DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3881 of 5267

INSPECTION

Inspect the front clutch components. Replace the clutch discs if warped, worn, scored, burned or charred, the lugs

are damaged, or if the facing is flaking off. Replace the steel plates and reaction plate if heavily scored, warped, or

broken. Be sure the driving lugs on the discs and plate are also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston springs and spring retainer if either are distorted, warped or broken.

Check the lug grooves in the clutch piston retainer. The steel plates should slide freely in the slots. Replace the

piston retainer if the grooves are worn or damaged. Also check action of thecheck ball in the piston retainer. The

ball must move freely and not stick.

Replace the retainer bushing if worn, scored, or there is any doubt about bushing condition.

Inspect the piston and retainer seal surfaces for nicks or scratches. Minor scratches can be removed with crocus

cloth. However, replace the piston and/or retainer if the seal surfaces are seriously scored.

Check the clutch piston check ball. The ball should be securely in place. Replace the piston if the ball is missing,

or seized in place.

ASSEMBLY

NOTE: The 48RE transmission uses five plates

and discs for the front clutch.

1. Soak clutch discs in transmission fluid.

2. Install new inner piston seal onto the outer diame-

ter of the clutch retainer inner hub.

3. Install new outer seal onto the clutch piston. Be

sure seal lips of both seals face the interior of the

retainer.

4. Lubricate new inner and outer piston seals with

petroleum jelly.

5. Install clutch piston in retainer. Use twisting motion

to seat piston in bottom of retainer. A thin strip of

plastic (about 0.015 - 0.020 in. thick), can be used to guide seals into placeifnecessary.

CAUTION: Never push the clutch piston straight in. This will fold the sealsover causing leakage and clutch

slip. In addition, never use any type of metal tool to help ease the piston seals into place. Metal tools will

cut, shave, or score the seals.

