Fuel injector removal DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2262 of 5267

1. Remove fuel tank filler tube cap.

2. Perform fuel system pressure release procedure.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE)

3. Remove negative battery cable at battery.

4. Remove flex tube (air cleaner housing to engine).

5. Remove air resonator box at throttle body.

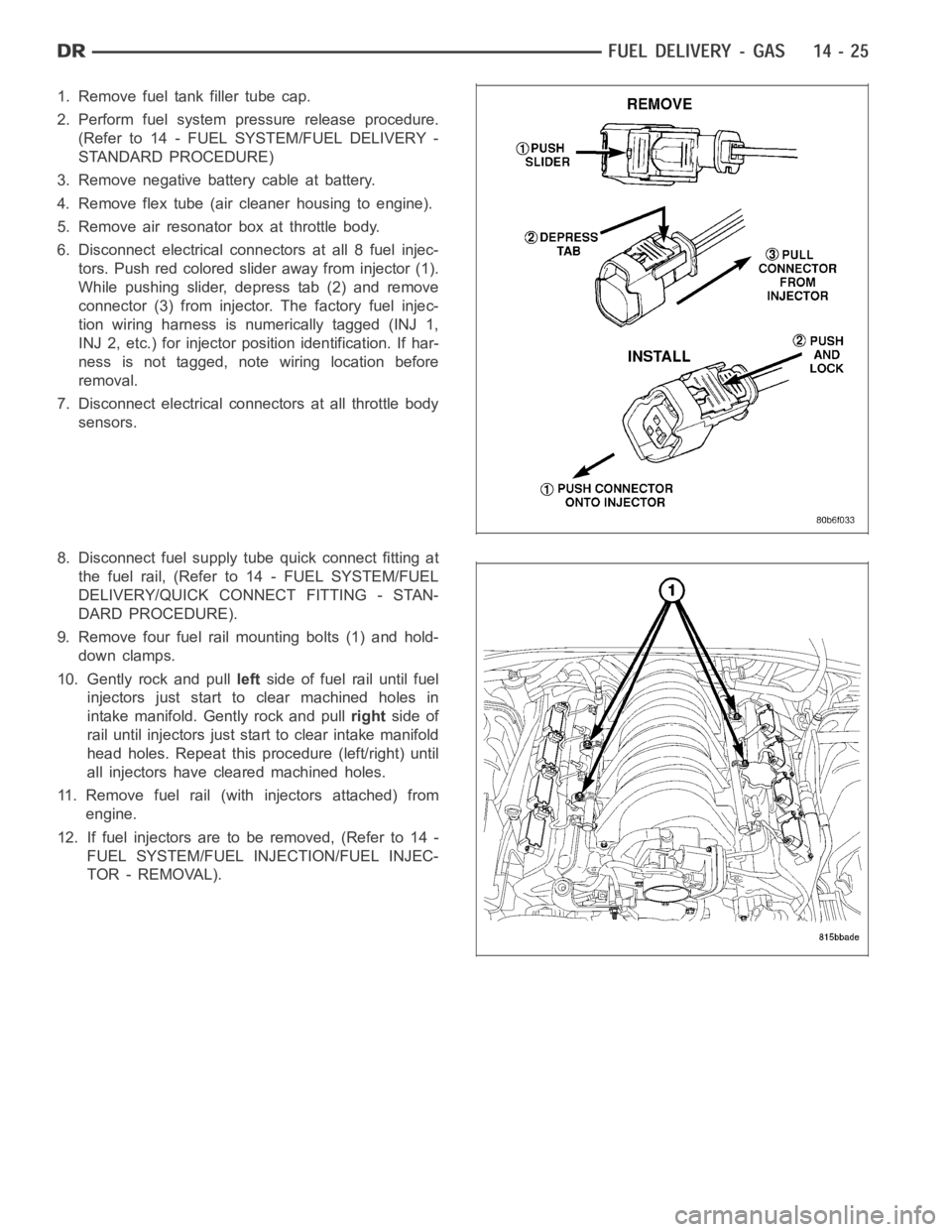

6. Disconnect electrical connectors at all 8 fuel injec-

tors. Push red colored slider away from injector (1).

While pushing slider, depress tab (2) and remove

connector (3) from injector. The factory fuel injec-

tion wiring harness is numerically tagged (INJ 1,

INJ 2, etc.) for injector position identification. If har-

ness is not tagged, note wiring location before

removal.

7. Disconnect electrical connectors at all throttle body

sensors.

