stop start DODGE RAM 2500 DIESEL 2004 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2004 3.GPages: 426, PDF Size: 7.22 MB

Page 239 of 426

WARNING!

²Always fully apply the parking brake when leav-

ing your vehicle, or it may roll and cause damage

or injury. Also be certain to leave an automatic

transmission in Park, a manual transmission in

Reverse or first gear. Failure to do so may allow

the vehicle to roll and cause damage or injury.

²Leaving children in a vehicle unattended is dan-

gerous for a number of reasons. A child or others

could be injured. Children should be warned not

to touch the parking brake or the gear selector

lever. Don't leave the keys in the ignition. A child

could operate power windows, other controls, or

move the vehicle.

²Be sure the parking brake is fully disengaged before

driving, failure to do so can lead to brake problems

due to excessive heating of the rear brakes.

When parking on a hill, turn the front wheels toward the

curb on a downhill grade and away from the curb on an

uphill grade.

The parking brake should always be applied whenever

the driver is not in the vehicle.

BRAKE SYSTEM

If power assist is lost for any reason (for example,

repeated brake applications with the engine off), the

brakes will still function. However, you will experience a

substantial increase in braking effort to stop the vehicle.

If either the front or rear hydraulic systems lose normal

capability, the remaining system will still function with

some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application,

greater pedal force required to slow or stop, and activa-

tion of the BRAKE warning lamp and the ABS lamp (if

equipped) during brake use.

STARTING AND OPERATING 239

5

Page 241 of 426

WARNING!

²Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

This Anti-lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lockup and help avoid skidding on slippery surfaces.

The system's pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation. This is

normal.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a complete stop.

This is the result of the system reverting to the base brake

system and is normal.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning.

STARTING AND OPERATING 241

5

Page 242 of 426

ABS Warning Light

The Anti-lock Brake System includes an amber warning

light, located in the instrument cluster. When the light is

illuminated, the Anti-lock Brake System is not function-

ing. The system reverts to standard non-anti-lock brakes.

WARNING!

Pumping of the anti-lock brakes will diminish their

effectiveness and may lead to an accident. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

POWER STEERING

Your power steering system will provide mechanical

steering capability if power assist is lost.

If for any reason the hydraulic pressure is interrupted, it

will still be possible to steer your vehicle. Under these

conditions you will experience a substantial increase in

steering effort.

242 STARTING AND OPERATING

Page 251 of 426

WARNING!

Overloading of your tire is dangerous. Overloading

can cause tire failure, affect vehicle handling, and

increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never

overload them.

TIRESÐGENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the safe and

satisfactory operation of your vehicle. Three primary

areas are affected by improper tire pressure:1. SafetyÐ

WARNING!

Improperly inflated tires are dangerous and can

cause accidents.

²Under inflation increases tire flexing and can result

in tire failure.

²Over inflation reduces a tire's ability to cushion

shock. Objects on the road and chuck holes can cause

damage that results in tire failure.

²Unequal tire pressures can cause steering prob-

lems. You could lose control of your vehicle.

²Over inflated or under inflated tires can affect

vehicle handling and can fail suddenly, resulting in

loss of vehicle control.

²Unequal tire pressures from one side of the vehicle

to the other can cause the vehicle to drift to the right

or left.

Always drive with each tire inflated to the recom-

mended cold tire inflation pressure.

STARTING AND OPERATING 251

5

Page 259 of 426

Improper alignment will not cause vehicle vibration.

Vibration may be a result of tire and wheel out-of-

balance. Proper balancing will reduce vibration and

avoid tire cupping and spotty wear.

SUPPLEMENTAL TIRE PRESSURE INFORMATION

A light load vehicle condition is defined as two passen-

gers {150 lbs (68 kg) each} plus 200 lbs (91kg) of cargo.

Cold tire inflation pressures for a lightly loaded vehicle

will be found on a ªSupplemental Tire Pressure Inflationº

label located on the face of the driver's door or in the Tire

Information Pressures pamphlet in the glove box.

TIRE CHAINS

Use ªClass Uº chains on 2500/3500 Ram Trucks, or other

traction aids that meet SAE Type ªUº specifications.

NOTE:Chains must be the proper size for the vehicle,

as recommended by the chain manufacturer.

CAUTION!

To avoid damage to your vehicle, tires or chains, observe

the following precautions:

²Because of limited chain clearance between tires and other

suspension components, it is important that only chains

in good condition are used. Broken chains can cause

serious vehicle damage. Stop the vehicle immediately if

noise occurs that could suggest chain breakage. Remove

the damaged parts of the chain before further use.

²Install chains as tightly as possible and then retighten

after driving about 1/2 mile (0.8 km).

