lock DODGE RAM 2500 POWER WAGON 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 POWER WAGON, Model: DODGE RAM 2500 POWER WAGON 2008 3.GPages: 504, PDF Size: 8.17 MB

Page 395 of 504

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

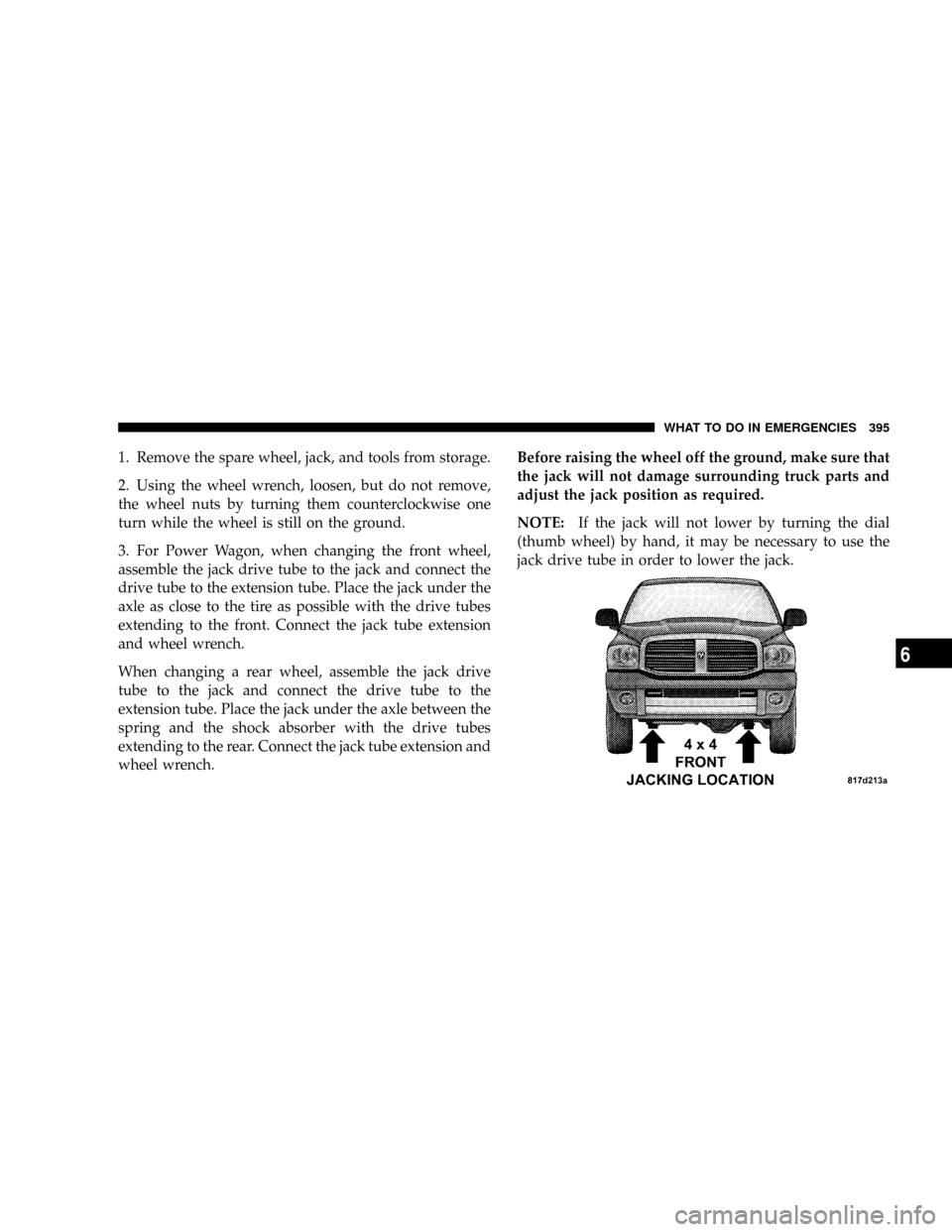

3. For Power Wagon, when changing the front wheel,

assemble the jack drive tube to the jack and connect the

drive tube to the extension tube. Place the jack under the

axle as close to the tire as possible with the drive tubes

extending to the front. Connect the jack tube extension

and wheel wrench.

