sensor DODGE RAM SRT-10 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 165 of 5267

Theory of Operation

This DTC sets when an unexpected high intake manifold air flow condition exists that can lead to increased engine

speed and puts the NGC into a High Air flow Protection limiting mode. The High Air flow Protection feature includes

RPM limits for when a Throttle and/or MAP sensor limp-in fault is present.

When Monitored:

During all drive modes

Set Condition:

If vacuum drops below 1.5

Hg with engine RPM greater than 2000 RPM and closed throttle. One Trip Fault.

Three good trips to turn off the MIL.

Possible Causes

VACUUM LEAK

RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K1) MAP SIGNAL CIRCUIT

(K1) MAP SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K22) TP SENSOR NO.1 SIGNAL CIRCUIT

(K22) TP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

MAP SENSOR

THROTTLE POSITION SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Diagnose any TP Sensor or MAP Sensor component DTCs before continuing.

NOTE: If the P0501 - No Vehicle Speed Signal is set long with this DTC, refer to the P0501 diagnostics

before continuing.

NOTE: The throttle plate and linkage should be free from binding and carbonbuild up.

NOTE: Make sure the throttle plate is at the idle position.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 166 of 5267

2.VACUUM LEAK

NOTE: This code is enabled on engines with a plastic intake manifold and is intended to shut down the

engine if a large crack occurs.

NOTE: A large vacuum leak is most likely the cause of this DTC.

Inspect the Intake Manifold for leaks and cracks.

Inspect the Power Brake Booster for any vacuum leaks.

Inspect the PCV system for proper operation and vacuum leaks.

Inspect the throttle plate to see if it is bent and will close entirely, if itis bent it may need to be replaced.

Inspect the MAP Sensor for proper installation.

Verify the engine is free from any mechanical failures.

Were any vacuum leaks found?

Ye s>>

Repair the vacuum leak as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.MAP SENSOR OPERATION

Start the engine.

With a scan tool, monitor the MAP Sensor voltage.

Snap the throttle.

Does the MAP Sensor voltage vary from below 2.0 volts at idle to above 3.5 volts at wide open throt-

tle?

Ye s>>

Go To 4

No>>

Go To 11

4.TP SENSOR OPERATION

Ignition on, engine not running.

With a scan tool, monitor the TP Sensor voltage while slowly pressing the throttle pedal from closed to wide open

throttle.

Does voltage start at approximately 0.8 of a volt and go above 3.5 volts witha smooth transition?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 167 of 5267

