brake pads DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 121 of 2895

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Remove wheels and tires.

(2) Remove brake calipers and rotors.

(3) Disconnect ABS wheel speed sensors.

(4) Disconnect axle vent hose.

(5) Remove front propeller shaft.

(6) Disconnect stabilizer bar links at the axle

brackets.

(7) Disconnect shock absorbers from axle brackets.

(8) Disconnect track bar from the axle bracket.

(9) Disconnect tie rod and drag link from the steer-

ing knuckles.

(10) Position suitable lifting device under the axle

assembly.

(11) Secure axle to lifting device.

(12) Mark suspension alignment cams for installa-

tion reference.

(13) Disconnect upper and lower suspension arms

from the axle bracket.(14) Lower the axle. The coil springs will drop

with the axle.

(15) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the weight of the

vehicle on the suspension, at normal height. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur. Rubber bushings must never

be lubricated.

(1) Support the axle on a suitable lifting device.

(2) Secure axle to lifting device.

(3) Position the axle under the vehicle.

(4) Install springs, retainer clip and bolts.

(5) Raise axle and align it with the spring pads.

3 - 48 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 228 of 2895

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 39

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM.............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................5

STANDARD PROCEDURE - PRESSURE

BLEEDING............................5

SPECIAL TOOLS

BASE BRAKES........................5

ADJUSTABLE PEDAL SWITCH

REMOVAL.............................6

INSTALLATION..........................6

HYDRAULIC/MECHANICAL

SPECIFICATIONS

SPECIFICATIONS - TORQUE CHART.......6

BASE BRAKE.........................7

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING....................7

STANDARD PROCEDURE - ISO FLARING . . . 7

REMOVAL

REMOVAL - REAR BRAKE HOSE..........8

REMOVAL - REAR TUBE / HOSE

ASSEMBLY...........................8

REMOVAL - FRONT HOSE...............9

INSTALLATION

INSTALLATION - REAR BRAKE HOSE......9

INSTALLATION - REAR TUBE / HOSE

