buttons DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 418 of 2895

WARNING: ALWAYS WEAR APPROPRIATE EYE

PROTECTION AND USE EXTREME CAUTION WHEN

WORKING WITH BATTERIES.

BATTERY TESTING

(1) If testing the battery OUT-OF-VEHICLE, clean

the battery terminals with a wire brush before test-

ing. If the battery is equipped with side post termi-

nals, install and tighten the supplied lead terminal

stud adapters. Do not use steel bolts. Failure to prop-

erly install the stud adapters, or using stud adapters

that are dirty or worn-out may result in false test

readings.

(2) If testing the battery IN-THE-VEHICLE, make

certain all of the vehicle accessory loads are OFF,

including the ignition.The preferred test position

is at the battery terminal. If the battery is not

accessible, you may test using both the positive and

negative jumper posts. Select TESTING AT JUMPER

POST when connecting to that location.

(3) Connect the tester (Fig. 9) to the battery or

jumper posts, the red clamp to positive (+) and the

black clamp to negative (±).

NOTE: Multiple batteries connected in parallel must

have the ground cable disconnected to perform a

battery test. Failure to disconnect may result in

false battery test readings.

(4) Using the ARROW key selectinoroutof vehi-

cle testing and press ENTER to make a selection.

(5) If not selected, choose the Cold Cranking Amp

(CCA) battery rating. Or select the appropriate bat-

tery rating for your area (see menu). The tester will

then run its self programmed test of the battery and

display the results. Refer to the test result table

noted below.

CAUTION: If REPLACE BATTERY is the result of the

test, this may mean a poor connection between the

vehicle's cables and battery exists. After discon-

necting the vehicle's battery cables from the bat-

tery, retest the battery using the OUT-OF-VEHICLE

test before replacing.

