DODGE RAM 2500 POWER WAGON 2008 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2008, Model line: RAM 2500 POWER WAGON, Model: DODGE RAM 2500 POWER WAGON 2008 3.GPages: 504, PDF Size: 8.17 MB

Page 391 of 504

JACKING AND TIRE CHANGING

WARNING!

²Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you

need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

²The jack is designed to use as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or

slippery areas.

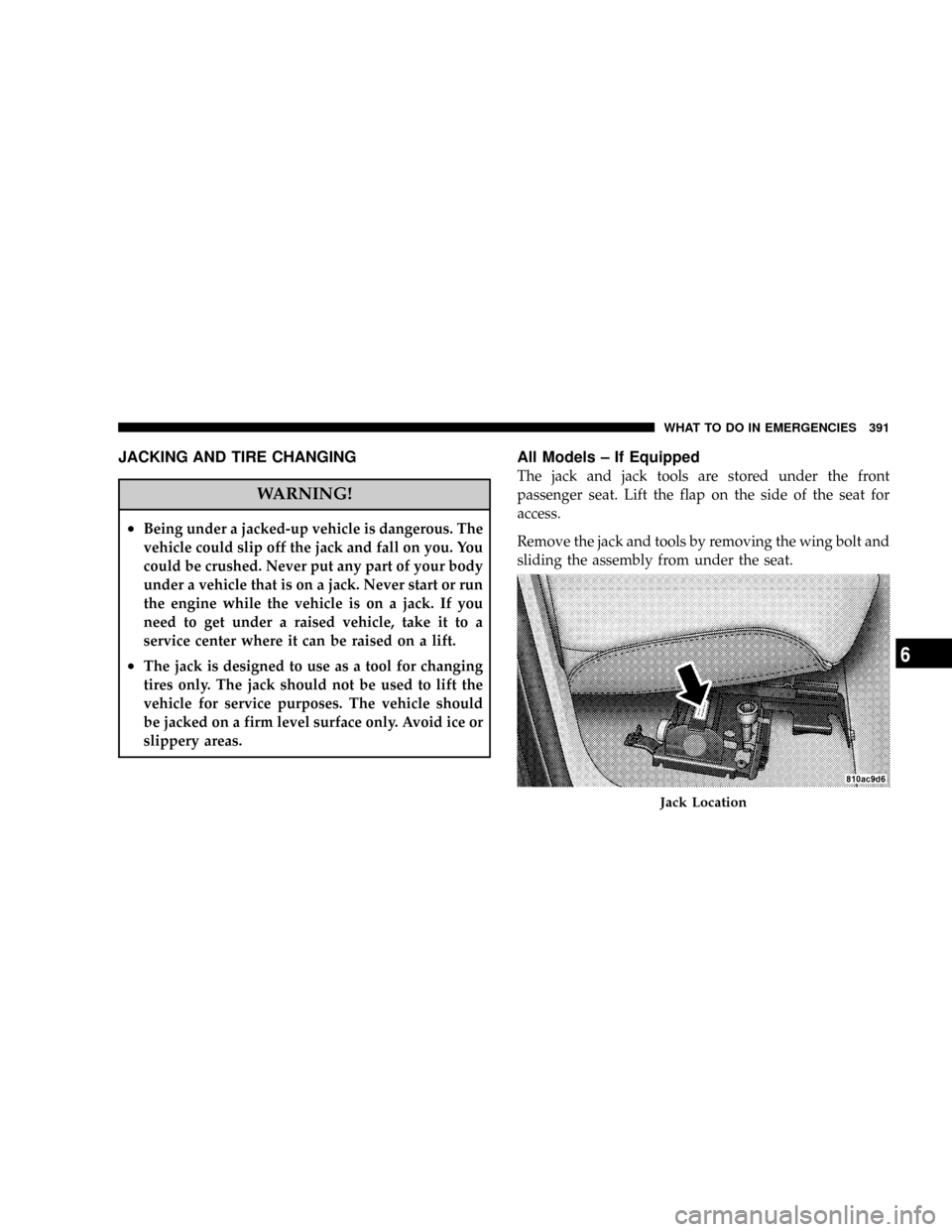

All Models ± If Equipped

The jack and jack tools are stored under the front

passenger seat. Lift the flap on the side of the seat for

access.