ASSEMBLY...........................9

INSTALLATION - FRONT BRAKE HOSE.....9

BRAKE PADS/SHOES

REMOVAL.............................10

INSTALLATION.........................10

DISC BRAKE CALIPERS

DESCRIPTION.........................11OPERATION...........................12

REMOVAL

REMOVAL - REAR.....................12

REMOVAL - FRONT....................12

DISASSEMBLY.........................13

INSPECTION..........................14

ASSEMBLY............................15

INSTALLATION

INSTALLATION - REAR.................16

INSTALLATION - FRONT................16

DISC BRAKE CALIPER ADAPTER

REMOVAL

REMOVAL - REAR.....................16

REMOVAL - FRONT....................16

INSTALLATION

INSTALLATION - REAR.................17

INSTALLATION - FRONT................17

DISC BRAKE CALIPER ADAPTER MOUNT

REMOVAL - REAR......................17

INSTALLATION.........................17

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................18

STANDARD PROCEDURE - BRAKE FLUID

LEVEL..............................18

SPECIFICATIONS

BRAKE FLUID........................18

FLUID RESERVOIR

REMOVAL.............................19

INSTALLATION.........................19

BRAKE JUNCTION BLOCK

REMOVAL.............................19

INSTALLATION.........................19

MASTER CYLINDER

DESCRIPTION.........................19

OPERATION...........................20

DRBRAKES 5 - 1

Page 237 of 2895

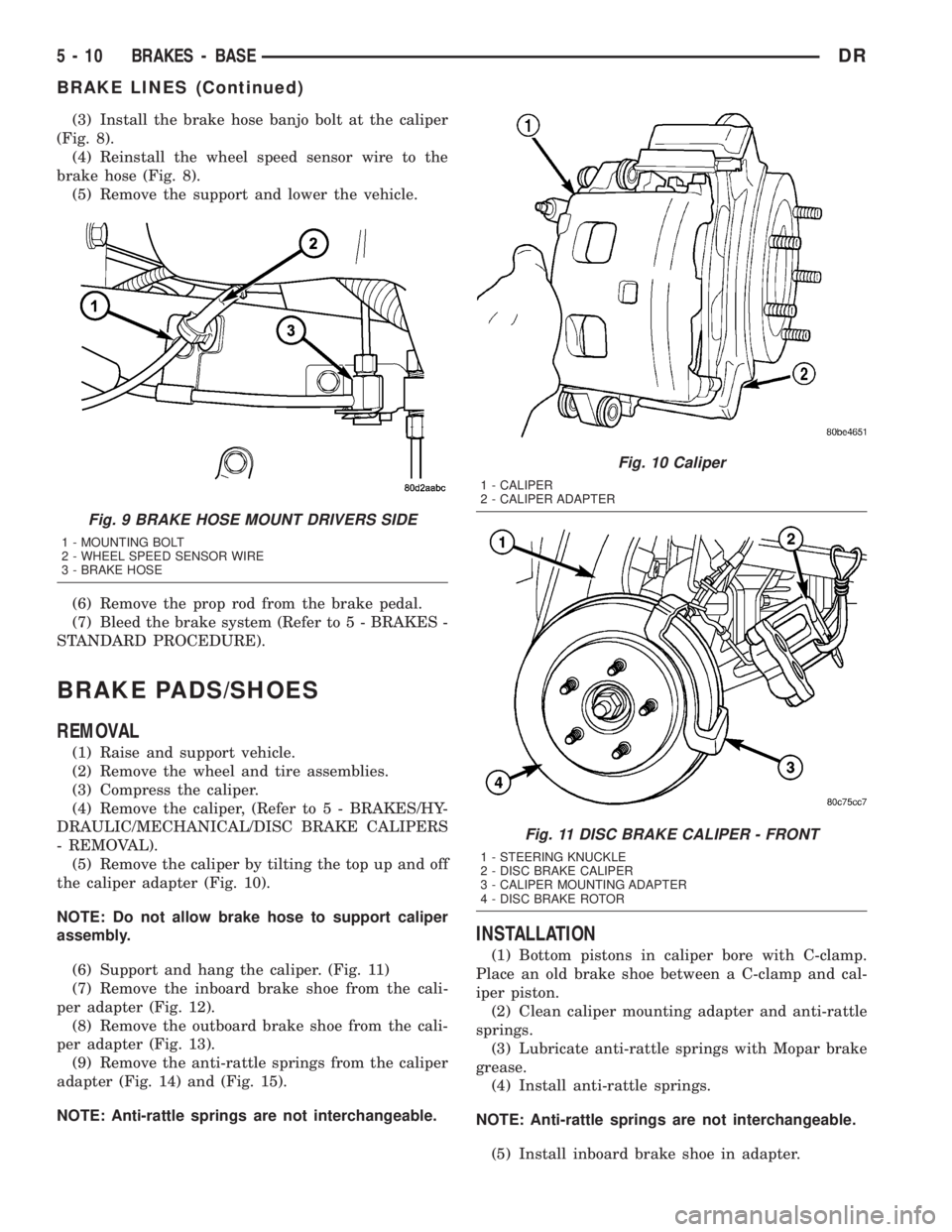

(3) Install the brake hose banjo bolt at the caliper

(Fig. 8).

(4) Reinstall the wheel speed sensor wire to the

brake hose (Fig. 8).

(5) Remove the support and lower the vehicle.

(6) Remove the prop rod from the brake pedal.

(7) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

BRAKE PADS/SHOES

REMOVAL

(1) Raise and support vehicle.

(2) Remove the wheel and tire assemblies.

(3) Compress the caliper.

(4) Remove the caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- REMOVAL).

(5) Remove the caliper by tilting the top up and off

the caliper adapter (Fig. 10).

NOTE: Do not allow brake hose to support caliper

assembly.

(6) Support and hang the caliper. (Fig. 11)

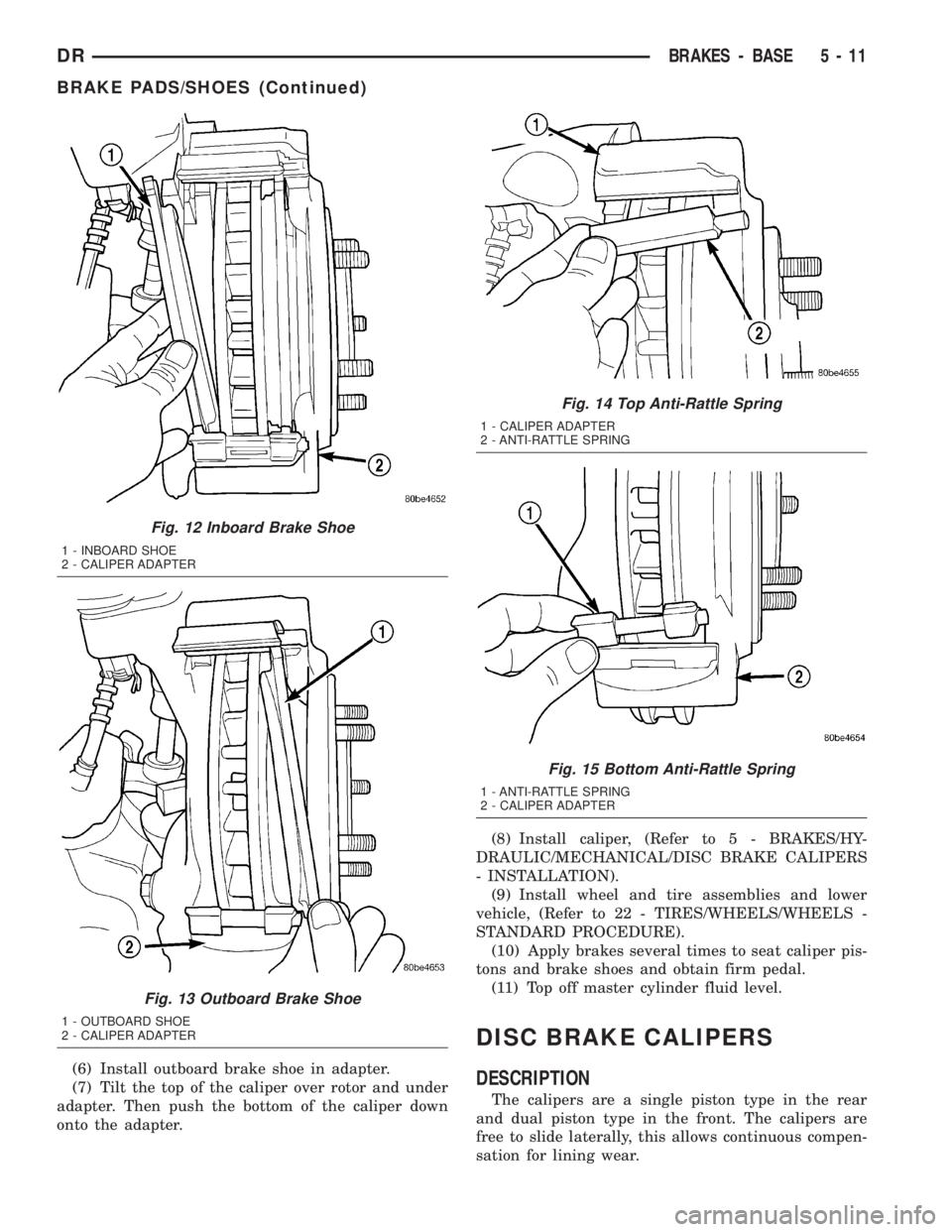

(7) Remove the inboard brake shoe from the cali-

per adapter (Fig. 12).

