Compression DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1777 of 5267

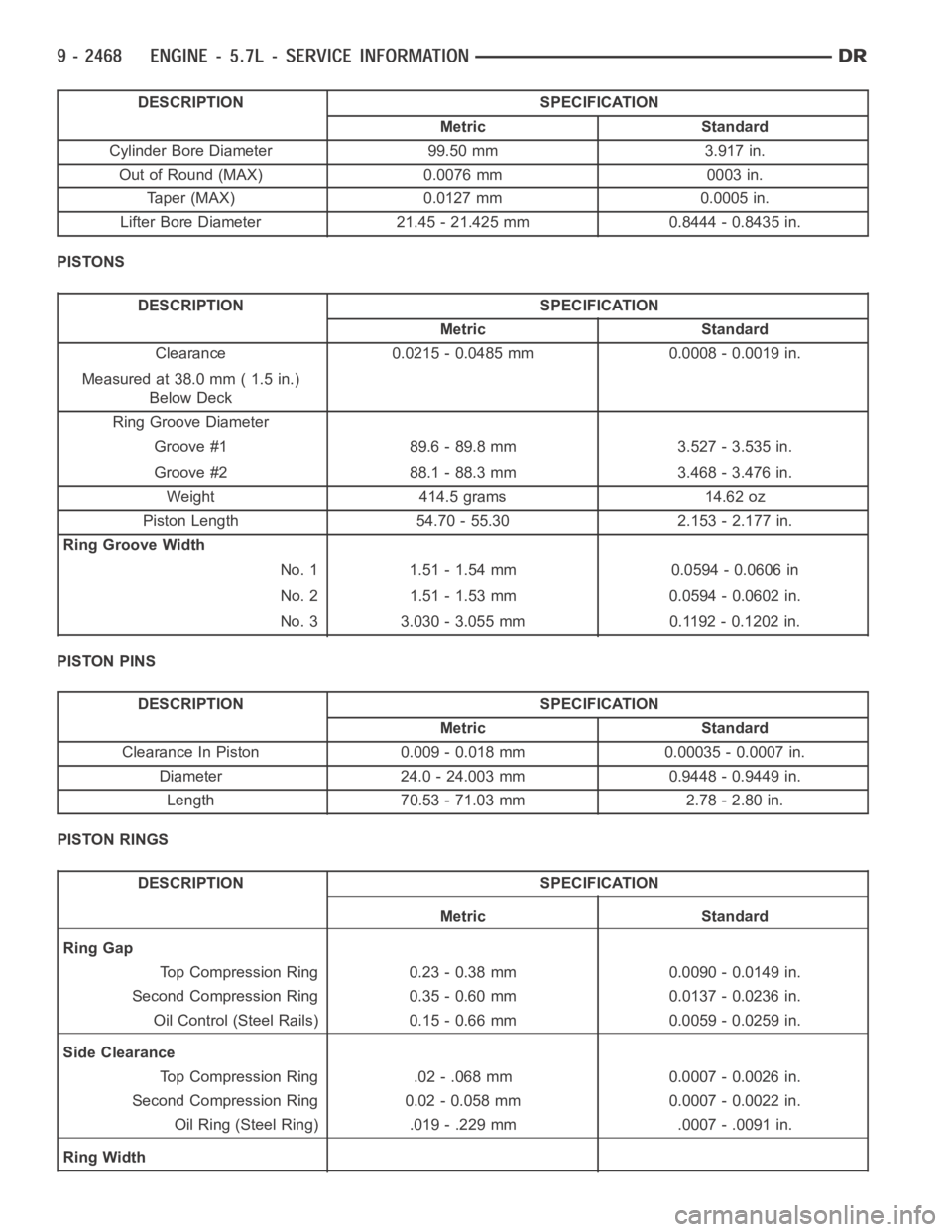

DESCRIPTION SPECIFICATION

Metric Standard

Cylinder Bore Diameter 99.50 mm 3.917 in.

Out of Round (MAX) 0.0076 mm 0003 in.

Taper (MAX) 0.0127 mm 0.0005 in.

Lifter Bore Diameter 21.45 - 21.425 mm 0.8444 - 0.8435 in.

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Clearance 0.0215 - 0.0485 mm 0.0008 - 0.0019 in.

Measured at 38.0 mm ( 1.5 in.)

Below Deck

Ring Groove Diameter

Groove #1 89.6 - 89.8 mm 3.527 - 3.535 in.

Groove #2 88.1 - 88.3 mm 3.468 - 3.476 in.

Weight 414.5 grams 14.62 oz

Piston Length 54.70 - 55.30 2.153 - 2.177 in.

Ring Groove Width

No. 1 1.51 - 1.54 mm 0.0594 - 0.0606 in

No. 2 1.51 - 1.53 mm 0.0594 - 0.0602 in.

No. 3 3.030 - 3.055 mm 0.1192 - 0.1202 in.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Clearance In Piston 0.009 - 0.018 mm 0.00035 - 0.0007 in.

Diameter 24.0 - 24.003 mm 0.9448 - 0.9449 in.

Length 70.53 - 71.03 mm 2.78 - 2.80 in.

PISTON RINGS

DESCRIPTION SPECIFICATION

Metric Standard

Ring Gap

Top Compression Ring 0.23 - 0.38 mm 0.0090 - 0.0149 in.

Second Compression Ring 0.35 - 0.60 mm 0.0137 - 0.0236 in.

Oil Control (Steel Rails) 0.15 - 0.66 mm 0.0059 - 0.0259 in.

Side Clearance

Top Compression Ring .02 - .068 mm 0.0007 - 0.0026 in.

Second Compression Ring 0.02 - 0.058 mm 0.0007 - 0.0022 in.

Oil Ring (Steel Ring) .019 - .229 mm .0007 - .0091 in.

