DODGE RAM 3500 GAS 2008 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2008, Model line: RAM 3500 GAS, Model: DODGE RAM 3500 GAS 2008 3.GPages: 554, PDF Size: 9.93 MB

Page 431 of 554

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack parts and the extra tire and wheel

in the places provided.

7. Install wheel center cap and remove wheel blocks. Do

not install chrome or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the bottle

jack will not lower by turning the dial (thumbwheel) by

hand, it may be necessary to use the jack drive tube in

order to lower the jack. Stow the replaced tire, jack, and

tools as previously described.

9. Adjust the tire pressure when possible.NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.Hub Caps/Wheel Covers

The hub caps must be removed before raising the vehicle

off the ground.

For 2500/3500 single rear-wheel (SRW) models, use the

blade on the end of the lug wrench to pry the hub cap off.

Insert the blade end into the pryoff notch and carefully

pop off the hub cap with a back-and-forth motion.

On 3500 models with dual rear wheels (DRW), you must

first remove the hub caps. The jack handle driver has a

hook at one end that will fit in the pry off notch of the

rear hub caps. Position the hook and pull out on the

ratchet firmly. The hub cap should pop off. The wheel

skins can now be removed. For the front hub cap on 3500

models use the blade on the end of the lug wrench to pry

the caps off. The wheel skin can now be removed.

WHAT TO DO IN EMERGENCIES 429

6

Page 432 of 554

CAUTION!

Use a back-and-forth motion to remove the hub cap.

Do not use a twisting motion when removing the hub

cap, damage to the hub cap finish may occur.

CAUTION!

The rear hub caps on the dual rear wheel has two

pry-off notches. Make sure that the hook of the jack

handle driver is located squarely in the cap notch

before attempting to pull off.You must use the flat end of the lug wrench to pry off the

wheel skins. Insert the flat tip completely and using a

back-and-forth motion, loosen the wheel skin. Repeat this

procedure around the tire until the skin pops off.

Replace the wheel skins first using a rubber mallet. When

replacing the hub caps, tilt the cap retainer over the

lugnut bolt circle and strike the high side down with a

rubber mallet. Be sure that the hub caps and wheel skins

are firmly seated around the wheel.