Remove the jack and tools by removing the wing bolt and

sliding the assembly from under the seat.

Jack Location

WHAT TO DO IN EMERGENCIES 391

6

Page 392 of 504

WARNING!

After using the jack and tools, always reinstall them

in the original carrier and location. While driving

you may experience, abrupt stopping, rapid accelera-

tion, or sharp turns. A loose jack, tools, bracket or

other objects in the vehicle may move around with

force, resulting in serious injury.

JACKING INSTRUCTIONS

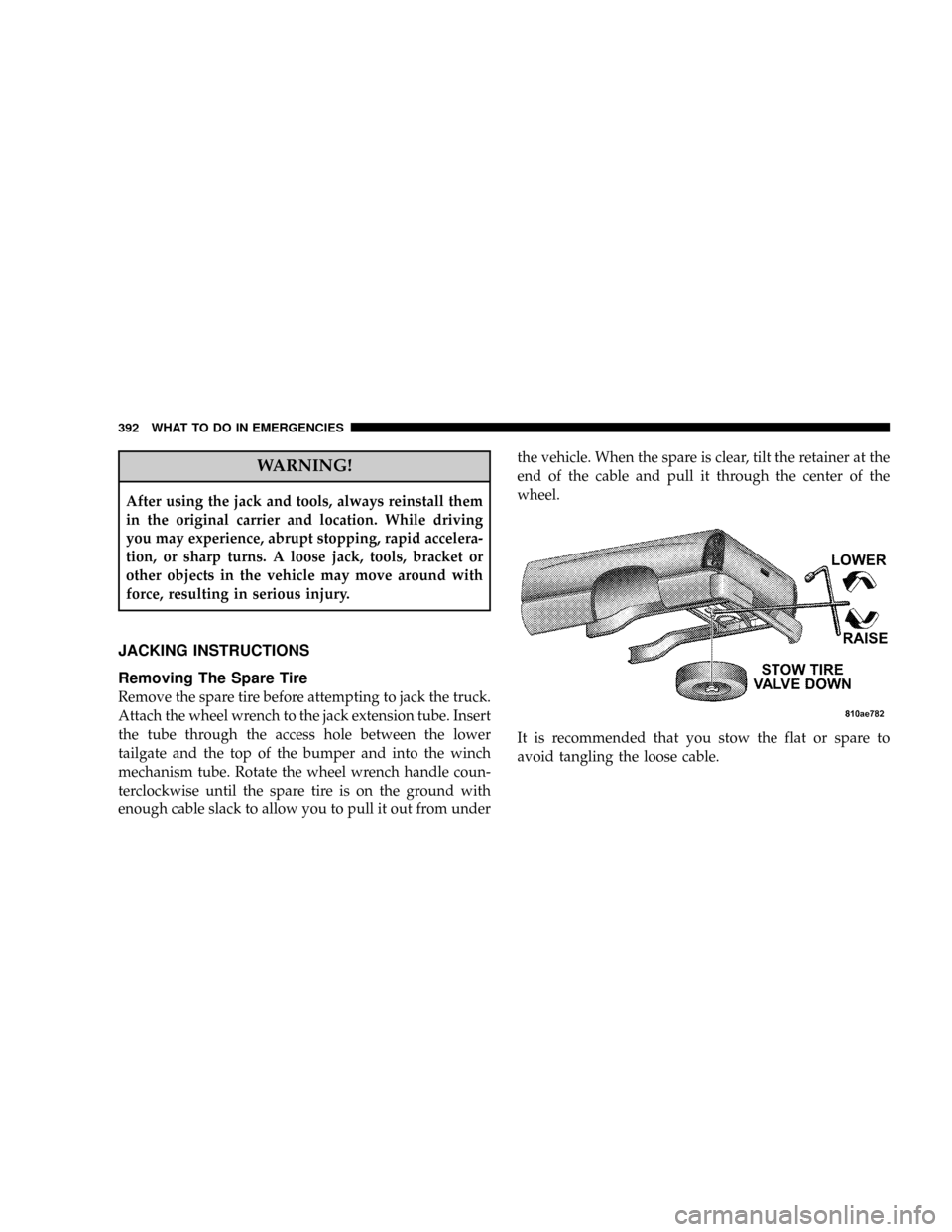

Removing The Spare Tire

Remove the spare tire before attempting to jack the truck.

