engine oil capacity DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 18 of 2895

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

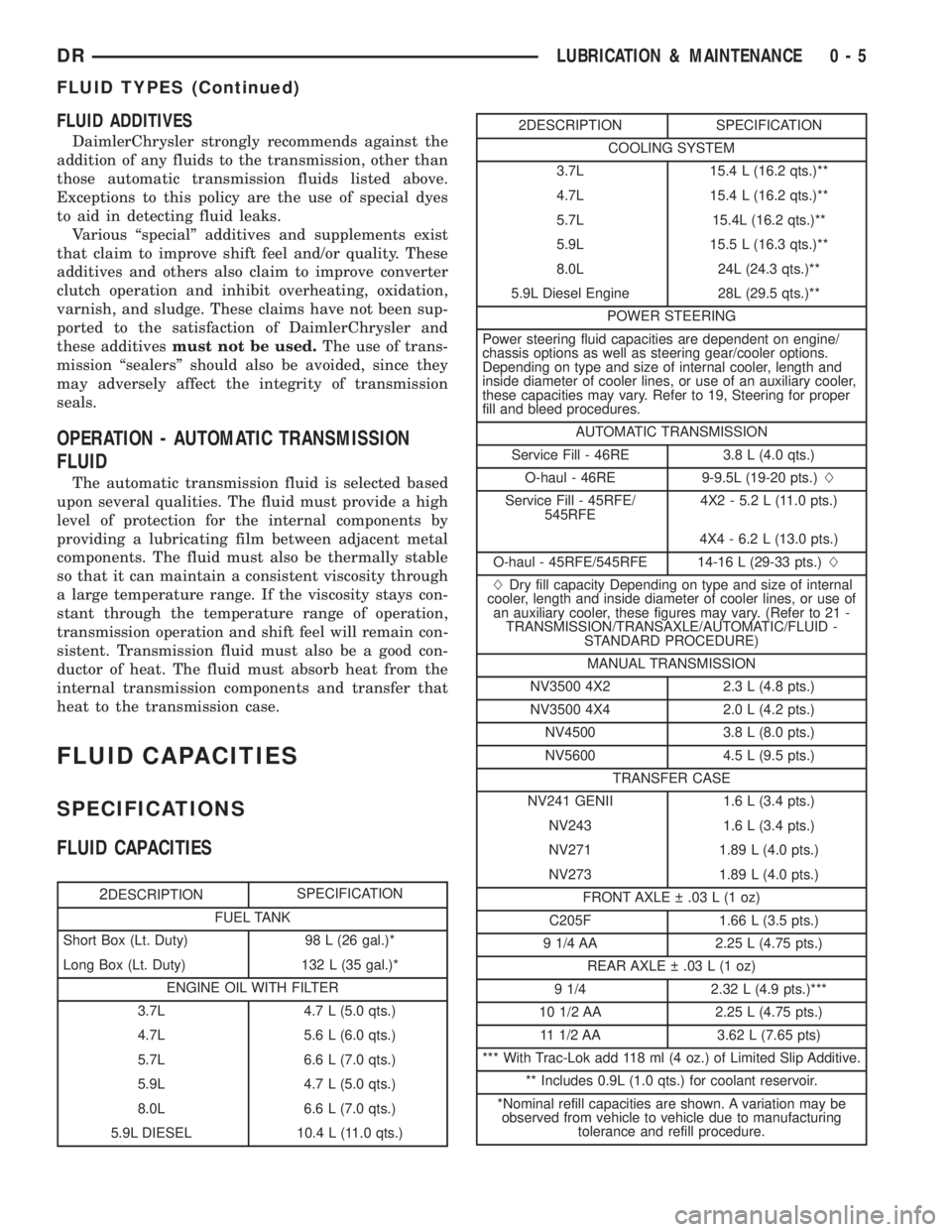

2DESCRIPTIONSPECIFICATION

FUEL TANK

Short Box (Lt. Duty) 98 L (26 gal.)*

Long Box (Lt. Duty) 132 L (35 gal.)*

ENGINE OIL WITH FILTER

3.7L 4.7 L (5.0 qts.)

4.7L 5.6 L (6.0 qts.)

5.7L 6.6 L (7.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

2DESCRIPTION SPECIFICATION

COOLING SYSTEM

3.7L 15.4 L (16.2 qts.)**

4.7L 15.4 L (16.2 qts.)**

5.7L 15.4L (16.2 qts.)**

5.9L 15.5 L (16.3 qts.)**

8.0L 24L (24.3 qts.)**

5.9L Diesel Engine 28L (29.5 qts.)**

POWER STEERING

Power steering fluid capacities are dependent on engine/

chassis options as well as steering gear/cooler options.

Depending on type and size of internal cooler, length and

inside diameter of cooler lines, or use of an auxiliary cooler,

these capacities may vary. Refer to 19, Steering for proper

fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5L (19-20 pts.)L

Service Fill - 45RFE/

545RFE4X2 - 5.2 L (11.0 pts.)

4X4 - 6.2 L (13.0 pts.)

O-haul - 45RFE/545RFE 14-16 L (29-33 pts.)L

LDry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or use of

an auxiliary cooler, these figures may vary. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC/FLUID -

STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 4X2 2.3 L (4.8 pts.)

NV3500 4X4 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV241 GENII 1.6 L (3.4 pts.)

NV243 1.6 L (3.4 pts.)

NV271 1.89 L (4.0 pts.)

NV273 1.89 L (4.0 pts.)

FRONT AXLE .03 L (1 oz)

C205F 1.66 L (3.5 pts.)

9 1/4 AA 2.25 L (4.75 pts.)

REAR AXLE .03 L (1 oz)

9 1/4 2.32 L (4.9 pts.)***

10 1/2 AA 2.25 L (4.75 pts.)