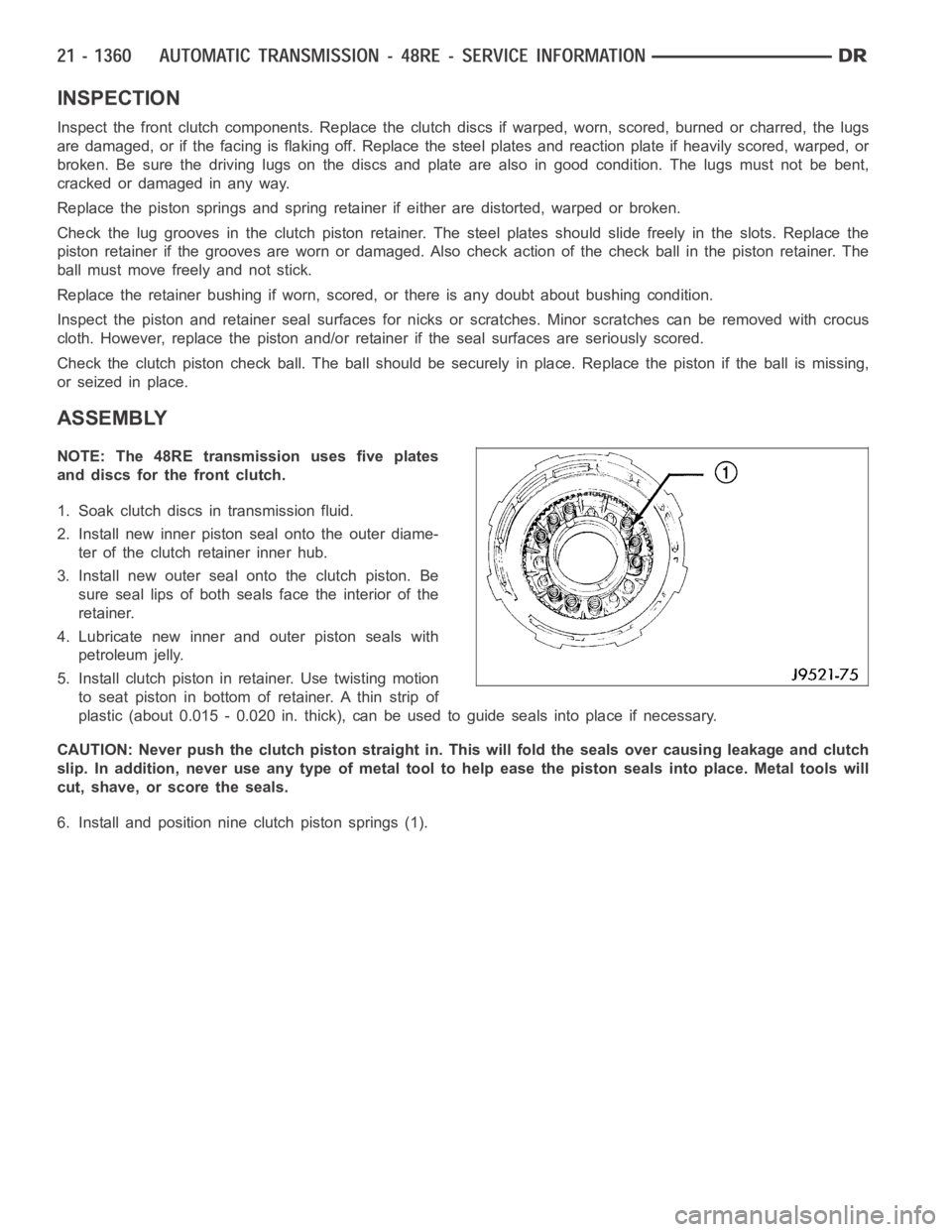

6. Install and position nine clutch piston springs (1).

Page 3882 of 5267

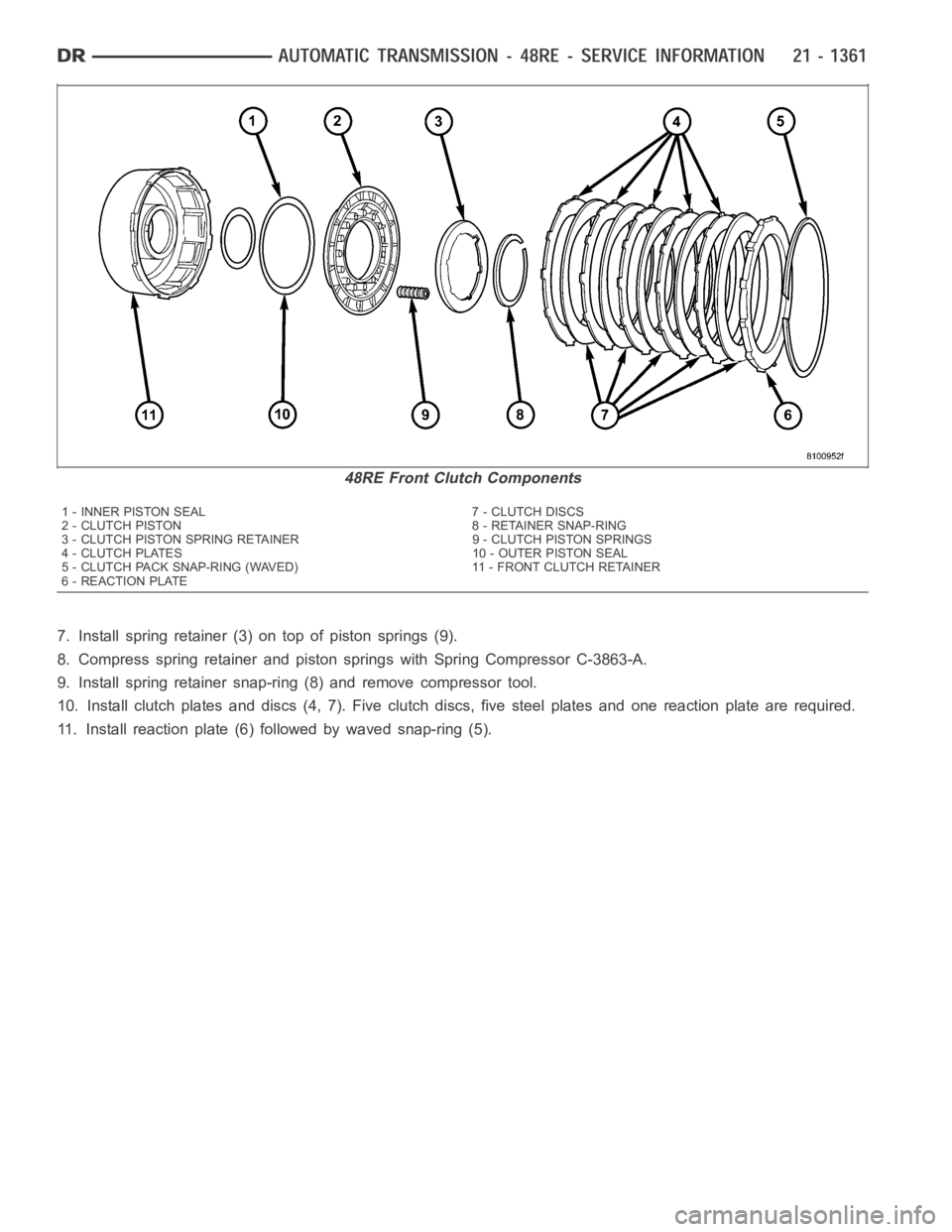

7. Install spring retainer (3) on top of piston springs (9).

8. Compress spring retainer and piston springs with Spring Compressor C-3863-A.

9. Install spring retainer snap-ring (8) and remove compressor tool.

10. Install clutch plates and discs (4, 7). Five clutch discs, five steel plates and one reaction plate are required.

11. Install reaction plate (6) followed by waved snap-ring (5).

48RE Front Clutch Components

1 - INNER PISTON SEAL 7 - CLUTCH DISCS

2 - CLUTCH PISTON 8 - RETAINER SNAP-RING

3 - CLUTCH PISTON SPRING RETAINER 9 - CLUTCH PISTON SPRINGS