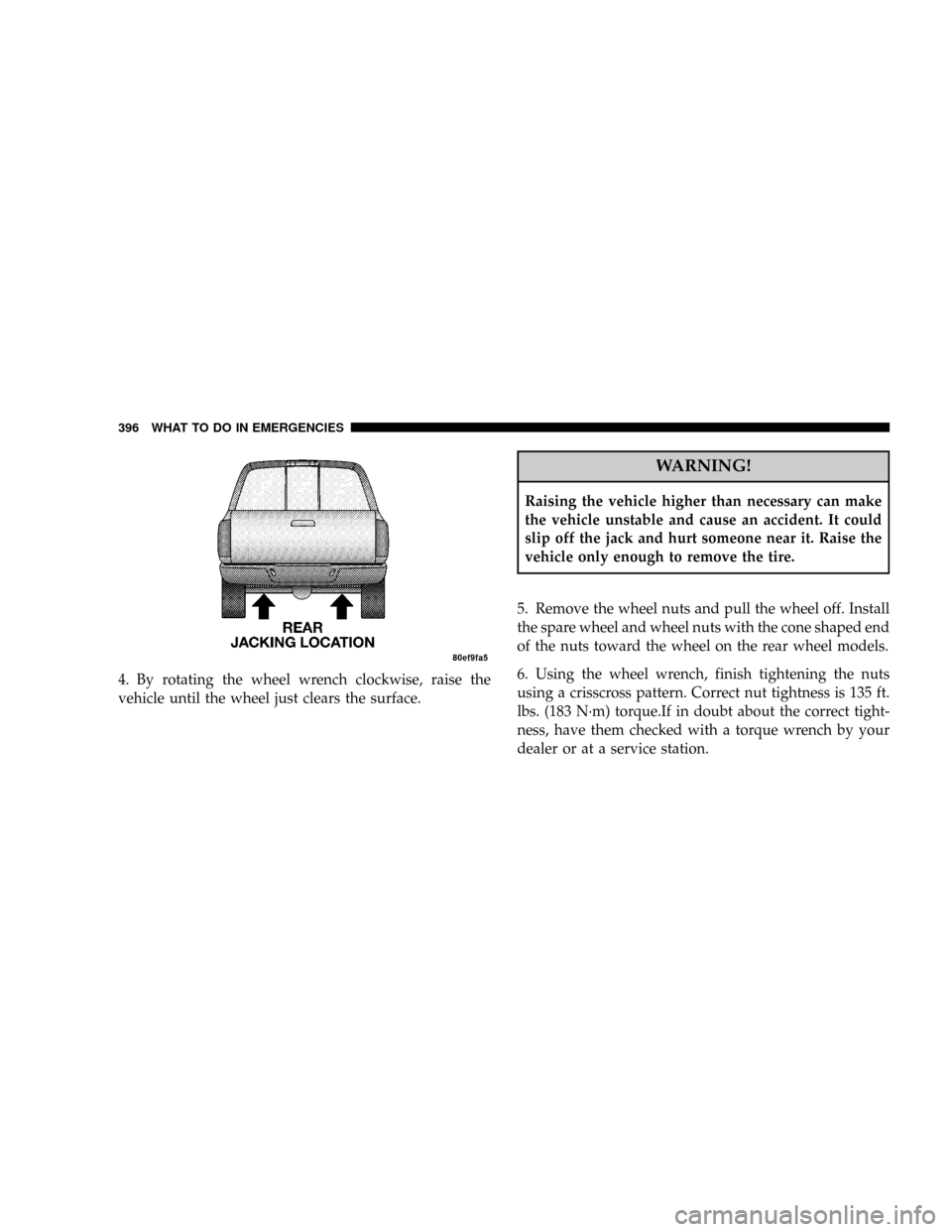

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear. Connect the jack tube extension and

wheel wrench.Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

NOTE:If the jack will not lower by turning the dial

(thumb wheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

WHAT TO DO IN EMERGENCIES 395

6

Page 396 of 504

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel on the rear wheel models.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N´m) torque.If in doubt about the correct tight-

ness, have them checked with a torque wrench by your

dealer or at a service station.

