checking oil DODGE RAM 3500 DIESEL 2008 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 3500 DIESEL, Model: DODGE RAM 3500 DIESEL 2008 3.GPages: 527, PDF Size: 8.88 MB

Page 415 of 527

Engine Oil

Checking Oil Level

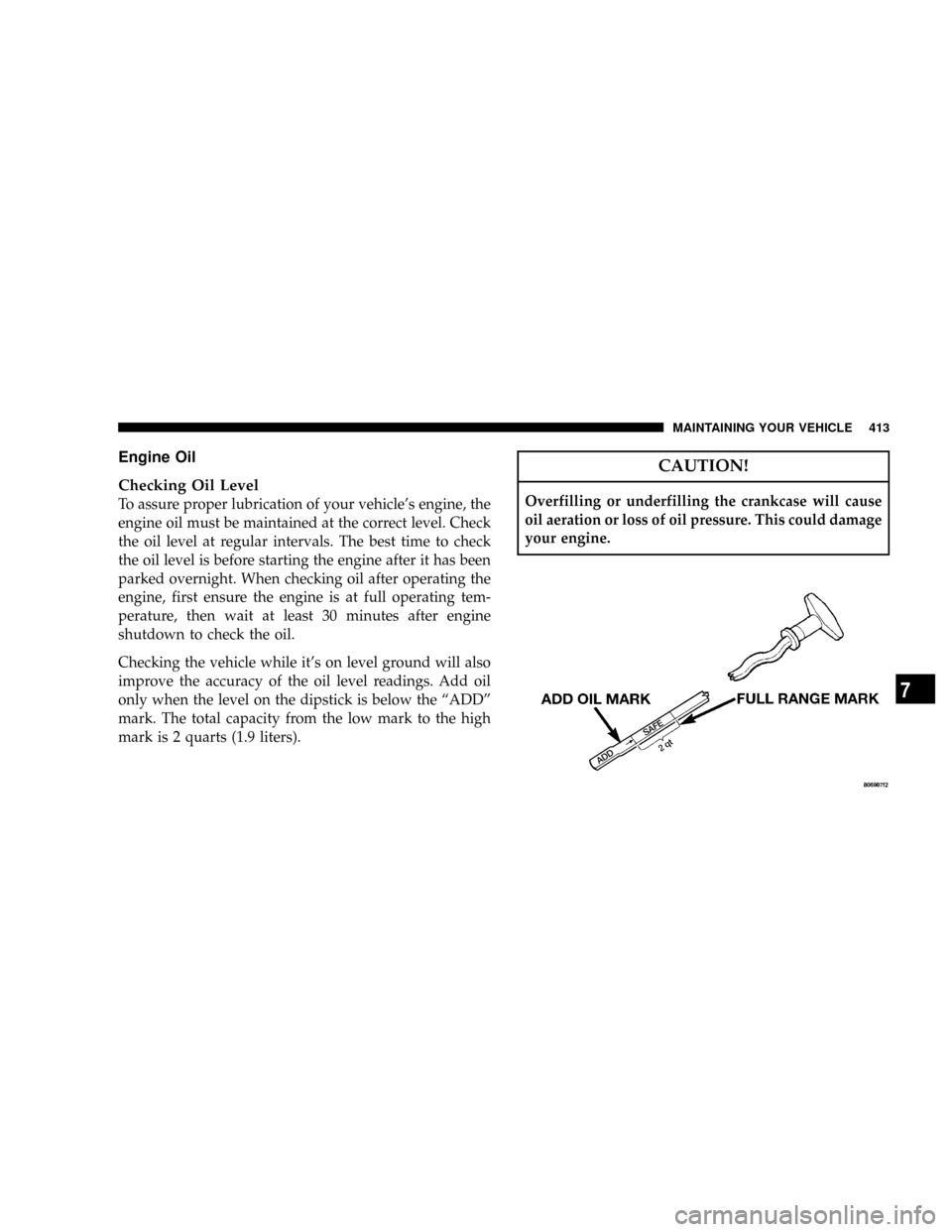

To assure proper lubrication of your vehicle's engine, the

engine oil must be maintained at the correct level. Check

the oil level at regular intervals. The best time to check

the oil level is before starting the engine after it has been

parked overnight. When checking oil after operating the

engine, first ensure the engine is at full operating tem-

perature, then wait at least 30 minutes after engine

shutdown to check the oil.

Checking the vehicle while it's on level ground will also

improve the accuracy of the oil level readings. Add oil

only when the level on the dipstick is below the ªADDº

mark. The total capacity from the low mark to the high

mark is 2 quarts (1.9 liters).

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could damage

your engine.

