clock DODGE RAM 3500 CHASSIS CAB 2008 3.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 3500 CHASSIS CAB, Model: DODGE RAM 3500 CHASSIS CAB 2008 3.GPages: 528, PDF Size: 7.84 MB

Page 223 of 528

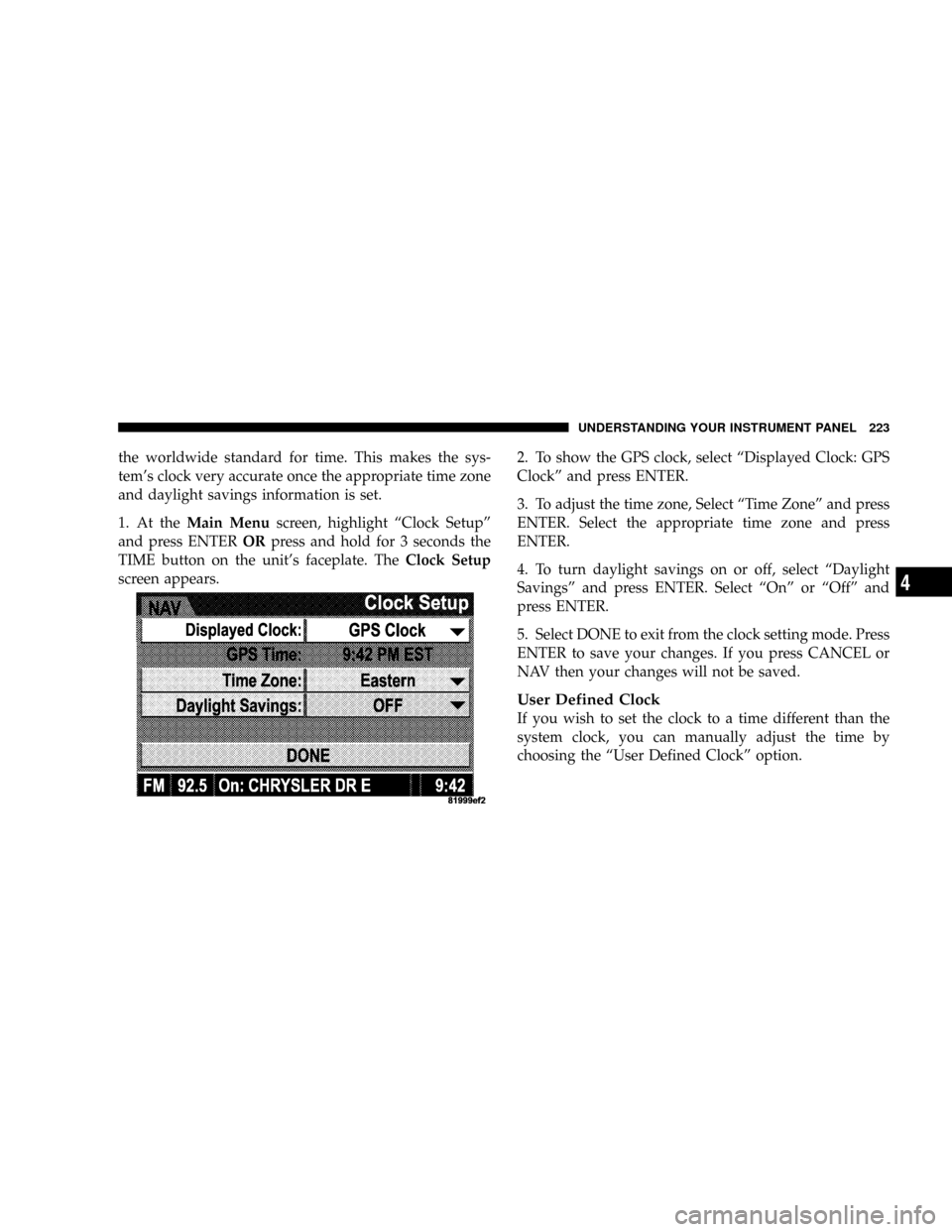

the worldwide standard for time. This makes the sys-

tem's clock very accurate once the appropriate time zone

and daylight savings information is set.

