maintenance DODGE RAM 4500 CHASSIS CAB 2008 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: RAM 4500 CHASSIS CAB, Model: DODGE RAM 4500 CHASSIS CAB 2008 3.GPages: 528, PDF Size: 7.84 MB

Page 406 of 528

pressure. Do not check for pressure leaks with your

hand. High pressure oil or fuel can cause personal

injury.

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

²Important:All maintenance other than that listed in

this manual, as well as some procedures listed here,

MUSTbe performed by your local Dodge Truck

Dealer. Your authorized Dodge Dealer has been

trained and has the necessary parts to maintain your

engine.

MAINTENANCE PROCEDURES

The pages that follow contain therequiredmaintenance

services determined by the engineers who designed your

vehicle.

Besides the maintenance items for which there are fixed

maintenance intervals, there are other items that should

operate satisfactorily without periodic maintenance.

However, if a malfunction of these items does occur, it

could adversely affect the engine or vehicle performance.

These items should be inspected if a malfunction is

observed or suspected.

Engine Oil

Checking Oil Level

To assure proper lubrication of your vehicle's engine, the

engine oil must be maintained at the correct level. Check

the oil level at regular intervals. The best time to check

the oil level is before starting the engine after it has been

parked overnight. When checking oil after operating the

406 MAINTAINING YOUR VEHICLE

Page 407 of 528

engine, first ensure the engine is at full operating tem-

perature, then wait for 30 minutes (6.7L Diesel Engine),

and 15 minutes (5.7L Gas Engine) after engine shutdown

to check the oil.