²Do not exceed 45 mph (72 km/h).

²Drive cautiously and avoid severe turns and large

bumps, especially with a loaded vehicle.

²Do not install tire chains on front wheels of 4x2 vehicles.

²Do not drive for a prolonged period on dry pavement.

²Observe the tire chain manufacturer's instructions on

method of installation, operating speed, and conditions

for usage. Always use the lower suggested operating

speed of the chain manufacturer if different than the

speed recommended by the manufacturer.

STARTING AND OPERATING 259

5

Page 275 of 426

²Use an approved wiring harness connector on the

trailer. Standard equipment on all RAM pickup mod-

els provides a 4-way trailer tow connector located

under the bumper. This connector contains the follow-

ing vehicle circuits: park/tail lamps, left stop/turn

lamp, right stop/turn lamp, and ground. With the

optional Trailer Tow Prep package a 7-way connector

is provided with the following additional circuits:

backup lamp, trailer battery and electric brake.

NOTE:Connect trailer lighting and brakes using factory

harnesses only. Do not cut or splice wiring to the brake

circuits.

²Be sure the trailer is loaded heavier in front, with 60%

to 65% of the weight in front of the axle(s). Loads

balanced over the wheels or heavier in the rear can

cause the trailer to sway severely side to side which

will cause loss of control of vehicle and trailer. Failureto load trailers heavier in front is the cause of many

trailer accidents. (For a95th Wheel9style trailer, this

range of loading on the9King Pin9should be between

15% and 25%.)

²Make certain that the load is secured in the trailer and

will not shift during travel. When towing cargo such

as livestock, dynamic load shifts can occur that require

the driver to maintain attention.

Trailer Towing Ð Hitches

With a Class I Hitch, your vehicle can be equipped to tow

trailers with a Gross Trailer Weight (GTW) of 2,000 lbs

(907 kg) maximum.

With a Class II Hitch, your vehicle can be equipped to

tow trailers with a Gross Trailer Weight (GTW) of 3,500

lbs (1 587 kg) maximum. Tongue weight must be equal to

at least 10% of GTW, but no more than 15% of GTW.

STARTING AND OPERATING 275

5

Page 276 of 426

With a Class III Hitch, your vehicle can be equipped to

tow trailers with a Gross Trailer Weight (GTW) of 5,000

lbs (2 268 kg) maximum. Factory-installed rear step

bumpers are rated a Class III hitch. Tongue weight must

be equal to at least 10% of the gross trailer weight (GTW),

but no more than 15% of the GTW.

A frame mounted hitch of up to Class IV rating, as rated

by the hitch manufacturer, is supplied as part of the

trailer tow prep package. With a Class IV Hitch, you can

tow a trailer with a Gross Trailer Weight of up to 12,000

lbs (5 443 kg) maximum depending on your vehicle

equipment. Tongue weight must be equal to at least 10%

of the gross trailer weight (GTW), but no more than 15%

of the GTW.Connecting Trailer Lighting And Electric Trailer

Brakes

NOTE:A 4-way trailer tow connector, located behind

the bumper, is standard equipment on all Ram pickup

models. This connector contains the following vehicle

circuits: park/tail lamps, left stop/turn lamp, right stop/

turn lamp, and ground. With the optional Trailer Tow

Prep package a 7-way connector is also provided with the

following additional circuits: backup lamp, trailer battery

and electric brake.

NOTE:There is also a 4±way connector located under

the instrument panel, located to the left of the brake

pedal that is used for the electric brake. This connector

contains the following vehicle circuits; power ground,

battery, stop lamp switch and electric brake feed. The

4±way is optional with the trailer tow prep package.