11 1/2 AA 3.62 L (7.65 pts)

*** With Trac-Lok add 118 ml (4 oz.) of Limited Slip Additive.

** Includes 0.9L (1.0 qts.) for coolant reservoir.

*Nominal refill capacities are shown. A variation may be

observed from vehicle to vehicle due to manufacturing

tolerance and refill procedure.

DRLUBRICATION & MAINTENANCE 0 - 5

FLUID TYPES (Continued)

Page 347 of 2895

(6) Remove the power steering cooler mounting

bolts and position the power steering cooler out of

the way.

(7) Disconnect the transmission cooler lines at the

transmission. The transmission cooler will remain on

the radiator and can be removed as an assembly.

(8) Remove the lower shroud assembly and the

electronic viscous fan wiring from the upper shroud

assembly.

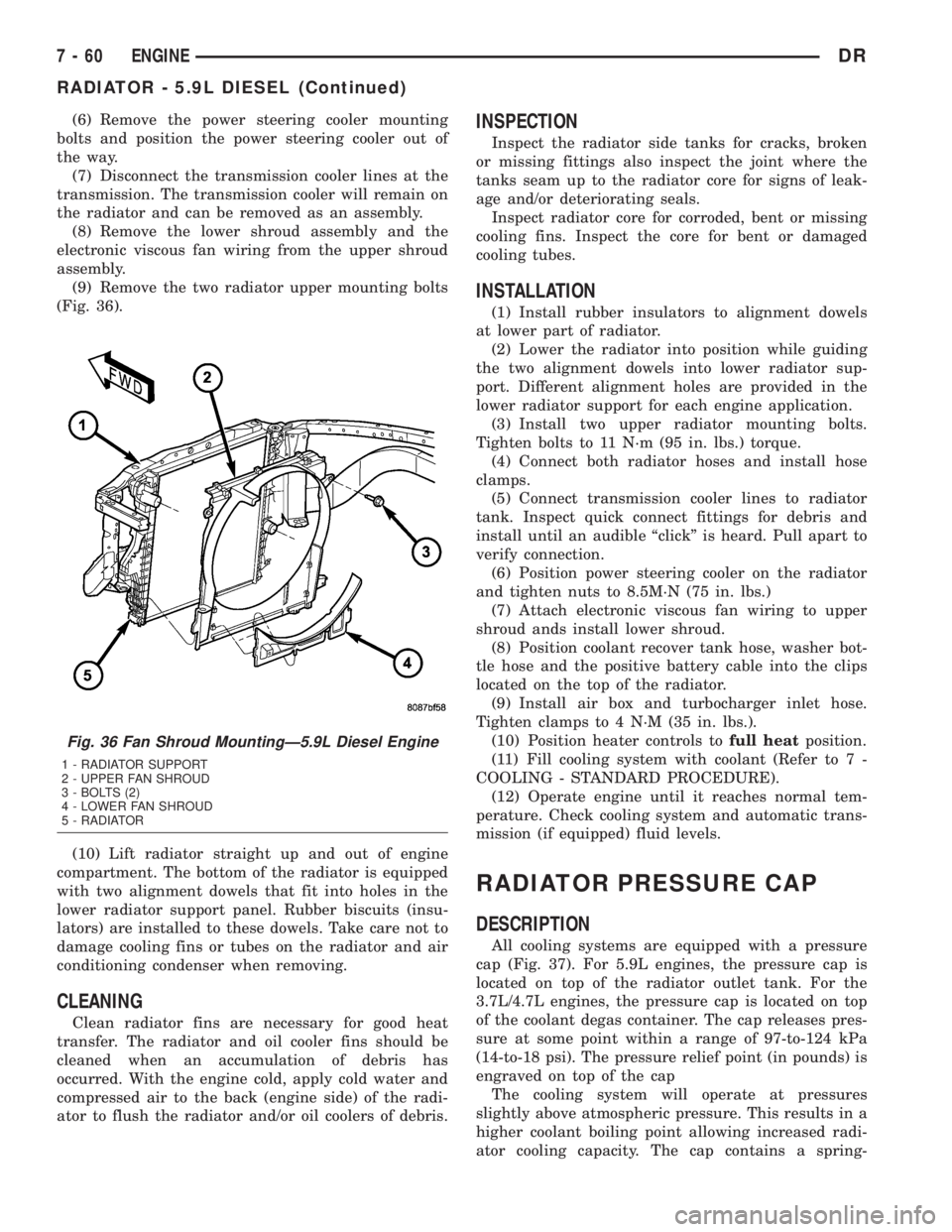

(9) Remove the two radiator upper mounting bolts

(Fig. 36).

(10) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel. Rubber biscuits (insu-

lators) are installed to these dowels. Take care not to

damage cooling fins or tubes on the radiator and air

conditioning condenser when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Install rubber insulators to alignment dowels

at lower part of radiator.

(2) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(3) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(4) Connect both radiator hoses and install hose

clamps.

(5) Connect transmission cooler lines to radiator

tank. Inspect quick connect fittings for debris and

install until an audible ªclickº is heard. Pull apart to

verify connection.

(6) Position power steering cooler on the radiator

and tighten nuts to 8.5M´N (75 in. lbs.)

(7) Attach electronic viscous fan wiring to upper

shroud ands install lower shroud.

(8) Position coolant recover tank hose, washer bot-

tle hose and the positive battery cable into the clips

located on the top of the radiator.

(9) Install air box and turbocharger inlet hose.

Tighten clamps to 4 N´M (35 in. lbs.).

(10) Position heater controls tofull heatposition.