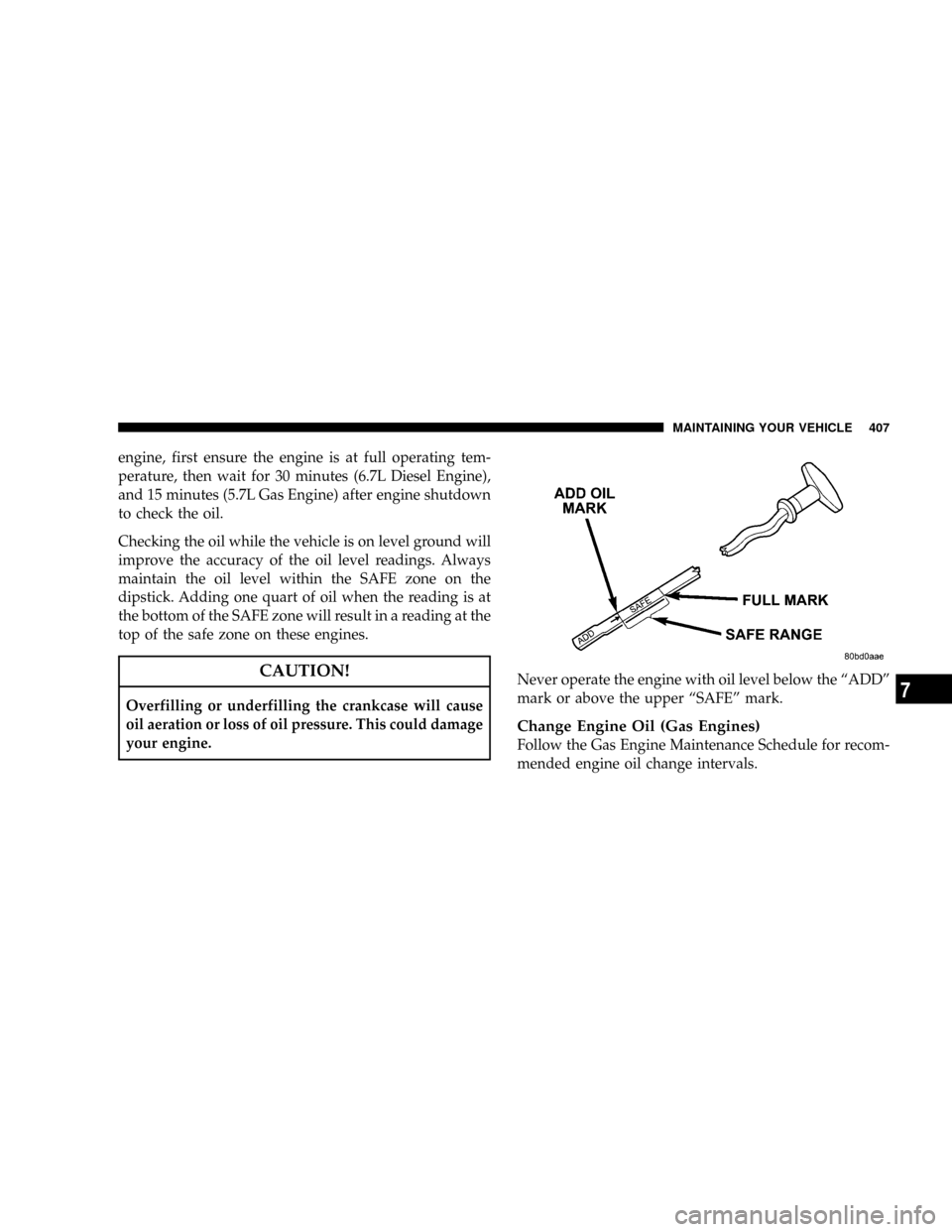

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Always

maintain the oil level within the SAFE zone on the

dipstick. Adding one quart of oil when the reading is at

the bottom of the SAFE zone will result in a reading at the

top of the safe zone on these engines.

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could damage

your engine.Never operate the engine with oil level below the ªADDº

mark or above the upper ªSAFEº mark.

Change Engine Oil (Gas Engines)

Follow the Gas Engine Maintenance Schedule for recom-

mended engine oil change intervals.

MAINTAINING YOUR VEHICLE 407

7

Page 409 of 528

Change Engine Oil (Diesel Engines)

Follow the Diesel Maintenance Schedule for recom-

mended engine oil change intervals.

Engine Oil Selection (Diesel Engines)

For best performance and maximum protection under all

types of operating conditions, the manufacture only

recommends engine oils that are API CJ-4 certified and

meet the requirements of DaimlerChrysler. Use Mopar or

an equivalent oil meeting the specification MS-10902.

Products meeting Cummins CES 20081 may also be used.

The identification of these engine oils are typically lo-

cated on the back of the oil container.

American Petroleum Institute (API) Engine Oil

Identification Symbol

This symbol means that the oil has

been certified by the American Petro-

leum Institute (API). The manufacture

only recommends API Certified en-

gine oils.

Oils with a high ash content may produce deposits on

valves that can progress to guttering and valve burning.

A maximum sulfated ash content of 1.00 mass % is

recommended for all oil used in the engine.

The same oil change interval is to be followed for

synthetic oil as for petroleum based oil. Also, synthetic oil

must meet the same performance specifications as petro-

leum oil.

MAINTAINING YOUR VEHICLE 409

7

Page 410 of 528

Engine Oil Viscosity (SAE Grade)

Use SAE 15W-40 Engine Oil that meets

DaimlerChrysler Materials Standard MS-10902 and the

API CJ-4 engine oil category.

Engine oil not designated by the DaimlerChrysler or

Cummins Material Standards and API CJ-4 should not be

used, engine and exhaust system durability may be

compromised. For lower temperature operation SAE

5W-40 engine oils may be used. These oils must meet the

same requirements as stated previously. Your engine oil

filler cap also shows the recommended engine oil viscos-

ity for your vehicle.

Synthetic Engine Oils

You may use synthetic engine oils provided the recom-

mended oil quality requirements are met, and the recom-

mended maintenance intervals for oil and filter changes

are followed.

Materials Added to Engine Oil

The manufacture strongly recommends against the addi-

tion of any additives (other than leak detection dyes or

lube odorants) to the engine oil. Engine oil is an engi-

neered product and it's performance may be impaired by

supplemental additives.

