tire type DODGE RAM 2500 DIESEL 2006 3.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2006 3.GPages: 493, PDF Size: 2 MB

Page 362 of 493

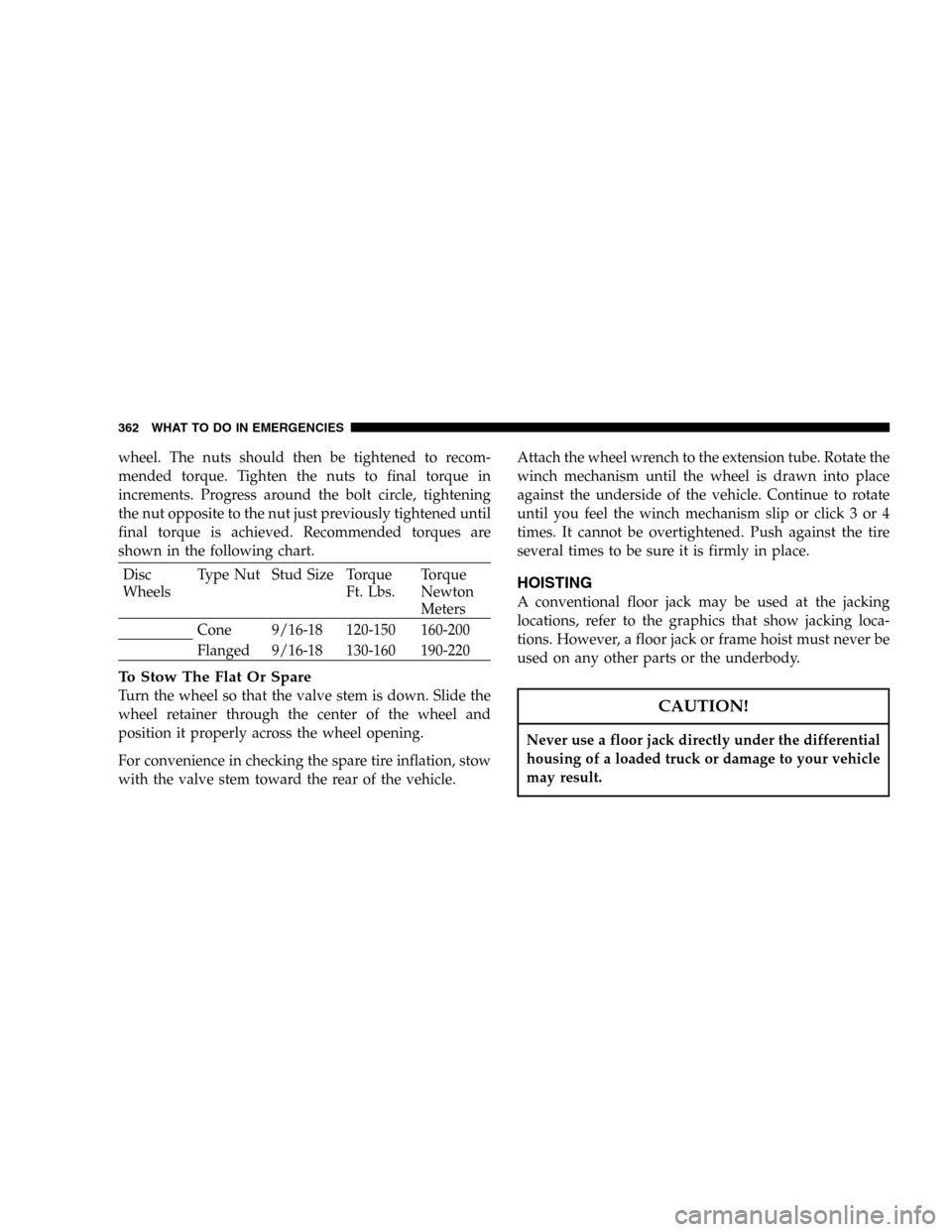

wheel. The nuts should then be tightened to recom-

mended torque. Tighten the nuts to final torque in

increments. Progress around the bolt circle, tightening

the nut opposite to the nut just previously tightened until

final torque is achieved. Recommended torques are

shown in the following chart.

Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip or click 3 or 4

times. It cannot be overtightened. Push against the tire

several times to be sure it is firmly in place.

HOISTING

A conventional floor jack may be used at the jacking

locations, refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

362 WHAT TO DO IN EMERGENCIES

Page 397 of 493

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO) which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing CO, fol-

low the preceding safety tips.

Exhaust System Rubber Isolator and Loop-Type

Hanger — If Equipped

Inspect surfaces whenever the vehicle is hoisted for

rubber to metal separation or deep cracks. If, however,

excessively deep localized cracks are present, or any part

of the exhaust system abnormally contacts the under-

body hardware, the isolator and/or hanger should be

replaced.

Cooling System

Cooling System Maintenance

At the intervals shown in the Maintenance Schedules

Section of the manual, the system should be drained,

flushed and filled.

Inspection

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty in appearance, the system

should be drained, flushed and refilled with fresh coolant

as specified.

Inspect the entire cooling system for leaks. Check the face

of the radiator for any accumulation of bugs, leaves, or

other foreign matter. If dirty, clean the radiator core with

a garden hose. With the engine OFF, gently spray water

from the back of the radiator core. Check coolant bottle

tube for condition and tightness of connections at coolant

bottle and radiator.

MAINTAINING YOUR VEHICLE 397

7

Page 478 of 493

Air Cleaner, Engine (Engine Air Cleaner Filter) . 385,412

Air Conditioner Maintenance............... 391

Air Conditioning Refrigerant.............391,392

Air Conditioning System................234,391

Air Conditioning System, Zone Control........ 238

Air Filter.............................. 385

Air Pressure, Tires....................301,309

Airbag..............................43,49

Airbag Light.........................72,178

Airbag On/Off Switch..................... 49

Airbag, Side............................ 52

Alarm, Out of Park Sense.................. 271

Alarm (Security Alarm).................26,180

Alignment and Balance................... 308

Alterations/Modifications, Vehicle............. 7

Antenna, Satellite Radio................... 227

Antifreeze (Engine Coolant)................ 400

Capacities........................... 437

Anti-Lock Warning Light...............182,290Anti-Theft System.....................26,180

Appearance Care........................ 416

Ashtray............................... 152

Automatic Transmission................... 407

Adding Fluid......................... 407

Fluid and Filter Changes................. 408

Fluid Level Check...................... 407

Fluid Type........................408,439

Shift Indicator........................ 180

Shifting............................. 266

Special Additives...................... 409

Axle Fluid..........................406,439

Axle Lubrication (Axle Fluid)............... 406

Ball Joints............................. 393

Battery............................... 390

Blanket..........................261,391

Emergency Starting..................... 363

Saving Feature (Protection)............... 121

478 INDEX