(11) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(12) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

All cooling systems are equipped with a pressure

cap (Fig. 37). For 5.9L engines, the pressure cap is

located on top of the radiator outlet tank. For the

3.7L/4.7L engines, the pressure cap is located on top

of the coolant degas container. The cap releases pres-

sure at some point within a range of 97-to-124 kPa

(14-to-18 psi). The pressure relief point (in pounds) is

engraved on top of the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

Fig. 36 Fan Shroud MountingÐ5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - UPPER FAN SHROUD

3 - BOLTS (2)

4 - LOWER FAN SHROUD

5 - RADIATOR

7 - 60 ENGINEDR

RADIATOR - 5.9L DIESEL (Continued)

Page 413 of 2895

MICRO 420 BATTERY TESTER

The Micro 420 automotive battery tester is

designed to help the dealership technician diagnose

the cause of a defective battery. Follow the instruc-

tion manual supplied with the tester to properly

diagnose a battery. If the instruction manual is not

available, refer to the standard procedure in this sec-

tion, which includes the directions for using the

Micro 420 battery tester.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

A battery that will not accept a charge is faulty,

and must be replaced. Further testing is not

required. A fully-charged battery must be load tested

to determine its cranking capacity. A battery that is

fully-charged, but does not pass the load test, is

faulty and must be replaced. Always test battery

using the Micro 420 battery tester before attempting

to replace a battery under the manufactures war-

ranty provisions.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging proce-

dures.

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging can be performed fast or slow, in

terms of time.Slowbattery charging is the best

means of restoring a battery to full potential. Fast

battery charging should only be performed whenabsolutely necessary due to time restraints. A battery

is fully-charged when:

²All of the battery cells are gassing freely during

battery charging.

²A green color is visible in the sight glass of the

battery built-in test indicator.

²Three hydrometer tests, taken at one-hour inter-

vals, indicate no increase in the temperature-cor-

rected specific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.65 volts

or above.

WARNING: NEVER EXCEED TWENTY AMPERES

WHEN CHARGING A COLD (-1É C [30É F] OR

LOWER) BATTERY. THE BATTERY MAY ARC INTER-

NALLY AND EXPLODE. PERSONAL INJURY AND/OR

VEHICLE DAMAGE MAY RESULT.

CAUTION: Always disconnect and isolate the bat-

tery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system compo-

nents may result.

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Elec-

trolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

CAUTION: The battery should not be hot to the

touch. If the battery feels hot to the touch, turn off

the charger and let the battery cool before continu-

ing the charging operation. Damage to the battery

may result.

NOTE: Models equipped with the diesel engine are

equipped with two 12-volt batteries, connected in

parallel (positive-to-positive and negative-to-nega-

tive). In order to ensure proper charging of each

battery, these batteries MUST be disconnected from

each other, as well as from the vehicle electrical

system while being charged.

Some battery chargers are equipped with polarity-

sensing circuitry. This circuitry protects the battery

charger and the battery from being damaged if they

are improperly connected. If the battery state-of-

charge is too low for the polarity-sensing circuitry to

detect, the battery charger will not operate. This

makes it appear that the battery will not accept

charging current. See the instructions provided by

8F - 8 BATTERY SYSTEMDR

BATTERY (Continued)