MAINTAINING YOUR VEHICLE 413

7

Page 433 of 527

NOTE:Use only manufacturer approved A/C System

Sealers, Stop Leak Products, Seal Conditioners, Compres-

sor Oil, or Refrigerants.

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to ensure accurate fluid level reading. Do

not overfill. Use only manufacturer recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Fluids, Lubricants, and Genuine Parts

for correct fluid type.

Front Suspension Ball Joints

The ball joints originally supplied with the vehicle are

permanently lubricated at the factory and do not require

service. The ball joints and seals should be inspected

whenever the vehicle is serviced for other reasons.

MAINTAINING YOUR VEHICLE 431

7

Page 448 of 527

Rear Axle And 4x4 Front Driving Axle Fluid Level

For Model 9.25 Front Axles and 10.5º/11.5º Rear Axles

refer to Fluids, Lubricants and Genuine Parts for the

correct lubricant type. For normal service, periodic fluid

level checks are not required. When the vehicle is ser-

viced for other reasons, the exterior surfaces of the axle

assembly should be inspected.

When checking the fluid level, the vehicle should be in a

level position. The fluid level should be 1/4º 1/4º (6.4

mm 6.4 mm) below the fill hole on the 9.25º Front Axle.

The fluid level should be 3/4º 1/4º (19 mm 6.4 mm)

below the fill hole on all 10.5º and 1/4º 1/4º (6.4 mm

6.4 mm) on 11.5º Rear Axles.

Drain And Refill

Follow the Maintenance Schedule for recommended fron

and rear axle fluid change intervals.

Lubricant Selection

Refer to Fluids, Lubricants and Genuine Parts for the

correct lubricant type.

NOTE:The presence of water in the gear lubricant will

result in corrosion and possible failure of differential

components. Operation of the vehicle in water, as may be

encountered in some off-highway types of service, will

require draining and refilling the axle to avoid damage.

Limited-Slip Differentialsin vehicles equipped with

10.5º/11.5º AxlesDO NOT REQUIREany limited slip

oil additive (friction modifiers).

Transfer Case Ð If Equipped

Fluid Level Check

This fluid level can be checked by removing the filler

plug. The fluid level should be to the bottom edge of the

filler plug hole with the vehicle in a level position.

446 MAINTAINING YOUR VEHICLE

Page 451 of 527

5. Remove the dipstick, wipe it clean and reinsert it until

seated.

6. Remove the dipstick again and note the fluid level on

both sides. The fluid level should be between the ªHOTº

(upper) reference holes on the dipstick at normal operat-

ing temperature. Verify that a solid coating of oil is seen

on both sides of the dipstick. If the fluid is low, add as

required into the dipstick tube.Do not overfill.After

adding any quantity of oil through the oil fill tube, wait

a minimum of two minutes for the oil to fully drain into

the transmission before rechecking the fluid level.

NOTE:If it is necessary to check the transmissionbelow

the operating temperature, the fluid level should be

between the two ªCOLDº (lower) holes on the dipstick

with the fluid at approximately 70ÉF (21ÉC) (room tem-

perature). If the fluid level is correctly established at

room temperature, it should be between the ªHOTº(upper) reference holes when the transmission reaches

180ÉF (82ÉC). Remember it is best to check the level at the

normal operating temperature.

CAUTION!

Be aware that if the fluid temperature is below 50ÉF

(10ÉC) it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough to

produce an accurate reading.

7. Check for leaks. Release parking brake.

To prevent dirt and water from entering the transmission

after checking or replenishing fluid, make certain that the

dipstick cap is properly reseated. It is normal for the

dipstick cap to spring back slightly from its fully seated

position, as long as its seal remains engaged in the

dipstick tube.

MAINTAINING YOUR VEHICLE 449

7

Page 486 of 527

EMISSION CONTROL SYSTEM MAINTENANCE

The Scheduled maintenance services, listed inbold type

in this section (Section 8) must be done at the times or

mileages specified to assure the continued proper func-

tioning of the emission control system. These, and all

other maintenance services included in this manual,

should be done to provide best vehicle performance and

reliability. More frequent maintenance may be needed for

vehicles in severe operating conditions, such as dusty

areas and very short trip driving.

Inspection and service also should be done anytime a

malfunction is suspected.

NOTE:Maintenance, replacement, or repair of the emis-

sion control devices and systems on your vehicle may be

performed by any automotive repair establishment or

individual using any automotive part which has been

certified pursuant to U.S. EPA or, in the State of Califor-

nia, California Air Resources Board regulations.

MAINTENANCE SCHEDULES Ð 6.7L TURBO

DIESEL

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 30 minutes after a

fully warmed engine is shut off. Checking the oil level

while the vehicle is on level ground will improve the

accuracy of the oil level reading. Add oil only when

the level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required. When refilling the washer fluid reservoir,

484 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S