warning light DODGE RAM 2500 GAS 2008 3.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 GAS, Model: DODGE RAM 2500 GAS 2008 3.GPages: 554, PDF Size: 9.93 MB

Page 370 of 554

WARNING!

It is the driver 's responsibility to change to the max

load inflation pressure (cold) low pressure warning

threshold condition when not driving in the light

load condition as defined as two occupants ( 150 lbs

each) plus 200 pounds of cargo. The vehicle ªLight

Load Definitionº is found in the Supplemental Tire

Pressure Information label located on the rear face of

the driver door. Failure to do so may cause you to lose

control resulting in an accident, causing serious or

fatal injury.

To switch back to the max load inflation pressure (cold)

low pressure warning threshold, press the ªLight Loadº

reset switch. It is not necessary to first fill the tires to the

max load inflation pressure (cold) values to switch the

TPMS system to the max load inflation pressure (cold)low pressure warning threshold. If after pressing the

ªLight Loadº reset switch and tire pressures are below

the max load inflation pressure (cold) low pressure

warning thresholds, the TPMS low pressure warning

telltale lamp located in the Instrument Cluster will turn

ON and a chime will sound. The tire pressures are now

required to be inflated to the max load inflation pressure

(cold) values described on the Tire and Loading Informa-

tion label. The Tire and Loading Information label is

located on the drivers side B-pillar. If the ªLight Loadº

reset switch LED turns OFF the TPMS has been reset and

the TPMS is using the max load inflation pressure (cold)

low pressure warning thresholds.

Tire Pressure Monitor System Components

The Tire Pressure Monitor System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to the Receiver Module.

368 STARTING AND OPERATING

Page 371 of 554

NOTE:It is particularly important, for you to check the

tire pressure in all of your tires regularly and to maintain

the proper pressure.

The Tire Pressure Monitoring System (TPMS) consists of

the following components:

²Receiver Module

²4 Wheel Sensors

²2 Trigger Modules (mounted in the front wheel-wells)

²ªLight Loadº Reset Switch (located in the instrument

panel)

²Tire Pressure Monitoring Telltale Lamp

Tire Pressure Monitoring Low Pressure Warnings

The Tire Pressure Monitoring Telltale Lamp will

illuminate in the instrument cluster, and an au-

dible chime will be activated when one or more of

the four active road tire pressures are low. Should this

occur, you should stop as soon as possible, check the

inflation pressure of each tire on your vehicle and inflate

each tire to the vehicle's recommended cold placard

pressure value. The system will automatically update

and the Tire Pressure Monitoring Lamp will extinguish

once the updated tire pressures have been received. The

vehicle may need to be driven for up to 10 minutes above

15 mph (25 km/h) to receive this information.

Check TPMS Warnings

The Tire Pressure Monitoring Telltale Warning Light

located in the Instrument Cluster will flash on and off for

75 seconds and will remain on solid when a system fault

is detected. The system fault will also sound a chime. If

STARTING AND OPERATING 369

5

Page 372 of 554

the ignition key is cycled, this sequence will repeat,

providing the system fault still exists. A system fault can

occur by any of the following scenarios:

1. Signal interference due to electronic devices or driving

next to facilities emitting the same Radio Frequencies as

the TPM sensors.

2. Installing aftermarket window tinting that affects ra-

dio wave signals.

3. Accumulation of snow or ice around the wheels or

wheel housings.

4. Using tire chains on the vehicle.

5. Using wheels/tires not equipped with TPM sensors.

6. Loss of communication with the trigger modules or

tire pressure monitoring sensors.

NOTE: Your vehicle is equipped with a non-matching

full size spare wheel and tire assembly.1. This spare tire does not have a tire pressure monitor-

ing sensor. Therefore, the TPMS will not monitor the tire

pressure in the spare tire.

2. If you install the full size spare tire in place of a road

tire that has a pressure below the low-pressure warning

limit, upon the next ignition key cycle, a chime will

sound and the TPM Telltale Light will still turn ON due

to the low tire.

3. However, after driving the vehicle for up to 10 min-

utes above 15 mph (25 km/h), the TPM Telltale Light will

flash on and off for 75 seconds and then remain on solid.

4. For each subsequent ignition key cycle, a chime will

sound and the TPM Telltale Light will flash on and off for

75 seconds and then remain on solid.

5. Once you repair or replace the original road tire, and

reinstall it on the vehicle in place of the full size spare tire,

the TPMS will update automatically and the TPM Telltale

370 STARTING AND OPERATING

Page 373 of 554

Light will turn OFF, as long as no tire pressure is below

the low-pressure warning limit in any of the four active

road tires. The vehicle may need to be driven for up to 10

minutes above 15 mph (25 km/h) in order for the TPMS

to receive this information.

General Information

This device complies with part 15 of the FCC rules and

RSS 210 of Industry Canada. Operation is subject to the

following conditions:

²This device may not cause harmful interference.

²This device must accept any interference received,

including interference that may cause undesired op-

eration.