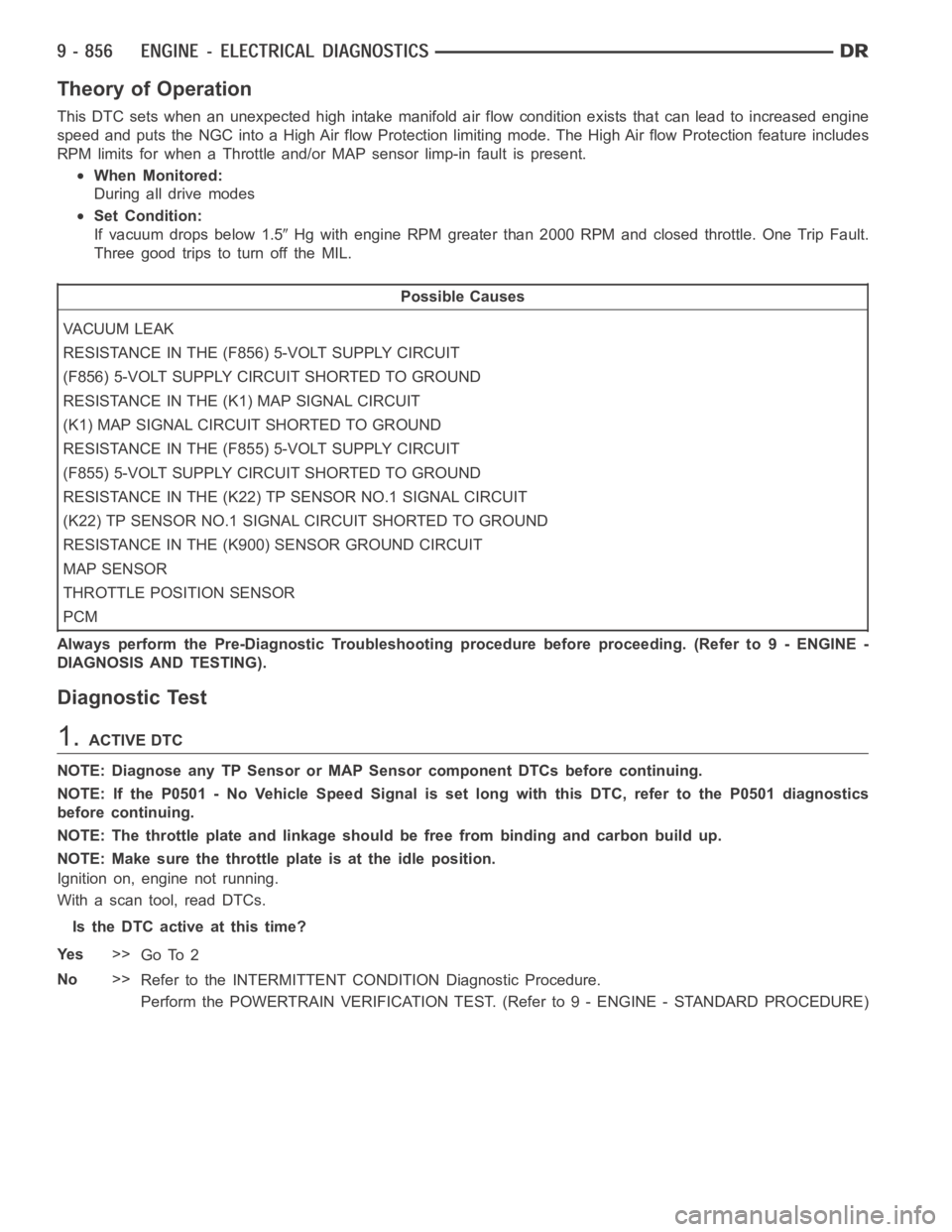

5.EXCESSIVE RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the TP Sensor harness connector.

Disconnect the C2 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (F855) 5-volt Supply circuit from the TP

Sensor harness connector to the appropriate terminal of special tool

#8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the excessive resistance in the (F855) 5-volt Supply

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

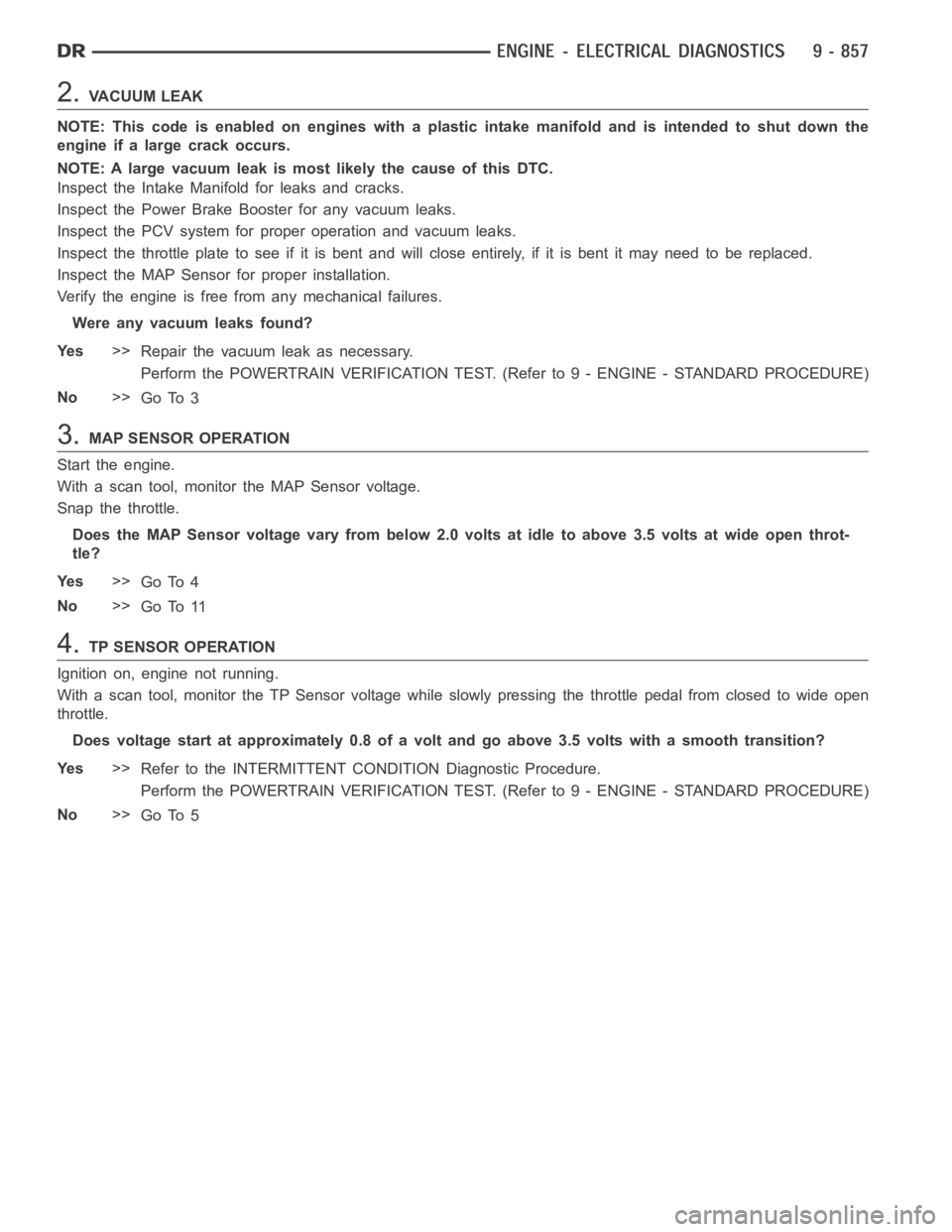

6.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and (F855) 5-volt Supply circuit

in the TP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) 5-volt Supply cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