(8) Remove the outboard brake shoe from the cali-

per adapter (Fig. 13).

(9) Remove the anti-rattle springs from the caliper

adapter (Fig. 14) and (Fig. 15).

NOTE: Anti-rattle springs are not interchangeable.

INSTALLATION

(1) Bottom pistons in caliper bore with C-clamp.

Place an old brake shoe between a C-clamp and cal-

iper piston.

(2) Clean caliper mounting adapter and anti-rattle

springs.

(3) Lubricate anti-rattle springs with Mopar brake

grease.

(4) Install anti-rattle springs.

NOTE: Anti-rattle springs are not interchangeable.

(5) Install inboard brake shoe in adapter.

Fig. 9 BRAKE HOSE MOUNT DRIVERS SIDE

1 - MOUNTING BOLT

2 - WHEEL SPEED SENSOR WIRE

3 - BRAKE HOSE

Fig. 10 Caliper

1 - CALIPER

2 - CALIPER ADAPTER

Fig. 11 DISC BRAKE CALIPER - FRONT

1 - STEERING KNUCKLE

2 - DISC BRAKE CALIPER

3 - CALIPER MOUNTING ADAPTER

4 - DISC BRAKE ROTOR

5 - 10 BRAKES - BASEDR

BRAKE LINES (Continued)

Page 238 of 2895

(6) Install outboard brake shoe in adapter.

(7) Tilt the top of the caliper over rotor and under

adapter. Then push the bottom of the caliper down

onto the adapter.(8) Install caliper, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(9) Install wheel and tire assemblies and lower

vehicle, (Refer to 22 - TIRES/WHEELS/WHEELS -

STANDARD PROCEDURE).

(10) Apply brakes several times to seat caliper pis-

tons and brake shoes and obtain firm pedal.

(11) Top off master cylinder fluid level.

DISC BRAKE CALIPERS

DESCRIPTION

The calipers are a single piston type in the rear

and dual piston type in the front. The calipers are

free to slide laterally, this allows continuous compen-

sation for lining wear.

Fig. 12 Inboard Brake Shoe

1 - INBOARD SHOE

2 - CALIPER ADAPTER

Fig. 13 Outboard Brake Shoe

1 - OUTBOARD SHOE

2 - CALIPER ADAPTER

Fig. 14 Top Anti-Rattle Spring

1 - CALIPER ADAPTER

2 - ANTI-RATTLE SPRING

Fig. 15 Bottom Anti-Rattle Spring

1 - ANTI-RATTLE SPRING

2 - CALIPER ADAPTER

DRBRAKES - BASE 5 - 11

BRAKE PADS/SHOES (Continued)