396 WHAT TO DO IN EMERGENCIES

Page 397 of 504

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Remove wheel blocks. Do not install chrome or alu-

minum wheel center caps on the spare wheel. This may

result in cap damage.

8. Lower the jack to its fully closed position. If the jack

will not lower by turning the dial (thumb wheel) by

hand, it may be necessary to use the jack drive tube in

order to lower the jack. Stow the replaced tire, jack, and

tools as previously described.

9. Adjust the tire pressure when possible.NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.Hub Caps

The hub caps must be removed before raising the vehicle

off the ground.

For 2500/3500 single rear wheel (SRW) models, use the

blade on the end of the lug wrench to pry the hub cap off.

Insert the blade end into the pryoff notch and carefully

pop off the hub cap with a back and forth motion.

CAUTION!

Use a back and forth motion to remove the hub cap.

Do not use a twisting motion when removing the hub

cap, damage to the hub cap finish may occur.

WHAT TO DO IN EMERGENCIES 397

6

Page 424 of 504

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, tailgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

The rubber edges of the wiper blades and the windshield

should be cleaned periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove accu-

mulations of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

Windshield Washers

The fluid reservoir is located under the hood and should

be checked for fluid level at regular intervals. Fill the

reservoir with windshield washer solvent only (not ra-

diator antifreeze).