8. Disconnect fuel supply tube quick connect fitting at

the fuel rail, (Refer to14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

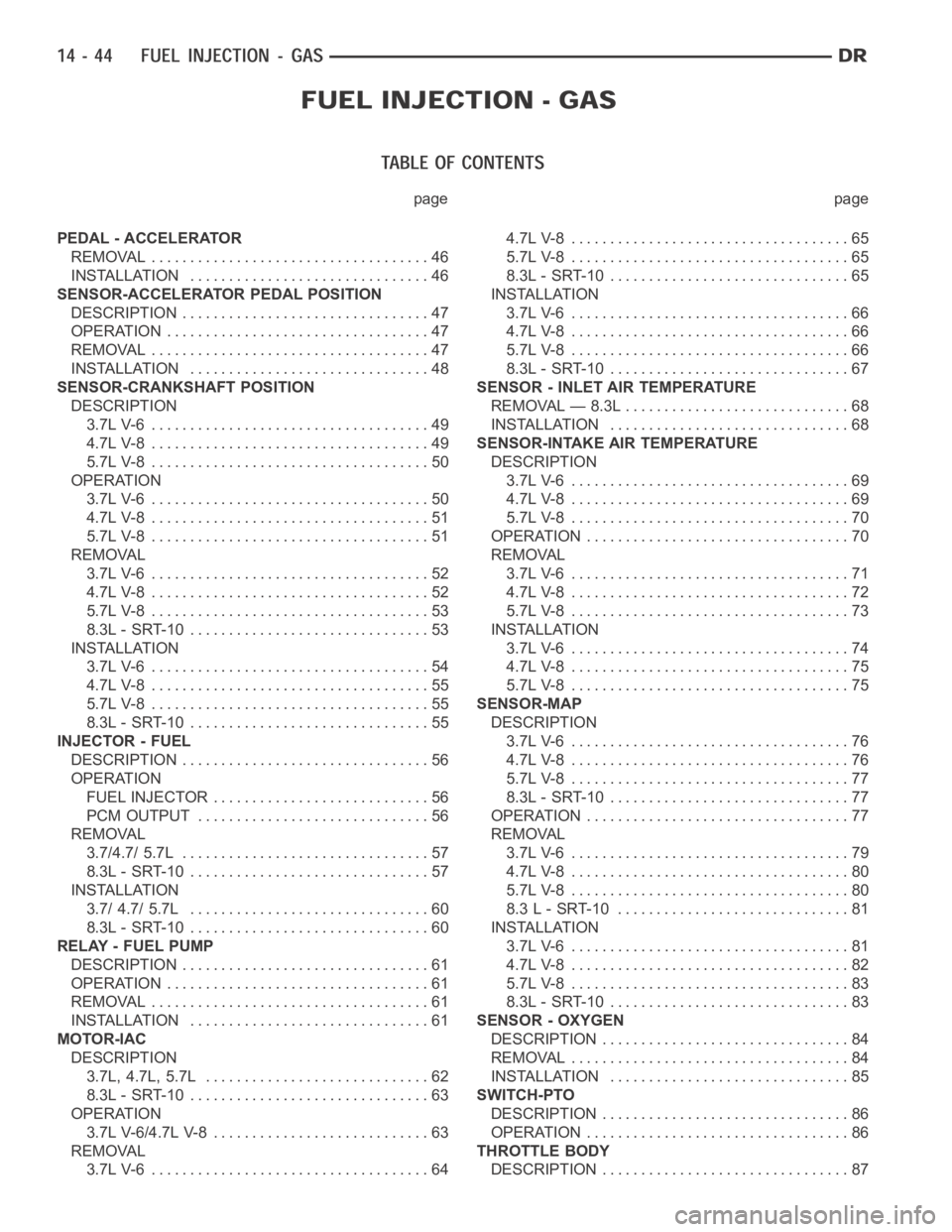

9. Remove four fuel rail mounting bolts (1) and hold-

down clamps.

10. Gently rock and pullleftside of fuel rail until fuel

injectors just start to clear machined holes in

intake manifold. Gently rock and pullrightside of

rail until injectors just start to clear intake manifold

head holes. Repeat this procedure (left/right) until

all injectors have cleared machined holes.

11. Remove fuel rail (with injectors attached) from

engine.