Page 239 of 2895

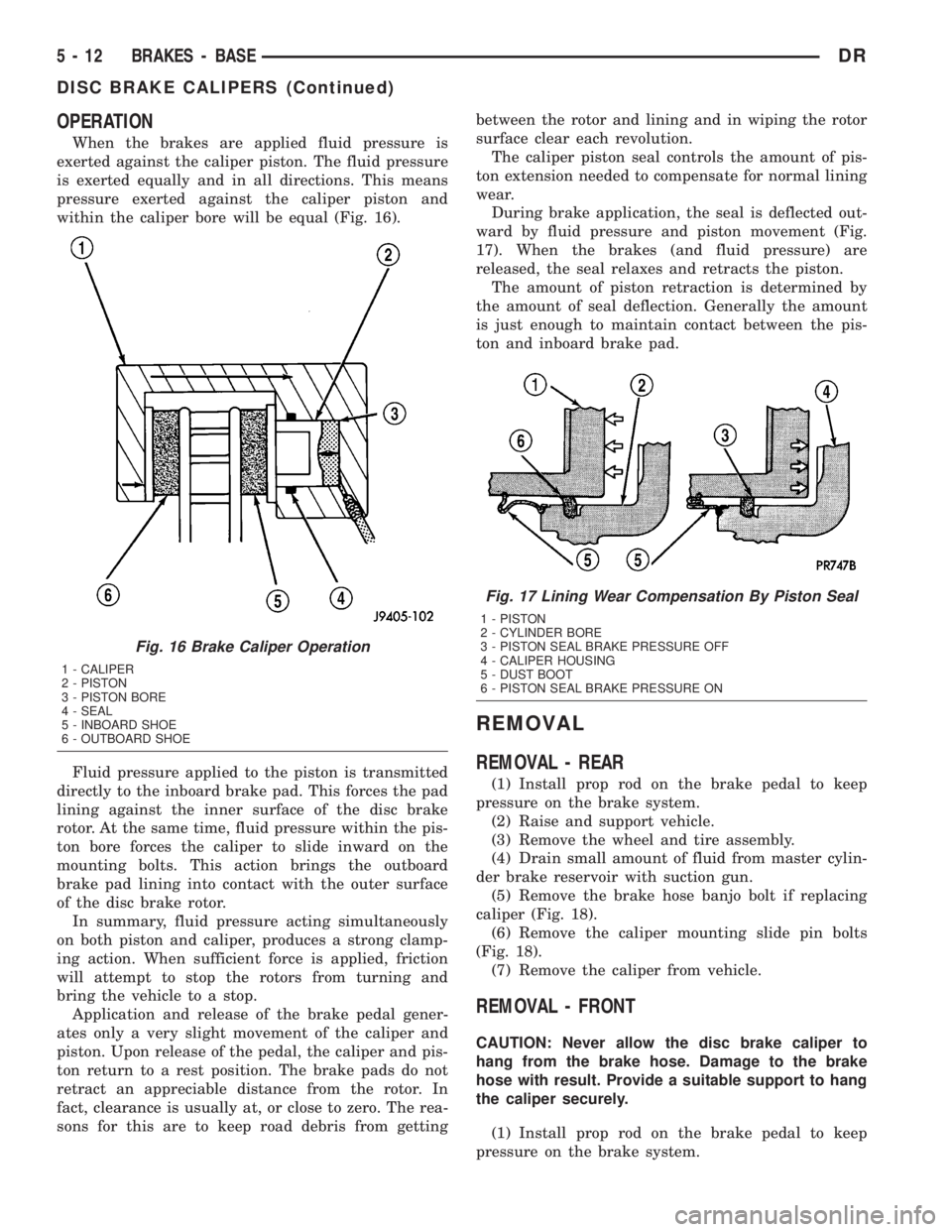

OPERATION

When the brakes are applied fluid pressure is

exerted against the caliper piston. The fluid pressure

is exerted equally and in all directions. This means

pressure exerted against the caliper piston and

within the caliper bore will be equal (Fig. 16).

Fluid pressure applied to the piston is transmitted

directly to the inboard brake pad. This forces the pad

lining against the inner surface of the disc brake

rotor. At the same time, fluid pressure within the pis-

ton bore forces the caliper to slide inward on the

mounting bolts. This action brings the outboard

brake pad lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake pads do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from gettingbetween the rotor and lining and in wiping the rotor

surface clear each revolution.

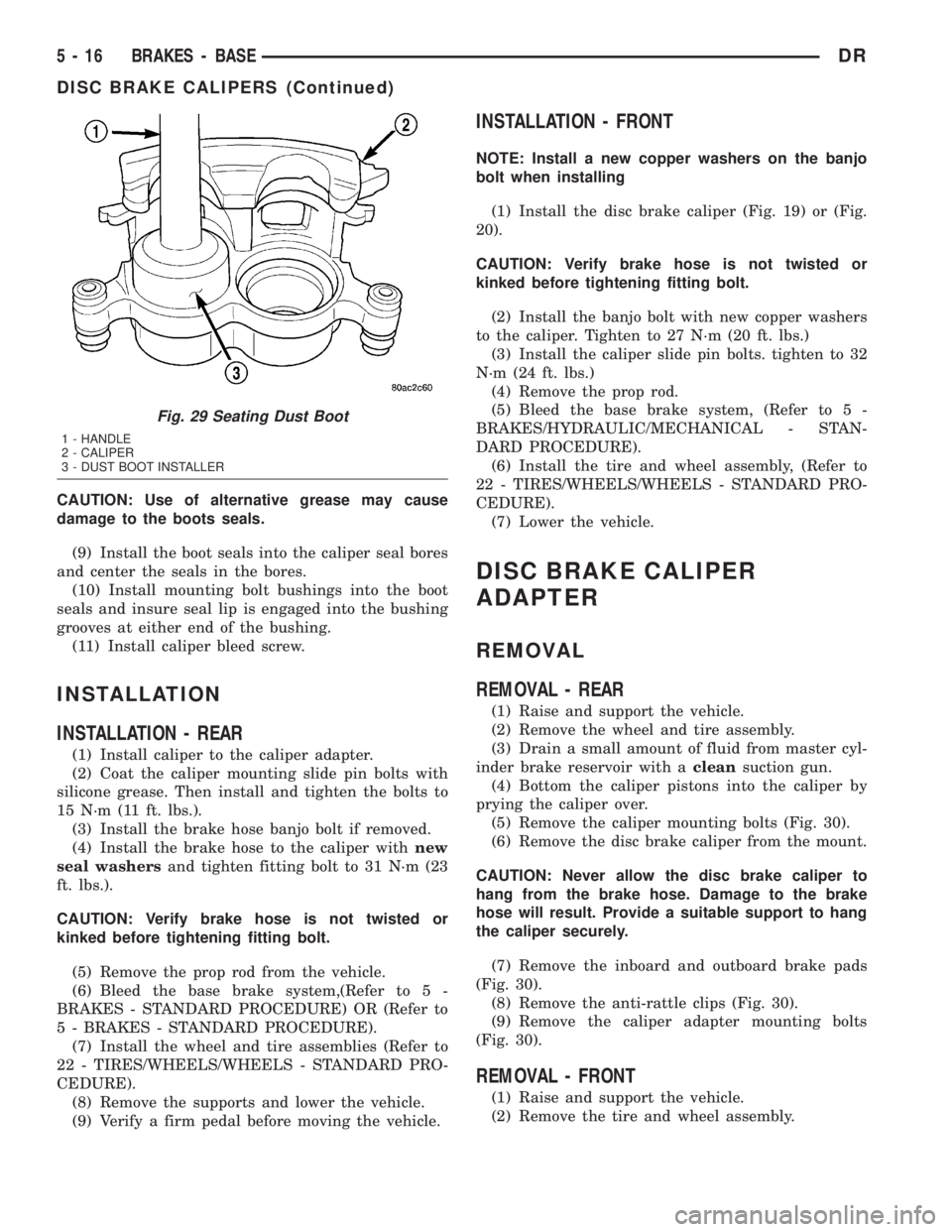

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig.

17). When the brakes (and fluid pressure) are

released, the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amount

is just enough to maintain contact between the pis-

ton and inboard brake pad.

REMOVAL

REMOVAL - REAR

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove the wheel and tire assembly.

(4) Drain small amount of fluid from master cylin-

der brake reservoir with suction gun.

(5) Remove the brake hose banjo bolt if replacing

caliper (Fig. 18).

(6) Remove the caliper mounting slide pin bolts

(Fig. 18).

(7) Remove the caliper from vehicle.

REMOVAL - FRONT

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose with result. Provide a suitable support to hang

the caliper securely.

