wheel torque DODGE RAM 2500 DIESEL 2009 4.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2009, Model line: RAM 2500 DIESEL, Model: DODGE RAM 2500 DIESEL 2009 4.GPages: 532, PDF Size: 9.37 MB

Page 201 of 532

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system opera-

tion or sensor damage may result when using re-

placement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or

balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result.

26. Electronic Stability Program (ESP) Indicator Light/

Traction Control System (TCS) Indicator Light — If

Equipped If this indicator light flashes during accelera-

tion, apply as little throttle as possible. While

driving, ease up on the accelerator. Adapt your speed and driving to the prevailing road conditions, and

do not switch off the Electronic Stability Program (ESP),

or Traction Control System (TCS).

27. Transmission Temperature Indicator (Automatic

Transmissions Only)

This light indicates that there is excessive trans-

mission fluid temperature that might occur

with severe usage such as trailer towing. It may

also occur when operating the vehicle in a high

torque converter slip condition, such as 4-wheel-drive

operation (e.g., snow plowing, off- road operation). If this

light comes on, stop the vehicle and run the engine at idle

or faster, with the transmission in NEUTRAL until the

light goes off.

28. Odometer/Trip Odometer Button

Press this button to toggle between the odometer and the

trip odometer display. Holding the button in resets the

trip odometer reading when in trip mode.

UNDERSTANDING YOUR INSTRUMENT PANEL 199

4

Page 262 of 532

the upper gears. When the vehicle speed drops or during

acceleration when the transmission downshifts to second

gear, the clutch automatically disengages.

NOTE:•

The torque converter clutch will not engage until the

transmission fluid and engine coolant are warm [usu-

ally after 1-3 miles (1.6 - 4.8 km) of driving]. Because

the engine speed is higher when the torque converter

clutch is not engaged, it may seem as if the transmis-

sion is not shifting into Overdrive when cold. This is

normal. Pressing the “TOW HAUL O/D OFF” button,

when the transmission is sufficiently warm, will dem-

onstrate that the transmission is able to shift into and

out of overdrive.

•

If the vehicle has not been driven in several days, the

first few seconds of operation after shifting the trans-

mission into gear may seem sluggish. This is due to the

fluid partially draining from the torque converter intothe transmission. This condition is normal and will not

cause damage to the transmission. The torque con-

verter will refill within five seconds of shifting from

PARK into any other gear position.

FOUR-WHEEL DRIVE OPERATION — IF

EQUIPPEDFour-wheel drive trucks are equipped with either a

manually shifted transfer case or an electronically shifted

transfer case. Refer to the operating instructions for your

transfer case, located in this section.Manually Shifted Transfer Case Operating

Information/PrecautionsThe transfer case provides four mode positions.•

Two-wheel drive high range (2H)

•

Four-wheel drive high range (4H)

•

Neutral (N)

•

Four-wheel drive low range (4L)

260 STARTING AND OPERATING

Page 282 of 532

The locking axles are controlled by the axle locker switch

located on the center console.

The switch has three positions, AXLE UNLOCK, REAR

LOCK, and FRONT/REAR LOCK. Under normal driv-

ing conditions, the switch should be left in the AXLE

UNLOCK position. In the AXLE UNLOCK position, thefront and rear axles are unlocked. In the REAR LOCK

position, the rear axle is locked. In the FRONT/REAR

LOCK position, the front and rear axles are locked.

NOTE:

Even when the axles are in the AXLE UNLOCK

position, the limited slip differential in the rear axle still

provides torque biasing capability for moderate low

traction environments.

During the command to lock the axle, the indicator light

will flash until the axle is locked. After the lock command

has been successfully executed, the light will remain on

solid.

To lock the rear axle, place the vehicle in 4LO. Refer to

“Four Wheel Drive Operation” in this section of the

manual. Move the axle locker switch position to REAR

LOCK while traveling less than 3 mph (5 km/h). The RR

indicator light will remain on when the rear axle is

locked.

Locking Axle Switch

280 STARTING AND OPERATING

Page 283 of 532

NOTE:Left to right wheel speed difference may be

necessary to allow the axle to fully lock. If the indicator

light is flashing after placing the switch in the REAR

LOCK or FRONT/REAR LOCK position, drive the ve-

hicle in a turn or on loose gravel to expedite the locking

action.

WARNING!

Do not use the locked axle position for normal

driving. A locked front axle is intended for off-road

driving only. Locking the front axle during on-road

driving will reduce the steering ability. This could

cause an accident and you may be seriously injured.