12. If fuel injectors are to be removed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - REMOVAL).

Page 2281 of 5267

page page

PEDAL - ACCELERATOR

REMOVAL .................................... 46

INSTALLATION ............................... 46

SENSOR-ACCELERATOR PEDAL POSITION

DESCRIPTION ................................ 47

OPERATION .................................. 47

REMOVAL .................................... 47

INSTALLATION ............................... 48

SENSOR-CRANKSHAFT POSITION

DESCRIPTION

3.7L V-6 .................................... 49

4.7L V-8 .................................... 49

5.7L V-8 .................................... 50

OPERATION

3.7L V-6 .................................... 50

4.7L V-8 .................................... 51

5.7L V-8 .................................... 51

REMOVAL

3.7L V-6 .................................... 52

4.7L V-8 .................................... 52

5.7L V-8 .................................... 53

8.3L - SRT-10 ............................... 53

INSTALLATION

3.7L V-6 .................................... 54

4.7L V-8 .................................... 55

5.7L V-8 .................................... 55

8.3L - SRT-10 ............................... 55

INJECTOR - FUEL

DESCRIPTION ................................ 56

OPERATION

FUEL INJECTOR ............................ 56

PCM OUTPUT .............................. 56

REMOVAL

3.7/4.7/ 5.7L ................................ 57

8.3L - SRT-10 ............................... 57

INSTALLATION

3.7/ 4.7/ 5.7L ............................... 60

8.3L - SRT-10 ............................... 60

RELAY - FUEL PUMP

DESCRIPTION ................................ 61

OPERATION .................................. 61

REMOVAL .................................... 61

INSTALLATION ............................... 61

MOTOR-IAC

DESCRIPTION

3.7L, 4.7L, 5.7L ............................. 62

8.3L - SRT-10 ............................... 63

OPERATION

3.7L V-6/4.7L V-8 ............................ 63

REMOVAL

3.7L V-6 .................................... 644.7L V-8 .................................... 65

5.7L V-8 .................................... 65

8.3L - SRT-10 ............................... 65

INSTALLATION

3.7L V-6 .................................... 66

4.7L V-8 .................................... 66

5.7L V-8 .................................... 66

8.3L - SRT-10 ............................... 67

SENSOR - INLET AIR TEMPERATURE

REMOVAL — 8.3L ............................. 68

INSTALLATION ............................... 68

SENSOR-INTAKE AIR TEMPERATURE

DESCRIPTION

3.7L V-6 .................................... 69

4.7L V-8 .................................... 69

5.7L V-8 .................................... 70

OPERATION .................................. 70

REMOVAL

3.7L V-6 .................................... 71

4.7L V-8 .................................... 72

5.7L V-8 .................................... 73

INSTALLATION

3.7L V-6 .................................... 74

4.7L V-8 .................................... 75

5.7L V-8 .................................... 75

SENSOR-MAP

DESCRIPTION

3.7L V-6 .................................... 76

4.7L V-8 .................................... 76

5.7L V-8 .................................... 77

8.3L - SRT-10 ............................... 77

OPERATION .................................. 77

REMOVAL

3.7L V-6 .................................... 79

4.7L V-8 .................................... 80

5.7L V-8 .................................... 80

8.3 L - SRT-10 .............................. 81

INSTALLATION

3.7L V-6 .................................... 81

4.7L V-8 .................................... 82

5.7L V-8 .................................... 83

8.3L - SRT-10 ............................... 83

SENSOR - OXYGEN

DESCRIPTION ................................ 84

REMOVAL .................................... 84

INSTALLATION ............................... 85

SWITCH-PTO

DESCRIPTION ................................ 86

OPERATION .................................. 86

THROTTLE BODY

DESCRIPTION ................................ 87

Page 2294 of 5267

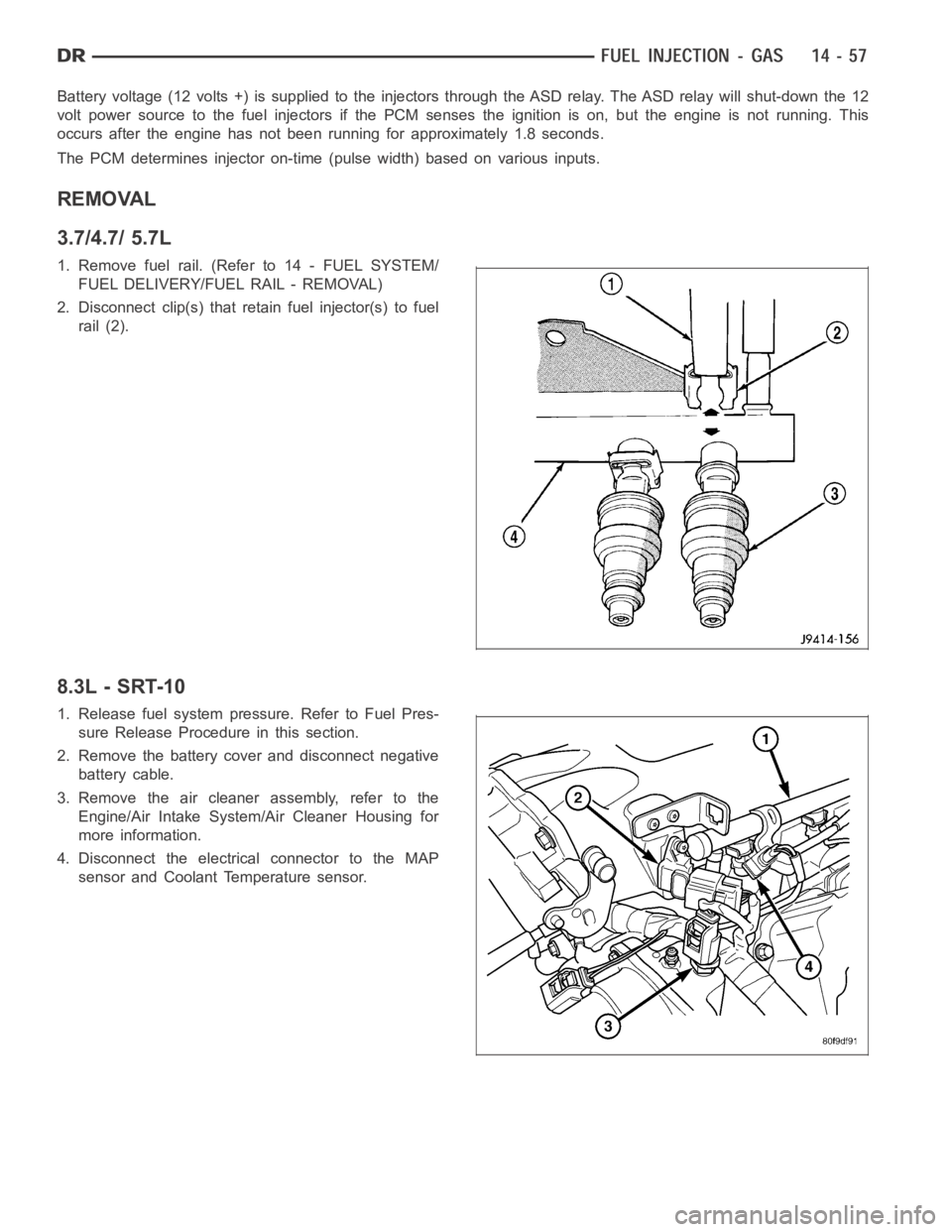

Battery voltage (12 volts +) is supplied to the injectors through the ASD relay. The ASD relay will shut-down the 12

volt power source to the fuel injectors if the PCM senses the ignition is on,but the engine is not running. This

occurs after the engine has not been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width) based on various inputs.

REMOVAL

3.7/4.7/ 5.7L

1. Remove fuel rail. (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - REMOVAL)

2. Disconnect clip(s) that retain fuel injector(s) to fuel

rail (2).

8.3L - SRT-10

1. Release fuel system pressure. Refer to Fuel Pres-

sure Release Procedure in this section.

2. Remove the battery cover and disconnect negative

battery cable.

3. Remove the air cleaner assembly, refer to the

Engine/Air Intake System/Air Cleaner Housing for

more information.

4. Disconnect the electrical connector to the MAP

sensor and Coolant Temperature sensor.

