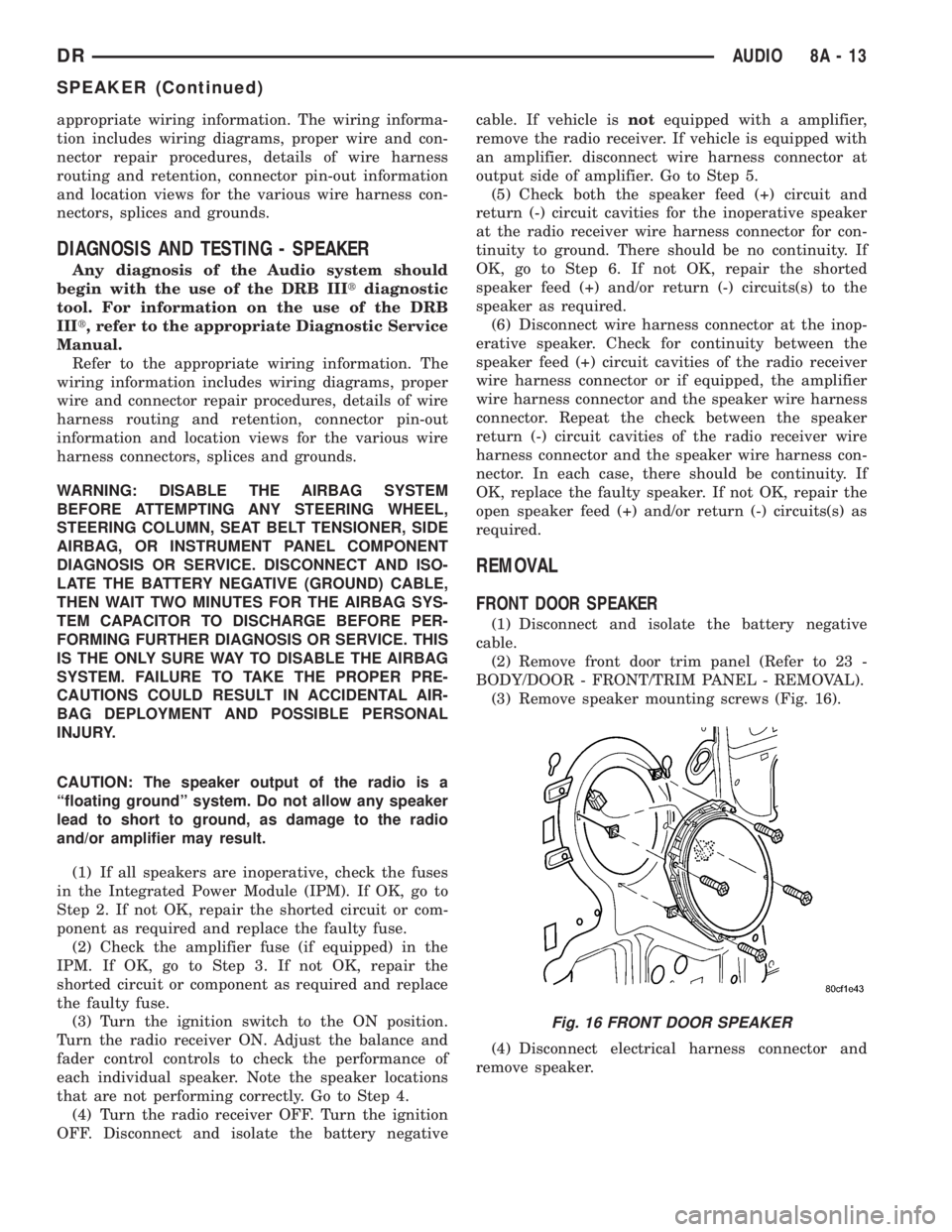

REMOVAL

FRONT DOOR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove front door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove speaker mounting screws (Fig. 16).

(4) Disconnect electrical harness connector and

remove speaker.