Page 168 of 5267

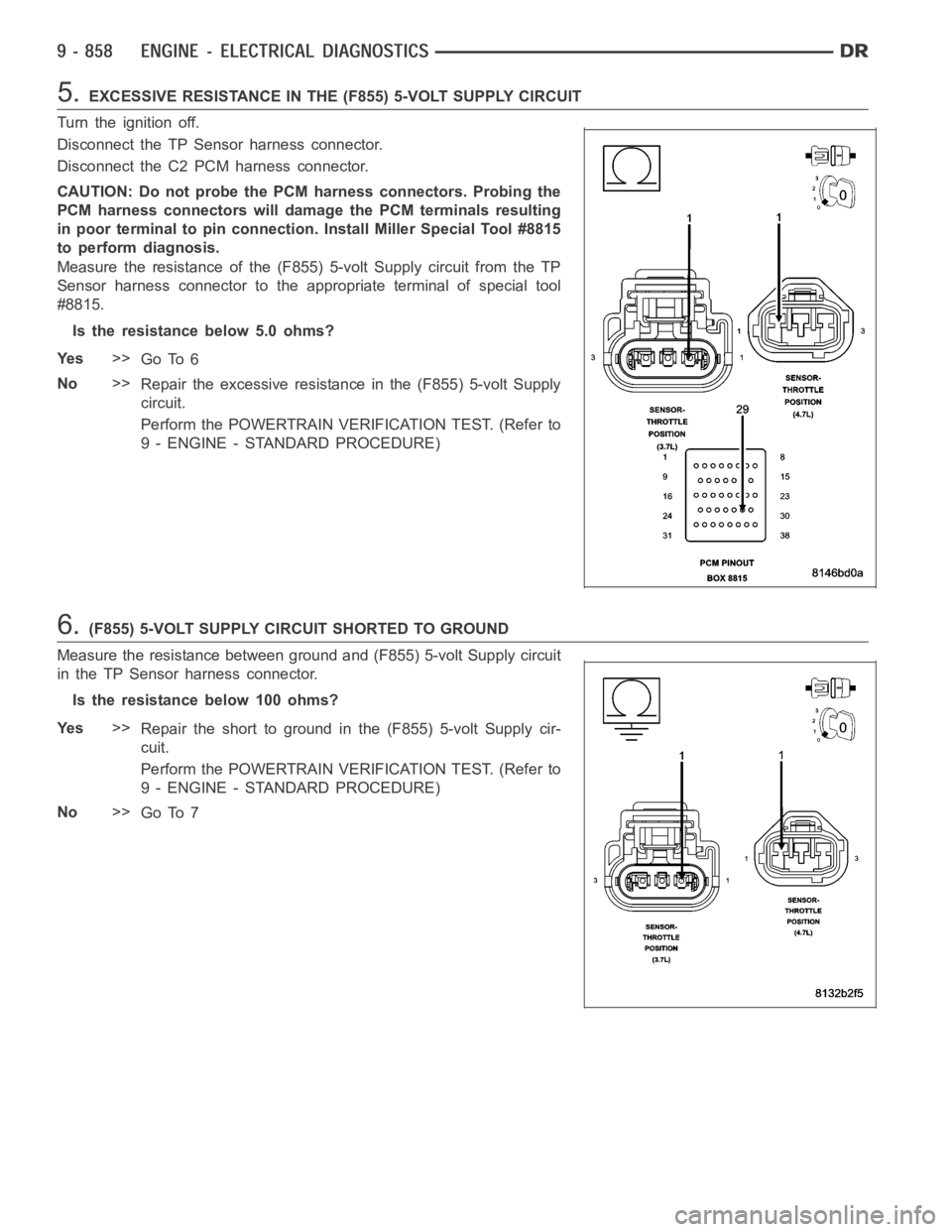

7.THROTTLE POSITION SENSOR

Connect the C2 PCM harness connector.

Ignition on, engine not running.

With a scan tool, monitor the TP Sensor voltage.

Connect a jumper wire between the (K22) TP Sensor No.1 Signal circuit

and the (K900) Sensor ground circuit in the Sensor harness connector.

Does the TP Sensor voltage change from approximately 4.9

volts to below 0.5 of a volt with the jumper wire installed?

Ye s>>

ReplacetheThrottlePositionSensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

NOTE: Remove the jumper wire before continuing.

