service DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5191 of 5267

TUBE-A/C ORIFICE

DESCRIPTION

The fixed A/C orifice tube is installed in the A/C liquid

line and provides a restriction in the liquid refrigerant

line between the A/C condenser and the A/C evapora-

tor. This restriction established the pressure differential

between the high and low-pressure sides of the A/C

system.

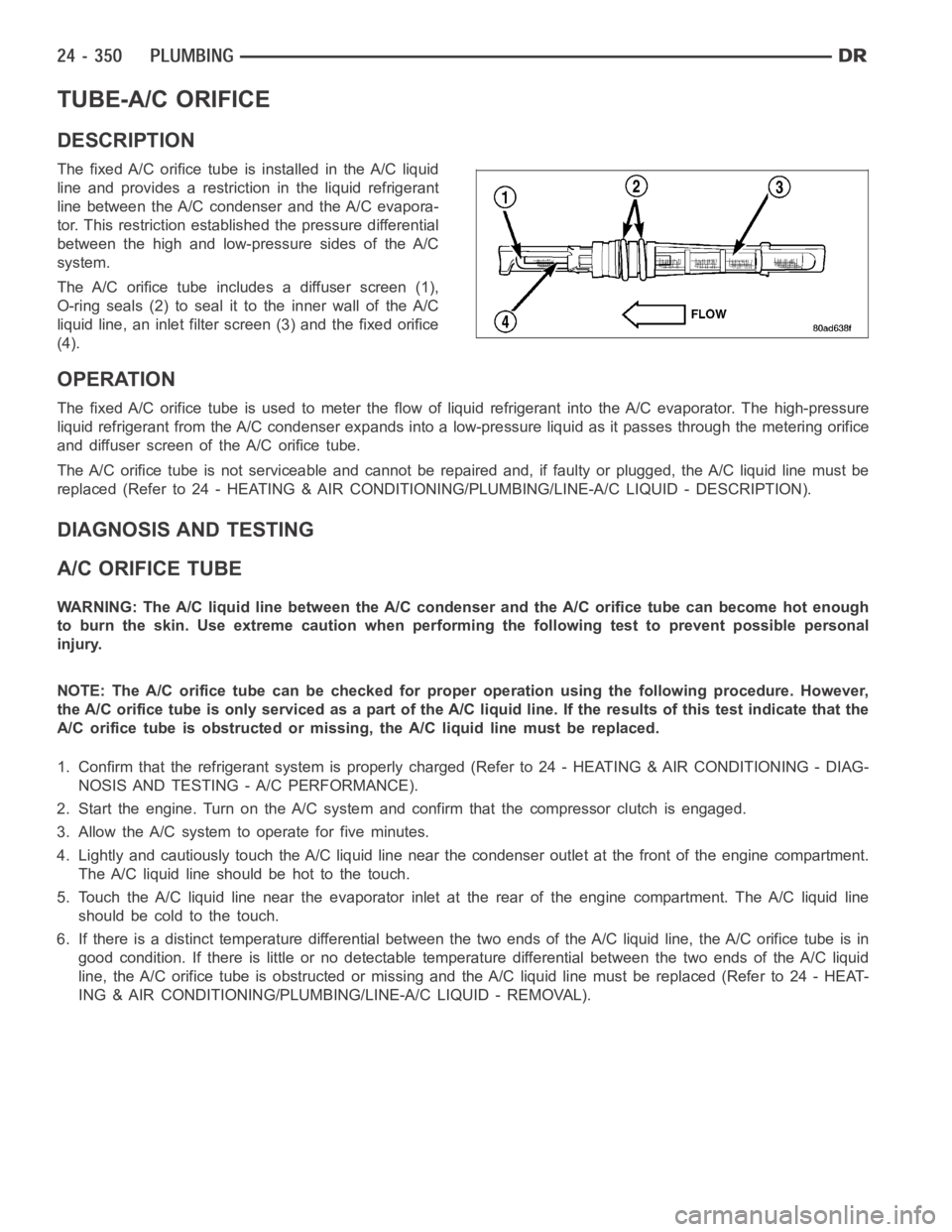

The A/C orifice tube includes a diffuser screen (1),

O-ring seals (2) to seal it to the inner wall of the A/C

liquid line, an inlet filter screen (3) and the fixed orifice

(4).

OPERATION

The fixed A/C orifice tube is used to meter the flow of liquid refrigerant into the A/C evaporator. The high-pressure

liquid refrigerant from the A/C condenser expands into a low-pressure liquid as it passes through the metering orifice

and diffuser screen of the A/C orifice tube.