1. At theMain Menuscreen, highlight ªClock Setupº

and press ENTERORpress and hold for 3 seconds the

TIME button on the unit's faceplate. TheClock Setup

screen appears.2. To show the GPS clock, select ªDisplayed Clock: GPS

Clockº and press ENTER.

3. To adjust the time zone, Select ªTime Zoneº and press

ENTER. Select the appropriate time zone and press

ENTER.

4. To turn daylight savings on or off, select ªDaylight

Savingsº and press ENTER. Select ªOnº or ªOffº and

press ENTER.

5. Select DONE to exit from the clock setting mode. Press

ENTER to save your changes. If you press CANCEL or

NAV then your changes will not be saved.

User Defined Clock

If you wish to set the clock to a time different than the

system clock, you can manually adjust the time by

choosing the ªUser Defined Clockº option.

UNDERSTANDING YOUR INSTRUMENT PANEL 223

4

Page 224 of 528

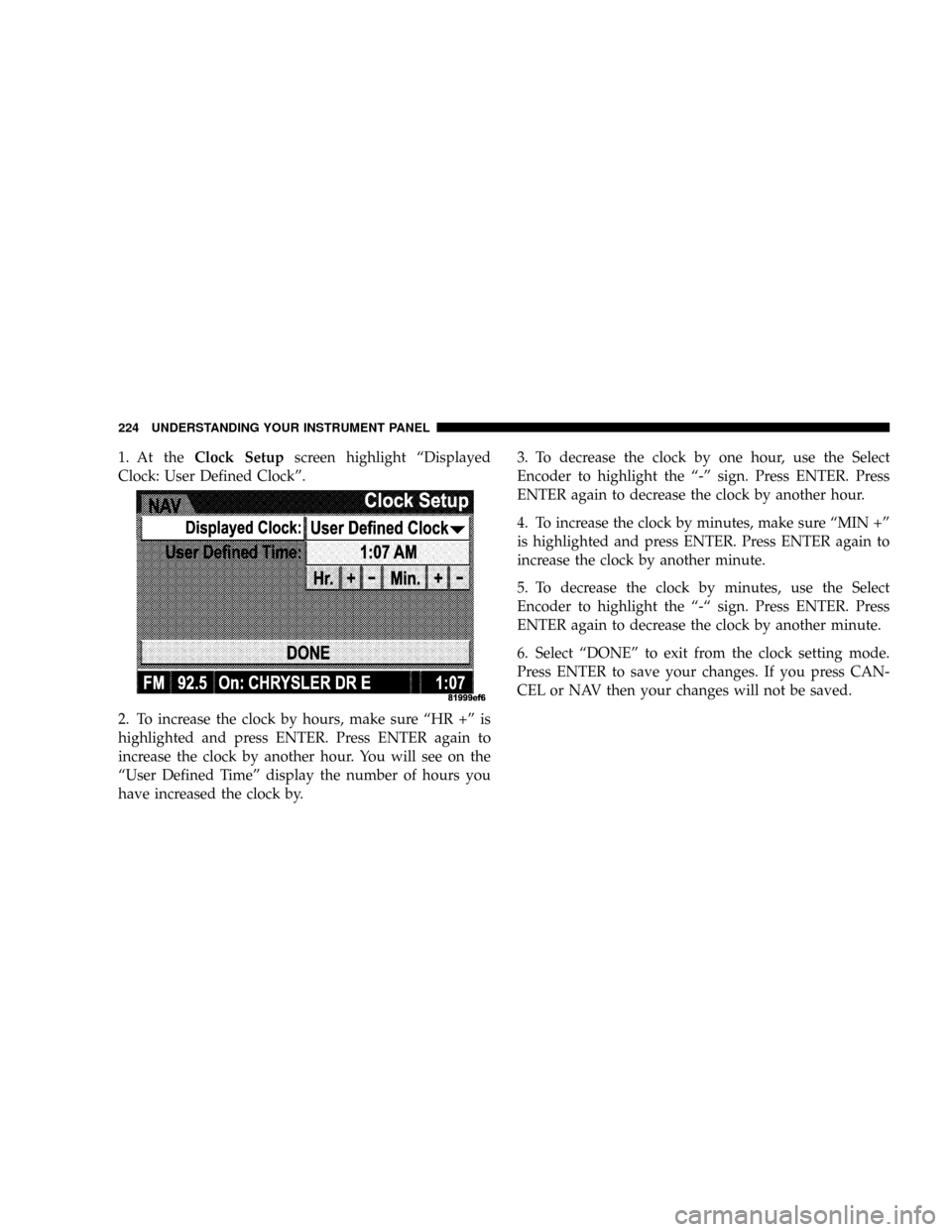

1. At theClock Setupscreen highlight ªDisplayed

Clock: User Defined Clockº.

2. To increase the clock by hours, make sure ªHR +º is

highlighted and press ENTER. Press ENTER again to

increase the clock by another hour. You will see on the

ªUser Defined Timeº display the number of hours you

have increased the clock by.3. To decrease the clock by one hour, use the Select

Encoder to highlight the ª-º sign. Press ENTER. Press

ENTER again to decrease the clock by another hour.

4. To increase the clock by minutes, make sure ªMIN +º

is highlighted and press ENTER. Press ENTER again to

increase the clock by another minute.

5. To decrease the clock by minutes, use the Select

Encoder to highlight the ª-ª sign. Press ENTER. Press

ENTER again to decrease the clock by another minute.

6. Select ªDONEº to exit from the clock setting mode.

Press ENTER to save your changes. If you press CAN-

CEL or NAV then your changes will not be saved.