(6) While viewing the battery test result, press the

CODE button and the tester will prompt you for the

last 4 digits of the VIN. Use the UP/DOWN arrow

buttons to scroll to the correct character; then press

ENTER to select and move to the next digit. Then

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

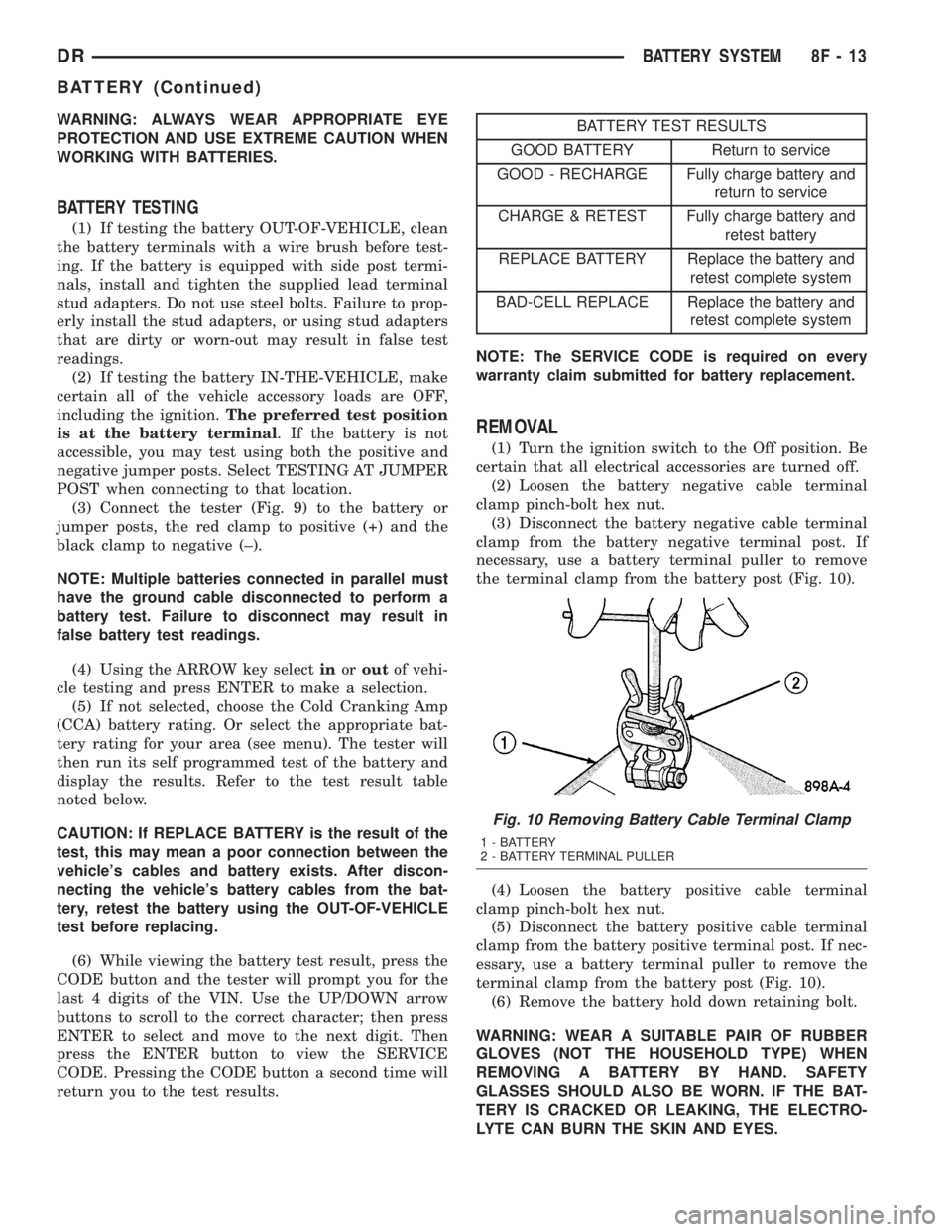

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 10).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post (Fig. 10).

(6) Remove the battery hold down retaining bolt.

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

Fig. 10 Removing Battery Cable Terminal Clamp

1 - BATTERY

2 - BATTERY TERMINAL PULLER

DRBATTERY SYSTEM 8F - 13

BATTERY (Continued)

Page 566 of 2895

(1) With the ignition switch in the Off position,

simultaneously depress and hold theSTEP and

RESET buttons.

(2) Turn the ignition switch to the On position.

(3) Following completion of the test, the electronics

module will display one of the following messages:

a.Pass Self Test (EVIC only), PASS (CMTC)-

The electronics module is working properly.

b.Failed Self Test (EVIC only), FAIL (CMTC)-

The electronics module has an internal failure. The

electronics module is faulty and must be replaced.

c.Failed J1850 Communication (EVIC only),

BUS (CMTC)- The electronics module is not receiv-

ing proper message input through the J1850 PCI

data bus circuit. This can result from one or more

faulty electronic modules in the vehicle, or from a

faulty PCI data bus. The use of a DRB IIItscan tool

and the proper Diagnostic Procedures manual are

required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Stan-

dard Procedures section of this group.

NOTE: If the compass reading displays dashes, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Standard Procedures section

of this group.

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the read-

ing/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.

(5) Reverse the above procedure to install.

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOV-

AL).

(2) Remove the electronics module from the over-

head console. Refer to the procedure later in this sec-

tion.

(3) Unsnap the lens from the module and replace

lens as necessary.