Ring Width

Page 1778 of 5267

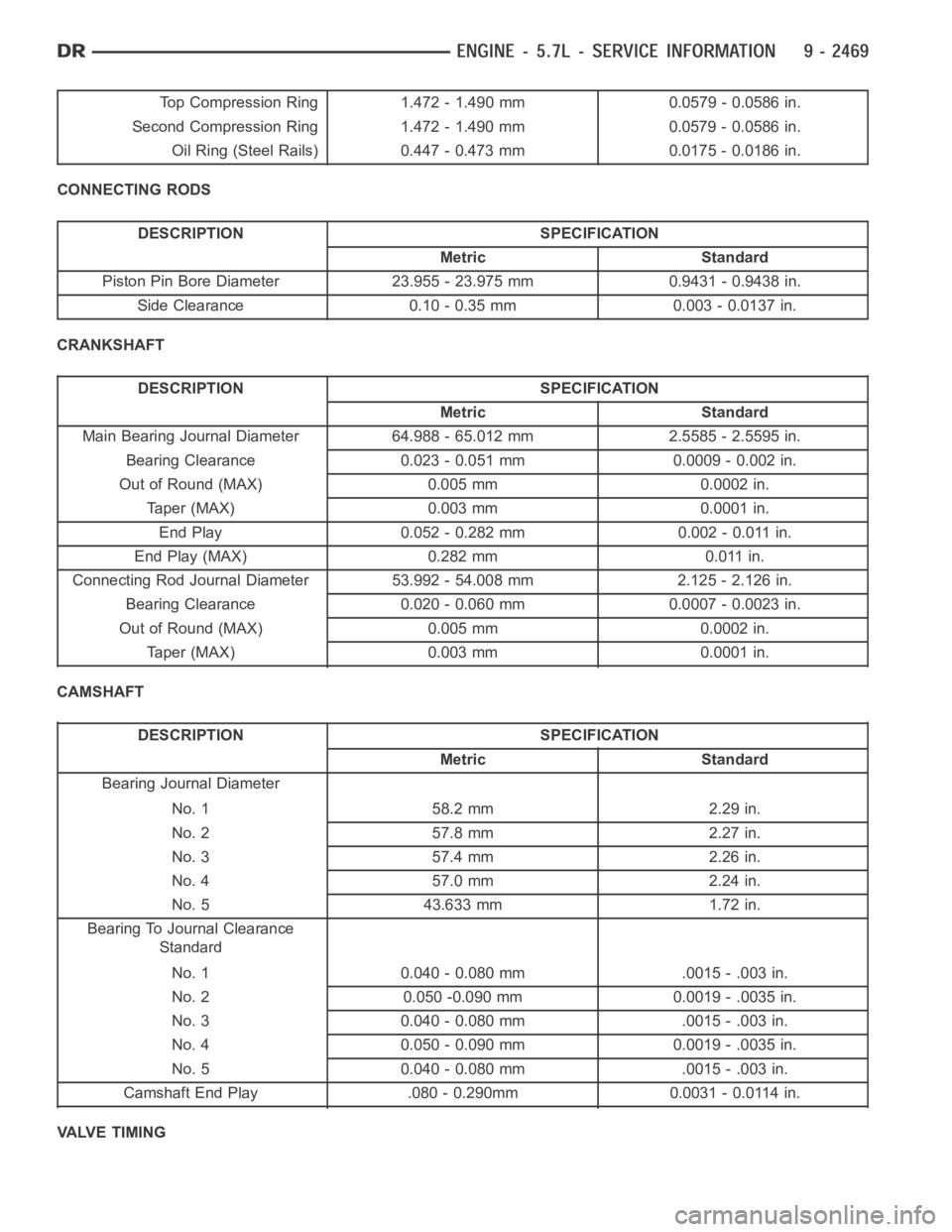

Top Compression Ring 1.472 - 1.490 mm 0.0579 - 0.0586 in.

Second Compression Ring 1.472 - 1.490 mm 0.0579 - 0.0586 in.

Oil Ring (Steel Rails) 0.447 - 0.473 mm 0.0175 - 0.0186 in.

CONNECTING RODS

DESCRIPTION SPECIFICATION

Metric Standard

Piston Pin Bore Diameter 23.955 - 23.975 mm 0.9431 - 0.9438 in.

Side Clearance 0.10 - 0.35 mm 0.003 - 0.0137 in.

CRANKSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Main Bearing Journal Diameter 64.988 - 65.012 mm 2.5585 - 2.5595 in.

Bearing Clearance 0.023 - 0.051 mm 0.0009 - 0.002 in.

Out of Round (MAX) 0.005 mm 0.0002 in.

Taper (MAX) 0.003 mm 0.0001 in.

End Play 0.052 - 0.282 mm 0.002 - 0.011 in.

End Play (MAX) 0.282 mm 0.011 in.

Connecting Rod Journal Diameter 53.992 - 54.008 mm 2.125 - 2.126 in.

Bearing Clearance 0.020 - 0.060 mm 0.0007 - 0.0023 in.

Out of Round (MAX) 0.005 mm 0.0002 in.

Taper (MAX) 0.003 mm 0.0001 in.

CAMSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Bearing Journal Diameter

No. 1 58.2 mm 2.29 in.

No. 2 57.8 mm 2.27 in.

No. 3 57.4 mm 2.26 in.

No. 4 57.0 mm 2.24 in.

No. 5 43.633 mm 1.72 in.

Bearing To Journal Clearance

Standard

No. 1 0.040 - 0.080 mm .0015 - .003 in.

No. 2 0.050 -0.090 mm 0.0019 - .0035 in.

No. 3 0.040 - 0.080 mm .0015 - .003 in.

No. 4 0.050 - 0.090 mm 0.0019 - .0035 in.

No. 5 0.040 - 0.080 mm .0015 - .003 in.

Camshaft End Play .080 - 0.290mm 0.0031 - 0.0114 in.

VALVE TIMING

Page 1790 of 5267

CYLINDER HEAD

OPERATION—CYLINDER HEAD

The cylinder head closes the combustion chamber allowing the pistons to compress the air fuel mixture to the cor-

rect ratio for ignition. The valves located in the cylinder head open and close to either allow clean air into the com-

bustion chamber or to allow the exhaust gases out, depending on the stroke of the engine.

DIAGNOSIS AND TESTING—CYLINDER HEAD GASKET FAILURE

A cylinder head gasket leak can be located between adjacent cylinders or between a cylinder and the adjacent

water jacket.

Possible indications of the cylinder head gasket leaking between adjacent cylinders are:

− Loss of engine power

− Engine misfiring

− Poor fuel economy

Possible indications of the cylinder head gasket leaking between a cylinder and an adjacent water jacket are:

− Engine overheating

− Loss of coolant

− Excessive steam (white smoke) emitting from exhaust

− Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is leaking between adjacentcylinders, follow the procedures in Cyl-

inder Compression Pressure Test in this section. An engine cylinder head gasket leaking between adjacent cylinders

will result in approximately a 50–70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE ENGINE IS OPERATING WITH COOLANT PRESSURE CAP

REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure cap. Start the engine andallow it to warm up until thermostat

opens.

If a large combustion/compression pressure leak exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN PLACE, PRESSURE WILL BUILD UP FAST.EXCESSIVE

PRESSURE BUILT UP, BY CONTINUOUS ENGINE OPERATION, MUST BE RELEASED TO A SAFE PRESSURE

POINT. NEVER PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to pressure cap neck. Start the engine and observe the tester’s

pressure gauge. If gauge pulsates with every power stroke of a cylinder a combustion pressure leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also be checked by using Bloc-Chek Kit C-3685-A or equivalent.

Perform test following the procedures supplied with the tool kit.

