trailer DODGE RAM 2500 DIESEL 2004 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2004 3.GPages: 426, PDF Size: 7.22 MB

Page 278 of 426

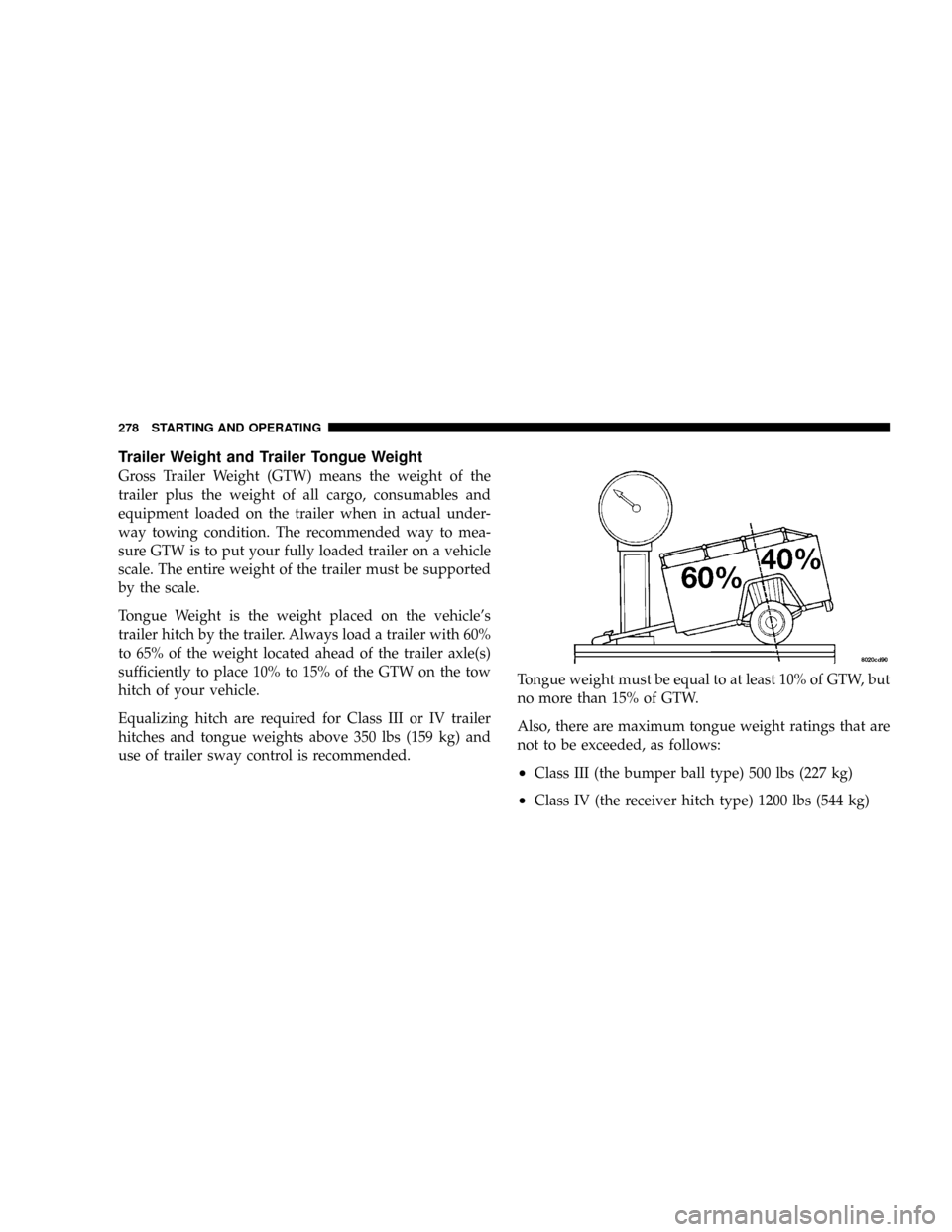

Trailer Weight and Trailer Tongue Weight

Gross Trailer Weight (GTW) means the weight of the

trailer plus the weight of all cargo, consumables and

equipment loaded on the trailer when in actual under-

way towing condition. The recommended way to mea-

sure GTW is to put your fully loaded trailer on a vehicle

scale. The entire weight of the trailer must be supported

by the scale.

Tongue Weight is the weight placed on the vehicle's

trailer hitch by the trailer. Always load a trailer with 60%

to 65% of the weight located ahead of the trailer axle(s)

sufficiently to place 10% to 15% of the GTW on the tow

hitch of your vehicle.