NOTE:The manufacturer offers a lube odorant (Mopar

Diesel Fresh) for diesel engines crankcases. The lube

odorant is recommended by the manufacturer to reduce

the sulfur smell that may occur during engine idling.

Engine Oil Filter

Refer to Fluids, Lubricants and Genuine Parts for the

correct part number. The engine oil filter should be

changed ateveryengine oil change.

Engine Oil And Filter Ð Change

Operate the engine until the coolant temperature reaches

140ÉF (60ÉC). Shut the engine off. Remove the oil drain

plug.

410 MAINTAINING YOUR VEHICLE

Page 413 of 528

Drive Belts (Gas Engines)

Belt tension is controlled by means of an automatic

tensioner. No belt tension adjustments are required.

However, belt and belt tensioner condition should be

inspected at the specified intervals and replaced if re-

quired. See your authorized dealer for service.

At the mileage indicated in the maintenance schedule, all

belts and tensioner should be checked for condition.

Improper belt tension can cause belt slippage and failure.

Belts should be inspected for evidence of cuts, cracks,

glazing or frayed cords and replaced if there is indication

of damage which could result in belt failure. Low gen-

erator belt tension can cause battery failure.

Also check belt routing to make sure there is no interfer-

ence between the belts and other engine components.

Drive Belt (Diesel Engines)

Inspection

Check the belt for intersecting cracks.

²Transverse (across the belt width) cracks are accept-

able.

²Longitudinal (direction of belt length) cracks that

intersect with transverse cracks are NOT acceptable.

Replace the belt if it has unacceptable cracks, is frayed or

has pieces of material missing.

The engine speed sensor, located near the damper, should

be inspected for damage if a belt is frayed.

Engine Air Cleaner Filter (Gas Engines)

Follow the appropriate Maintenance Schedule for recom-

mended Air Cleaner Replacement intervals.

MAINTAINING YOUR VEHICLE 413

7

Page 414 of 528

WARNING!

The air induction system (air cleaner, hoses, etc) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner,

hoses, etc) removed. Failure to do so can result in

serious personal injury.

Engine Air Cleaner Filter (Diesel Engines)

CAUTION!

All air entering the engine intake must be filtered.

The abrasive particles in unfiltered air will cause

rapid wear to engine components.

The air filter housing on your Diesel Ram is equipped

with a Filter MinderŸ. This is an air flow restriction

gauge that will indicate when the filter element needs to

be replaced.

Do not remove the top of the air filter housing to

inspect the filter element on your diesel engine under

normal operating conditions.

NOTE:The air filter housing contains a Mass Air Flow

sensor. This sensor is critical to proper engine operation

and component longevity. Any damage or modification

414 MAINTAINING YOUR VEHICLE

Page 420 of 528

mixture in excess of 5% can negatively impact the on-

engine fuel filter's ability to separate water from the fuel,

resulting in high pressure fuel system corrosion or dam-

age.

NOTE:As sufficient testing has not been completed,

ethanol blends are not recommended or approved for use

with your Cummins Diesel equipped vehicle.

NOTE:In addition, commercially available fuel addi-

tives are not necessary for the proper operation of your

Cummins Diesel equipped vehicle.

Engine Fuel Filter (Gas Engines)

A plugged fuel filter can cause stalling, limit the speed at

which a vehicle can be driven or cause hard starting.

Should an excessive amount of dirt accumulate in the

fuel tank, frequent filter replacement may be necessary.

Spark Plugs (Gas Engines)

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New plugs should be in-

stalled at the specified mileage. The entire set should be

replaced if there is any malfunction due to a faulty spark

plug, malfunctioning spark plugs can damage the cata-

lytic converter. For proper type of replacement spark

plugs, refer to the Fluids, Lubricants and Genuine Parts

section in this manual.

Catalytic Converter (Gas Engines)

The catalytic converter requires the use of unleaded fuel

only. Leaded gasoline will destroy the effectiveness of the

catalyst as an emission control device.

Under normal operating conditions, the catalytic con-

verter will not require maintenance. However, it is im-

portant to keep the engine properly tuned to assure

proper catalyst operation and prevent possible catalyst

damage.