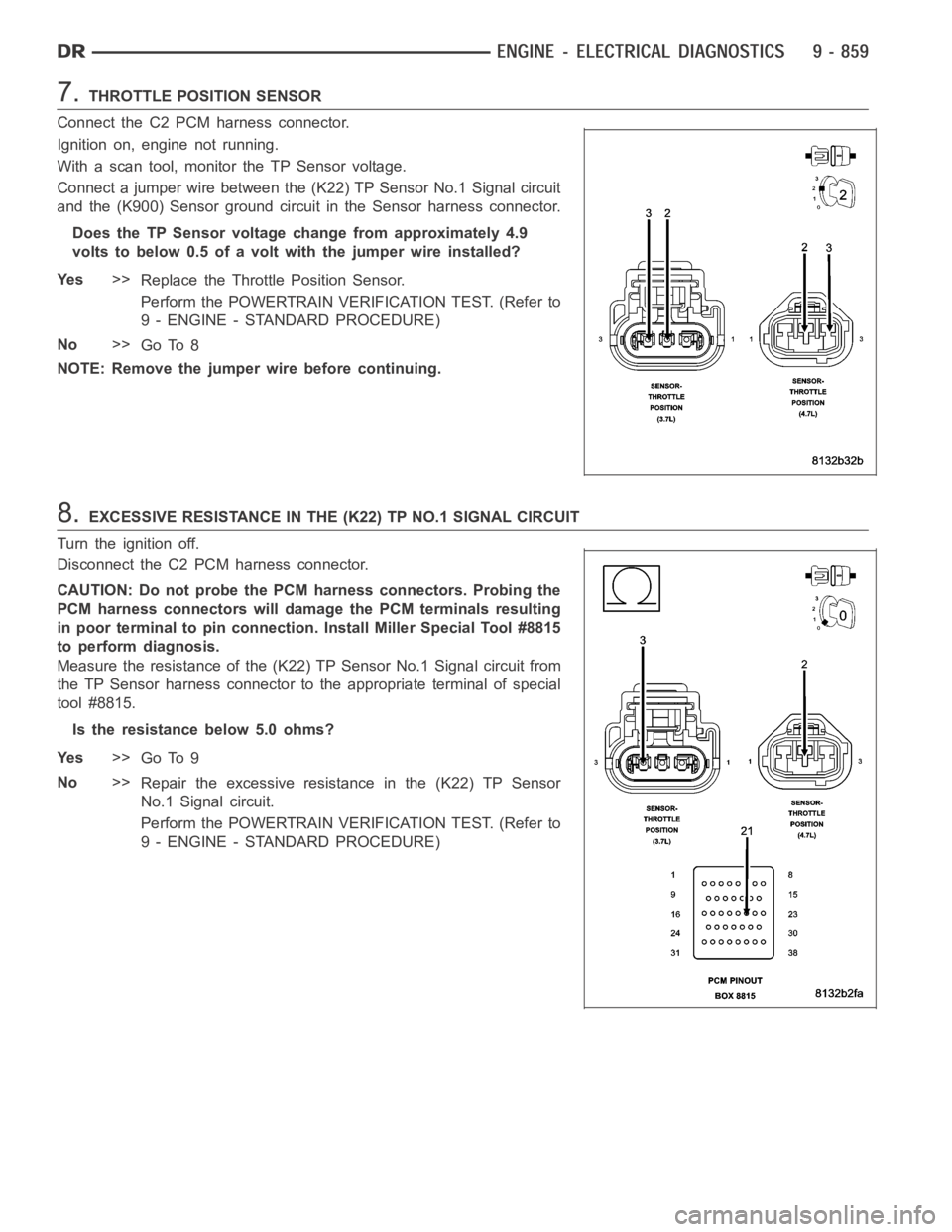

8.EXCESSIVE RESISTANCE IN THE (K22) TP NO.1 SIGNAL CIRCUIT

Turn the ignition off.

Disconnect the C2 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (K22) TP Sensor No.1 Signal circuit from