The tire pressure sensors are covered under one of the

following licenses:

United States.....................KR5S120123

Canada........................2671-S120123

FUEL REQUIREMENTS

All engines (except 5.7L engines) are de-

signed to meet all emissions regulations

and provide excellent fuel economy and

performance when using high-quality un-

leaded ªregularº gasoline having an oc-

tane rating of 87. The use of premium

gasoline is not recommended. Under nor-

mal conditions, the use of premium gasoline will not

provide a benefit over high-quality regular gasolines, and

in some circumstances may result in poorer performance.

The 5.7L engine is designed to meet all

emissions regulations and provide satisfac-

tory fuel economy and performance when

using high-quality unleaded gasoline hav-

ing an octane range of 87 to 89. The manu-

facturer recommends the use of 89 octane

All Engines

Except 5.7L

5.7L Engines

STARTING AND OPERATING 371

5

Page 378 of 554

CAUTION!

Damage to the fuel system or emission control sys-

tem could result from using an improper fuel tank

filler tube cap (gas cap). A poorly fitting cap could let

impurities into the fuel system. Also, a poorly-fitted

aftermarket cap can cause the MIL (Malfunction

Indicator Light) to illuminate, due to fuel vapors

escaping from the system.

CAUTION!

A poorly fitting gas cap may cause the Malfunction

Indicator Light to turn on.

CAUTION!

To avoid fuel spillage and overfilling, do not ªtop

offº the fuel tank after filling.

NOTE:When the fuel nozzle ªclicksº or shuts off, the

fuel tank is full.

WARNING!

²Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank filled.

²Never add fuel to the vehicle when the engine is

running. This is in violation of most state and

federal fire regulations and will cause the Mal-

function Indicator Light to turn on.

376 STARTING AND OPERATING

Page 379 of 554

NOTE:Tighten the gas cap 1/4 turn until you hear one

click. This is an indication that the cap is properly

tightened.

If the gas cap is not tightened properly, the Malfunction

Indicator Light will come on, Be sure the gas cap is

tightened every time the vehicle is refueled.

WARNING!

A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on the

ground while filling.

Loose Fuel Filler Cap (Gas Cap) Message

If the vehicles diagnostic system determines that the fuel

filler cap in loose, improperly installed, or damaged, a

GASCAP message will be displayed in the instrumentcluster. Tighten the gas cap until a ªclickingº sound is

heard. This is an indication that the gas cap is properly

tightened. Press the odometer reset button to turn the

message off. If the problem persists, the message will

appear the next time the vehicle is started. This might

indicate a damaged cap. If the problem is detected twice

in a row, the system will turn on the Malfunction

Indicator Light (MIL). Resolving the problem will turn

the MIL light off.

FLEXIBLE FUEL Ð IF EQUIPPED

E-85 General Information

The information in this section is for Flexible Fuel ve-

hicles only. These vehicles can be identified by the unique

yellow gas cap that states, Ethanol (E-85) or Unleaded

Gasoline Only. This section only covers those subjects

that are unique to these vehicles. Please refer to the other

STARTING AND OPERATING 377

5

Page 403 of 554

SNOWPLOW

Snowplow Prep Packages are available as a factory-

installed option. These packages include components

necessary to equip your vehicle with a snowplow.

1500 Models (Light Duty)

NOTE:Do not use 1500 (light duty) Models for snow-

plow applications.

WARNING!

On 1500 Models, snowplows, winches, and other

aftermarket equipment should not be added to the

front end of your vehicle. The airbag crash sensors

may be affected by the change in the front end

structure. The airbags could deploy unexpectedly or

could fail to deploy during a collision resulting in

serious injury or death.