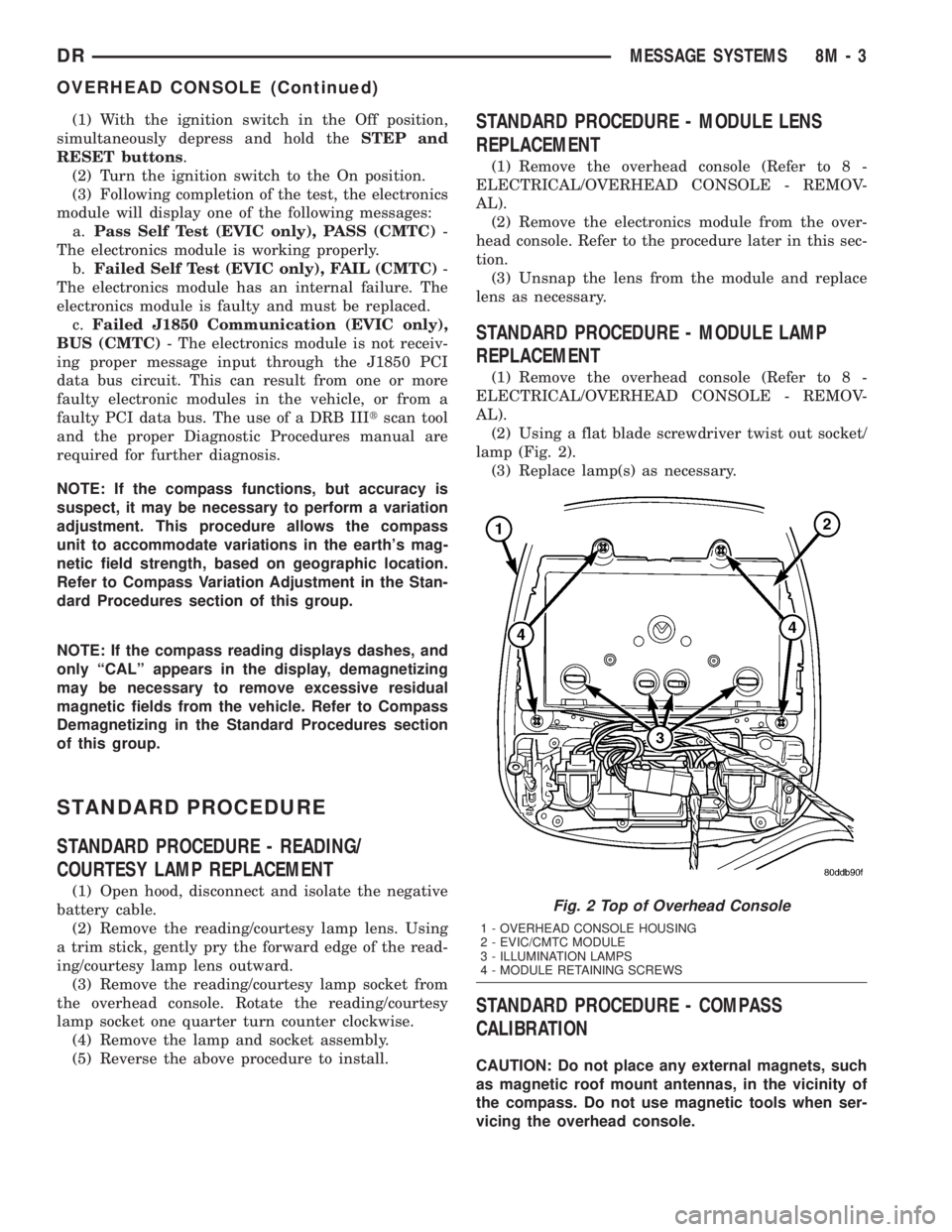

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOV-

AL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 2).

(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

Fig. 2 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC/CMTC MODULE

3 - ILLUMINATION LAMPS

4 - MODULE RETAINING SCREWS

DRMESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

Page 570 of 2895

OPERATION

The Compass Mini-Trip Computer module in the

overhead console has buttons used to select various

functions. The CMTC selector buttons will not oper-

ate until the ignition is in the RUN position.

When the ignition switch is first turned to the

RUN position the CMTC display;

²Returns to the last mode setting selected before

the ignition was last switched OFF.

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

Compass Mini-Trip Computer (CMTC) data is

obtained from other electronic modules (CCN, FCM

and JTEC) on the J1850 Data Bus circuit. The

CMTC will display dashes (- -) for any of the screens

it did not receive the bus messages. The label corre-

sponding to the missing information will be lit. If no

compass mini-trip computer data is displayed, check

the J1850 Data Bus circuit communications and the

other modules.

Refer to Overhead Console Diagnosis and Testing

for instructions on performing a CMTC module Self-

Diagnostic Test. The DRB IIItis recommended for

checking the J1850 Data Bus circuit and the other

modules. Perform the CMTC self diagnosis before

replacing the CMTC module.