Page 2047 of 2895

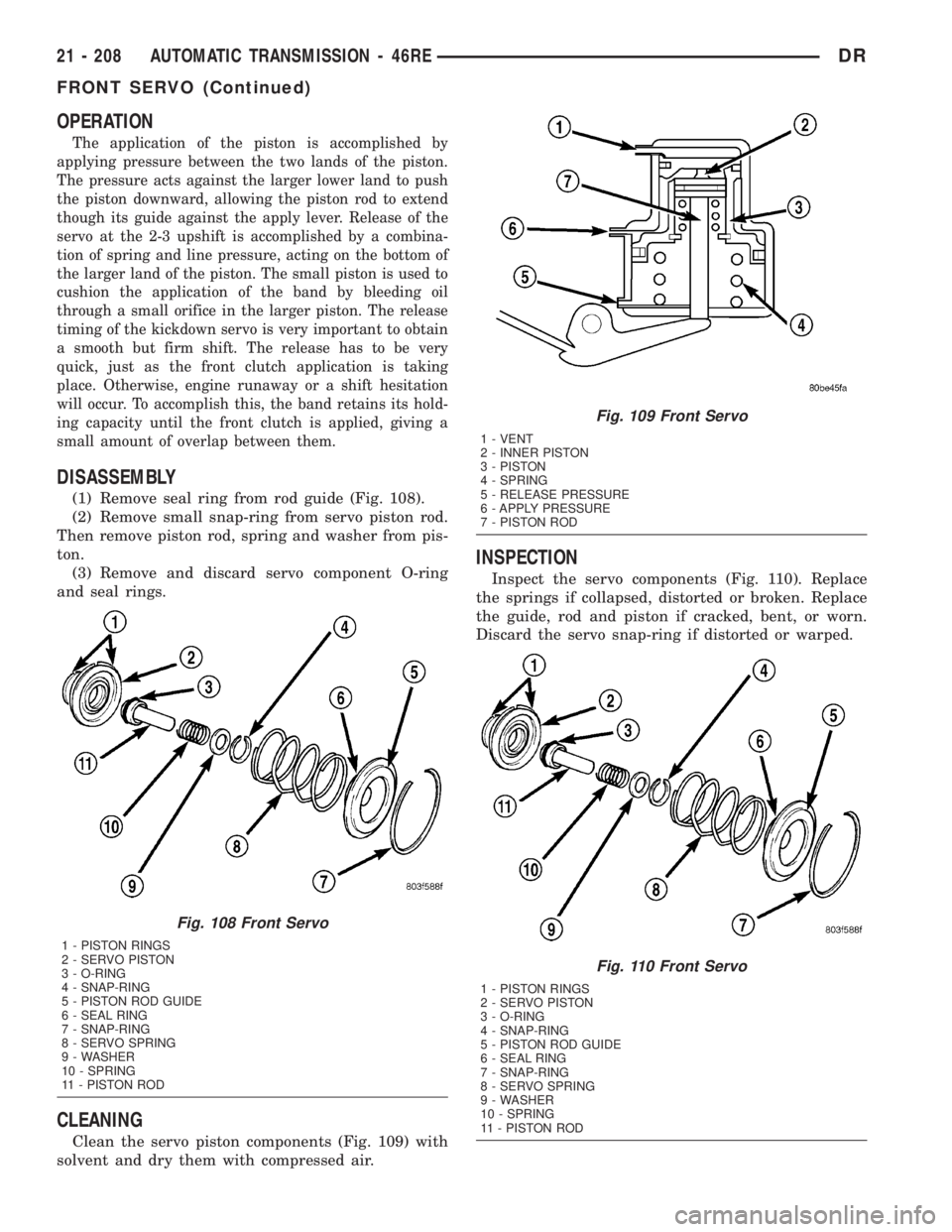

OPERATION

The application of the piston is accomplished by

applying pressure between the two lands of the piston.

The pressure acts against the larger lower land to push

the piston downward, allowing the piston rod to extend

though its guide against the apply lever. Release of the

servo at the 2-3 upshift is accomplished by a combina-

tion of spring and line pressure, acting on the bottom of

the larger land of the piston. The small piston is used to

cushion the application of the band by bleeding oil

through a small orifice in the larger piston. The release

timing of the kickdown servo is very important to obtain

a smooth but firm shift. The release has to be very

quick, just as the front clutch application is taking

place. Otherwise, engine runaway or a shift hesitation

will occur. To accomplish this, the band retains its hold-

ing capacity until the front clutch is applied, giving a

small amount of overlap between them.

DISASSEMBLY

(1) Remove seal ring from rod guide (Fig. 108).

(2) Remove small snap-ring from servo piston rod.

Then remove piston rod, spring and washer from pis-

ton.

(3) Remove and discard servo component O-ring

and seal rings.

CLEANING

Clean the servo piston components (Fig. 109) with

solvent and dry them with compressed air.

INSPECTION

Inspect the servo components (Fig. 110). Replace

the springs if collapsed, distorted or broken. Replace

the guide, rod and piston if cracked, bent, or worn.

Discard the servo snap-ring if distorted or warped.

Fig. 108 Front Servo

1 - PISTON RINGS

2 - SERVO PISTON

3 - O-RING

4 - SNAP-RING

5 - PISTON ROD GUIDE

6 - SEAL RING

7 - SNAP-RING

8 - SERVO SPRING

9 - WASHER

10 - SPRING

11 - PISTON ROD

Fig. 109 Front Servo

1 - VENT

2 - INNER PISTON

3 - PISTON

4 - SPRING

5 - RELEASE PRESSURE

6 - APPLY PRESSURE

7 - PISTON ROD

Fig. 110 Front Servo

1 - PISTON RINGS

2 - SERVO PISTON

3 - O-RING

4 - SNAP-RING

5 - PISTON ROD GUIDE

6 - SEAL RING

7 - SNAP-RING

8 - SERVO SPRING

9 - WASHER

10 - SPRING

11 - PISTON ROD

21 - 208 AUTOMATIC TRANSMISSION - 46REDR

FRONT SERVO (Continued)