Page 1903 of 5267

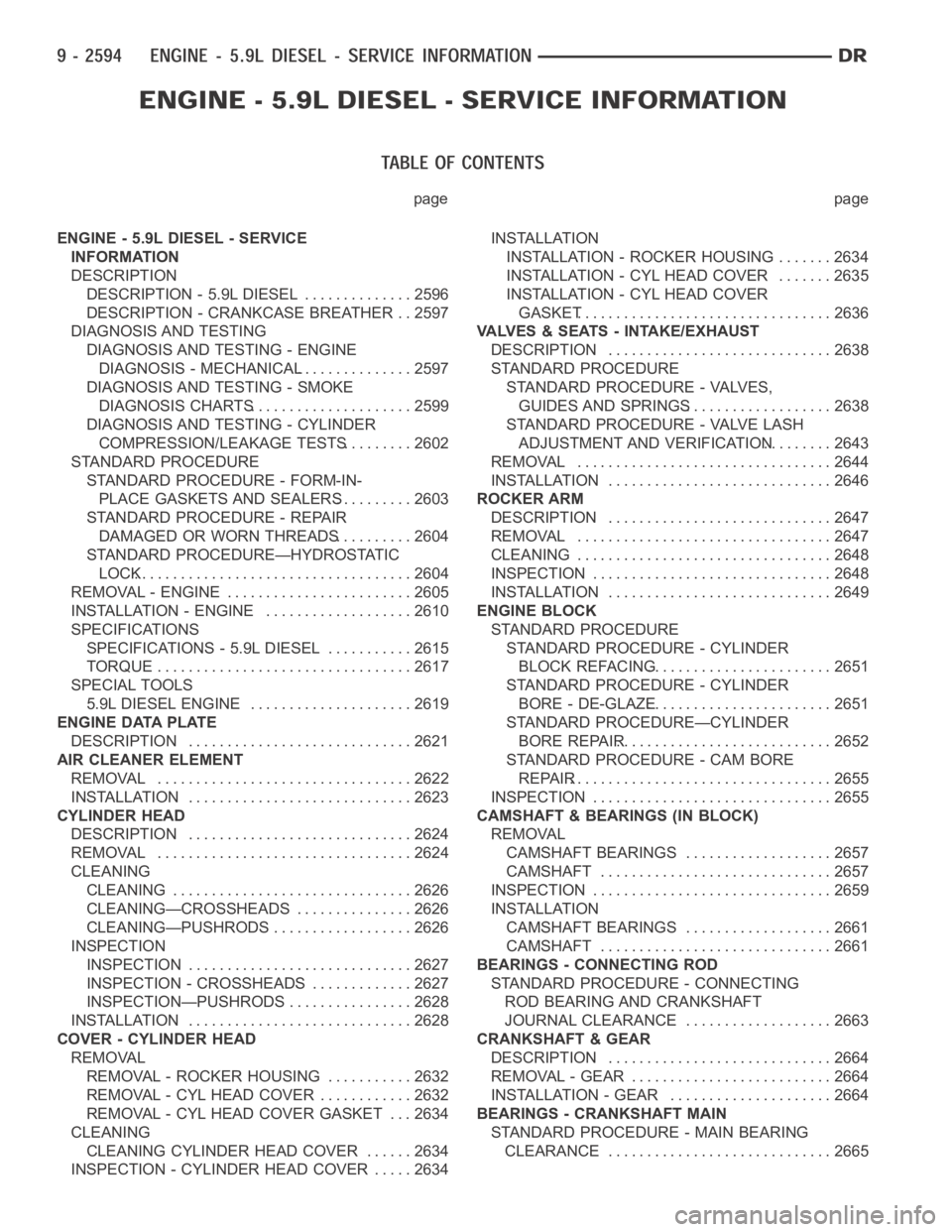

page page

ENGINE - 5.9L DIESEL - SERVICE

INFORMATION

DESCRIPTION

DESCRIPTION - 5.9L DIESEL .............. 2596

DESCRIPTION - CRANKCASE BREATHER . . 2597

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............... 2597

DIAGNOSIS AND TESTING - SMOKE

DIAGNOSIS CHARTS..................... 2599

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION/LEAKAGE TESTS......... 2602