4 - CLUTCH PLATES 10 - OUTER PISTON SEAL

5 - CLUTCH PACK SNAP-RING (WAVED) 11 - FRONT CLUTCH RETAINER

6 - REACTION PLATE

Page 3883 of 5267

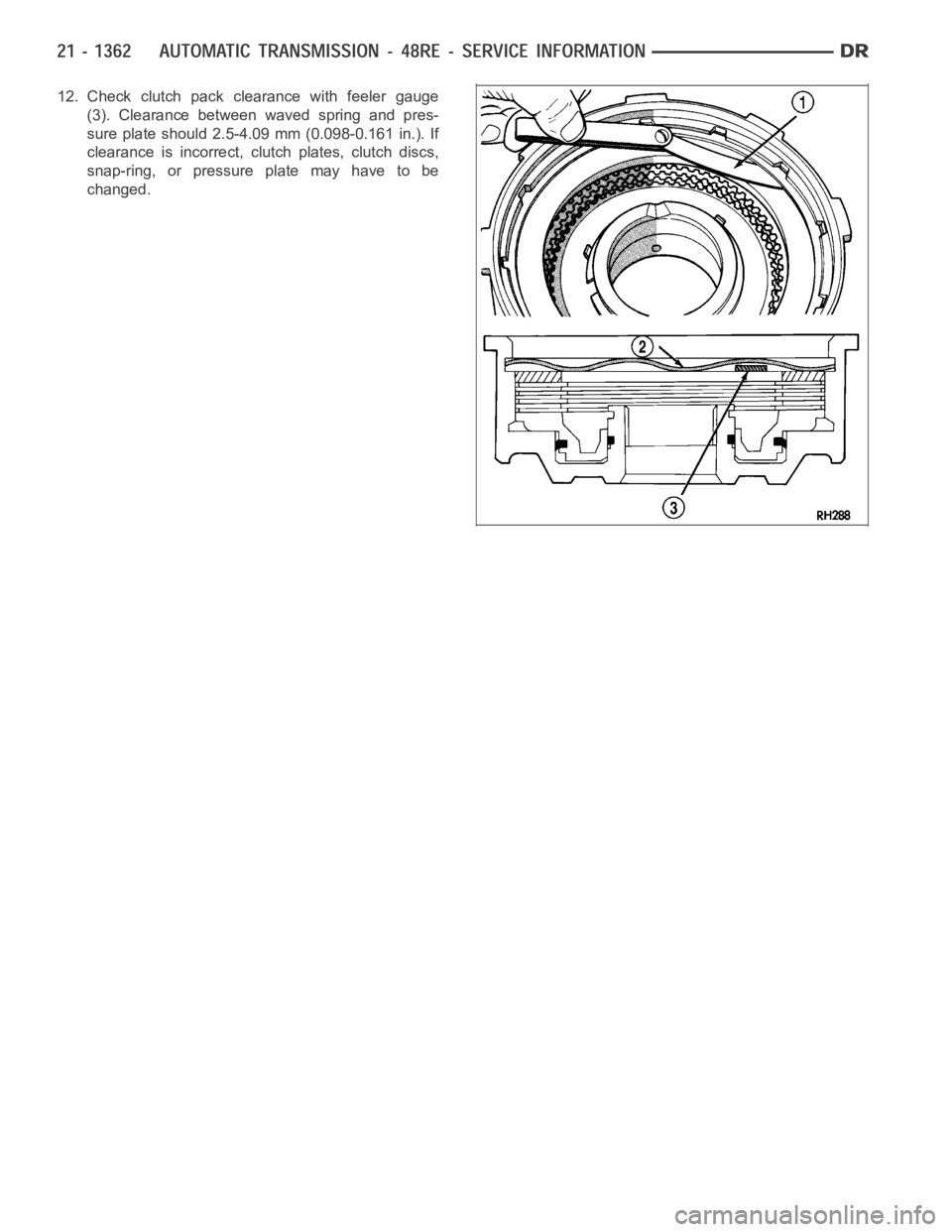

12. Check clutch pack clearance with feeler gauge

(3). Clearance between waved spring and pres-

sure plate should 2.5-4.09 mm (0.098-0.161 in.). If

clearance is incorrect, clutch plates, clutch discs,

snap-ring, or pressure plate may have to be

changed.

Page 3884 of 5267

SERVO-FRONT

DESCRIPTION

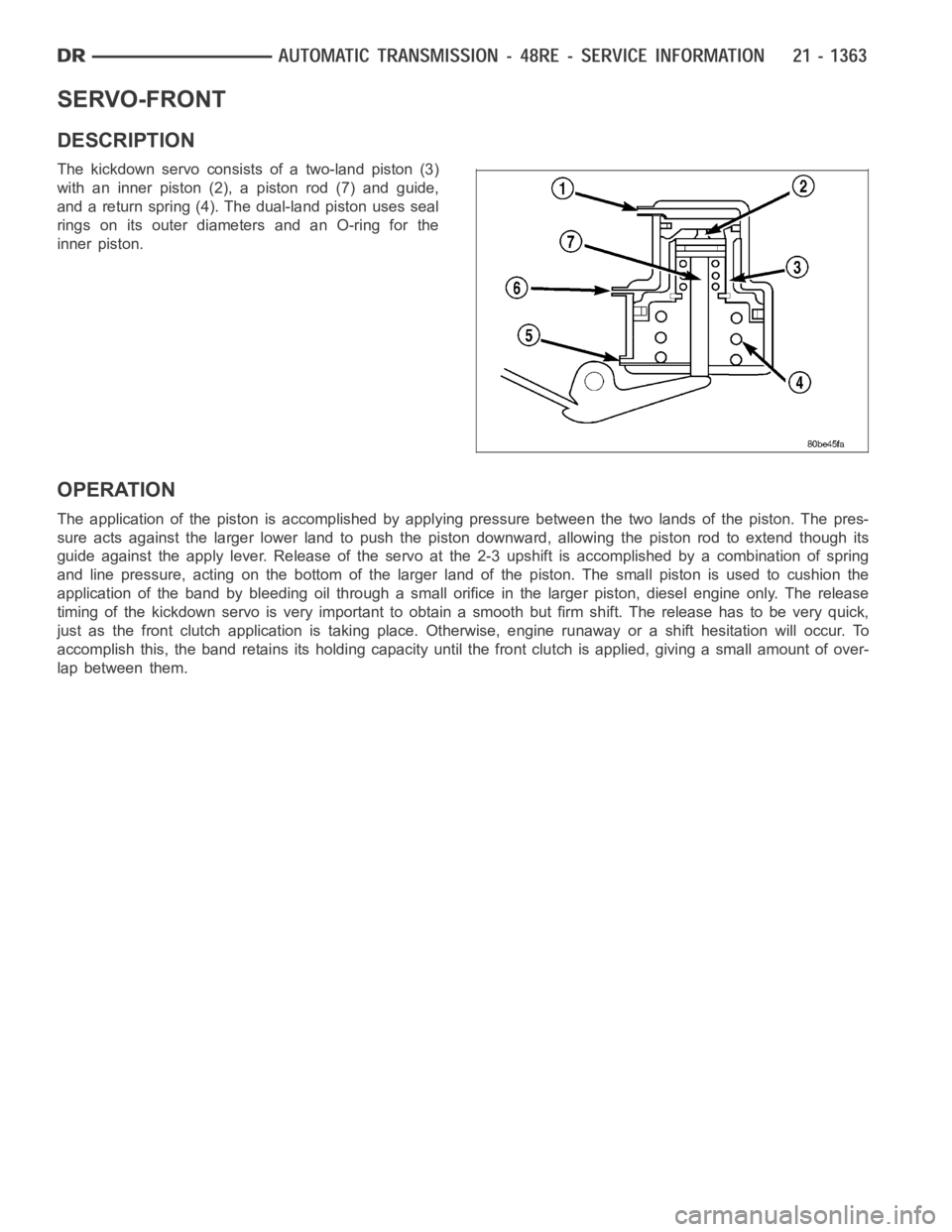

The kickdown servo consists of a two-land piston (3)

with an inner piston (2), a piston rod (7) and guide,

and a return spring (4). The dual-land piston uses seal

rings on its outer diameters and an O-ring for the

inner piston.