Page 2324 of 5267

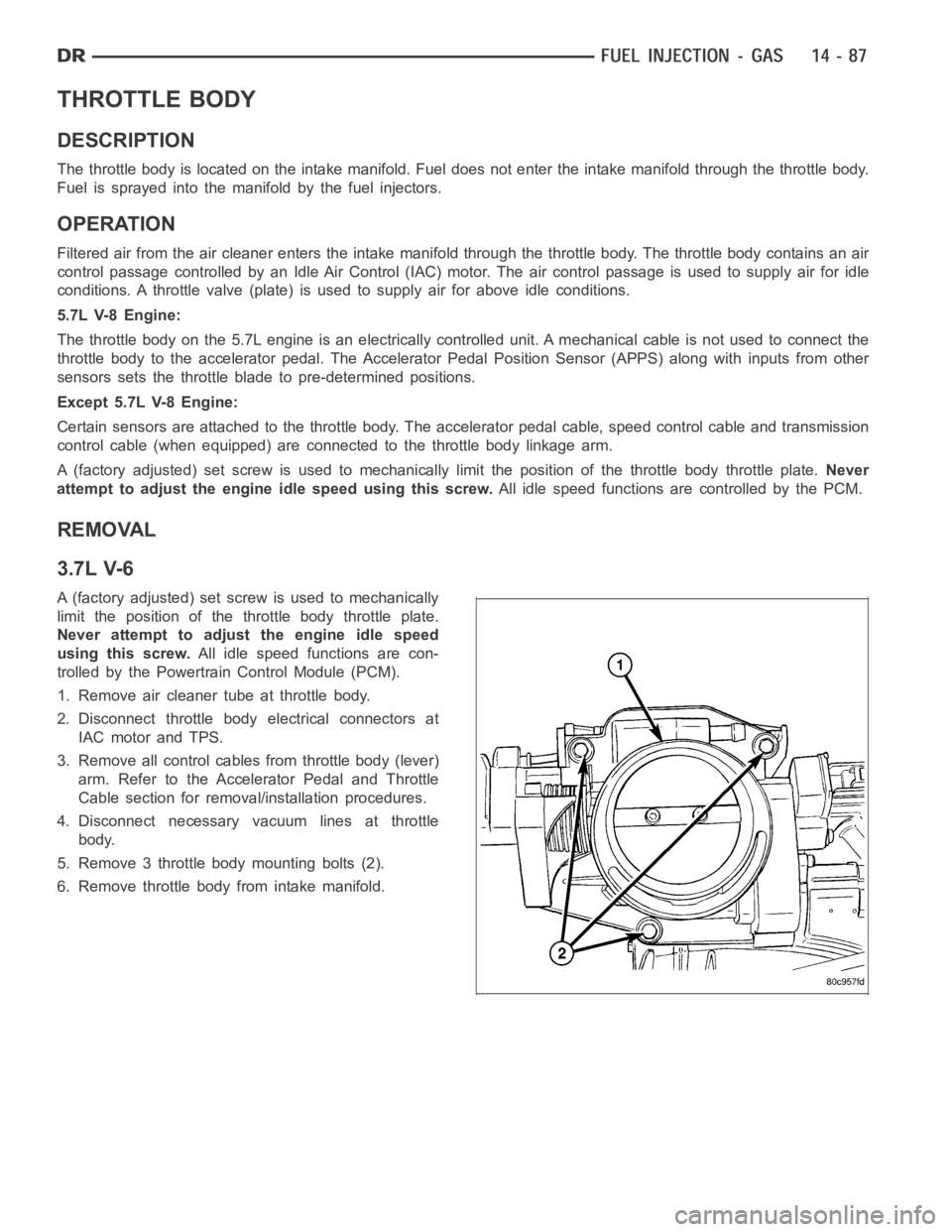

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold. Fuel does not enter theintake manifold through the throttle body.

Fuel is sprayed into the manifold by the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake manifold through the throttle body. The throttle body contains an air

control passage controlled by an Idle Air Control (IAC) motor. The air control passage is used to supply air for idle

conditions. A throttle valve (plate) is used to supply air for above idle conditions.

5.7L V-8 Engine:

The throttle body on the 5.7L engine is an electrically controlled unit. A mechanical cable is not used to connect the

throttle body to the accelerator pedal. The Accelerator Pedal Position Sensor (APPS) along with inputs from other

sensors sets the throttle blade to pre-determined positions.

Except 5.7L V-8 Engine:

Certain sensors are attached to the throttle body. The accelerator pedal cable, speed control cable and transmission

control cable (when equipped) are connected to the throttle body linkage arm.

A (factory adjusted) set screw is usedto mechanically limit the position of the throttle body throttle plate.Never

attempt to adjust the engine idle speed using this screw.All idle speed functions are controlled by the PCM.

REMOVAL

3.7L V-6

A (factory adjusted) set screw is used to mechanically

limit the position of the throttle body throttle plate.

Never attempt to adjust the engine idle speed

using this screw.All idle speed functions are con-

trolled by the Powertrain Control Module (PCM).

1. Remove air cleaner tube at throttle body.

2. Disconnect throttle body electrical connectors at

IAC motor and TPS.

3. Remove all control cables from throttle body (lever)

arm. Refer to the Accelerator Pedal and Throttle

Cable section for removal/installation procedures.

4. Disconnect necessary vacuum lines at throttle

body.