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

Fig. 16 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

Fig. 17 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 12 BRAKES - BASEDR

DISC BRAKE CALIPERS (Continued)

Page 243 of 2895

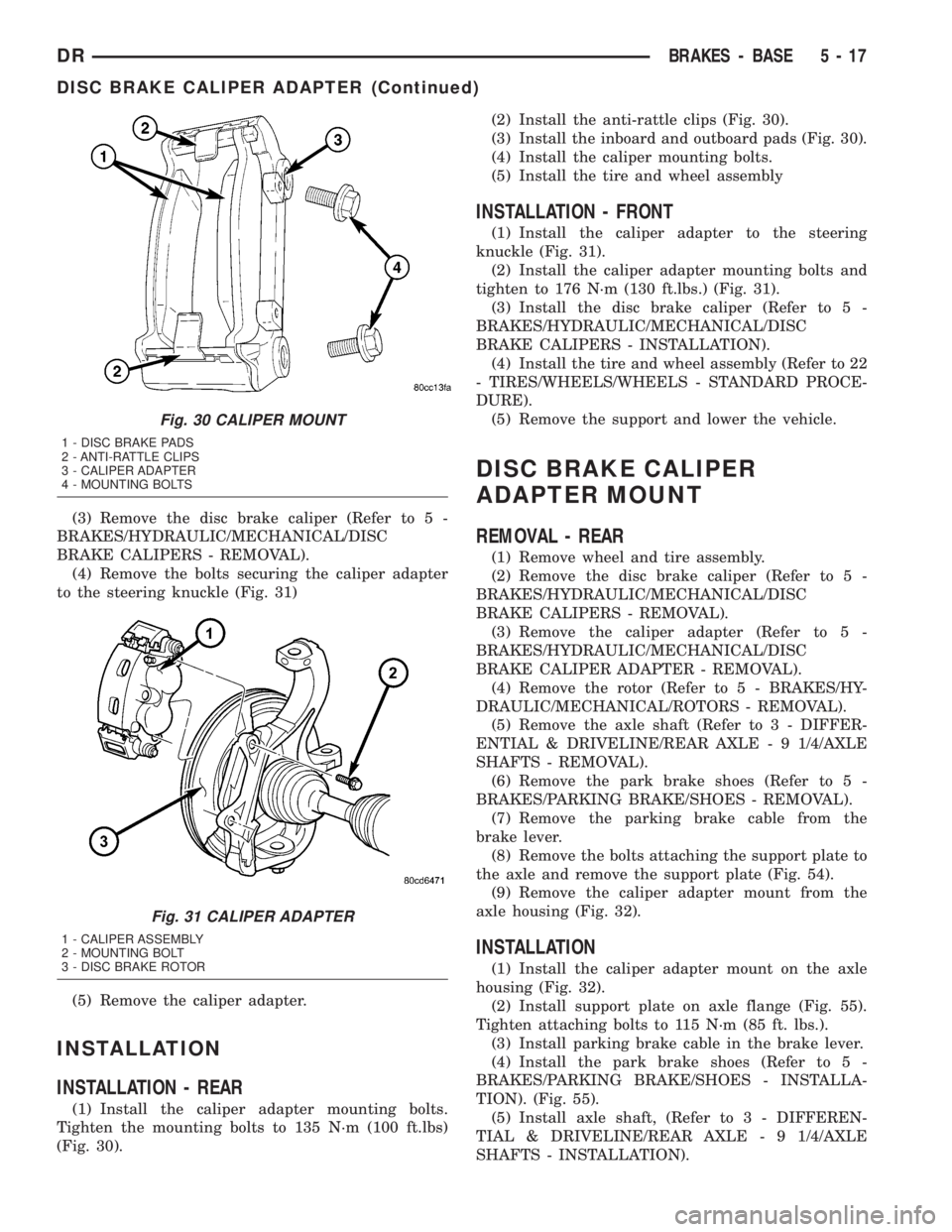

CAUTION: Use of alternative grease may cause

damage to the boots seals.

(9) Install the boot seals into the caliper seal bores

and center the seals in the bores.

(10) Install mounting bolt bushings into the boot

seals and insure seal lip is engaged into the bushing

grooves at either end of the bushing.

(11) Install caliper bleed screw.

INSTALLATION

INSTALLATION - REAR

(1) Install caliper to the caliper adapter.

(2) Coat the caliper mounting slide pin bolts with

silicone grease. Then install and tighten the bolts to

15 N´m (11 ft. lbs.).

(3) Install the brake hose banjo bolt if removed.

(4) Install the brake hose to the caliper withnew

seal washersand tighten fitting bolt to 31 N´m (23

ft. lbs.).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(5) Remove the prop rod from the vehicle.

(6) Bleed the base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(7) Install the wheel and tire assemblies (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

INSTALLATION - FRONT

NOTE: Install a new copper washers on the banjo

bolt when installing

(1) Install the disc brake caliper (Fig. 19) or (Fig.

20).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(2) Install the banjo bolt with new copper washers

to the caliper. Tighten to 27 N´m (20 ft. lbs.)

(3) Install the caliper slide pin bolts. tighten to 32

N´m (24 ft. lbs.)

(4) Remove the prop rod.