Fig. 16 FRONT DOOR SPEAKER

DRAUDIO 8A - 13

SPEAKER (Continued)

Page 416 of 2895

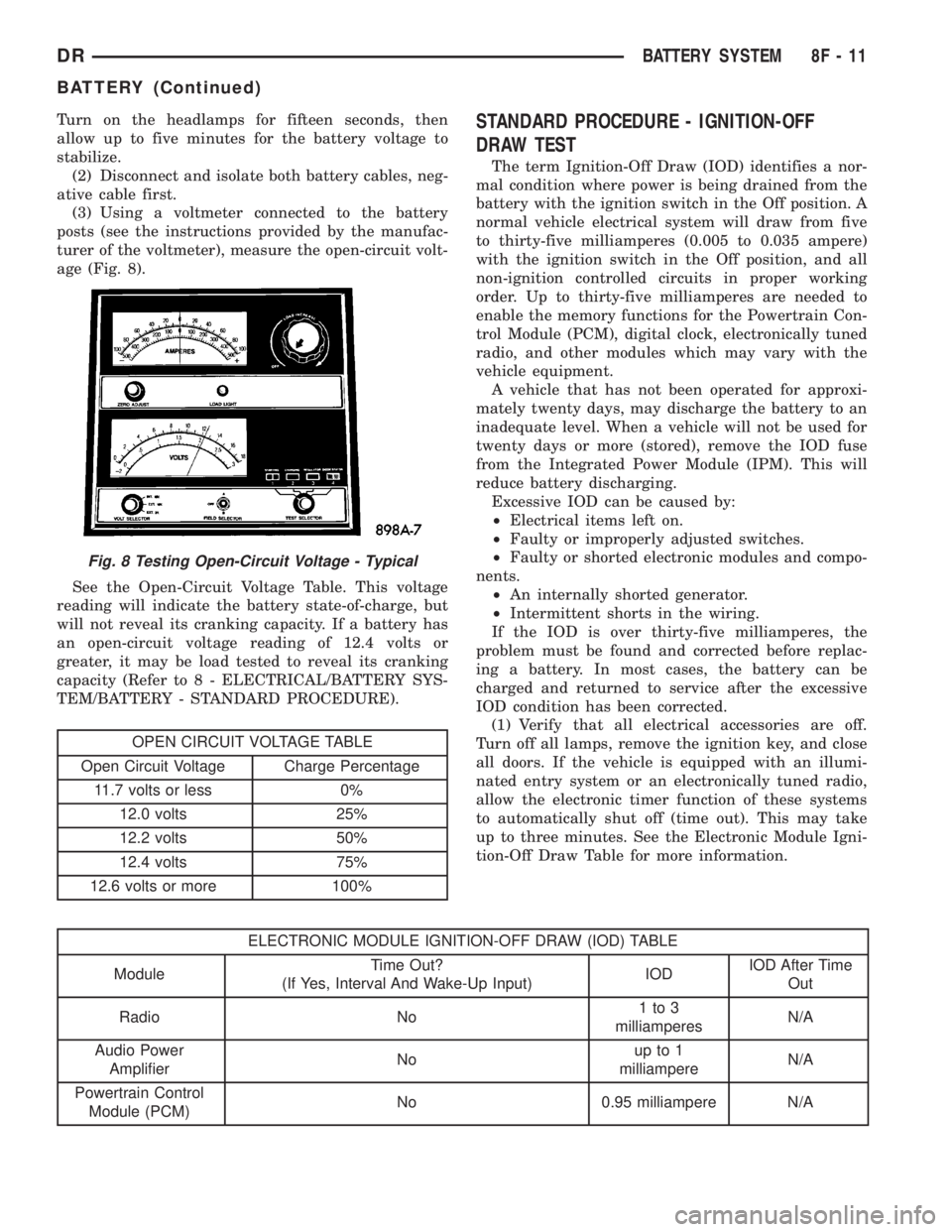

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 8).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Integrated Power Module (IPM). This will

reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes. See the Electronic Module Igni-

tion-Off Draw Table for more information.