Page 2226 of 2895

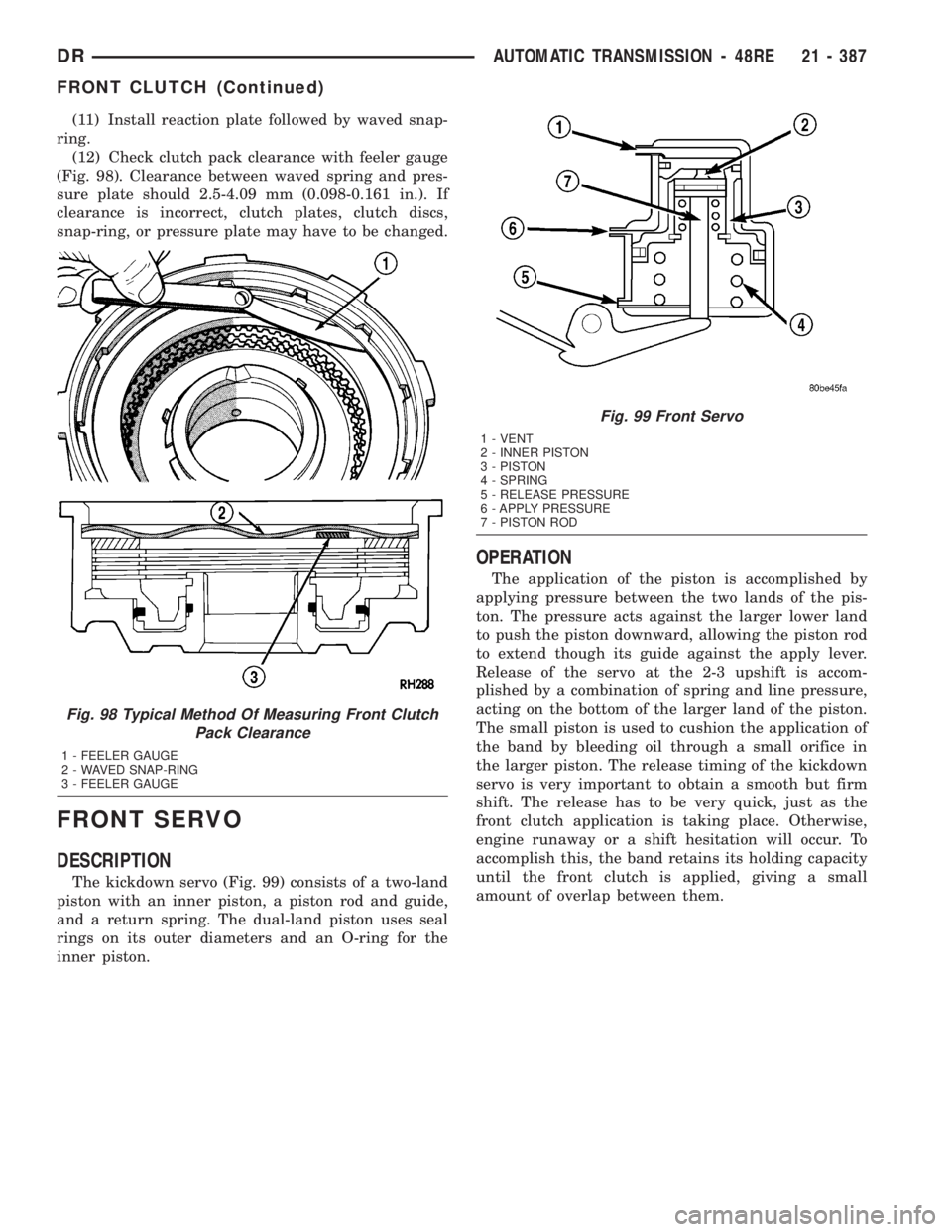

(11) Install reaction plate followed by waved snap-

ring.

(12) Check clutch pack clearance with feeler gauge

(Fig. 98). Clearance between waved spring and pres-

sure plate should 2.5-4.09 mm (0.098-0.161 in.). If

clearance is incorrect, clutch plates, clutch discs,

snap-ring, or pressure plate may have to be changed.

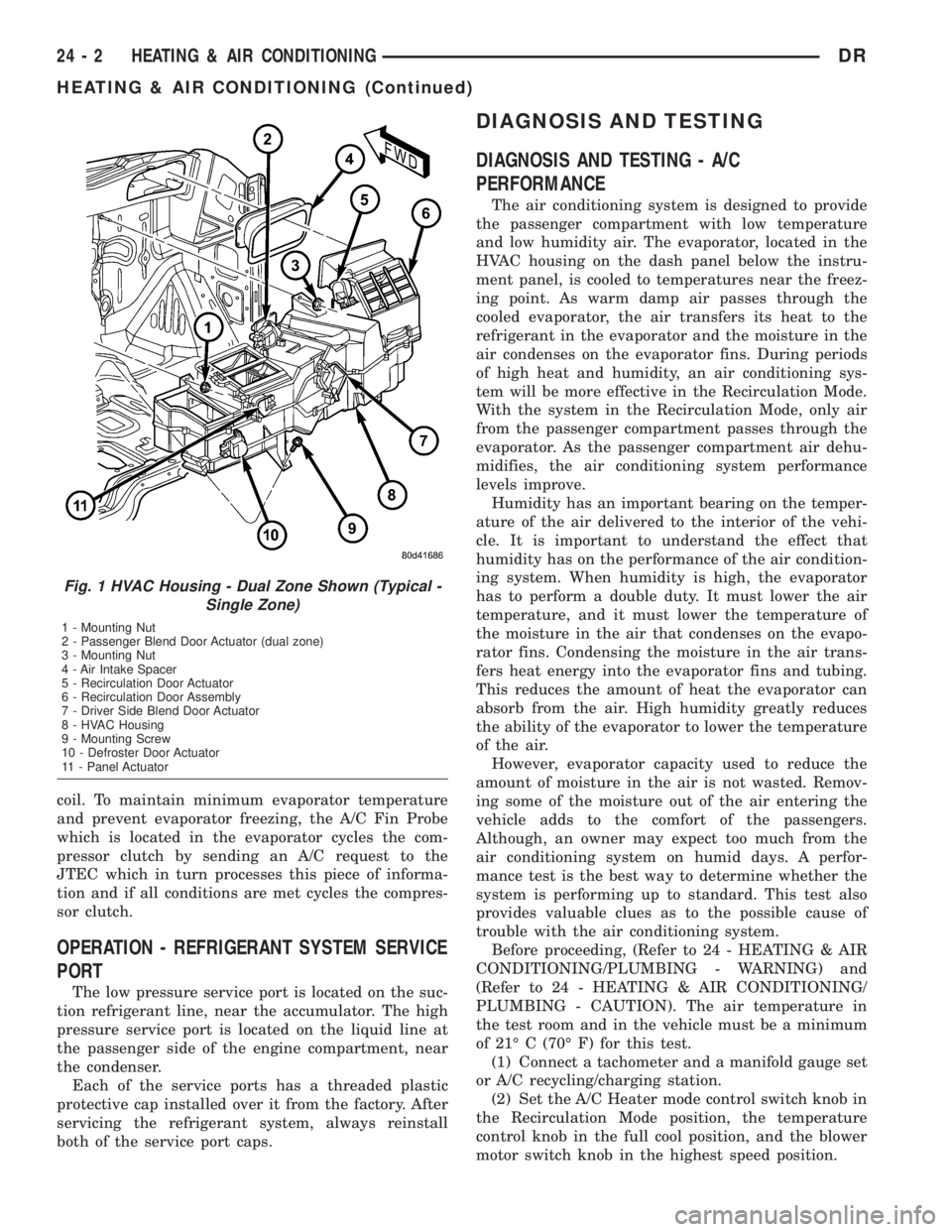

FRONT SERVO

DESCRIPTION

The kickdown servo (Fig. 99) consists of a two-land

piston with an inner piston, a piston rod and guide,

and a return spring. The dual-land piston uses seal

rings on its outer diameters and an O-ring for the

inner piston.