Equalizing hitch are required for Class III or IV trailer

hitches and tongue weights above 350 lbs (159 kg) and

use of trailer sway control is recommended.Tongue weight must be equal to at least 10% of GTW, but

no more than 15% of GTW.

Also, there are maximum tongue weight ratings that are

not to be exceeded, as follows:

²Class III (the bumper ball type) 500 lbs (227 kg)

²Class IV (the receiver hitch type) 1200 lbs (544 kg)

278 STARTING AND OPERATING

Page 279 of 426

NOTE: When towing a trailer, the following require-

ments must be adhered to:

²GCWR must not be exceeded

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

(4) ratings are not exceeded:

1.GVWR

2.GTW

3.Tongue weight rating for the trailer hitch utilized

(This requirement may limit the ability to always

achieve the 10% to 15% range of tongue weight [15%

to 25% for a(5th Wheel(style trailer] as a percentage

of total trailer weight.)

4.GAWR ratings

Trailer Towing Information (Maximum Trailer

Weight Ratings)

(Trailer Towing Guide(

NOTE:For trailer towing information (maximum trailer

weight ratings) refer to the following website address:

http:// www.dodge.com/towing.

In Canada, refer to the following website address:http://

www.dodge.ca.

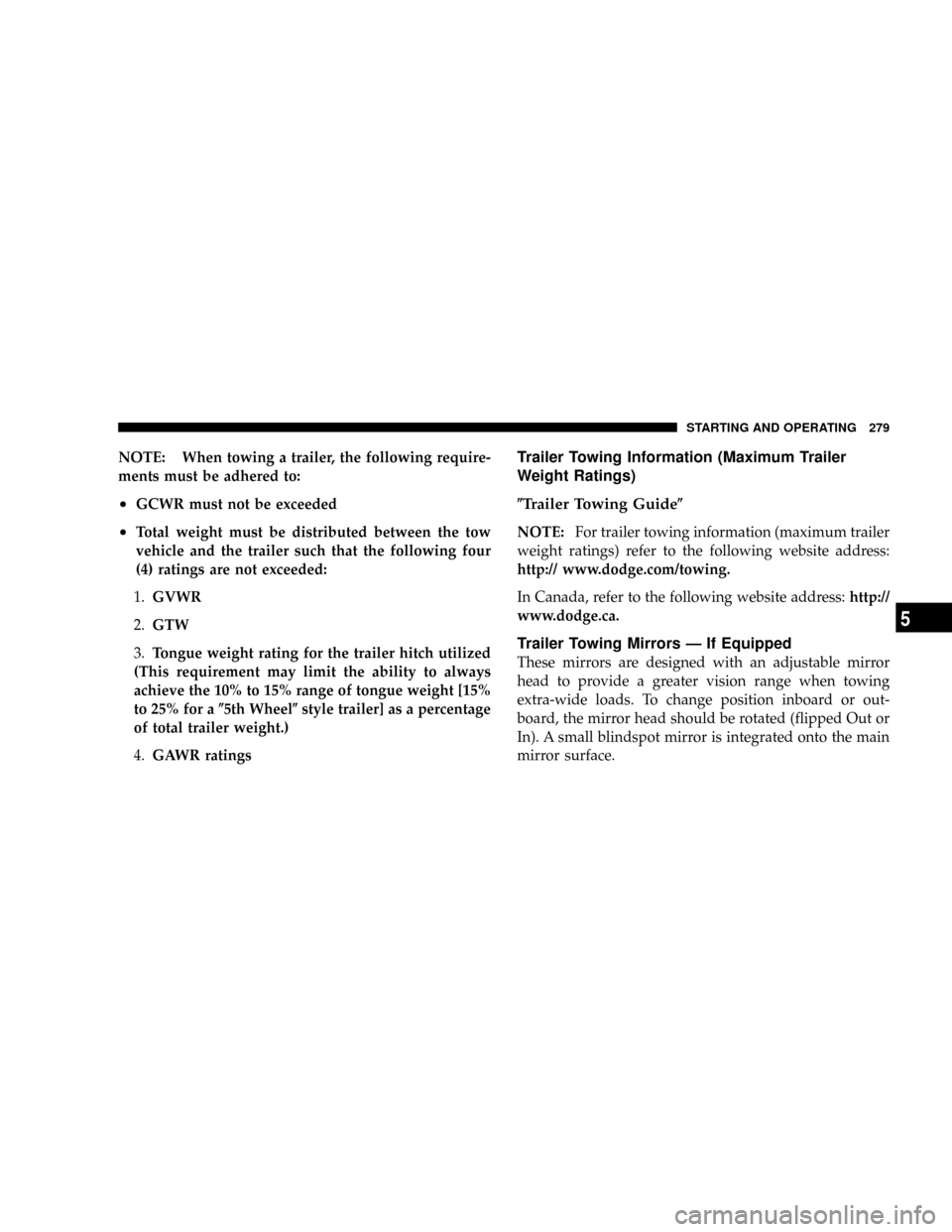

Trailer Towing Mirrors Ð If Equipped

These mirrors are designed with an adjustable mirror

head to provide a greater vision range when towing

extra-wide loads. To change position inboard or out-

board, the mirror head should be rotated (flipped Out or

In). A small blindspot mirror is integrated onto the main

mirror surface.

STARTING AND OPERATING 279

5

Page 280 of 426

NOTE:

²These mirrors are power adjustable and heated.

²The passenger side main mirror is flat.

Cooling System Tips Ð Trailer Towing

To reduce potential for engine and transmission over-

heating, take the following actions in high ambient

temperatures:

²City DrivingÐwhen stopped, put the transmission in

N (Neutral) and increase the engine idle speed.

280 STARTING AND OPERATING

Page 282 of 426

If your vehicle has an automatic transmission and you

tow a trailer frequently, change transmission fluid and

filter every 30,000 miles (48 000 km)

SNOWPLOW

Snowplow Prep Packages are available as a factory

installed option. These packages include components

necessary to equip your vehicle with a snowplow.

NOTE:Before installation of a snowplow it is highly

recommended that the owner / installer obtain and

follow the recommendations contained within the Dodge

2004 BODY BUILDER'S GUIDE. See your dealer, installer

or snowplow manufacture for this information. There are

unique electrical systems that must be connected to

properly assure operator safety and prevent overloading

vehicle systems that would void the vehicle warranty.

WARNING!

Attaching a snowplow to this vehicle could ad-