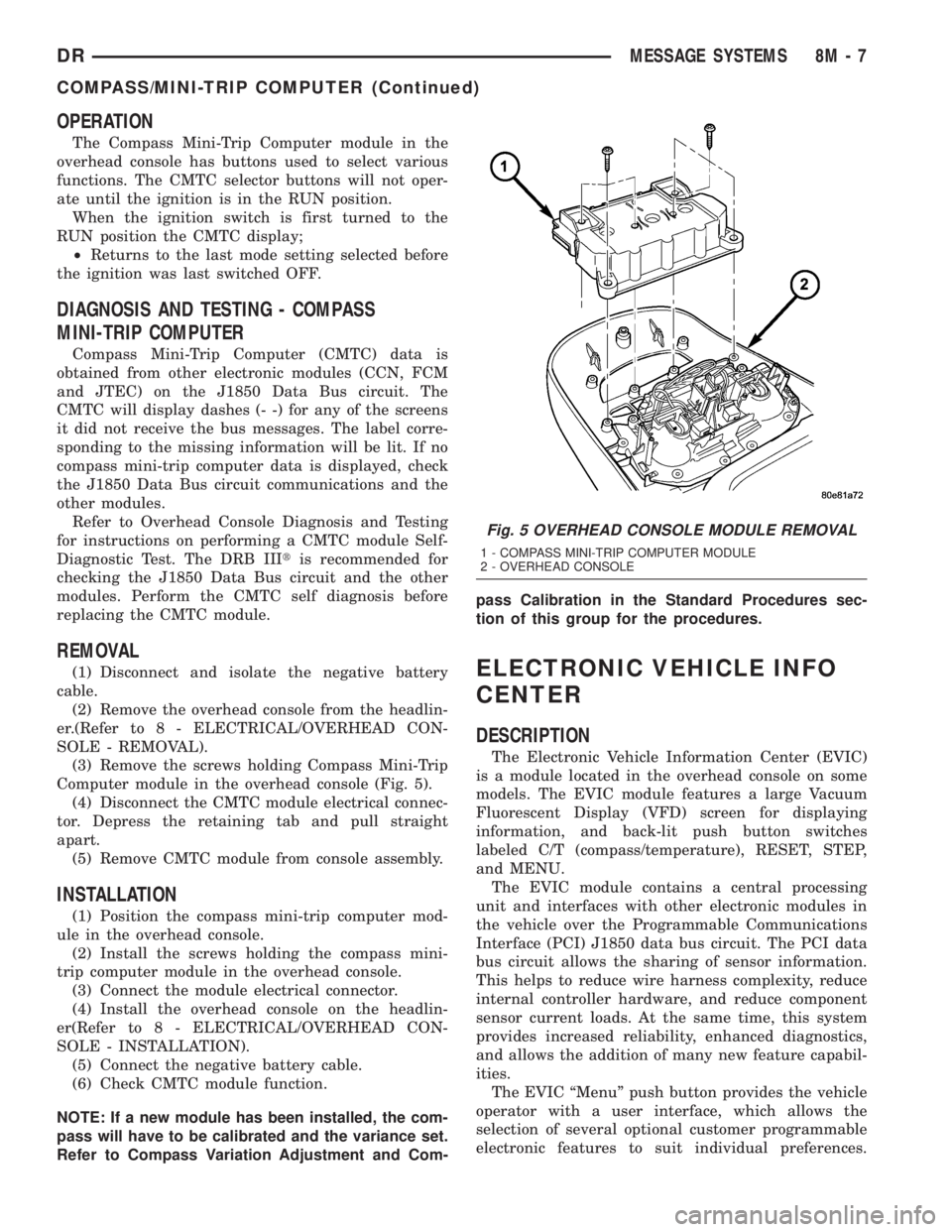

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the overhead console from the headlin-

er.(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(3) Remove the screws holding Compass Mini-Trip

Computer module in the overhead console (Fig. 5).

(4) Disconnect the CMTC module electrical connec-

tor. Depress the retaining tab and pull straight

apart.

(5) Remove CMTC module from console assembly.

INSTALLATION

(1) Position the compass mini-trip computer mod-

ule in the overhead console.

(2) Install the screws holding the compass mini-

trip computer module in the overhead console.

(3) Connect the module electrical connector.

(4) Install the overhead console on the headlin-

er(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - INSTALLATION).

(5) Connect the negative battery cable.

(6) Check CMTC module function.

NOTE: If a new module has been installed, the com-

pass will have to be calibrated and the variance set.

Refer to Compass Variation Adjustment and Com-pass Calibration in the Standard Procedures sec-

tion of this group for the procedures.

ELECTRONIC VEHICLE INFO

CENTER

DESCRIPTION

The Electronic Vehicle Information Center (EVIC)

is a module located in the overhead console on some

models. The EVIC module features a large Vacuum

Fluorescent Display (VFD) screen for displaying

information, and back-lit push button switches

labeled C/T (compass/temperature), RESET, STEP,

and MENU.

The EVIC module contains a central processing

unit and interfaces with other electronic modules in

the vehicle over the Programmable Communications

Interface (PCI) J1850 data bus circuit. The PCI data

bus circuit allows the sharing of sensor information.

This helps to reduce wire harness complexity, reduce

internal controller hardware, and reduce component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities.

The EVIC ªMenuº push button provides the vehicle

operator with a user interface, which allows the

selection of several optional customer programmable

electronic features to suit individual preferences.

Fig. 5 OVERHEAD CONSOLE MODULE REMOVAL

1 - COMPASS MINI-TRIP COMPUTER MODULE

2 - OVERHEAD CONSOLE

DRMESSAGE SYSTEMS 8M - 7

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 571 of 2895

Refer toELECTRONIC VEHICLE INFORMA-

TION CENTER PROGRAMMINGin the Standard

Procedures section of this group for more information

on the customer programmable feature options.

If the vehicle is equipped with the optional univer-

sal transmitter transceiver, the EVIC will also dis-

play messages and an icon indicating when the

universal transmitter transceiver is being trained,

which of the three transmitter buttons is transmit-

ting, and when the transceiver is cleared.

Data input for all EVIC functions, including VFD

dimming level, is received through the J1850 PCI

data bus circuit. The EVIC module uses its internal

programming and all of its data inputs to calculate

and display the requested data. If the data displayed

is incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclu-

sive, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the EVIC module and the J1850

PCI data bus circuit.

The EVIC module cannot be repaired, and is avail-

able for service only as a unit. If any part is faulty or

damaged, the complete EVIC module must be

replaced.

OPERATION

The Electronic Vehicle Information Center is wired

to both constant 12v and ignition switched sources of

battery current so that some of its features remain

operational at any time, while others may only oper-

ate with the ignition switch in the On position. When

the ignition switch is turned to the On position, the

EVIC module display will return to the last function

being displayed before the ignition was turned to the

Off position.