(5) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

DISC BRAKE CALIPER

ADAPTER

REMOVAL

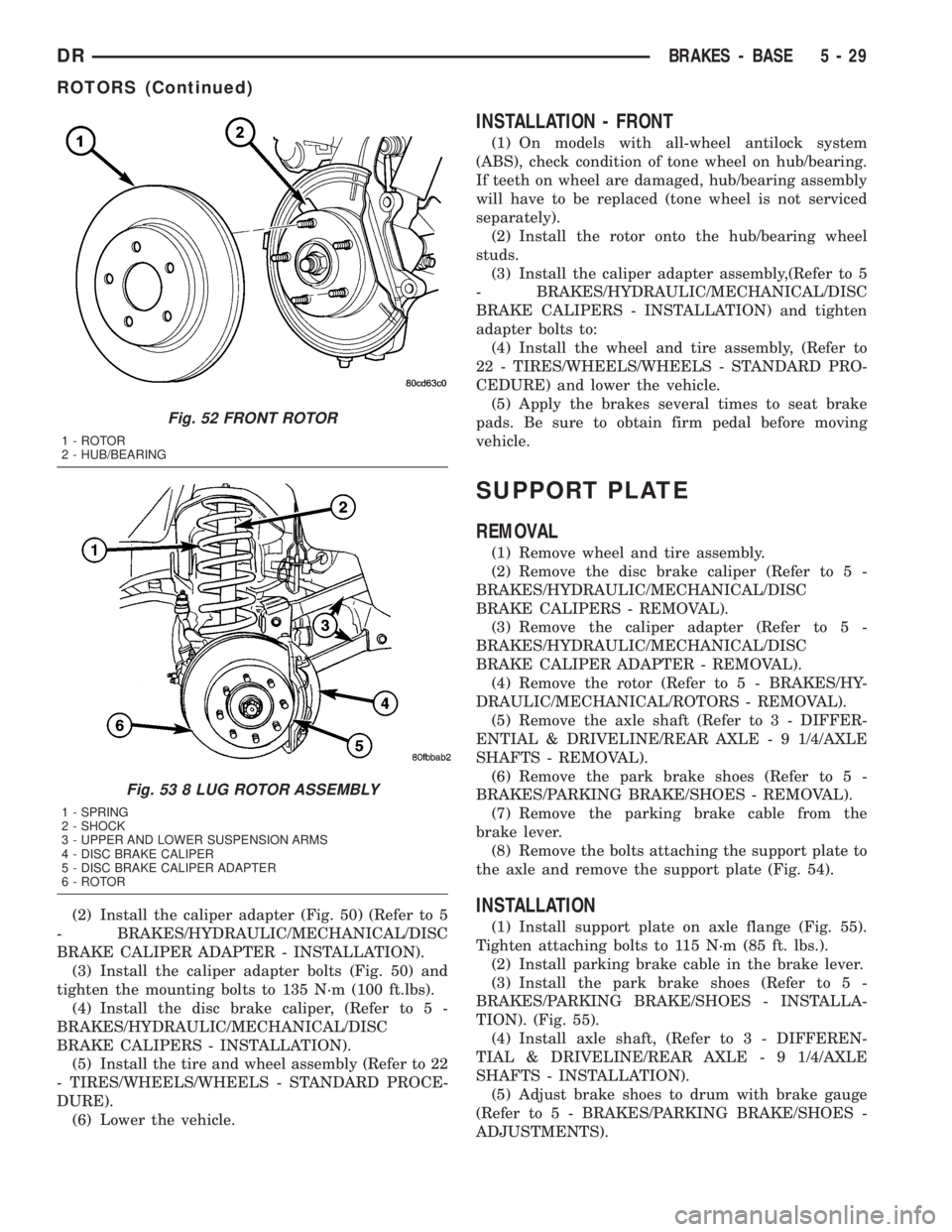

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Drain a small amount of fluid from master cyl-

inder brake reservoir with acleansuction gun.

(4) Bottom the caliper pistons into the caliper by

prying the caliper over.

(5) Remove the caliper mounting bolts (Fig. 30).

(6) Remove the disc brake caliper from the mount.

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(7) Remove the inboard and outboard brake pads

(Fig. 30).

(8) Remove the anti-rattle clips (Fig. 30).

(9) Remove the caliper adapter mounting bolts

(Fig. 30).

REMOVAL - FRONT

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

Fig. 29 Seating Dust Boot

1 - HANDLE

2 - CALIPER

3 - DUST BOOT INSTALLER

5 - 16 BRAKES - BASEDR

DISC BRAKE CALIPERS (Continued)

Page 244 of 2895

(3) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the bolts securing the caliper adapter

to the steering knuckle (Fig. 31)

(5) Remove the caliper adapter.

INSTALLATION

INSTALLATION - REAR

(1) Install the caliper adapter mounting bolts.

Tighten the mounting bolts to 135 N´m (100 ft.lbs)

(Fig. 30).(2) Install the anti-rattle clips (Fig. 30).

(3) Install the inboard and outboard pads (Fig. 30).

(4) Install the caliper mounting bolts.

(5) Install the tire and wheel assembly

INSTALLATION - FRONT

(1) Install the caliper adapter to the steering

knuckle (Fig. 31).

(2) Install the caliper adapter mounting bolts and

tighten to 176 N´m (130 ft.lbs.) (Fig. 31).

(3) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(4) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(5) Remove the support and lower the vehicle.

DISC BRAKE CALIPER

ADAPTER MOUNT

REMOVAL - REAR

(1) Remove wheel and tire assembly.

(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 54).

(9) Remove the caliper adapter mount from the

axle housing (Fig. 32).

INSTALLATION

(1) Install the caliper adapter mount on the axle

housing (Fig. 32).

(2) Install support plate on axle flange (Fig. 55).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(3) Install parking brake cable in the brake lever.

(4) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 55).

(5) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

Fig. 30 CALIPER MOUNT

1 - DISC BRAKE PADS

2 - ANTI-RATTLE CLIPS

3 - CALIPER ADAPTER

4 - MOUNTING BOLTS

Fig. 31 CALIPER ADAPTER

1 - CALIPER ASSEMBLY

2 - MOUNTING BOLT

3 - DISC BRAKE ROTOR

DRBRAKES - BASE 5 - 17

DISC BRAKE CALIPER ADAPTER (Continued)

Page 256 of 2895

(2) Install the caliper adapter (Fig. 50) (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the caliper adapter bolts (Fig. 50) and

tighten the mounting bolts to 135 N´m (100 ft.lbs).

