DODGE RAM 3500 DIESEL 2006 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM 3500 DIESEL, Model: DODGE RAM 3500 DIESEL 2006 3.GPages: 493, PDF Size: 2 MB

Page 311 of 493

SNOW TIRES

Snow tires should be of the same size and type construc-

tion as the front tires. Consult the manufacturer of the

snow tire to determine any maximum vehicle speed

requirement associated with the tire. These tires should

always be operated at the vehicle maximum capacity

inflation pressures under any load condition.

While studded tires improve performance on ice, skid

and traction capability on wet or dry surfaces may be

poorer than that of non-studded tires. Some states pro-

hibit studded tires; therefore, local laws should be

checked before using these tire types.

TIRE ROTATION RECOMMENDATIONS

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving,

and braking functions. For these reasons, they wear at

unequal rates, and develop irregular wear patterns.

These effects can be reduced by timely rotation of tires.

The benefits of rotation are especially worthwhile with

aggressive tread designs such as those on On/Off Road

type tires. Rotation will increase tread life, help to main-

tain mud, snow, and wet traction levels, and contribute to

a smooth, quiet ride.

STARTING AND OPERATING 311

5

Page 312 of 493

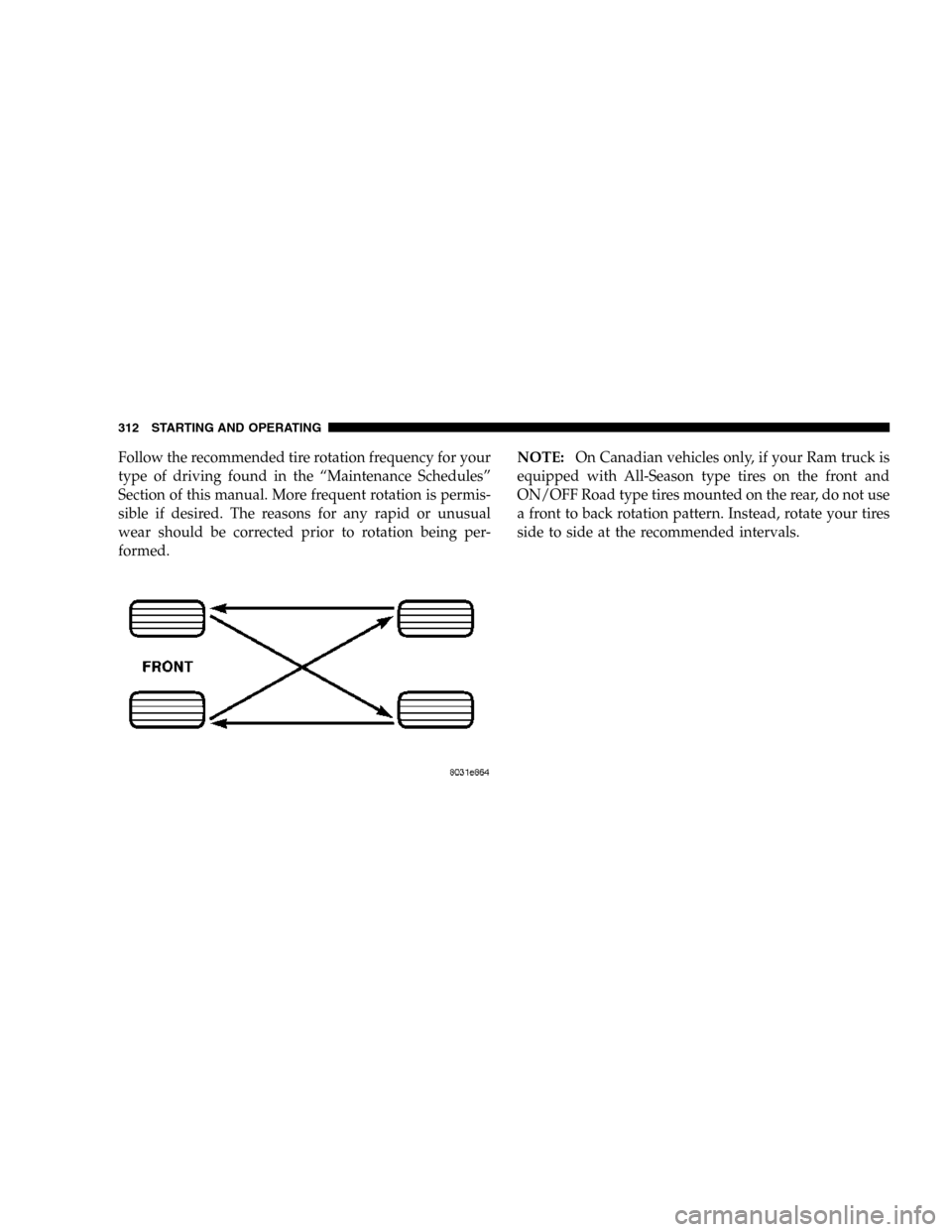

Follow the recommended tire rotation frequency for your

type of driving found in the “Maintenance Schedules”

Section of this manual. More frequent rotation is permis-

sible if desired. The reasons for any rapid or unusual

wear should be corrected prior to rotation being per-

formed.NOTE:On Canadian vehicles only, if your Ram truck is

equipped with All-Season type tires on the front and

ON/OFF Road type tires mounted on the rear, do not use

a front to back rotation pattern. Instead, rotate your tires

side to side at the recommended intervals.