ELECTRONIC MODULE IGNITION-OFF DRAW (IOD) TABLE

ModuleTime Out?

(If Yes, Interval And Wake-Up Input)IODIOD After Time

Out

Radio No1to3

milliamperesN/A

Audio Power

AmplifierNoup to 1

milliampereN/A

Powertrain Control

Module (PCM)No 0.95 milliampere N/A

Fig. 8 Testing Open-Circuit Voltage - Typical

DRBATTERY SYSTEM 8F - 11

BATTERY (Continued)

Page 720 of 2895

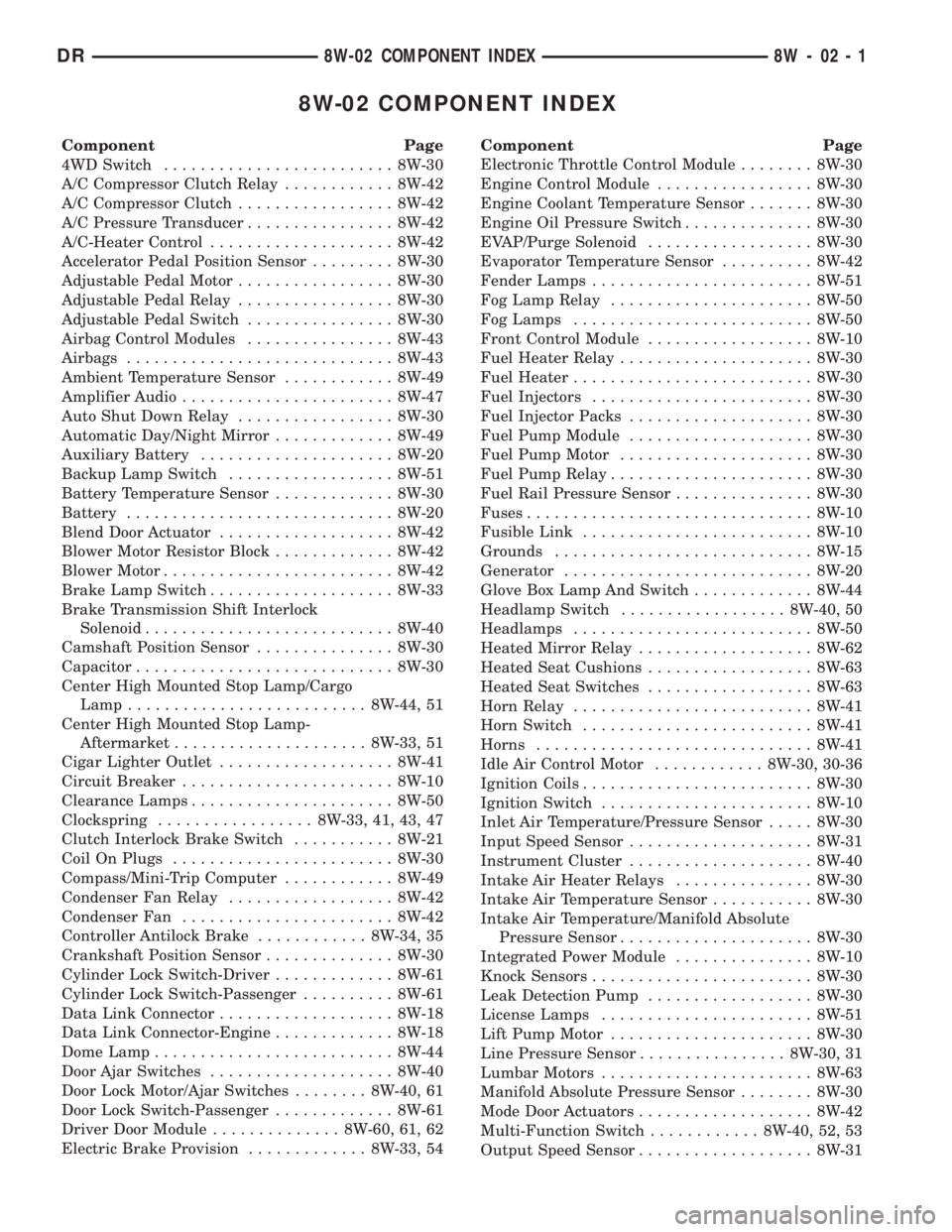

8W-02 COMPONENT INDEX

Component Page

4WD Switch......................... 8W-30

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Modules................ 8W-43