The compass/temperature display is the normal

EVIC display. With the ignition switch in the On

position, momentarily depressing and releasing the

C/T (compass/temperature) push button switch will

cause the EVIC to return to the compass/tempera-

ture display mode from any other mode. While in the

compass/temperature display mode, momentarily

depressing and releasing the Step push button will

step through the available trip computer display

options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and thefunction that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Standard Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from other electronic modules (CCN,

FCM, JTEC) on the J1850 Data Bus circuit. The

EVIC will display dashes (- -) for any of the screens

it did not receive the bus messages. The label corre-

sponding to the missing information will be lit. If no

EVIC data is displayed, check the J1850 Data Bus

circuit communications and the other modules. If the

brightness level is improper check the J1850 Data

Bus circuit.

Refer to Overhead Console Diagnosis and Testing

for instructions on performing a EVIC module Self-

Diagnostic Test. The DRB IIItis recommended for

checking the J1850 Data Bus circuit and other mod-

ules. Perform the EVIC self diagnosis before replac-

ing the EVIC module.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehi-

cle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter the

EVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

8M - 8 MESSAGE SYSTEMSDR

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 574 of 2895

then sends the proper ambient temperature mes-

sages to the EVIC, CMTC over the PCI J1850 data

bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Front Control Module, the Programmable Communi-

cations Interface (PCI) data bus, and a portion of the

Electronics module. If any portion of the ambient

temperature sensor circuit fails, the Front Control

Module will self-diagnose the circuit.

For complete circuit diagrams, refer toWiring.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At 24É C (75É F), the sensor resistance

should be approximately 10.3 kilohms. At 30É C (86É

F), the sensor resistance should be approximately

7.57 kilohms. The sensor resistance should decrease

as the temperature rises. If OK, refer toDiagnosis

and Testing - Ambient Temperature Sensor Cir-

cuitin this group. If not OK, replace the faulty

ambient temperature sensor.

NOTE: The ambient temperature sensor is a very

sensitive device. When testing, be certain the tem-

perature sensor has had time to stabilize (room

temperature) before attempting to read the sensor

resistance. Failure to let the ambient temperature

sensor temperature stabilize could result in a mis-

leading test.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Front Control Module wire

harness connector.

(2) Connect a jumper wire between the two termi-

nals of the ambient temperature sensor wire harness

connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the Front Control Module wire har-

ness connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return or

signal circuit as required.(4) Remove the jumper wire from the ambient tem-

perature sensor wire harness connector. Check for

continuity between the sensor return circuit cavity of

the Front Control Module wire harness connector

and a good ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted sen-

sor return circuit as required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the Front

Control Module wire harness connector and a good

ground. There should be no continuity. If OK, refer to

Diagnosis and Testing - Overhead Consolein

this group. If not OK, repair the shorted ambient

temperature sensor signal circuit as required.

REMOVAL

(1) Open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Working on the underside of the hood, remove

screw holding sensor to hood panel.

(4) Disconnect the sensor electrical connector and

remove sensor from vehicle.

INSTALLATION

(1) Connect the sensor electrical connector.

(2) Working on the underside of the hood, install

screw holding sensor to hood panel.

(3) Connect the battery negative cable.

(4) Close the hood.

UNIVERSAL TRANSMITTER

DESCRIPTION

Some DR models are equipped with a universal

transmitter transceiver. The universal transmitter is

integral to the Electronic Vehicle Information Center

(EVIC) and the Compass Mini-Trip Computer

(CMTC), which is located in the overhead console.

The only visible component of the universal transmit-

ter are the three transmitter push buttons centered

between the modules push buttons located just rear-

ward of the display screen in the overhead console.

The three universal transmitter push buttons are

identified with one, two or three light indicators so

that they be easily identified.

Each of the three universal transmitter push but-

tons control an independent radio transmitter chan-

nel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-

tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

DRMESSAGE SYSTEMS 8M - 11

AMBIENT TEMP SENSOR (Continued)

Page 575 of 2895

tion. The universal transmitter is capable of operat-

ing systems using either rolling code or non-rolling

code technology.

The electronics module displays messages and a

small house-shaped icon with one, two or three dots

corresponding to the three transmitter buttons to

indicate the status of the universal transmitter. The

EVIC messages are:

²Clearing Channels- Indicates that all of the

transmitter codes stored in the universal transmitter

have been successfully cleared.

²Channel ªXº Training- Indicates that the uni-

versal transmitter is in its transmitter learning

mode.

²Channel ªXº Trained- Indicates that the uni-

versal transmitter has successfully acquired a new

transmitter code.

²Channel ªXº Transmitting- Indicates that a

trained universal transmitter button has been

depressed and that the universal transmitter is

transmitting.