Attach the wheel wrench to the jack extension tube. Insert

the tube through the access hole between the lower

tailgate and the top of the bumper and into the winch

mechanism tube. Rotate the wheel wrench handle coun-

terclockwise until the spare tire is on the ground with

enough cable slack to allow you to pull it out from underthe vehicle. When the spare is clear, tilt the retainer at the

end of the cable and pull it through the center of the

wheel.

It is recommended that you stow the flat or spare to

avoid tangling the loose cable.

392 WHAT TO DO IN EMERGENCIES

Page 393 of 504

NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to a service center

where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The jack is

designed as a tool for changing tires on this vehicle only.It is not recommended that the jack be used for service

purposes or to lift more than one wheel at a time.

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the gear

selector in PARK (automatic transmission) or REVERSE

(manual transmission). On four-wheel drive vehicles,

shift the transfer case to the ª4Lº position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the Hazard Warning Flasher.

WHAT TO DO IN EMERGENCIES 393

6

Page 394 of 504

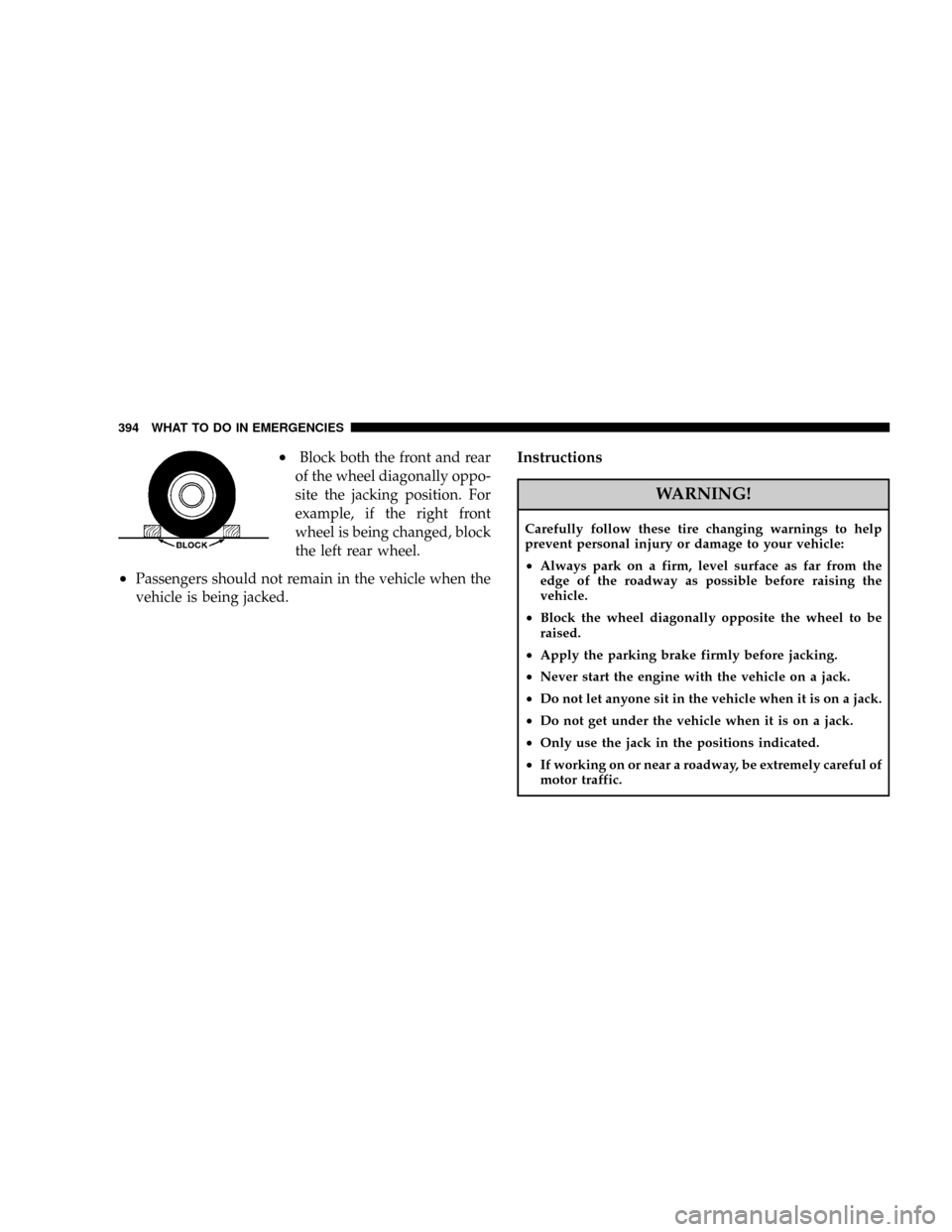

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Block the wheel diagonally opposite the wheel to be

raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely careful of

motor traffic.