Airbags............................. 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror............. 8W-49

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Center High Mounted Stop Lamp-

Aftermarket..................... 8W-33, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan Relay.................. 8W-42

Condenser Fan....................... 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Cylinder Lock Switch-Passenger.......... 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp.......................... 8W-44

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61

Driver Door Module.............. 8W-60, 61, 62

Electric Brake Provision............. 8W-33, 54Component Page

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Heater Relay..................... 8W-30

Fuel Heater.......................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuel Rail Pressure Sensor............... 8W-30

Fuses............................... 8W-10

Fusible Link......................... 8W-10

Grounds............................ 8W-15

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Heated Seat Switches.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horns.............................. 8W-41

Idle Air Control Motor............ 8W-30, 30-36

Ignition Coils......................... 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature/Pressure Sensor..... 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensors........................ 8W-30

Leak Detection Pump.................. 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Mode Door Actuators................... 8W-42

Multi-Function Switch............ 8W-40, 52, 53

Output Speed Sensor................... 8W-31

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 722 of 2895

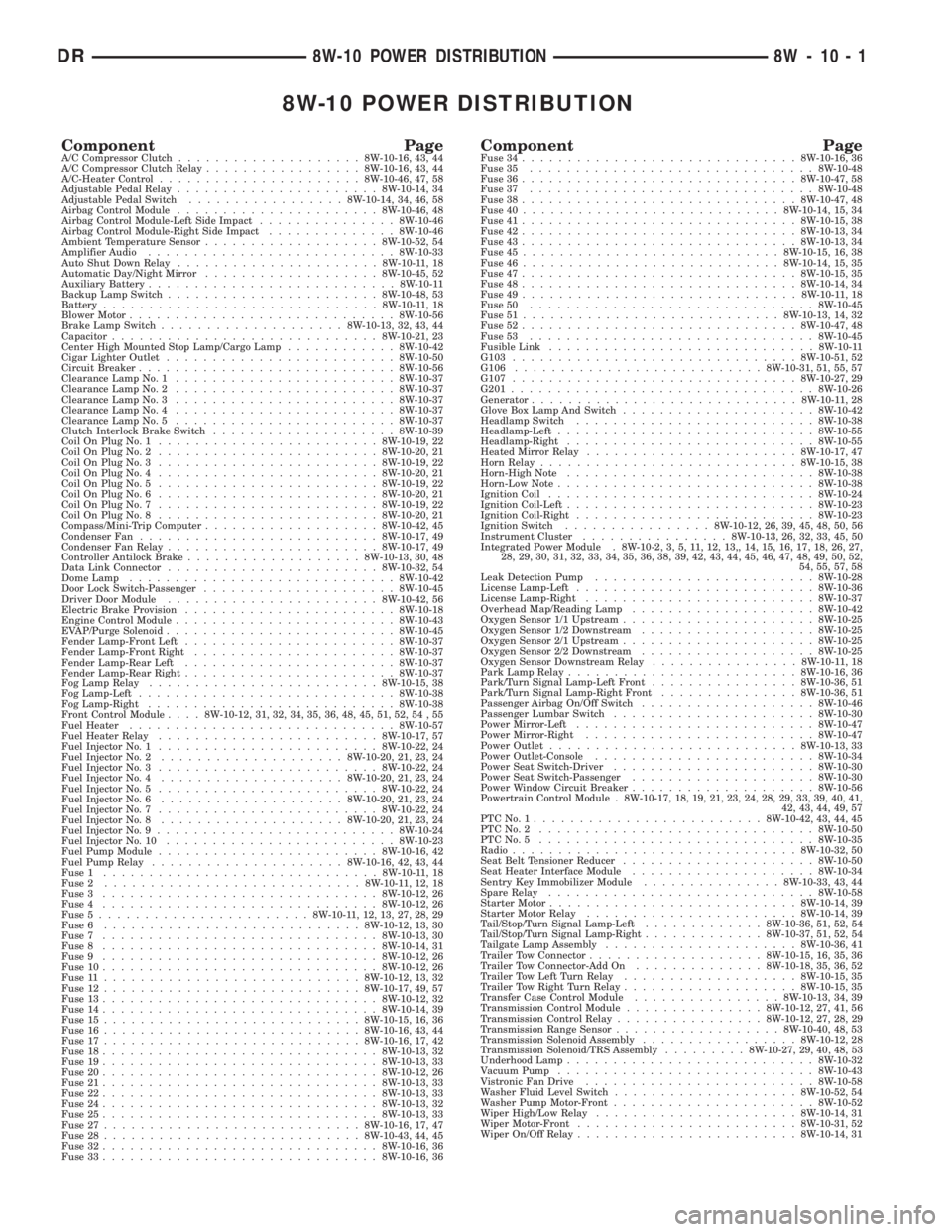

8W-10 POWER DISTRIBUTION

Component PageA/C Compressor Clutch....................8W-10-16, 43, 44

A/C Compressor Clutch Relay.................8W-10-16, 43, 44

A/C-Heater Control......................8W-10-46, 47, 58

Adjustable Pedal Relay......................8W-10-14, 34

Adjustable Pedal Switch.................8W-10-14, 34, 46, 58

Airbag Control Module......................8W-10-46, 48

Airbag Control Module-Left Side Impact...............8W-10-46

Airbag Control Module-Right Side Impact..............8W-10-46

Ambient Temperature Sensor...................8W-10-52, 54

Amplifier Audio...........................8W-10-33

Auto Shut Down Relay......................8W-10-11, 18

Automatic Day/Night Mirror...................8W-10-45, 52

Auxiliary Battery...........................8W-10-11

Backup Lamp Switch.......................8W-10-48, 53

Battery..............................8W-10-11, 18

Blower Motor.............................8W-10-56

Brake Lamp Switch....................8W-10-13, 32, 43, 44

Capacitor.............................8W-10-21, 23

Center High Mounted Stop Lamp/Cargo Lamp............8W-10-42

Cigar Lighter Outlet.........................8W-10-50

Circuit Breaker............................8W-10-56