The A/C orifice tube is not serviceable and cannot be repaired and, if faulty or plugged, the A/C liquid line must be

replaced (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C LIQUID - DESCRIPTION).

DIAGNOSIS AND TESTING

A/C ORIFICE TUBE

WARNING: The A/C liquid line between the A/C condenser and the A/C orifice tube can become hot enough

to burn the skin. Use extreme caution when performing the following test toprevent possible personal

injury.

NOTE: The A/C orifice tube can be checked for proper operation using the following procedure. However,

the A/C orifice tube is only serviced as a part of the A/C liquid line. If the results of this test indicate that the

A/C orifice tube is obstructed or missing, the A/C liquid line must be replaced.

1. Confirm that the refrigerant system is properly charged (Refer to 24 - HEATING & AIR CONDITIONING - DIAG-

NOSIS AND TESTING - A/C PERFORMANCE).

2. Start the engine. Turn on the A/Csystem and confirm that the compressor clutch is engaged.

3. Allow the A/C system to operate for five minutes.

4. Lightly and cautiously touch the A/C liquid line near the condenser outlet at the front of the engine compartment.

TheA/Cliquidlineshouldbehottothetouch.

5. Touch the A/C liquid line near the evaporator inlet at the rear of the engine compartment. The A/C liquid line

should be cold to the touch.

6. If there is a distinct temperature differential between the two ends of the A/C liquid line, the A/C orifice tube is in

good condition. If there is little or no detectable temperature differential between the two ends of the A/C liquid

line, the A/C orifice tube is obstructed or missing and the A/C liquid line must be replaced (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/LINE-A/C LIQUID - REMOVAL).

Page 5207 of 5267

PUMP-LEAK DETECTION

DESCRIPTION

Vehicles equipped with JTEC engine control modules use a leak detection pump. Vehicles equipped with NGC

engine control modules use an NVLD pump. Refer to Natural Vacuum - Leak Detection (NVLD) for additional infor-

mation.

The evaporative emission system is designed to prevent the escape of fuel vapors from the fuel system. Leaks in

the system, even small ones, can allow fuel vapors to escape into the atmosphere. Government regulations require

onboard testing to make sure that the evaporative (EVAP) system is functioning properly. The leak detection system

tests for EVAP system leaks and blockage. It also performs self-diagnostics. During self-diagnostics, the Powertrain

Control Module (PCM) first checks the Leak Detection Pump (LDP) for electrical and mechanical faults. If the first

checks pass, the PCM then uses the LDP to seal the vent valve and pump air intothe system to pressurize it. If a

leak is present, the PCM will continue pumping the LDP to replace the air that leaks out. The PCM determines the

size of the leak based on how fast/long it must pump the LDP as it tries to maintain pressure in the system.