424 MAINTAINING YOUR VEHICLE

Page 448 of 504

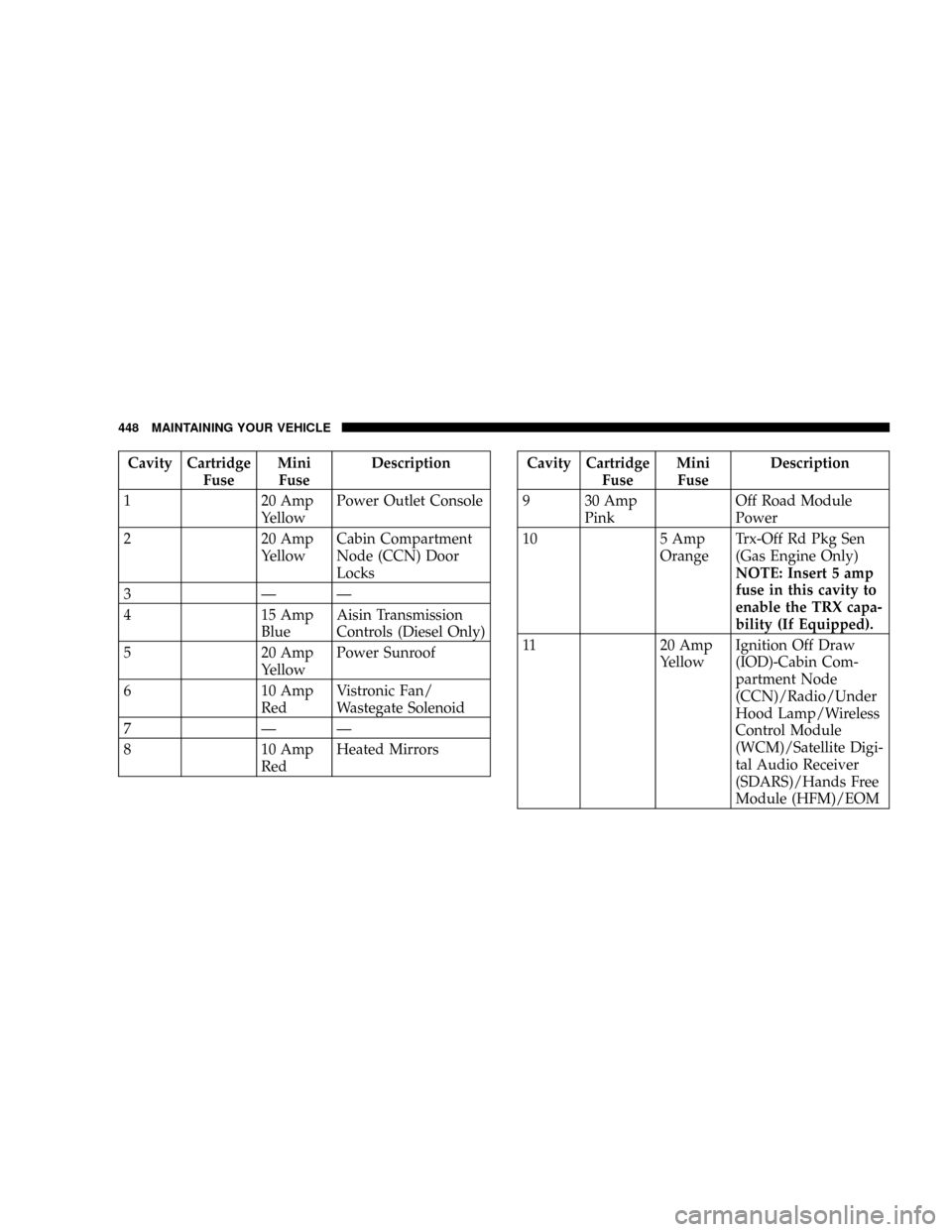

Cavity Cartridge

FuseMini

FuseDescription

1 20 Amp

YellowPower Outlet Console

2 20 Amp

YellowCabin Compartment

Node (CCN) Door

Locks

3ÐÐ

4 15 Amp

BlueAisin Transmission

Controls (Diesel Only)

5 20 Amp

YellowPower Sunroof

6 10 Amp

RedVistronic Fan/

Wastegate Solenoid

7ÐÐ

8 10 Amp

RedHeated MirrorsCavity Cartridge

FuseMini

FuseDescription

9 30 Amp

PinkOff Road Module

Power

10 5 Amp

OrangeTrx-Off Rd Pkg Sen

(Gas Engine Only)

NOTE: Insert 5 amp

fuse in this cavity to

enable the TRX capa-

bility (If Equipped).

11 20 Amp

YellowIgnition Off Draw

(IOD)-Cabin Com-

partment Node

(CCN)/Radio/Under

Hood Lamp/Wireless

Control Module

(WCM)/Satellite Digi-

tal Audio Receiver

(SDARS)/Hands Free

Module (HFM)/EOM

448 MAINTAINING YOUR VEHICLE

Page 452 of 504

VEHICLE STORAGE

If you are storing your vehicle for more than 21 days, we

recommend that you take the following steps to mini-

mize the drain on your vehicle's battery:

²Disconnect the Ignition-Off Draw fuse (I.O.D.) fuse

located in the Integrated Power Module, located in the

engine compartment. The I.O.D. cavity includes a

snap-in retainer that allows the fuse to be discon-

nected, without removing it from the fuse block.

²The electronic shift transfer case should be placed in

the 4HI mode and kept in this position to minimize the

battery drain.

²As an alternative to the above steps you may, discon-

nect the negative cables from both batteries.

²Anytime you store your vehicle, or keep it out of

service (i.e. vacation) for two weeks or more, run the

air conditioning system at idle for about five minutesin the fresh air and high blower setting. This will

insure adequate system lubrication to minimize the

possibility of compressor damage when the system is

started again.

NOTE:When reinstalling the IOD fuse push firmly until

fully seated, the gages in the Instrument Cluster will do

a full sweep, when the ignition key is cycled to RUN. This

is a normal condition.