394 WHAT TO DO IN EMERGENCIES

Page 395 of 504

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

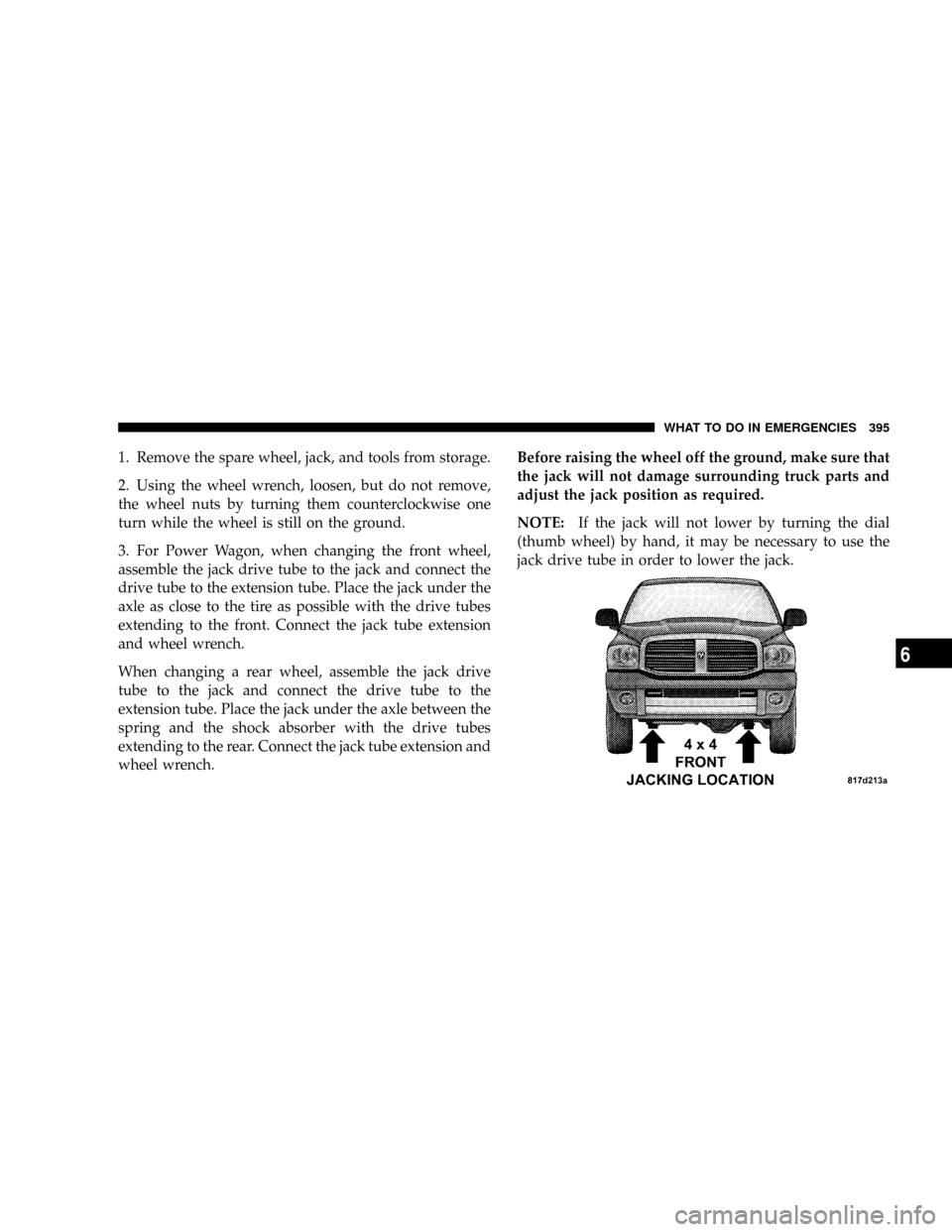

3. For Power Wagon, when changing the front wheel,

assemble the jack drive tube to the jack and connect the

drive tube to the extension tube. Place the jack under the