the TP Sensor harness connector to the appropriate terminal of special

tool #8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 9

No>>

Repair the excessive resistance in the (K22) TP Sensor

No.1 Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 169 of 5267

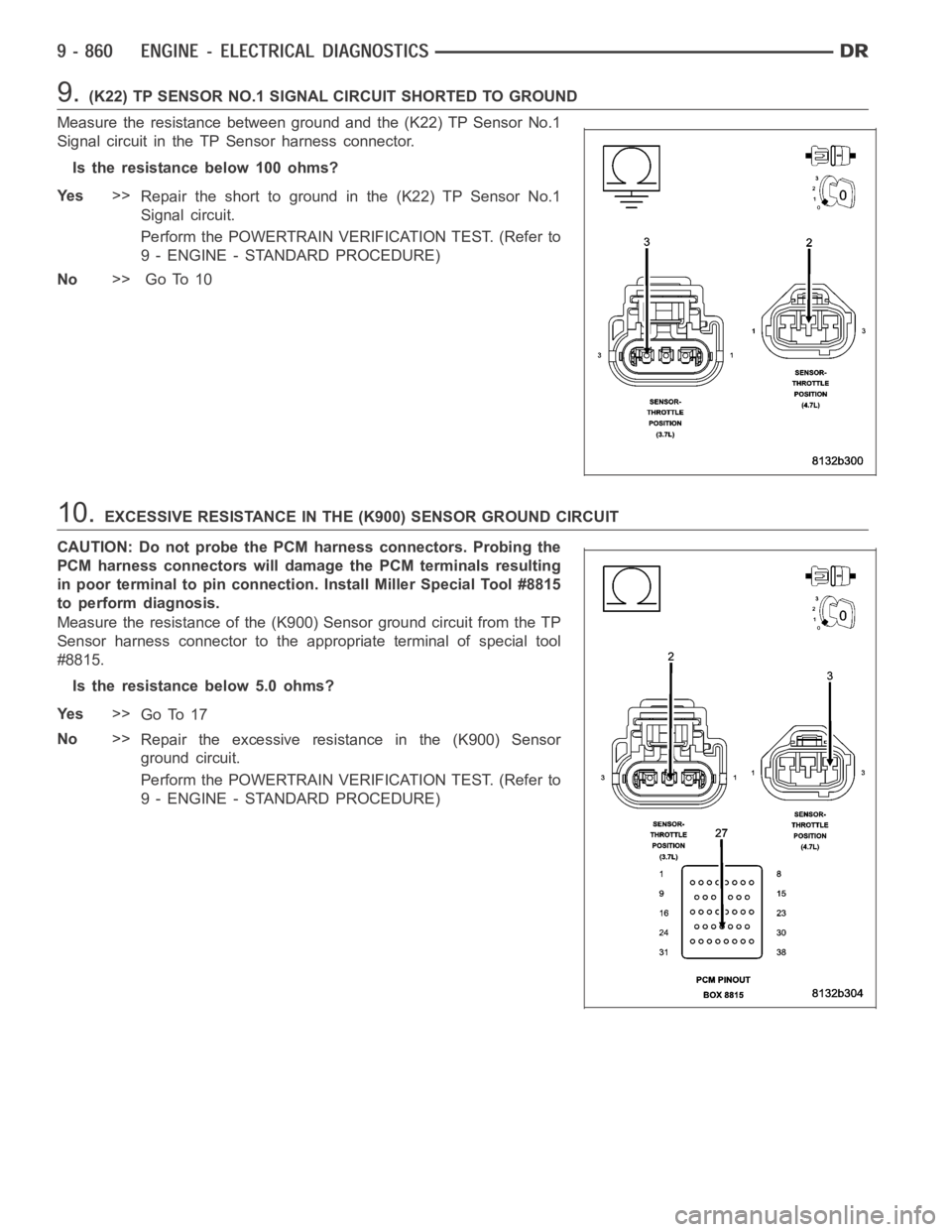

9.(K22) TP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (K22) TP Sensor No.1

Signal circuit in the TP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K22) TP Sensor No.1

Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>> Go To 10

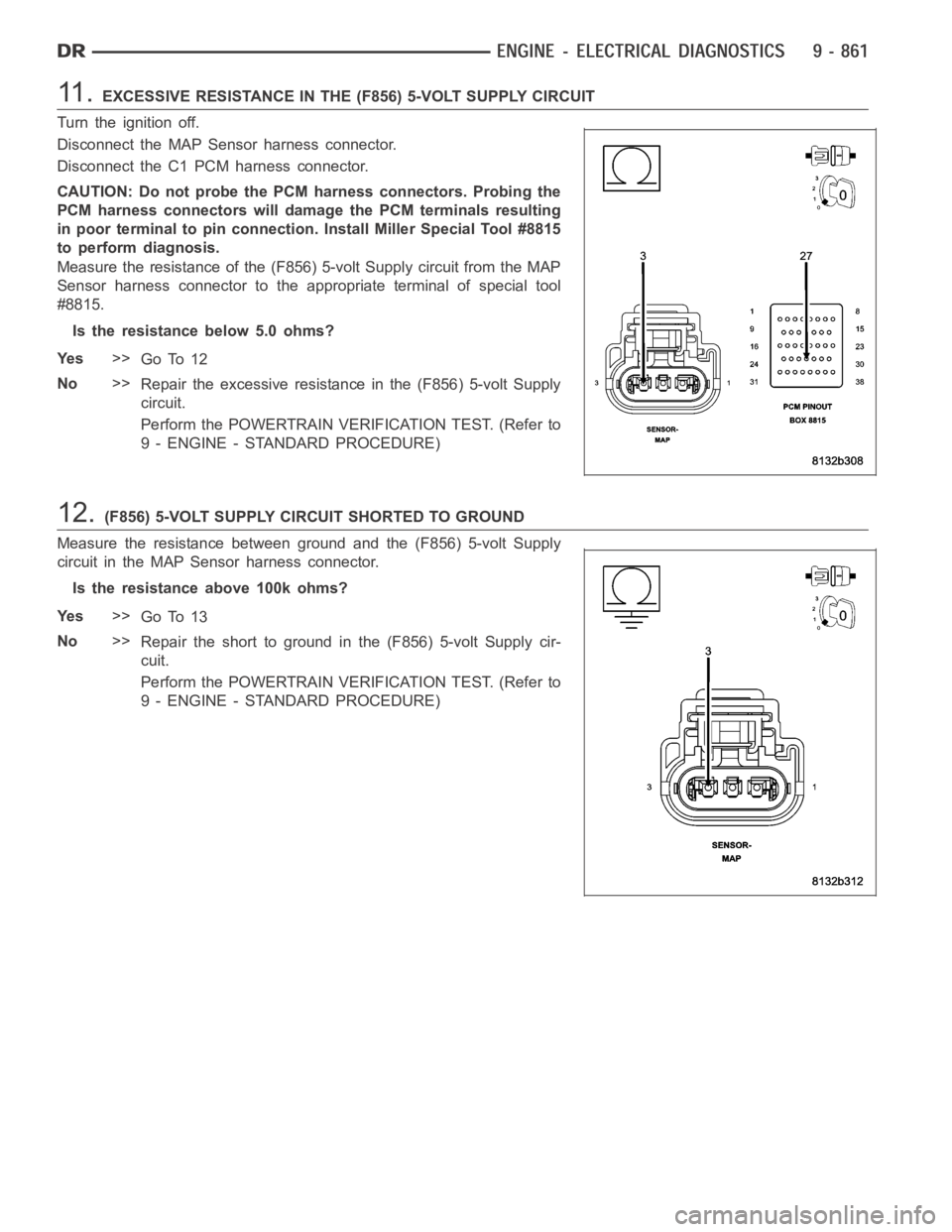

10.EXCESSIVE RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (K900) Sensor ground circuit from the TP