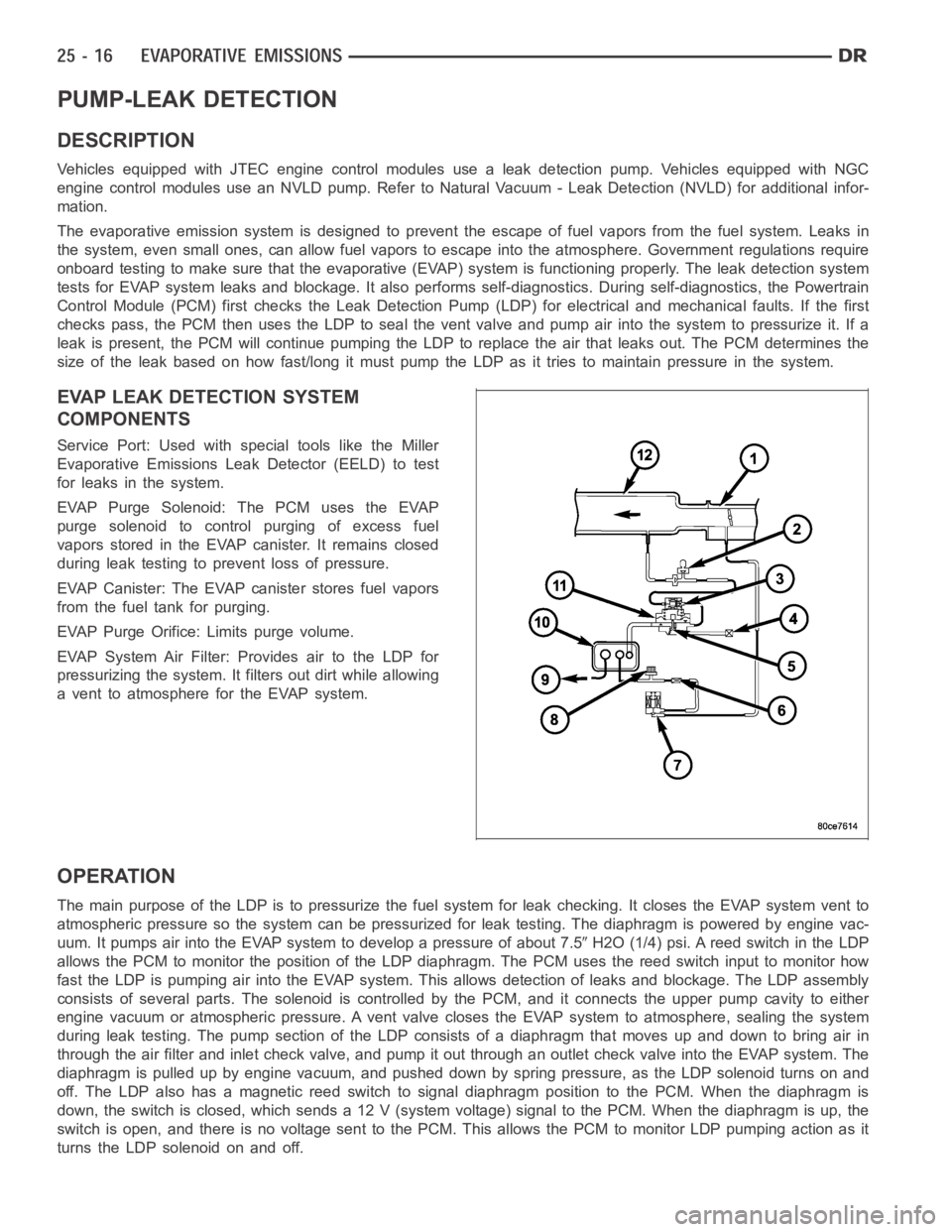

EVAP LEAK DETECTION SYSTEM

COMPONENTS

Service Port: Used with special tools like the Miller

Evaporative Emissions Leak Detector (EELD) to test

for leaks in the system.

EVAP Purge Solenoid: The PCM uses the EVAP

purge solenoid to control purging of excess fuel

vapors stored in the EVAP canister. It remains closed

during leak testing to prevent loss of pressure.

EVAP Canister: The EVAP canister stores fuel vapors

from the fuel tank for purging.

EVAP Purge Orifice: Limits purge volume.

EVAP System Air Filter: Provides air to the LDP for

pressurizing the system. It filters out dirt while allowing

a vent to atmosphere for the EVAP system.

OPERATION

The main purpose of the LDP is to pressurize the fuel system for leak checking. It closes the EVAP system vent to

atmospheric pressure so the system can be pressurized for leak testing. The diaphragm is powered by engine vac-

uum. It pumps air into the EVAP system to develop a pressure of about 7.5

H2O (1/4) psi. A reed switch in the LDP

allows the PCM to monitor the position of the LDP diaphragm. The PCM uses thereed switch input to monitor how

fast the LDP is pumping air into the EVAP system. This allows detection of leaks and blockage. The LDP assembly

consists of several parts. The solenoid is controlled by the PCM, and it connects the upper pump cavity to either

engine vacuum or atmospheric pressure. A vent valve closes the EVAP systemto atmosphere, sealing the system

during leak testing. The pump section of the LDP consists of a diaphragm that moves up and down to bring air in

through the air filter and inlet check valve, and pump it out through an outlet check valve into the EVAP system. The

diaphragm is pulled up by engine vacuum, and pushed down by spring pressure, as the LDP solenoid turns on and

off. The LDP also has a magnetic reed switch to signal diaphragm position tothe PCM. When the diaphragm is

down, the switch is closed, which sends a 12 V (system voltage) signal to thePCM. When the diaphragm is up, the

switch is open, and there is no voltage sent to the PCM. This allows the PCM tomonitor LDP pumping action as it

turns the LDP solenoid on and off.