OPERATION

The application of the piston is accomplished by applying pressure between the two lands of the piston. The pres-

sure acts against the larger lower land to push the piston downward, allowing the piston rod to extend though its

guide against the apply lever. Release of the servo at the 2-3 upshift is accomplished by a combination of spring

and line pressure, acting on the bottom of the larger land of the piston. Thesmallpistonisusedtocushionthe

application of the band by bleeding oil through a small orifice in the larger piston, diesel engine only. The release

timing of the kickdown servo is very important to obtain a smooth but firm shift. The release has to be very quick,

just as the front clutch application is taking place. Otherwise, engine runaway or a shift hesitation will occur. To

accomplish this, the band retains itsholding capacity until the front clutch is applied, giving a small amount of over-

lap between them.

Page 3885 of 5267

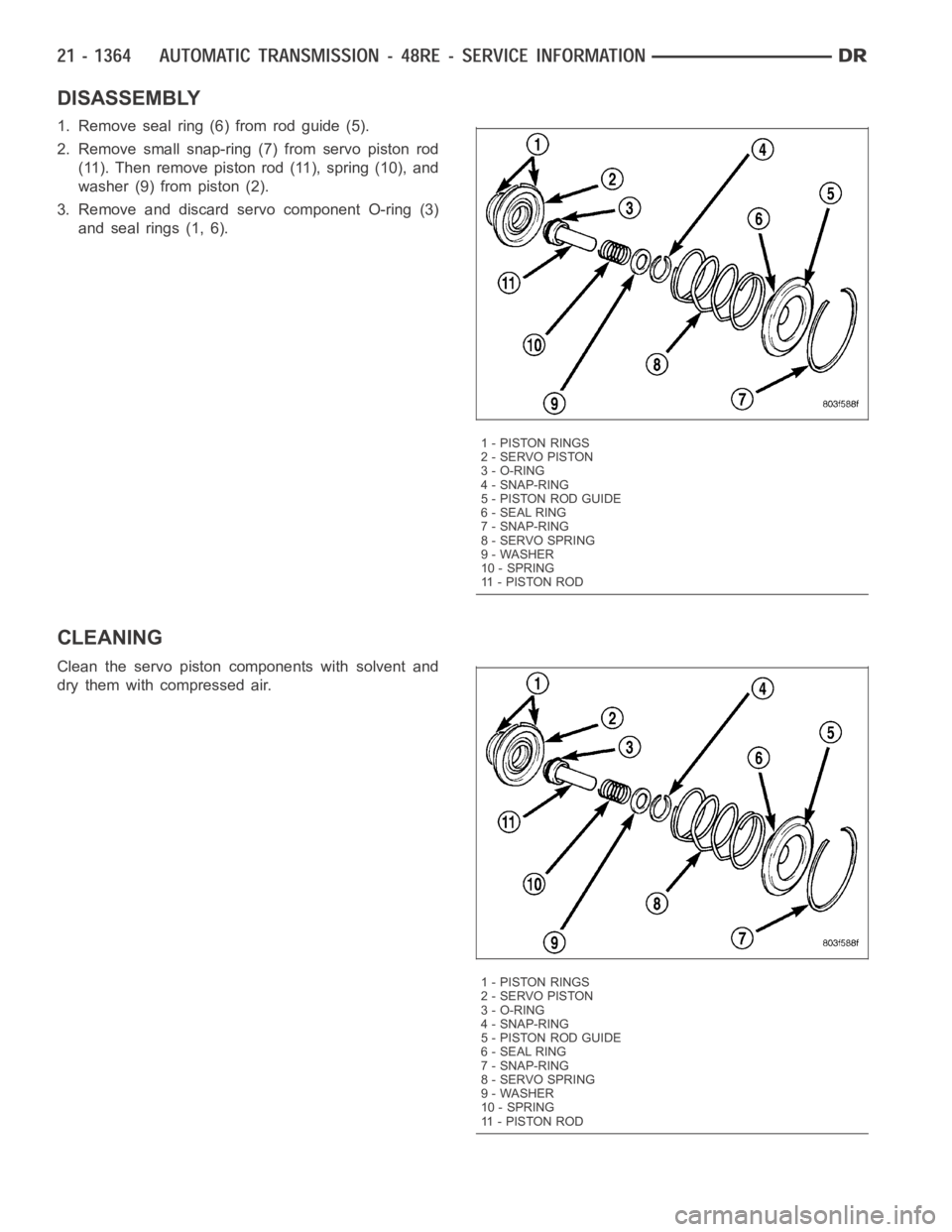

DISASSEMBLY

1. Remove seal ring (6) from rod guide (5).

2. Remove small snap-ring (7) from servo piston rod

(11). Then remove piston rod (11), spring (10), and

washer (9) from piston (2).

3. Remove and discard servo component O-ring (3)

and seal rings (1, 6).