5. Remove 3 throttle body mounting bolts (2).

6. Remove throttle body from intake manifold.

Page 2336 of 5267

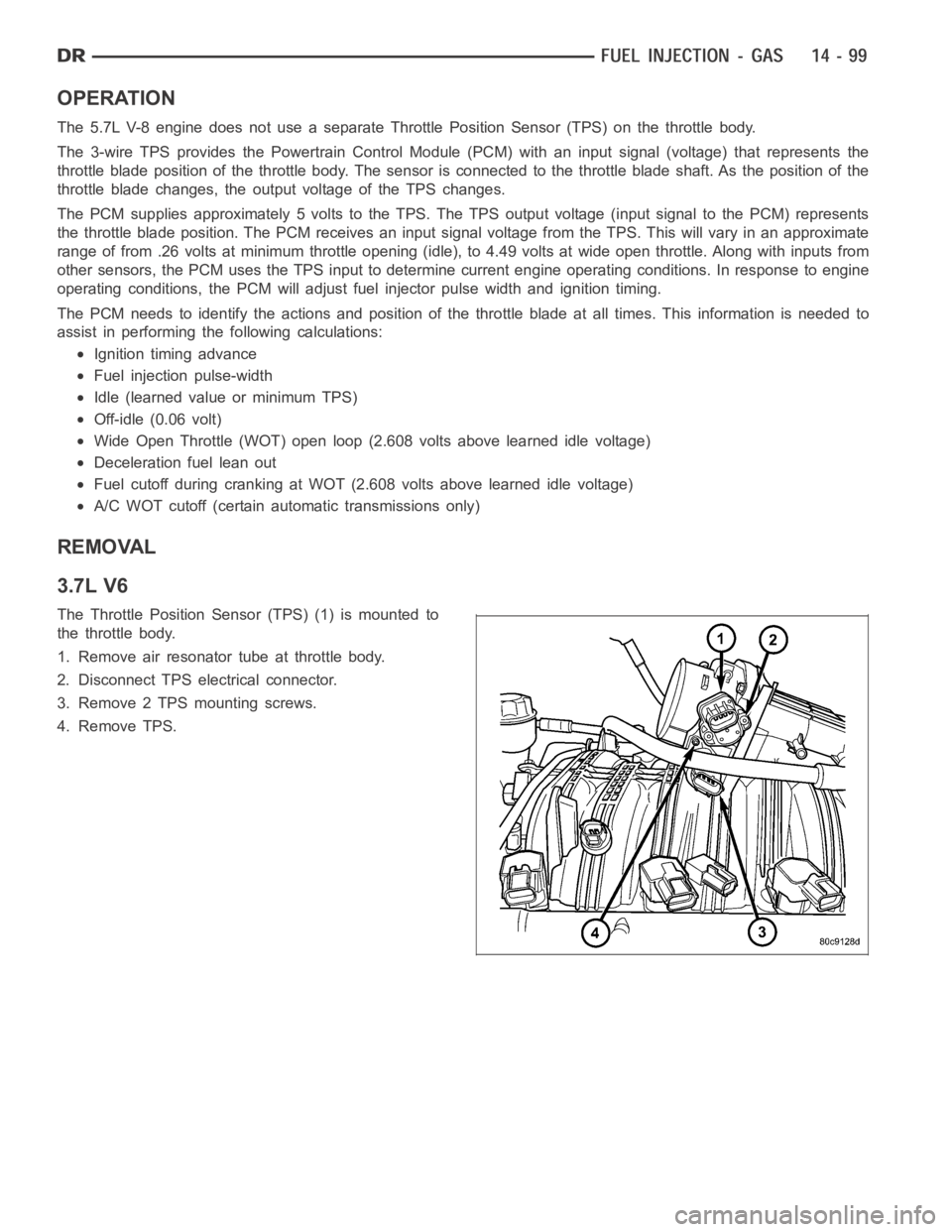

OPERATION

The 5.7L V-8 engine does not use a separate Throttle Position Sensor (TPS) on the throttle body.

The 3-wire TPS provides the Powertrain Control Module (PCM) with an input signal (voltage) that represents the

throttle blade position of the throttle body. The sensor is connected to the throttle blade shaft. As the position of the

throttle blade changes, the output voltage of the TPS changes.

The PCM supplies approximately 5 volts to the TPS. The TPS output voltage (input signal to the PCM) represents

the throttle blade position. The PCM receives an input signal voltage fromthe TPS. This will vary in an approximate

range of from .26 volts at minimum throttle opening (idle), to 4.49 volts atwide open throttle. Along with inputs from

other sensors, the PCM uses the TPS input to determine current engine operating conditions. In response to engine

operating conditions, the PCM will adjust fuel injector pulse width and ignition timing.

The PCM needs to identify the actions and position of the throttle blade at all times. This information is needed to

assist in performing the following calculations:

Ignition timing advance

Fuel injection pulse-width

Idle (learned value or minimum TPS)

Off-idle (0.06 volt)

Wide Open Throttle (WOT) open loop (2.608 volts above learned idle voltage)

Deceleration fuel lean out

Fuel cutoff during cranking at WOT (2.608 volts above learned idle voltage)

A/C WOT cutoff (certain automatic transmissions only)

REMOVAL

3.7L V6

The Throttle Position Sensor (TPS) (1) is mounted to

the throttle body.