312 STARTING AND OPERATING

Page 313 of 493

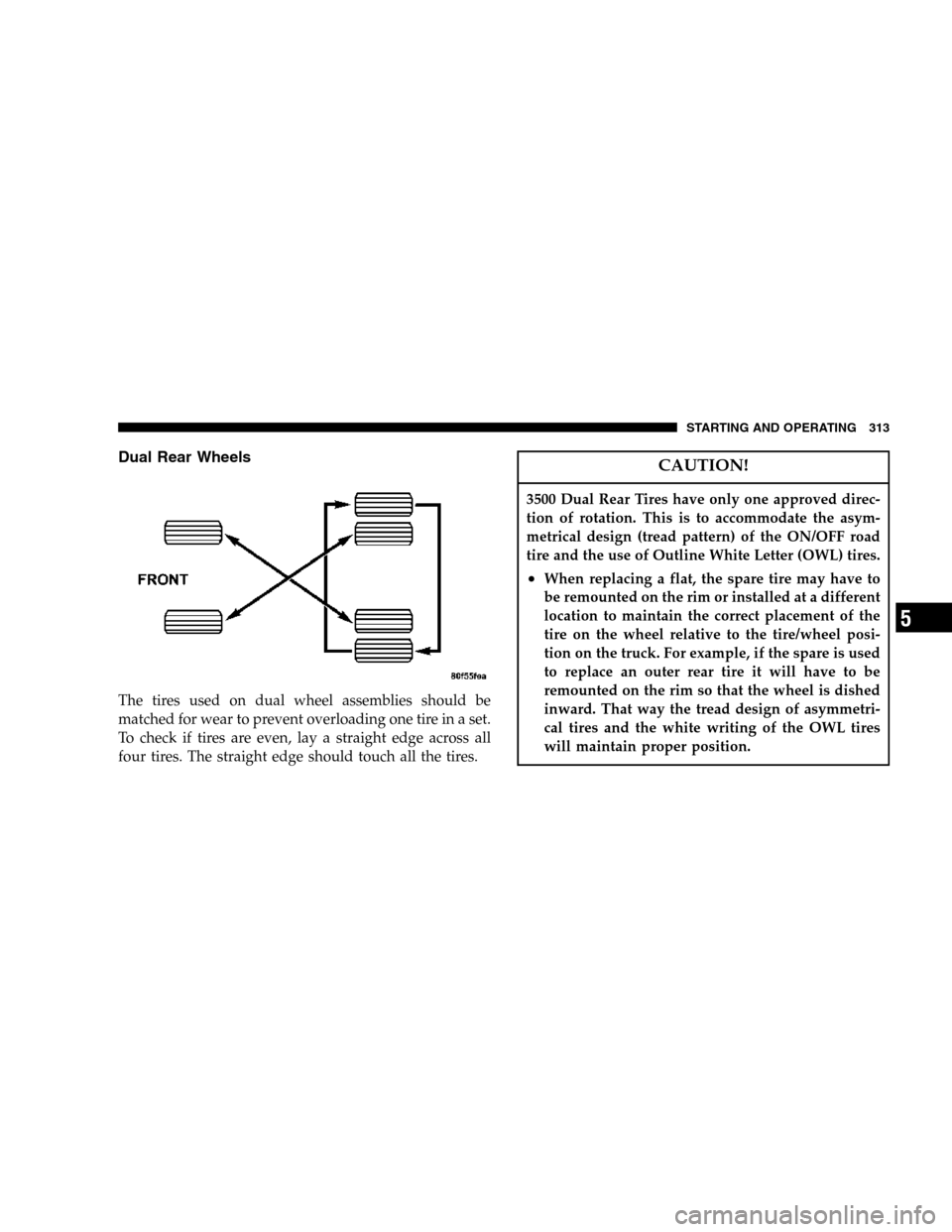

Dual Rear Wheels

The tires used on dual wheel assemblies should be

matched for wear to prevent overloading one tire in a set.

To check if tires are even, lay a straight edge across all

four tires. The straight edge should touch all the tires.

CAUTION!

3500 Dual Rear Tires have only one approved direc-

tion of rotation. This is to accommodate the asym-

metrical design (tread pattern) of the ON/OFF road

tire and the use of Outline White Letter (OWL) tires.

•When replacing a flat, the spare tire may have to

be remounted on the rim or installed at a different

location to maintain the correct placement of the

tire on the wheel relative to the tire/wheel posi-

tion on the truck. For example, if the spare is used

to replace an outer rear tire it will have to be

remounted on the rim so that the wheel is dished

inward. That way the tread design of asymmetri-

cal tires and the white writing of the OWL tires

will maintain proper position.

STARTING AND OPERATING 313

5

Page 314 of 493

ENGINE RUNAWAY

WARNING!

In case of engine runaway due to flammable fumes

from gasoline spills or turbocharger oil leaks being

sucked into the engine do the following to help

avoid personal injury and/or vehicle damage:

1. Shut off engine ignition switch.

2. Using a CO

2or dry chemical type fire extin-

guisher, direct the spray from the fire extinguisher

into the grille on the passenger side so that the spray

enters the engine air intake.

The inlet for the engine air intake is located behind the

passenger side headlamp and receives air through the

grille

FUEL REQUIREMENTS

Use good quality diesel fuel from a reputable supplier in

your Dodge truck. For most year-round service, No. 2

diesel fuel meeting ASTM specification D-975 will pro-

vide good performance. If the vehicle is exposed to

extreme cold (below 20°F or -7°C), or is required to

operate at colder-than-normal conditions for prolonged

periods, use climatized No. 2 diesel fuel or dilute the No.