Page 5210 of 5267

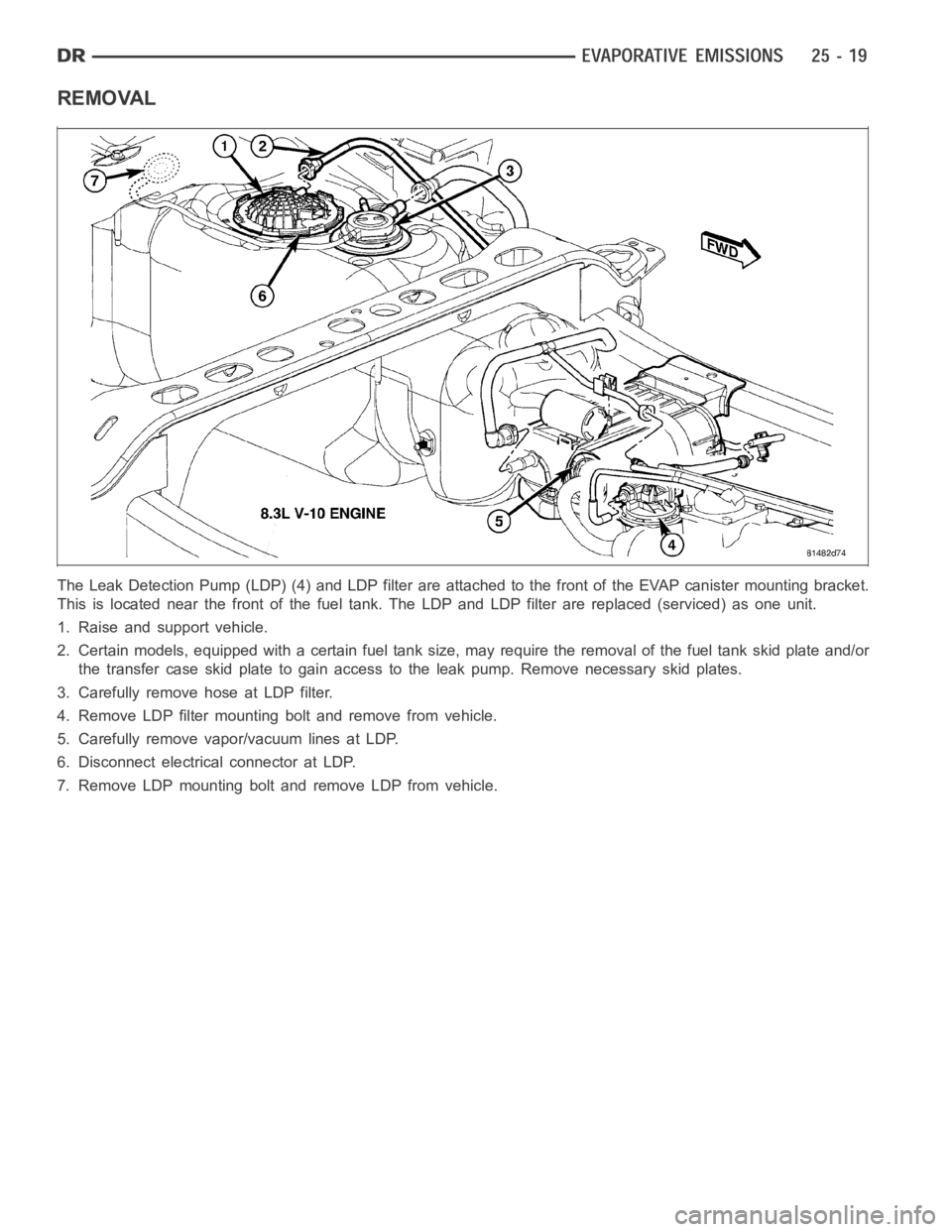

REMOVAL

The Leak Detection Pump (LDP) (4) and LDP filter are attached to the front ofthe EVAP canister mounting bracket.

This is located near the front of the fuel tank. The LDP and LDP filter are replaced (serviced) as one unit.

1. Raise and support vehicle.

2. Certain models, equipped with a certain fuel tank size, may require the removal of the fuel tank skid plate and/or

the transfer case skid plate to gain access to the leak pump. Remove necessary skid plates.

