power steering DODGE RAM 3500 CHASSIS CAB 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 3500 CHASSIS CAB, Model: DODGE RAM 3500 CHASSIS CAB 2008 3.GPages: 528, PDF Size: 7.84 MB

Page 78 of 528

mSeats................................114

N40-20-40 Front Seat....................114

NReclining Seats.......................115

NAdjustable Head Restraints..............116

NManual Rotary Lumbar Support Adjustment Ð

If Equipped.........................117

NPower Seats Ð If Equipped..............117

NHeated Seats Ð If Equipped.............119

mTo Open And Close The Hood.............120

mLights...............................122

NInterior Lights.......................122

NBattery Saver........................123

NHeadlamp Delay......................124

NHeadlights, Parking Lights, Panel Lights.....124NDaytime Running Lights

(Canada Only And Fleet Vehicles)..........125

NLights-On Reminder...................125

NFog Lights Ð If Equipped...............125

NMultifunction Control Lever..............126

mWindshield Wipers And Washers............128

NWindshield Wipers....................128

NWindshield Washers...................129

mTilt Steering Column....................130

mDriver Adjustable Pedals Ð If Equipped......131

NAdjustment.........................131

mElectronic Speed Control Ð If Equipped......132

NTo Activate..........................133

NTo Set At A Desired Speed...............133

78 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 131 of 528

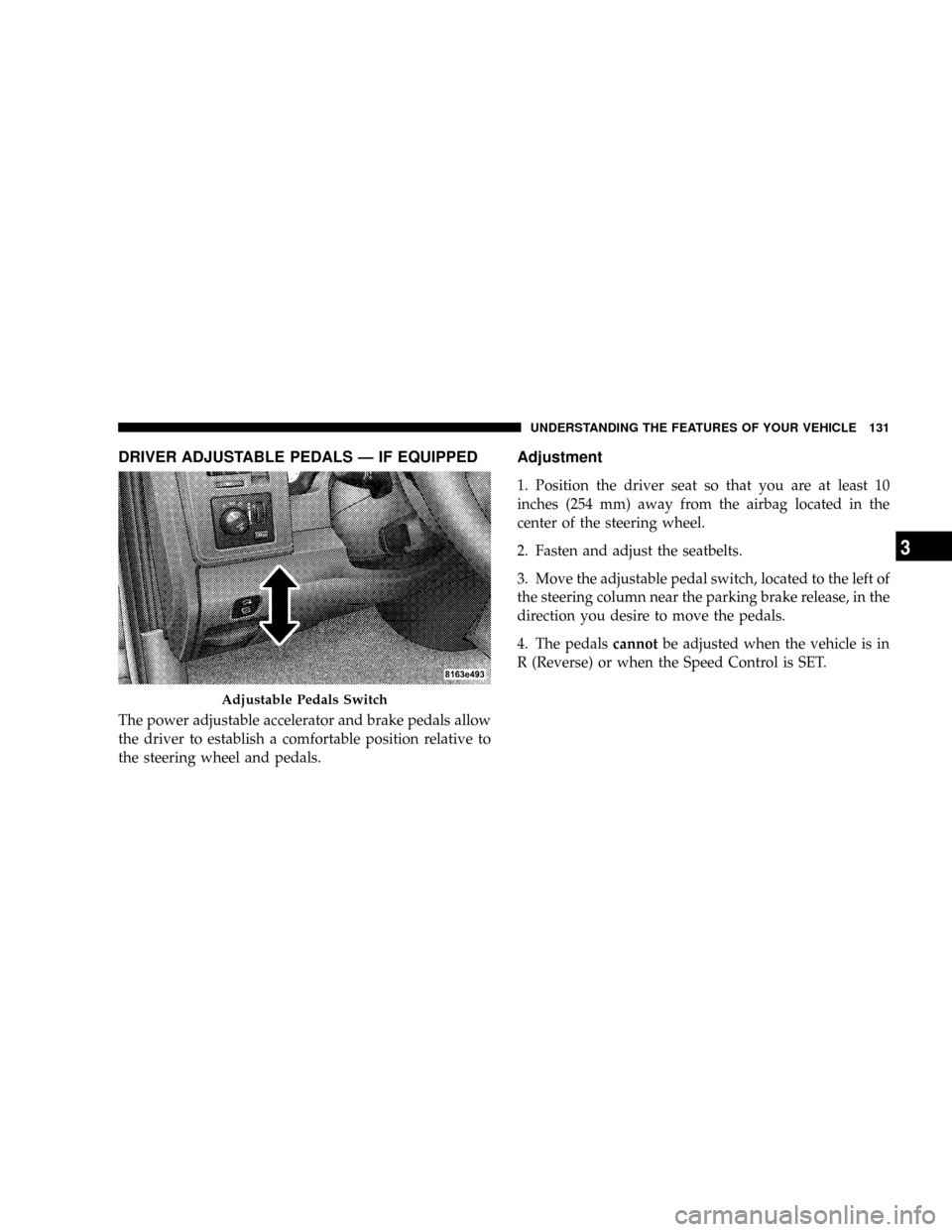

DRIVER ADJUSTABLE PEDALS Ð IF EQUIPPED

The power adjustable accelerator and brake pedals allow

the driver to establish a comfortable position relative to

the steering wheel and pedals.

Adjustment

1. Position the driver seat so that you are at least 10

inches (254 mm) away from the airbag located in the

center of the steering wheel.

2. Fasten and adjust the seatbelts.

3. Move the adjustable pedal switch, located to the left of

the steering column near the parking brake release, in the

direction you desire to move the pedals.

4. The pedalscannotbe adjusted when the vehicle is in

R (Reverse) or when the Speed Control is SET.

Adjustable Pedals Switch

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 131

3

Page 185 of 528

Electrical Disturbances

Radio waves may pick up electrical disturbances during