2 diesel fuel with 50% No. 1 diesel fuel. This will provide

better protection from fuel gelling or wax-plugging of the

fuel filters.

WARNING!

Do not use alcohol or gasoline as a fuel blending

agent. They can be unstable under certain conditions

and hazardous or explosive when mixed with diesel

fuel.

314 STARTING AND OPERATING

Page 315 of 493

Diesel fuel is seldom completely free of water. To prevent

fuel system trouble, drain the accumulated water from

the fuel/water separator using the fuel/water separator

drain provided. If you buy good quality fuel and follow

the cold weather advice above, fuel conditioners should

not be required in your vehicle. If available in your area,

a high cetane “premium” diesel fuel may offer improved

cold-starting and warm-up performance.

ADDING FUEL

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

NOTE:

•When the fuel nozzle “clicks” or shuts off, the fuel

tank is full.

•Tighten the gas cap until you hear a “clicking” sound.

This is an indication that the gas cap is properly

tightened.

•Make sure that the gas cap is tightened each time the

vehicle is refueled.

WARNING!

A fire may result if fuel is pumped into a container

that is inside of a vehicle or in the bed or on the

opened tailgate. Always place fuel containers on the

ground while filling.

Fuel Filler Cap (Gas Cap)

The gas cap is behind the fuel filler door. If the gas cap is

lost or damaged, be sure the replacement cap is for use

with this vehicle.

STARTING AND OPERATING 315

5

Page 316 of 493

CAUTION!

Damage to the fuel system or emission control

system could result from using an improper fuel

tank filler tube cap (gas cap). A poorly fitting cap

could let impurities into the fuel system.

WARNING!

•Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank filled.

•Never add fuel to the vehicle when the engine is

running.

Avoid Using Contaminated Fuel

Fuel that is contaminated by water or dirt can cause

severe damage to the engine fuel system. Proper main-

tenance of the engine fuel filter and fuel tank is essential.