224 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 225 of 528

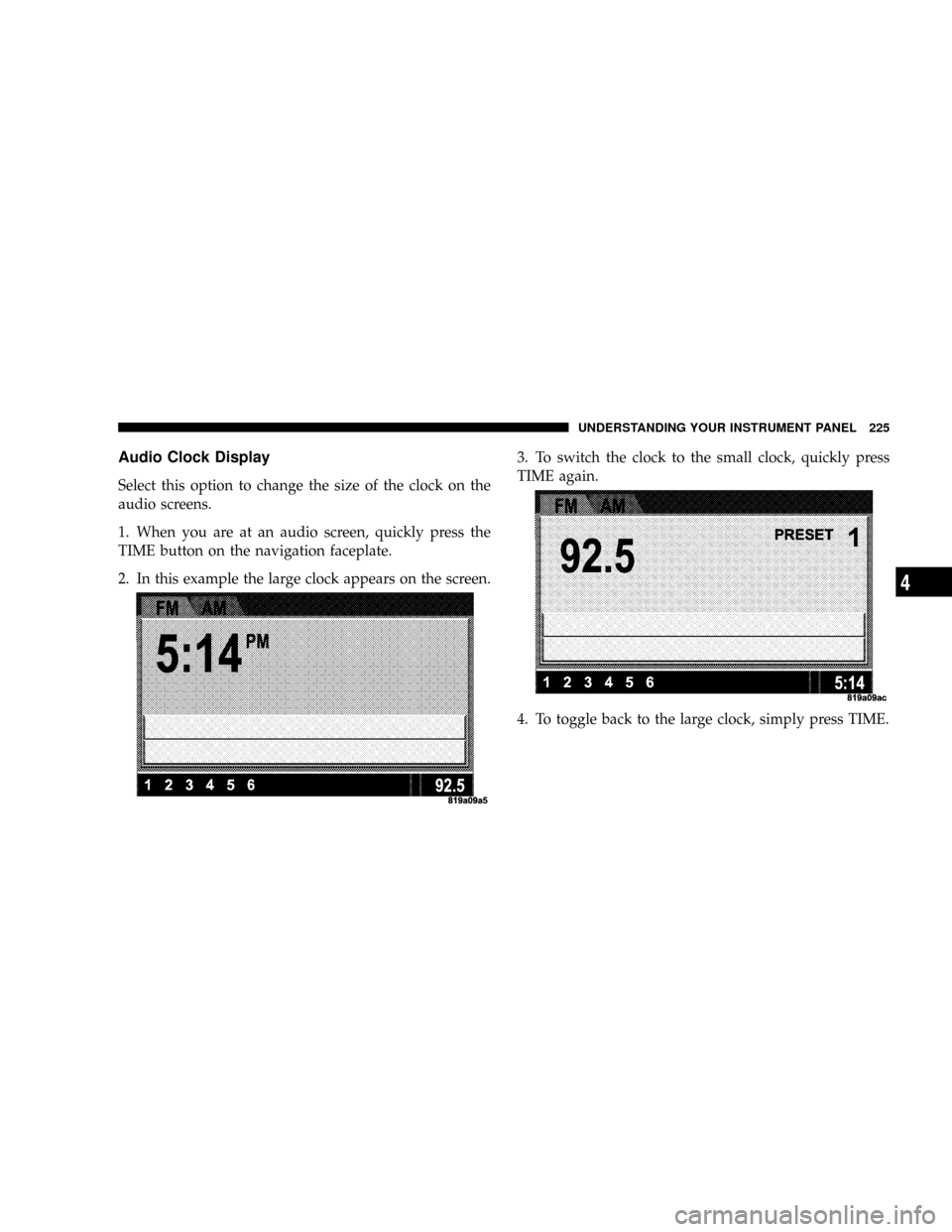

Audio Clock Display

Select this option to change the size of the clock on the

audio screens.

1. When you are at an audio screen, quickly press the

TIME button on the navigation faceplate.

2. In this example the large clock appears on the screen.3. To switch the clock to the small clock, quickly press

TIME again.

4. To toggle back to the large clock, simply press TIME.

UNDERSTANDING YOUR INSTRUMENT PANEL 225

4

Page 236 of 528

Defrost

Outside air is primarily directed to the windshield

through the defroster outlets located at the base of

the windshield, and the demister outlets located at the

edge of each side of the instrument panel.

Blower Control

The rotary knob on the left of the

control panel is the blower control.

Turn the knob clockwise to one of the

four positions to obtain the blower

speed you desire. To turn the blower

off, turn the knob to the far left posi-

tion.

Temperature Control

The rotary knob at the center of the

control panel controls the temperature

of the interior air. You can choose your

degree of comfort by rotating the

knob. The coldest temperature setting

is to the extreme left (blue region) and

the warmest setting is to the extreme

right (red region) of the rotation.

236 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 239 of 528

Defrost

Outside air is primarily directed to the windshield

through the defroster outlets located at the base of

the windshield, and the demister outlets located at the

edge of each side of the instrument panel, and the air

conditioning may be on.

Blower Control

The rotary knob on the left of the

control panel is the blower control.

Turn the knob clockwise to one of the

four positions to obtain the blower

speed you desire. To turn the blower

off, turn the knob to the far left posi-

tion.

Temperature Control

The rotary knob at the center of the

control panel controls the temperature

of the interior air. You can choose your

degree of comfort by rotating the

knob. The coldest temperature setting

is to the extreme left (blue region) and

the warmest setting is to the extreme

right (red region) of the rotation.

Circulation

The cab is designed with features to promote outside air

circulation. There are grilles in the cab back panel. These

are air exhausters that provide the means for regular

exchange of cab air.