NOTE:When the vehicle is shipped from the factory,

the IOD fuse is in the up, or extracted position. If the

radio, interior lamps, keyless entry, or other features do

not work with the key off, check the position of the fuse

(or check to see if the fuse is blown) to ensure that it is

fully seated. When the IOD fuse is extracted, the instru-

ment cluster, in the odometer window, will display9NO

FUSE

452 MAINTAINING YOUR VEHICLE

Page 456 of 504

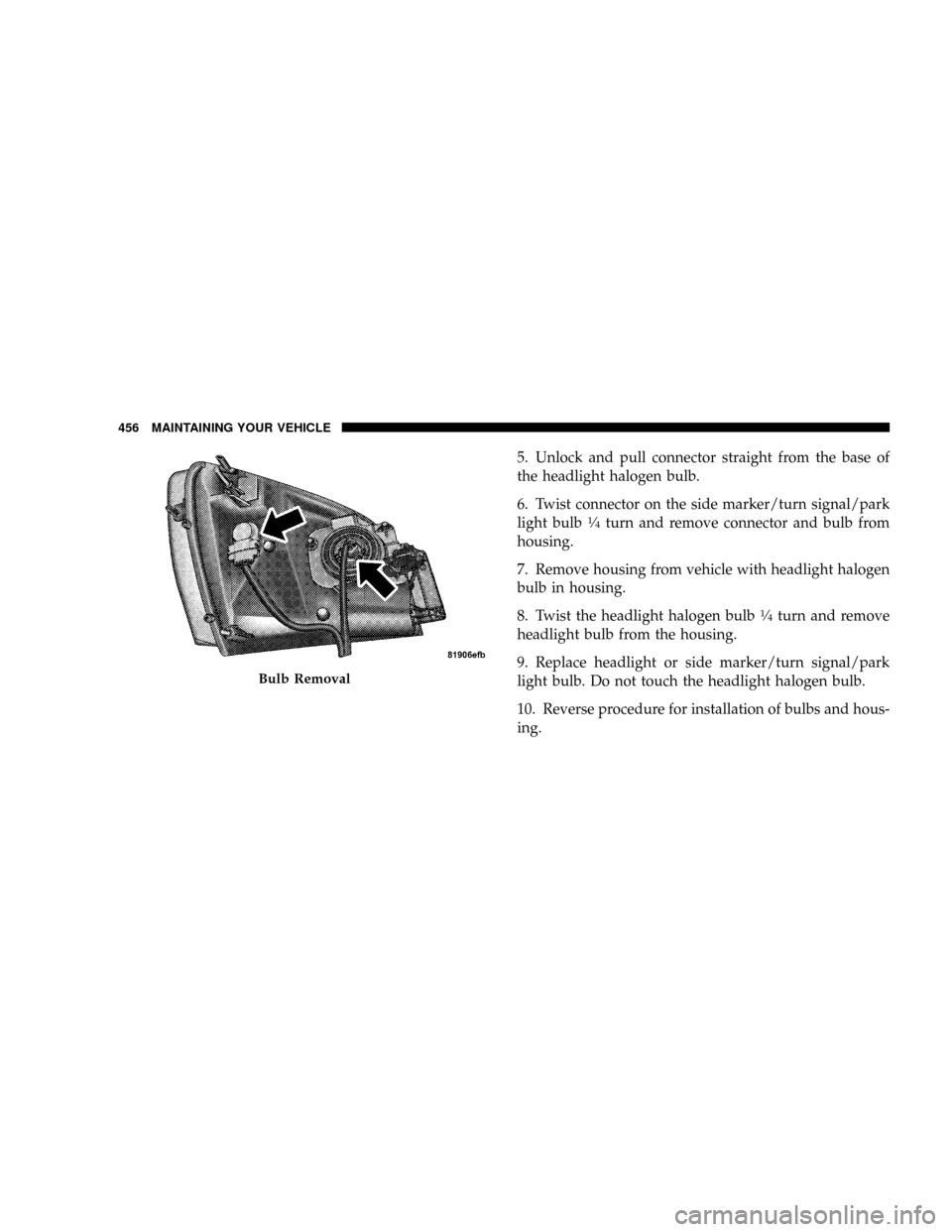

5. Unlock and pull connector straight from the base of

the headlight halogen bulb.

6. Twist connector on the side marker/turn signal/park

light bulb

1¤4turn and remove connector and bulb from

housing.

7. Remove housing from vehicle with headlight halogen

bulb in housing.

8. Twist the headlight halogen bulb

1¤4turn and remove

headlight bulb from the housing.

9. Replace headlight or side marker/turn signal/park

light bulb. Do not touch the headlight halogen bulb.

10. Reverse procedure for installation of bulbs and hous-

ing.

Bulb Removal

456 MAINTAINING YOUR VEHICLE

Page 458 of 504

3. Rotate the bulb socket counterclockwise to remove

from the housing.4. Pull bulb straight out of socket.