versely affect performance of the airbag system in an

accident. Do not expect that the airbag will perform

as described earlier in this manual

CAUTION!

The ªLamp Outº indicator could illuminate if exte-

rior lamps are not properly installed.

282 STARTING AND OPERATING

Page 327 of 426

²Driving in dusty conditions.

²Frequent trailer towing.

²Taxi, police, or delivery service (commercial service).

²Off-road or desert operation.

²Extensive operation at high engine speeds (greater

than 2900 rpm) and loads (greater than 70% throttle).

IfANYof these apply to you, then change your engine oil

at every interval shown in schedule9B9of the9Mainte-

nance Schedules9section of this manual.

If none of these apply to you, then change your engine oil

at every interval shown on schedule9A9of the9Mainte-

nance Schedules9section of this manual.

NOTE:Most vehicles are operated under the conditions

listed for Schedule9B.9

Engine Oil Selection

1. Engine Oil Quality

Use only oils conforming to API

Service CI-4. A sulfated ash limit

is specified for lubrication oil used

in Cummins engines. Oils with a

high ash content may produce de-

posits on valves that can progress

to guttering and valve burning. A

maximum sulfated ash content of

1.85 mass % is recommended for

all oil used in the engine.

2. Engine Oil Viscosity (SAE Grade)

The proper SAE viscosity of engine oil for the expected

ambient temperature range should be selected, as indi-

cated in the following chart:

MAINTAINING YOUR VEHICLE 327

7

Page 355 of 426

It is important that proper lubricant is used in the

transmission. Refer to Recommended Fluids, Lubricants

and Genuine Parts for the correct lubricant type. A band

adjustment and filter change should be made at the time

of the oil change.

The fluid and filter should be changed and the bands

adjusted as specified in the Maintenance Schedule (Sec-

tion 8). Vehicles having severe usage should follow

Maintenance Schedule ªBº of the Maintenance Schedule

(Section 8).

Severe usage consists of:

²Off-the-highway operation;

²Trailer towing;

²Snow plow operation;

²Prolonged operation with heavy loading, especially in

hot weather.NOTE:If the transmission is disassembled for any

reason, the fluid and filter should be changed, and the

bands adjusted.

Special Additives

The manufacturer recommends against the addition of

any additives to the transmission. Exception to this

policy is the use of special dyes to aid in detecting fluid

leaks. The use of transmission sealers should be avoided,

since they may adversely affect seals.

Front Wheel Bearings

Front wheel bearings for all Dodge Ram Trucks are

sealed-for-life. They do not require greasing or seal

replacement. In some instances, these bearings will

ªpurgeº excess grease and the bearing housing will look

slightly wet. This is normal.