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.......... 2603

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS.......... 2604

STANDARD PROCEDURE—HYDROSTATIC

LOCK.................................... 2604

REMOVAL - ENGINE ........................ 2605

INSTALLATION - ENGINE ................... 2610

SPECIFICATIONS

SPECIFICATIONS - 5.9L DIESEL ........... 2615

TORQUE ................................. 2617

SPECIAL TOOLS

5.9L DIESEL ENGINE ..................... 2619

ENGINE DATA PLATE

DESCRIPTION ............................. 2621

AIR CLEANER ELEMENT

REMOVAL ................................. 2622

INSTALLATION ............................. 2623

CYLINDER HEAD

DESCRIPTION ............................. 2624

REMOVAL ................................. 2624

CLEANING

CLEANING ............................... 2626

CLEANING—CROSSHEADS ............... 2626

CLEANING—PUSHRODS .................. 2626

INSPECTION

INSPECTION............................. 2627

INSPECTION - CROSSHEADS . . ........... 2627

INSPECTION—PUSHRODS................ 2628

INSTALLATION ............................. 2628

COVER - CYLINDER HEAD

REMOVAL

REMOVAL - ROCKER HOUSING ........... 2632

REMOVAL - CYL HEAD COVER ............ 2632

REMOVAL - CYL HEAD COVER GASKET . . . 2634

CLEANING

CLEANING CYLINDER HEAD COVER ...... 2634

INSPECTION - CYLINDER HEAD COVER ..... 2634INSTALLATION

INSTALLATION - ROCKER HOUSING ....... 2634

INSTALLATION - CYL HEAD COVER ....... 2635

INSTALLATION - CYL HEAD COVER

GASKET................................. 2636

VALVES & SEATS - INTAKE/EXHAUST

DESCRIPTION ............................. 2638

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVES,

GUIDES AND SPRINGS................... 2638

STANDARD PROCEDURE - VALVE LASH

ADJUSTMENT AND VERIFICATION......... 2643

REMOVAL ................................. 2644

INSTALLATION ............................. 2646

ROCKER ARM

DESCRIPTION ............................. 2647

REMOVAL ................................. 2647

CLEANING ................................. 2648

INSPECTION............................... 2648

INSTALLATION ............................. 2649

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER

BLOCK REFACING........................ 2651

STANDARD PROCEDURE - CYLINDER

BORE - DE-GLAZE........................ 2651

STANDARD PROCEDURE—CYLINDER

BORE REPAIR............................ 2652

STANDARD PROCEDURE - CAM BORE

REPAIR.................................. 2655

INSPECTION............................... 2655

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

CAMSHAFT BEARINGS................... 2657

CAMSHAFT .............................. 2657

INSPECTION

............................... 2659

INSTALLATION

CAMSHAFT BEARINGS................... 2661

CAMSHAFT .............................. 2661

BEARINGS - CONNECTING ROD

STANDARD PROCEDURE - CONNECTING

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE................... 2663

CRANKSHAFT & GEAR

DESCRIPTION ............................. 2664

REMOVAL - GEAR .......................... 2664

INSTALLATION - GEAR ..................... 2664

BEARINGS - CRANKSHAFT MAIN

STANDARD PROCEDURE - MAIN BEARING

CLEARANCE ............................. 2665

Page 1907 of 5267

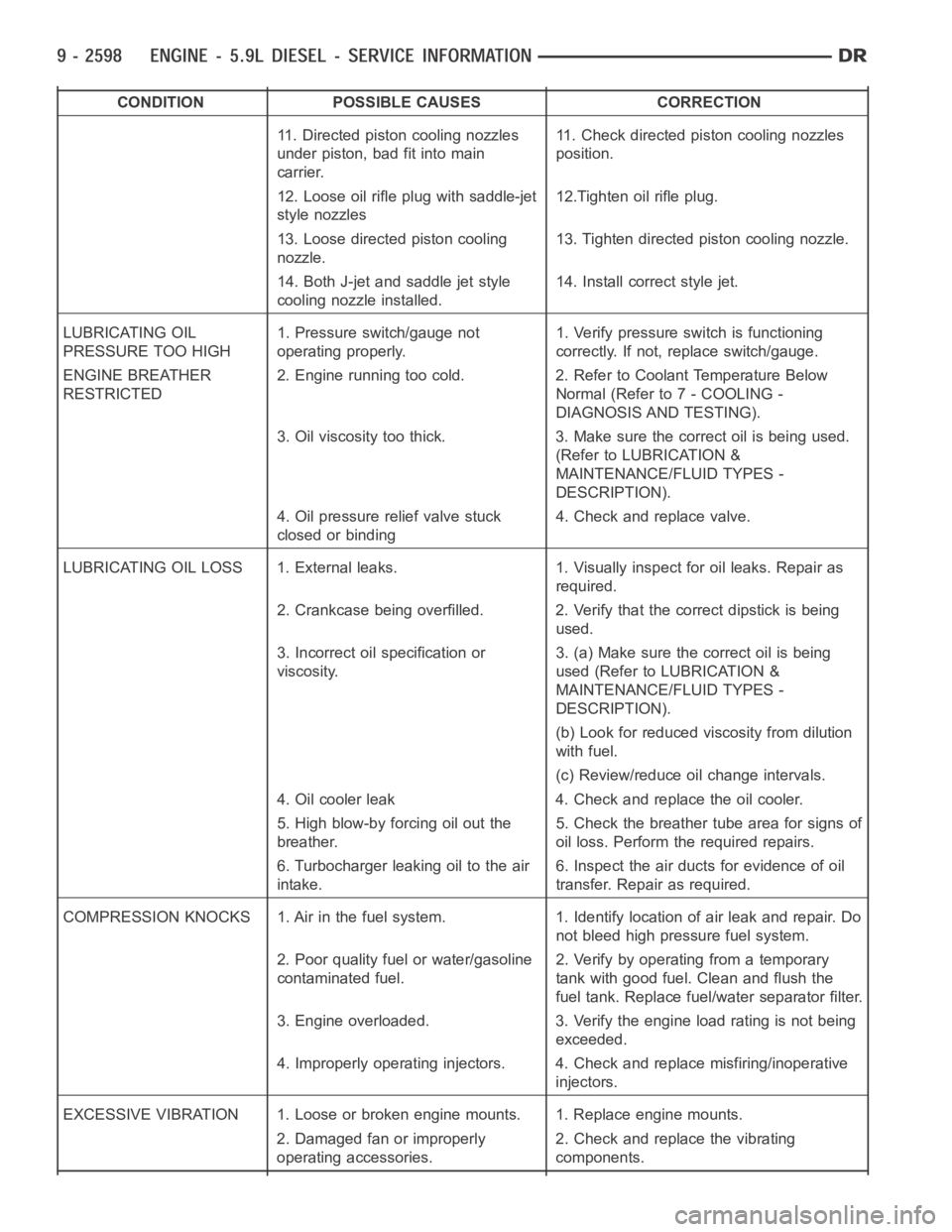

CONDITION POSSIBLE CAUSES CORRECTION

11. Directed piston cooling nozzles

under piston, bad fit into main

carrier.11. Check directed piston cooling nozzles

position.

12. Loose oil rifle plug with saddle-jet

style nozzles12.Tighten oil rifle plug.

13. Loose directed piston cooling

nozzle.13. Tighten directed piston cooling nozzle.

14. Both J-jet and saddle jet style

cooling nozzle installed.14. Install correct style jet.

LUBRICATING OIL

PRESSURE TOO HIGH1. Pressure switch/gauge not

operating properly.1. Verify pressure switch is functioning

correctly. If not, replace switch/gauge.

ENGINE BREATHER

RESTRICTED2. Engine running too cold. 2. Refer to Coolant Temperature Below

Normal (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

3. Oil viscosity too thick. 3. Make sure the correct oil is being used.

(Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION).

4. Oil pressure relief valve stuck

closed or binding4. Check and replace valve.

LUBRICATING OIL LOSS 1. External leaks. 1. Visually inspect for oil leaks.Repair as

required.

2. Crankcase being overfilled. 2. Verify that the correct dipstick is being

used.

3. Incorrect oil specification or

viscosity.3. (a) Make sure the correct oil is being

used (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(b) Look for reduced viscosity from dilution

with fuel.

(c) Review/reduce oil change intervals.

4. Oil cooler leak 4. Check and replace the oil cooler.

5. High blow-by forcing oil out the

breather.5. Check the breather tube area for signs of

oil loss. Perform the required repairs.

6. Turbocharger leaking oil to the air

intake.6. Inspect the air ducts for evidence of oil

transfer. Repair as required.

COMPRESSION KNOCKS 1. Air in the fuel system. 1. Identify location of air leak and repair. Do

not bleed high pressure fuel system.

2. Poor quality fuel or water/gasoline

contaminated fuel.2. Verify by operating from a temporary

tank with good fuel. Clean and flush the

fuel tank. Replace fuel/water separator filter.

3. Engine overloaded. 3. Verify the engine load rating is not being

exceeded.

4. Improperly operating injectors. 4. Check and replace misfiring/inoperative

injectors.

EXCESSIVE VIBRATION 1. Loose or broken engine mounts. 1. Replace engine mounts.

2. Damaged fan or improperly

operating accessories.2. Check and replace the vibrating

components.