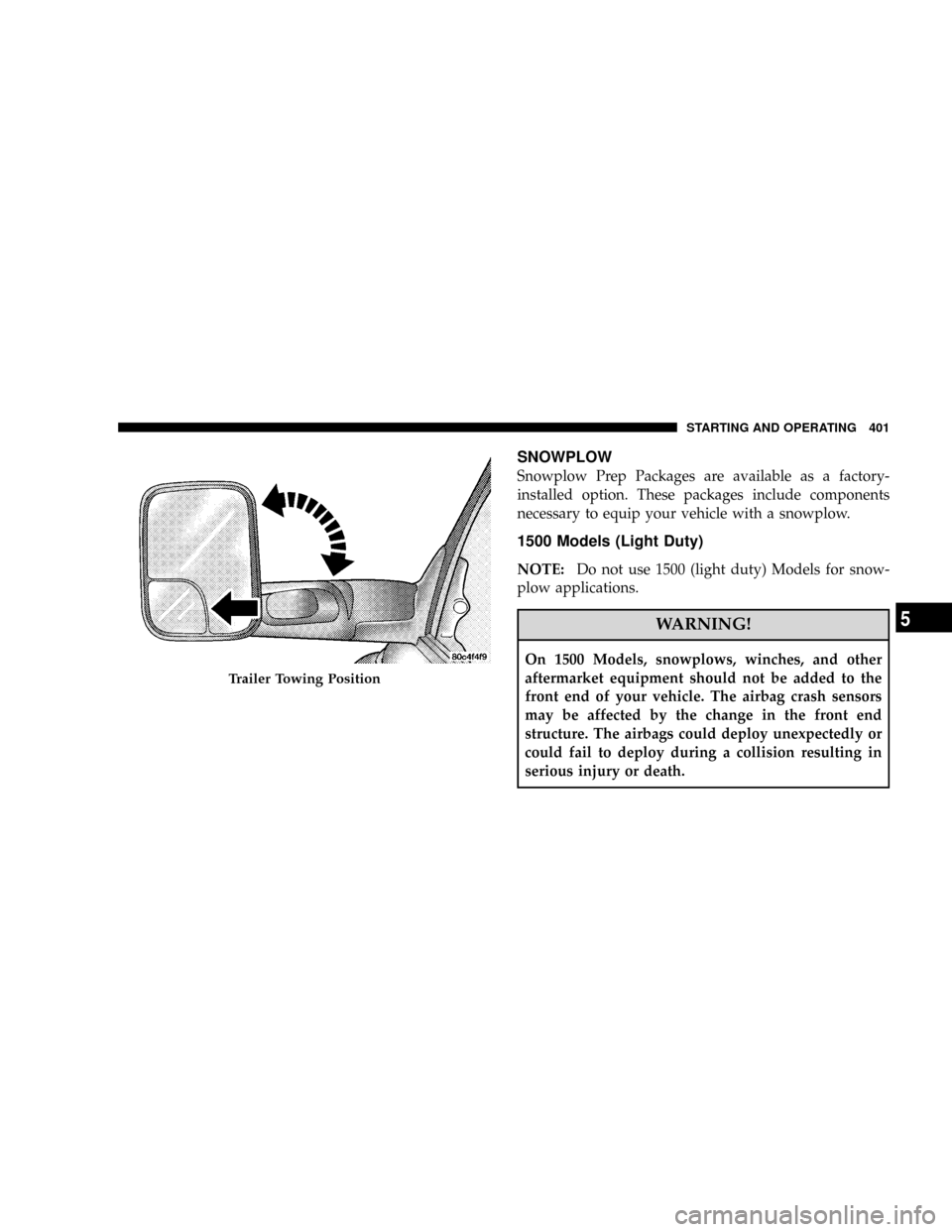

Trailer Towing Position

STARTING AND OPERATING 401

5

Page 414 of 554

NOTE:Steps 1 through 5 are requirements that must be

met prior to depressing the transfer case Neutral (N)

button, and must continue to be met until one second

elapses and the shift has been completed. If any of these

requirements (with the exception of step 3 - key ON) are

not met prior to depressing the Neutral (N) button, or are

no longer met during the one second time, then all of the

mode position indicator lights will flash continuously

until all requirements are met, or until the Neutral (N)

button is released.

NOTE:The ignition key must be ON for a transfer case

shift to take place and for the position indicator lights to

be operable. If the key is not ON, the shift will not take

place and no position indicator lights will be on or

flashing.NOTE:Flashing Neutral position indicator light indi-

cates that shift requirements have not been met.

WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

NEUTRAL position without first fully engaging the

parking brake. The transfer case NEUTRAL position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

despite the transmission position. The parking brake

should always be applied when the driver is not in

the vehicle.

412 STARTING AND OPERATING

Page 418 of 554

HAZARD WARNING FLASHER

The Hazard Warning switch is mounted on the top of the

steering column as shown in the illustration.To engage the Hazard Warning lights, depress the button

on the top of the steering column. When the Hazard

Warning switch is activated, all directional turn signals

will flash off and on to warn oncoming traffic of an

emergency. Push the button a second time to turn off the

flashers.

This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning lights will continue to operate even

though the ignition switch is OFF.

NOTE:With extended use, the Hazard Warning lights

may discharge your battery.

Hazard Light Warning Switch

416 WHAT TO DO IN EMERGENCIES

Page 430 of 554

²Connect the jack tube extension and wheel wrench.

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck

parts and adjust the jack position as required.

NOTE:If the 2500/3500 bottle jack will not lower by

turning the dial (thumbwheel) by hand, it may be neces-

sary to use the jack drive tube in order to lower the jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel on 1500/2500/3500 single

rear-wheel (SRW) models. On 3500 dual rear-wheel mod-

els (DRW) the lug nuts are a two-piece assembly with a

flat face. Lightly tighten the nuts. To avoid risk of forcing

the vehicle off the jack, do not fully tighten the nuts until

the vehicle has been lowered.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft

lbs (183 N´m) torque for 1500/2500/3500 single-rear

wheel (SRW) models, and 145 ft lbs (197 N´m) for 3500

dual rear-wheel models. If in doubt about the correct

tightness, have them checked with a torque wrench by

your authorized dealer or at a service station.

428 WHAT TO DO IN EMERGENCIES