1. Remove air resonator tube at throttle body.

2. Disconnect TPS electrical connector.

3. Remove 2 TPS mounting screws.

4. Remove TPS.

Page 2341 of 5267

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM ....... 105

STANDARD PROCEDURE

WATER DRAINING AT FUEL FILTER ......... 106

CLEANING FUEL SYSTEM PARTS .......... 106

FUEL SYSTEM PRIMING................... 106

DRAINING FUEL TANK - DIESEL............ 107

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL . . 107

TORQUE .................................. 107

SPECIAL TOOLS

DIESEL FUEL SYSTEM . .................... 109

FILTER - FUEL / WATER SEPARATOR

DESCRIPTION ............................... 111

OPERATION ................................. 111

REMOVAL ................................... 111

INSTALLATION .............................. 113

HEATER-FUEL

DESCRIPTION ............................... 115

OPERATION ................................. 115

DIAGNOSIS AND TESTING

FUEL HEATER ............................. 115

REMOVAL ................................... 116

PUMP - FUEL INJECTION

DESCRIPTION ............................... 117

OPERATION ................................. 117

DIAGNOSIS AND TESTING

FUEL INJECTION PUMP TIMING ............ 117

REMOVAL ................................... 117

INSTALLATION .............................. 120

SENSOR - FUEL LEVEL SENDING UNIT

DESCRIPTION ............................... 124

OPERATION ................................. 124

REMOVAL

REMOVAL/INSTALLATION .................. 124

LINES - FUEL

DESCRIPTION ............................... 125

OPERATION ................................. 125DIAGNOSIS AND TESTING

HIGH-PRESSURE FUEL LINE LEAKS........ 125

REMOVAL ................................... 126

INSTALLATION .............................. 127

SENSOR - FUEL PRESSURE

DESCRIPTION ............................... 129

OPERATION ................................. 129

REMOVAL ................................... 129

INSTALLATION .............................. 129

VALVE - FUEL PRESSURE LIMITING

DESCRIPTION ............................... 130

OPERATION ................................. 130

REMOVAL ................................... 130

INSTALLATION .............................. 131

TA N K - F U E L

DESCRIPTION ............................... 132

REMOVAL ................................... 132

INSTALLATION .............................. 133

MODULE - FUEL TANK

DESCRIPTION ............................... 134

OPERATION ................................. 134

REMOVAL ................................... 134

INSTALLATION .............................. 134

PUMP - FUEL TRANSFER

DESCRIPTION ............................... 136

OPERATION ................................. 136

REMOVAL ................................... 136

INSTALLATION .............................. 136

VALVE - CASCADE OVERFLOW

DESCRIPTION ............................... 137

OPERATION ................................. 137

SENSOR-WATER IN FUEL

DESCRIPTION ............................... 138

OPERATION ................................. 138

REMOVAL ................................... 138

CIRCUIT - FUEL DRAIN

OPERATION ................................. 139

Page 2343 of 5267

Fuel enters the system from the electric fuel transfer (lift) pump, which is located inside of the fuel tank and attached

to the fuel tank module (the fuel transfer pump is no longer attached to the engine). Fuel is forced through the fuel

filter element and then enters the Fuel Pump/Gear Pump, which is attached to the rear of the fuel injection pump.

The Fuel Pump/Gear Pump is a low-pressure pump and produce pressures ranging from 551.5 kpa (80 psi) to 1241

kpa (180) psi. Fuel then enters the fuel injection pump. Low pressure fuel is then supplied to the FCA (Fuel Control

Actuator).

The FCA is an electronically controlled solenoid valve. The ECM controls the amount of fuel that enters the high-

pressure pumping chambers by opening and closing the FCA based on a demanded fuel pressure. The FPS (Fuel

Pressure Sensor) on the fuel rail monitors the actual fuel pressure and provides it as an input to the ECM. When

the actuator is opened, the maximum amount of fuel is being supplied to the fuel injection pump. Any fuel that does

not enter the injection pump is directed to the overflow valve. The overflow valve regulates how much excess fuel

is used for lubrication of the pump and how much is returned to the tank through the drain manifold.

Fuel entering the injection pump is pressurized to between 300-1600 bar (4351-23,206 psi) by three radial pumping

chambers. The pressurized fuel is then supplied to the fuel rail.

STANDARD PROCEDURE

WATER DRAINING AT FUEL FILTER

Refer to Fuel Filter/Water Separatorremoval/installation for procedures.

CLEANING FUEL SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.

FUEL SYSTEM PRIMING

A certain amount of air becomes trappedin the fuel system when fuel system components on the supply and/or

high-pressure side are serviced or replaced. Fuel system priming is accomplished using the electric fuel transfer (lift)

pump.

Servicing or replacing fuel system components will not require fuel systempriming.

The fuel transfer (lift) pump is self-priming: When the key is first turnedon (without cranking engine), the pump

operates for approximately 1 to 2 second and then shuts off (Note: When ambient temperatures are cold enough to

cause the intake air heaters to operate, the fuel lift pump will operate during the entire intake air pre-heat cycle).

The pump will also operate for up to 25 seconds after the starter is quickly engaged, and then disengaged without

allowing the engine to start. The pump shuts off immediately if the key is onand the engine stops running.

1. Turn key to CRANK position and quickly release key to ON position before engine starts. This will operate fuel

transfer pump for approximately 25 seconds.

2. Crank engine. If the engine does not start after 25 seconds, turn key to OFF position, and leave it off for at least

5 seconds. Repeat previous step until engine starts.

3. Fuel system priming is now completed.

4. Attempt to start engine. If engine will not start, proceed to following steps.When engine does start, it may run

erratically and be noisy for a few minutes. This is a normal condition.

CAUTION: Do not engage the starter motor for more than 30 seconds at a time. Allow two minutes between

cranking intervals.

5. Perform previous fuel priming procedure steps using fuel transfer pump. Be sure fuel is present at fuel tank.

6. Crank the engine for 30 seconds at a time to allow fuel system to prime.

Page 2354 of 5267

PUMP - FUEL INJECTION

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump is used. The pump is attached to the back of the timing gear

housing at the left /front side of the engine.

OPERATION

The fuel injection pump supplies high pressure to the fuel rail independent of engine speed. This high pressure is

then accumulated in the fuel rail. High pressure fuel is constantly supplied to the injectors by the fuel rail. The

Engine Control Module (ECM) controls the fueling and timing of the engine by actuating the injectors.