Sensor harness connector to the appropriate terminal of special tool

#8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 17

No>>

Repair the excessive resistance in the (K900) Sensor

ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 170 of 5267

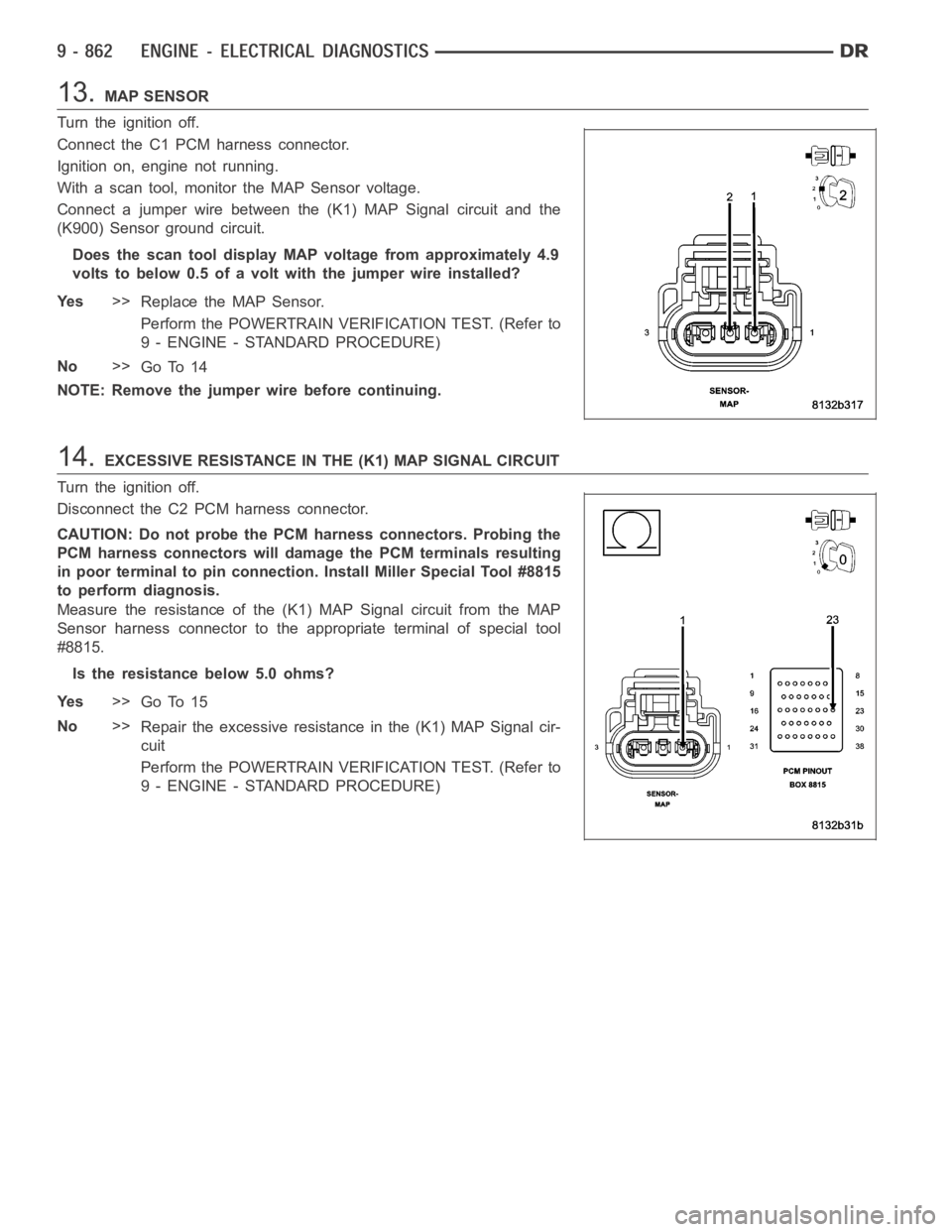

11 .EXCESSIVE RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the MAP Sensor harness connector.

Disconnect the C1 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (F856) 5-volt Supply circuit from the MAP

Sensor harness connector to the appropriate terminal of special tool

#8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 12

No>>

Repair the excessive resistance in the (F856) 5-volt Supply

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

12.(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (F856) 5-volt Supply

circuit in the MAP Sensor harness connector.

Is the resistance above 100k ohms?

Ye s>>

Go To 13

No>>

Repair the short to ground in the (F856) 5-volt Supply cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 171 of 5267

13.MAP SENSOR

Turn the ignition off.