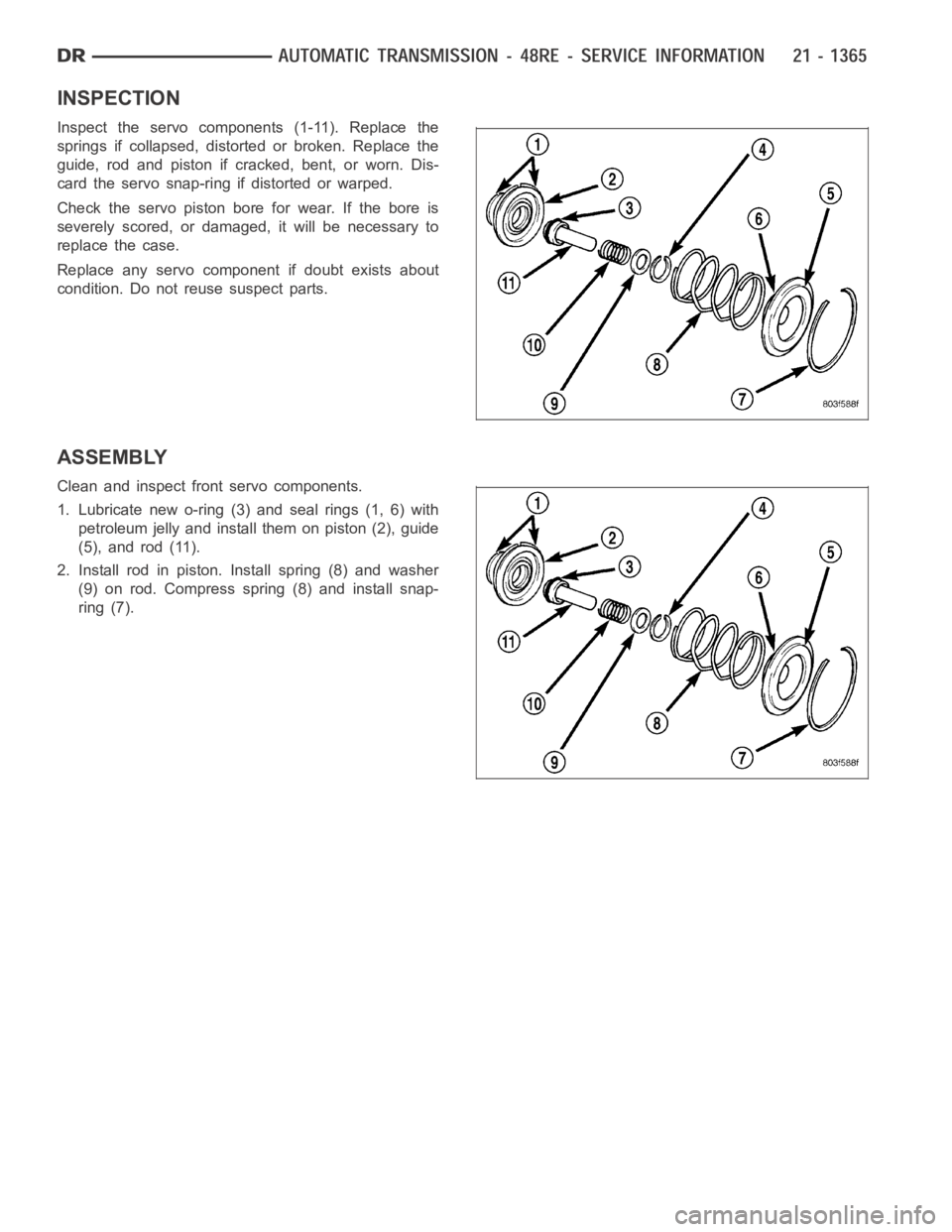

CLEANING

Clean the servo piston components with solvent and

dry them with compressed air.

1 - PISTON RINGS

2-SERVOPISTON

3 - O-RING

4 - SNAP-RING

5 - PISTON ROD GUIDE

6 - SEAL RING

7 - SNAP-RING

8 - SERVO SPRING

9 - WASHER

10 - SPRING

11 - P I S T O N R O D

1 - PISTON RINGS

2-SERVOPISTON

3 - O-RING

4 - SNAP-RING

5 - PISTON ROD GUIDE

6 - SEAL RING

7 - SNAP-RING

8 - SERVO SPRING

9 - WASHER

10 - SPRING

11 - P I S T O N R O D

Page 3886 of 5267

INSPECTION

Inspect the servo components (1-11). Replace the

springs if collapsed, distorted or broken. Replace the

guide, rod and piston if cracked, bent, or worn. Dis-

card the servo snap-ring if distorted or warped.

Check the servo piston bore for wear. If the bore is

severely scored, or damaged, it will be necessary to

replace the case.

Replace any servo component if doubt exists about

condition. Do not reuse suspect parts.

ASSEMBLY

Clean and inspect front servo components.

1. Lubricate new o-ring (3) and seal rings (1, 6) with

petroleum jelly and install them on piston (2), guide

(5), and rod (11).

2. Install rod in piston. Install spring (8) and washer

(9) on rod. Compress spring (8) and install snap-

ring (7).

Page 3887 of 5267

CABLE-GEARSHIFT

DIAGNOSIS AND TESTING - GEARSHIFT CABLE

1. Engine starts must be possible with shift lever in PARK or NEUTRAL positions only. Engine starts must not be

possible in any other gear position.

2. With the shift lever in the:

a. PARK position - Apply upward force on the shift arm and remove pressure. Engine starts must be possible.

b. PARK position - Apply downward force on the shift arm and remove pressure. Engine starts must be pos-

sible.

c. NEUTRAL position - Normal position. Engine starts must be possible.

d. NEUTRAL position - Engine running and brakes applied, apply upward forceontheshiftarm.Transmission

shall not be able to shift from neutral to reverse.