axle as close to the tire as possible with the drive tubes

extending to the front. Connect the jack tube extension

and wheel wrench.

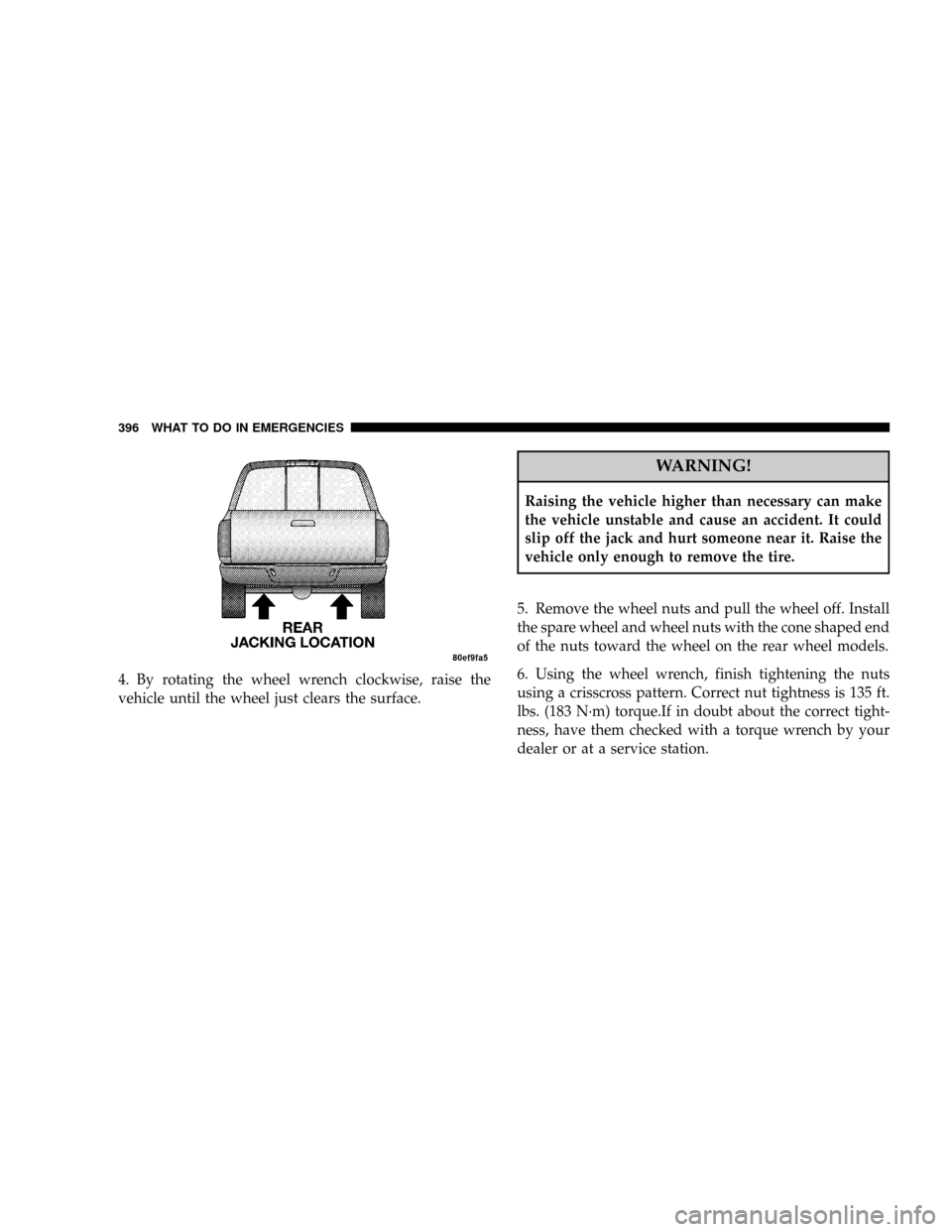

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear. Connect the jack tube extension and