(See Section 7 for Maintenance Procedures).

NOTE:Climatized diesel fuel is a blend of Number 2

and Number 1 Diesel fuel which reduces the temperature

at which wax crystals form in the fuel.

Bulk Fuel Storage

If you store quantities of fuel, good maintenance of the

stored fuel is also essential. Fuel contaminated with

water will promote the growth of “microbes.” These

microbes form “slime” that will clog fuel filters and lines.

Drain condensation from the supply tank and change the

line filter on a regular basis.

316 STARTING AND OPERATING

Page 317 of 493

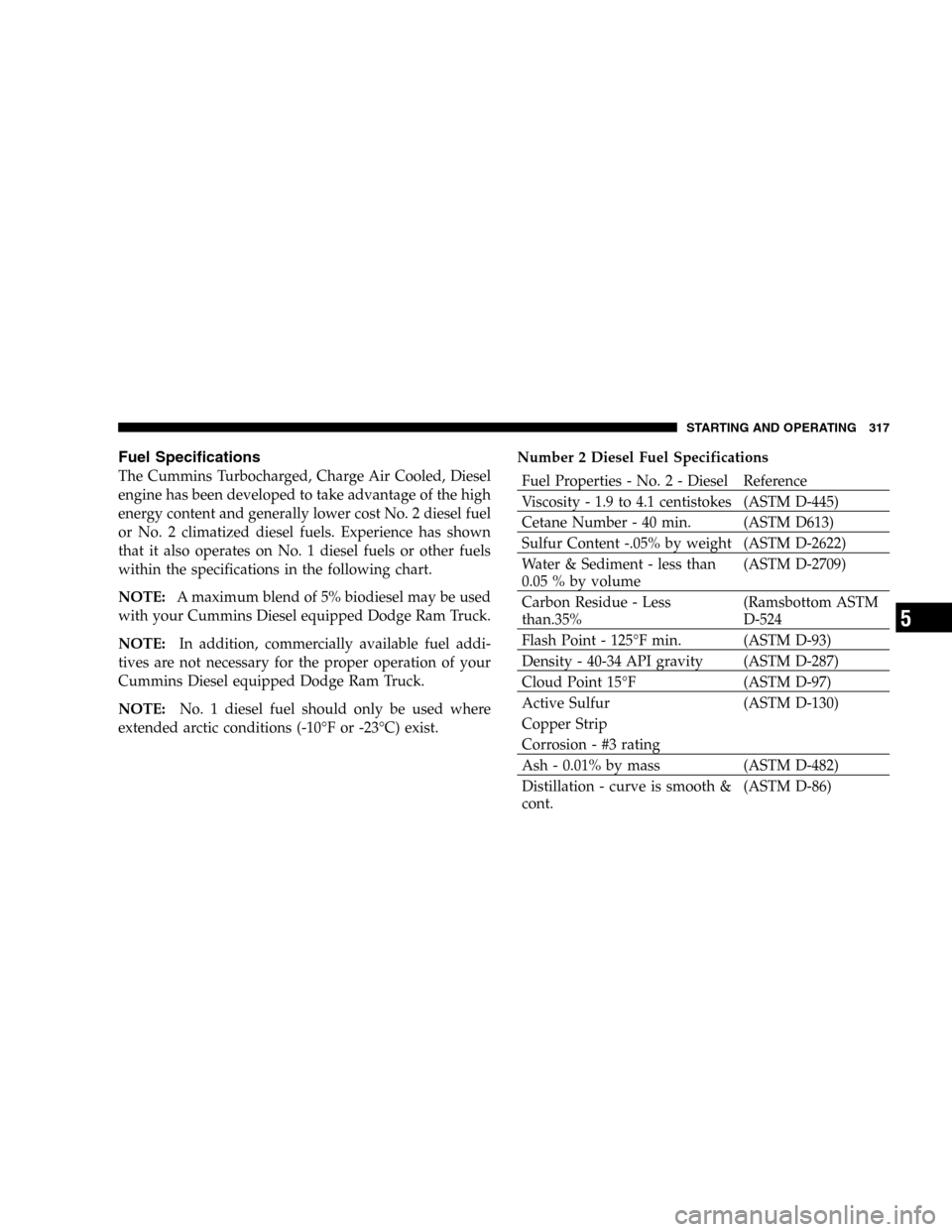

Fuel Specifications

The Cummins Turbocharged, Charge Air Cooled, Diesel

engine has been developed to take advantage of the high

energy content and generally lower cost No. 2 diesel fuel

or No. 2 climatized diesel fuels. Experience has shown

that it also operates on No. 1 diesel fuels or other fuels

within the specifications in the following chart.