(4) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(6) Lower the vehicle.

INSTALLATION - FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake

pads. Be sure to obtain firm pedal before moving

vehicle.

SUPPORT PLATE

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 54).

INSTALLATION

(1) Install support plate on axle flange (Fig. 55).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(2) Install parking brake cable in the brake lever.

(3) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 55).

(4) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(5) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

Fig. 52 FRONT ROTOR

1 - ROTOR

2 - HUB/BEARING

Fig. 53 8 LUG ROTOR ASSEMBLY

1 - SPRING

2 - SHOCK

3 - UPPER AND LOWER SUSPENSION ARMS

4 - DISC BRAKE CALIPER

5 - DISC BRAKE CALIPER ADAPTER

6 - ROTOR

DRBRAKES - BASE 5 - 29

ROTORS (Continued)

Page 260 of 2895

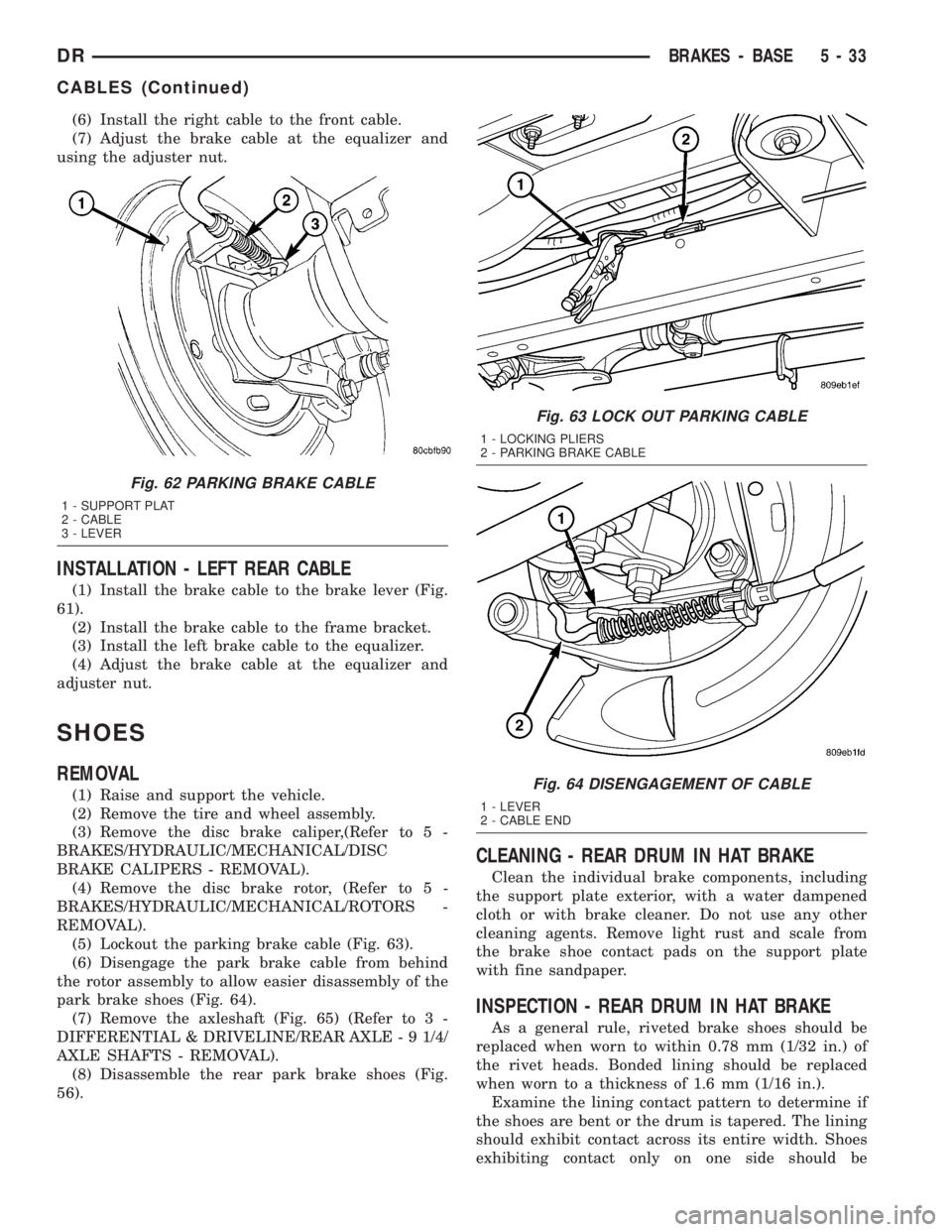

(6) Install the right cable to the front cable.

(7) Adjust the brake cable at the equalizer and

using the adjuster nut.

INSTALLATION - LEFT REAR CABLE

(1) Install the brake cable to the brake lever (Fig.

61).

(2) Install the brake cable to the frame bracket.

(3) Install the left brake cable to the equalizer.

(4) Adjust the brake cable at the equalizer and

adjuster nut.

SHOES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Lockout the parking brake cable (Fig. 63).

(6) Disengage the park brake cable from behind

the rotor assembly to allow easier disassembly of the

park brake shoes (Fig. 64).