The universal transmitter cannot be repaired, and

is available for service only as a unit with the EVIC

or CMTC modules. If any part of the universal trans-

mitter is faulty or damaged, the complete EVIC or

CMTC module must be replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

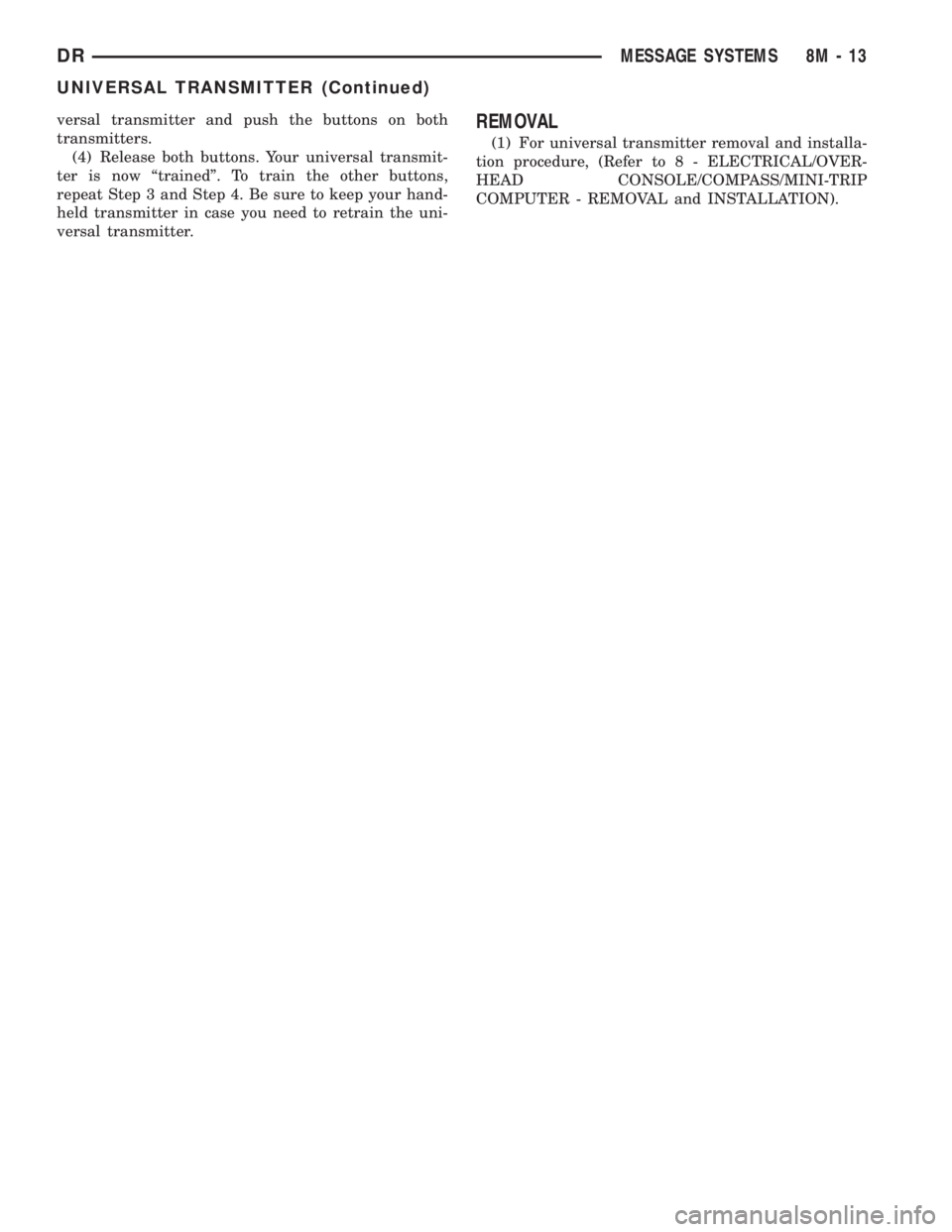

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is oper-

ating normally, see the owner's manual in the vehicle

glove box for instructions on training the Transmit-

ter. Retrain the Transmitter with a known good

transmitter as instructed in the owner's manual and

test the Transmitter operation again. If the unit is

still inoperative, test the universal transmitter with

Radio Frequency Detector special tool. If both the

Transmitter and the EVIC module are inoperative,

refer toElectronic Vehicle Information Center

Diagnosis and Testingin this group for further

diagnosis. For complete circuit diagrams, refer to

Wiring Diagrams. (Fig. 8) as described below:

(1) Turn the Radio Frequency (RF) Detector ON. A

ªchirpº will sound and the green power LED will

light. If the green LED does not light, replace the

battery.(2) Hold the RF detector within one inch of the

TRAINED universal transmitter and press any of the

transmitters buttons.

(3) The red signal detection LEDs will light and

the tool will beep if a radio signal is detected. Repeat

this test three times.