transmission. They mainly affect the wave amplitude,

and thus remain a part of the AM reception. They

interfere very little with the frequency variations that

carry the FM signal.

AM Reception

AM sound is based on wave amplitude, so AM reception

can be disrupted by such things as lightning, power lines

and neon signs.

FM Reception

Because FM transmission is based on frequency varia-

tions, interference that consists of amplitude variations

can be filtered out, leaving the reception relatively clear,

which is the major feature of FM radio.

NOTE:The radio, steering wheel radio controls (if

equipped), and 6 disc CD/DVD changer (if equipped)

will remain active for up to 10 minutes after the ignition

switch has been turned off. Opening a vehicle front door

will cancel this feature.

UNDERSTANDING YOUR INSTRUMENT PANEL 185

4

Page 249 of 528

NStationary Mode......................302

NMobile Mode........................303

NPower Take Off ± Aftermarket Installation....304

mDriving On Slippery Surfaces..............304

mDriving Through Water..................305

NFlowing/Rising Water..................305

NShallow Standing Water.................305

mDriving Off-Road.......................307

mParking Brake.........................308

mBrake System..........................309

NBrake Noise.........................310

NFour-Wheel Anti-Lock Brake System........310

mPower Steering........................312mTire Safety Information...................313

NTire Markings........................313

NTire Identification Number (TIN)..........317

NTire Loading And Tire Pressure...........318

mTires Ð General Information...............322

NTire Pressure.........................322

NTire Inflation Pressures.................323

NRadial-Ply Tires......................328

NLimited Use Spare Ð If Equipped.........329

NTire Spinning........................329

NTread Wear Indicators..................330

NLife Of Tire.........................331

NReplacement Tires.....................331

STARTING AND OPERATING 249

5

Page 312 of 528

ABS Warning Light

The Anti-lock Brake System includes an amber warning

light, located in the instrument cluster. When the light is

illuminated, the Anti-lock Brake System is not function-

ing. The system reverts to standard non-anti-lock brakes.