Clearance Lamp No. 1........................8W-10-37

Clearance Lamp No. 2........................8W-10-37

Clearance Lamp No. 3........................8W-10-37

Clearance Lamp No. 4........................8W-10-37

Clearance Lamp No. 5........................8W-10-37

Clutch Interlock Brake Switch....................8W-10-39

Coil On Plug No. 1........................8W-10-19, 22

Coil On Plug No. 2........................8W-10-20, 21

Coil On Plug No. 3........................8W-10-19, 22

Coil On Plug No. 4........................8W-10-20, 21

Coil On Plug No. 5........................8W-10-19, 22

Coil On Plug No. 6........................8W-10-20, 21

Coil On Plug No. 7........................8W-10-19, 22

Coil On Plug No. 8........................8W-10-20, 21

Compass/Mini-Trip Computer...................8W-10-42, 45

Condenser Fan..........................8W-10-17, 49

Condenser Fan Relay.......................8W-10-17, 49

Controller Antilock Brake...................8W-10-13, 30, 48

Data Link Connector.......................8W-10-32, 54

Dome Lamp.............................8W-10-42

Door Lock Switch-Passenger.....................8W-10-45

Driver Door Module.......................8W-10-42, 56

Electric Brake Provision.......................8W-10-18

Engine Control Module........................8W-10-43

EVAP/Purge Solenoid.........................8W-10-45

Fender Lamp-Front Left.......................8W-10-37

Fender Lamp-Front Right......................8W-10-37

Fender Lamp-Rear Left.......................8W-10-37

Fender Lamp-Rear Right.......................8W-10-37

Fog Lamp Relay.........................8W-10-15, 38

Fog Lamp-Left............................8W-10-38

Fog Lamp-Right...........................8W-10-38

Front Control Module....8W-10-12, 31, 32, 34, 35, 36, 48, 45, 51, 52, 54 , 55

Fuel Heater.............................8W-10-57

Fuel Heater Relay........................8W-10-17, 57

Fuel Injector No. 1........................8W-10-22, 24

Fuel Injector No. 2....................8W-10-20, 21, 23, 24

Fuel Injector No. 3........................8W-10-22, 24

Fuel Injector No. 4....................8W-10-20, 21, 23, 24

Fuel Injector No. 5........................8W-10-22, 24

Fuel Injector No. 6....................8W-10-20, 21, 23, 24

Fuel Injector No. 7........................8W-10-22, 24

Fuel Injector No. 8....................8W-10-20, 21, 23, 24

Fuel Injector No. 9..........................8W-10-24

Fuel Injector No. 10.........................8W-10-23

Fuel Pump Module........................8W-10-16, 42

Fuel Pump Relay.....................8W-10-16, 42, 43, 44

Fuse 1..............................8W-10-11, 18

Fuse 2............................8W-10-11, 12, 18

Fuse 3..............................8W-10-12, 26

Fuse 4..............................8W-10-12, 26

Fuse 5.......................8W-10-11, 12, 13, 27, 28, 29

Fuse 6............................8W-10-12, 13, 30

Fuse 7..............................8W-10-13, 30

Fuse 8..............................8W-10-14, 31