NOTE:A maximum blend of 5% biodiesel may be used

with your Cummins Diesel equipped Dodge Ram Truck.

NOTE:In addition, commercially available fuel addi-

tives are not necessary for the proper operation of your

Cummins Diesel equipped Dodge Ram Truck.

NOTE:No. 1 diesel fuel should only be used where

extended arctic conditions (-10°F or -23°C) exist.Number 2 Diesel Fuel SpecificationsFuel Properties - No. 2 - Diesel Reference

Viscosity - 1.9 to 4.1 centistokes (ASTM D-445)

Cetane Number - 40 min. (ASTM D613)

Sulfur Content -.05% by weight (ASTM D-2622)

Water & Sediment - less than

0.05 % by volume(ASTM D-2709)

Carbon Residue - Less

than.35%(Ramsbottom ASTM

D-524

Flash Point - 125°F min. (ASTM D-93)

Density - 40-34 API gravity (ASTM D-287)

Cloud Point 15°F (ASTM D-97)

Active Sulfur (ASTM D-130)

Copper Strip

Corrosion - #3 rating

Ash - 0.01% by mass (ASTM D-482)

Distillation - curve is smooth &

cont.(ASTM D-86)

STARTING AND OPERATING 317

5

Page 318 of 493

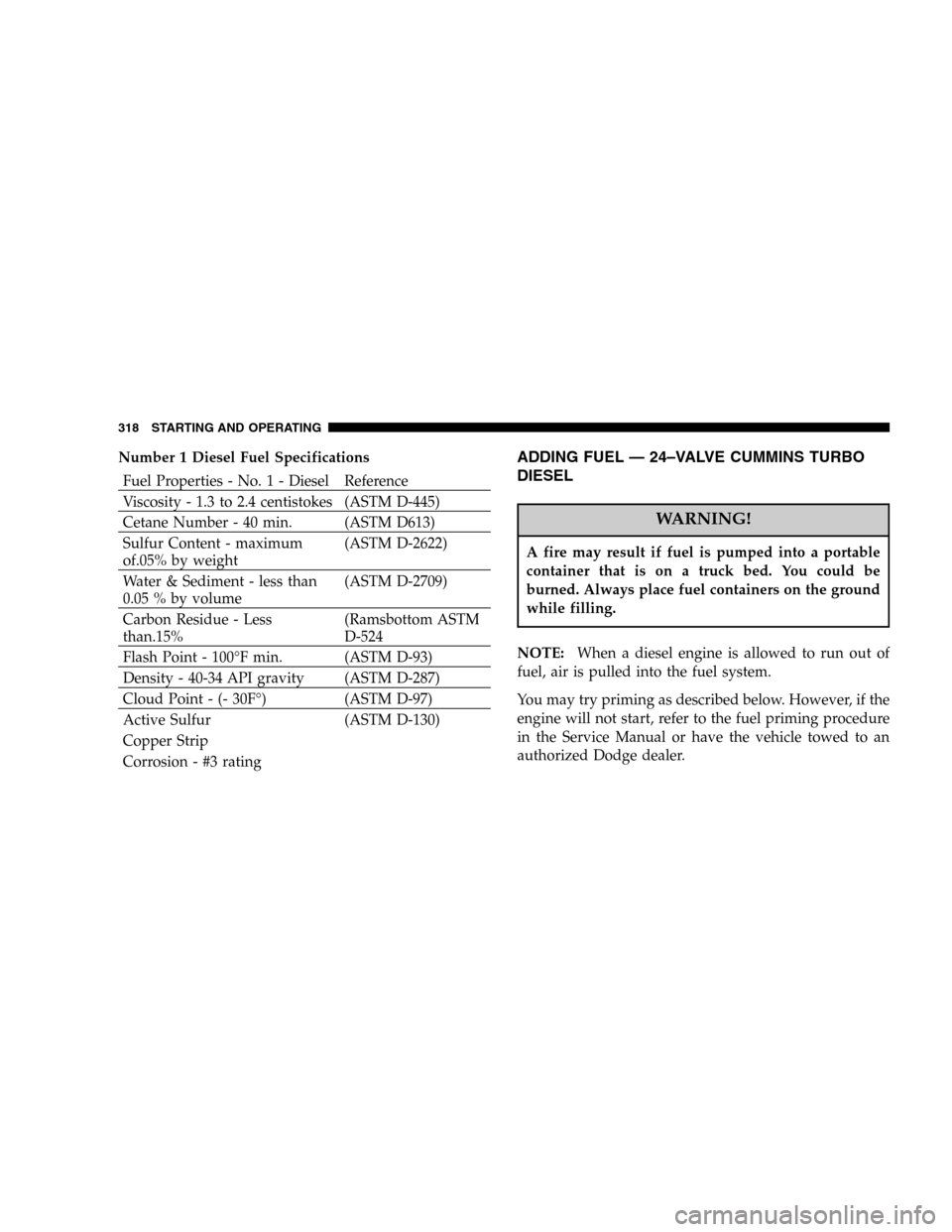

Number 1 Diesel Fuel Specifications

Fuel Properties - No. 1 - Diesel Reference

Viscosity - 1.3 to 2.4 centistokes (ASTM D-445)

Cetane Number - 40 min. (ASTM D613)

Sulfur Content - maximum

of.05% by weight(ASTM D-2622)

Water & Sediment - less than

0.05 % by volume(ASTM D-2709)

Carbon Residue - Less

than.15%(Ramsbottom ASTM

D-524

Flash Point - 100°F min. (ASTM D-93)

Density - 40-34 API gravity (ASTM D-287)

Cloud Point - (- 30F°) (ASTM D-97)

Active Sulfur (ASTM D-130)

Copper Strip

Corrosion - #3 rating

ADDING FUEL — 24–VALVE CUMMINS TURBO

DIESEL

WARNING!

A fire may result if fuel is pumped into a portable

container that is on a truck bed. You could be

burned. Always place fuel containers on the ground

while filling.

NOTE:When a diesel engine is allowed to run out of

fuel, air is pulled into the fuel system.

You may try priming as described below. However, if the

engine will not start, refer to the fuel priming procedure

in the Service Manual or have the vehicle towed to an

authorized Dodge dealer.

318 STARTING AND OPERATING

Page 319 of 493

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

Priming if the engine has run out of fuel

1. Add a substantial quantity of fuel to the tank 5 to 10

gallons (19 to 38L).