Rotating Bulb Socket From Housing

Pulling Bulb From Socket

458 MAINTAINING YOUR VEHICLE

Page 459 of 504

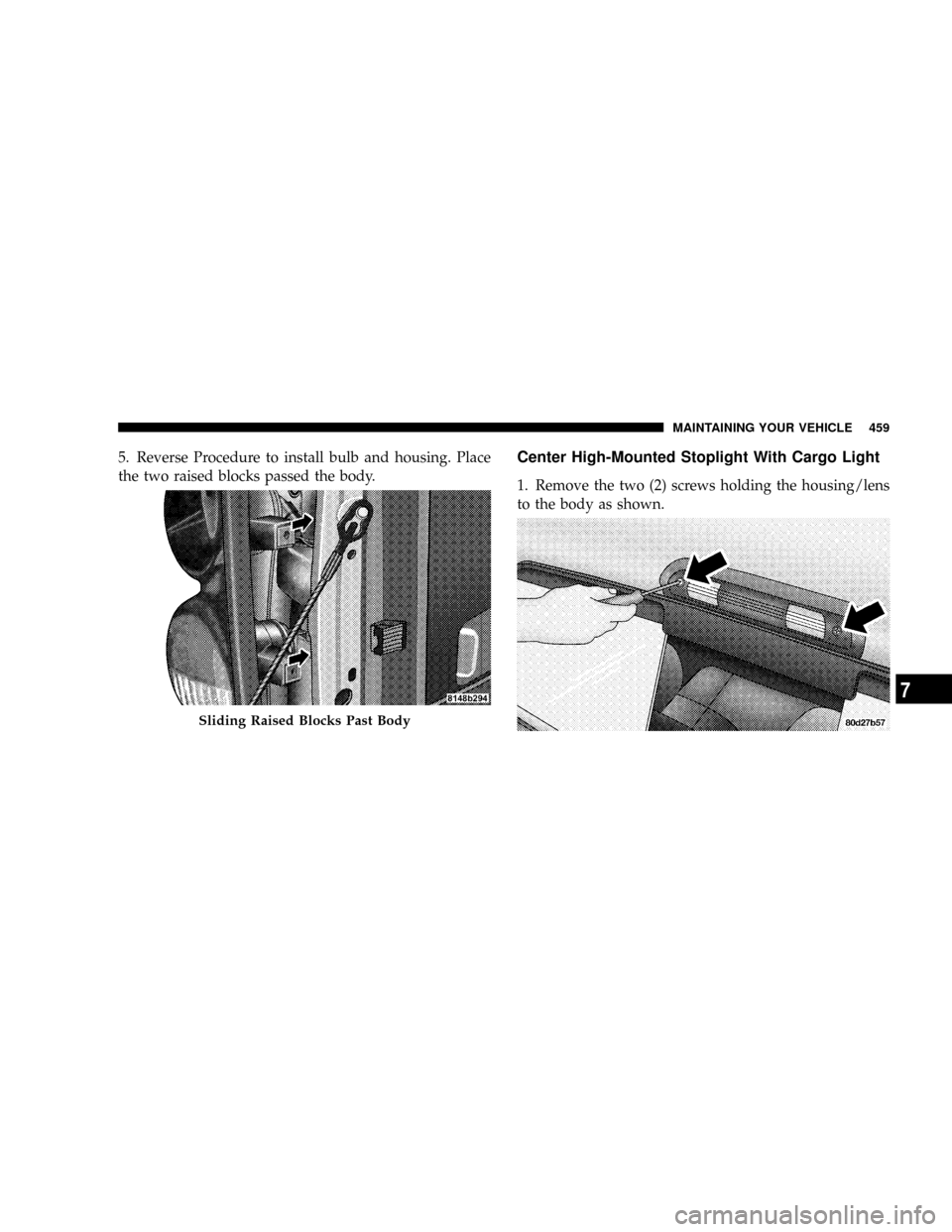

5. Reverse Procedure to install bulb and housing. Place

the two raised blocks passed the body.Center High-Mounted Stoplight With Cargo Light

1. Remove the two (2) screws holding the housing/lens

to the body as shown.