wheel wrench.Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

NOTE:If the jack will not lower by turning the dial

(thumb wheel) by hand, it may be necessary to use the

jack drive tube in order to lower the jack.

WHAT TO DO IN EMERGENCIES 395

6

Page 396 of 504

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel on the rear wheel models.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N´m) torque.If in doubt about the correct tight-

ness, have them checked with a torque wrench by your

dealer or at a service station.

396 WHAT TO DO IN EMERGENCIES

Page 397 of 504

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Remove wheel blocks. Do not install chrome or alu-

minum wheel center caps on the spare wheel. This may

result in cap damage.

8. Lower the jack to its fully closed position. If the jack

will not lower by turning the dial (thumb wheel) by

hand, it may be necessary to use the jack drive tube in

order to lower the jack. Stow the replaced tire, jack, and

tools as previously described.

9. Adjust the tire pressure when possible.NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.Hub Caps

The hub caps must be removed before raising the vehicle

off the ground.

For 2500/3500 single rear wheel (SRW) models, use the

blade on the end of the lug wrench to pry the hub cap off.

Insert the blade end into the pryoff notch and carefully

pop off the hub cap with a back and forth motion.

CAUTION!

Use a back and forth motion to remove the hub cap.

Do not use a twisting motion when removing the hub

cap, damage to the hub cap finish may occur.