WARNING!

Pumping of the anti-lock brakes will diminish their

effectiveness and may lead to an accident. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

POWER STEERING

The standard power steering system will give you good

vehicle response and increased ease of maneuverability

in tight spaces. The system will provide mechanical

steering capability if power assist is lost.

If for some reason, the power assist is interrupted, it will

still be possible to steer your vehicle. Under these condi-

tions you will observe a substantial increase in steering

effort, especially at very low vehicle speeds and during

parking maneuvers.

NOTE:Increased noise levels at the end of the steering

wheel travel are considered normal and does not indicate

that there is a problem with the power steering system.

Upon initial start-up in cold weather, the power steering

pump may make noise for a short period of time. This is

due to the cold, thick fluid in the steering system. This

noise should be considered normal, and does not in any

way damage the steering system.

312 STARTING AND OPERATING

Page 313 of 528

WARNING!

Continued operation with reduced power steering

assist could pose a safety risk to yourself and others.

Service should be obtained as soon as possible.

CAUTION!

Prolonged operation of the steering system at the end

of the steering wheel travel will increase the steering

fluid temperature and should be avoided when pos-

sible. Damage to the power steering pump may occur.

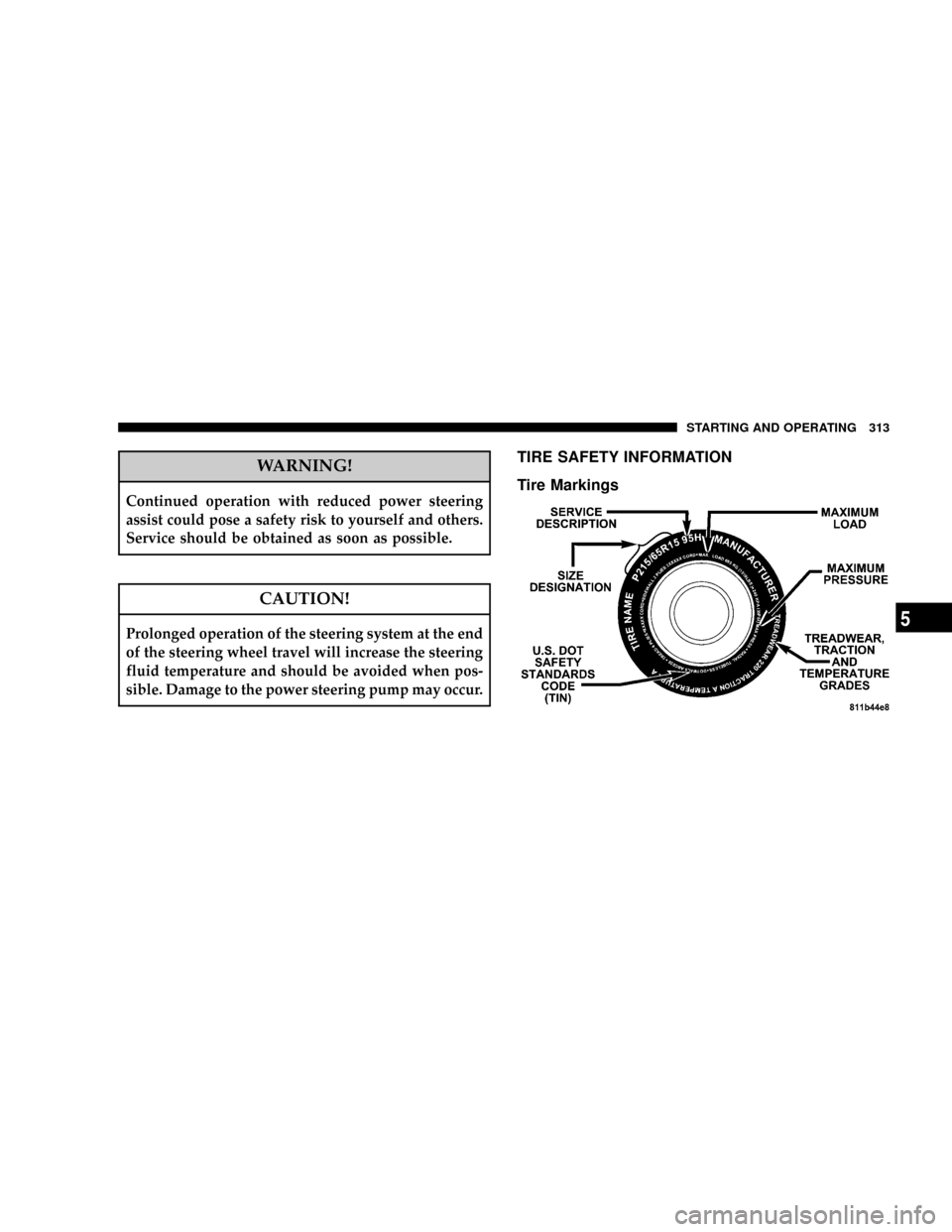

TIRE SAFETY INFORMATION

Tire Markings

STARTING AND OPERATING 313

5

Page 398 of 528

NCatalytic Converter (Gas Engines).........420

NIntervention Regeneration Strategy ± EVIC

Message Process Flow (Catalyst Full Message)

(Diesel Engines Only)..................422

NEmission-Related Components (Gas Engines) . . 425

NMaintenance Free Battery (Gas Engines).....425

NMaintenance Free Batteries (Diesel Engines) . . . 426

NAir Conditioner Maintenance.............427

NPower Steering Ð Fluid Check............428

NFront Suspension Ball Joints..............429

NSteering Linkage Ð Inspection............429

NFront Prop Shaft Lubrication.............430

NFront Axle Universal Drive Joints And

Ball Joints...........................430NBody Lubrication.....................430

NWindshield Wiper Blades................431

NWindshield Washers...................431

NExhaust System......................432

NCooling System.......................433