276 STARTING AND OPERATING

Page 280 of 426

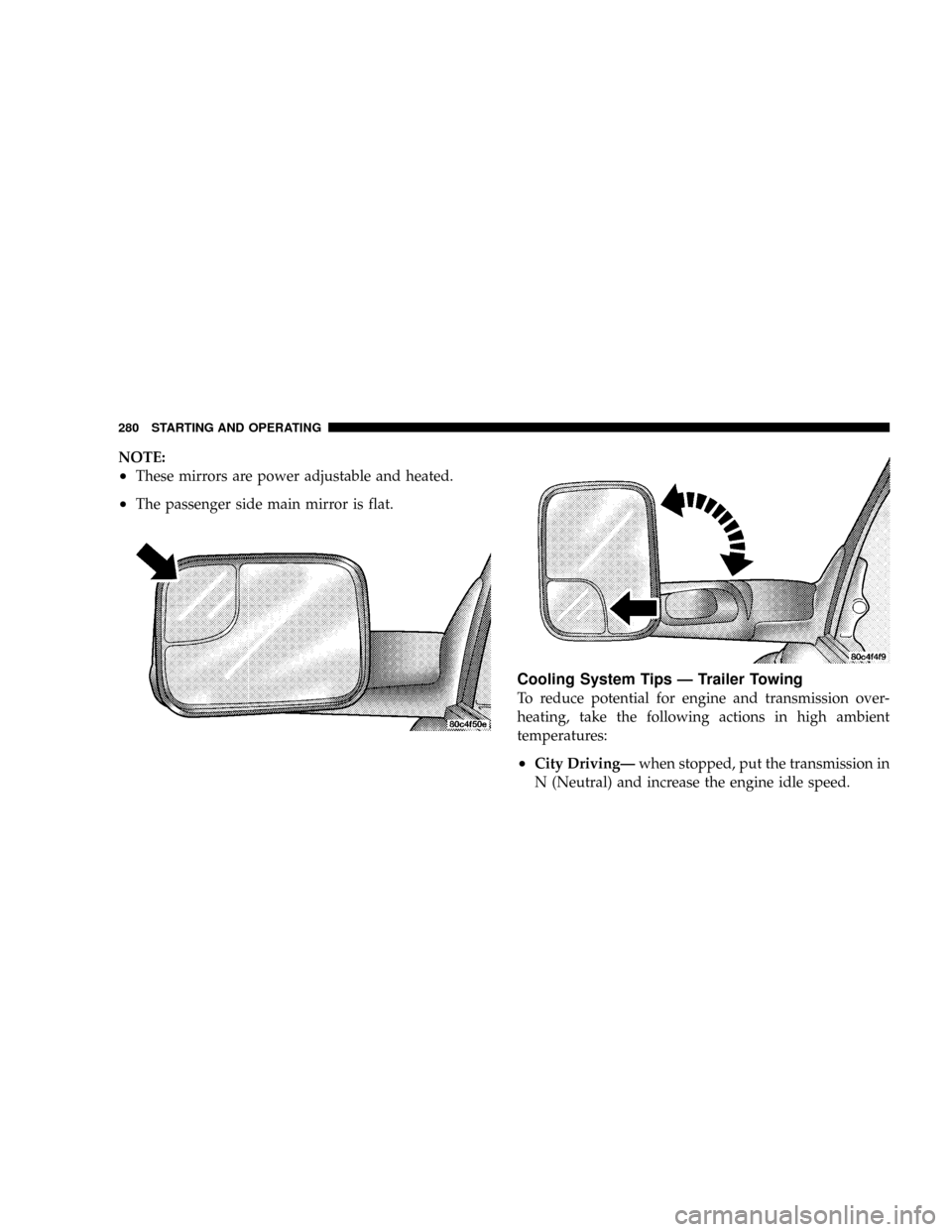

NOTE:

²These mirrors are power adjustable and heated.

²The passenger side main mirror is flat.

Cooling System Tips Ð Trailer Towing

To reduce potential for engine and transmission over-

heating, take the following actions in high ambient

temperatures:

²City DrivingÐwhen stopped, put the transmission in

N (Neutral) and increase the engine idle speed.

280 STARTING AND OPERATING

Page 281 of 426

²Highway DrivingÐreduce your speed.

²Air ConditioningÐturn it off temporarily.

²Hilly TerrainÐTurn overdrive off.

See Cooling System Operating information in the Service

and Maintenance section of this manual for more infor-

mation.

Automatic Transmission Oil Temperature Warning

Light

All vehicles with heavy duty transmission oil cooling are

equipped with a transmission sump oil temperature

sensor and warning light. If elevated transmission tem-

peratures are encountered, the engine controller will

select the most desirable gear until the transmission

temperatures are reduced. If transmission oil tempera-

tures continue to rise, a warning light located in theinstrument cluster will illuminate. If this should occur,

stop the vehicle, shift to Neutral, and run the engine at

idle or faster until the light goes off.

Towing With An Automatic Transmission

Vehicles equipped with an automatic transmission may

shift into and out of Overdrive, or a lower gear, when

driving in hilly areas, when heavily loaded, or when

towing into heavy winds.

When this condition occurs, press the ªTOW/HAULº

button or shift into a lower gear to prevent excessive

transmission wear and/or overheating, and to provide

better engine braking.

NOTE:Do not exceed the following RPM while manu-

ally downshifting:

²5.9L Diesel Engines 3200 RPM.

STARTING AND OPERATING 281

5

Page 284 of 426

of the plow. Front end tow-in should be checked and

reset if necessary at the beginning and end of the

snowplow season. This will help prevent uneven tire

wear.