Page 1911 of 5267

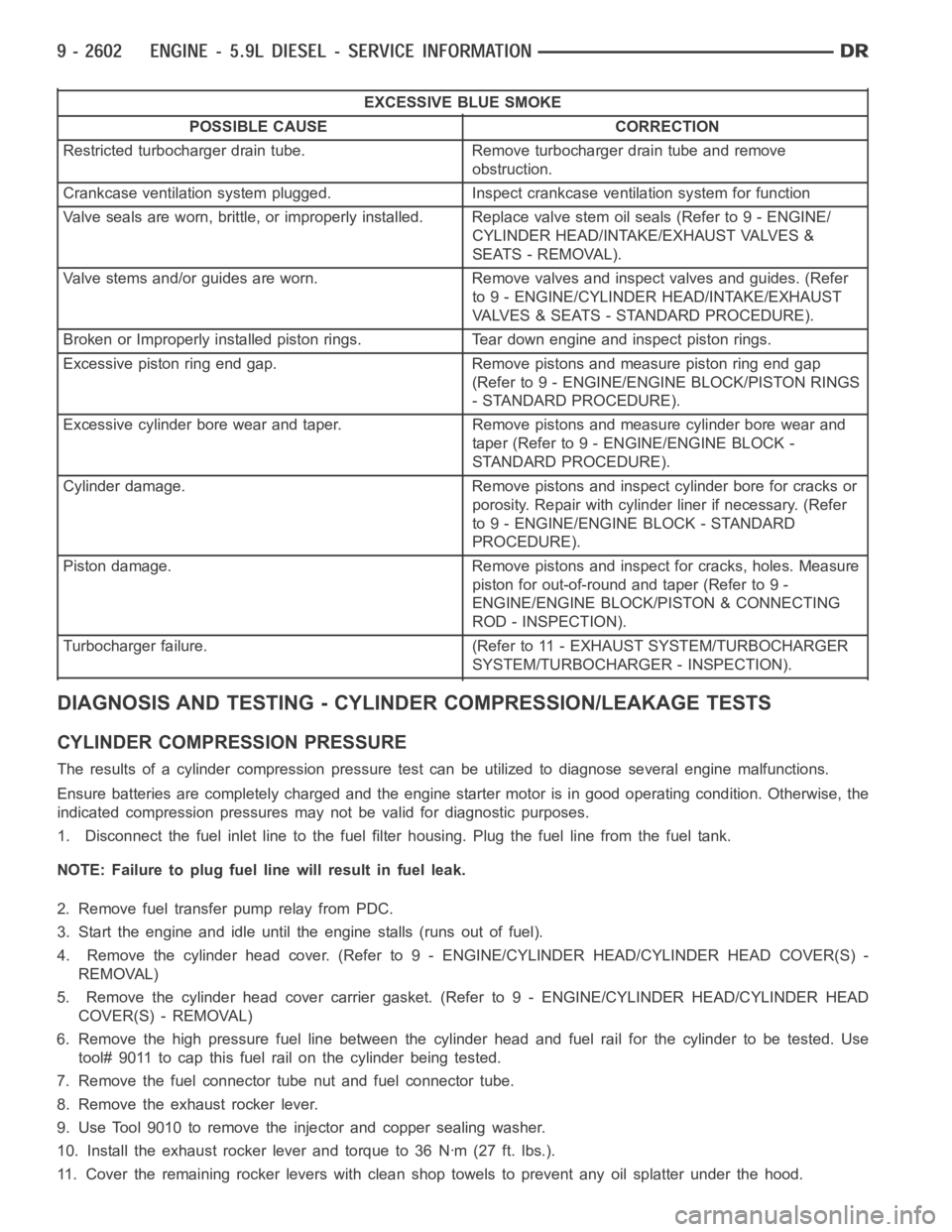

EXCESSIVE BLUE SMOKE

POSSIBLE CAUSE CORRECTION

Restricted turbocharger drain tube. Remove turbocharger drain tube and remove

obstruction.

Crankcase ventilation system plugged. Inspect crankcase ventilation system for function

Valve seals are worn, brittle, or improperly installed. Replace valve stemoilseals(Referto9-ENGINE/

CYLINDER HEAD/INTAKE/EXHAUST VALVES &

SEATS - REMOVAL).

Valve stems and/or guides are worn. Remove valves and inspect valves and guides. (Refer

to 9 - ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

Broken or Improperly installed piston rings. Tear down engine and inspectpiston rings.

Excessive piston ring end gap. Remove pistons and measure piston ring end gap

(Refer to 9 - ENGINE/ENGINE BLOCK/PISTON RINGS

- STANDARD PROCEDURE).

Excessive cylinder bore wear and taper. Remove pistons and measure cylinder bore wear and

taper (Refer to 9 - ENGINE/ENGINE BLOCK -

STANDARD PROCEDURE).

Cylinder damage. Remove pistons and inspect cylinder bore for cracks or

porosity. Repair with cylinder liner if necessary. (Refer

to 9 - ENGINE/ENGINE BLOCK - STANDARD

PROCEDURE).

Piston damage. Remove pistons and inspect for cracks, holes. Measure

piston for out-of-round and taper (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECTING

ROD - INSPECTION).

Turbocharger failure. (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - INSPECTION).

DIAGNOSIS AND TESTING - CYLINDER COMPRESSION/LEAKAGE TESTS

CYLINDER COMPRESSION PRESSURE

The results of a cylinder compressionpressure test can be utilized to diagnose several engine malfunctions.

Ensure batteries are completely charged and the engine starter motor is ingood operating condition. Otherwise, the

indicated compression pressures may not be valid for diagnostic purposes.

1. Disconnect the fuel inlet line to the fuel filter housing. Plug the fuel line from the fuel tank.

NOTE: Failure to plug fuel line will result in fuel leak.

2. Remove fuel transfer pump relay from PDC.

3. Start the engine and idle until the engine stalls (runs out of fuel).

4. Remove the cylinder head cover. (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL)

5. Remove the cylinder head cover carrier gasket. (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

6. Remove the high pressure fuel line between the cylinder head and fuel rail for the cylinder to be tested. Use

tool# 9011 to cap this fuel rail on the cylinder being tested.

7. Remove the fuel connector tube nut and fuel connector tube.

8. Remove the exhaust rocker lever.

9. Use Tool 9010 to remove the injector and copper sealing washer.

10. Install the exhaust rocker lever and torque to 36 Nꞏm (27 ft. lbs.).

11. Cover the remaining rocker levers with clean shop towels to prevent anyoil splatter under the hood.

Page 1912 of 5267

12. Place a rag over the compression test tool fitting. Crank the engine for2–3 seconds to purge any fuel that may

have drained into the cylinder when the injector was removed.

13. Connect the compression test gauge.

14. Crank the engine for 5 seconds and record the pressure reading. Repeat this step three times and calculate the

average of the three readings.

NOTE: The minimum cylinder pressure is 350 psi. Cylinder pressure should be within 20% from cylinder to

cylinder.

15. Combustion pressure leakage can be checked if cylinder pressure is below the specification. Perform the leak-

age test procedure on each cylinder according to the tester manufacturer instructions.

16. Upon completion of the test check and erase any engine related fault codes.

CYLINDER COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

Exhaust and intake valve leaks (improper seating).