OPERATION

The application of the piston is accomplished by

applying pressure between the two lands of the pis-

ton. The pressure acts against the larger lower land

to push the piston downward, allowing the piston rod

to extend though its guide against the apply lever.

Release of the servo at the 2-3 upshift is accom-

plished by a combination of spring and line pressure,

acting on the bottom of the larger land of the piston.

The small piston is used to cushion the application of

the band by bleeding oil through a small orifice in

the larger piston. The release timing of the kickdown

servo is very important to obtain a smooth but firm

shift. The release has to be very quick, just as the

front clutch application is taking place. Otherwise,

engine runaway or a shift hesitation will occur. To

accomplish this, the band retains its holding capacity

until the front clutch is applied, giving a small

amount of overlap between them.

Fig. 98 Typical Method Of Measuring Front Clutch

Pack Clearance

1 - FEELER GAUGE

2 - WAVED SNAP-RING

3 - FEELER GAUGE

Fig. 99 Front Servo

1 - VENT

2 - INNER PISTON

3 - PISTON

4 - SPRING

5 - RELEASE PRESSURE

6 - APPLY PRESSURE

7 - PISTON ROD

DRAUTOMATIC TRANSMISSION - 48RE 21 - 387

FRONT CLUTCH (Continued)

Page 2777 of 2895

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, the A/C Fin Probe

which is located in the evaporator cycles the com-

pressor clutch by sending an A/C request to the

JTEC which in turn processes this piece of informa-

tion and if all conditions are met cycles the compres-

sor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The low pressure service port is located on the suc-

tion refrigerant line, near the accumulator. The high

pressure service port is located on the liquid line at

the passenger side of the engine compartment, near

the condenser.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Remov-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from the

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C Heater mode control switch knob in

the Recirculation Mode position, the temperature

control knob in the full cool position, and the blower

motor switch knob in the highest speed position.

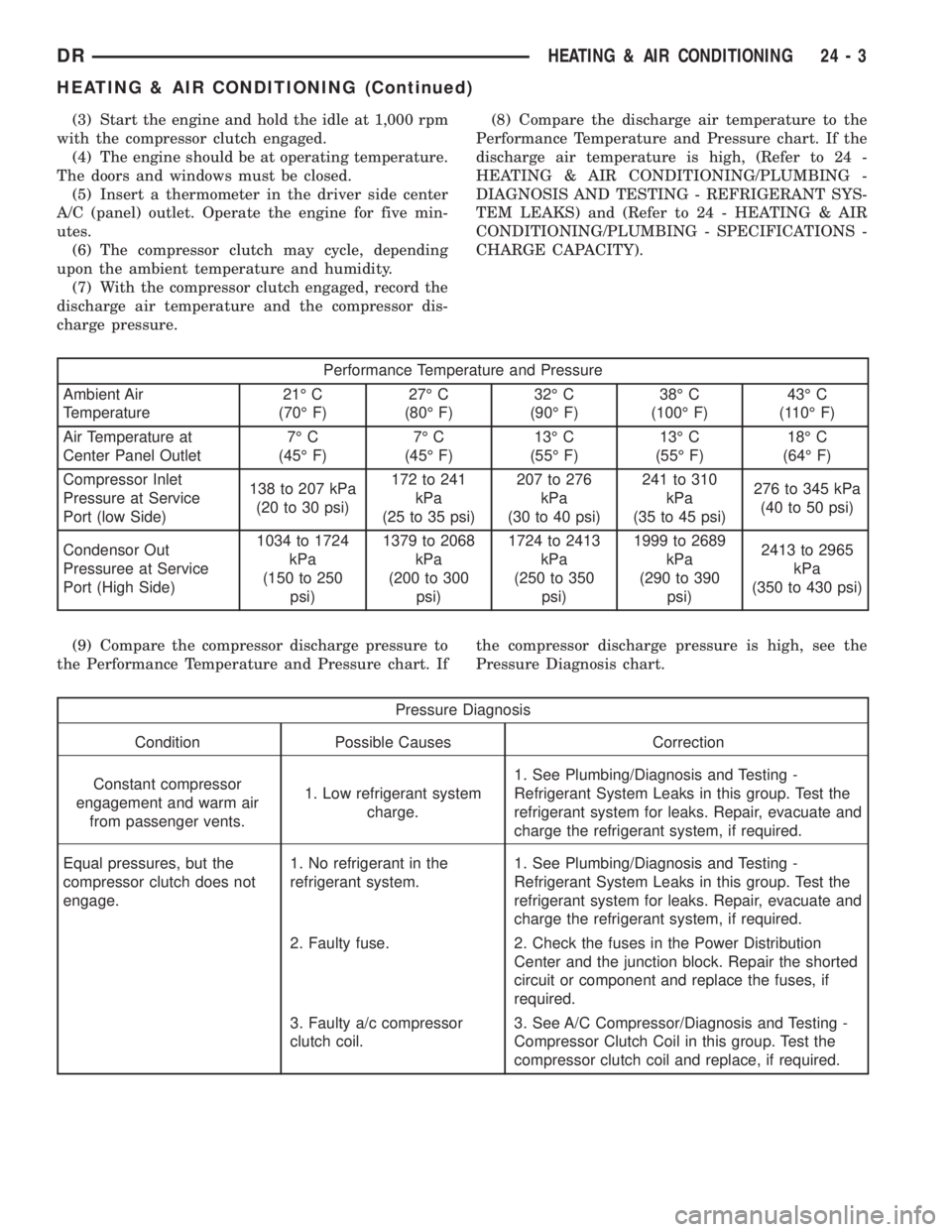

Fig. 1 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2778 of 2895

(3) Start the engine and hold the idle at 1,000 rpm

with the compressor clutch engaged.