3. Carefully remove hose at LDP filter.

4. Remove LDP filter mounting bolt and remove from vehicle.

5. Carefully remove vapor/vacuum lines at LDP.

6. Disconnect electrical connector at LDP.

7. Remove LDP mounting bolt and remove LDP from vehicle.

Page 5211 of 5267

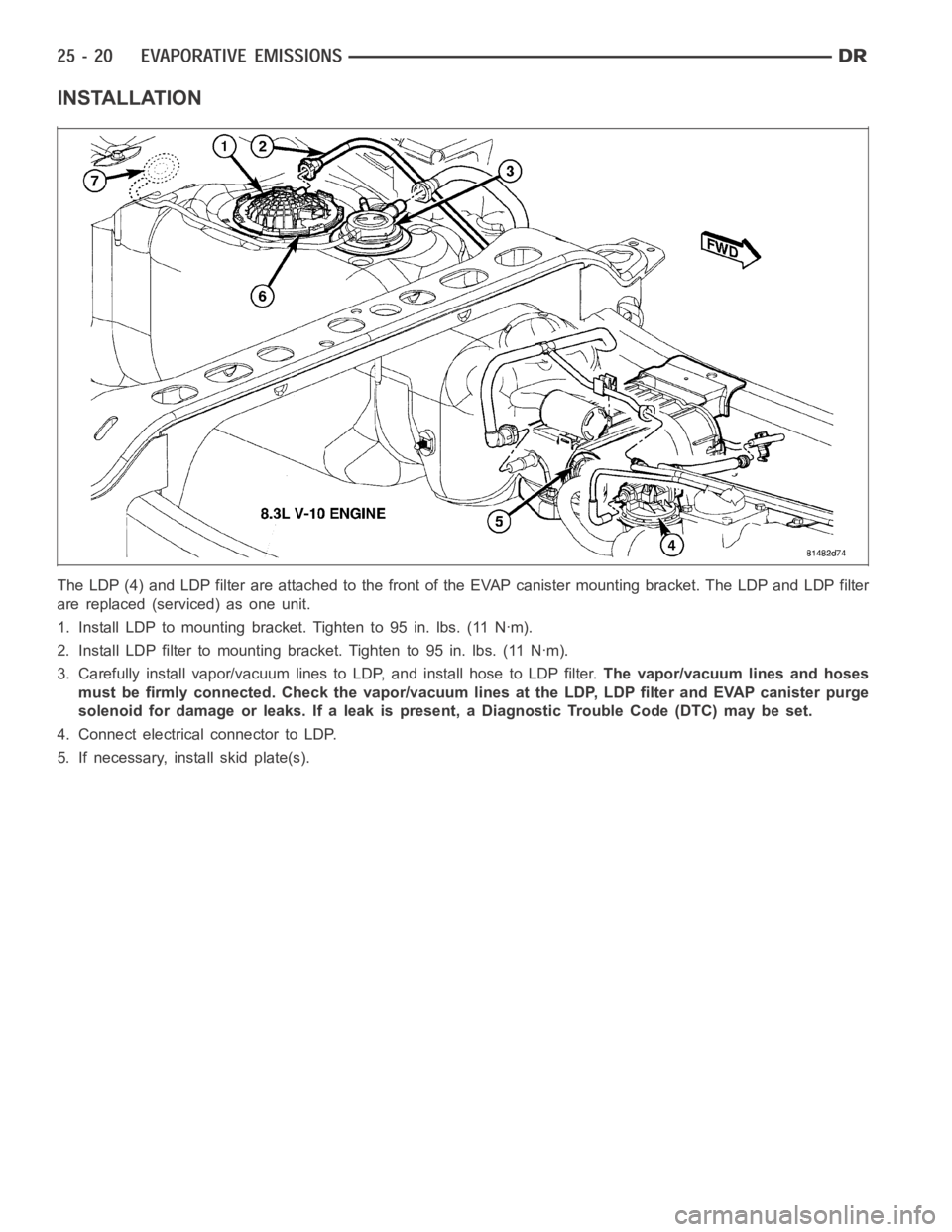

INSTALLATION

The LDP (4) and LDP filter are attached to the front of the EVAP canister mounting bracket. The LDP and LDP filter

are replaced (serviced) as one unit.

1. Install LDP to mounting bracket. Tighten to 95 in. lbs. (11 Nꞏm).

2. Install LDP filter to mounting bracket. Tighten to 95 in. lbs. (11 Nꞏm).

3. Carefully install vapor/vacuum lines to LDP, and install hose to LDP filter.The vapor/vacuum lines and hoses

must be firmly connected. Check the vapor/vacuum lines at the LDP, LDP filter and EVAP canister purge

solenoid for damage or leaks. If a leak is present, a Diagnostic Trouble Code (DTC) may be set.

4. Connect electrical connector to LDP.

5. If necessary, install skid plate(s).

Page 5266 of 5267

SERVICE MANUAL COMMENTS

What errors(s) have you found?

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

In order for us to assist you, please include as much details as possible when reporting an error

Comments / Suggestions

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Dealership Technician

Dealer Code:Retail Customer

M a n u a l Ti t l e , Ye a r, N u m b e r a nd P a g e : _________________________________________________

______________________________________________________________________________________

Yo u r N a m e : ________________________________________________________________________

Address: ________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

All comments become property of DaimlerChrysler and may be used without compensation.