STANDARD PROCEDURE

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down the two outside buttons until the display

confirms the operation.

NOTE: Individual channels cannot be erased. Eras-

ing the transmitter codes will erase ALL pro-

grammed codes.

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the codes by pressing the two outside

buttons. Release the buttons when the display con-

firms the operation (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

Fig. 8 RADIO FREQUENCY DETECTOR

1 - SIGNAL DETECTION LED'S

2 - POWER LED

3 - ON/OFF SWITCH

4 - 9V BATTERY

8M - 12 MESSAGE SYSTEMSDR

UNIVERSAL TRANSMITTER (Continued)

Page 576 of 2895

versal transmitter and push the buttons on both

transmitters.

(4) Release both buttons. Your universal transmit-

ter is now ªtrainedº. To train the other buttons,

repeat Step 3 and Step 4. Be sure to keep your hand-

held transmitter in case you need to retrain the uni-

versal transmitter.REMOVAL

(1) For universal transmitter removal and installa-

tion procedure, (Refer to 8 - ELECTRICAL/OVER-

HEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - REMOVAL and INSTALLATION).

DRMESSAGE SYSTEMS 8M - 13

UNIVERSAL TRANSMITTER (Continued)

Page 582 of 2895

DOOR LOCK MOTOR

DESCRIPTION

The lock mechanisms are actuated by a reversible

electric motor mounted within each door. The power

lock motors are integral to the door latch units.

The power lock motors cannot be adjusted or

repaired and, if faulty or damaged, the door latch

unit must be replaced.

OPERATION

The door lock motors are controlled by the instru-

ment cluster. A positive and negative battery connec-

tion to the two motor terminals will cause the motor

to move in one direction. Reversing the current will

cause the motor to move in the opposite direction.

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual. The DRBIIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the power lock motors are being sent the proper

hard wired outputs by the door modules for them to

perform their power lock system functions.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DRIVER DOOR MODULE

DESCRIPTION

A Driver Door Module (DDM) is used on all models

equipped with power locks, power windows, and

power mirrors. The DDM houses the following

switches:

²Power Lock Switch- The DDM includes a

two-way, momentary, resistor multiplexed switch to

control the power lock system.

²Power Mirror Selector Switch- A three-posi-

tion rocker switch in the DDM selects the right or

left power mirror for adjustment, or turns the power

mirror system Off.

²Power Mirror Adjustment Switches- Four

momentary, arrowhead shaped, directional switches

allow the driver to adjust the selected power mirror

in the Up, Down, Right, or Left directions.²Power Window Lockout Switch- A two-way,

latching, push-button switch in the DDM allows the

vehicle operator to lock out the power window

switches on each passenger door so that the passen-

ger door power windows may be operated only from

the master switches in the DDM.

²Power Window Switches- The DDM houses a

two-way, momentary power window switch for the

driver side front door. This switch also has a second

detent in the Down direction and internal circuitry to

provide an Auto-Down feature for the driver side

front door power window. In addition to the power

window switch for its own door, the DDM houses

individual master switches for each passenger door

power window.

The DDM also incorporates several green Light-

Emitting Diodes (LEDs) that illuminate the power

lock and power window switch paddles, and the

power mirror switch directional buttons to improve

switch visibility in dark ambient lighting conditions.

The DDM cannot be adjusted or repaired and, if

faulty or damaged, the entire DDM unit must be

replaced.

OPERATION

The Driver Door Module (DDM) combines a power

lock switch, a driver power window switch with an

Auto-down feature, master switches for each passen-

ger door power window, a power window lockout

switch, a power mirror selector switch, and four

power mirror adjustment switches in a single unit.

The switches in the DDM can be diagnosed using

conventional diagnostic tools and methods.

Power Lock Switch

The DDM power lock switch circuitry is connected

in series between ground and the driver door switch

mux input of the instrument cluster. Each power lock

switch position (Lock, Unlock, and Neutral) provides

a different resistance value to the instrument cluster

input, which allows the instrument cluster to sense

the switch position. Based upon the power lock

switch input, the instrument cluster controls the bat-

tery and ground feed outputs to the individual power

lock motors to lock or unlock the door latches. The

Light-Emitting Diode (LED) in the DDM power lock

switch is connected to battery current through the

power window circuit breaker in the Integrated

Power Module (IPM) on a fused ignition switch out-

put (run-acc) circuit so that the switch will be illumi-

nated whenever the ignition switch is in the On or

Accessory positions.

Power Window Switches

The DDM power window switch circuitry is con-

nected to battery current through a circuit breaker in

DRPOWER LOCKS 8N - 5

Page 586 of 2895

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE TRANSMITTER

BATTERIES

NOTE: Do not disturb the metal terminal near the

batteries. Avoid touching the new batteries. Skin

oils may cause battery deterioration. If batteries are

touched, clean with rubbing alcohol.