(4) The engine should be at operating temperature.

The doors and windows must be closed.

(5) Insert a thermometer in the driver side center

A/C (panel) outlet. Operate the engine for five min-

utes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.

(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.(8) Compare the discharge air temperature to the

Performance Temperature and Pressure chart. If the

discharge air temperature is high, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM LEAKS) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - SPECIFICATIONS -

CHARGE CAPACITY).

Performance Temperature and Pressure

Ambient Air

Temperature21É C

(70É F)27É C

(80É F)32É C

(90É F)38É C

(100É F)43É C

(110É F)

Air Temperature at

Center Panel Outlet7É C

(45É F)7É C

(45É F)13É C

(55É F)13É C

(55É F)18É C

(64É F)

Compressor Inlet

Pressure at Service

Port (low Side)138 to 207 kPa

(20 to 30 psi)172 to 241

kPa

(25 to 35 psi)207 to 276

kPa

(30 to 40 psi)241 to 310

kPa

(35 to 45 psi)276 to 345 kPa

(40 to 50 psi)

Condensor Out

Pressuree at Service

Port (High Side)1034 to 1724

kPa

(150 to 250

psi)1379 to 2068

kPa

(200 to 300

psi)1724 to 2413

kPa

(250 to 350

psi)1999 to 2689

kPa

(290 to 390

psi)2413 to 2965

kPa

(350 to 430 psi)

(9) Compare the compressor discharge pressure to

the Performance Temperature and Pressure chart. Ifthe compressor discharge pressure is high, see the

Pressure Diagnosis chart.

Pressure Diagnosis

Condition Possible Causes Correction

Constant compressor

engagement and warm air

from passenger vents.1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Faulty fuse. 2. Check the fuses in the Power Distribution

Center and the junction block. Repair the shorted

circuit or component and replace the fuses, if

required.

3. Faulty a/c compressor

clutch coil.3. See A/C Compressor/Diagnosis and Testing -

Compressor Clutch Coil in this group. Test the

compressor clutch coil and replace, if required.

DRHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)

Page 2788 of 2895

NOTE: The air gap is determined by the spacer

shims. When installing an original, or a new clutch

assembly, try the original shims first. When install-

ing a new clutch onto a compressor that previously

did not have a clutch, use a 1.0, 0.50, and 0.13 mil-

limeter (0.040, 0.020, and 0.005 inch) shims from the

new clutch hardware package that is provided with

the new clutch.

(9) To complete the procedure, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