The blade should be lowered whenever the vehicle is

parked.

Maintain and operate your vehicle and snowplow equip-

ment following the recommendations provided by the

specific snowplow manufacturer.

Over the Road Operation With Snowplow

Attached

The blade restricts air flow to the radiator and causes the

engine to operate at higher than normal temperatures.

Therefore, when transporting the plow, angle the blade

completely and position it as low as road or surface

conditions permit. Do not exceed 40 mph (64 km/h). The

operator should always maintain a safe stopping distance

and allow adequate passing clearance.

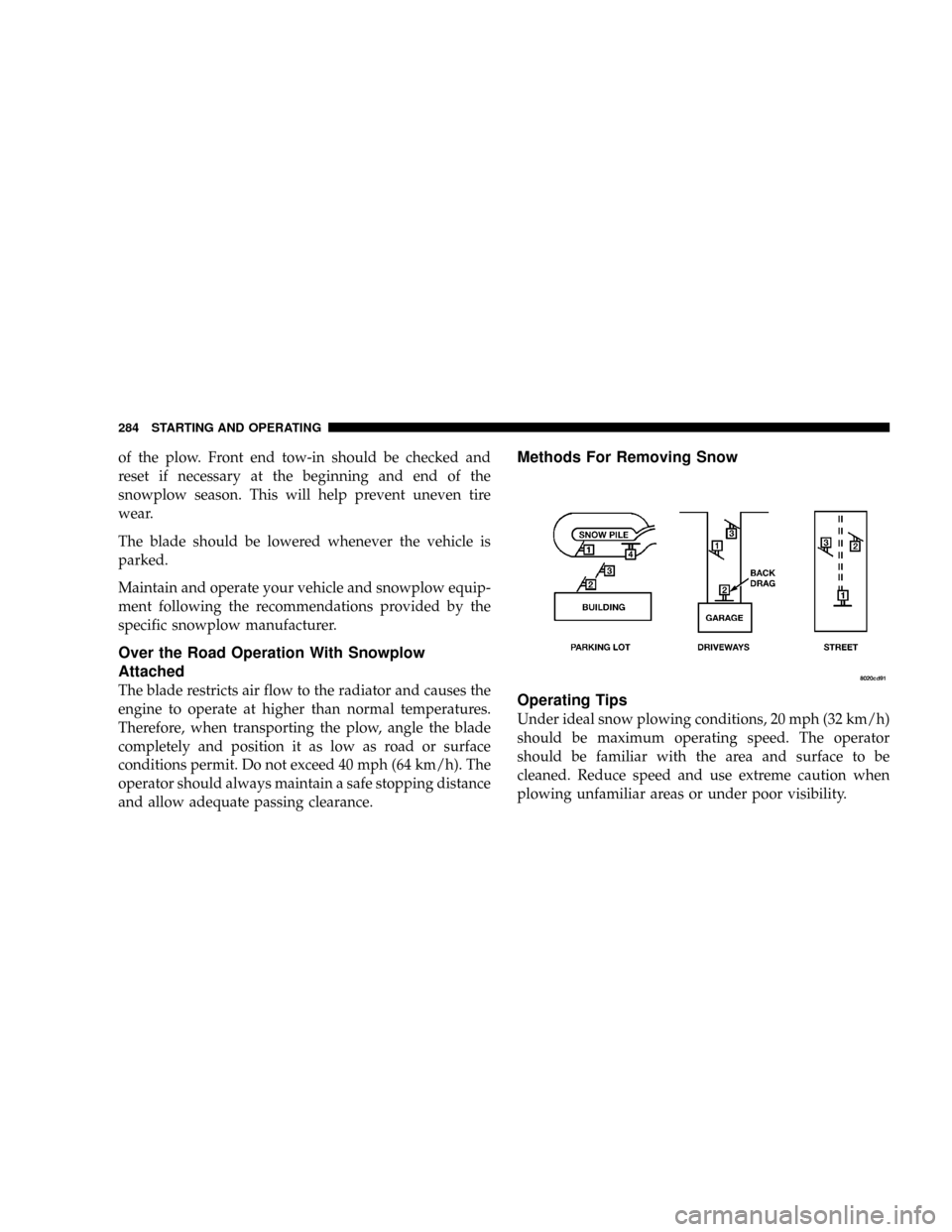

Methods For Removing Snow

Operating Tips

Under ideal snow plowing conditions, 20 mph (32 km/h)

should be maximum operating speed. The operator

should be familiar with the area and surface to be

cleaned. Reduce speed and use extreme caution when

plowing unfamiliar areas or under poor visibility.

284 STARTING AND OPERATING