WHAT TO DO IN EMERGENCIES 397

6

Page 398 of 504

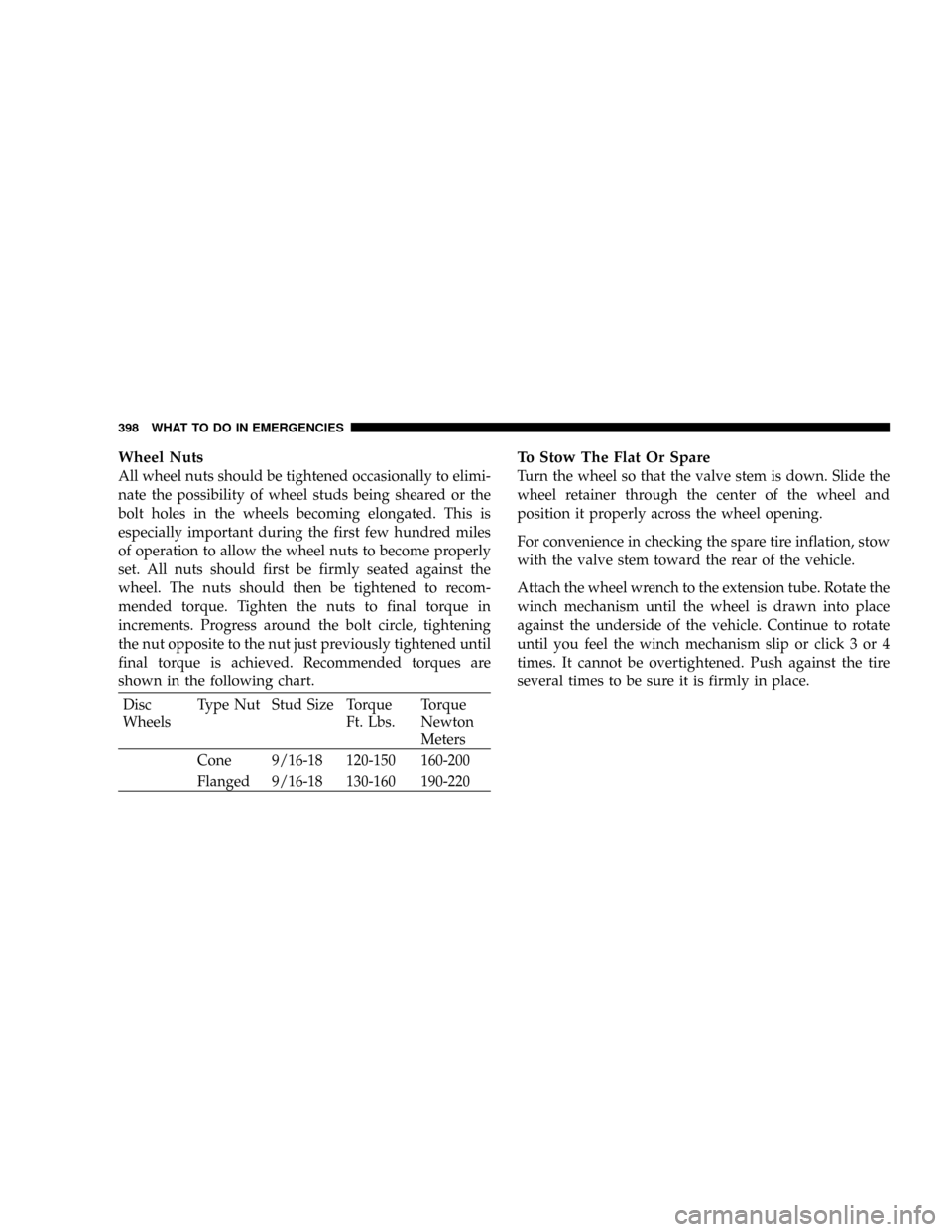

Wheel Nuts

All wheel nuts should be tightened occasionally to elimi-

nate the possibility of wheel studs being sheared or the

bolt holes in the wheels becoming elongated. This is

especially important during the first few hundred miles

of operation to allow the wheel nuts to become properly

set. All nuts should first be firmly seated against the

wheel. The nuts should then be tightened to recom-

mended torque. Tighten the nuts to final torque in

increments. Progress around the bolt circle, tightening

the nut opposite to the nut just previously tightened until

final torque is achieved. Recommended torques are

shown in the following chart.

Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip or click 3 or 4

times. It cannot be overtightened. Push against the tire

several times to be sure it is firmly in place.

398 WHAT TO DO IN EMERGENCIES

Page 399 of 504

HOISTING

A conventional floor jack may be used at the jacking

locations, refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

JUMP-STARTING

You should not try to start your vehicle by pushing or

towing. Vehicles equipped with an automatic transmis-

sion cannot be started this way and pushing or towing a

vehicle equipped with a manual transmission may over-

heat and damage the catalytic converter. Also, there is a

greater risk of an accident when a vehicle is being pushed

or towed. If the vehicle has a discharged battery, booster

cables may be used to obtain a start from a booster

battery or the battery in another vehicle. This type of start

can be dangerous if done improperly, so follow this

procedure carefully.

WHAT TO DO IN EMERGENCIES 399

6

Page 400 of 504

WARNING!

Battery fluid is a corrosive acid solution; do not allow

battery fluid to contact eyes, skin or clothing. Don't

lean over battery when attaching clamps or allow the

clamps to touch each other. If acid splashes in eyes or

on skin, flush contaminated area immediately with

large quantities of water.

A battery generates hydrogen gas which is flam-

mable and explosive. Keep flame or spark away from

the vent holes.

Do not use a booster battery or any other booster

source that has a greater than 12 volt system, i.e. Do

not use a 24 volt power source.

1. Remove all metal jewelry such as watch bands or

bracelets which might make an unintended electrical

contact.2. Park the booster vehicle within cable reach but with-

out letting the vehicles touch. Set the parking brake on

both vehicles, place the automatic transmission in Park or

the manual transmission in Neutral, and turn the ignition

OFF.

3. Turn off the heater, radio, and all unnecessary electri-

cal loads.

4. Connect one end of a jumper cable to the positive

terminal of the booster battery. Connect the other end of

the same cable to the positive terminal of the discharged

battery.

WARNING!

Do not permit vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

400 WHAT TO DO IN EMERGENCIES