Fuse 9..............................8W-10-12, 26

Fuse 10..............................8W-10-12, 26

Fuse 11............................8W-10-12, 13, 32

Fuse 12............................8W-10-17, 49, 57

Fuse 13..............................8W-10-12, 32

Fuse 14..............................8W-10-14, 39

Fuse 15............................8W-10-15, 16, 36

Fuse 16............................8W-10-16, 43, 44

Fuse 17............................8W-10-16, 17, 42

Fuse 18..............................8W-10-13, 32

Fuse 19..............................8W-10-13, 33

Fuse 20..............................8W-10-12, 26

Fuse 21..............................8W-10-13, 33

Fuse 22..............................8W-10-13, 33

Fuse 24..............................8W-10-13, 32

Fuse 25..............................8W-10-13, 33

Fuse 27............................8W-10-16, 17, 47

Fuse 28............................8W-10-43, 44, 45

Fuse 32..............................8W-10-16, 36

Fuse 33..............................8W-10-16, 36Component PageFuse 34..............................8W-10-16, 36

Fuse 35...............................8W-10-48

Fuse 36..............................8W-10-47, 58

Fuse 37...............................8W-10-48

Fuse 38..............................8W-10-47, 48

Fuse 40............................8W-10-14, 15, 34

Fuse 41..............................8W-10-15, 38

Fuse 42..............................8W-10-13, 34

Fuse 43..............................8W-10-13, 34

Fuse 45............................8W-10-15, 16, 38

Fuse 46............................8W-10-14, 15, 35

Fuse 47..............................8W-10-15, 35

Fuse 48..............................8W-10-14, 34

Fuse 49..............................8W-10-11, 18

Fuse 50...............................8W-10-45

Fuse 51............................8W-10-13, 14, 32

Fuse 52..............................8W-10-47, 48

Fuse 53...............................8W-10-45

Fusible Link.............................8W-10-11

G103...............................8W-10-51, 52

G106...........................8W-10-31, 51, 55, 57

G107...............................8W-10-27, 29

G201.................................8W-10-26

Generator.............................8W-10-11, 28

Glove Box Lamp And Switch.....................8W-10-42

Headlamp Switch..........................8W-10-38

Headlamp-Left............................8W-10-55

Headlamp-Right...........................8W-10-55

Heated Mirror Relay.......................8W-10-17, 47

Horn Relay............................8W-10-15, 38

Horn-High Note...........................8W-10-38

Horn-Low Note............................8W-10-38

Ignition Coil.............................8W-10-24

Ignition Coil-Left...........................8W-10-23

Ignition Coil-Right..........................8W-10-23

Ignition Switch................8W-10-12, 26, 39, 45, 48, 50, 56

Instrument Cluster................8W-10-13, 26, 32, 33, 45, 50

Integrated Power Module . 8W-10-2, 3, 5, 11, 12, 13,, 14, 15, 16, 17, 18, 26, 27,