Side window demisters direct air flow specifically to the

window glass to help prevent interior fogging of the

glass. They are located in the extreme outside upper

UNDERSTANDING YOUR INSTRUMENT PANEL 239

4

Page 242 of 528

the major modes. These intermediate positions are iden-

tified by the small dots and give an even blend of both

modes.

Panel

Outside air flows through the outlets located in the

instrument panel. These outlets can be adjusted to

direct the airflow.

Bi-Level

Air flows through the outlets located in the instru-

ment panel and those located on the floor.

NOTE:There is a difference in temperature between the

upper and lower outlets for added comfort. The warmer

air goes to the floor outlets. This feature gives improved

comfort during sunny but cool conditions.

Heat

Outside air flows primarily through the floor out-

lets located under the instrument panel.

Mix

Outside air flows in equal proportions through the

floor and defroster outlets.

Defrost

Outside air is primarily directed to the windshield

through the defroster outlets located at the base of

the windshield and side window demist outlets.

NOTE:The air conditioning compressor operates in

both Mix and Defrost or a blend of these modes, even if

the A/C button has not been pressed. This dehumidifies

the air to help dry the windshield.

Blower Control

The rotary knob on the left of the con-

trol panel is the blower control. Turn the

knob clockwise to one of the four posi-

tions to obtain the blower speed you

desire. To turn the blower off, turn the

knob to the far left position.

242 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 382 of 528

Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from

the edge of the roadway as possible before raising

the vehicle.

²Block the wheel diagonally opposite the wheel to

be raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a

jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely

careful of motor traffic.1. If equipped, remove the spare wheel, jack, and tools

from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

3. When changing the front wheel, assemble the jack

drive tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle as close to

the tire as possible with the drive tubes extending to the

front. Connect the jack tube extension and wheel wrench.

382 WHAT TO DO IN EMERGENCIES

Page 384 of 528

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel on single rear wheel (SRW)

models. On dual rear wheel models (DRW) the lug nuts

are a two piece assembly with a flat face. Lightly tighten

the nuts. To avoid risk of forcing the vehicle off the jack,

do not fully tighten the nuts until the vehicle has been

lowered.6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N´m) torque for single rear wheel (SRW) models

and 145 ft. lbs. (197 N´m) for dual rear wheel models. If in

doubt about the correct tightness, have them checked

with a torque wrench by your dealer or at a service

station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Install wheel center cap (if equipped) and remove

wheel blocks. Do not install chrome or aluminum wheel

center caps on the spare wheel. This may result in cap

damage.

384 WHAT TO DO IN EMERGENCIES

Page 418 of 528

agency for advice on recycling programs and for where

used fluids and filters can be properly disposed of in

your area.

Drain a small amount from the fuel/water separator

filter monthly or when the WATER IN FUEL indicator

lamp is on. Turn the drain valve, located on the bottom of

the filter, counterclockwise and allow any accumulated

water to drain. Leave the drain valve open until all water

and contaminants have been removed. Close the drain

valve, by turning it clockwise, when clean fuel is visible.

NOTE:The Fuel / Water separator drain valve is

located on the bottom of the fuel filter housing.

If more than a couple ounces of fuel has been drained,

follow the directions below for ªPriming if the engine has

run out of fuel.ºWARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

Priming if the engine has run out of fuel

1. Add a substantial quantity of fuel to the tank 5 to 10

gallons (19L to 38L).

2. Crank the engine for 1 to 2 seconds. If the engine does

not start, then release the key or starter button back to the

RUN position (do not turn the key back to the OFF

position). The electric fuel transfer pump will continue to

run and purge air from the system for about 25 seconds.

After 25 seconds, attempt to start the engine again.