Fuel enters the system from the electric fuel transfer (lift) pump, which is located in the fuel tank. Fuel is forced

through the fuel filter element and then enters the Fuel Pump/Gear Pump, which is attached to the rear of the fuel

injection pump. The Fuel Pump/Gear Pump is a low-pressure pump and producepressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the fuel injection pump. Lowpressure fuel is then supplied to the

FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid valve. The ECM controls the amount of fuel that enters the high-

pressure pumping chambers by opening and closing the FCA based on a demanded fuel pressure. The FPS (Fuel

Pressure Sensor) on the fuel rail provides the actual fuel pressure. When the actuator is opened, the maximum

amount of fuel is being supplied to the fuel injection pump. Any fuel that does not enter the injection pump is

directed to the cascade overflow valve. The cascade overflow valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to the tank through the drain manifold.

Fuel entering the injection pump is pressurized to between 300-1600 bar (4351-23206 psi) by three radial pumping

chambers. The pressurized fuel is then supplied to the fuel rail.

DIAGNOSIS AND TESTING

FUEL INJECTION PUMP TIMING

With the Bosch injection pump, there are no mechanical adjustments neededor necessary to accomplish fuel injec-

tion timing. All timing and fuel adjustments are electrically made by the engine mounted Engine Control Module

(ECM).

REMOVAL

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.

Page 2363 of 5267

REMOVAL

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.

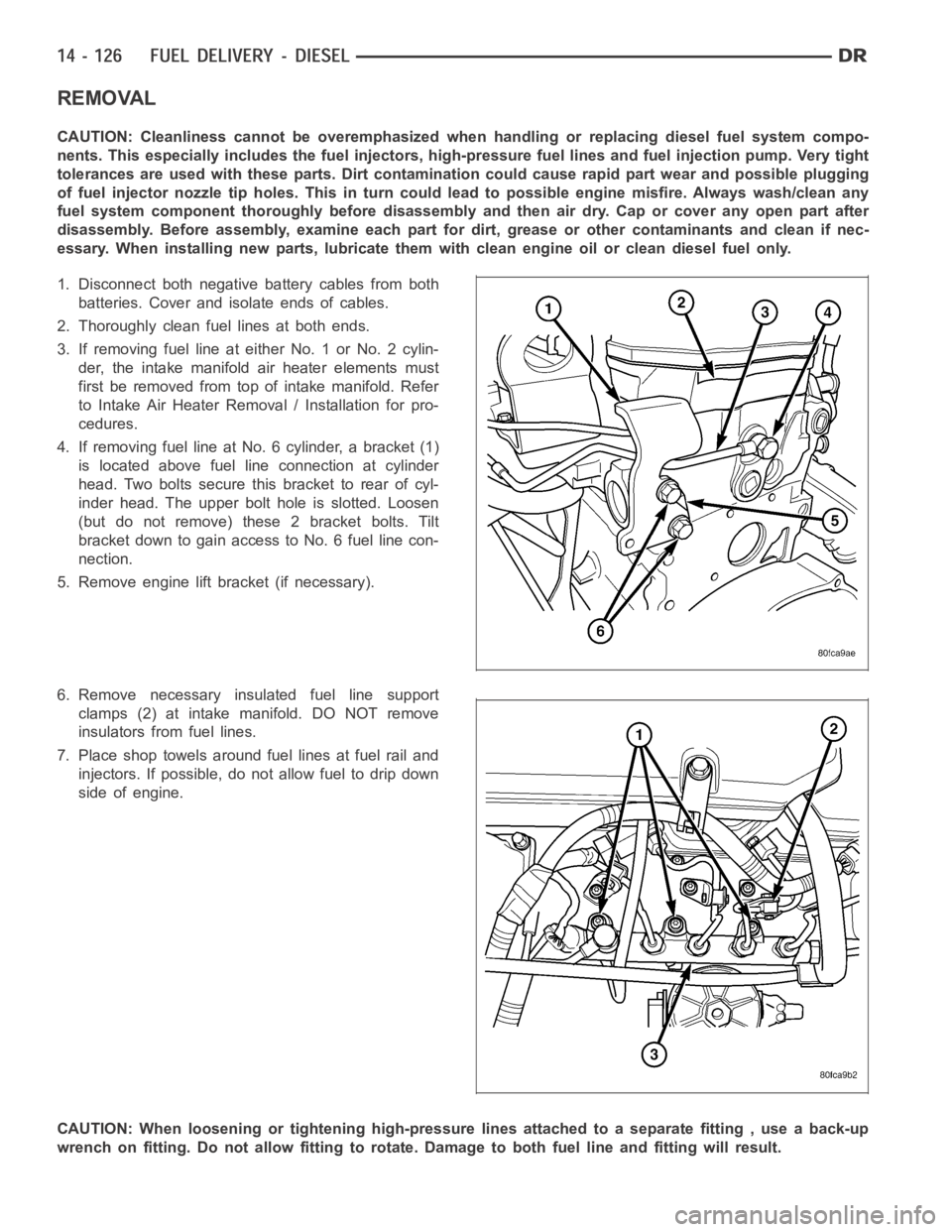

1. Disconnect both negative battery cables from both

batteries. Cover and isolate ends of cables.

2. Thoroughly clean fuel lines at both ends.

3. If removing fuel line at either No. 1 or No. 2 cylin-

der, the intake manifold air heater elements must

first be removed from top of intake manifold. Refer

to Intake Air Heater Removal / Installation for pro-

cedures.