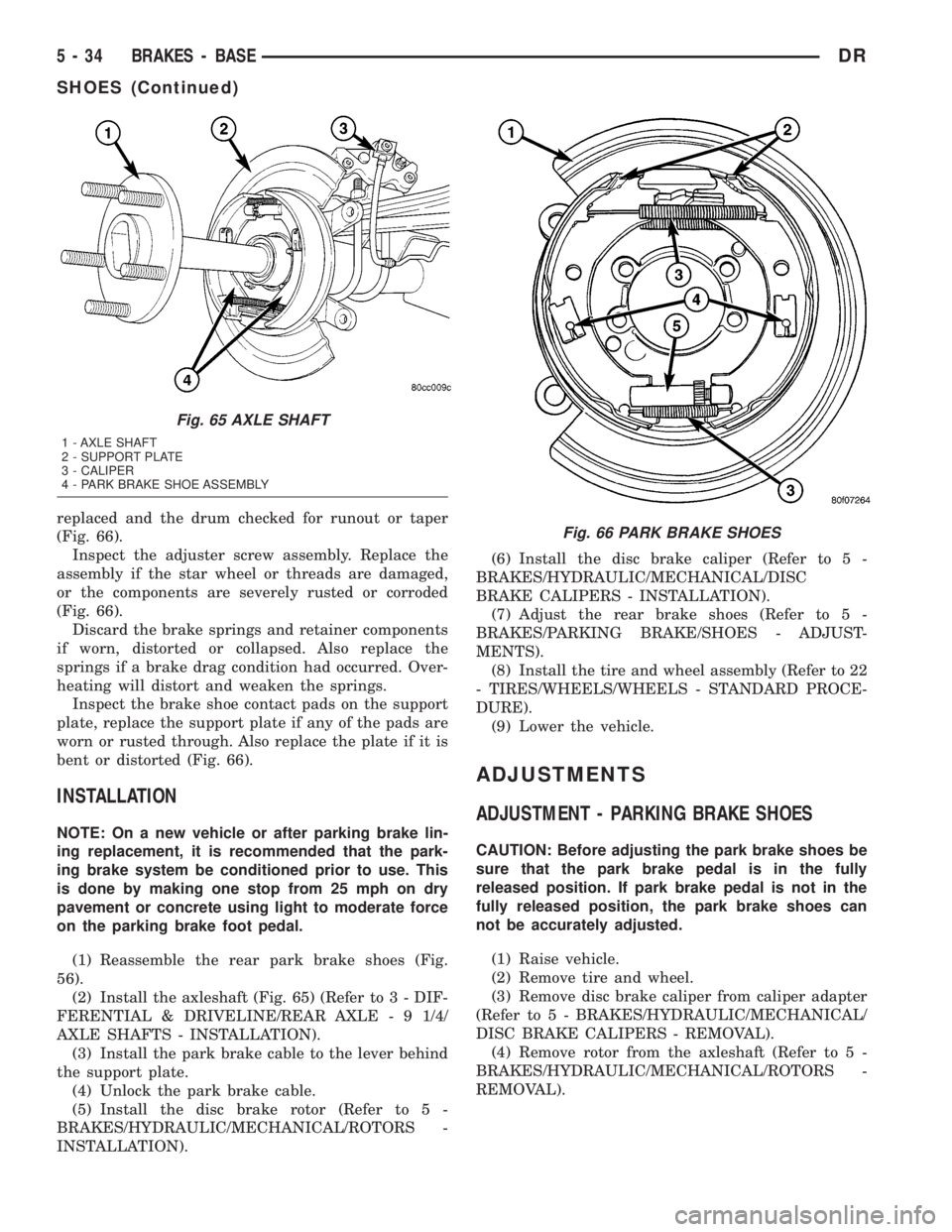

(7) Remove the axleshaft (Fig. 65) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - REMOVAL).

(8) Disassemble the rear park brake shoes (Fig.

56).

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including

the support plate exterior, with a water dampened

cloth or with brake cleaner. Do not use any other

cleaning agents. Remove light rust and scale from

the brake shoe contact pads on the support plate

with fine sandpaper.

INSPECTION - REAR DRUM IN HAT BRAKE

As a general rule, riveted brake shoes should be

replaced when worn to within 0.78 mm (1/32 in.) of

the rivet heads. Bonded lining should be replaced

when worn to a thickness of 1.6 mm (1/16 in.).

Examine the lining contact pattern to determine if

the shoes are bent or the drum is tapered. The lining

should exhibit contact across its entire width. Shoes

exhibiting contact only on one side should be

Fig. 62 PARKING BRAKE CABLE

1 - SUPPORT PLAT

2 - CABLE

3 - LEVER

Fig. 63 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 64 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 33

CABLES (Continued)

Page 261 of 2895

replaced and the drum checked for runout or taper

(Fig. 66).

Inspect the adjuster screw assembly. Replace the

assembly if the star wheel or threads are damaged,

or the components are severely rusted or corroded

(Fig. 66).

Discard the brake springs and retainer components

if worn, distorted or collapsed. Also replace the

springs if a brake drag condition had occurred. Over-

heating will distort and weaken the springs.

Inspect the brake shoe contact pads on the support

plate, replace the support plate if any of the pads are

worn or rusted through. Also replace the plate if it is

bent or distorted (Fig. 66).

INSTALLATION

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(1) Reassemble the rear park brake shoes (Fig.

56).

(2) Install the axleshaft (Fig. 65) (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - INSTALLATION).

(3) Install the park brake cable to the lever behind

the support plate.

(4) Unlock the park brake cable.

(5) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).(6) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(7) Adjust the rear brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - ADJUST-

MENTS).

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Lower the vehicle.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES

CAUTION: Before adjusting the park brake shoes be

sure that the park brake pedal is in the fully

released position. If park brake pedal is not in the

fully released position, the park brake shoes can

not be accurately adjusted.

(1) Raise vehicle.

(2) Remove tire and wheel.

(3) Remove disc brake caliper from caliper adapter

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL).

(4) Remove rotor from the axleshaft (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

Fig. 65 AXLE SHAFT

1 - AXLE SHAFT

2 - SUPPORT PLATE

3 - CALIPER

4 - PARK BRAKE SHOE ASSEMBLY

Fig. 66 PARK BRAKE SHOES

5 - 34 BRAKES - BASEDR

SHOES (Continued)