430 WHAT TO DO IN EMERGENCIES

Page 433 of 554

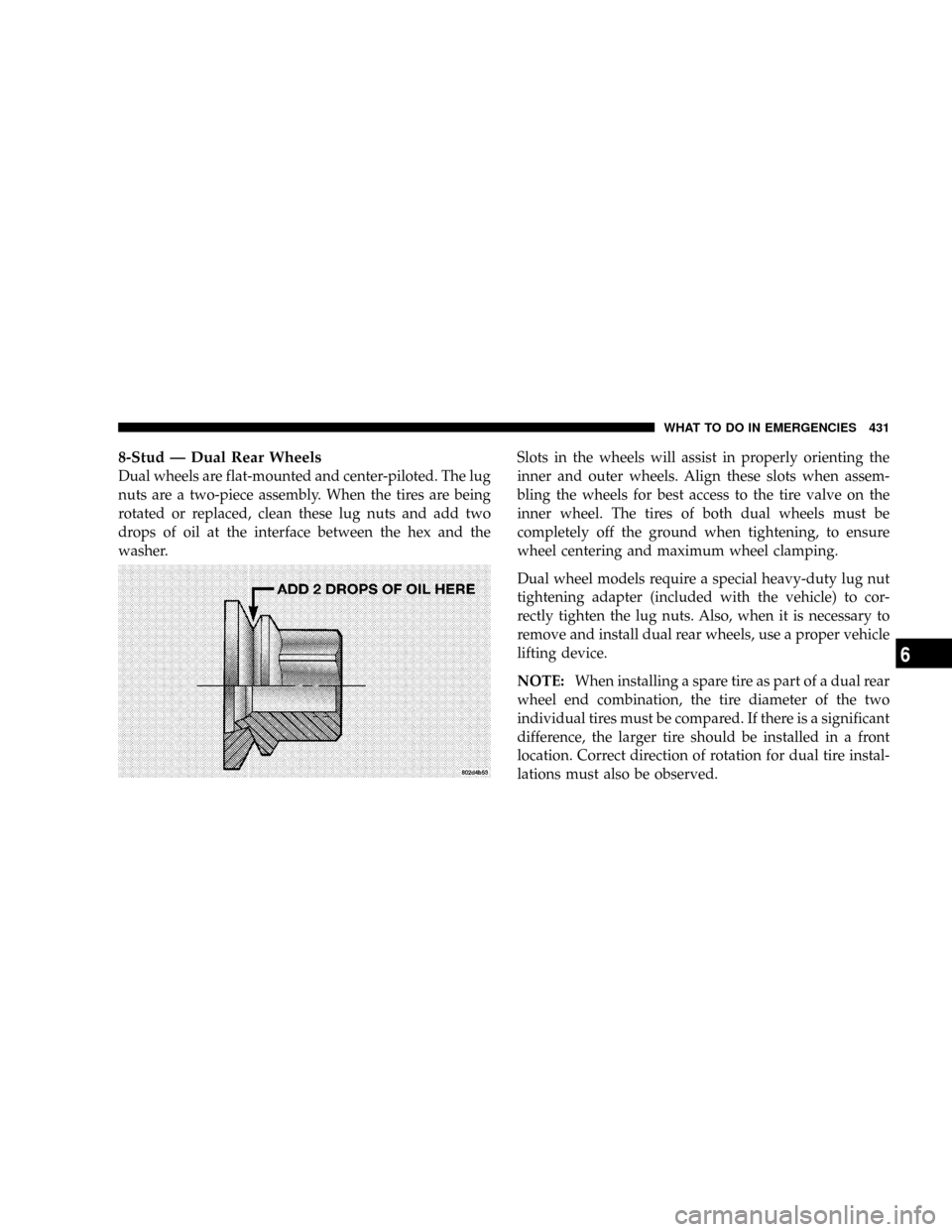

8-Stud Ð Dual Rear Wheels

Dual wheels are flat-mounted and center-piloted. The lug

nuts are a two-piece assembly. When the tires are being

rotated or replaced, clean these lug nuts and add two

drops of oil at the interface between the hex and the

washer.Slots in the wheels will assist in properly orienting the

inner and outer wheels. Align these slots when assem-

bling the wheels for best access to the tire valve on the

inner wheel. The tires of both dual wheels must be

completely off the ground when tightening, to ensure

wheel centering and maximum wheel clamping.

Dual wheel models require a special heavy-duty lug nut

tightening adapter (included with the vehicle) to cor-

rectly tighten the lug nuts. Also, when it is necessary to

remove and install dual rear wheels, use a proper vehicle

lifting device.

NOTE:When installing a spare tire as part of a dual rear

wheel end combination, the tire diameter of the two

individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front

location. Correct direction of rotation for dual tire instal-

lations must also be observed.

WHAT TO DO IN EMERGENCIES 431

6

Page 434 of 554

These dual rear wheels should be tightened as follows:1. Tighten the wheel nuts in the numbered sequence to a

snug fit.

2. Retighten the wheel nuts in the same sequence to the

torques listed in the table. Go through the sequence a

second time to verify that specific torque has been

achieved. Retighten to specifications at 100 mi (160 km)

and after 500 mi (800 km).

It is recommended that wheel stud nuts be kept torqued

to specifications at all times. Torque wheel stud nuts to

specifications at each lubrication interval.

Wheel Nuts

All wheel nuts should be tightened occasionally to elimi-

nate the possibility of wheel studs being sheared or the

bolt holes in the wheels becoming elongated. This is

especially important during the first few hundred miles/

kilometers of operation to allow the wheel nuts to

become properly set. All nuts should first be firmly

seated against the wheel. The nuts should then be

432 WHAT TO DO IN EMERGENCIES

Page 435 of 554

tightened to recommended torque. Tighten the nuts to

final torque in increments. Progress around the bolt

circle, tightening the nut opposite to the nut just previ-

ously tightened until final torque is achieved. Recom-

mended torques are shown in the following chart.

Disc

WheelsType Nut Stud Size Torque

Ft. Lbs.Torque

Newton

Meters

Cone 9/16-18 120-150 160-200

Flanged 9/16-18 130-160 190-220

To Stow The Flat Or Spare

NOTE: 1500 Regular and Quad Cabtvehicles

equipped with aluminum wheels cannot be stored under

the vehicle because the wheel retainer will not fit through

the wheel pilot hole. Secure the (flat) tire in the bed of the

truck.Have the (flat) tire repaired or replaced immedi-

ately.

WARNING!

A loose tire thrown forward in a collision or hard stop

could injure the occupants in the vehicle. Have the

deflated (flat) tire repaired or replaced immediately.

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip, or click three or

four times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

WHAT TO DO IN EMERGENCIES 433

6

Page 436 of 554

HOISTING

A conventional floor jack may be used at the jacking

locations. Refer to the graphics that show jacking loca-

tions. However, a floor jack or frame hoist must never be

used on any other parts or the underbody.

CAUTION!