Sliding Raised Blocks Past Body

MAINTAINING YOUR VEHICLE 459

7

Page 463 of 504

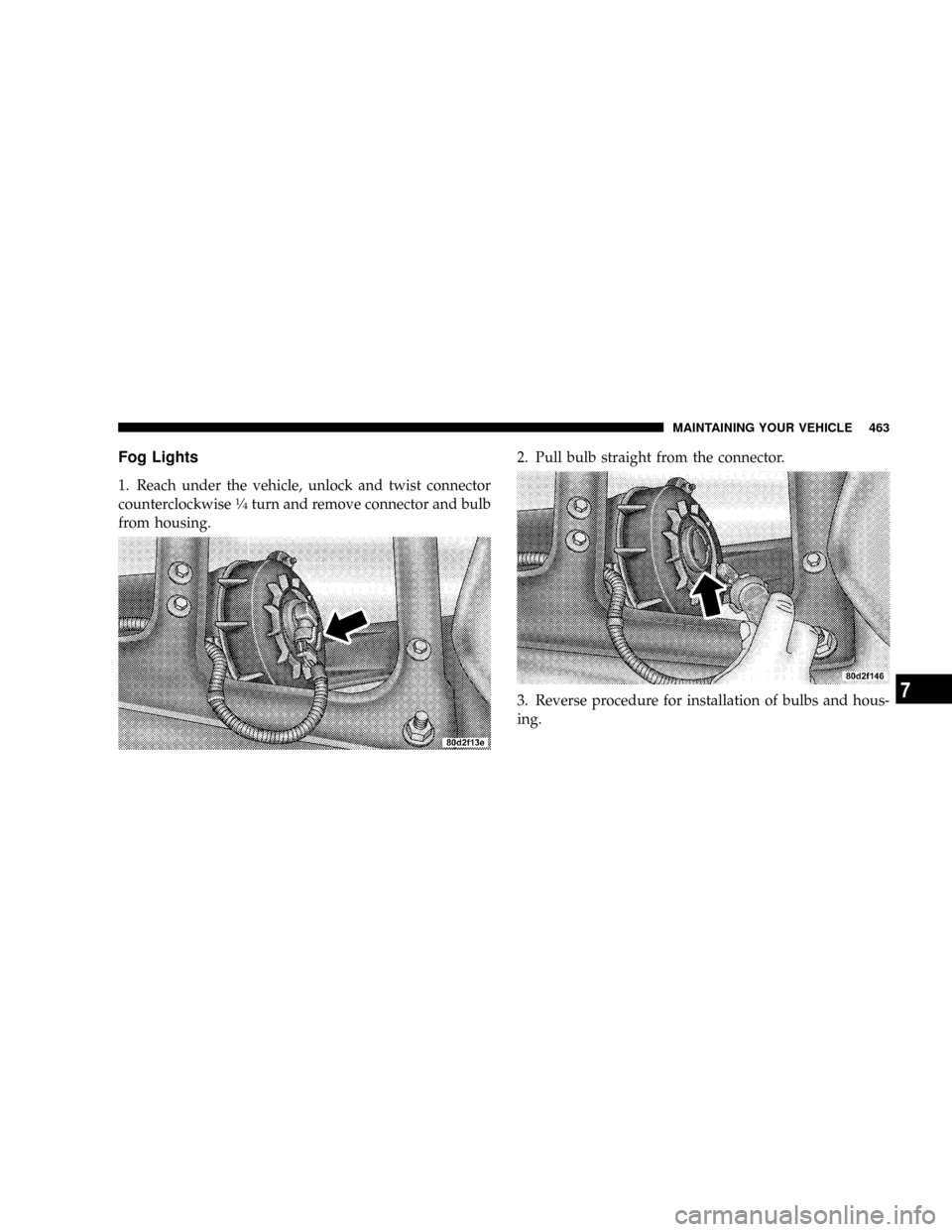

Fog Lights

1. Reach under the vehicle, unlock and twist connector

counterclockwise1¤4turn and remove connector and bulb

from housing.2. Pull bulb straight from the connector.

3. Reverse procedure for installation of bulbs and hous-

ing.

MAINTAINING YOUR VEHICLE 463

7