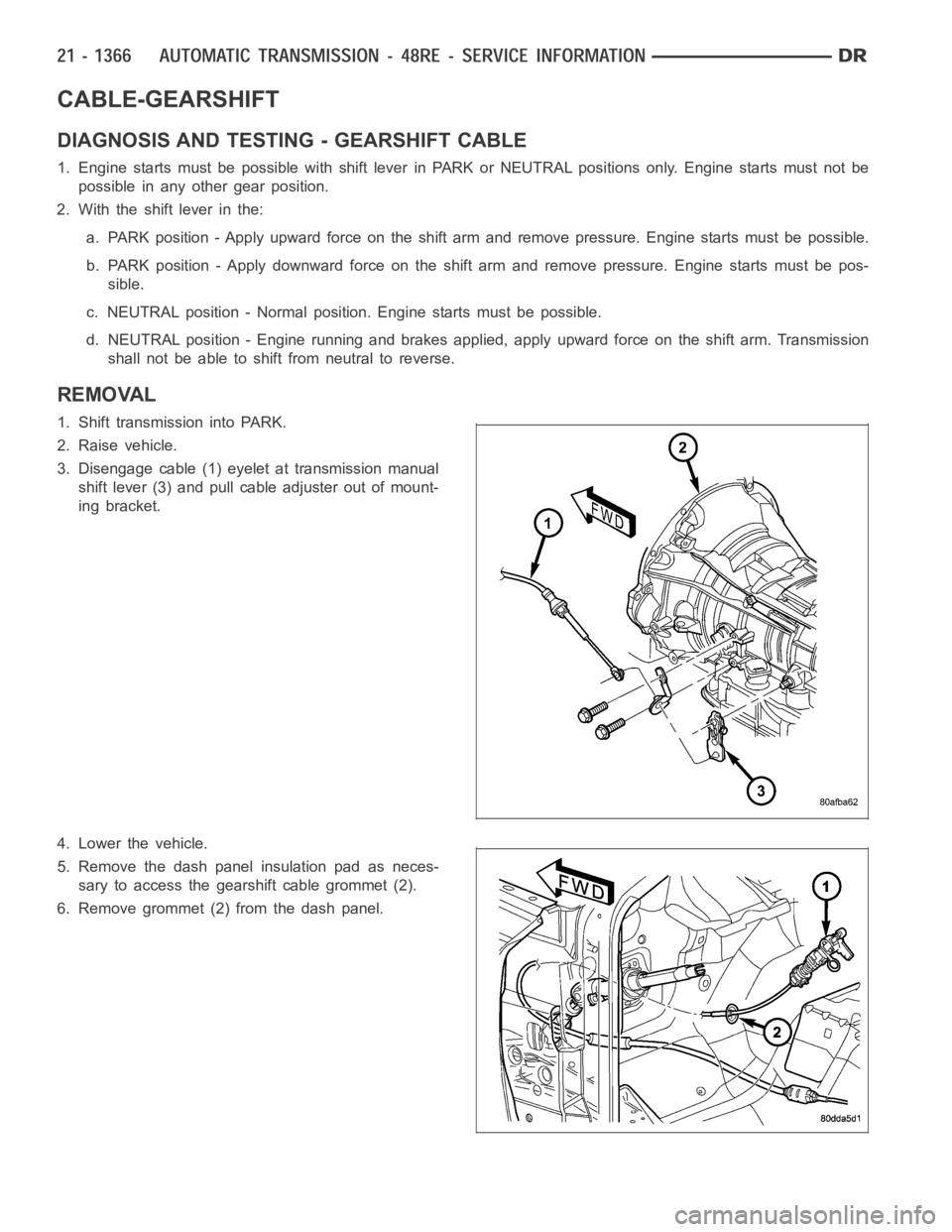

REMOVAL

1. Shift transmission into PARK.

2. Raise vehicle.

3. Disengage cable (1) eyelet at transmission manual

shift lever (3) and pull cable adjuster out of mount-

ing bracket.

4. Lower the vehicle.

5. Remove the dash panel insulation pad as neces-

sary to access the gearshift cable grommet (2).