2. Crank the engine for 1 to 2 seconds. If the engine does

not start, then release the key or starter button back to the

RUN position (do not turn the key back to the OFF

position). The electric fuel transfer pump will continue to

run and purge air from the system for about 20 seconds.

After 20 seconds, attempt to start the engine again.

3. Start the engine using the Normal Starting Procedure.4. Repeat the procedure if the engine does not start.

CAUTION!

Do not engage the starter motor for more than 15

seconds at a time. Allow two minutes between the

cranking intervals.

NOTE:The engine may run rough until the air is forced

from all the fuel lines.

VEHICLE LOADING

Certification Label

As required by National Highway Traffic Safety Admin-

istration Regulations, your vehicle has a certification

label affixed to the driver’s side door or pillar.

This label contains the month and year of manufacture,

Gross Vehicle Weight Rating (GVWR), Gross Axle Weight

STARTING AND OPERATING 319

5

Page 320 of 493

Rating (GAWR) front and rear, and Vehicle Identification

Number (VIN). A Month-Day-Hour (MDH) number is

included on this label and indicates the Month, Day and

Hour of manufacture. The bar code that appears on the

bottom of the label is your Vehicle Identification Number

(VIN).

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your vehicle

including driver, passengers, vehicle, options and cargo.

The label also specifies maximum capacities of front and

rear axle systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable load

weight a truck can carry, including the weight of the

driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the front

and rear axles. The load must be distributed in the cargo

area so that the GAWR of each axle is not exceeded.

Each axle GAWR is determined by the components in the

system with the lowest load carrying capacity (axle,

springs, tires or wheels). Heavier axles or suspension

components sometimes specified by purchasers for in-

creased durability does not necessarily increase the vehi-

cle’s GVWR.

Tire Size

The tire size on the Label represents the actual tire size on

your vehicle. Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire size

listed.

320 STARTING AND OPERATING