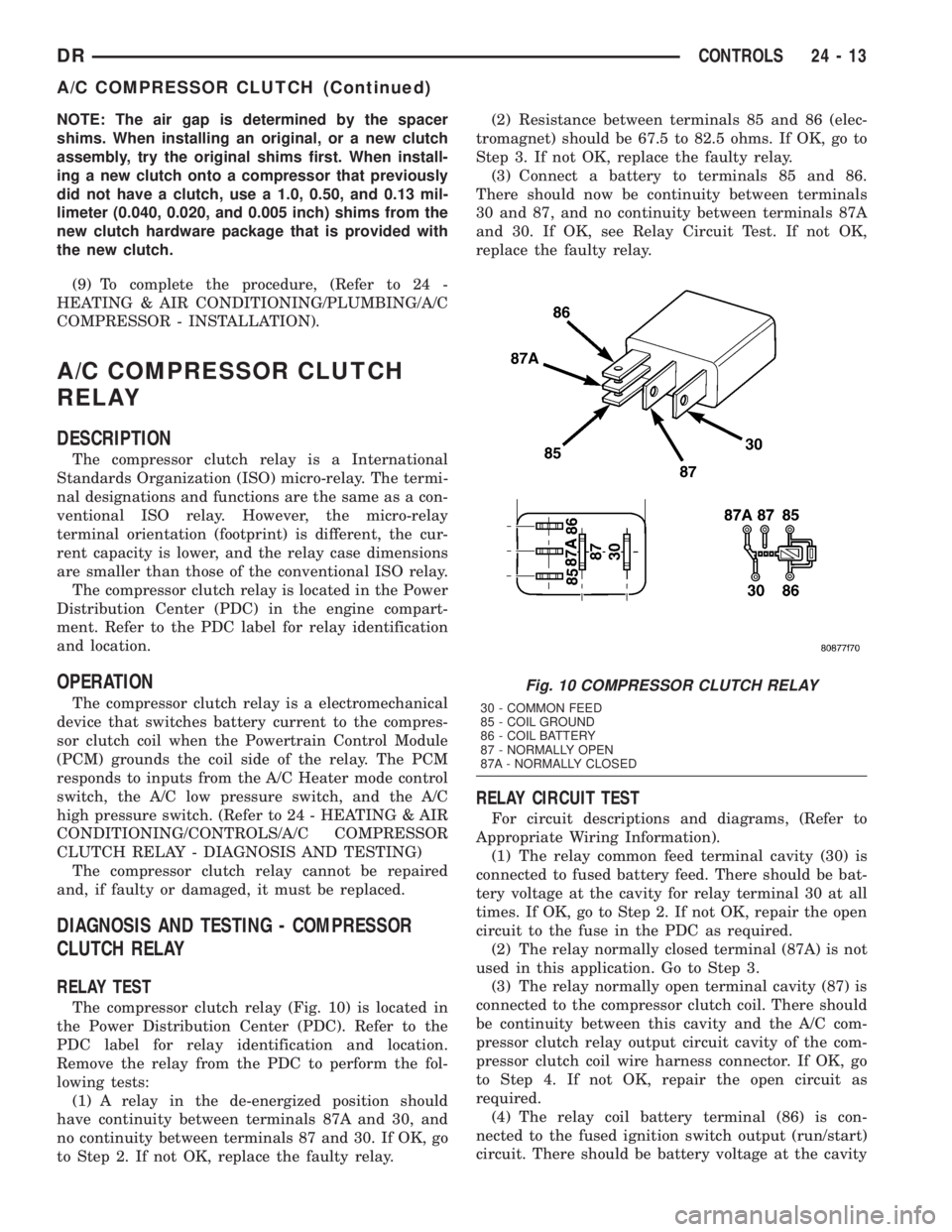

A/C COMPRESSOR CLUTCH

RELAY

DESCRIPTION

The compressor clutch relay is a International

Standards Organization (ISO) micro-relay. The termi-

nal designations and functions are the same as a con-

ventional ISO relay. However, the micro-relay

terminal orientation (footprint) is different, the cur-

rent capacity is lower, and the relay case dimensions

are smaller than those of the conventional ISO relay.

The compressor clutch relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment. Refer to the PDC label for relay identification

and location.

OPERATION

The compressor clutch relay is a electromechanical

device that switches battery current to the compres-

sor clutch coil when the Powertrain Control Module

(PCM) grounds the coil side of the relay. The PCM

responds to inputs from the A/C Heater mode control

switch, the A/C low pressure switch, and the A/C

high pressure switch. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH RELAY - DIAGNOSIS AND TESTING)

The compressor clutch relay cannot be repaired

and, if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY

RELAY TEST

The compressor clutch relay (Fig. 10) is located in

the Power Distribution Center (PDC). Refer to the

PDC label for relay identification and location.

Remove the relay from the PDC to perform the fol-

lowing tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 67.5 to 82.5 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)

circuit. There should be battery voltage at the cavity

Fig. 10 COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRCONTROLS 24 - 13

A/C COMPRESSOR CLUTCH (Continued)

Page 2811 of 2895

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION

The compressor is driven by the engine through an

electric clutch, drive rotor and belt arrangement. The

compressor is lubricated by refrigerant oil that is cir-

culated throughout the refrigerant system with the

refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

NOISE

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressornoise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and rotor are properly aligned and have

the correct air gap. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION)

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

to be certain that the discharge pressure does not

exceed 2760 kPa (400 psi).

(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which can

cause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAU-

TION)

(5) If the noise is from opening and closing of the

high pressure relief valve, evacuate and recharge the

refrigerant system. (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM CHARGE) If the high pressure

relief valve still does not seat properly, replace the

compressor.

(6) If the noise is from liquid slugging on the suc-

tion line. Check the refrigerant oil level and the

refrigerant system charge. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT OIL - STANDARD PROCEDURE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

SPECIFICATIONS - CHARGE CAPACITY) If either

is out of specification range reclaim, evacuate and

recharge the refrigerent system(Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE), (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/RE-

24 - 36 PLUMBINGDR

A/C COMPRESSOR (Continued)

Page 2827 of 2895

air and boil the moisture out of the system at near

room temperature. To evacuate the refrigerant sys-

tem, use the following procedure:

(1) Connect a R-134a refrigerant recovery/recy-

cling/charging station that meets SAE Standard

J2210 and a manifold gauge set (if required) to the

refrigerant system of the vehicle and recover refrig-

erant.

(2) Open the low and high side valves and start

the charging station vacuum pump. When the suc-

tion gauge reads 88 kPa (26 in. Hg.) vacuum or

greater, close all of the valves and turn off the vac-

uum pump.

(a) If the refrigerant system fails to reach the

specified vacuum, the system has a leak that must

be corrected. See Refrigerant System Leaks in the

Diagnosis and Testing section of this group for the

procedures.

(b) If the refrigerant system maintains the spec-

ified vacuum for five minutes, restart the vacuum

pump, open the suction and discharge valves and

evacuate the system for an additional ten minutes.

(3) Close all of the valves, and turn off the charg-

ing station vacuum pump.

(4) The refrigerant system is now ready to be

charged with R-134a refrigerant(Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

STANDARD PROCEDURE- REFRIGERANT

RECOVERY

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) AND (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

STANDARD PROCEDURE- REFRIGERANT

SYSTEM CHARGE

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) AND (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can beinjected into the system. See Refrigerant Charge

Capacity in the Service Procedures section of this

group for the proper amount of the refrigerant

charge, this fill level can also be found on a label

attached under the hood of the vehicle..

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

The R-134a refrigerant system charge capacity for

this vehicle is:

²If equipped with a 3.7L or a 4.7L engine charge

to 0.6804 Kg. (24 oz.).

²If equipped with a 5.9L engine charge to 0.7371

Kg. ( 26 oz.).

REFRIGERANT LINE COUPLER

DESCRIPTION

Spring-lock type refrigerant line couplers are used

to connect many of the refrigerant lines and other

components to the refrigerant system. These couplers

require a special tool for disengaging the two coupler

halves.

OPERATION

The spring-lock coupler is held together by a garter

spring inside a circular cage on the male half of the

fitting (Fig. 16). When the two coupler halves are

connected, the flared end of the female fitting slips

behind the garter spring inside the cage on the male

fitting. The garter spring and cage prevent the flared

end of the female fitting from pulling out of the cage.

Three O-rings on the male half of the fitting are

used to seal the connection. These O-rings are com-

patible with R-134a refrigerant and must be replaced

with O-rings made of the same material.

Secondary clips are installed over the two con-

nected coupler halves at the factory for added blowoff

protection.

REMOVAL

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

(1) Recover the refrigerant from the refrigerant

system(Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT - STANDARD

PROCEDURE).

24 - 52 PLUMBINGDR

REFRIGERANT (Continued)