NFan ...............................439

NCharge Air Cooler Ð Inter-Cooler

(Diesel Engines)......................439

NHoses And Vacuum/Vapor Harnesses.......440

NFuel System Connections................440

NBrake System........................440

NClutch Hydraulic System................443

NClutch Linkage.......................443

398 MAINTAINING YOUR VEHICLE

Page 428 of 528

WARNING!

²Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi-

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause

the system to fail, requiring costly repairs. Refer to

Section 3 of the Warranty Information book for

further warranty information.

²The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal

injury or damage to the system, adding refrigerant

or any repair requiring lines to be disconnected

should be done by an experienced repairman.

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

428 MAINTAINING YOUR VEHICLE

Page 429 of 528

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Fluids, Lubricants, and Genuine Parts

for correct fluid type.

Front Suspension Ball Joints

The ball joints originally supplied with the vehicle are

permanently lubricated at the factory and do not require

service. The ball joints and seals should be inspected

whenever the vehicle is serviced for other reasons.

Steering Linkage Ð Inspection

Whenever the vehicle is hoisted, all steering linkage

joints should be inspected for evidence of damage. If

seals are damaged, parts should be replaced to prevent

leakage or contamination of the grease.

MAINTAINING YOUR VEHICLE 429

7

Page 440 of 528

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component which may cause heat

damage or mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

Fuel System Connections

Electronic Fuel Injection high pressure fuel systems are

designed with tubes and special connects, connections

and clamps which have unique material characteristics to

provide adequate sealing and resist attack by deterio-

rated gasoline.

You are urged to use only the manufactures-specified

tubes, connections and clamps, or their equivalent in

material and specification, in any fuel system servicing.

Brake System

Power Disc Brakes (Front and Rear)

Disc brakes do not require adjustment; however, several

hard stops during the break-in period are recommended

to seat the linings and wear off any foreign material.

Brake And Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

440 MAINTAINING YOUR VEHICLE