To lock the front axle; move the axle locker switch to

FRONT/REAR LOCK while traveling less than 3 mph

(5 km/h). The indicator light will be solid when the front

axle is locked. NOTE:

The rear axle must be locked before the front

axle will lock.

To unlock the front axle; move the axle locker switch to

REAR LOCK. The FRONT/REAR LOCK indicator light

will go out when the axle is unlocked.

NOTE: The axle lockers could be torque locked due to

side to side loads on the axle. Driving slowly while

turning the steering wheel from a left hand turn to a right

hand turn or driving in REVERSE for a short distance

may be required to release the torque lock and unlock the

axles.

To unlock the rear axle; move the axle locker switch to

AXLE UNLOCK. The REAR LOCK indicator light will go

out when the rear axle is unlocked.

STARTING AND OPERATING 281

5

Page 285 of 532

WARNING!

Do not disconnect the stabilizer bar and drive on

hard surfaced roads or at speeds above 18 mph

(29 km/h), you may lose control of the vehicle, which

could result in serious injury. The front stabilizer bar

enhances vehicle stability and is necessary for main-

taining control of the vehicle. The system monitors

vehicle speed and will attempt to reconnect the

stabilizer bar at speeds over 18 mph (29 km/h). This is

indicated by a flashing off road light and solid on

road light. Once vehicle speed is reduced below

14 mph (22 km/h), the system will attempt to return to

the Off-Road mode.

To disconnect the stabilizer/sway bar, shift to either 4HI

or 4LO as shown in “Four Wheel Drive Operation” and

press the top of the stabilizer/sway bar button to obtain the Off-Road position. The amber indicator light will

flash until the stabilizer/sway bar has been fully discon-

nected.

NOTE:

The stabilizer/sway bar may be torque locked

due to left and right suspension height differences. This

condition is due to driving surface differences or vehicle

loading. In order for the stabilizer/sway bar to

disconnect/reconnect, the right and left halves of the bar

must be aligned. This alignment may require that the

vehicle be driven onto level ground or rocked from side

to side.

To return to the On-Road mode; press the bottom of the

stabilizer/sway bar button.

STARTING AND OPERATING 283

5

Page 305 of 532

•

Completely inspect the underbody of your vehicle.

Check tires, body structure, steering, suspension, and

exhaust system for damage.

•

Check threaded fasteners for looseness, particularly on

the chassis, drivetrain components, steering, and sus-

pension. Retighten them, if required, and torque to the

values specified in the Service Manual.

•

Check for accumulations of plants or brush. These

things could be a fire hazard, or they might hide

damage to fuel lines, brake hoses, axle pinion seals,

and propeller shafts.

•

After extended operation in mud, sand, water, or

similar dirty conditions, have brake drums and rotors,

brake linings, and axle yokes inspected and cleaned as

soon as possible.

•

If you experience unusual vibration after driving in

mud, slush or similar conditions, check the wheels for

packed material. Packed foreign material can cause a

wheel imbalance and cleaning the wheels will correct

the situation.

WARNING!

Abrasive material in any part of the brakes may cause

excessive wear or unpredictable braking. You might

not have full braking power when you need it to

prevent an accident. If you have been operating your

vehicle in dirty conditions, get your brakes checked

and cleaned as necessary. Failure to do so may result

is serious injury.

STARTING AND OPERATING 303

5

Page 336 of 532

NOTE:ABS improves steering control of the vehicle

during hard braking maneuvers.

WARNING!

•

ABS cannot prevent the natural laws of physics

from acting on the vehicle, nor can it increase

braking or steering efficiency beyond that af-

forded by the condition of the vehicle brakes and

tires or the traction afforded.

•

The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

•

The capabilities of an ABS-equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user’s safety

or the safety of others.

Traction Control System (TCS)The TCS monitors the amount of wheel spin of each of

the driven wheels. If wheel spin is detected, brake

pressure is applied to the slipping wheel(s), and engine

power is reduced to provide enhanced acceleration and

stability. A feature of the TCS functions similar to a

limited-slip differential and controls the wheel spin

across a driven axle. If one wheel on a driven axle is

spinning faster than the other, the system will apply the

brake of the spinning wheel. This will allow more engine

torque to be applied to the wheel that is not spinning.

This feature remains active even if TCS and ESP are in the

“Partial Off” mode. Refer to “Electronic Stability Pro-

gram (ESP)” in this section of this manual. This brake

pressure modulation transfers drive torque from slipping

to non-slipping wheels to provide optimal forward

traction.