The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:

(1) Using a thin coin, gently pry at the notch in

the center seam of the RKE transmitter case halves

near the key ring until the two halves unsnap. Be

careful not to damage the rubber gasket when sepa-

rating the case halves.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.

(4) Replace the two batteries with new 3V lithium

2016 cell. Install the batteries with the positive ter-

minal up. Reference the ª+ SIDE UPº on the inside of

the bottom half of the transmitter case.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together until they snap back into place. Test trans-

mitter operation.

STANDARD PROCEDURE - RKE TRANSMITTER

CUSTOMER PREFERENCES

AUTOMATIC (ROLLING) LOCKS

The rolling locks feature can be toggled ON/OFF

by using the DRB IIItonly.

HORN CHIRP DISABLING / ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter that is already programmed to the vehicle.

To DISABLE (cancel) the horn chirp feature:

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime).

(3) Turn the ignition to the ON position.

(4) Press and hold the LOCK button for 4 seconds.

Within 6 seconds with the LOCK button still

depressed, press the UNLOCK button. When a single

chime is heard, release both buttons.

(5) Turn the ignition OFF.

(6) Turn the ignition ON or wait 60 seconds.(7) Test the horn chirp feature by pressing the

LOCK button.

If a chime is not heard, program mode was can-

celed before the feature could be disabled. If neces-

sary, repeat the procedure.

To ENABLE the horn chirp feature, repeat the

above procedure.

OPTICAL CHIRP (FLASH) DISABLING / ENABLING

The optical chirp can be toggled using a DRB IIIt

or by using the Remote Keyless Entry (RKE) trans-

mitter that is already programmed to the vehicle.

To DISABLE (cancel) the optical chirp feature:

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime).

(3) Turn the ignition to the ON position.

(4) Press and hold the LOCK button for 4 seconds.

Within 6 seconds with the LOCK button still

depressed, press the PANIC button. When a single

chime is heard, release both buttons.

(5) Turn the ignition OFF.

(6) Turn the ignition ON or wait 60 seconds.

(7) Test the optical chirp feature by pressing the

LOCK button.

If a chime is not heard, program mode was can-

celed before the feature could be disabled. If neces-

sary, repeat the procedure.

To ENABLE the optical chirp feature, repeat the

above procedure.

UNLOCK SEQUENCE

The unlock sequence can be toggled using a DRB

IIItor by using the Remote Keyless Entry (RKE)

transmitter that is already programmed to the vehi-

cle.

To toggle between Driver door first and Unlock all

doors function:

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime).

(3) Turn the ignition to the ON position.

(4) Press and hold the UNLOCK button for 4 sec-

onds. Within 6 seconds with the UNLOCK button

still depressed, press the LOCK button. When a sin-

gle chime is heard, release both buttons.

(5) Turn the ignition OFF.

(6) Turn the ignition ON or wait 60 seconds.

If a chime is not heard, program mode was can-

celed before the feature could be disabled. If neces-

sary, repeat the procedure.

To toggle this feature, repeat the above procedure.

DRPOWER LOCKS 8N - 9

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 587 of 2895

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

New Remote Keyless Entry (RKE) transmitters can

be programed using the DRB IIItscan tool and the

proper Diagnostic Procedures manual. The DRB IIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.

The following procedure can be used as long as one

programmed transmitter is available:

NOTE: When entering program mode using that

programmed fob, ALL currently programmed fobs

will be erased and they will have to be repro-

grammed for the vehicle. If program mode is

entered and no action is performed, the previously

programmed fobs will continue to function.

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime). Turn the ignition to the RUN position.

(3) Press and hold the UNLOCK button on a pro-

grammed transmitter for 4 to 10 seconds. Within the

4 to 10 seconds with the UNLOCK button still

depressed, press the PANIC button for one second.

When a single chime is heard, release both button-

s.The chime indicates the system is in program

mode.(4) Press and release both the LOCK and

UNLOCK buttons simultaneously on a fob to be pro-

grammed. A single chime will be heard, this indicates

the fob has been recognized.

(5) Press and release any button on the same fob.

A single chime will be heard, this indicates the fob

has been programmed.

(6) Repeat steps 4 and 5 for up to a total of 4 fobs.

(7) Turn the ignition OFF.

(8) Turn the ignition ON or wait 60 seconds.

The vehicle will remain in program mode for up to

60 seconds from when the original chime (step 3) was

heard. After 60 seconds, all programmed transmitters

will function normally.

SPECIFICATIONS - REMOTE KEYLESS ENTRY

TRANSMITTER

RANGE

Normal operation range is up to a distance of 3 to

7 meters (10 to 23 ft.) of the vehicle. Range may be

better or worse depending on the environment

around the vehicle.

8N - 10 POWER LOCKSDR

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)