Never use a floor jack directly under the differential

housing of a loaded truck or damage to your vehicle

may result.

JUMP-STARTING PROCEDURES

Do not attempt to push or tow your vehicle to get it

started. Vehicles equipped with an automatic transmis-

sion cannot be started this way. Pushing or towing a

vehicle equipped with a manual transmission may over-

heat and damage the catalytic converter. Also, there is a

greater risk of an accident when a vehicle is being pushed

or towed. If the vehicle has a discharged battery, booster

cables may be used to obtain a start from a booster

battery or the battery in another vehicle. This type of start

can be dangerous if done improperly, so follow this

procedure carefully.

434 WHAT TO DO IN EMERGENCIES

Page 437 of 554

WARNING!

Battery fluid is a corrosive acid solution; do not allow

battery fluid to contact eyes, skin or clothing. Don't

lean over battery when attaching clamps or allow the

clamps to touch each other. If acid splashes in eyes or

on skin, flush contaminated area immediately with

large quantities of water.

A battery generates hydrogen gas which is flam-

mable and explosive. Keep flame or spark away from

the vent holes.

Do not use a booster battery or any other booster

source that has a greater than 12-volt system, i.e., do

not use a 24-volt power source.

1. Remove all metal jewelry such as watch bands or

bracelets which might make an unintended electrical

contact.2. Park the booster vehicle within cable reach but with-

out letting the vehicles touch. Set the parking brake on

both vehicles, place the automatic transmission in PARK

or the manual transmission in NEUTRAL, and turn the

ignition OFF.

3. Turn off the heater, radio, and all unnecessary electri-

cal loads.

4. Connect one end of a jumper cable to the positive

terminal of the booster battery. Connect the other end of

the same cable to the positive terminal of the discharged

battery.

WARNING!

Do not permit vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

WHAT TO DO IN EMERGENCIES 435

6

Page 438 of 554

5. Connect the other cable; first to the negative terminal

of the booster battery, and then to the engine of the

vehicle with the discharged battery. Make sure you have

a good contact on the engine.

WARNING!

²You should not try to start your vehicle by pushing

or towing.

²Do not connect the cable to the negative post of the

discharge battery. The resulting electrical spark

could cause the battery to explode.

²During cold weather when temperatures are be-

low freezing point, electrolyte in a discharged

battery may freeze. Do not attempt jump-starting

because the battery could rupture or explode. The

battery temperature must be brought up above

freezing point before attempting jump-start.

6. Start the engine in the vehicle which has the booster

battery, let the engine idle a few minutes, then start the

engine in the vehicle with the discharged battery.

436 WHAT TO DO IN EMERGENCIES

Page 439 of 554

7. When removing the jumper cables, reverse the above

sequence exactly. Be careful of the moving belts and fan.

WARNING!

Any procedure other than above could result in:

1. Personal injury caused by electrolyte squirting out

the battery vent;

2. Personal injury or property damage due to battery

explosion;

3. Damage to charging system of booster vehicle or

of immobilized vehicle.

FREEING A STUCK VEHICLE

If the vehicle becomes stuck in snow, sand, or mud, it can

often be moved by a rocking motion. Move the gear

selector rhythmically between DRIVE and REVERSE

(automatic transmissions) or between 1st and REVERSE

(manual transmissions), while applying slight pressure to

the accelerator.

In general, the least amount of accelerator pedal pressure

to maintain the rocking motion without spinning the

wheels or racing the engine, is most effective. Racing the

engine or spinning the wheels, due to the frustration of

not freeing the vehicle, may lead to transmission over-

heating and failure. Allow the engine to idle with the

transmission selector in NEUTRAL for at least one

minute after every five rocking-motion cycles. This will

minimize overheating and reduce the risk of transmis-

sion failure during prolonged efforts to free a stuck

vehicle.

WHAT TO DO IN EMERGENCIES 437

6

Page 440 of 554

EMERGENCY TOW HOOKS Ð IF EQUIPPED

Your vehicle may be equipped with emergency tow

hooks.

NOTE:For off-road recovery, it is recommended to use

both of the front tow hooks to minimize the risk of

damage to the vehicle.

WARNING!

Chains are not recommended for freeing a stuck

vehicle. Chains may break, causing serious injury or

death.

WARNING!

Stand clear of vehicles when pulling with tow hooks.

Tow straps and chains may break, causing serious

injury.

CAUTION!

Tow hooks are for emergency use only, to rescue a

vehicle stranded off-road. Do not use tow hooks for

tow truck hookup or highway towing. You could

damage your vehicle.

438 WHAT TO DO IN EMERGENCIES