Leaks between adjacent cylinders or into water jacket.

Any causes for combustion/compression pressure loss

1. Start and operate the engine until it attains normal operating temperature.

2. Disconnect injector harness connectors.

3. Disconnect breather tube and breather drain tube from valve cover.

4. Remove the cylinder head cover. (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL)

5. Disconnect harness from injectors.

6. Remove the cylinder head cover carrier gasket. (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

7. BringthecylindertobetestedtoTDC.

8. Remove the high pressure fuel line between the cylinder head and the fuelrail for the cylinder to be tested.

9. Install capping Tool 9011 onto the rail.

10. Remove the high pressure connector nut and high pressure connector with Tool 9015.

11. Remove the exhaust and intake rocker lever.

12. Use Tool # 9010 to remove the injector and copper sealing washer.

13. Install compression test Tool # 9007 into the injector bore.

14. Connect the leakage tester and perform the leakage test procedure on each cylinder according to the tester

manufacturer’s instructions.

15. Upon completion of the test check and erase any engine related fault codes.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE GASKETS AND SEALERS

There are numerous places where form-in-place gaskets are used on the engine. Care must be taken when apply-

ing form-in-place gaskets to assure obtaining the desired results.Do not use form-in-place gasket material

unless specified.Bead size, continuity, and location are of great importance. Too thin a bead can result in leakage

while too much can result in spill-overwhich can break off and obstruct fluid feed lines. A continuous bead of the

proper width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket materials that are used in the engine area. Mopar

Engine RTV

GEN II, Mopar

ATF-RTV, and MoparGasket Maker gasket materials, each have different properties and can not

be used in place of the other.