420 MAINTAINING YOUR VEHICLE

Page 422 of 528

To minimize the possibility of catalyst damage:

²Do not shut off the engine or interrupt the ignition

when the transmission is in gear and the vehicle is in

motion.

²Do not try to start engine by pushing or towing the

vehicle.

²Do not idle the engine with any spark plug wires

disconnected or removed, such as when diagnostic

testing, or for prolonged periods during very rough

idling or malfunctioning operating conditions.

Intervention Regeneration Strategy ± EVIC

Message Process Flow (Catalyst Full Message)

(Diesel Engines Only)

Your new Cummins 6.7L diesel meets all EPA Heavy

Duty Diesel Engine Emissions Standards, resulting in the

lowest emitting diesel engine ever produced.To achieve these emission standards your vehicle is

equipped with state of the art engine and exhaust system.

The engine and exhaust aftertreatment system work

together to achieve the EPA Heavy Duty Diesel Engine

Emissions Standards. These systems are seamlessly inte-

grated into your vehicle and managed by the Cummins

6.7L engine Powertrain Control Module (PCM). The PCM

manages engine combustion to allow the exhaust sys-

tem's catalyst to trap and burn Particulate Matter (PM)

pollutants, with no input or interaction on your part.

Additionally, the overhead console in your vehicle has

the ability to alert you to additional maintenance re-

quired on your truck or engine. Refer to the following

messages that may be displayed on your Electronic

Vehicle Information Center (EVIC):

422 MAINTAINING YOUR VEHICLE

Page 423 of 528

WARNING!

A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be

grass or leaves coming into contact with your exhaust

system. Do not park or operate your vehicle in areas

where your exhaust system can contact anything that

can burn.

Service CCV Filter

The 6.7L Cummins engine utilizes a Closed Crankcase

Ventilation (CCV) system. This system filters and recycles

gasses produced in the crankcase during the normal

combustion process. Service CCV Filter will be displayed

on the overhead console of your Dodge truck if the CCV

filter is due for required maintenance. This filter is

located on the top of the engine valve cover. For addi-

tional information, see your Dodge truck dealer.

Catalyst Full See Owner Manual

Catalyst Full See Owner Manual will be displayed on the

overhead console of your vehicle if the exhaust particu-

late filter reaches 80% of its maximum storage capacity.

Under conditions of exclusive short duration and low

speed driving cycles, your Cummins engine and exhaust

aftertreatment system may never reach the conditions

required to remove the trapped PM, if this occurs Cata-

lyst Full See Owner Manual will be displayed on the

overhead console in your vehicle. If this message is

displayed you will hear one chime to assist in alerting

you of this condition.

Catalyst Stat::::::::::80%

Catalyst Stat::::::::::80% will replace the message Catalyst

Full See Owner Manual after it is displayed for one

minute. The engine Powertrain Control Module (PCM)

will continue to monitor the amount of particulate matter

MAINTAINING YOUR VEHICLE 423

7

Page 425 of 528

Emission-Related Components (Gas Engines)

Positive Crankcase (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging from deposits. Deposits can accumulate in the PCV

valve and passages with increasing mileage. Have the

PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valveÐdo not

attempt to clean the old PCV valve!Check the ventila-

tion hoses for indications of damage, weepage or plug-

ging with deposits. Replace if necessary.

Maintenance Free Battery (Gas Engines)

The top of the maintenance free battery is permanently

sealed. You will never have to add water, nor is periodic

maintenance required.

WARNING!

²Battery fluid is a corrosive acid solution and can

burn or even blind you. Don't allow battery fluid

to contact your eyes, skin or clothing. Don't lean

over a battery when attaching clamps. If acid

splashes in eyes or on skin, flush the area imme-

diately with large amounts of water.

²Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Don't use a

booster battery or any other booster source with an

output greater than 12 volts. Don't allow cable

clamps to touch each other.

²Battery posts, terminals and related accessories

contain lead and lead compounds. Wash hands

after handling.

MAINTAINING YOUR VEHICLE 425

7