4. If removing fuel line at No. 6 cylinder, a bracket (1)

is located above fuel line connection at cylinder

head. Two bolts secure this bracket to rear of cyl-

inder head. The upper bolt hole is slotted. Loosen

(but do not remove) these 2 bracket bolts. Tilt

bracket down to gain access to No. 6 fuel line con-

nection.

5. Remove engine lift bracket (if necessary).

6. Remove necessary insulated fuel line support

clamps (2) at intake manifold. DO NOT remove

insulators from fuel lines.

7. Place shop towels around fuel lines at fuel rail and

injectors. If possible, do not allow fuel to drip down

side of engine.

CAUTION: When loosening or tightening high-pressure lines attached to a separate fitting , use a back-up

wrench on fitting. Do not allow fitting to rotate. Damage to both fuel line and fitting will result.

Page 2367 of 5267

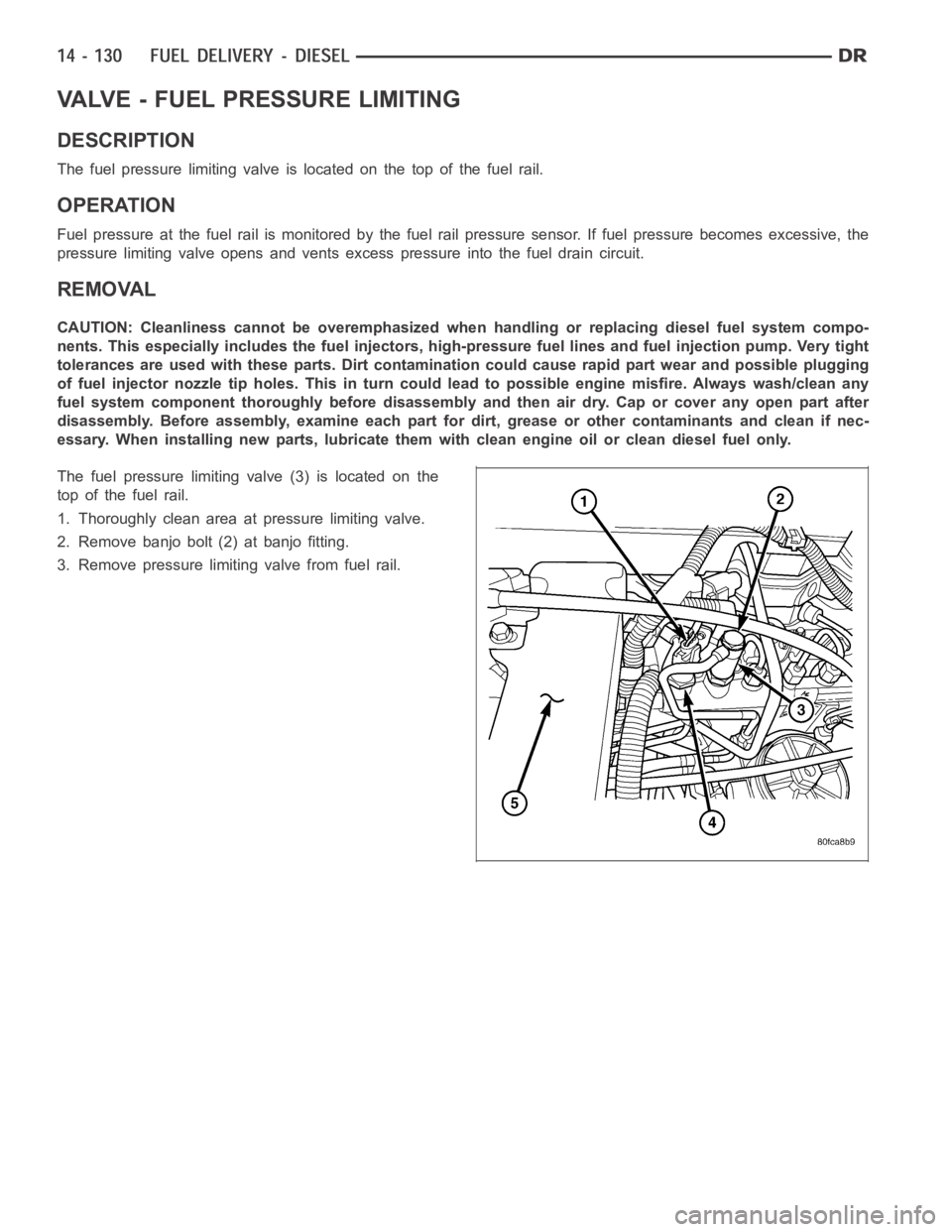

VALVE - FUEL PRESSURE LIMITING

DESCRIPTION

The fuel pressure limiting valve is located on the top of the fuel rail.

OPERATION

Fuel pressure at the fuel rail is monitored by the fuel rail pressure sensor. If fuel pressure becomes excessive, the

pressure limiting valve opens and vents excess pressure into the fuel draincircuit.

REMOVAL

CAUTION: Cleanliness cannot be overemphasized when handling or replacingdieselfuelsystemcompo-

nents. This especially includes the fuel injectors, high-pressure fuel lines and fuel injection pump. Very tight

tolerances are used with these parts. Dirt contamination could cause rapid part wear and possible plugging

of fuel injector nozzle tip holes. This in turn could lead to possible engine misfire. Always wash/clean any

fuel system component thoroughly before disassembly and then air dry. Capor cover any open part after

disassembly. Before assembly, examine each part for dirt, grease or othercontaminants and clean if nec-

essary. When installing new parts, lubricate them with clean engine oil orclean diesel fuel only.

The fuel pressure limiting valve (3) is located on the

top of the fuel rail.

1. Thoroughly clean area at pressure limiting valve.

2. Remove banjo bolt (2) at banjo fitting.

3. Remove pressure limiting valve from fuel rail.