6. Remove grommet (2) from the dash panel.

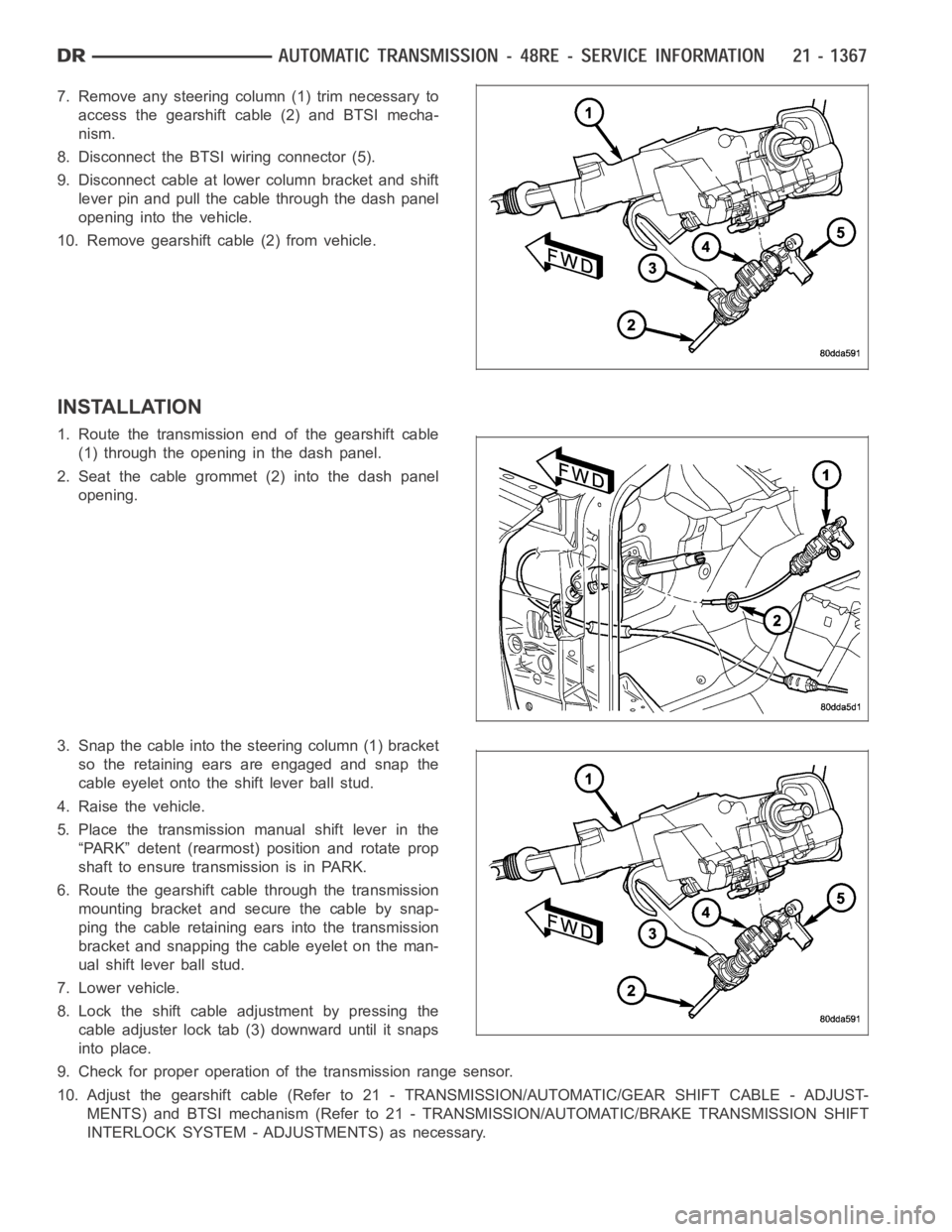

Page 3888 of 5267

7. Remove any steering column (1) trim necessary to

access the gearshift cable (2) and BTSI mecha-

nism.

8. Disconnect the BTSI wiring connector (5).

9. Disconnect cable at lower column bracket and shift

lever pin and pull the cable through the dash panel

opening into the vehicle.

10. Remove gearshift cable (2) from vehicle.

INSTALLATION

1. Route the transmission end of the gearshift cable

(1) through the opening in the dash panel.

2. Seat the cable grommet (2) into the dash panel

opening.

3. Snap the cable into the steering column (1) bracket

so the retaining ears are engaged and snap the

cable eyelet onto the shift lever ball stud.

4. Raise the vehicle.

5. Place the transmission manual shift lever in the

“PARK” detent (rearmost) position and rotate prop

shaft to ensure transmission is in PARK.

6. Route the gearshift cable through the transmission

mounting bracket and secure the cable by snap-

ping the cable retaining ears into the transmission

bracket and snapping the cable eyelet on the man-

ual shift lever ball stud.

7. Lower vehicle.

8. Lock the shift cable adjustment by pressing the

cable adjuster lock tab (3) downward until it snaps

into place.

9. Check for proper operation of the transmission range sensor.

10. Adjust the gearshift cable (Refer to 21 - TRANSMISSION/AUTOMATIC/GEAR SHIFT CABLE - ADJUST-

MENTS) and BTSI mechanism (Refer to 21 - TRANSMISSION/AUTOMATIC/BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - ADJUSTMENTS) as necessary.

Page 3889 of 5267

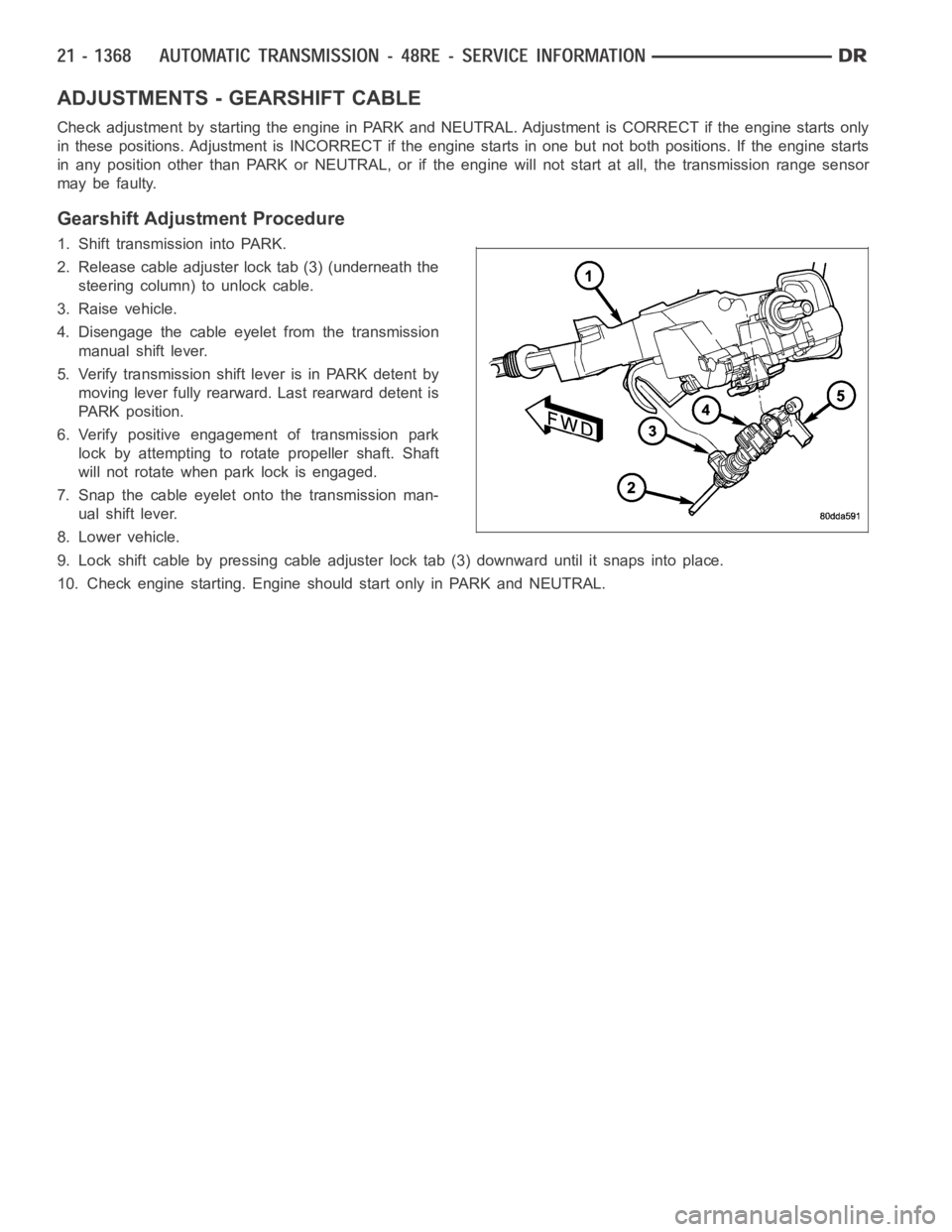

ADJUSTMENTS - GEARSHIFT CABLE

Check adjustment by starting the engine in PARK and NEUTRAL. Adjustment isCORRECT if the engine starts only

in these positions. Adjustment is INCORRECT if the engine starts in one butnot both positions. If the engine starts

in any position other than PARK or NEUTRAL, or if the engine will not start atall, the transmission range sensor

may be faulty.