MOPAR

ENGINE RTV GEN II

Page 1925 of 5267

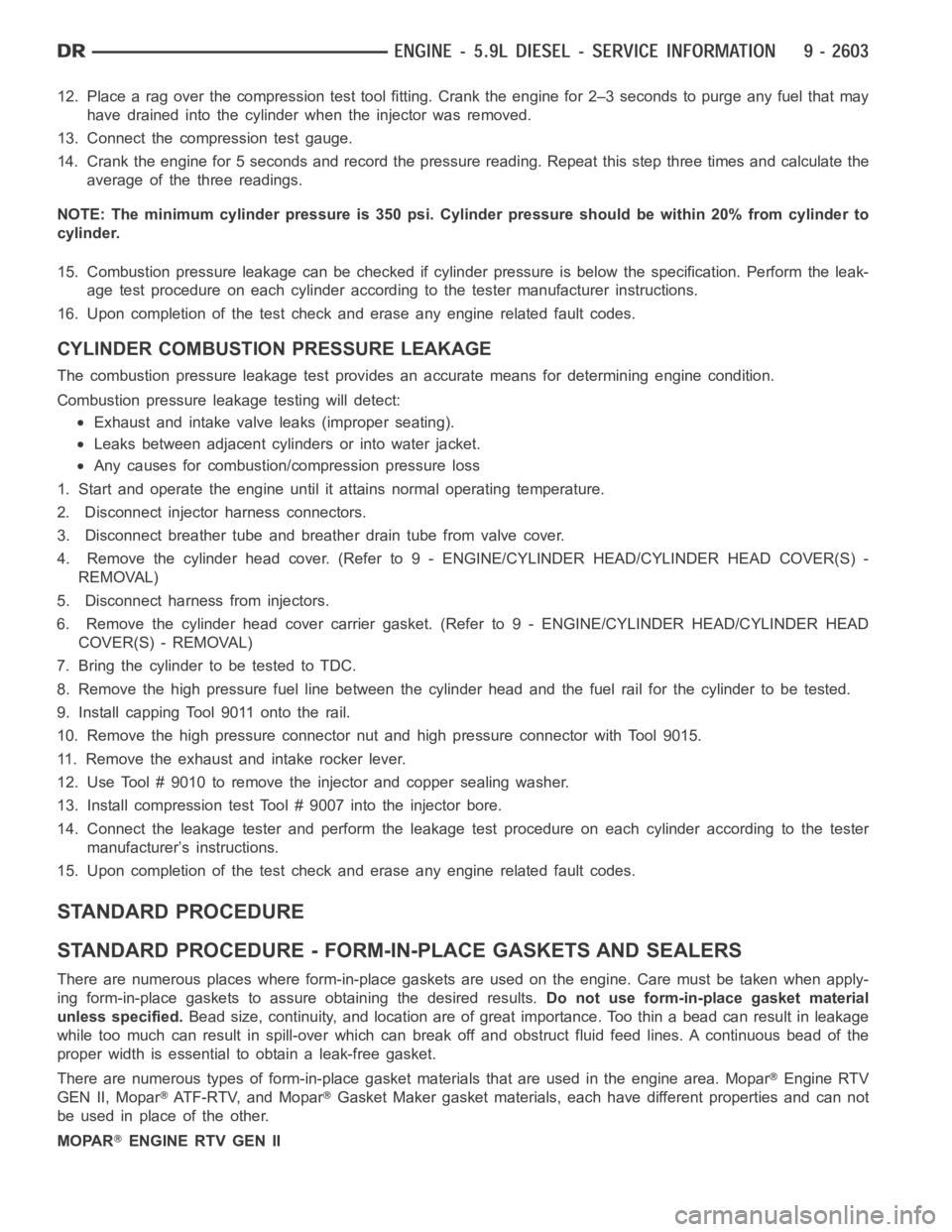

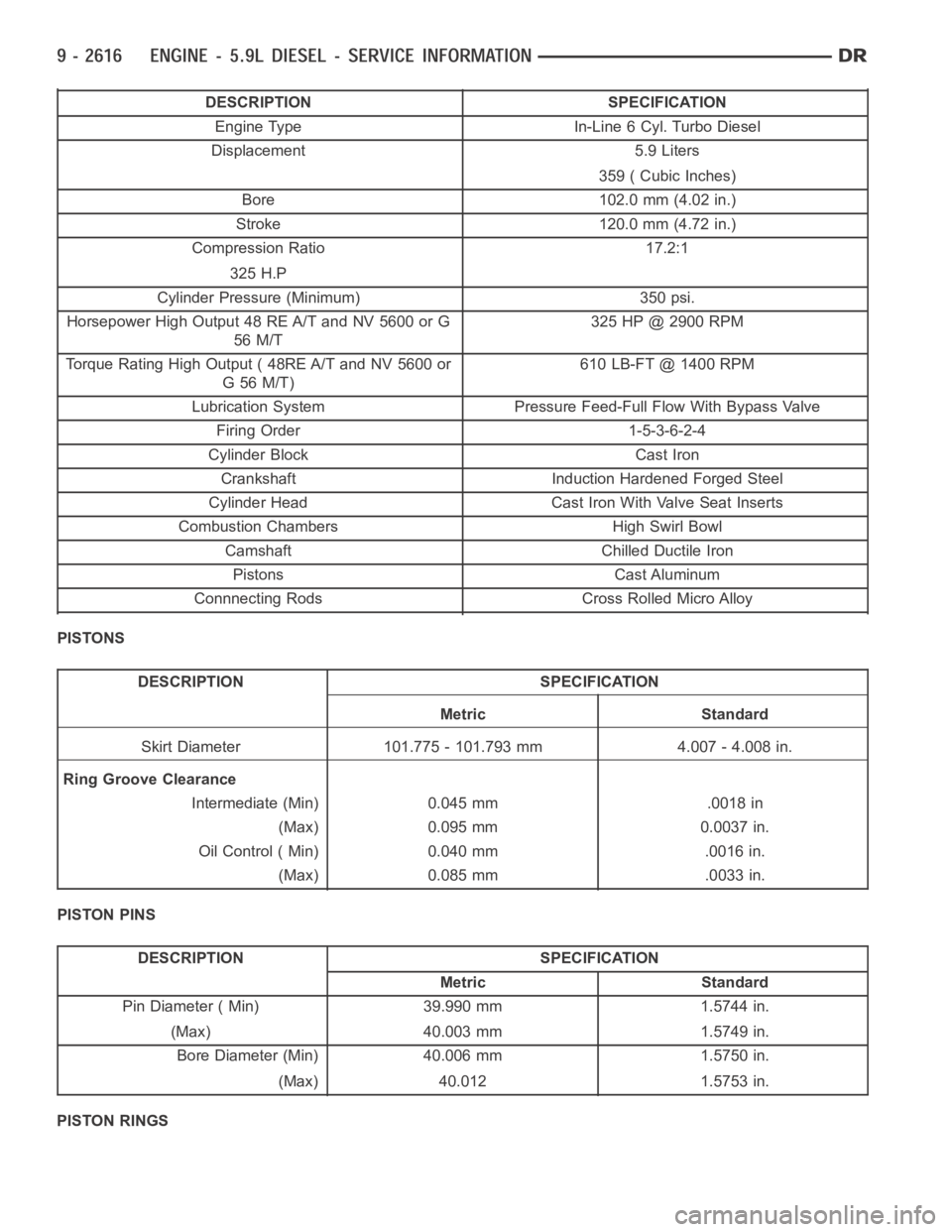

DESCRIPTION SPECIFICATION

Engine Type In-Line 6 Cyl. Turbo Diesel

Displacement 5.9 Liters

359 ( Cubic Inches)

Bore 102.0 mm (4.02 in.)

Stroke 120.0 mm (4.72 in.)

Compression Ratio 17.2:1

325 H.P

Cylinder Pressure (Minimum) 350 psi.

Horsepower High Output 48 RE A/T and NV 5600 or G

56 M/T325 HP @ 2900 RPM

Torque Rating High Output ( 48RE A/T and NV 5600 or

G56M/T)610 LB-FT @ 1400 RPM

Lubrication System Pressure Feed-Full Flow With Bypass Valve

Firing Order 1-5-3-6-2-4

Cylinder Block Cast Iron

Crankshaft Induction Hardened Forged Steel

Cylinder Head Cast Iron With Valve Seat Inserts

Combustion Chambers High Swirl Bowl

Camshaft Chilled Ductile Iron

Pistons Cast Aluminum

Connnecting Rods Cross Rolled Micro Alloy

PISTONS

DESCRIPTION SPECIFICATION

Metric Standard

Skirt Diameter 101.775 - 101.793 mm 4.007 - 4.008 in.

Ring Groove Clearance

Intermediate (Min) 0.045 mm .0018 in

(Max) 0.095 mm 0.0037 in.

Oil Control ( Min) 0.040 mm .0016 in.

(Max) 0.085 mm .0033 in.

PISTON PINS

DESCRIPTION SPECIFICATION

Metric Standard

Pin Diameter ( Min) 39.990 mm 1.5744 in.

(Max) 40.003 mm 1.5749 in.

Bore Diameter (Min) 40.006 mm 1.5750 in.

(Max) 40.012 1.5753 in.