Connect the C1 PCM harness connector.

Ignition on, engine not running.

With a scan tool, monitor the MAP Sensor voltage.

Connect a jumper wire between the (K1) MAP Signal circuit and the

(K900) Sensor ground circuit.

Does the scan tool display MAP voltage from approximately 4.9

volts to below 0.5 of a volt with the jumper wire installed?

Ye s>>

Replace the MAP Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 14

NOTE: Remove the jumper wire before continuing.

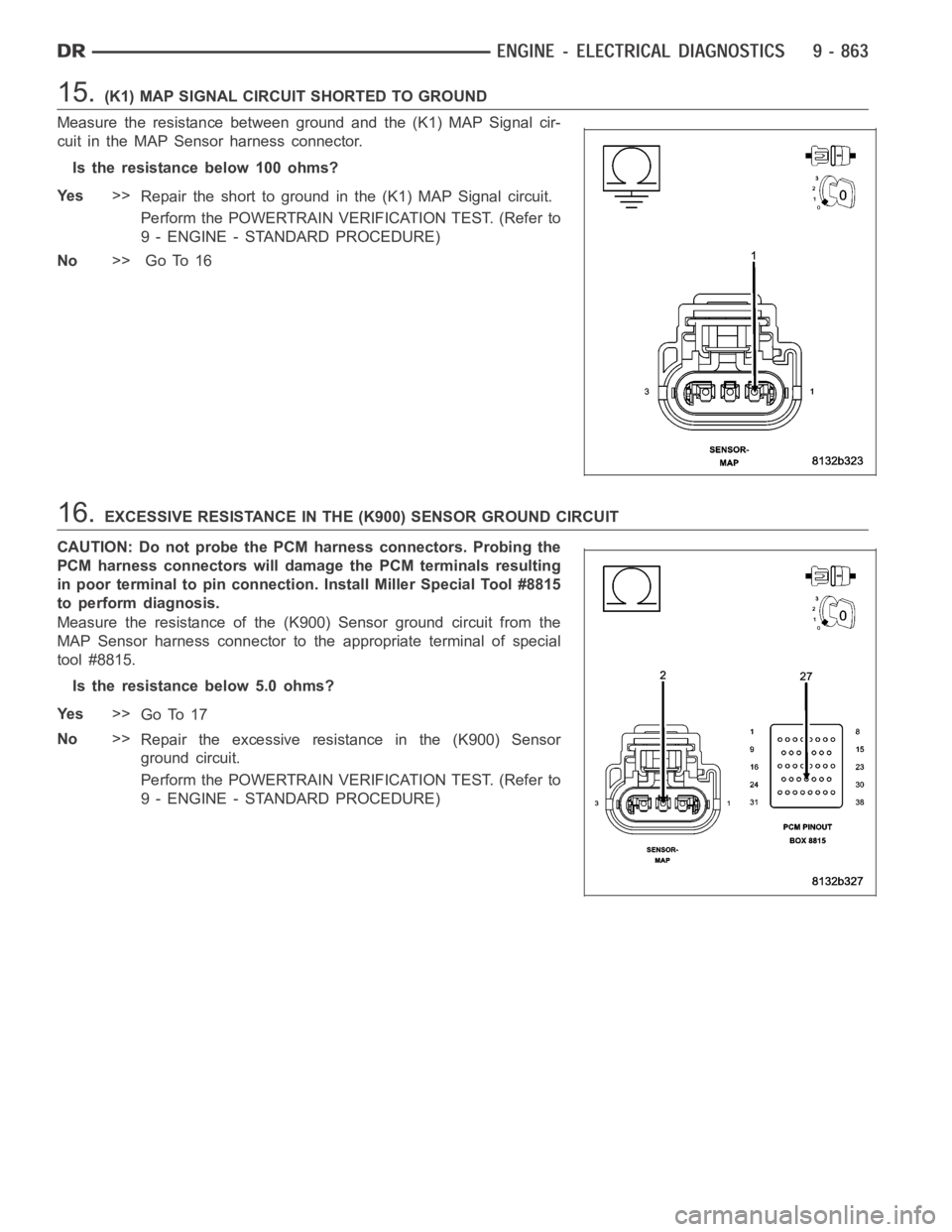

14.EXCESSIVE RESISTANCE IN THE (K1) MAP SIGNAL CIRCUIT

Turn the ignition off.

Disconnect the C2 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (K1) MAP Signal circuit from the MAP

Sensor harness connector to the appropriate terminal of special tool

#8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 15

No>>

Repair the excessive resistance in the (K1) MAP Signal cir-

cuit

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 172 of 5267

15.(K1) MAP SIGNAL CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (K1) MAP Signal cir-

cuit in the MAP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K1) MAP Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>> Go To 16

16.EXCESSIVE RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (K900) Sensor ground circuit from the

MAP Sensor harness connector to the appropriate terminal of special

tool #8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 17

No>>

Repair the excessive resistance in the (K900) Sensor

ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 175 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

1/2O2SENSOR

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT

(K299) O2 1/2 HEATER CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 1/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 176 of 5267

3.ENGINE MECHANICAL

Check for any of the following conditions/mechanical problems.