3. Start the engine using the Normal Starting Procedure.

418 MAINTAINING YOUR VEHICLE

Page 472 of 528

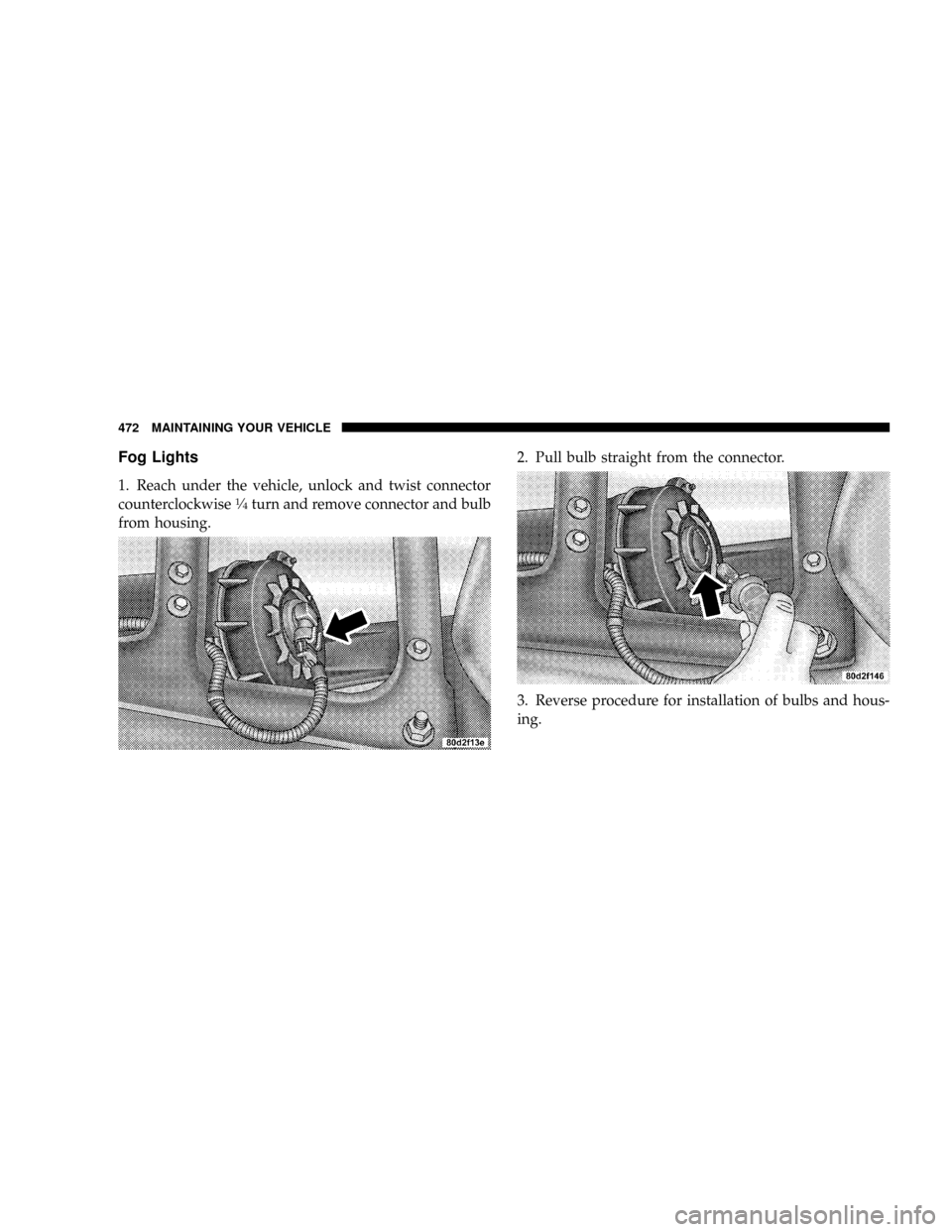

Fog Lights

1. Reach under the vehicle, unlock and twist connector

counterclockwise1¤4turn and remove connector and bulb

from housing.2. Pull bulb straight from the connector.

3. Reverse procedure for installation of bulbs and hous-

ing.

472 MAINTAINING YOUR VEHICLE