28, 29, 30, 31, 32, 33, 34, 35, 36, 38, 39, 42, 43, 44, 45, 46, 47, 48, 49, 50, 52,

54, 55, 57, 58

Leak Detection Pump........................8W-10-28

License Lamp-Left..........................8W-10-36

License Lamp-Right.........................8W-10-37

Overhead Map/Reading Lamp....................8W-10-42

Oxygen Sensor 1/1 Upstream.....................8W-10-25

Oxygen Sensor 1/2 Downstream...................8W-10-25

Oxygen Sensor 2/1 Upstream.....................8W-10-25

Oxygen Sensor 2/2 Downstream...................8W-10-25

Oxygen Sensor Downstream Relay................8W-10-11, 18

Park Lamp Relay.........................8W-10-16, 36

Park/Turn Signal Lamp-Left Front................8W-10-36, 51

Park/Turn Signal Lamp-Right Front...............8W-10-36, 51

Passenger Airbag On/Off Switch...................8W-10-46

Passenger Lumbar Switch......................8W-10-30

Power Mirror-Left..........................8W-10-47

Power Mirror-Right.........................8W-10-47

Power Outlet...........................8W-10-13, 33

Power Outlet-Console........................8W-10-34

Power Seat Switch-Driver......................8W-10-30

Power Seat Switch-Passenger....................8W-10-30

Power Window Circuit Breaker....................8W-10-56

Powertrain Control Module . 8W-10-17, 18, 19, 21, 23, 24, 28, 29, 33, 39, 40, 41,

42, 43, 44, 49, 57

PTCNo.1.........................8W-10-42, 43, 44, 45

PTCNo.2 ..............................8W-10-50

PTCNo.5 ..............................8W-10-35

Radio...............................8W-10-32, 50

Seat Belt Tensioner Reducer.....................8W-10-50

Seat Heater Interface Module....................8W-10-34

Sentry Key Immobilizer Module...............8W-10-33, 43, 44

Spare Relay.............................8W-10-58

Starter Motor...........................8W-10-14, 39

Starter Motor Relay.......................8W-10-14, 39

Tail/Stop/Turn Signal Lamp-Left.............8W-10-36, 51, 52, 54

Tail/Stop/Turn Signal Lamp-Right.............8W-10-37, 51, 52, 54

Tailgate Lamp Assembly.....................8W-10-36, 41

Trailer Tow Connector...................8W-10-15, 16, 35, 36

Trailer Tow Connector-Add On..............8W-10-18, 35, 36, 52

Trailer Tow Left Turn Relay...................8W-10-15, 35

Trailer Tow Right Turn Relay...................8W-10-15, 35

Transfer Case Control Module................8W-10-13, 34, 39

Transmission Control Module...............8W-10-12, 27, 41, 56

Transmission Control Relay................8W-10-12, 27, 28, 29

Transmission Range Sensor..................8W-10-40, 48, 53

Transmission Solenoid Assembly.................8W-10-12, 28

Transmission Solenoid/TRS Assembly.........8W-10-27, 29, 40, 48, 53

Underhood Lamp...........................8W-10-32

Vacuum Pump............................8W-10-43

Vistronic Fan Drive.........................8W-10-58

Washer Fluid Level Switch....................8W-10-52, 54

Washer Pump Motor-Front......................8W-10-52

Wiper High/Low Relay......................8W-10-14, 31

Wiper Motor-Front........................8W-10-31, 52

Wiper On/Off Relay........................8W-10-14, 31

DR8W-10 POWER DISTRIBUTION 8W - 10 - 1