AIR INDUCTION SYSTEM - must be free from leaks

ENGINE VACUUM - must be at least 13 inches in neutral

ENGINE VALVE TIMING - must be within specifications

ENGINE COMPRESSION - must be within specifications

ENGINE EXHAUST SYSTEM - must be free of any restrictions or leaks

ENGINE PCV SYSTEM - must flow freely

TORQUE CONVERTER STALL SPEED - must be within specifications

POWER BRAKE BOOSTER - no internal vacuum leaks

FUEL - must be free of contamination

FUEL INJECTOR - plugged or restricted injector; control wire not connectedtocorrectinjector

Are there any engine mechanical problems?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

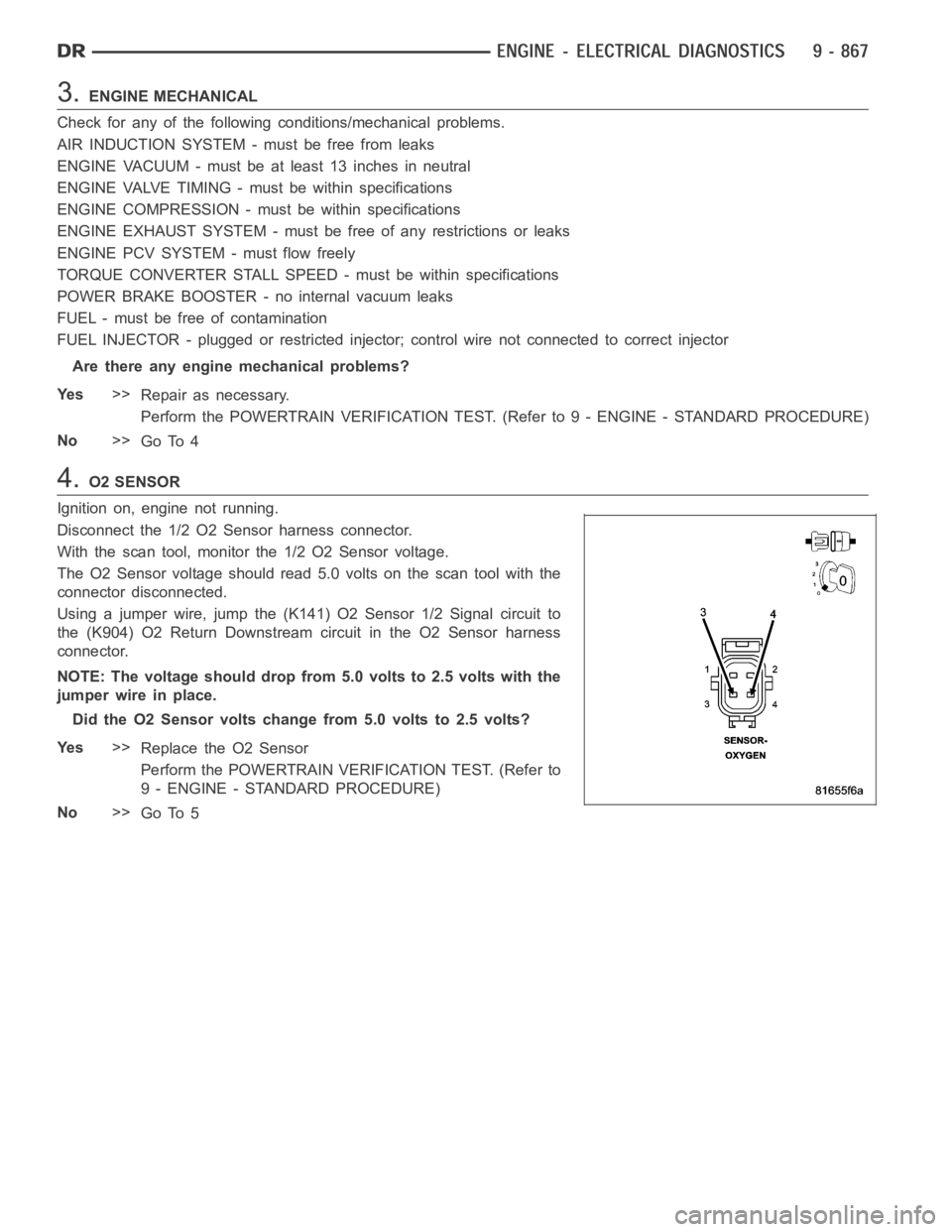

4.O2 SENSOR

Ignition on, engine not running.

Disconnect the 1/2 O2 Sensor harness connector.

With the scan tool, monitor the 1/2 O2 Sensor voltage.

The O2 Sensor voltage should read 5.0 volts on the scan tool with the

connector disconnected.

Using a jumper wire, jump the (K141) O2 Sensor 1/2 Signal circuit to

the (K904) O2 Return Downstream circuit in the O2 Sensor harness

connector.

NOTE: The voltage should drop from 5.0 volts to 2.5 volts with the

jumper wire in place.

Did the O2 Sensor volts change from 5.0 volts to 2.5 volts?

Ye s>>

Replace the O2 Sensor

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5