²Periodic inspection for excess play is recommended.

MAINTAINING YOUR VEHICLE 355

7

Page 384 of 426

EMISSION CONTROL SYSTEM MAINTENANCE

The ªScheduledº maintenance services, listed inbold

typein this section (Section 8) must be done at the times

or mileages specified to assure the continued proper

functioning of the emission control system. These, and all

other maintenance services included in this manual,

should be done to provide best vehicle performance and

reliability. More frequent maintenance may be needed for

vehicles in severe operating conditions such as dusty

areas and very short trip driving.

Inspection and service also should be done any time a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the emis-

sion control devices and systems on your vehicle may be

performed by any automotive repair establishment or

individual using any automotive part which has been

certified pursuant to U.S. EPA or, in the State of Califor-

nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULES Ð 24±VALVE

CUMMINS TURBO DIESEL

There are two maintenance schedules that show the

requiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are operated

under the conditions that are listed below and at the

beginning of the schedule.

²Frequent short trips where the engine does not achieve

full operating temperature (operating temperature de-

fined as 190É F (66É C ) coolant temperature).

²Extensive engine idling (over 10 minutes per hour of

operation) at ambient temperatures less than 32É F (0É

C).

²Driving in dusty conditions.

²Frequent trailer towing.

²Taxi, police, or delivery service (commercial service).

384 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 387 of 426

Schedule ªBº

Follow schedule ªBº if you usually operate your vehicle

under one or more of the following conditions.

²Frequent short trips where the engine does not achieve

full operating temperature (operating temperature de-

fined as 190É F (66É C ) coolant temperature).

²Extensive engine idling (over 10 minutes per hour of

operation) at ambient temperatures less than 32É F (0É

C).

²Driving in dusty conditions.

²Frequent trailer towing.

²Taxi, police, or delivery service (commercial service).

²Off-road or desert operation.

²Extensive operation at high engine speeds (greater

than 2900 rpm) and loads (greater than 70% throttle).

SCHEDULE ªBº 387

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 417 of 426

Glass Cleaning.......................... 365

GVWR............................... 269

Hands-Free Phone........................ 79

Hazard Warning Flasher................... 296

Head Restraints.......................... 93

Headlights..........................101,367

High Beam........................... 104

High Beam/Low Beam Select Switch........ 104

Lights On Reminder.................... 102

Passing............................. 104

Switch.............................. 101

Heated Mirrors....................78,191,195

Heated Seats............................ 96

Heater............................... 187

High Beam/Low Beam Select Switch.......... 104

Hitches

Trailer Towing........................ 275

Hoisting.............................. 309Homelink Transmitter.................... 120

Hood Release........................... 97

Hoses.............................348,350

Hub Caps............................. 306

Hydraulic Clutch Fluid.................... 351

Ignition.............................14,204

Key ............................... 11,14

Lock................................ 14

Infant Restraint........................55,56

Inflation Pressure Tires.................... 259

Inside Rearview Mirror.................... 75

Instrument Cluster....................142,143

Instrument Panel and Controls.............. 141

Instrument Panel Lens Cleaning............. 365

Interior Appearance Care.................. 364

Intermittent Wipers...................... 105

Introduction............................. 4

INDEX 417

10

Page 420 of 426

Trailer Towing......................79,279

Modifications/Alterations, Vehicle............. 7

Mopar Parts.........................322,407

Multi-Function Control Lever............... 103

New Vehicle Break-In Period................ 67

Noise Control

Maintenance.......................... 357

Tampering Prohibited................... 358

Noise Emission Warranty...............357,359

Occupant Restraints....................... 33

Odometer..........................148,149

Trip .............................148,149

Off-Pavement Driving.................... 292

Off-Road Driving........................ 292

Oil, Engine............................ 380

Capacity............................ 379

Change Interval....................... 326Dipstick............................. 325

Disposal............................ 331

Filter.........................325,328,380

Pressure Gauge....................... 145

Recommendation...................... 327

Viscosity............................ 327

Oil Filter, Change........................ 328

Onboard Diagnostic System................ 321

Opener, Garage Door..................... 120

Operating Precautions.................... 321

Outside Rearview Mirrors.................. 76

Overdrive............................. 220

Overdrive OFF Switch.................... 220

Overhead Console.................... 112,113

Overhead Travel Information Center.......... 113

Owner's Manual........................ 408

Parking Brake.......................... 238

Passenger Airbag On/Off Switch............. 50

420 INDEX