334 STARTING AND OPERATING

Page 416 of 532

face. Lightly tighten the nuts. To avoid risk of forcing the

vehicle off the jack, do not fully tighten the nuts until the

vehicle has been lowered.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. The correct nut tightness is

135 ft lbs (183 N·m) torque for 2500/3500 single-rear

wheel (SRW) models, and 145 ft lbs (197 N·m) for 3500

dual rear-wheel models. If in doubt about the correct

tightness, have them checked with a torque wrench by

your authorized dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.7. Install wheel center cap and remove wheel blocks. Do

not install chrome or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the bottle

jack will not lower by turning the dial (thumbwheel) by

hand, it may be necessary to use the jack drive tube in

order to lower the jack. Stow the replaced tire, jack, and

tools as previously described.

9. Adjust the tire pressure when possible.

NOTE:

Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

Hub Caps/Wheel CoversThe hub caps must be removed before raising the vehicle

off the ground.

For 2500/3500 single rear-wheel (SRW) models, use the

blade on the end of the lug wrench to pry the hub cap off.

414 WHAT TO DO IN EMERGENCIES

Page 419 of 532

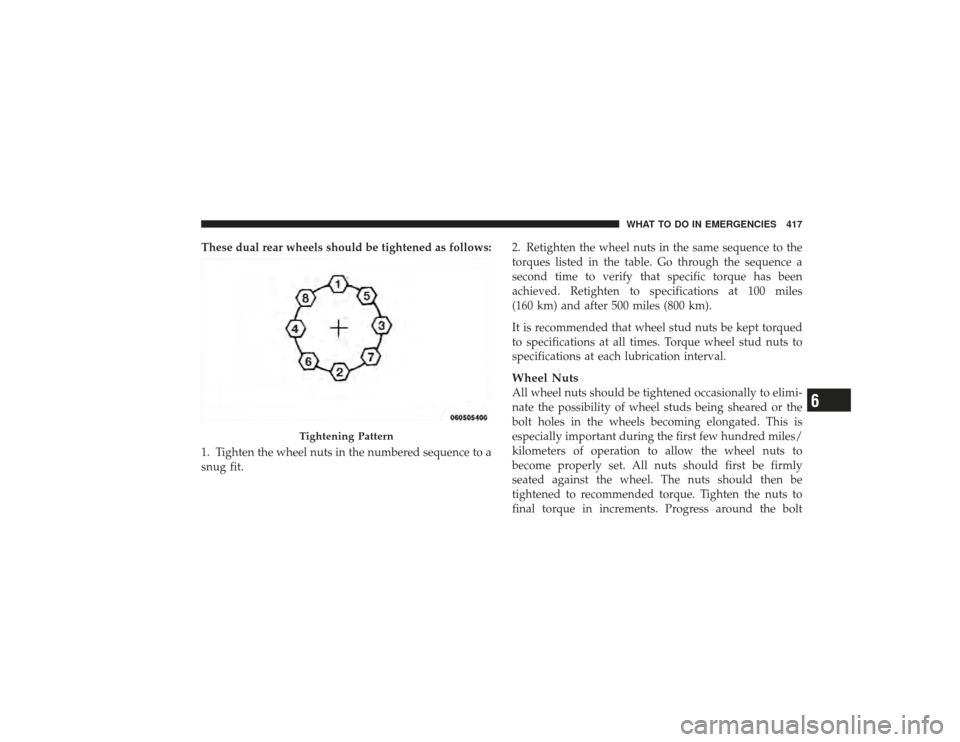

These dual rear wheels should be tightened as follows:

1. Tighten the wheel nuts in the numbered sequence to a

snug fit.2. Retighten the wheel nuts in the same sequence to the

torques listed in the table. Go through the sequence a

second time to verify that specific torque has been

achieved. Retighten to specifications at 100 miles

(160 km) and after 500 miles (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

Wheel NutsAll wheel nuts should be tightened occasionally to elimi-

nate the possibility of wheel studs being sheared or the

bolt holes in the wheels becoming elongated. This is

especially important during the first few hundred miles/

kilometers of operation to allow the wheel nuts to

become properly set. All nuts should first be firmly

seated against the wheel. The nuts should then be

tightened to recommended torque. Tighten the nuts to

final torque in increments. Progress around the bolt

Tightening Pattern

WHAT TO DO IN EMERGENCIES 417

6

Page 420 of 532

circle, tightening the nut opposite to the nut just previ-

ously tightened until final torque is achieved. Recom-

mended torques are shown in the following chart.Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220To Stow The Flat Or Spare

WARNING!

A loose tire thrown forward in a collision or hard

stop could injure the occupants in the vehicle. Have

the deflated (flat) tire repaired or replaced immedi-

ately. Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or click three or

four times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

HOISTINGA conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

418 WHAT TO DO IN EMERGENCIES