Gearshift Adjustment Procedure

1. Shift transmission into PARK.

2. Release cable adjuster lock tab (3) (underneath the

steering column) to unlock cable.

3. Raise vehicle.

4. Disengage the cable eyelet from the transmission

manual shift lever.

5. Verify transmission shift lever is in PARK detent by

moving lever fully rearward. Last rearward detent is

PARK position.

6. Verify positive engagement of transmission park

lock by attempting to rotate propeller shaft. Shaft

will not rotate when park lock is engaged.

7. Snap the cable eyelet onto the transmission man-

ual shift lever.

8. Lower vehicle.

9. Lock shift cable by pressing cable adjuster lock tab (3) downward until it snaps into place.

10. Check engine starting. Engine should start only in PARK and NEUTRAL.

Page 3890 of 5267

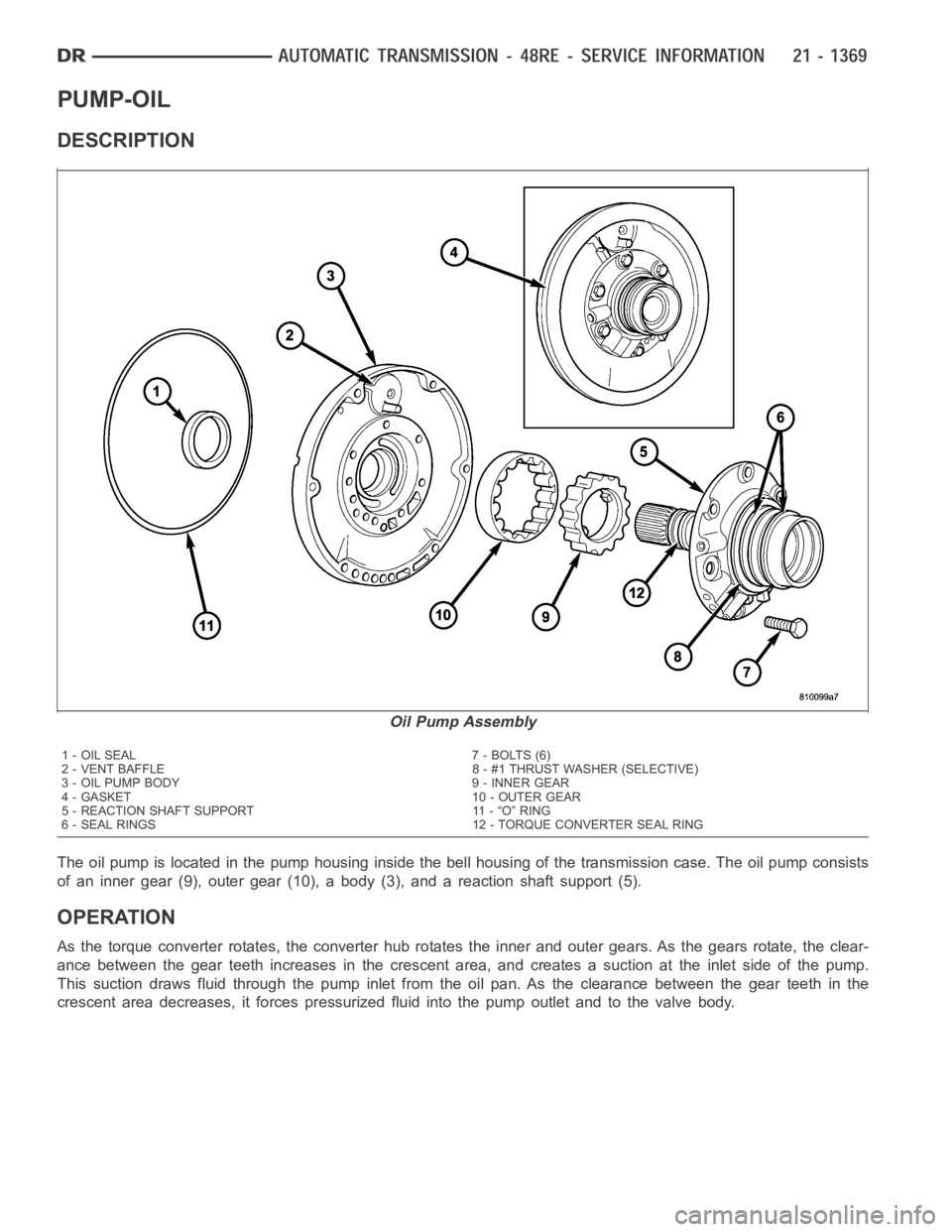

PUMP-OIL

DESCRIPTION

The oil pump is located in the pump housing inside the bell housing of the transmission case. The oil pump consists

of an inner gear (9), outer gear (10), a body (3), and a reaction shaft support(5).

OPERATION

As the torque converter rotates, the converter hub rotates the inner and outer gears. As the gears rotate, the clear-

ance between the gear teeth increases in the crescent area, and creates a suction at the inlet side of the pump.

This suction draws fluid through the pump inlet from the oil pan. As the clearance between the gear teeth in the

crescent area decreases, it forces pressurized fluid into the pump outletand to the valve body.

Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - “O” RING

6 - SEAL RINGS 12 - TORQUE CONVERTER SEAL RING