PISTON RINGS

Page 1929 of 5267

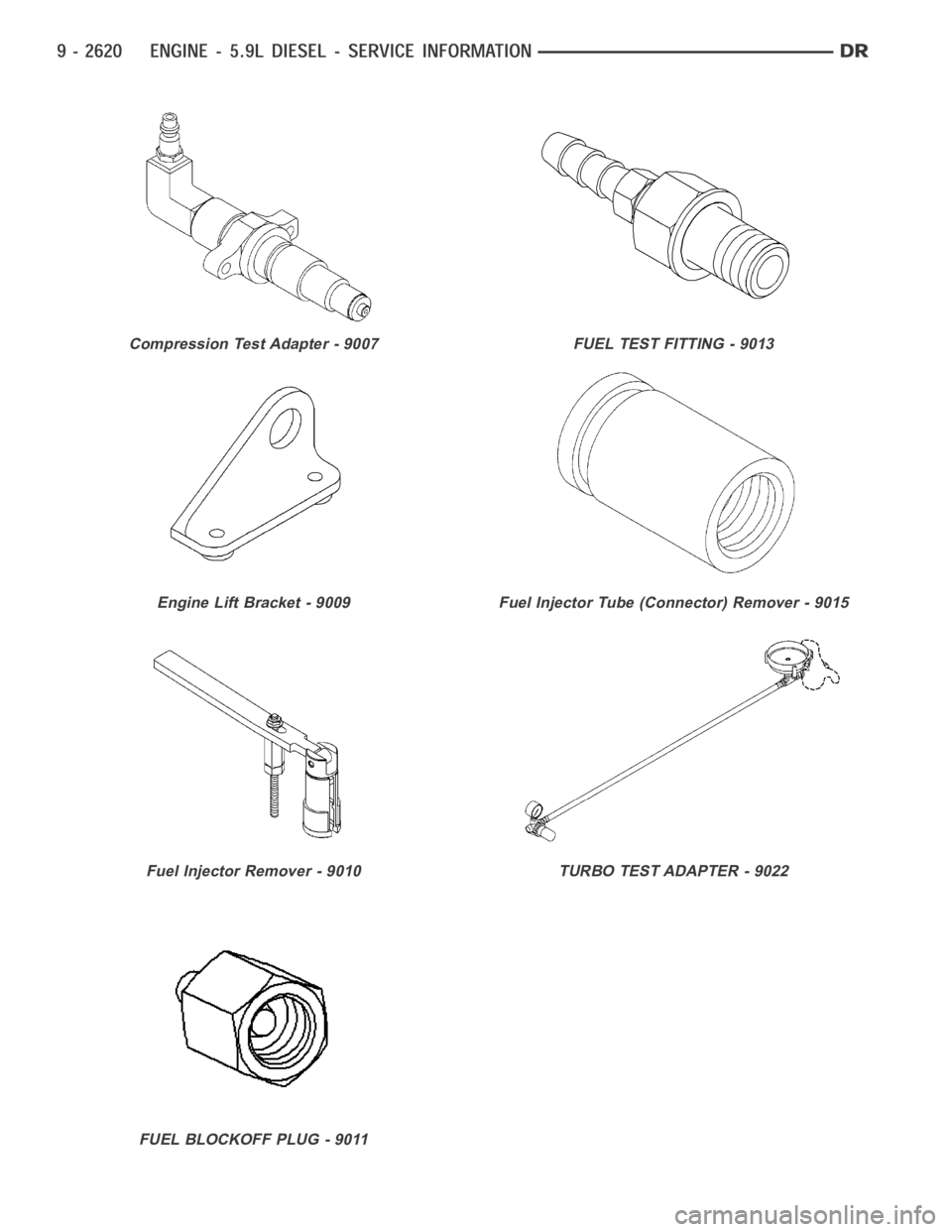

Compression Test Adapter - 9007

Engine Lift Bracket - 9009

Fuel Injector Remover - 9010

FUEL BLOCKOFF PLUG - 9011

FUEL TEST FITTING - 9013

Fuel Injector Tube (Connector) Remover - 9015

TURBO TEST ADAPTER - 9022

Page 1986 of 5267

PISTON & CONNECTING ROD

DESCRIPTION

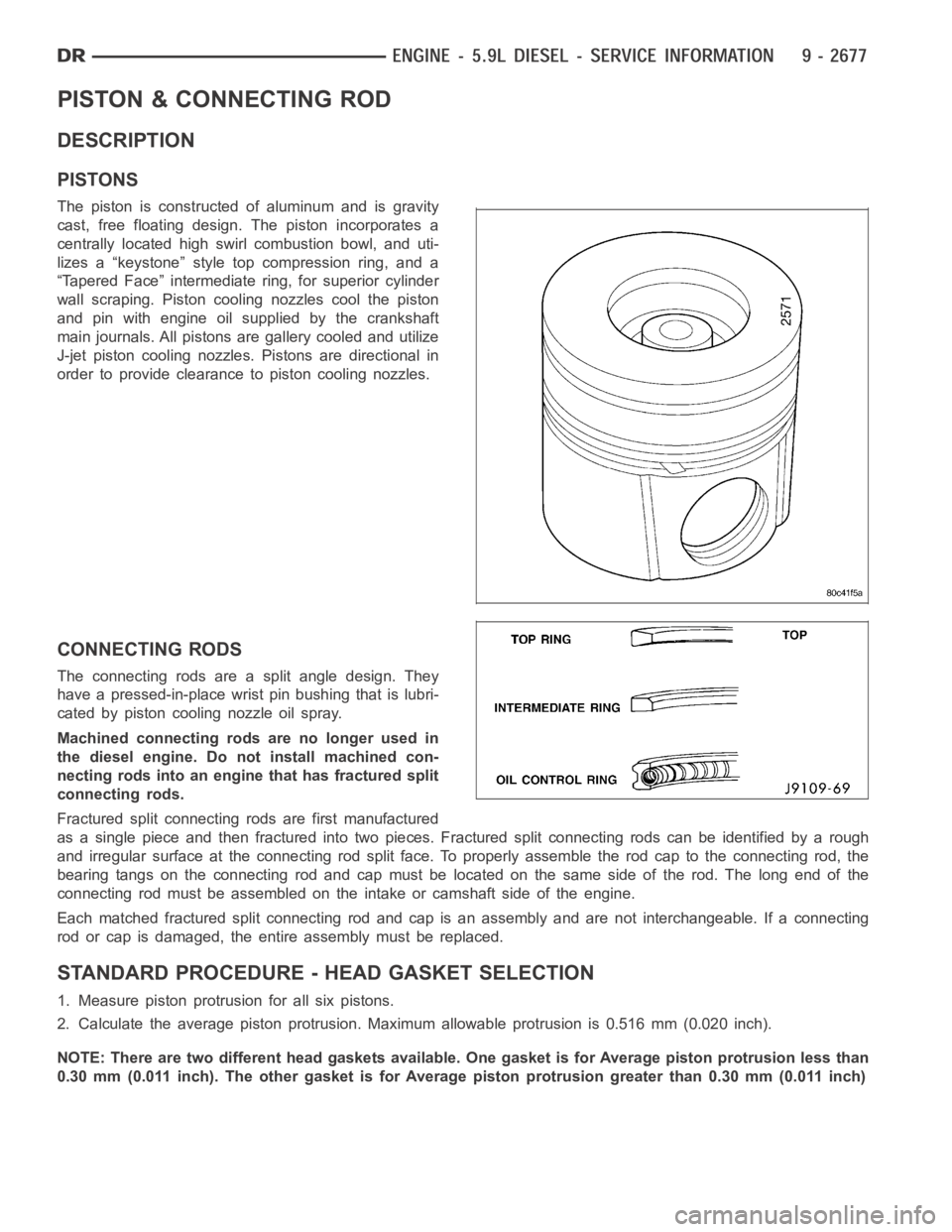

PISTONS

The piston is constructed of aluminum and is gravity

cast, free floating design. The piston incorporates a

centrally located high swirl combustion bowl, and uti-

lizes a “keystone” style top compression ring, and a

“Tapered Face” intermediate ring, for superior cylinder

wall scraping. Piston cooling nozzles cool the piston

and pin with engine oil supplied by the crankshaft

main journals. All pistons are gallery cooled and utilize

J-jet piston cooling nozzles. Pistons are directional in

order to provide clearance to piston cooling nozzles.

CONNECTING RODS

The connecting rods are a split angle design. They

have a pressed-in-place wrist pin bushing that is lubri-

cated by piston cooling nozzle oil spray.

Machined connecting rods are no longer used in

the diesel engine. Do not install machined con-

necting rods into an engine that has fractured split

connecting rods.

Fractured split connecting rods are first manufactured

asasinglepieceandthenfracturedintotwopieces.Fracturedsplitconnecting rods can be identified by a rough

and irregular surface at the connecting rod split face. To properly assemble the rod cap to the connecting rod, the

bearing tangs on the connecting rod and cap must be located on the same side of the rod. The long end of the

connecting rod must be assembled on theintake or camshaft side of the engine.

Each matched fractured split connecting rod and cap is an assembly and are not interchangeable. If a connecting

rod or cap is damaged, the entire assembly must be replaced.

STANDARD PROCEDURE - HEAD GASKET SELECTION

1. Measure piston protrusion for all six pistons.

2. Calculate the average piston protrusion. Maximum allowable protrusion is 0.516 mm (0.020 inch).

NOTE: There are two different head gaskets available. One gasket is for Average piston protrusion less than

0.30 mm (0.011 inch). The other gasket is for Average piston protrusion greater than 0.30 mm (0.011 inch)